3.2. Tensile Test Results

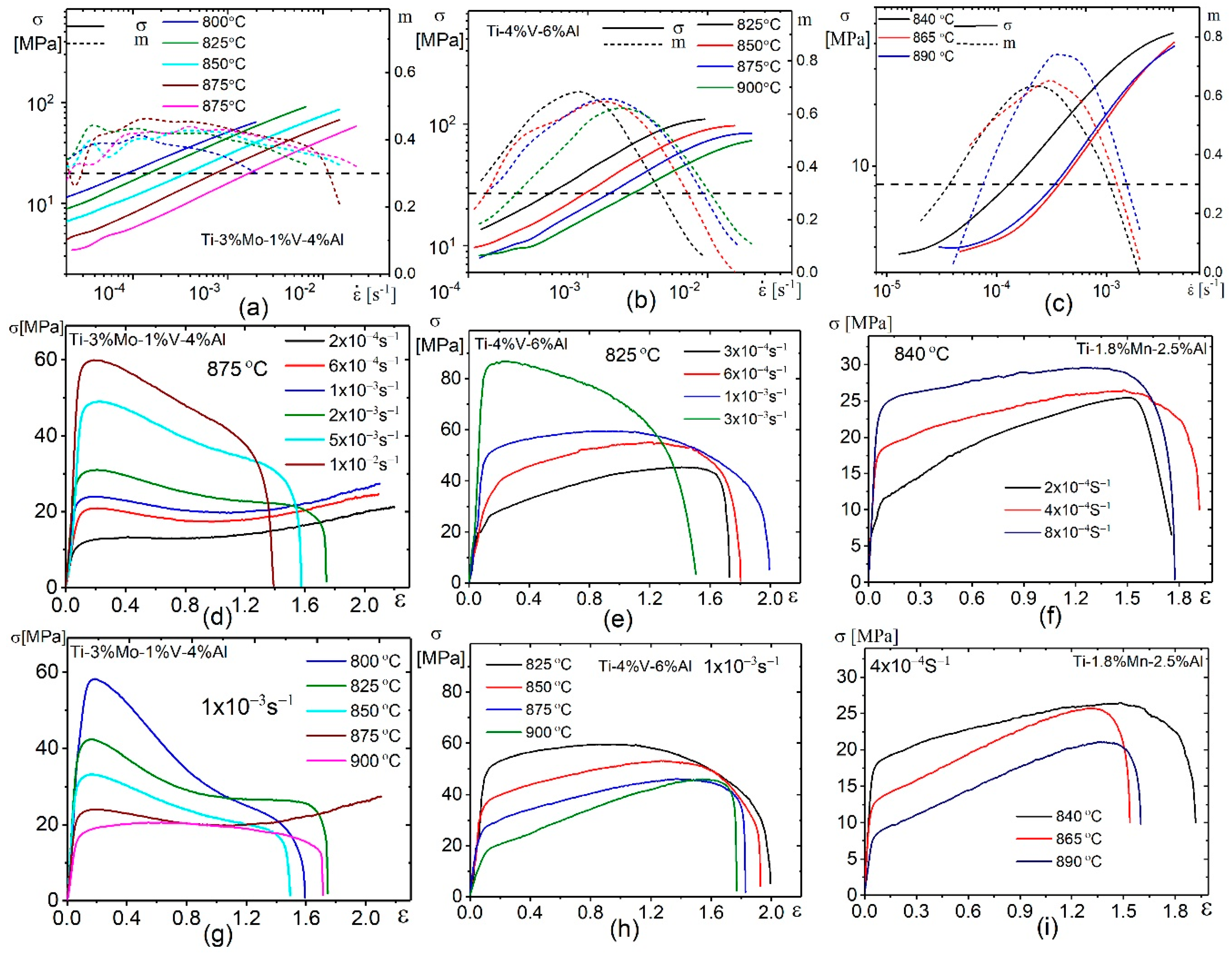

The result of the tensile tests at various temperatures and strain rates for the investigated alloys is shown in

Figure 3. Typical for superplastic behavior, a sigmoidal shape of the stress–strain rate curves was observed in the studied temperature range (

Figure 3a–c). Values of the constant strain rate tests (

Figure 3d–i) were chosen in the II range of the stress–strain rate curves. These strain rates belonged to the strain rate sensitivity index-m, above 0.3 (dash lines in

Figure 3a–c), and corresponded to the superplastic behavior of the alloys (

Figure 3a–c).

The experimental stress–strain curves at various strain rates and at various temperatures, within a strain rate–temperature range of superplastic deformation for each alloy are shown in

Figure 3d-i. The steady stage begins at a strain of around 0.1 in all testing conditions. The studied alloys exhibit different stress–strain behavior. The Ti-3%Mo-1%V-4%Al alloy demonstrates stress softening, up to 1.1 of strain and strain hardening, at a strain of more than 1.1, for the low strain rates (

Figure 3d,g). By contrast, the deformation of Ti-4%V-6%Al and Ti-1.8%Mn-2.5%Al alloys is mainly accompanied by strain hardening (

Figure 3e,f,h,i). The stress value is mainly affected by a strain-induced microstructure evolution, because we used the constant strain rate tests. Thus, strain softening can be a result of dynamic recrystallization, and strain hardening can be explained by dynamic grain growth. The similar flow behavior and the dynamic grain growth were observed in the Ti-4%V-6%Al [

37,

38] and Ti-1.8%Mn-2.5%Al alloys [

39]. Strain hardening, in the large strains of Ti-Al-Mo-V, could also be the result of dynamic grain growth.

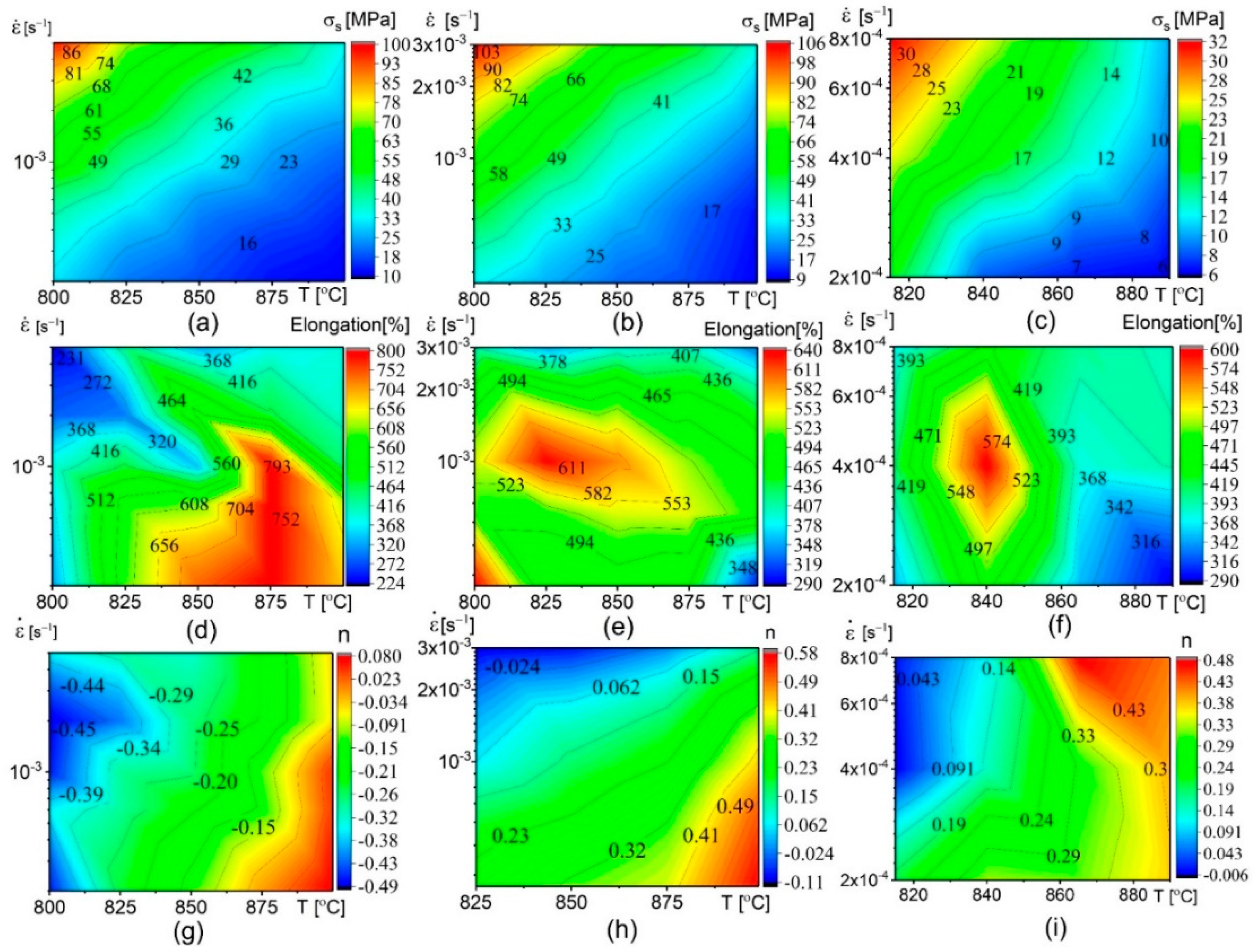

The values of the

σs (

Figure 4a–c), elongation to failure (

Figure 4d–f) and strain hardening coefficient (

Figure 4g–i) at the various temperatures and strain rates for the studied alloys are shown in

Figure 4. Typically, an increase of the

σs value was observed as the strain rate increased and the temperature decreased (

Figure 4a–c). The maximum elongation, corresponding to the red zones in (

Figure 4d–f), was achieved at different temperature–strain rate ranges for studied alloys (

Figure 4d–f). The strain-hardening coefficient depended on both deformation temperature and strain rate and effected to the elongation to failure. The strain-hardening coefficient, in a range of −0.2 to 0.2, corresponded to a high elongation to failure (

Figure 4g–i). It can be suggested that an insignificant strain hardening/softening effect and high elongation are the result of the high stability of the grain structure in deformation.

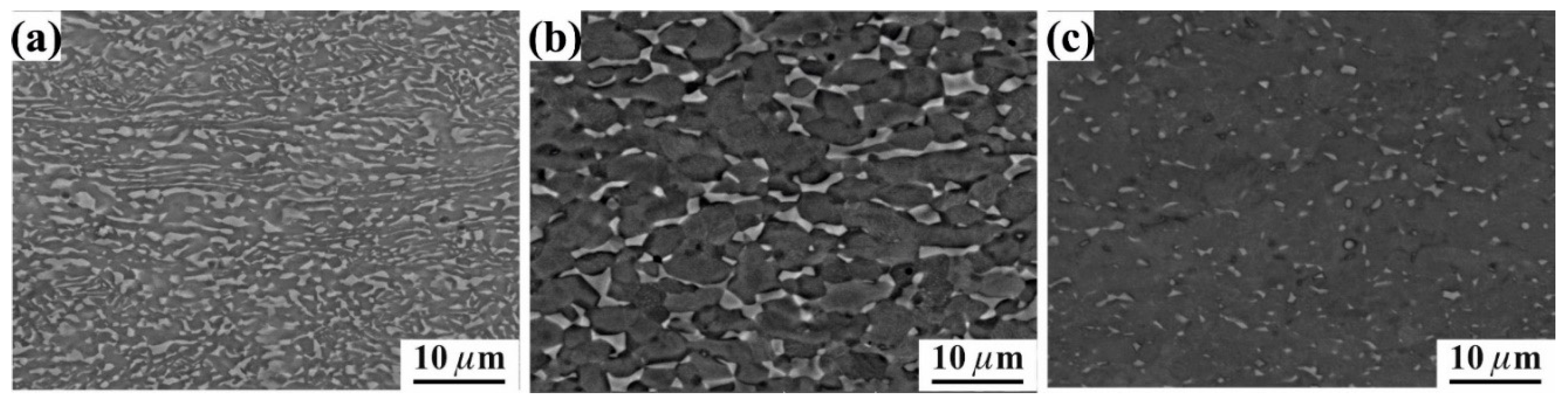

It is known that superplastic deformation depends on microstructure parameters and their strain-induced evolution [

38,

41]. The α/β phase ratio and the grain size of each phase are the most important microstructure parameters. The microstructure of the investigated alloys, after both annealing for 30 min and straining of 1.1, at the strain rate–temperature mode corresponding to the maximum elongation for each material, is shown in

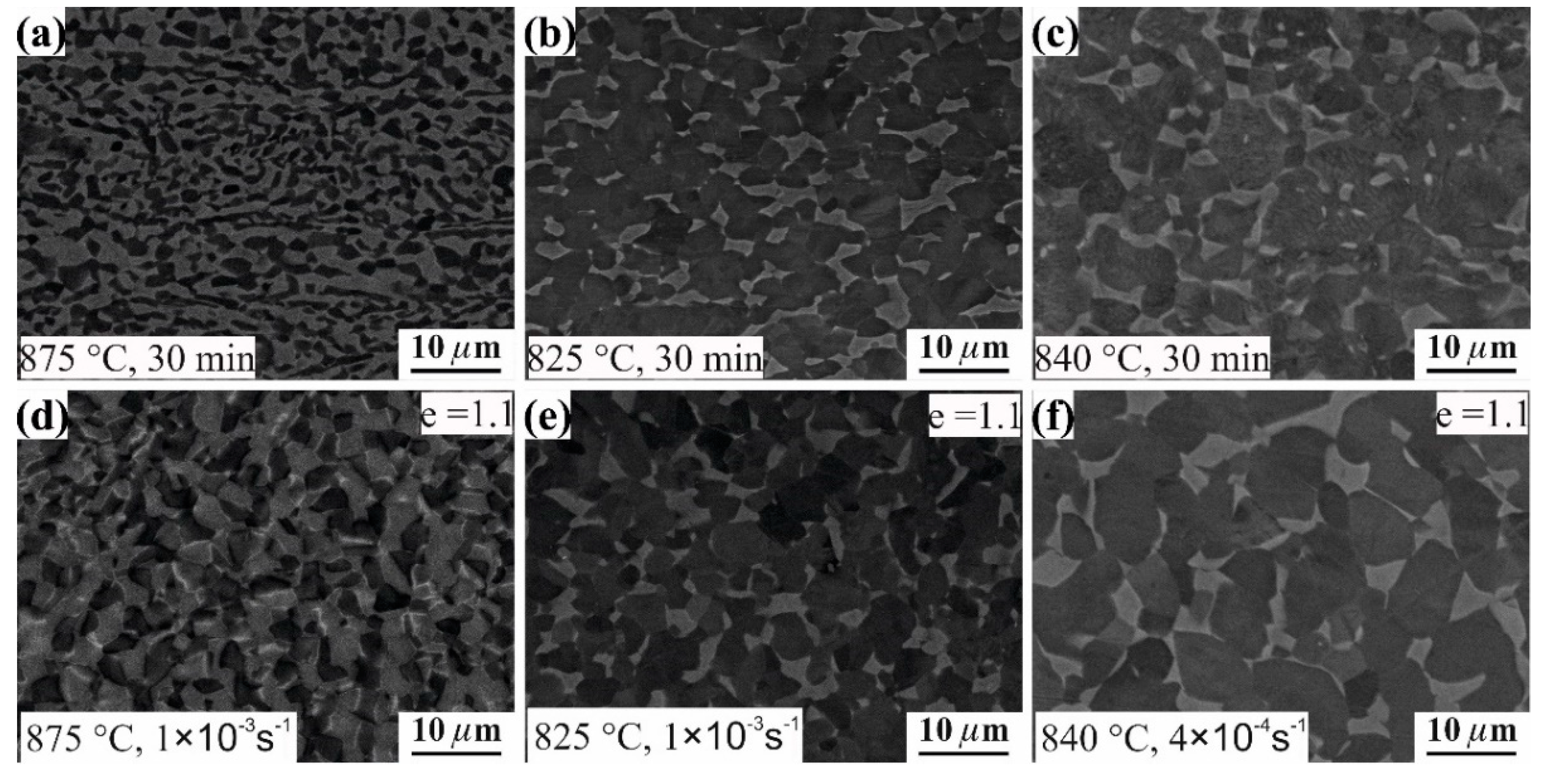

Figure 5.

Annealing for 30 min at 875 °C provided a partially globularized grain structure, with a β-phase fraction of 55% and mean grain size of

Lβ = 2.0 ± 0.1 μm in the recrystallized volume of the Ti-3%Mo-1%V-4%Al alloy (

Figure 5a). The equiaxed recrystallized grains, with a size of

Lα = 2.3 ± 0.09 μm and

Lβ = 2.5 ± 0.1 μm, were formed after 1.1 straining at 875 °C and 1 × 10

−3 s

−1 (

Figure 5d). Thus, a dynamic recrystallization/globularization occurred, with a strain increase of 0.8–1.1, which led to insignificant strain softening, with an average coefficient of

n = −0.16. The insignificant grain growth provided a high elongation of 800% in the Ti-4%Al-1%V-3Mo alloy at 875 °C and 1 × 10

−3 s

−1 (

Figure 4d).

Annealing for 30 min at 825 °C led to the formation of a recrystallized structure of both phases, with a β-phase percentage of 40% and grain size of

Lβ = 2.9 ± 0.1 μm in the Ti-4%V-6%Al alloy (

Figure 5b). Additionally, the mean grain size insignificantly increased after straining of 1.1 at 825 °C and 1 × 10

−3 s

−1 (

Figure 5b,e), which provided a maximum elongation of 620% (

Figure 4e). The α and β grain size after 1.1 straining increased to 3.3 ± 0.2 μm and 3.0 ± 0.15 μm, respectively. The strain hardening coefficient

n was 0.1 at the strain rate and temperature mode of the maximum elongation to failure in the Ti-4%V-6%Al alloy. The insignificant strain hardening is also the result of slight dynamic grain growth (

Figure 3e,h and

Figure 4h).

The Ti-1.8%Mn-2.5%Al alloy exhibited 30% of the β-phase and the mean grain size of recrystallized grains of

Lβ = 2.2 ± 0.1 μm, after annealing for 30 min at 840 °C (

Figure 5c). At the same temperature, and a strain rate of 4 × 10

−4 s

−1, the elongation was at the maximum for this alloy (

Figure 4f). The α and β grain size after 1.1 straining was 6.1 ± 0.2 μm and 3.8 ± 0.15 μm, respectively (

Figure 5f). The strain hardening coefficient

n was 0.2 at this testing condition (

Figure 4i), which was the minimum value for the Ti-1.8%Mn-2.5%Al alloy. More intensive dynamic grain growth is a reason for the higher

n-value and the lower elongation in Ti-1.8%Mn-2.5%Al, compared to the other investigated alloys.

The Ti-3%Mo-1%V-4%Al alloy demonstrated 800% elongation, which was the maximum value among the studied materials, and the Ti-1.8%Mn-2.5%Al alloy demonstrated 580% elongation, which was the minimum value. Such behavior can be explained by the low tendency toward dynamic grain growth in the first alloy and the high tendency toward this phenomenon in the second one. Generally, an α/β close to 50/50 provides a stable grain structure and good superplasticity in two-phase materials [

29]. In the current study, the maximum elongation was observed for a wide range of β fractions, which depended on the microstructure evolution during the deformation process and alloy composition.

Ti-3%Mo-1%V-4%Al and Ti-4%V-6%Al exhibited insignificant dynamic grain growth, providing the maximum elongation at the temperature of the β-phase fraction of 55% and 40%, respectively. This is close to the temperature of the α/β = 50/50 ratio. The Ti-1.8%Mn-2.5%Al alloy demonstrated the maximum elongation at a lower β-phase fraction. The increasing temperature led to an increase of the β-phase fraction to 50% but decreased the elongation to failure in Ti-1.8%Mn-2.5%Al because of significant dynamic grain growth [

39].

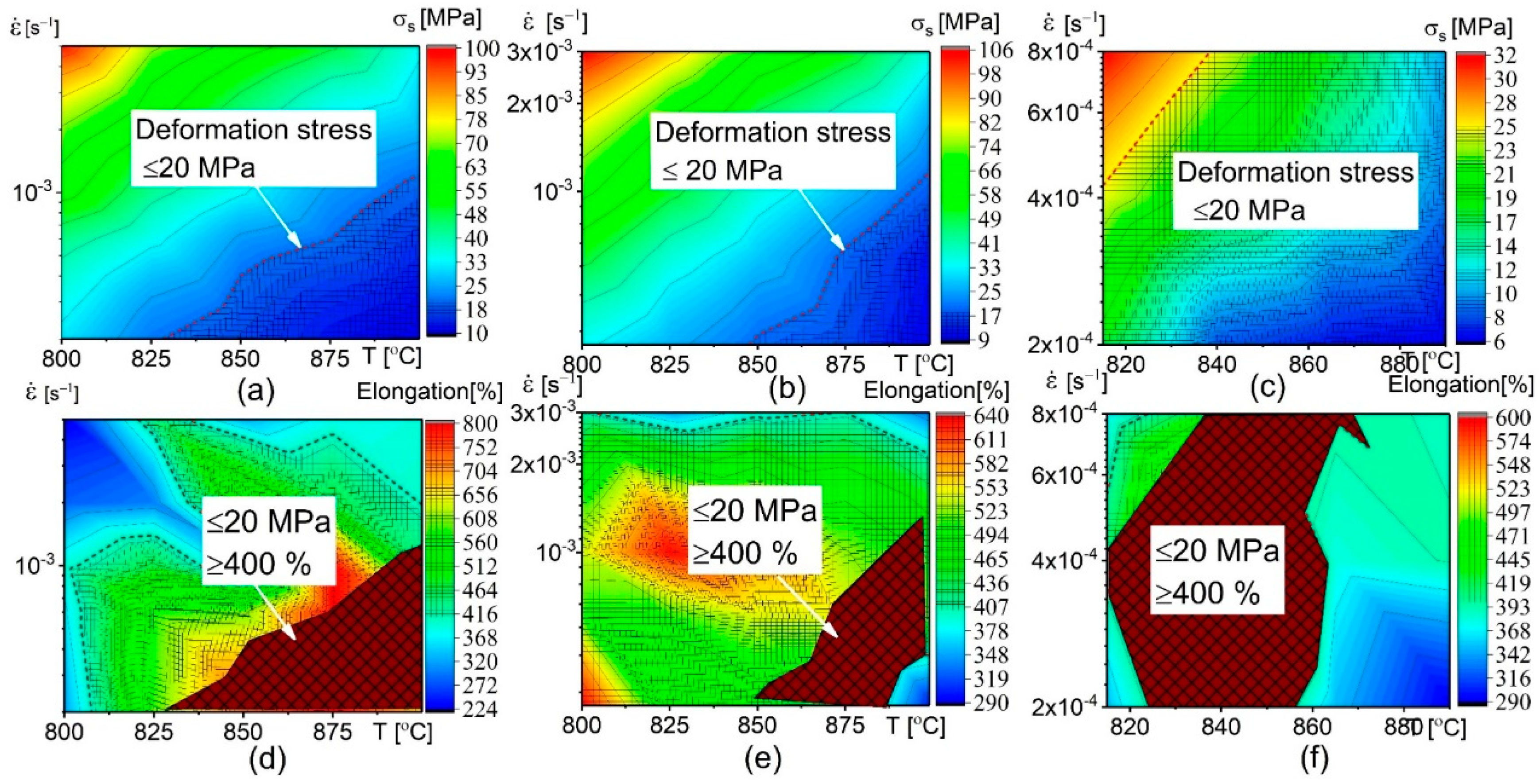

The deformation temperature and strain rate ranges for the investigated alloys, providing an elongation to failure larger than 400% and a stress at the start of the steady stage (

σs) of less than 20 MPa, are shown in

Figure 6.

To proceed to superplastic forming at a stress level of ≤20 MPa, in the studied strain rate–temperature ranges, the temperature must be above 825 °C for the Ti-3%Mo-1%V-4%Al alloy (

Figure 6a), above 850 °C for the Ti-4%V-6%Al alloy (

Figure 6b), and above 840 °C for the Ti-1.8%Mn-2.5%Al alloy (

Figure 6c). The temperature and strain rate values, which provided both the elongation to failure ≥400% and stress level ≤20 MPa, were determined (the shaded brown regions in

Figure 6d–f). Thus, the recommended temperature and strain rate ranges were ˃825 °C and ˂1 × 10

−3 s

−1 for the Ti-3%Mo-1%V-4%Al alloy, 850–890 °C and ˂1 × 10

−3 s

−1 for the Ti-4%V-6%Al alloy, and 815–860 °C and 2 × 10

−4–8 × 10

−4 s

−1 for the Ti-2.5%Al-1.8 % Mn alloy.

The empirical expressions of the stress as the steady stage begins and the elongation to failure were established as functions of the deformation temperature (

Td) and strain rate (

), as listed in

Table 2.

The accuracy of the developed regression models was evaluated by the correlation coefficient (

R2). The (

R2) for the (

σs) of the Ti-3%Mo-1%V-4%Al, Ti-4%V-6%Al and Ti-1.8%Mn-2.5%Al alloys were 0.995, 0.998 and 0.999, respectively. The (

R2) of the developed regression models for the elongation to failure of the Ti-3%Mo-1%V-4%Al, Ti-4%V-6%Al and Ti-1.8%Mn-2.5%Al alloys were 0.85, 0.91 and 0.97, respectively (

Table 2). The high values of the (

R2) confirmed the effectiveness of the developed models.

3.3. Most Influential Control Parameter Determination Using the Taguchi Method

Typically, titanium-based alloys are very sensitive to the deformation temperature due to the change in the α/β ratio and grain structure, which affect the superplastic deformation behavior [

39,

42]. A fine grain structure is required to activate grain boundary sliding, which is a dominant superplastic deformation mechanism for most metallic materials [

41,

42,

43]. The elevated temperature provided the grain boundary sliding phenomenon, as well as the necessary diffusion and dislocation creeping mechanisms, which accommodated the grain boundary sliding. All superplastic deformation mechanisms affect the diffusion kinetic, and, finally, depend on the deformation temperature, strain rate and grain structure. Therefore, choosing an appropriate temperature–strain rate range of superplastic deformation is very important.

On the other hand, the temperature of superplastic deformation should be kept at the minimum as far as possible, since doing so results in power saving in the manufacturing process and die wear. However, the strain rate should be maintained at the maximum as far as possible to minimize the forming time. Therefore, the relative contribution of the hot deformation process parameters (temperature and strain rate), the stress as the steady stage begins (σs) and the elongation to failure is required to provide useful information for the producer, resulting in power and time savings in the manufacturing process.

For titanium alloys, the deformation process is considered to be superplastic deformation when the elongation is at the minimum (400%) and the required stress for deformation (20 MPa) is at the maximum (

Figure 6). Thus, we needed to obtain a maximum elongation and a minimum deformation stress by choosing the best combination of the deformation temperature range and strain rate range on the basis of minimizing the deformation temperature and maximizing the deformation strain rate.

The design of the experimental (DOE) technique using the Taguchi method was performed. The Taguchi model studies the effect of the temperature and the strain rate on the

σs, elongation to failure and strain-hardening/softening coefficient. The control parameter levels for each alloy are shown in

Table 3. The number of the levels depended on the diapason of the possible superplastic deformation temperatures and strain rates. Thus, five levels were used for the Ti-3%Mo-1%V-4%Al alloy due to their wide superplastic temperature and strain rate ranges. The number of parameter levels was four for the Ti-4%V-6%Al alloy and three for the Ti-1.8%Mn-2.5%Al alloy, because the superplastic temperature and strain rate ranges were narrow for the Ti-1.8%Mn-2.5%Al alloy. MINITAB 16 software (Minitab Inc., State College, PA, USA) was utilized to design and analyze the experiments using the analysis of variance (ANOVA) technique procedure.

A standard experimental design, which requires a small number of experimental runs to indicate the effect of the most significant parameters on the target response, is known as orthogonal arrays (OA). The OA, according to Taguchi standard orthogonal arrays [

44] for the Ti-3%Mo-1%V-4%Al, Ti-4%V-6%Al and Ti-1.8%Mn-2.5%Al alloys, were L25 (5

2), L16 (4

2) and L9 (3

2), respectively.

The signal to noise (S/N) ratio is an ideal metric for selecting the best values of the control variables. In this work, the “larger—is better” principle (Equation (1)) was considered in maximizing the elongation to failure, and the “smaller—is better” principle (Equation (2)) was used to minimize the stress at the start of the steady stage (

σs) and the strain-hardening/softening effect. The S/N ratio can be computed using the following equations [

45]:

where

n is the number of the runs in a trail, and

y is the response value.

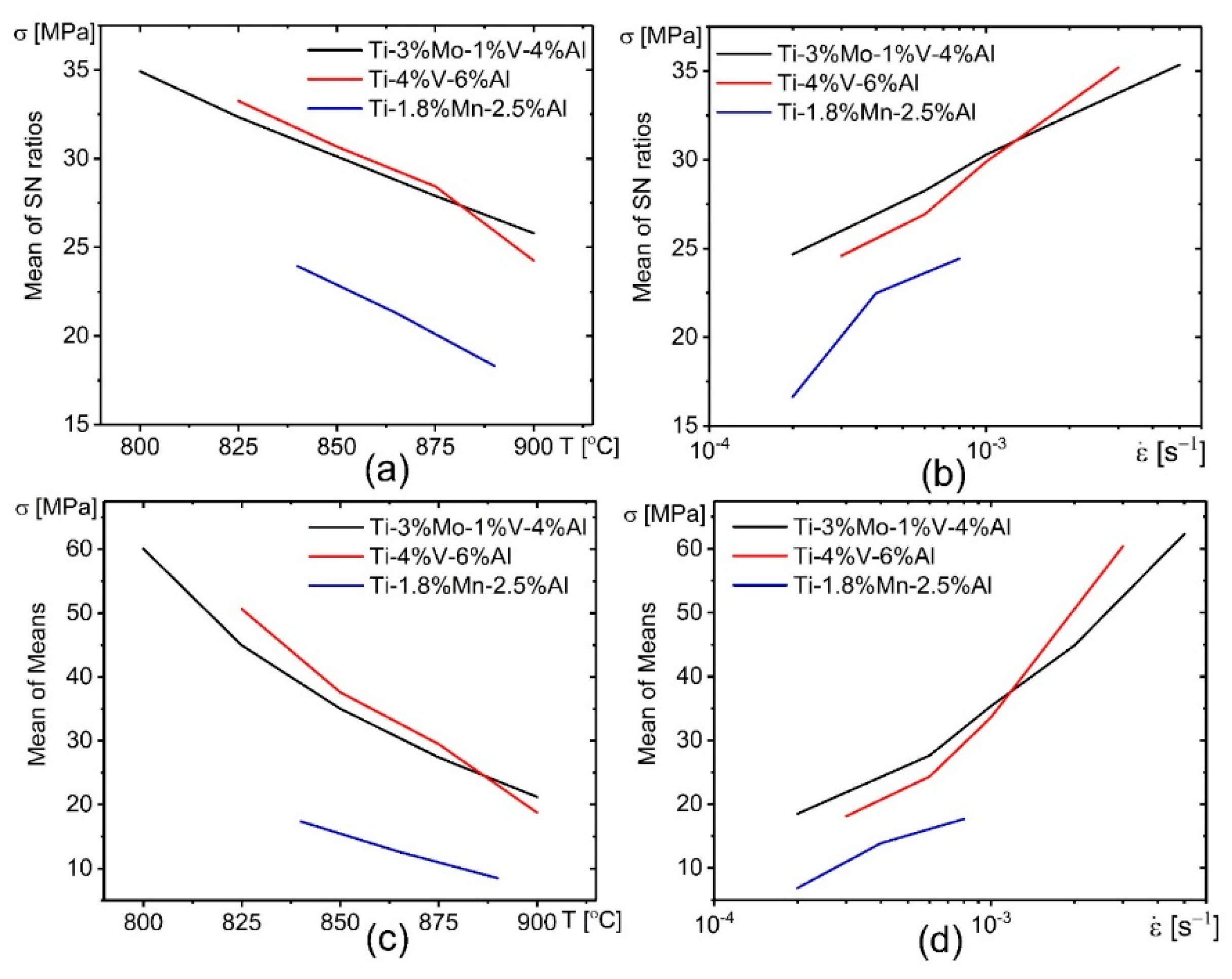

The

σs vs. the deformation temperature and the strain rate dependences, for the investigated alloys, are illustrated in

Figure 7. The mean of the S/N ratios and the mean of means of the

σs were found to give the same trend under the temperature and strain rate effects. These values decreased as the temperature increased, but increased as the strain rate increased, for all alloys. For the minimum σ

s value, the last temperature level (

Figure 7a,c) and the first strain rate level (

Figure 7b,d) were recommended for all studied alloys.

The analysis of variance (ANOVA) for the S/N ratio and the mean of the

σs, for all tested alloys, are shown in

Table 4 and

Table 5, respectively.

The percentage of the contribution and delta values for the strain rate was more than the percentage of the contribution and delta values for the temperature, for all tested alloys (

Table 4 and

Table 5). Thus, the rank of the strain rate was 1, and the rank of temperature was 2. Therefore, the strain rate affected the

σs more significantly than did the temperature. These results match those observed in [

36].

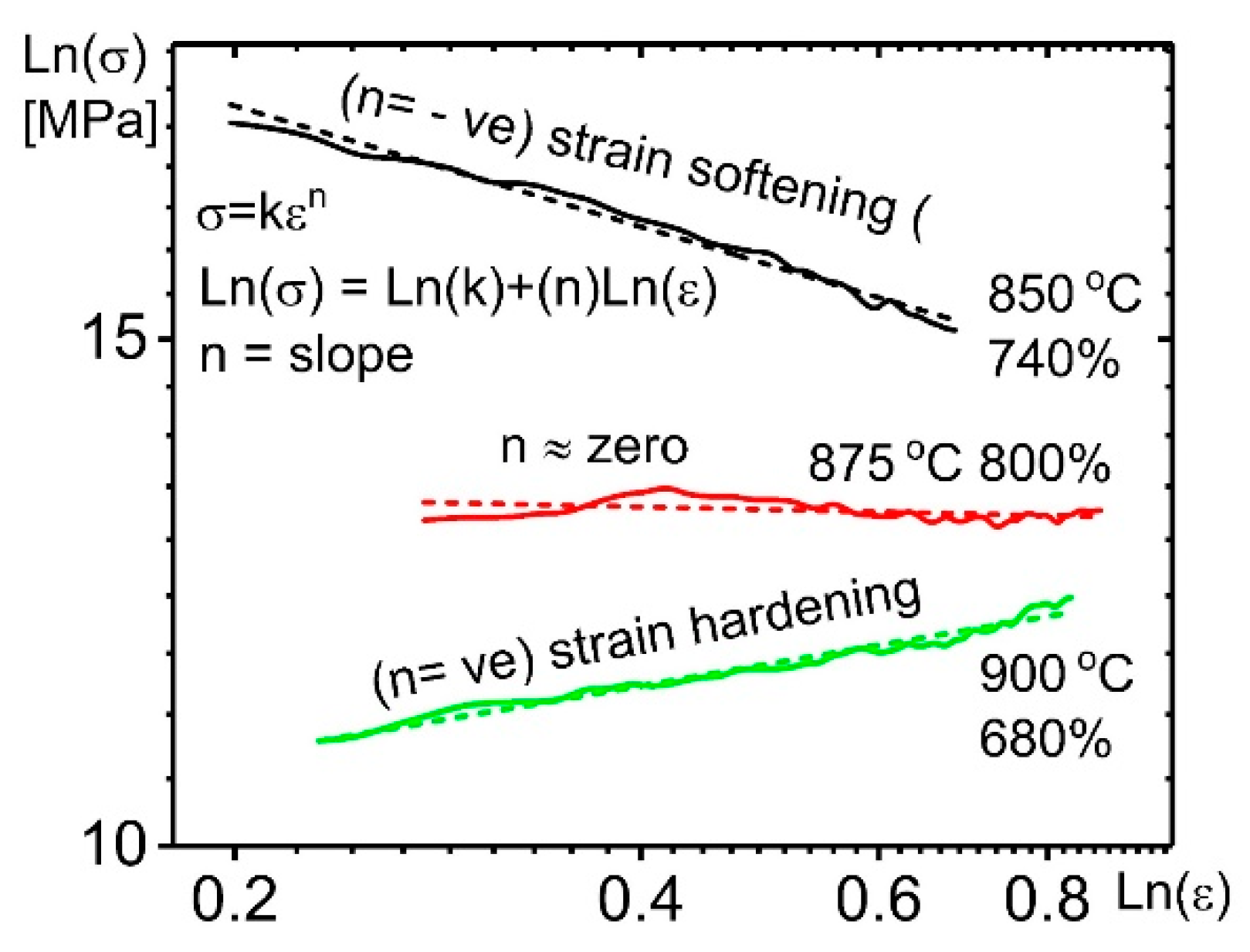

The maximum elongation can be obtained at the minimum strain hardening/softening effect, as shown in

Figure 8 for Ti-3%Mo-1%V-4%Al at 2 × 10

−4 s

−1 and different temperatures. Thus, the strain hardening/softening must be close to zero. The absolute values of strain softening were provided in the Taguchi model.

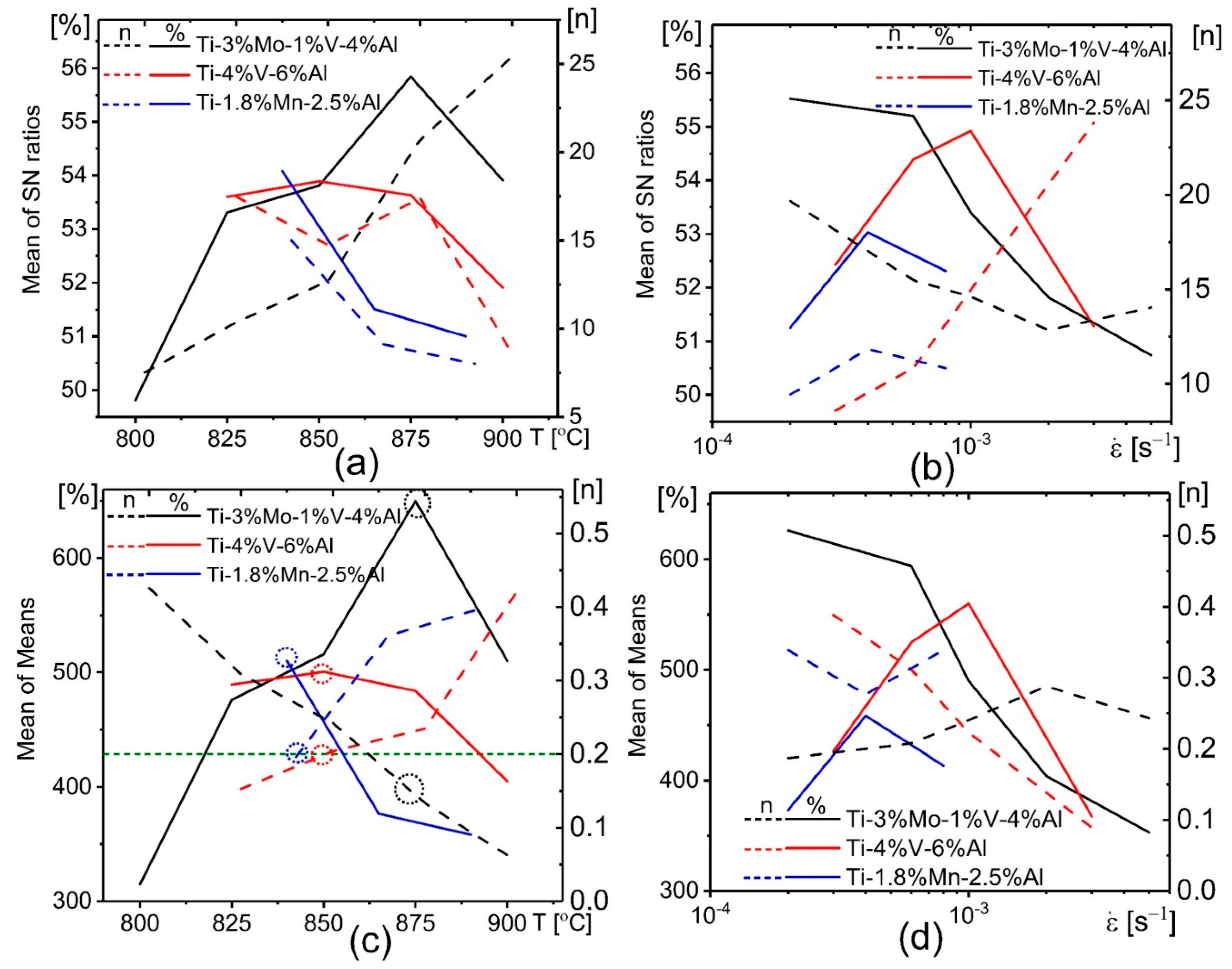

The effects of the temperature and strain rate on the elongation to failure and strain hardening/softening coefficient for the investigated alloys are shown in

Figure 9. The mean of the S/N ratios and the mean of the elongation to failure had the same response under the temperature and strain rate effects. For the Ti-3%Mo-1%V-4%Al alloy, the elongation increased as the temperature increased, up to an optimum value of 875 °C, and then decreased again. It also exhibited the maximum elongation at strain rates up to 1 × 10

−3 s

−1. For the Ti-4%V-6%Al alloy, the elongation insignificantly changed in a temperature range of 825–875 °C, and it exhibited the maximum value at a strain rate of 1 × 10

−3 s

−1. For the titanium alloy, Ti-1.8%Mn-2.5%Al, the maximum elongation to failure was obtained at a temperature of 840 °C and a strain rate of 8 × 10

−4 s

−1. Maximum mean elongations were noted at a mean strain hardening coefficient in the range of −0.2 to 0.2 for all the alloys (

Figure 9c).

The percentage of the contribution and the rank after the analysis of variance (ANOVA) for the S/N ratio and the means of elongation to failure, for the investigated alloys, are shown in

Table 6.

The percentage of contribution and the delta value for the temperature were higher than these parameters for the strain rate of the Ti-3%Mo-1%V-4%Al and Ti-1.8%Mn-2.5%Al alloys (

Table 6). By contrast, the percentage of contribution and the delta value for the strain rate were higher than these parameters for the temperature of the Ti-4%V-6%Al alloy (

Table 6). Therefore, the temperature affected the elongation to failure more significantly than did the strain rate for the Ti-3%Mo-1%V-4%Al and Ti-1.8%Mn-2.5%Al alloys, and, conversely, the elongation to failure more strongly depended on the strain rate than on the temperature for the Ti-4%V-6%Al alloy.

The percentage of contribution and the rank after the analysis of variance (ANOVA) for the S/N ratio and the mean of the strain hardening/softening coefficient, for the investigated alloys, are shown in

Table 7.

As can be seen in

Table 7, the effects of temperature and strain rate on both the elongation to failure and strain hardening were similar. The percentage of contribution and delta value show that the deformation temperature was a more important parameter than the strain rate for the Ti-3%Mo-1%V-4%Al and Ti-1.8%Mn-2.5%Al alloys. Conversely, the strain hardening/softening effect more significantly depended on the strain rate than the temperature, for the Ti-4%V-6%Al alloy. The percentage of the contribution of temperature is insignificantly higher than the percentage of the contribution of strain rate, for Ti-4%V-6%Al, but, in the case of the other alloys, the difference between the percentage of the contribution of temperature and strain rate is high. Thus, the temperature has a high impact on the strain hardening/softening effect in the case of the Ti-3%Mo-1%V-4%Al and Ti-1.8%Mn-2.5%Al alloys.

As has been shown, the most influential parameter on the superplastic behavior was the strain rate at low strain values for the investigated alloys. Thus, the strain rate affects the stress at the start of the steady stage (σs) more greatly than does the temperature. This is possibly due to the high temperature stability of the fine grain structure, confirming the high strain rate sensitivity of the studied alloys.

It is well known that the elongation to failure in superplastic deformation is very sensitive to the strain-induced microstructure evolution [

41,

42,

46,

47,

48]. For all studied alloys, the maximum elongation was obtained in the deformation regimes, providing close-to-zero values of the strain hardening coefficient. These deformation regimes also provided insignificant dynamic grain growth (

Figure 5), especially for Ti-4%V-6%Al.

The temperature affected the elongation to failure more so than did the strain rate, for the Ti-3%Mo-1%V-4%Al and Ti-1.8%Mn-2.5%Al alloys. The possible reason for such a temperature effect is a significant microstructure change as the temperature is increased. This is in agreement with the previous study of the Ti-1.8%Mn-2.5%Al alloy [

39]. However, the elongation to failure more strongly depends on the strain rate than on the temperature, for the Ti-4%V-6%Al alloy. This is possibly due to the low temperature sensitivity of the microstructure to the strain-induced changes in the studied deformation regimes.

The additional important result of the current study is the possibility to decrease the superplastic deformation temperature for all studied alloys. Thus, very good formability, with 400% of elongation and a stress value lower than 20 MPa, was observed at a temperature of 825 °C and strain rate of 2 × 10−4 s−1, for the Ti-3%Mo-1%V-4%Al alloy, of 850 °C and 3 × 10−4 s−1, for the Ti-4%V-6%Al alloy, and 815°C and 4 × 10-4 s−1, for the Ti-1.8%Mn-2.5%Al alloy.