Nominal Stress-Based Equal-Fatigue-Bearing-Capacity Design of under-matched HSLA Steel Butt-welded Joints

Abstract

1. Introduction

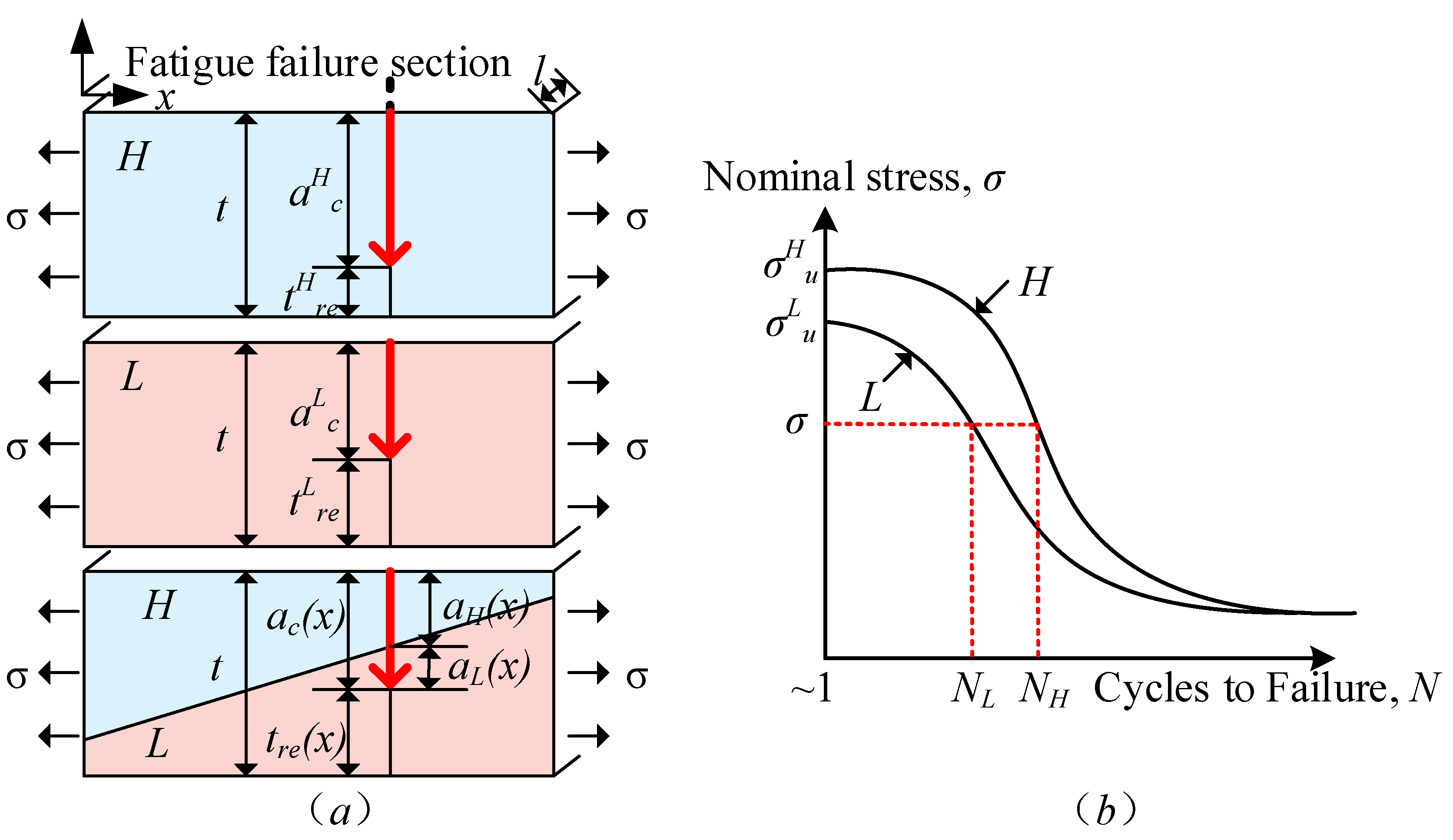

2. Nominal Stress Based Fatigue Assessment of Homogeneous Materials

3. Nominal Stress Based Fatigue Assessment of Heterogeneous Materials

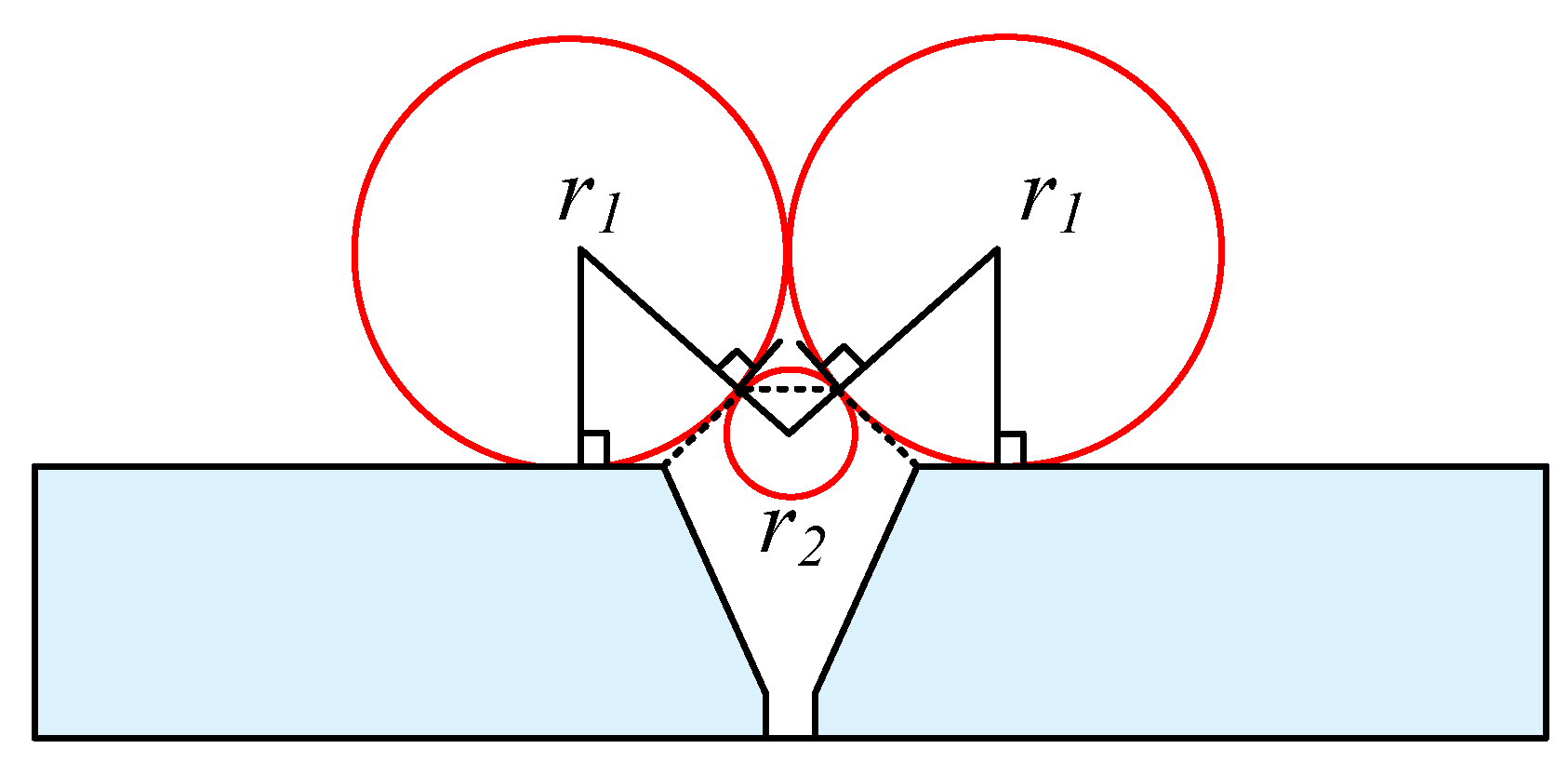

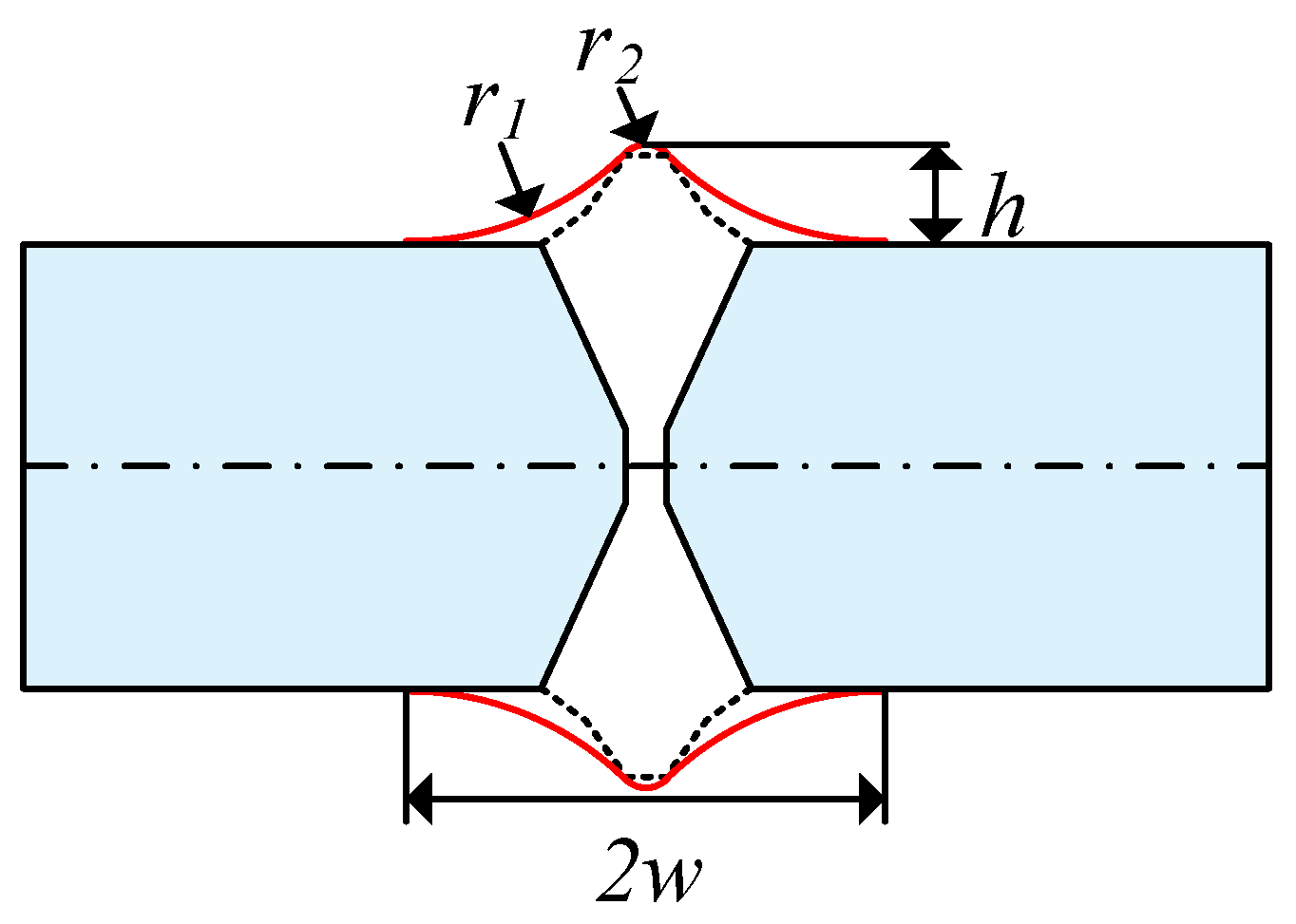

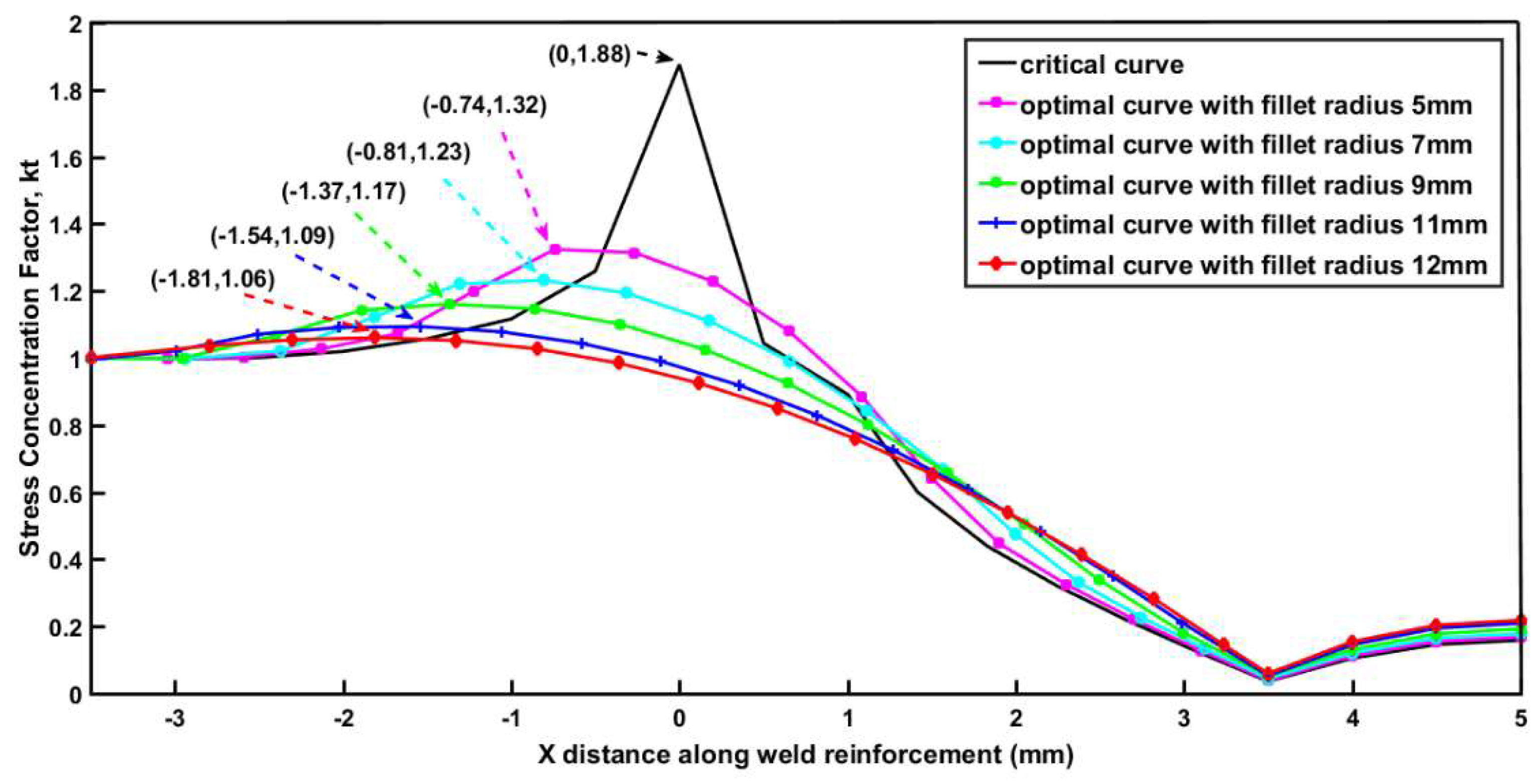

4. Nominal Stress based EFBC Design of Under-Matched Butt-Welded Joints

5. Experimental Verification

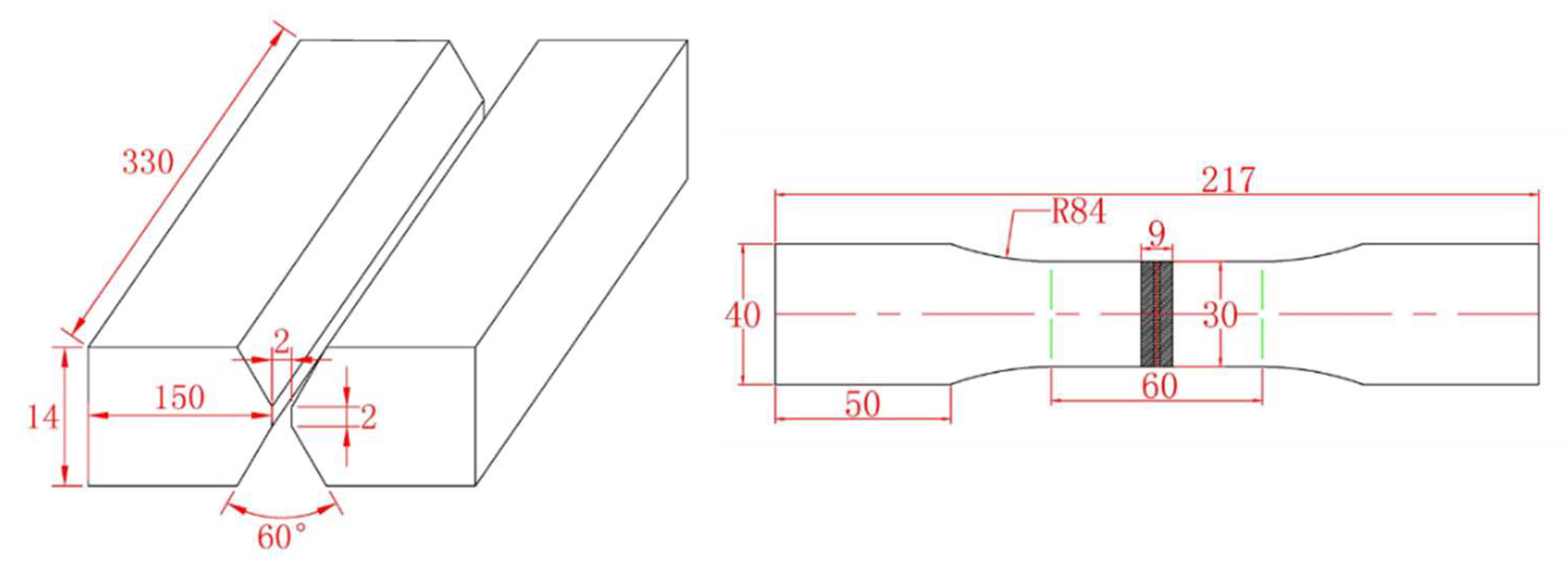

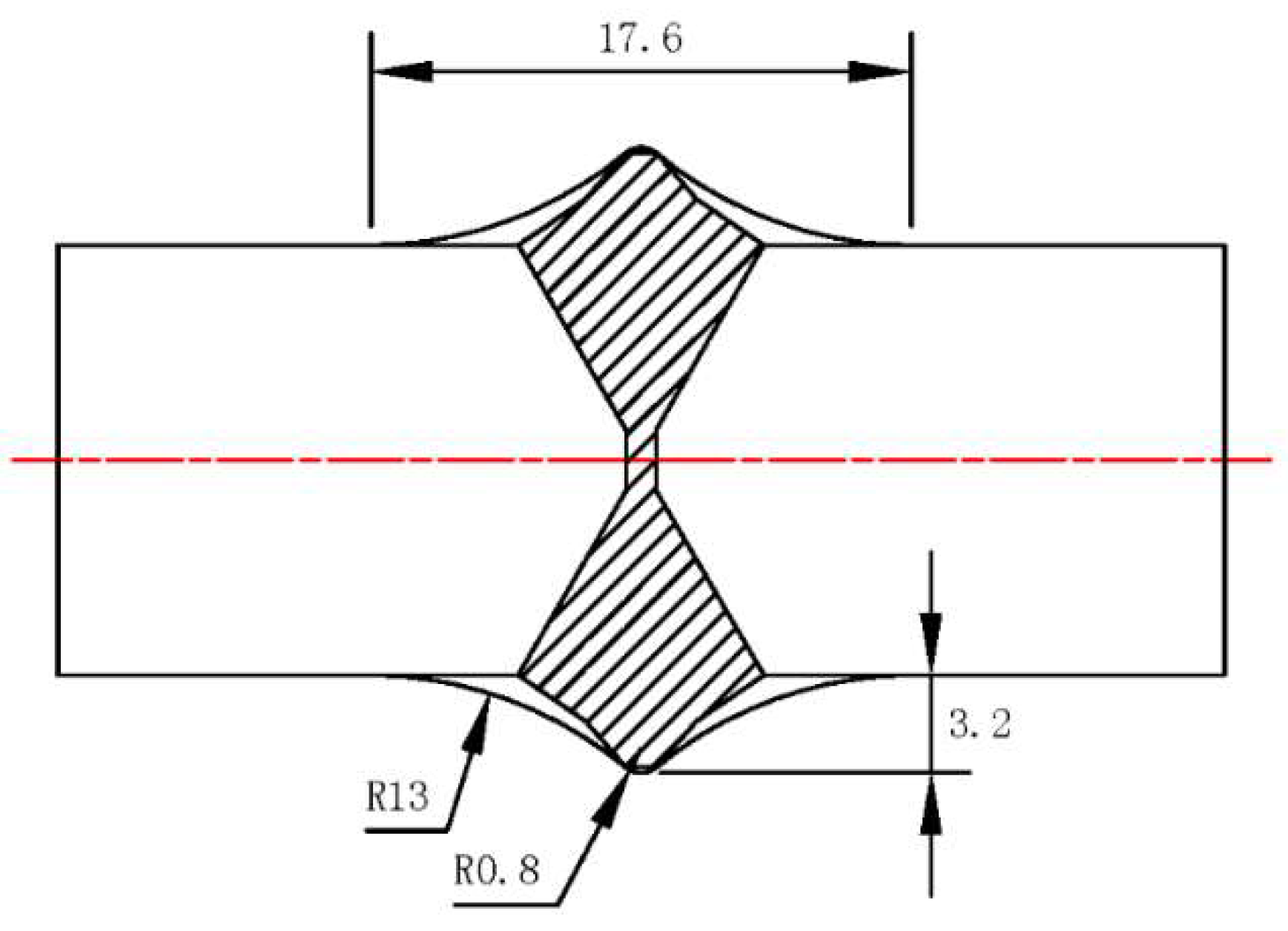

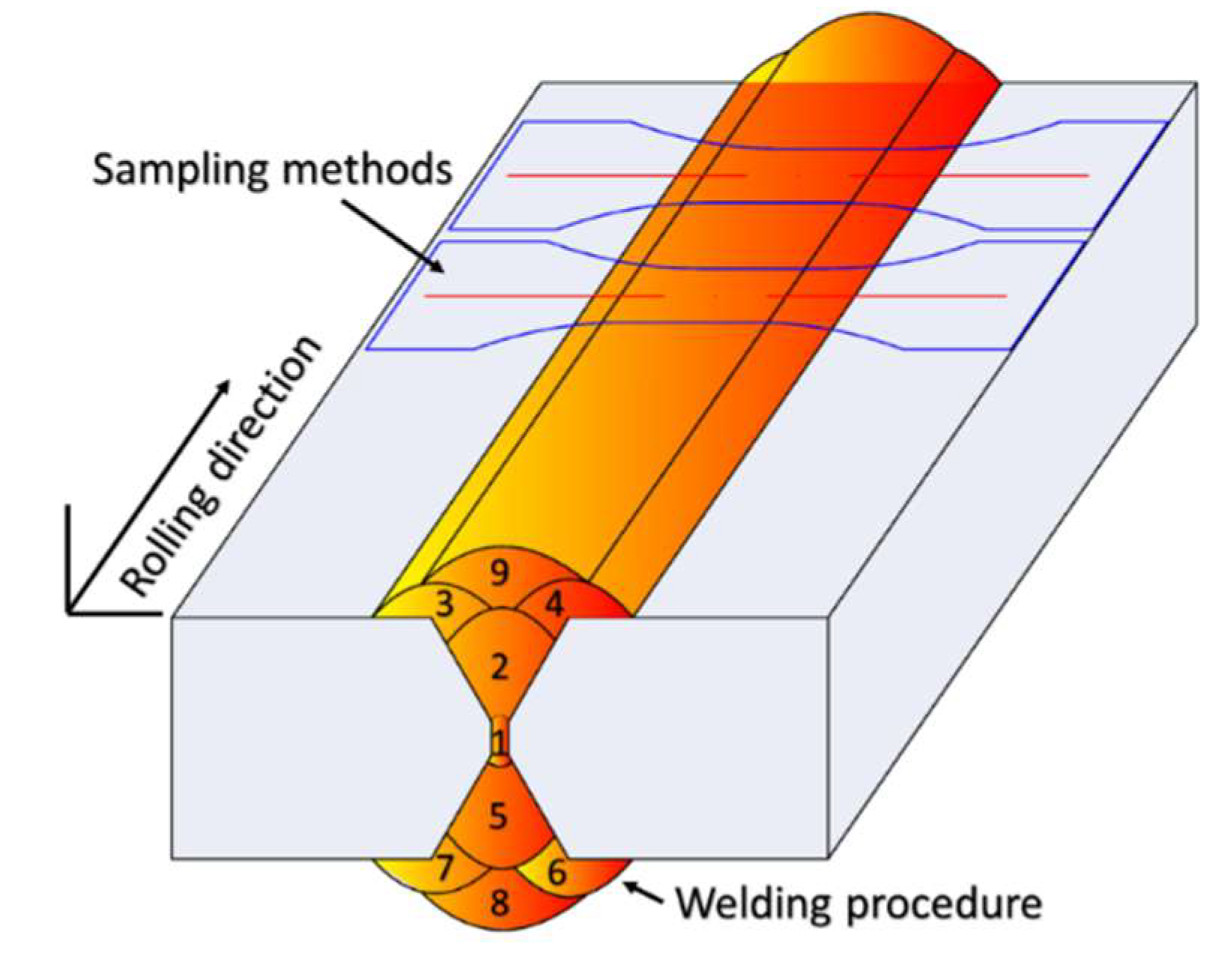

5.1. Test Specimen and Procedure

5.2. Results and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Koçak, M. Structural integrity of welded structures: Process–property–performance (3P) relationship. In Proceedings of the 63rd Annual Assembly and International Conference of the International Institute of Welding, Istanbul, Turkey, 11–16 July 2010. [Google Scholar]

- Rakin, M.; Medjo, B.; Gubeljak, N.; Sedmak, A. Micromechanical assessment of mismatch effects on fracture of high-strength low alloyed steel welded joints. Eng. Fract. Mech. 2013, 1093, 221–235. [Google Scholar] [CrossRef]

- Umekuni, A.; Masubuchi, K. Usefulness of under-matched welds for high-strength steels. Weld. J. 1997, 76, 256s. [Google Scholar]

- Loureiro, A.J.R. Effect of heat input on plastic deformation of under-matched welds. J. Mater. Process. Technol. 2002, 128, 240–249. [Google Scholar] [CrossRef]

- Ravi, S.; Balasubramanian, V.; Babu, S.; Nasser, S.N. Assessment of some factors influencing the fatigue life of strength mismatched HSLA steel weldments. Mater. Des. 2004, 25, 125–135. [Google Scholar] [CrossRef]

- Marquis, G.B.; Barsoum, Z. IIW Recommendations on High Frequency Mechanical Impact (HFMI) Treatment for Improving the Fatigue Strength of Welded Joints. In IIW Recommendations for the HFMI Treatment; Springer: Singapore, 2016; pp. 1–34. [Google Scholar]

- Walbridge, S.; Nussbaumer, A. A probabilistic assessment of the effect of post-weld treatment on the fatigue performance of tubular truss bridges. Eng. Struct. 2008, 30, 247–257. [Google Scholar] [CrossRef]

- Hobbacher, A. Recommendations for Fatigue Design of Welded Joints and Components; Springer: Berlin, Germany, 2016. [Google Scholar]

- Dong, P.; Hong, J.K.; De Jesus, A.M. Analysis of recent fatigue data using the structural stress procedure in ASME Div 2 rewrite. J. Press. Vessel Technol.-Trans. 2007, 129, 355–362. [Google Scholar] [CrossRef]

- Sonsino, C.M.; Fricke, W.; de Bruyne, F.; Hoppe, A.; Amhadi, A.; Zhang, G. Notch stress concepts for the fatigue assessment of welded joints–Background and applications. Int. J. Fatigue. 2012, 34, 2–16. [Google Scholar] [CrossRef]

- Zamzami, I.A.; Susmel, L. On the accuracy of nominal, structural, and local stress based approaches in designing aluminum welded joints against fatigue. Int. J. Fatigue. 2016, 101, 137–158. [Google Scholar] [CrossRef]

- Chebat, F.; Peron, M.; Viespoli, L.M.; Welo, T.; Berto, F. Fatigue Strength Assessment of Steel Rollers: On the Reliability of the Strain Energy Density Approach on Real Components. Appl. Sci. 2018, 8, 1015. [Google Scholar] [CrossRef]

- Kim, Y.J.; Koçak, M.; Ainsworth, R.A.; Zerbst, U. SINTAP defect assessment procedure for strength mismatched structures. Eng. Fract. Mech. 2000, 67, 529–546. [Google Scholar] [CrossRef]

- Koçak, M. FITNET fitness-for-service procedure: an overview. Weld. World. 2007, 51, 94–105. [Google Scholar] [CrossRef]

- Hadley, I. Validation of the European FITNET Fitness-For-Service Procedure: Incorporation of Weld Strength Mismatch into Fracture Assessment (Options 2 and 3); TWI Industrial Member Report Summary 890/2007; TWI: Cambridge, UK, 2007. [Google Scholar]

- Ravi, S.; Balasubramanian, V.; Nasser, S.N. Effect of notch location on fatigue crack growth behavior of strength-mismatched high-strength low-alloy steel weldments. J. Mater. Eng. Perform. 2004, 13, 758–765. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, P.; Hu, X.; Song, X. Effect of buffer layer and notch location on fatigue behavior in welded high-strength low-alloy. J. Mater. Process. Technol. 2012, 212, 2091–2101. [Google Scholar] [CrossRef]

- Shanmugam, K.; Lakshminarayanan, A.K.; Balasubramanian, V. Effect of weld metal properties on fatigue crack growth behavior of gas tungsten arc welded AISI 409M grade ferritic stainless steel joints. Int. J Pres. Ves Pip. 2009, 86, 517–524. [Google Scholar] [CrossRef]

- Donato, G.H.; Magnabosco, R.; Ruggieri, C. Effects of weld strength mismatch on J and CTOD estimation procedure for SE (B) specimens. Int. J. Fracture. 2009, 159, 1–20. [Google Scholar] [CrossRef]

- Świątczak, T.; Tomczyk, M.; Więcek, B.; Pawlak, R.; Olbrycht, R. Defect detection in wire welded joints using thermography investigations. Mater. Sci. Eng. B. 2012, 177, 1239–1242. [Google Scholar] [CrossRef]

- Ummenhofer, T.; Medgenberg, J. On the use of infrared thermography for the analysis of fatigue damage processes in welded joints. Int. J. Fatigu. 2009, 31, 130–137. [Google Scholar] [CrossRef]

- Palumbo, D.; De Finis, R.; Serio, L.M.; Galietti, U.; De Filippis, L.A.C. Thermographic signal analysis of friction stir welded AA 5754 H111 joints. Proceedings of SPIE—The International Society for Optics and Photonics, San Diego, CA, USA, 19–23 August 2018. [Google Scholar]

- Corigliano, P.; Epasto, G.; Guglielmino, E.; Risitano, G. Fatigue analysis of marine welded joints by means of DIC and IR images during static and fatigue tests. Eng. Fract. Mech. 2017, 183, 26–38. [Google Scholar] [CrossRef]

- De Filippis, L.A.C.; Serio, L.M.; Palumb, D.; De Finis, R.; Galietti, U. Optimization and characterization of the Friction Stir Welded Sheets of AA 5754-H111: Monitoring of the quality of joints with thermographic techniques. Materials 2017, 10, 1165. [Google Scholar] [CrossRef] [PubMed]

- Ganesh, K.C.; Vasudevan, M.; Balasubramanian, K.R.; Chandrasekhar, N.; Mahadevan, S.; Vasantharaja, P.; Jayakumar, T. Modeling, prediction and validation of thermal cycles, residual stresses and distortion in type 316 LN stainless steel weld joint made by TIG welding process. Procedia Eng. 2014, 86, 767–774. [Google Scholar] [CrossRef]

- Tomlinson, R.A.; Marsavina, L. Thermoelastic investigations for fatigue life assessment. Exp. Mech. 2004, 44, 487–494. [Google Scholar] [CrossRef]

- Chandran, K.R. A universal functional for the physical description of fatigue crack growth in high-cycle and low-cycle fatigue conditions and in various specimen geometries. Int. J. Fatigue 2017, 102, 261–269. [Google Scholar] [CrossRef]

- Chandran, K.R. A physically based universal functional to characterize the mechanism of fatigue crack growth in materials. Scr. Mater. 2015, 107, 115–118. [Google Scholar] [CrossRef]

- Meggiolaro, M.A.; Castro, J.T.P. Statistical evaluation of strain-life fatigue crack initiation predictions. Int. J. Fatigue 2004, 26, 463–476. [Google Scholar] [CrossRef]

- Brennan, F.P. The use of approximate strain-life fatigue crack initiation predictions. Int. J. Fatigue 1994, 16, 351–356. [Google Scholar] [CrossRef]

- Paris, P.C.; Gomez, M.P.; Anderson, W.E. A rational analytic theory of fatigue. Trend Eng. 1961, 13, 9. [Google Scholar]

- Paris, P.C. A critical analysis crack propagation laws. J. basic eng. 1963, 85, 528–533. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials. Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Basquin, O.H. The Exponential Law of Endurance Tests. Proc. Am. Soc. Test. Mater. 1910, 2, 625–630. [Google Scholar]

- Mattheck, C.; Baumgartner, A.; Kriechbaum, R.; Walther, F. Computational methods for the understanding of biological optimization mechanisms. Comp. Mater. Sci. 1993, 1, 302–312. [Google Scholar] [CrossRef]

- Sokołowski, J.; Zolésio, J.P. Introduction to Shape Optimization: Shape Sensitity Analysis; Springer: Berlin/Heidelberg, Germany, 1992; pp. 7432–7437. [Google Scholar]

- Pilkey, W.D.; Pilkey, D.F. Peterson’s Stress Concentration Factors; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- ISO 12107: 2012. Metallic Materials-Fatigue Testing-Statistical Planning and Analysis of Data; ISO Copyright Office: Geneva, Switzerland, 2012. [Google Scholar]

| Material 1 | C Wt.% | Si Wt.% | Mn Wt.% | σu (MPa) | σy (MPa) | S–N fitting formula |

|---|---|---|---|---|---|---|

| Q550D | 0.05 | 0.022 | 1.74 | 777 | 678 | |

| ER70S-6 | 0.07 | 0.84 | 1.49 | 543 | 438 |

| Sequence | Welding Process | Current Type/Polarity | Arc Voltage(V) | Welding Current(A) | Welding Speed(mm/s) | Shielding Gas/Flow Rate(L/min) |

|---|---|---|---|---|---|---|

| 1 | TIG(manual) | DC(+) | 23.5 | 220 | 1 | Ar/13 |

| 2–7 | MAG | DC(-) | 34 | 350 | 8.5 | CO2/5Ar/18 |

| 8–9 | MAG | DC(-) | 29.6 | 280 | 8.5 | CO2/5Ar/18 |

| Sample No. | σa (MPa) | f (Hz) | R | T (°C) | N (Stress Cycles) |

|---|---|---|---|---|---|

| 1# | 134.1 | 10 | 0.1 | 25 | 2,650,633 |

| 2# | 134.1 | 10 | 0.1 | 25 | 2,587,627 |

| 3# | 134.1 | 10 | 0.1 | 25 | 2,620,122 |

| p/% | (1−α) | k(p, 1−α) | N(p, 1−α) |

|---|---|---|---|

| 10 | 95 | −6.158 | 2,440,063 |

| 90 | −4.258 | 2,494,026 | |

| 5 | 95 | −7.655 | 2,398,369 |

| 90 | −5.31 | 2,464,002 | |

| 1 | 95 | −10.55 | 2,319,749 |

| 90 | −7.34 | 2,407,083 | |

| 0.1 | 95 | −13.86 | 2,233,012 |

| 90 | −9.651 | 2,343,883 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, X.; Wang, P.; Dong, Z.; Liu, Y.; Fang, H. Nominal Stress-Based Equal-Fatigue-Bearing-Capacity Design of under-matched HSLA Steel Butt-welded Joints. Metals 2018, 8, 880. https://doi.org/10.3390/met8110880

Wen X, Wang P, Dong Z, Liu Y, Fang H. Nominal Stress-Based Equal-Fatigue-Bearing-Capacity Design of under-matched HSLA Steel Butt-welded Joints. Metals. 2018; 8(11):880. https://doi.org/10.3390/met8110880

Chicago/Turabian StyleWen, Xue, Ping Wang, Zhibo Dong, Yong Liu, and Hongyuan Fang. 2018. "Nominal Stress-Based Equal-Fatigue-Bearing-Capacity Design of under-matched HSLA Steel Butt-welded Joints" Metals 8, no. 11: 880. https://doi.org/10.3390/met8110880

APA StyleWen, X., Wang, P., Dong, Z., Liu, Y., & Fang, H. (2018). Nominal Stress-Based Equal-Fatigue-Bearing-Capacity Design of under-matched HSLA Steel Butt-welded Joints. Metals, 8(11), 880. https://doi.org/10.3390/met8110880