Tensile Deformation Behavior of Medium Manganese Steels with High Carbon Concentrations and Austenitic Microstructures

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

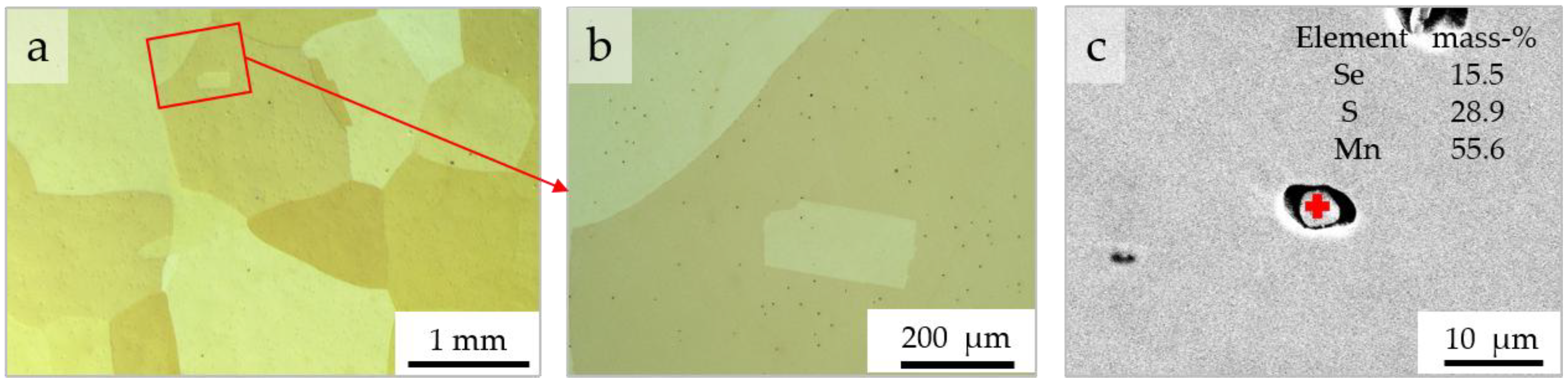

3.1. Microstructure Prior to Tensile Tests

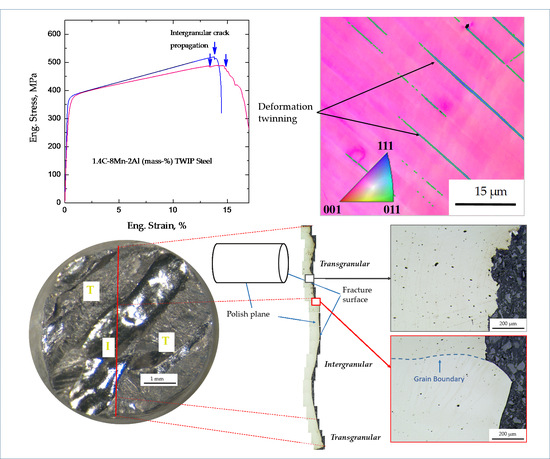

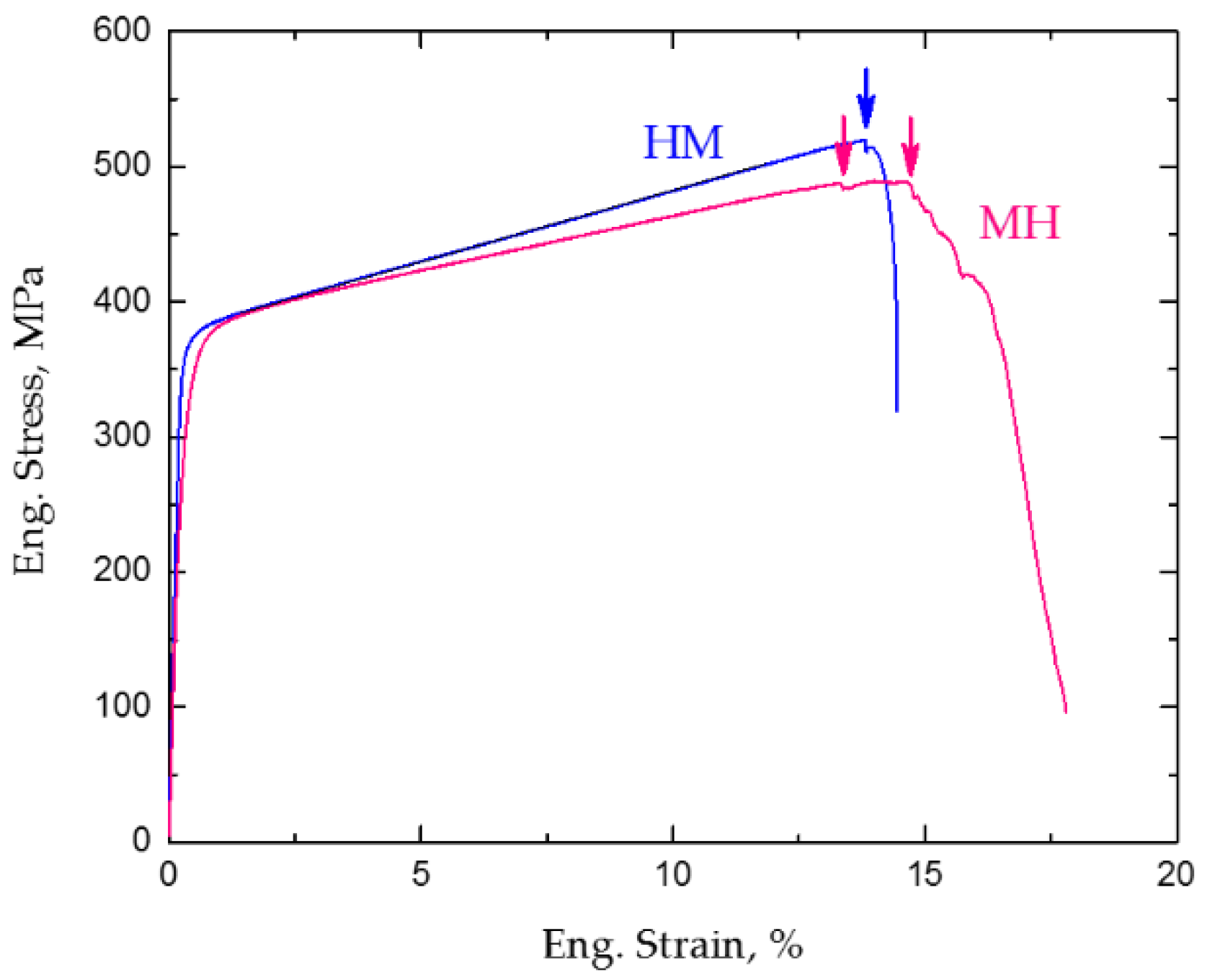

3.2. Tensile Properties and Work-Hardening Behavior

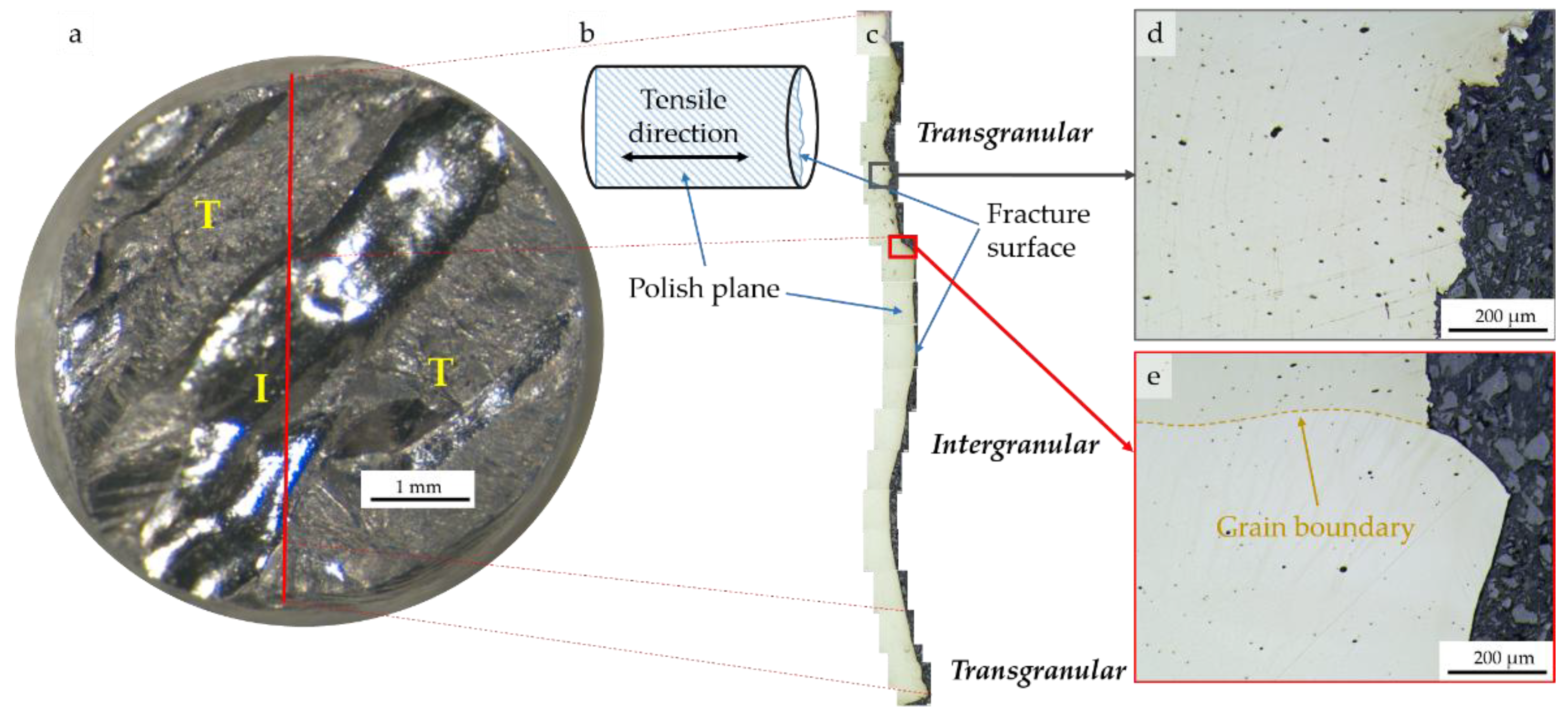

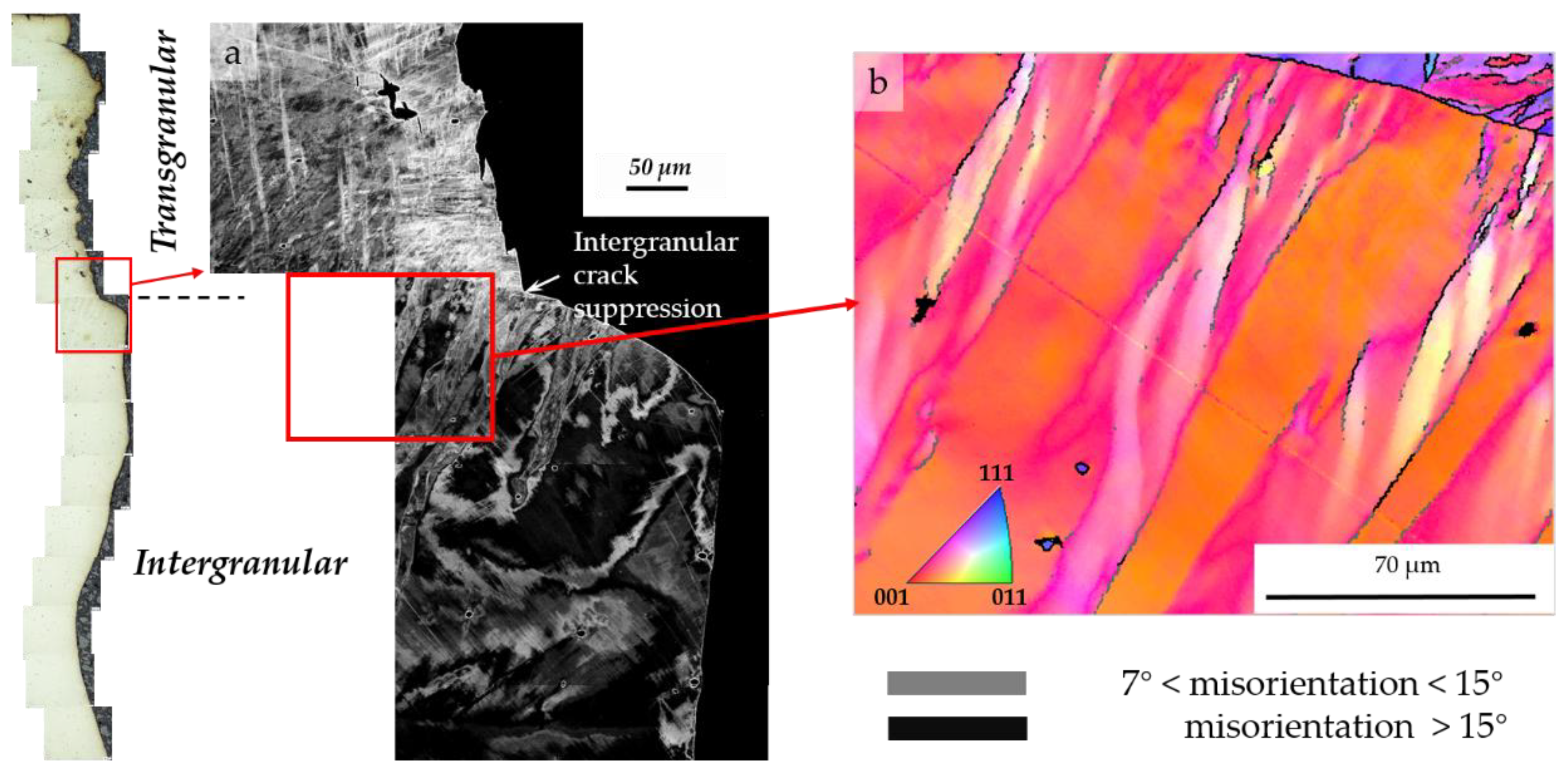

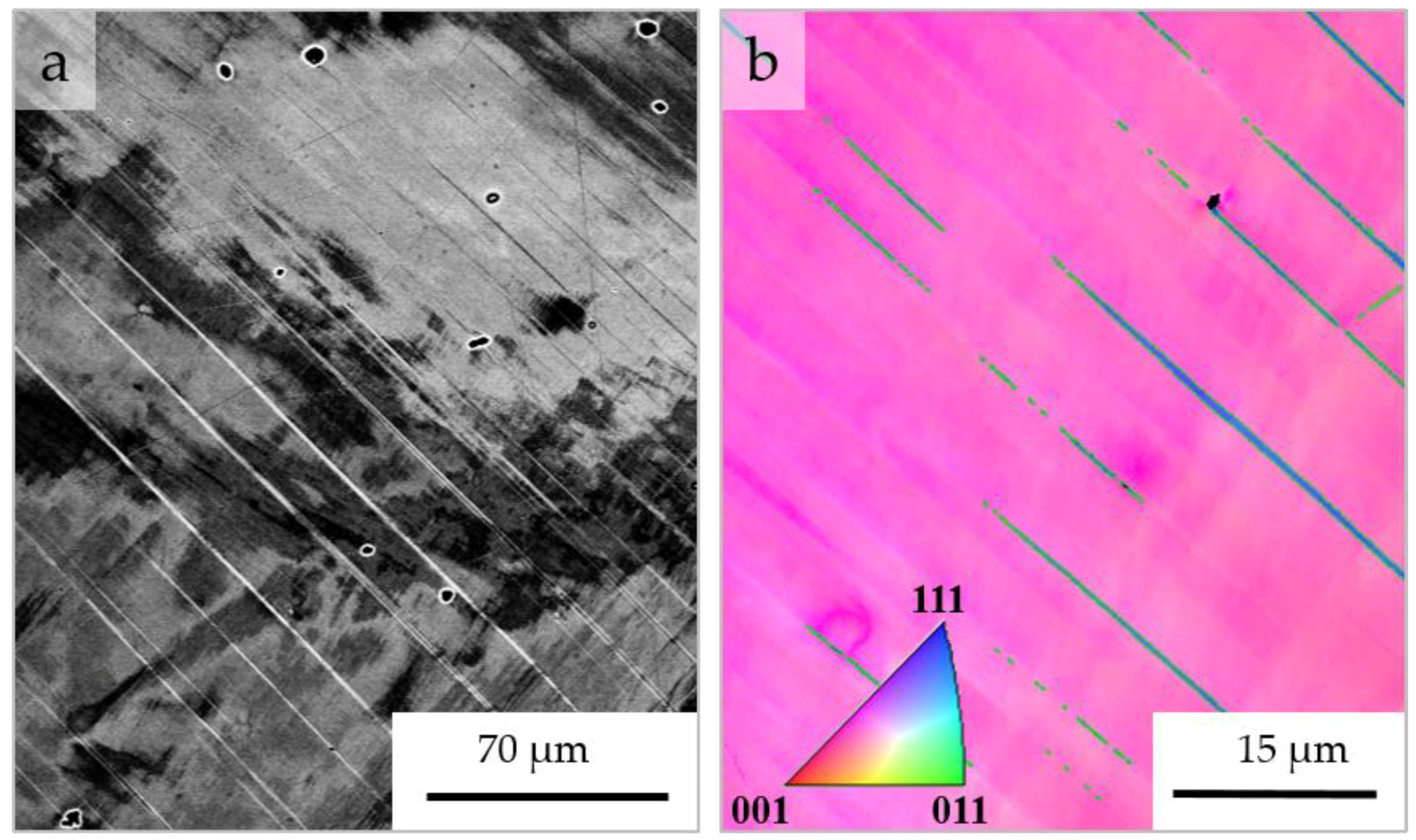

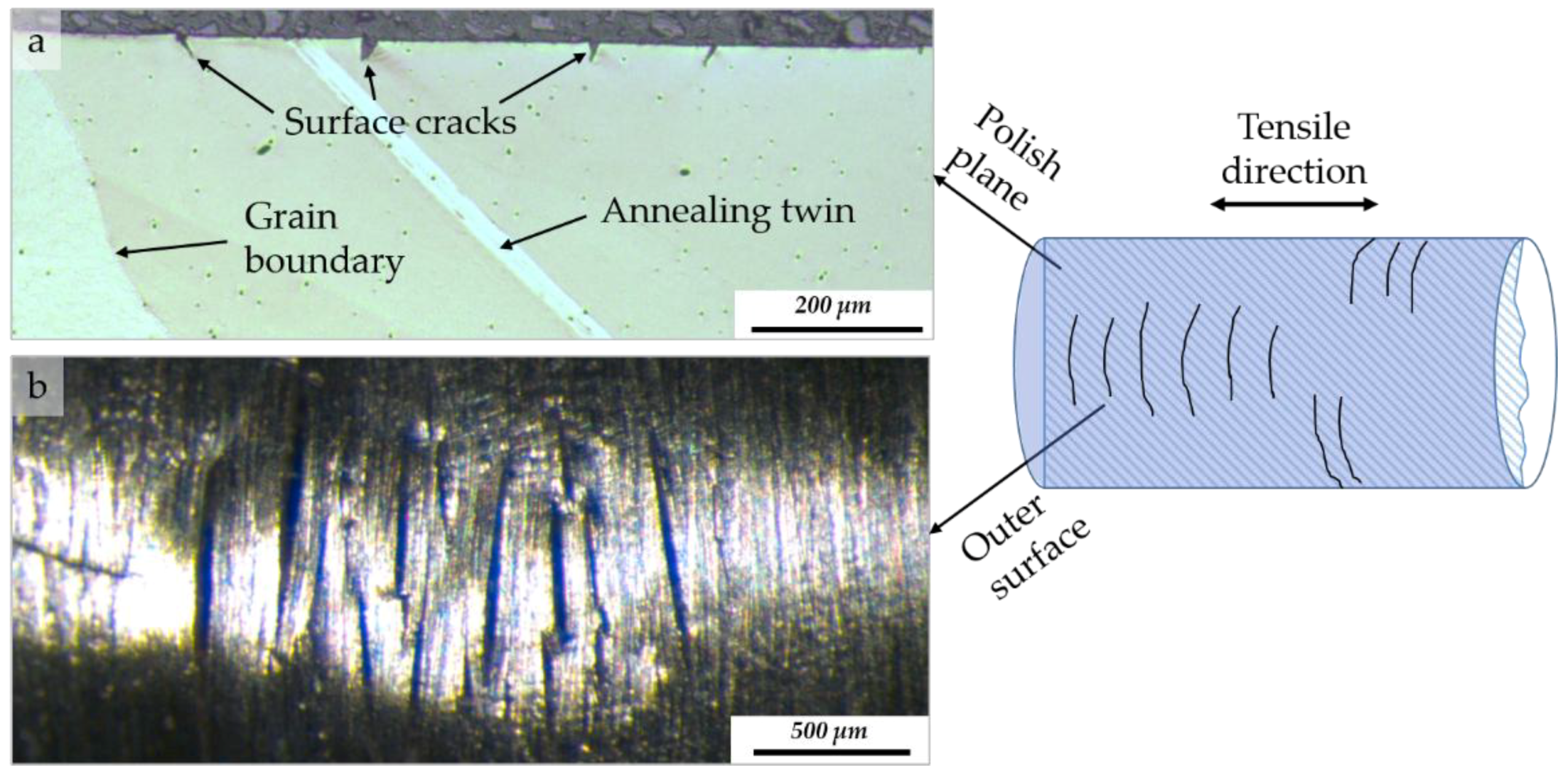

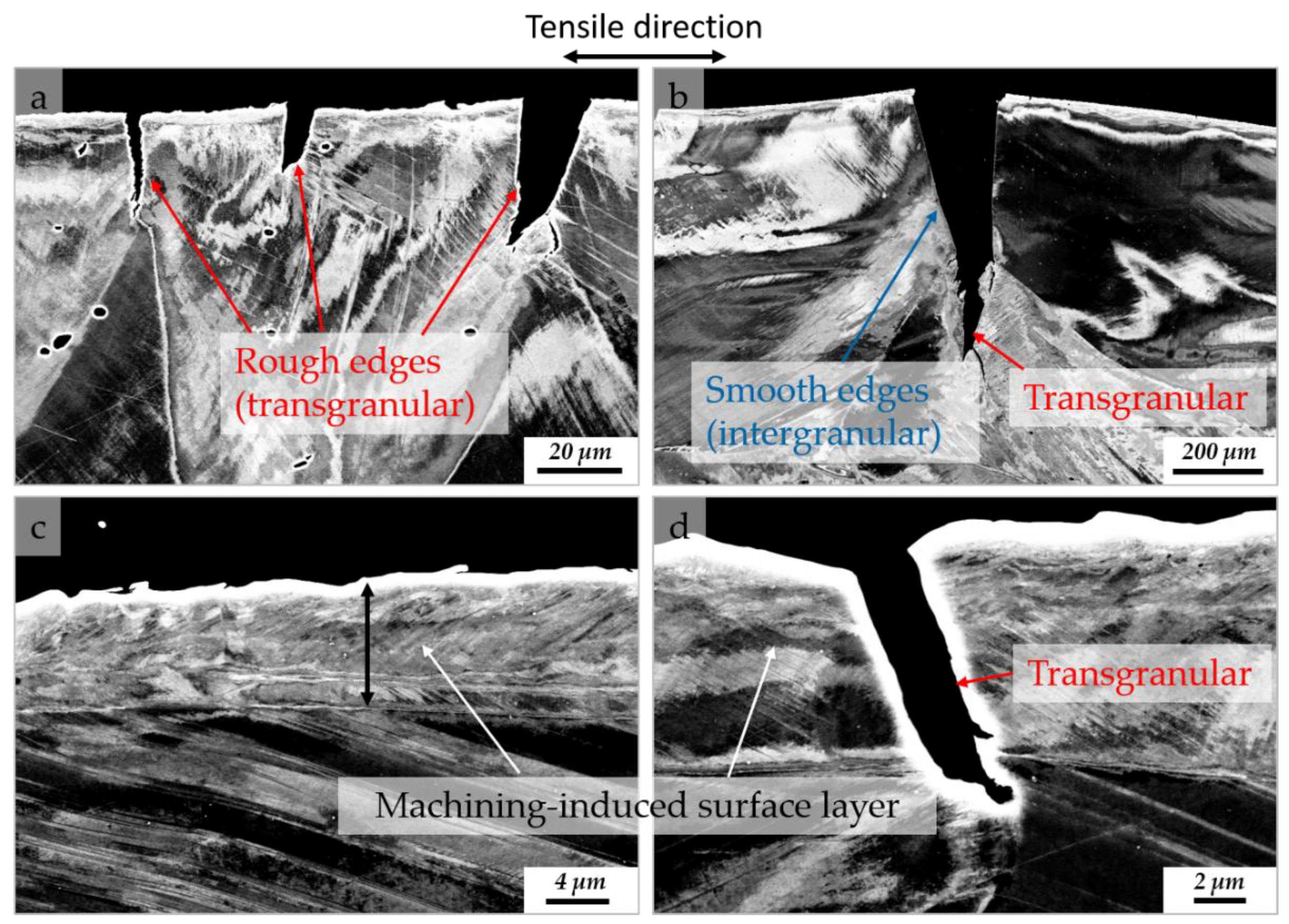

3.3. Macro- and Microstructural Examination of Fractured Tensile Specimens

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Hwang, S.W.; Ji, J.H.; Park, K.-T. Effects of Al addition on high strain rate deformation of fully austenitic high Mn steels. Mater. Sci. Eng. A 2011, 528, 7267–7275. [Google Scholar] [CrossRef]

- Chen, M.-S.; Cheng, H.-C.; Huang, C.-F.; Chao, C.-Y.; Ou, K.-L.; Yu, C.-H. Effects of C and Cr content on high-temperature microstructures of Fe–9Al–30Mn–xC–yCr alloys. Mater. Charact. 2010, 61, 206–211. [Google Scholar] [CrossRef]

- Yoo, J.D.; Park, K.-T. Microband-induced plasticity in a high Mn–Al–C light steel. Mater. Sci. Eng. A 2008, 496, 417–424. [Google Scholar] [CrossRef]

- Cooman, B.C.D.; Chen, L.; Kim, H.S.; Estrin, Y.; Kim, S.K.; Voswinckel, H. State-of-the-Science of High Manganese TWIP Steels for Automotive Applications. In Microstructure and Texture in Steels; Springer: London, UK, 2009; pp. 165–183. ISBN 978-1-84882-453-9. [Google Scholar]

- Sohn, S.S.; Hong, S.; Lee, J.; Suh, B.-C.; Kim, S.-K.; Lee, B.-J.; Kim, N.J.; Lee, S. Effects of Mn and Al contents on cryogenic-temperature tensile and Charpy impact properties in four austenitic high-Mn steels. Acta Mater. 2015, 100, 39–52. [Google Scholar] [CrossRef]

- Choi, J.K.; Lee, S.-G.; Park, Y.-H.; Han, I.-W.; Morris, J.W.J. High Manganese Austenitic Steel For Cryogenic Applications. In Proceedings of the Twenty-second International Offshore and Polar Engineering Conference, Rhodes, Greece, 17–22 June 2012. [Google Scholar]

- Lee, C.-Y.; Jeong, J.; Han, J.; Lee, S.-J.; Lee, S.; Lee, Y.-K. Coupled strengthening in a medium manganese lightweight steel with an inhomogeneously grained structure of austenite. Acta Mater. 2015, 84, 1–8. [Google Scholar] [CrossRef]

- Tsuchiyama, T.; Inoue, T.; Tobata, J.; Akama, D.; Takaki, S. Microstructure and mechanical properties of a medium manganese steel treated with interrupted quenching and intercritical annealing. Scr. Mater. 2016, 122, 36–39. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Findley, K.O.; Speer, J.G. Influence of Temperature and Grain Size on Austenite Stability in Medium Manganese Steels. Metall. Mater. Trans. A 2017, 48, 2140–2149. [Google Scholar] [CrossRef]

- Ghasri-Khouzani, M.; McDermid, J.R. Effect of carbon content on the mechanical properties and microstructural evolution of Fe–22Mn–C steels. Mater. Sci. Eng. A 2015, 621, 118–127. [Google Scholar] [CrossRef]

- Tian, Y.Z.; Bai, Y.; Chen, M.C.; Shibata, A.; Terada, D.; Tsuji, N. Enhanced Strength and Ductility in an Ultrafine-Grained Fe-22Mn-0.6C Austenitic Steel Having Fully Recrystallized Structure. Metall. Mater. Trans. A 2014, 45, 5300–5304. [Google Scholar] [CrossRef]

- Suh, D.-W.; Park, S.-J.; Oh, C.-S.; Kim, S.-J. Influence of partial replacement of Si by Al on the change of phase fraction during heat treatment of TRIP steels. Scr. Mater. 2007, 57, 1097–1100. [Google Scholar] [CrossRef]

- Lee, S.; Cooman, B.C.D. Effect of the Intercritical Annealing Temperature on the Mechanical Properties of 10 Pct Mn Multi-phase Steel. Metall. Mater. Trans. A 2014, 45, 5009–5016. [Google Scholar] [CrossRef]

- Seo, C.-H.; Kwon, K.H.; Choi, K.; Kim, K.-H.; Kwak, J.H.; Lee, S.; Kim, N.J. Deformation behavior of ferrite–austenite duplex lightweight Fe–Mn–Al–C steel. Scr. Mater. 2012, 66, 519–522. [Google Scholar] [CrossRef]

- Heo, Y.-U.; Suh, D.-W.; Lee, H.-C. Fabrication of an ultrafine-grained structure by a compositional pinning technique. Acta Mater. 2014, 77, 236–247. [Google Scholar] [CrossRef]

- Lee, S.; Lee, K.; De Cooman, B.C. Observation of the TWIP+TRIP Plasticity-Enhancement Mechanism in Al-Added 6 Wt Pct Medium Mn Steel. Metall. Mater. Trans. A 2015, 46, 2356–2363. [Google Scholar] [CrossRef]

- Cai, Z.H.; Ding, H.; Misra, R.D.K.; Ying, Z.Y. Austenite stability and deformation behavior in a cold-rolled transformation-induced plasticity steel with medium manganese content. Acta Mater. 2015, 84, 229–236. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.-P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels. Metall. Mater. Trans. A 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Seo, E.J.; Kim, J.K.; Cho, L.; Mola, J.; Oh, C.Y.; De Cooman, B.C. Micro-plasticity of medium Mn austenitic steel: Perfect dislocation plasticity and deformation twinning. Acta Mater. 2017, 135, 112–123. [Google Scholar] [CrossRef]

- Luan, G.; Volkova, O.; Mola, J. Design of Fully Austenitic Medium Manganese Steels. IOP Conf. Ser. Mater. Sci. Eng. 2018, 373, 012002. [Google Scholar] [CrossRef]

- Kozeschnik, E.; Bhadeshia, H.K.D.H. Influence of silicon on cementite precipitation in steels. Mater. Sci. Technol. 2008, 24, 343–347. [Google Scholar] [CrossRef]

- Mola, J.; Luan, G.; Huang, Q.; Schimpf, C.; Rafaja, D. Cementite evolution in medium manganese twinning-induced plasticity steels. Materialia 2018. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Chin, K.; Kim, J. High Mn TWIP Steels for Automotive Applications. In New Trends and Developments in Automotive System Engineering; Chiaberge, M., Ed.; InTech: London, UK, 2011; ISBN 978-953-307-517-4. [Google Scholar]

- Yang, H.K.; Zhang, Z.J.; Tian, Y.Z.; Zhang, Z.F. Negative to positive transition of strain rate sensitivity in Fe-22Mn-0.6C-x(Al) twinning-induced plasticity steels. Mater. Sci. Eng. A 2017, 690, 146–157. [Google Scholar] [CrossRef]

- Dini, G.; Najafizadeh, A.; Ueji, R.; Monir-Vaghefi, S.M. Tensile deformation behavior of high manganese austenitic steel: The role of grain size. Mater. Des. 2010, 31, 3395–3402. [Google Scholar] [CrossRef]

- Karaman, I.; Sehitoglu, H.; Gall, K.; Chumlyakov, Y.I.; Maier, H.J. Deformation of single crystal Hadfield steel by twinning and slip. Acta Mater. 2000, 48, 1345–1359. [Google Scholar] [CrossRef]

- Mola, J.; Ullrich, C.; Kuang, B.; Rahimi, R.; Huang, Q.; Rafaja, D.; Ritzenhoff, R. Austenitic Nickel- and Manganese-Free Fe-15Cr-1Mo-0.4N-0.3C Steel: Tensile Behavior and Deformation-Induced Processes between 298 K and 503 K (25 °C and 230 °C). Metall. Mater. Trans. A 2017, 48, 1033–1052. [Google Scholar] [CrossRef]

- Rahimi, R.; Ullrich, C.; Klemm, V.; Rafaja, D.; De Cooman, B.C.; Biermann, H.; Mola, J. Influence of Al on the temperature dependence of strain hardening behavior and glide planarity in Fe–Cr–Ni–Mn–C austenitic stainless steels. Mater. Sci. Eng. A 2016, 649, 301–312. [Google Scholar] [CrossRef]

- Rahimi, R.; Ullrich, C.; Rafaja, D.; Biermann, H.; Mola, J. Microstructural Evolution of an Al-Alloyed Duplex Stainless Steel During Tensile Deformation Between 77 K and 473 K (−196 °C and 200 °C). Metall. Mater. Trans. A 2016, 47, 2705–2716. [Google Scholar] [CrossRef]

- Huang, Q.; Volkova, O.; Biermann, H.; Mola, J. Tensile elongation of lean-alloy austenitic stainless steels: transformation-induced plasticity versus planar glide. Mater. Sci. Technol. 2017, 33, 1224–1230. [Google Scholar] [CrossRef]

- Dieter, G.E. Mechanical Metallurgy; McGraw-Hill: New York, NY, USA, 1976; ISBN 978-0-07-016891-6. [Google Scholar]

- Berns, H.; Nabiran, N.; Mujica, L. High-Interstitial Stainless Austenitic Steel Castings. Steel Res. Int. 2013, 84, 119–128. [Google Scholar] [CrossRef]

| Steel ID | C | Mn | Al | Si | Fe + Impurities |

|---|---|---|---|---|---|

| 2Al (HM, MH) | 1.44 | 8.0 | 1.9 | 0.005 | Balance |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luan, G.; Volkova, O.; Mola, J. Tensile Deformation Behavior of Medium Manganese Steels with High Carbon Concentrations and Austenitic Microstructures. Metals 2018, 8, 902. https://doi.org/10.3390/met8110902

Luan G, Volkova O, Mola J. Tensile Deformation Behavior of Medium Manganese Steels with High Carbon Concentrations and Austenitic Microstructures. Metals. 2018; 8(11):902. https://doi.org/10.3390/met8110902

Chicago/Turabian StyleLuan, Guoqing, Olena Volkova, and Javad Mola. 2018. "Tensile Deformation Behavior of Medium Manganese Steels with High Carbon Concentrations and Austenitic Microstructures" Metals 8, no. 11: 902. https://doi.org/10.3390/met8110902

APA StyleLuan, G., Volkova, O., & Mola, J. (2018). Tensile Deformation Behavior of Medium Manganese Steels with High Carbon Concentrations and Austenitic Microstructures. Metals, 8(11), 902. https://doi.org/10.3390/met8110902