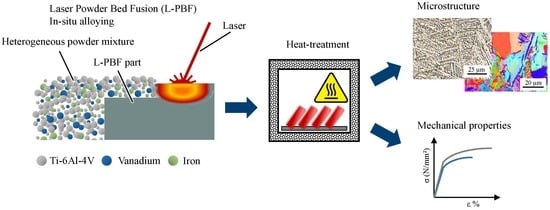

In Situ Formation of a Metastable β-Ti Alloy by Laser Powder Bed Fusion (L-PBF) of Vanadium and Iron Modified Ti-6Al-4V

Abstract

:1. Introduction

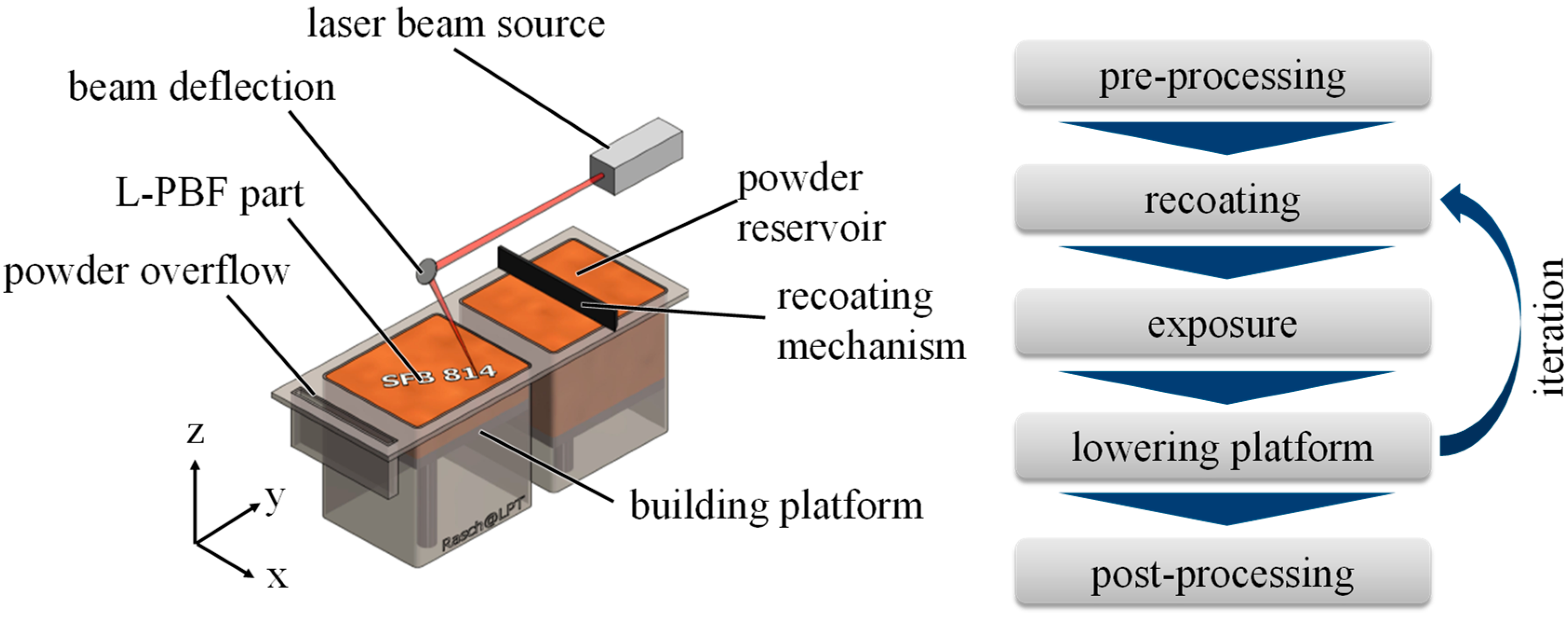

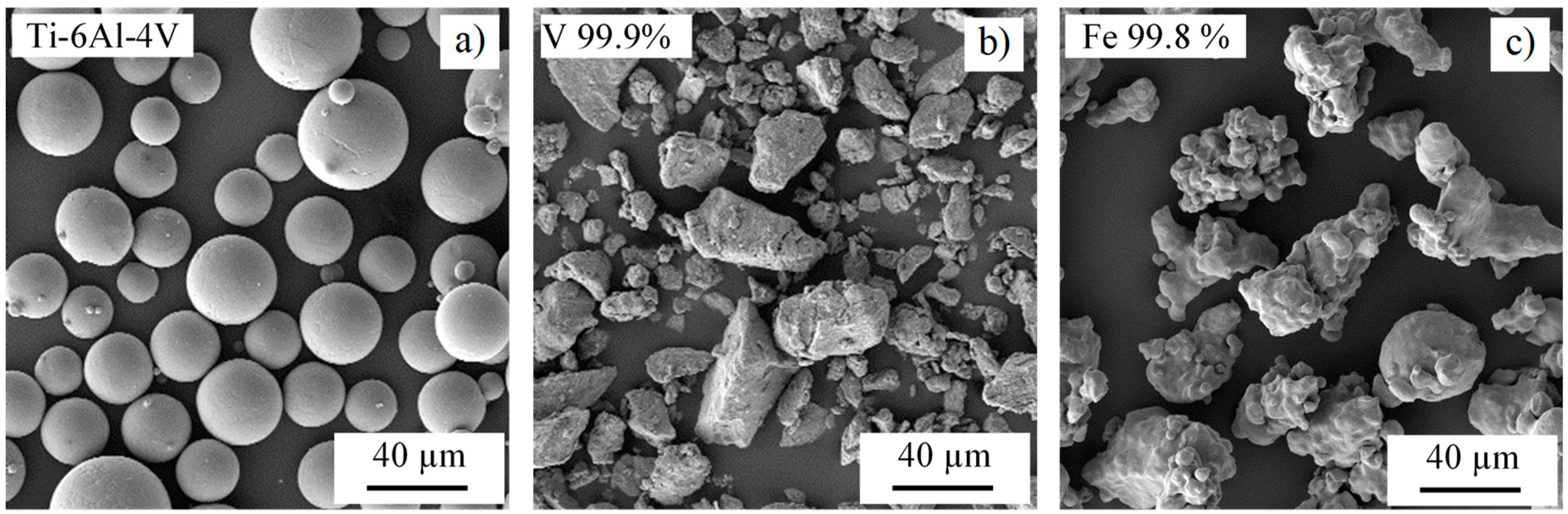

2. Materials and Methods

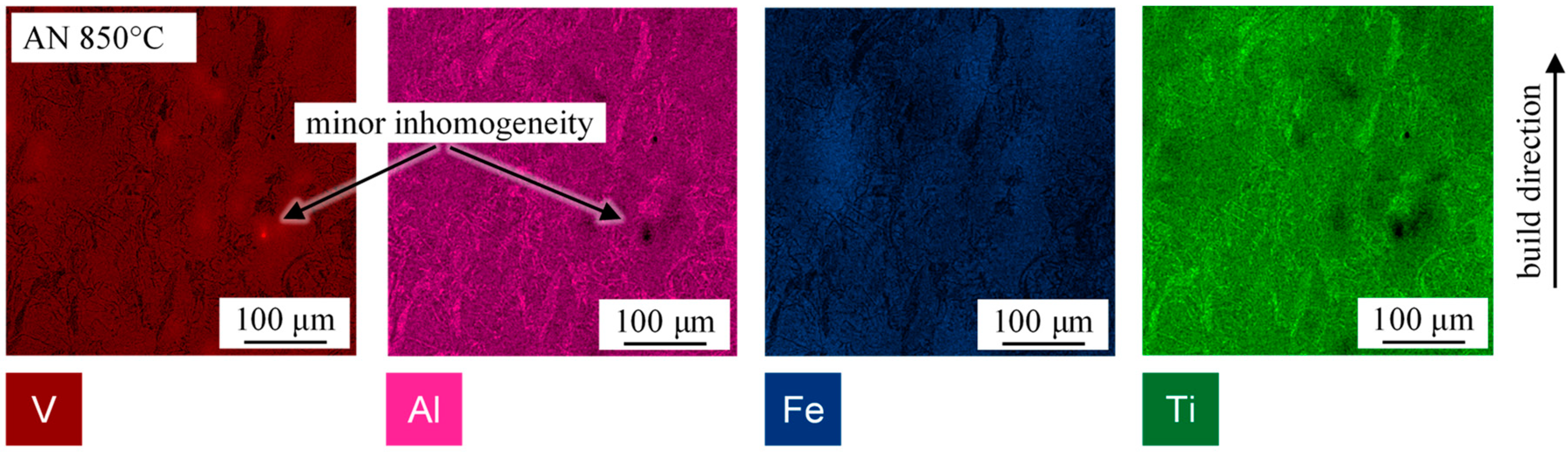

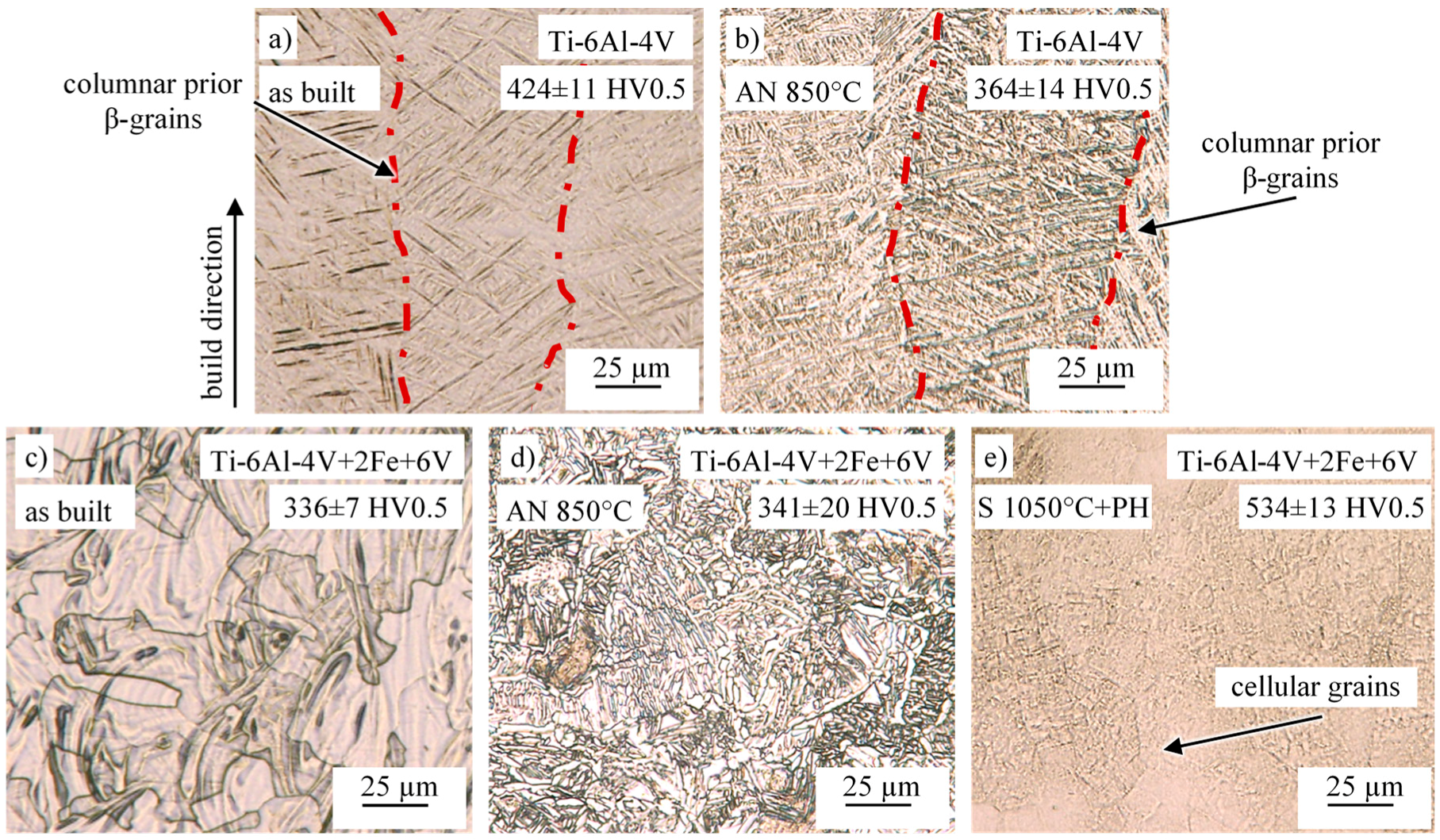

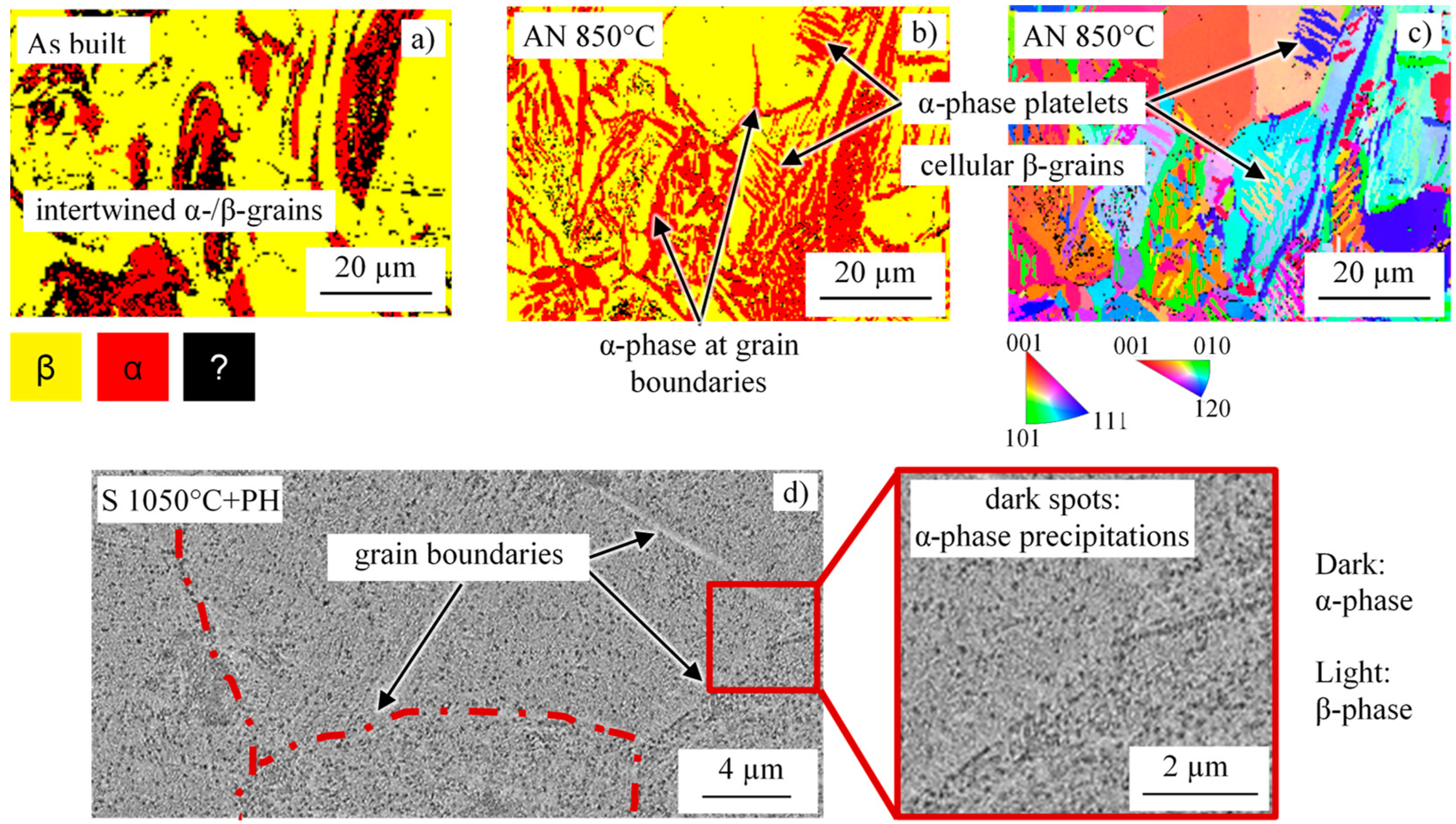

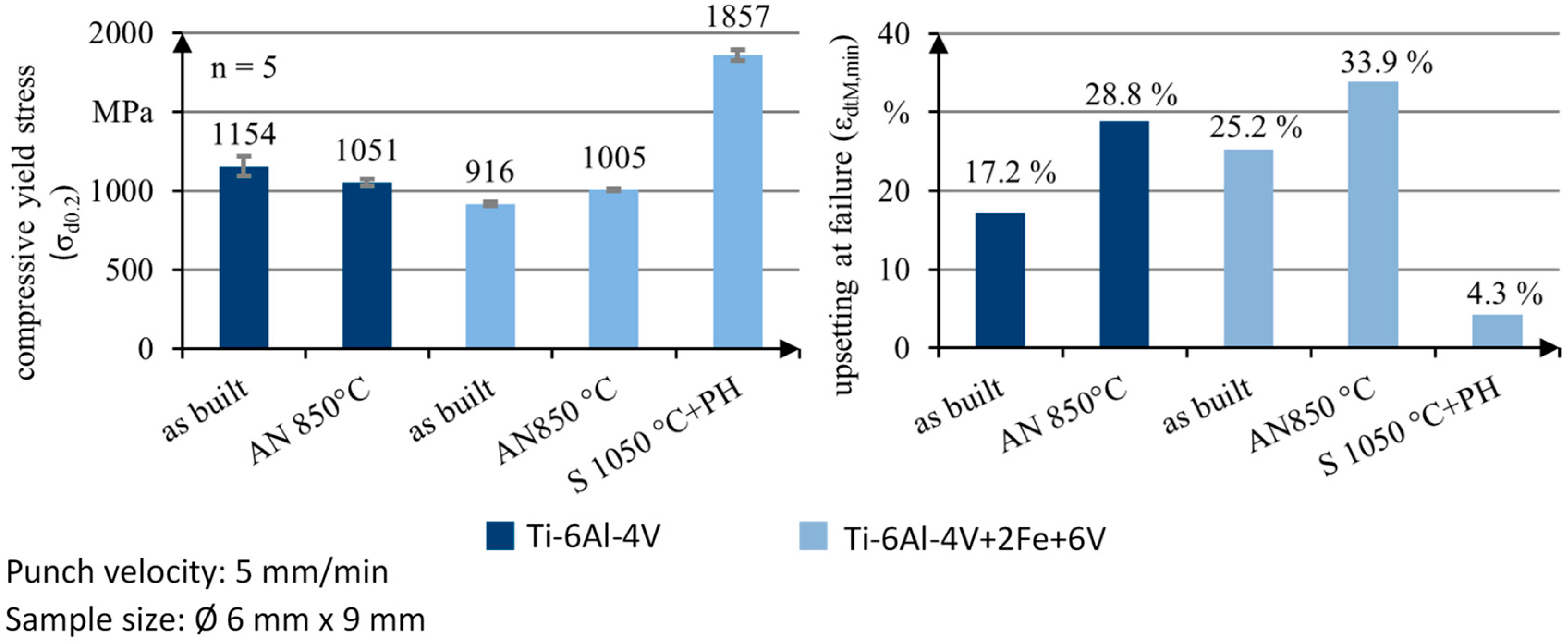

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wohlers, T.; Caffrey, T.; Campbell, I. Wohlers Report 2016 Published; Wohlers Associates, Inc.: Fort Collins, CO, USA, 2016; ISBN 9780991333226. [Google Scholar]

- Uhlmann, E.; Kersting, R.; Klein, T.B.; Cruz, M.F.; Borille, A.V. Additive manufacturing of titanium alloy for aircraft components. Procedia CIRP 2015, 35, 55–60. [Google Scholar] [CrossRef]

- Rotaru, H.; Schumacher, R.; Kim, S.-G.; Dinu, C. Selective laser melted titanium implants: a new technique for the reconstruction of extensive zygomatic complex defects. Maxillofac. Plast. Reconstr. Surg. 2015, 37, 12. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F.H. Additive manufacturing of Titanium Alloys: State of the Art, Challenges and Opportunities; Butterworth-Heinemann: Oxford, UK, 2015; ISBN 9780128047828. [Google Scholar]

- EOS GmbH No Title. Available online: https://www.eos.info/material-m (accessed on 10 September 2018).

- SLM Solutions GmbH No Title. Available online: https://slm-solutions.com/products/accessories-and-consumables/slmr-metal-powder (accessed on 11 September 2018).

- Zhai, Y.; Galarraga, H.; Lados, D.A. Microstructure evolution, tensile properties, and fatigue damage mechanisms in Ti-6Al-4V alloys fabricated by two additive manufacturing techniques. Procedia Eng. 2015, 114, 658–666. [Google Scholar] [CrossRef]

- Chastand, V.; Tezenas, A.; Cadoret, Y.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Fatigue characterization of Titanium Ti-6Al-4V samples produced by additive manufacturing. Procedia Struct. Integr. 2016, 2, 3168–3176. [Google Scholar] [CrossRef]

- Gu, D. Laser Additive Manufacturing of High-Performance Materials; Springer: Heidelberg, Germany, 2015. [Google Scholar]

- Macpherson, A.; Li, X.; McCormick, P.; Ren, L.; Yang, K.; Sercombe, T.B. Antibacterial titanium produced using selective laser melting. JOM 2017, 69, 2719–2724. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E. Selective laser melting of titanium alloy with 50 wt% tantalum: Microstructure and mechanical properties. J. Alloys Compd. 2016, 660, 461–470. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2003; ISBN 3527305343. [Google Scholar]

- DIN 17851. Titanium Alloys; Chemical Composition; Deutsches Institut für Normung E.V. (DIN): Berlin, Germany, 1990. [Google Scholar]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by selective laser melting: microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Butzhammer, L.; Dubjella, P.; Huber, F.; Schaub, A.; Aumüller, M.; Petrunenko, O.; Merklein, M.; Schmidt, M. Experimental Investigation of a Process Chain Combining Sheet Metal Bending and Laser Beam Melting of Ti-6Al-4V. In Proceedings of the Lasers in Manufacturing Conference, Munich, Germany, 26–29 June 2017. [Google Scholar]

- Papke, T.; Junker, D.; Schmidt, M.; Kolb, T.; Merklein, M. Bulk Metal Forming of Additively Manufactured Elements. In Proceedings of the 5th International Conference on New Forming Technology, Bremen, Germany, 18–21 September 2018. [Google Scholar]

- DIN 50106. Testing of Metallic Components—Compression Test at Room Temperature; Deutsches Institut für Normung E.V. (DIN): Berlin, Germany, 2016. [Google Scholar]

- Huber, F.; Rasch, M.; Butzhammer, L.; Karg, M.; Schmidt, M. Strahlschmelzen von Metallen mit unterschiedlichen Intensitäten und Belichtungsstrategien. In Proceedings of the 5. Industriekolloquium des Sonderforschungsbereichs 814—Additive Fertigung, Nürnberg, Germany, 12 December 2017. [Google Scholar]

- Mukherjee, T.; Wei, H.L.; De, A.; DebRoy, T. Heat and fluid flow in additive manufacturing—Part II: Powder bed fusion of stainless steel, and titanium, nickel and aluminum base alloys. Comput. Mater. Sci. 2018, 150, 369–380. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti-6Al-4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Titanium Metals Corporation Timetal® 10-2-3. Available online: http://www.timet.com/assets/local/documents/datasheets/metastablebetaalloys/10-2-3.pdf (accessed on 11 September 2018).

| Material | Ti | Al | V | Fe | Si |

|---|---|---|---|---|---|

| Specification Ti-6Al-4V (wt %) [13] | bal. | 5.5–6.75 | 3.5–4.5 | 0.0–0.3 | - |

| Ti-6Al-4V (wt %) | 89.3 | 6.3 | 4.2 | 0.2 | - |

| Fe (wt %) | - | - | - | 99.8 | 0.1 |

| V (wt %) | - | - | 99.9 | - | - |

| standard deviation < 0.1 wt % | |||||

| Material | Laser Power | Scan Speed | Spot Diameter | Hatch Distance | Layer Thickness |

|---|---|---|---|---|---|

| Ti-6Al-4V | 100 W | 600 mm/s | 70 µm | 60 µm | 30 µm |

| Ti-6Al-4V + 2Fe + 6V | 100 W | 600 mm/s | 40 µm | 60 µm | 30 µm |

| AN 850 °C | Annealed at 850 °C, 2 h |

| S 1050 °C + PH | Solution heat-treated at 1050 °C, 20 min; water quenched; precipitation-hardened at 500 °C, 8 h |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huber, F.; Papke, T.; Scheitler, C.; Hanrieder, L.; Merklein, M.; Schmidt, M. In Situ Formation of a Metastable β-Ti Alloy by Laser Powder Bed Fusion (L-PBF) of Vanadium and Iron Modified Ti-6Al-4V. Metals 2018, 8, 1067. https://doi.org/10.3390/met8121067

Huber F, Papke T, Scheitler C, Hanrieder L, Merklein M, Schmidt M. In Situ Formation of a Metastable β-Ti Alloy by Laser Powder Bed Fusion (L-PBF) of Vanadium and Iron Modified Ti-6Al-4V. Metals. 2018; 8(12):1067. https://doi.org/10.3390/met8121067

Chicago/Turabian StyleHuber, Florian, Thomas Papke, Christian Scheitler, Lukas Hanrieder, Marion Merklein, and Michael Schmidt. 2018. "In Situ Formation of a Metastable β-Ti Alloy by Laser Powder Bed Fusion (L-PBF) of Vanadium and Iron Modified Ti-6Al-4V" Metals 8, no. 12: 1067. https://doi.org/10.3390/met8121067

APA StyleHuber, F., Papke, T., Scheitler, C., Hanrieder, L., Merklein, M., & Schmidt, M. (2018). In Situ Formation of a Metastable β-Ti Alloy by Laser Powder Bed Fusion (L-PBF) of Vanadium and Iron Modified Ti-6Al-4V. Metals, 8(12), 1067. https://doi.org/10.3390/met8121067