Compensation of Vertical Position Error Using a Force–Deflection Model in Friction Stir Spot Welding

Abstract

1. Introduction

2. Materials and Methods

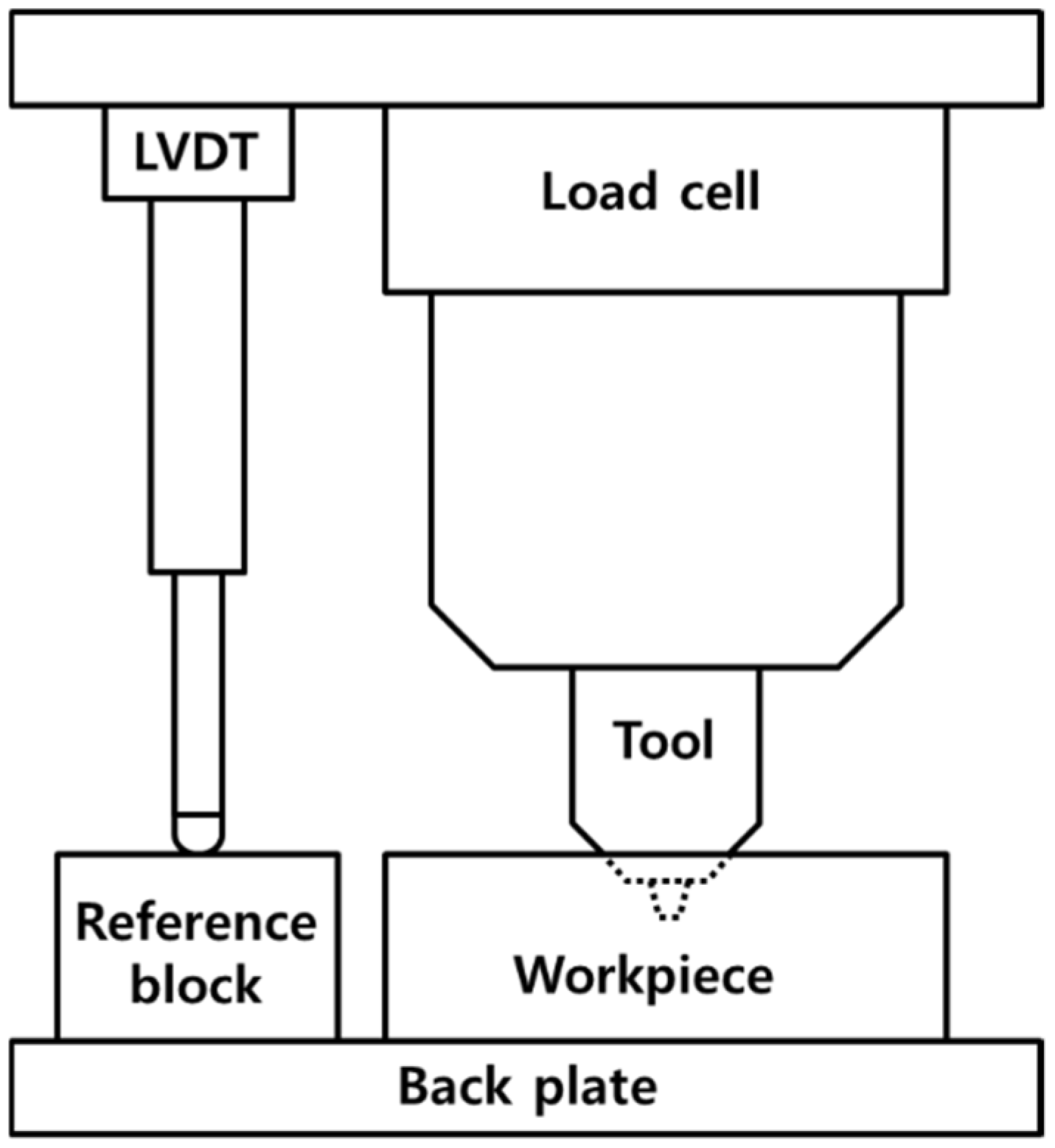

2.1. Experimental Set-Up

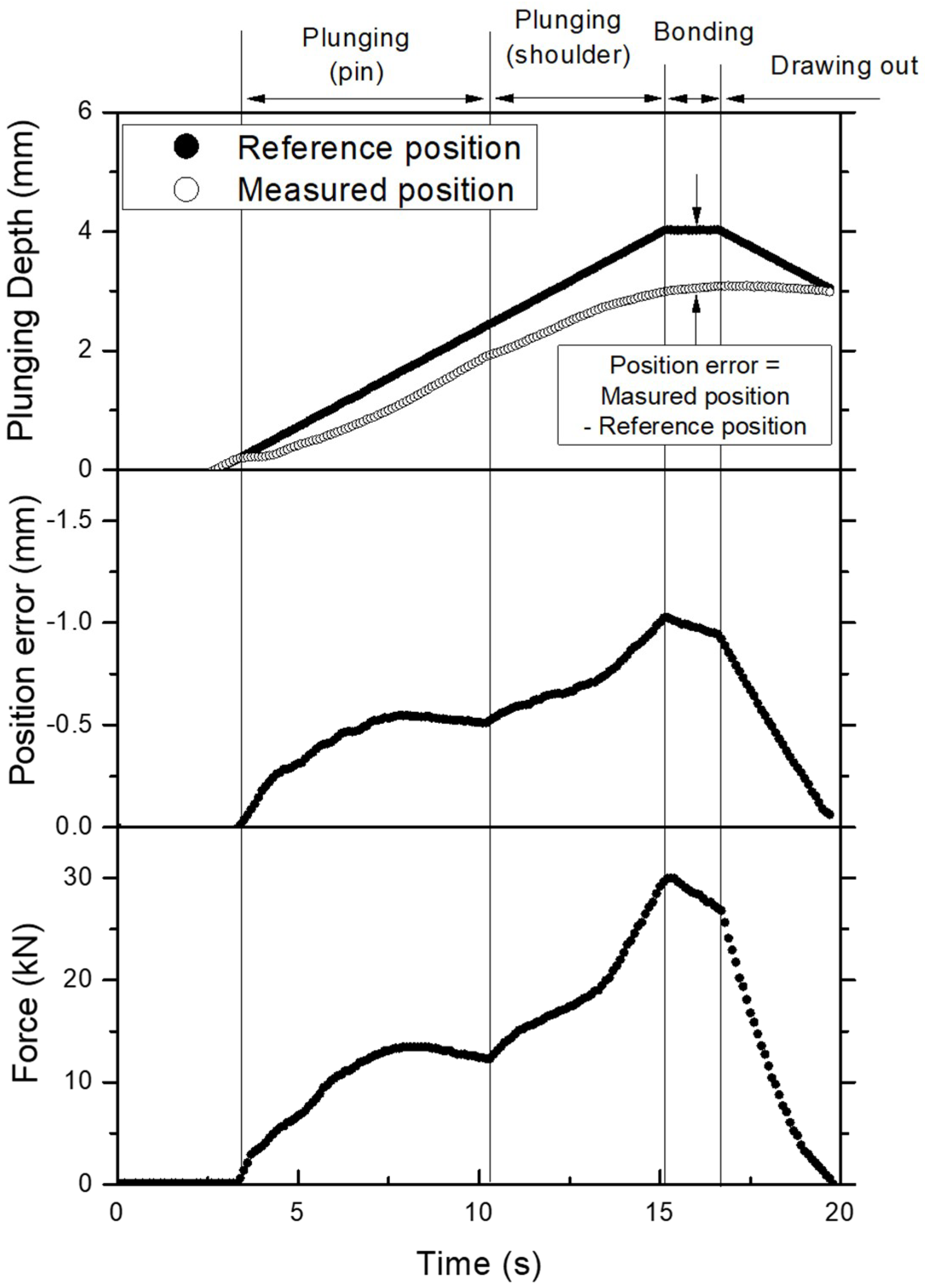

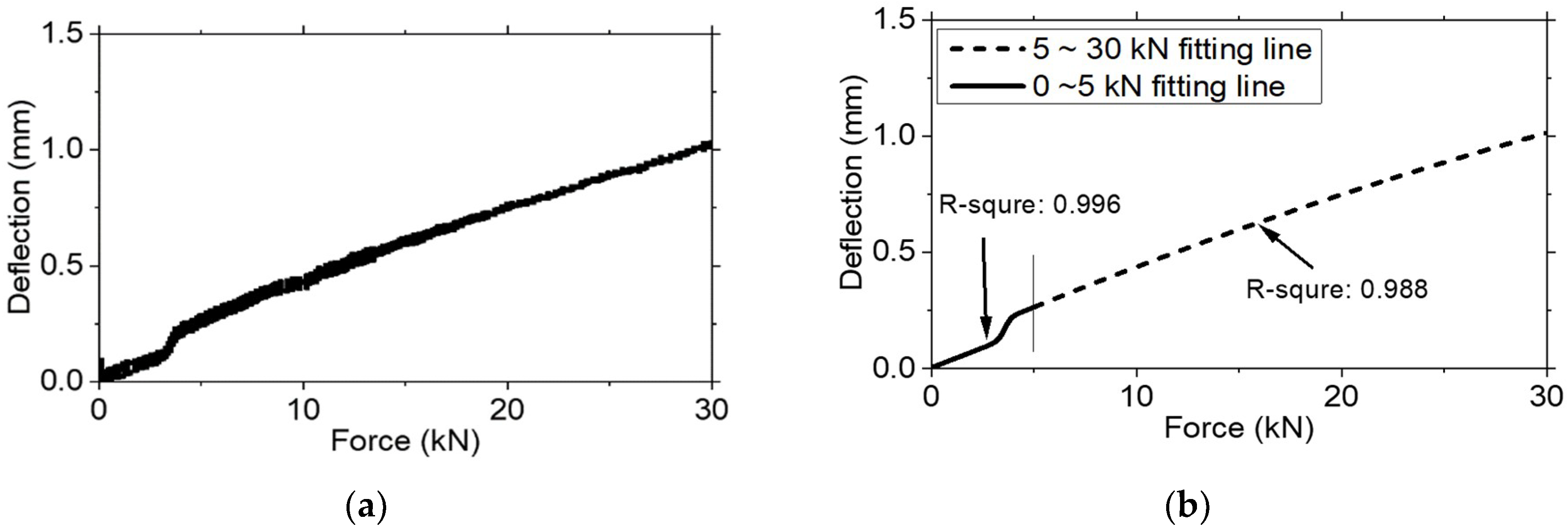

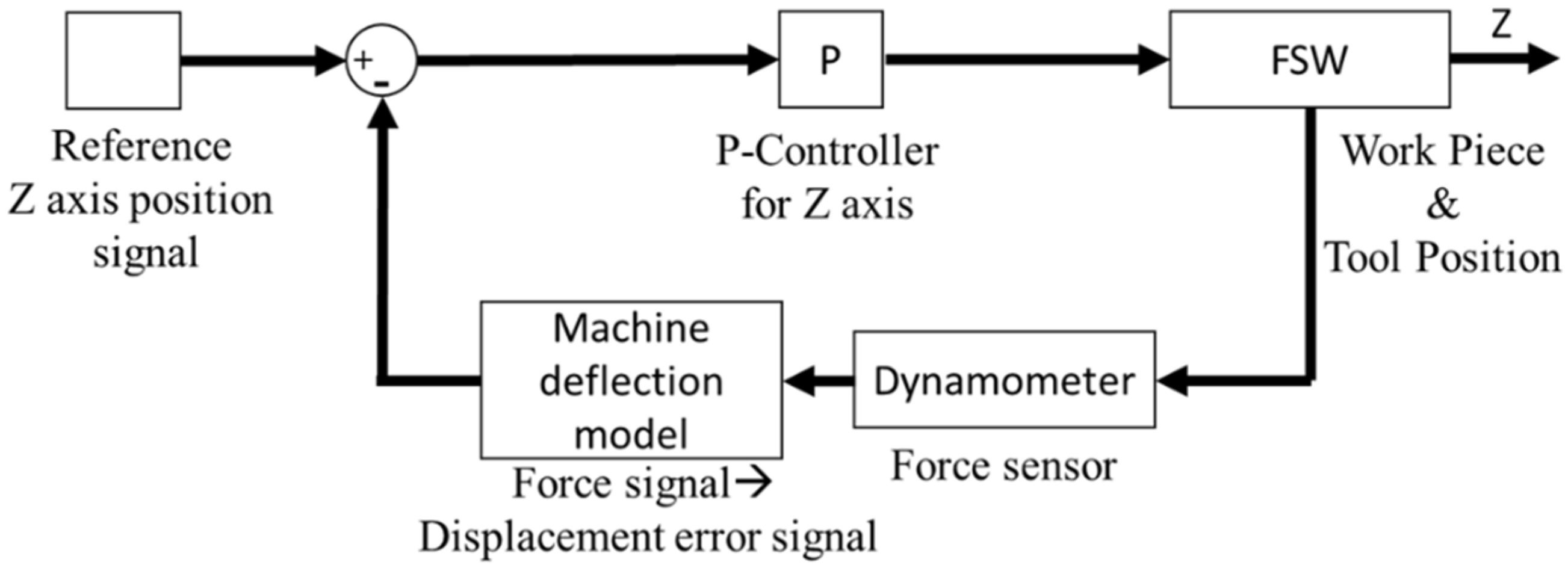

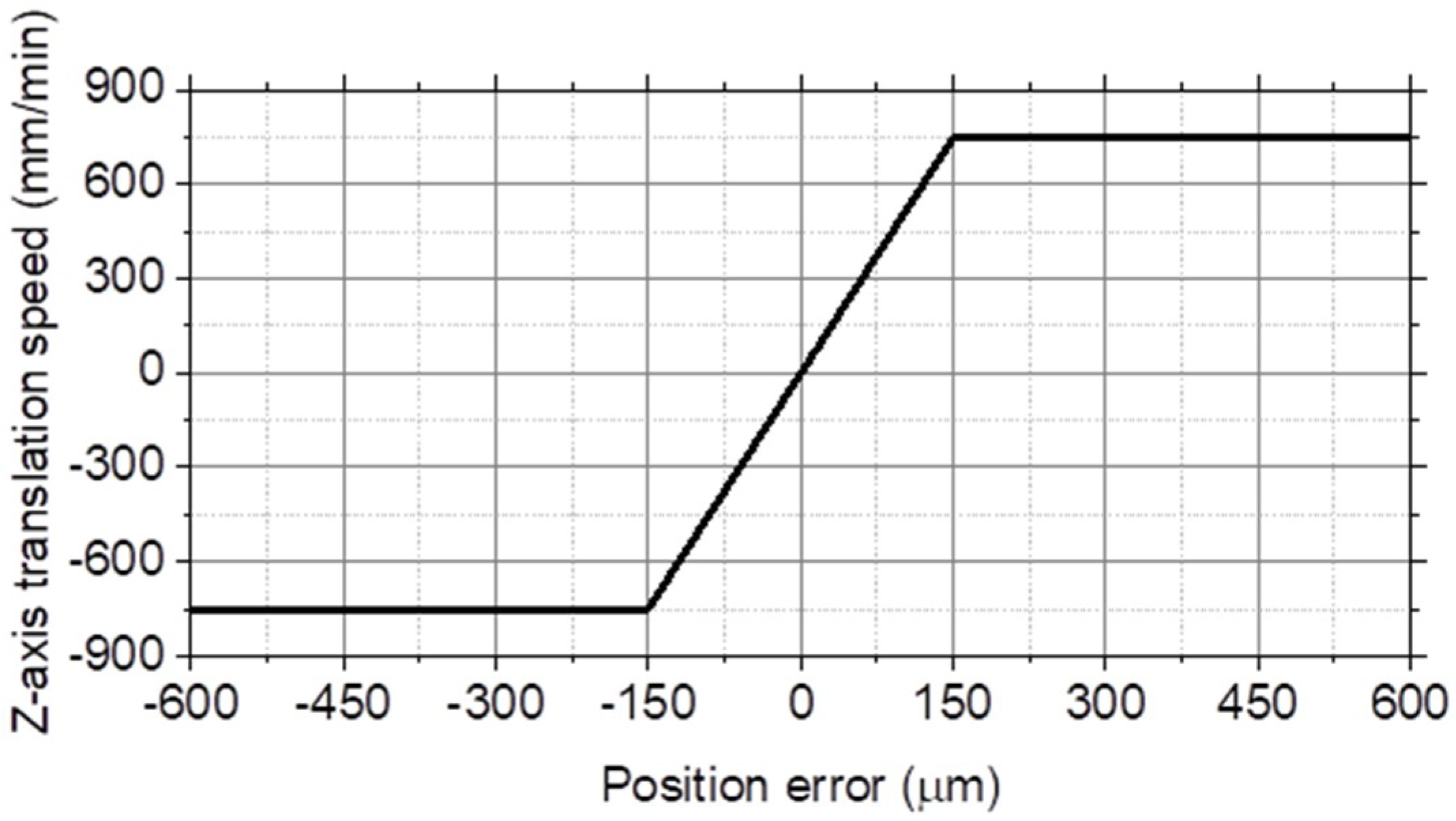

2.2. Force–Deflection Relationship

3. Results and Discussion

4. Conclusions

- (1)

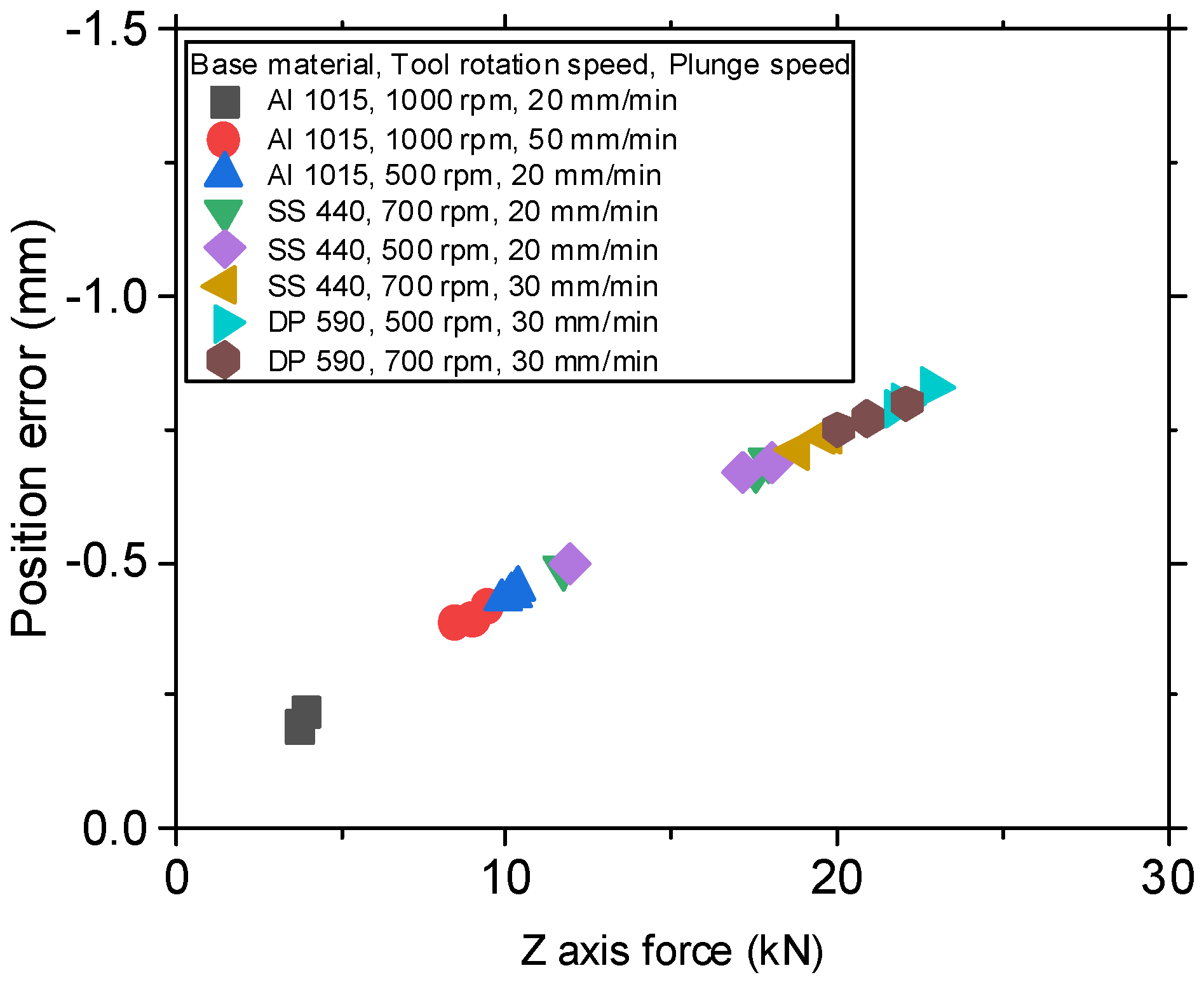

- The deflection of a system is linearly proportional to force and is measurable through a coaxial load cell. The relationship is dependent on nothing but the FSSW system, regardless of the base materials and process parameters (including tool shape).

- (2)

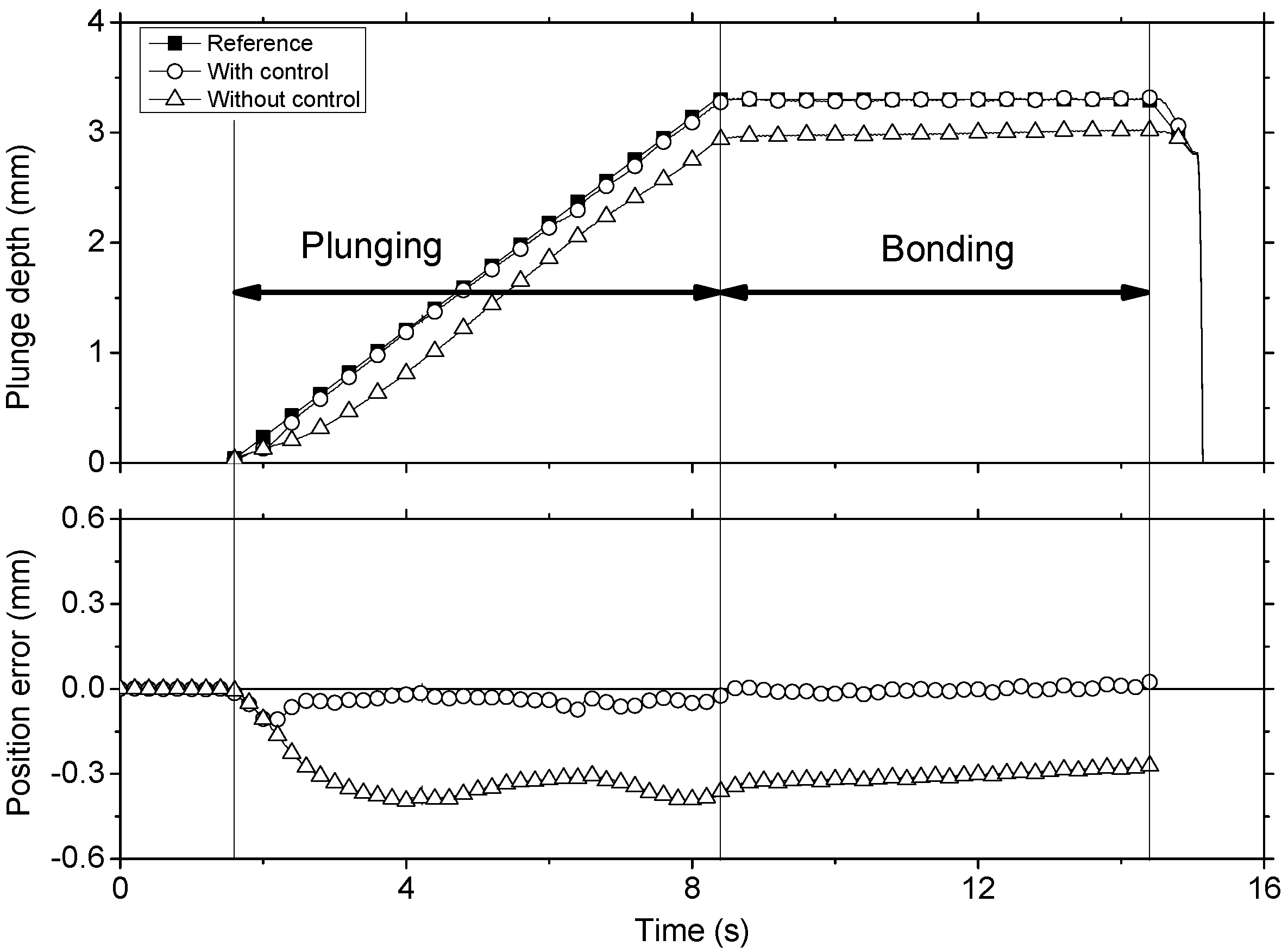

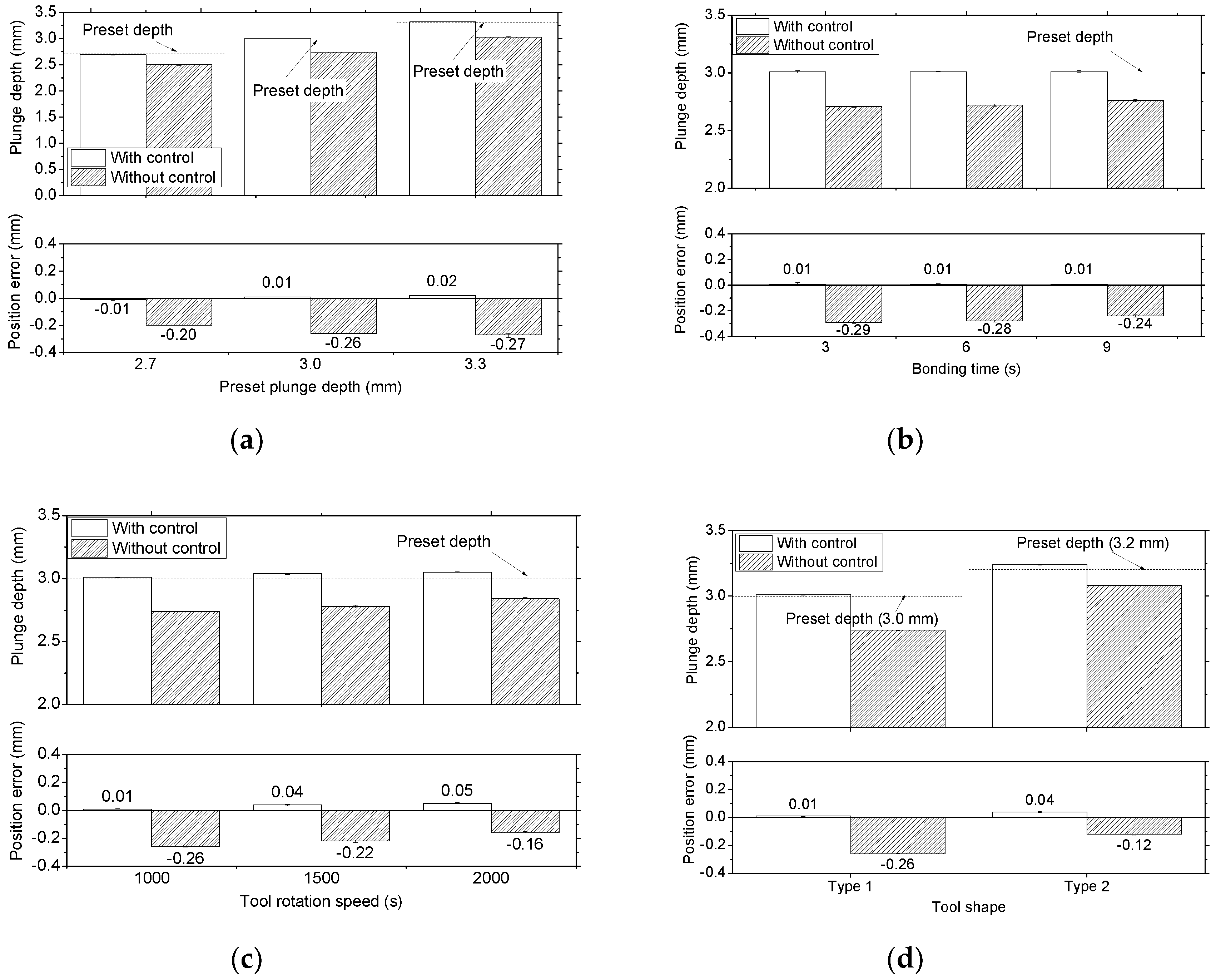

- The performance of the suggested control method was evaluated during the BOP FSSW of an Al alloy. Under varying welding conditions, the position error was corrected to under 50 μm (compared with 0.28 mm when the control was not applied).

- (3)

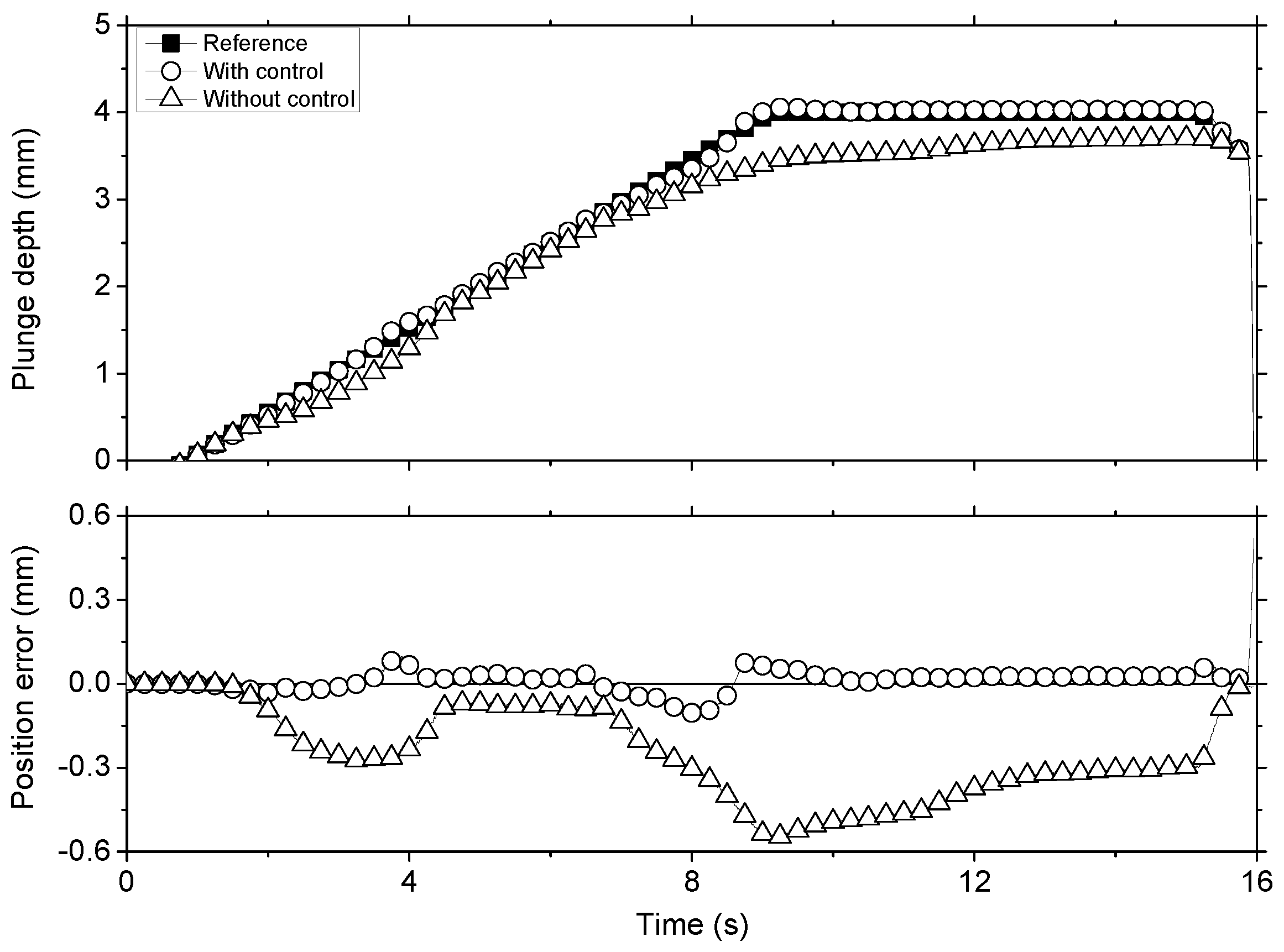

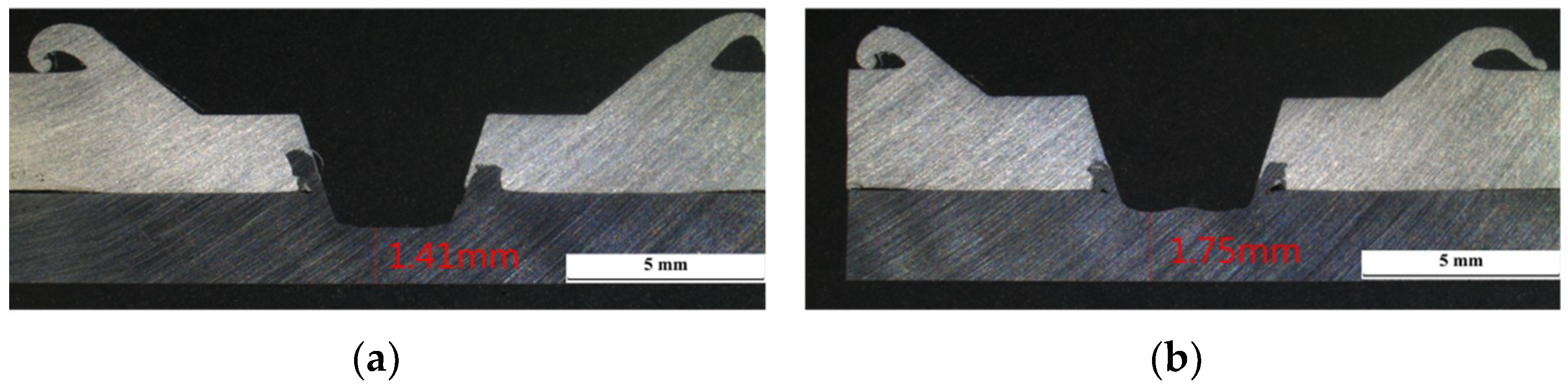

- The adaptive control for the plunge depth was successfully implemented in the FSSW of an Al/Fe dissimilar metal joint. The welding tool could plunge to the preset depth with an error of 30 μm. In the cross-section of welds, the plunge depth was almost equal to the preset depth, and a sufficiently high hook was formed to ensure the designed joint strength.

Author Contributions

Funding

Acknowledgements

Conflicts of Interest

References

- Thomas, W.; Nicholas, E.; Needham, J.C.; Murch, M.; Templesmith, P.; Dawes, C. Friction Stir Welding. Patent No. PCT/GB92102203, 1 December 1991. [Google Scholar]

- Threadgill, P.; Leonard, A.; Shercliff, H.; Withers, P. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z. Friction stir welding and processing. Mater. Sci. Eng. R Res. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H. Recent advances in friction-stir welding–process, weldment structure and properties. Prog. Mater Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Lee, W.-B.; Jung, S.-B. The joint properties of copper by friction stir welding. Mater. Lett. 2004, 58, 1041–1046. [Google Scholar] [CrossRef]

- Thomas, W.; Threadgill, P.; Nicholas, E. Feasibility of friction stir welding steel. Sci. Technol. Weld. Join. 1999, 4, 365–372. [Google Scholar] [CrossRef]

- Lienert, T.; Stellwag, W., Jr.; Grimmett, B.; Warke, R. Friction stir welding studies on mild steel. Weld. J. 2003, 82, 1s–9s. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Juhas, M.C. Microstructural evolution in Ti-6Al-4V friction stir welds. Mater. Sci. Forum 2003, 426, 2999–3004. [Google Scholar] [CrossRef]

- Prado, R.; Murr, L.; Shindo, D.; Soto, K. Tool wear in the friction-stir welding of aluminum alloy 6061+Al2O3: A preliminary study. Scripta Mater. 2001, 45, 75–80. [Google Scholar] [CrossRef]

- Hirano, S. Microstructure of dissimilar joint interface of magnesium alloy and aluminum alloy by friction stir welding. Q. J. Jpn. Weld. Soc. 2003, 21, 539–544. [Google Scholar] [CrossRef]

- Lee, W.-B.; Schmuecker, M.; Mercardo, U.A.; Biallas, G.; Jung, S.-B. Interfacial reaction in steel–aluminum joints made by friction stir welding. Scripta Mater. 2006, 55, 355–358. [Google Scholar] [CrossRef]

- Kimapong, K.; Watanabe, T. Friction stir welding of aluminum alloy to steel. Weld. J. 2004, 83, 277s–282s. [Google Scholar]

- McLean, A.; Powell, G.; Brown, I.; Linton, V. Friction stir welding of magnesium alloy AZ31B to aluminium alloy 5083. Sci. Technol. Weld. Join. 2003, 8, 462–464. [Google Scholar] [CrossRef]

- Chen, Y.C.; Nakata, K. Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater. Des. 2009, 30, 469–474. [Google Scholar] [CrossRef]

- Yang, X.W.; Fu, T.; Li, W.Y. Friction Stir Spot Welding: A Review on Joint Macro- and Microstructure, Property, and Process Modelling. Adv. Mater. Sci. Eng. 2014, 2014. [Google Scholar] [CrossRef]

- Nguyen, N.-T.; Kim, D.-Y.; Kim, H.Y. Assessment of the failure load for an AA6061-T6 friction stir spot welding joint. Proc. Inst. Mech. Eng. Pt. B J. Eng. Manuf. 2011, 225, 1746–1756. [Google Scholar] [CrossRef]

- Gerlich, A.; Su, P.; North, T.H. Tool penetration during friction stir spot welding of Al and Mg alloys. J. Mater. Sci. 2005, 40, 6473–6481. [Google Scholar] [CrossRef]

- Mendes, N.; Neto, P.; Loureiro, A.; Moreira, A.P. Machines and control systems for friction stir welding: A review. Mater. Des. 2016, 90, 256–265. [Google Scholar] [CrossRef]

- Smith, C.B. Robotic friction stir welding using a standard industrial robot. In Proceedings of the Second Friction Stir Welding International Symposium, Gothenburg, Sweden, 26–28 June 2000; TWI Ltd.: Cambridge, UK, 2000. [Google Scholar]

- Fehrenbacher, A.; Smith, C.B.; Duffie, N.A.; Ferrier, N.J.; Pfefferkorn, F.E.; Zinn, M.R. Combined Temperature and Force Control for Robotic Friction Stir Welding. J. Manuf. Sci. Eng. 2014, 136. [Google Scholar] [CrossRef]

- Gibson, B.T.; Lammlein, D.H.; Prater, T.J.; Longhurst, W.R.; Cox, C.D.; Ballun, M.C.; Dharmaraj, K.J.; Cook, G.E.; Strauss, A.M. Friction stir welding: Process, automation, and control. J. Manuf. Process. 2014, 16, 56–73. [Google Scholar] [CrossRef]

- Longhurst, W.R.; Strauss, A.M.; Cook, G.E.; Cox, C.D.; Hendricks, C.E.; Gibson, B.T.; Dawant, Y.S. Investigation of force-controlled friction stir welding for manufacturing and automation. Proc. Inst. Mech. Eng. Pt. B J. Eng. Manuf. 2009, 224, 937–949. [Google Scholar] [CrossRef]

- Guillo, M.; Dubourg, L. Dual control loop force/position with secondary encoders: Impact & improvement of industrial robot deviation on FSW quality. In Proceedings of the 11th International Symposium on Friction Stir Welding, Cambridge, UK, 17–19 May 2016. [Google Scholar]

- Gibson, B.T.; Cox, C.D.; Longhurst, W.R.; Strauss, A.M.; Cook, G.E. Exploiting robotic link deflection for low-cost force measurement in manufacturing. Measurement 2012, 45, 140–143. [Google Scholar] [CrossRef]

- De Backer, J.; Bolmsjö, G. Deflection model for robotic friction stir welding. Ind. Robot. Int. J. 2014, 41, 365–372. [Google Scholar] [CrossRef]

- Cederqvist, L.; Garpinger, O.; Nielsen, I. Depth and Temperature Control During Friction Stir Welding of 5 cm Thick Copper Canisters. In Friction Stir Welding and Processing IX; Hovanski, Y., Mishra, R., Sato, Y., Upadhyay, P., Yan, D., Eds.; Springer: Cham, Switzerland, 2017; pp. 249–260. [Google Scholar]

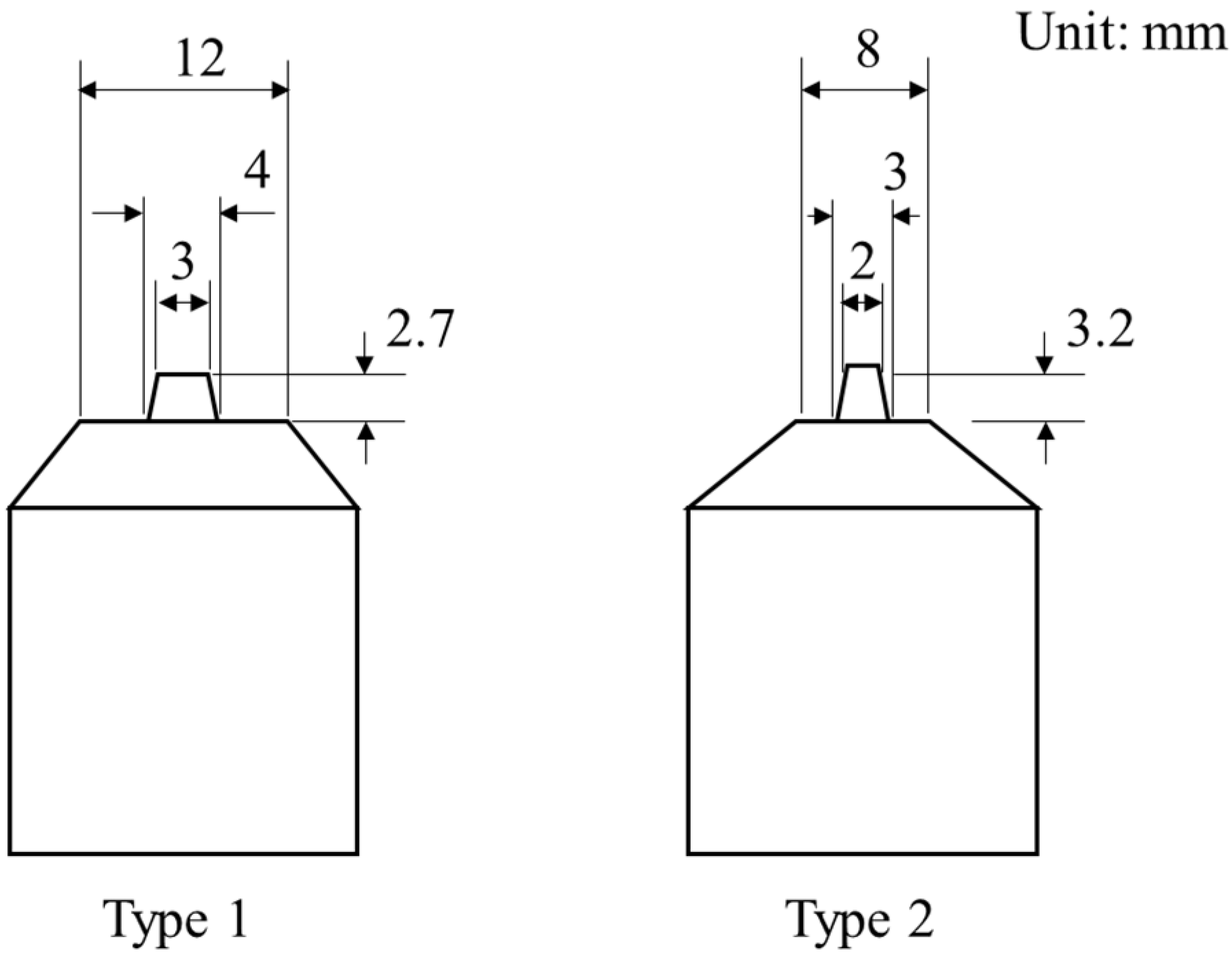

| Experiment No. | Plunge Depth (mm) | Bonding Time (s) | Tool Rotation Speed (rpm) | Tool Shape | Material | Thickness (mm) |

|---|---|---|---|---|---|---|

| 1 | 2.7 | 6 | 1000 | Type 1 | Al 6061-T6 | 4 |

| 2 | 3 | 6 | ||||

| 3 | 3.3 | 6 | ||||

| 4 | 3 | 3 | ||||

| 5 | 3 | 6 | ||||

| 6 | 3 | 9 | ||||

| 7 | 3 | 6 | ||||

| 8 | 3 | 6 | 1500 | |||

| 9 | 3 | 6 | 2000 | |||

| 10 | 3 | 6 | 1000 | |||

| 11 | 3.2 | 6 | Type 2 | |||

| 12 | 4 | 6 | 1500 | Al6061-T6/ DP 590 | 3 (upper)/2.3 (lower) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, J.; Kim, C.; Rhee, S. Compensation of Vertical Position Error Using a Force–Deflection Model in Friction Stir Spot Welding. Metals 2018, 8, 1049. https://doi.org/10.3390/met8121049

Yoon J, Kim C, Rhee S. Compensation of Vertical Position Error Using a Force–Deflection Model in Friction Stir Spot Welding. Metals. 2018; 8(12):1049. https://doi.org/10.3390/met8121049

Chicago/Turabian StyleYoon, Jinyoung, Cheolhee Kim, and Sehun Rhee. 2018. "Compensation of Vertical Position Error Using a Force–Deflection Model in Friction Stir Spot Welding" Metals 8, no. 12: 1049. https://doi.org/10.3390/met8121049

APA StyleYoon, J., Kim, C., & Rhee, S. (2018). Compensation of Vertical Position Error Using a Force–Deflection Model in Friction Stir Spot Welding. Metals, 8(12), 1049. https://doi.org/10.3390/met8121049