Analysis of Fracture Modes of Resistance Spot Welded Hot-Stamped Boron Steel

Abstract

1. Introduction

2. Experimental Procedure

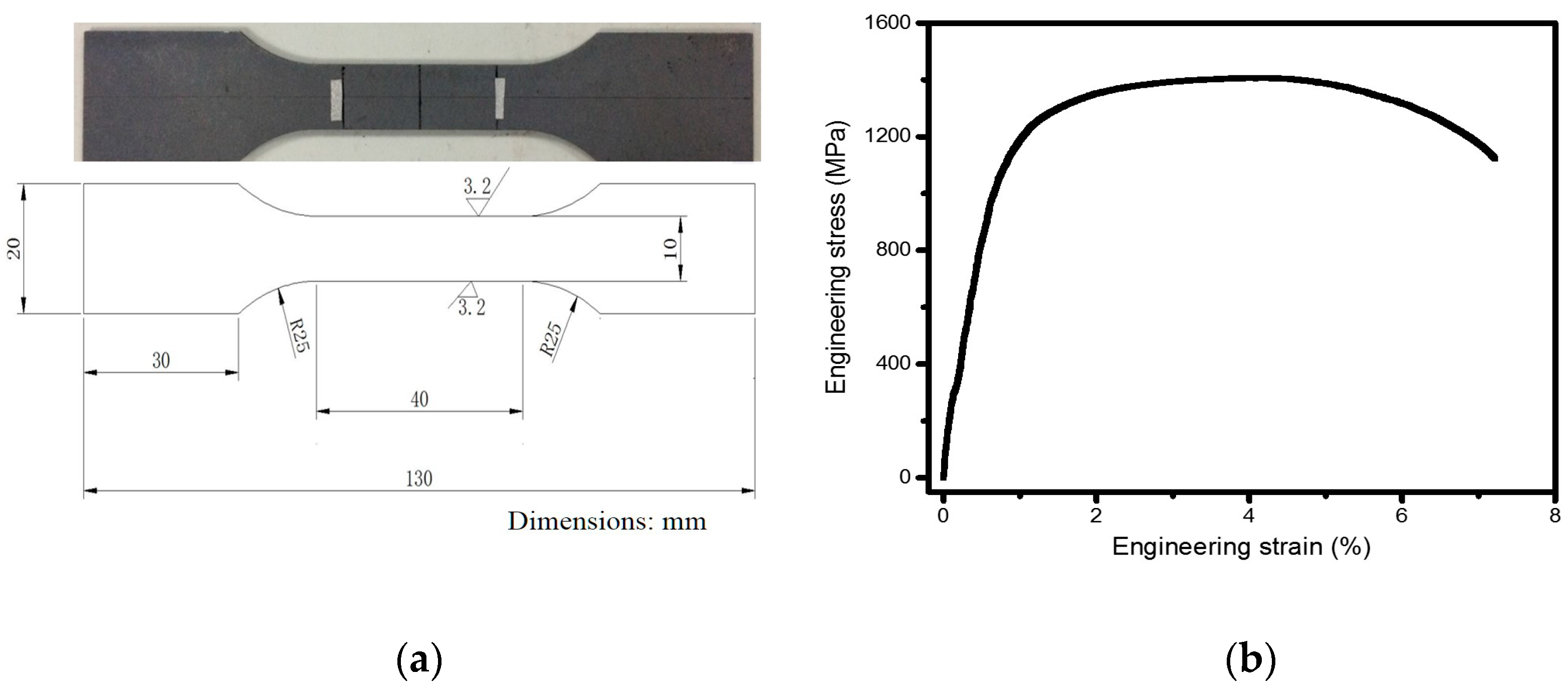

2.1. Materials

2.2. Sample Fabrication

2.3. Cross-Sectional Examinations

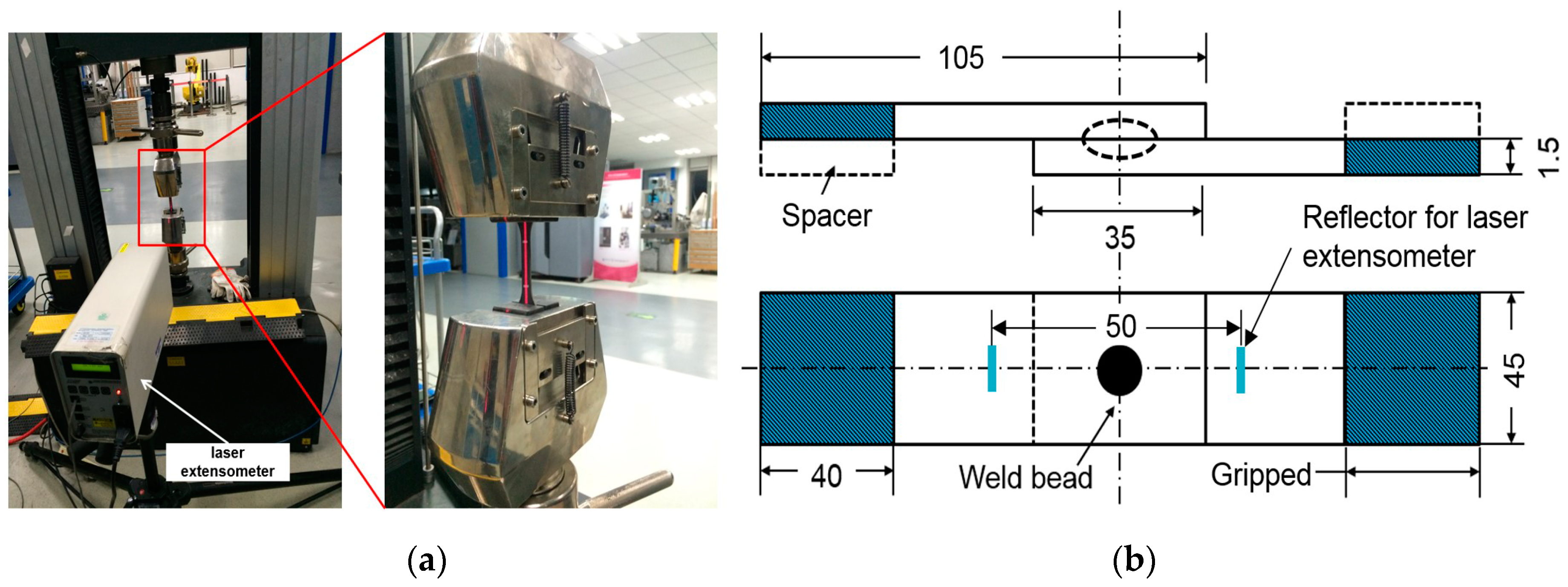

2.4. Tensile-Shear Test

3. Results and Discussion

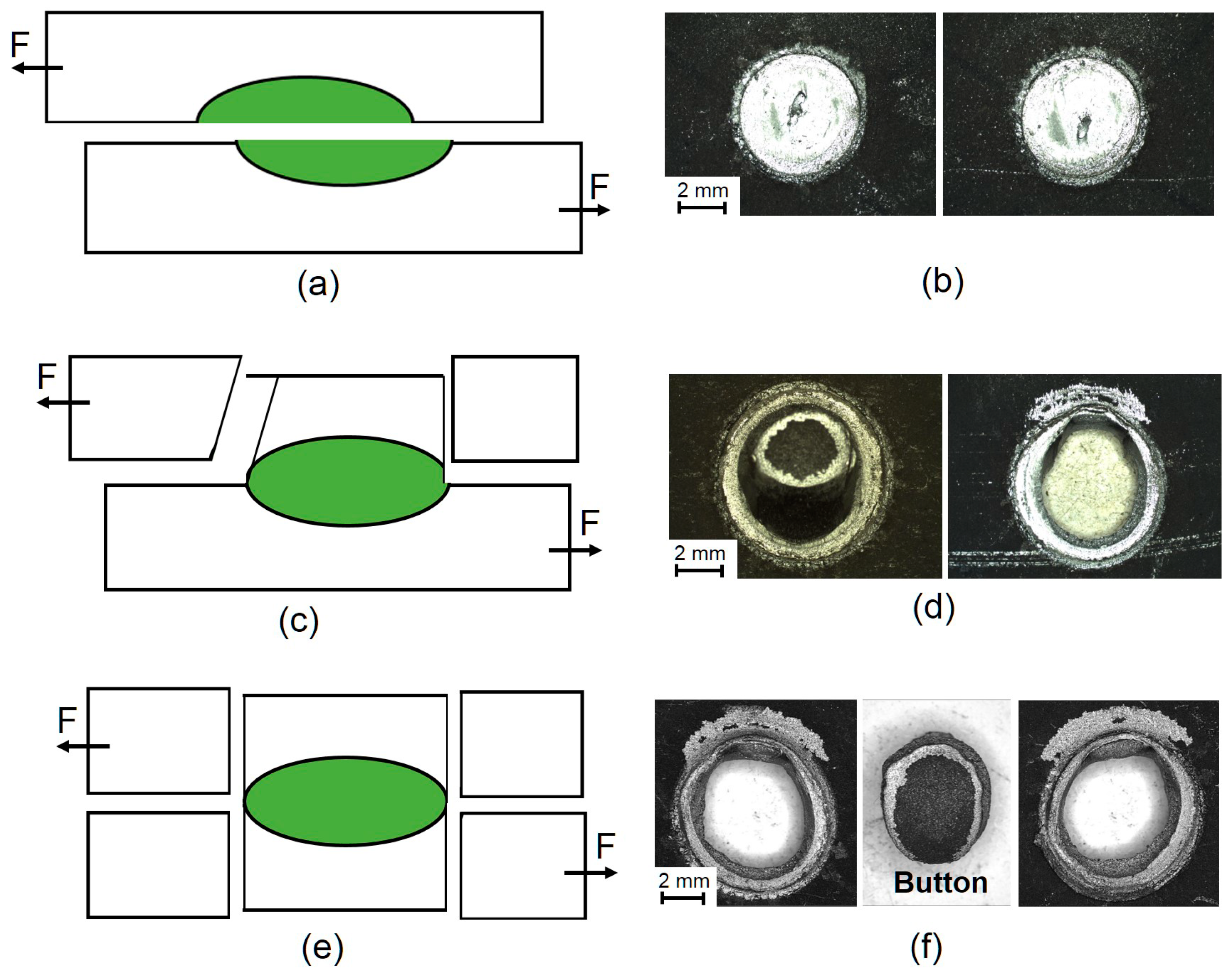

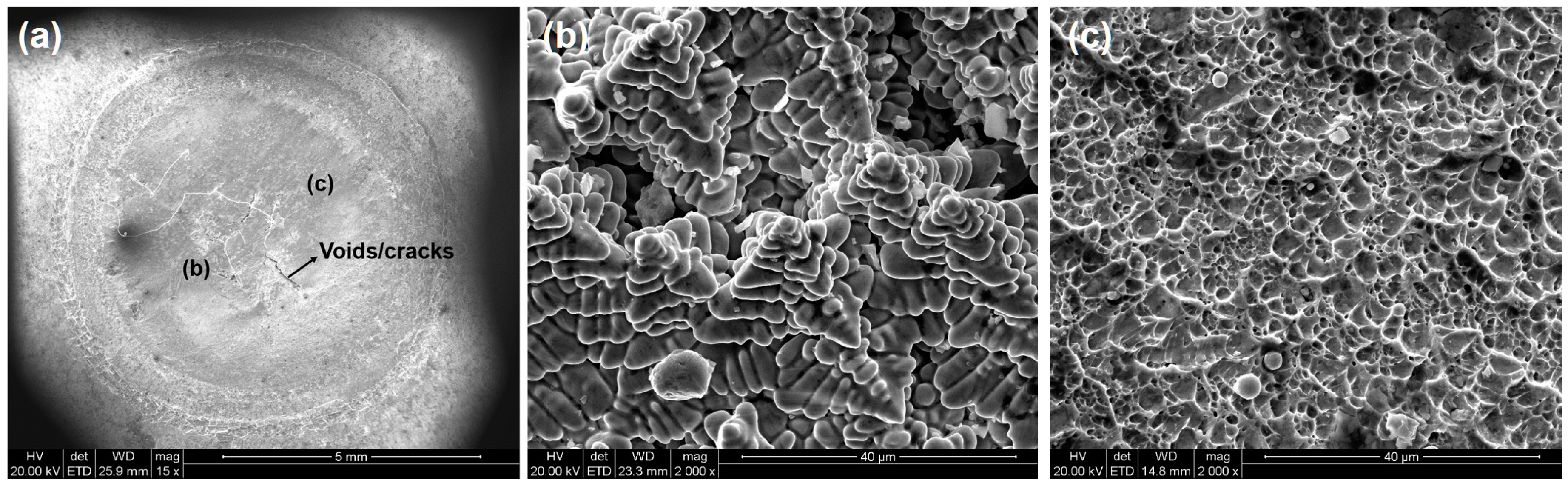

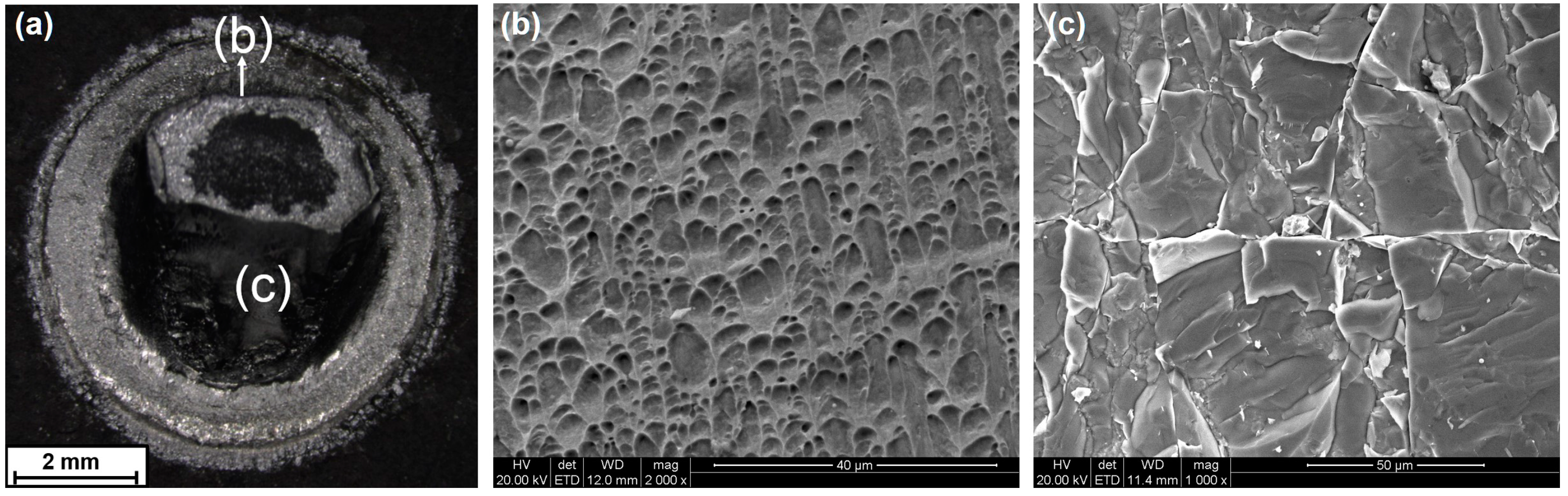

3.1. Typical Fracture Mode

3.2. Fracture Route

4. Discussion

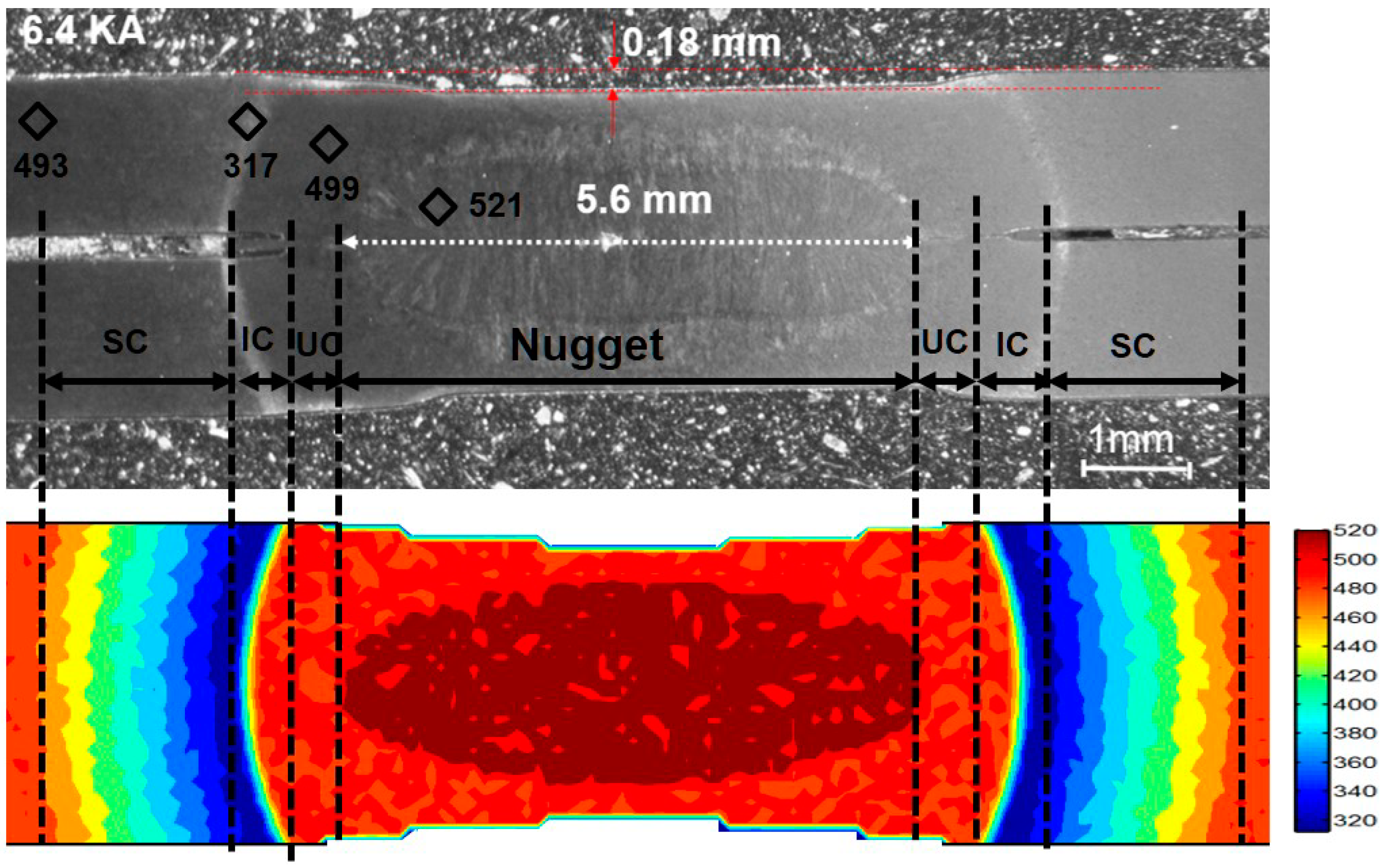

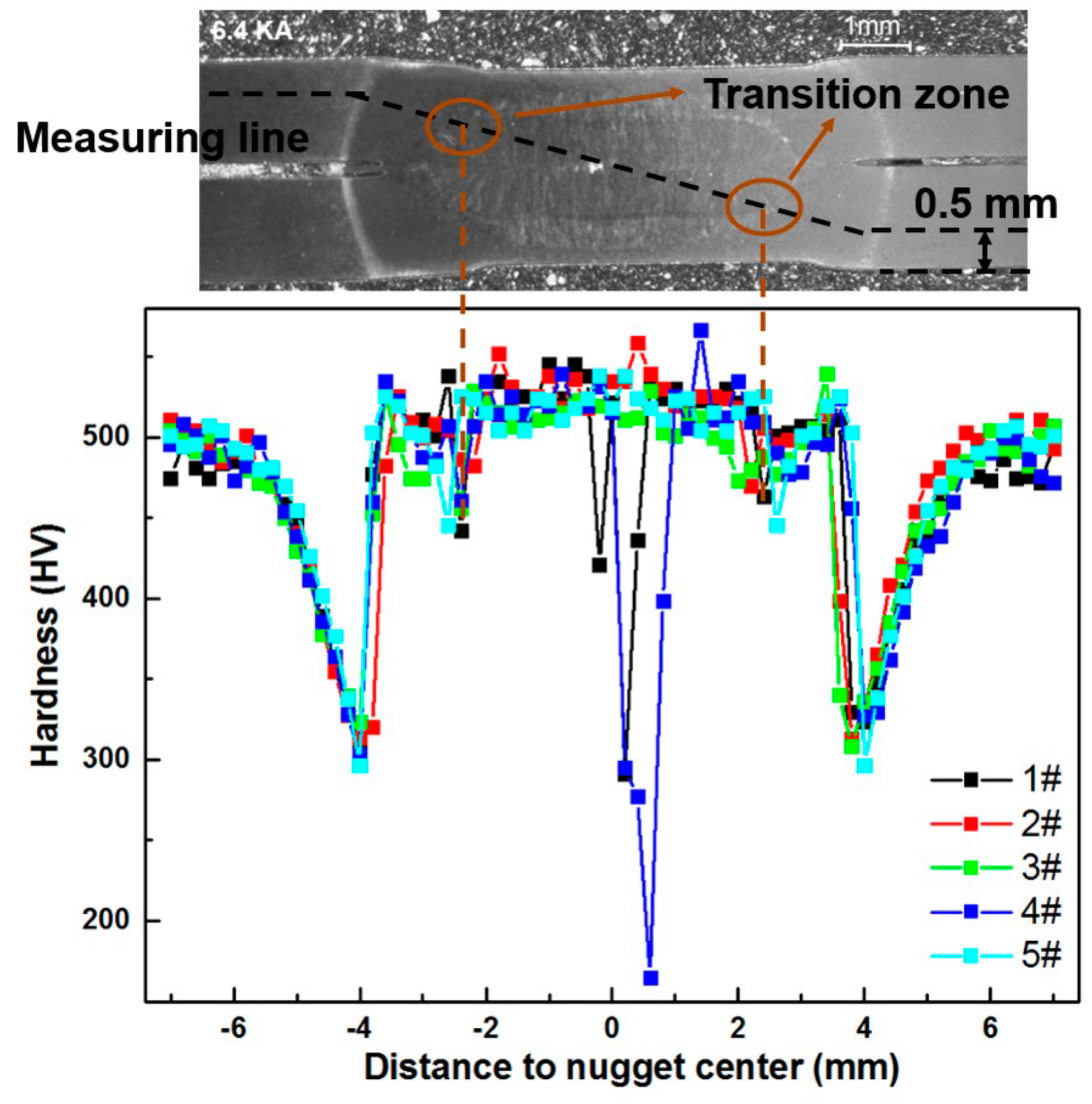

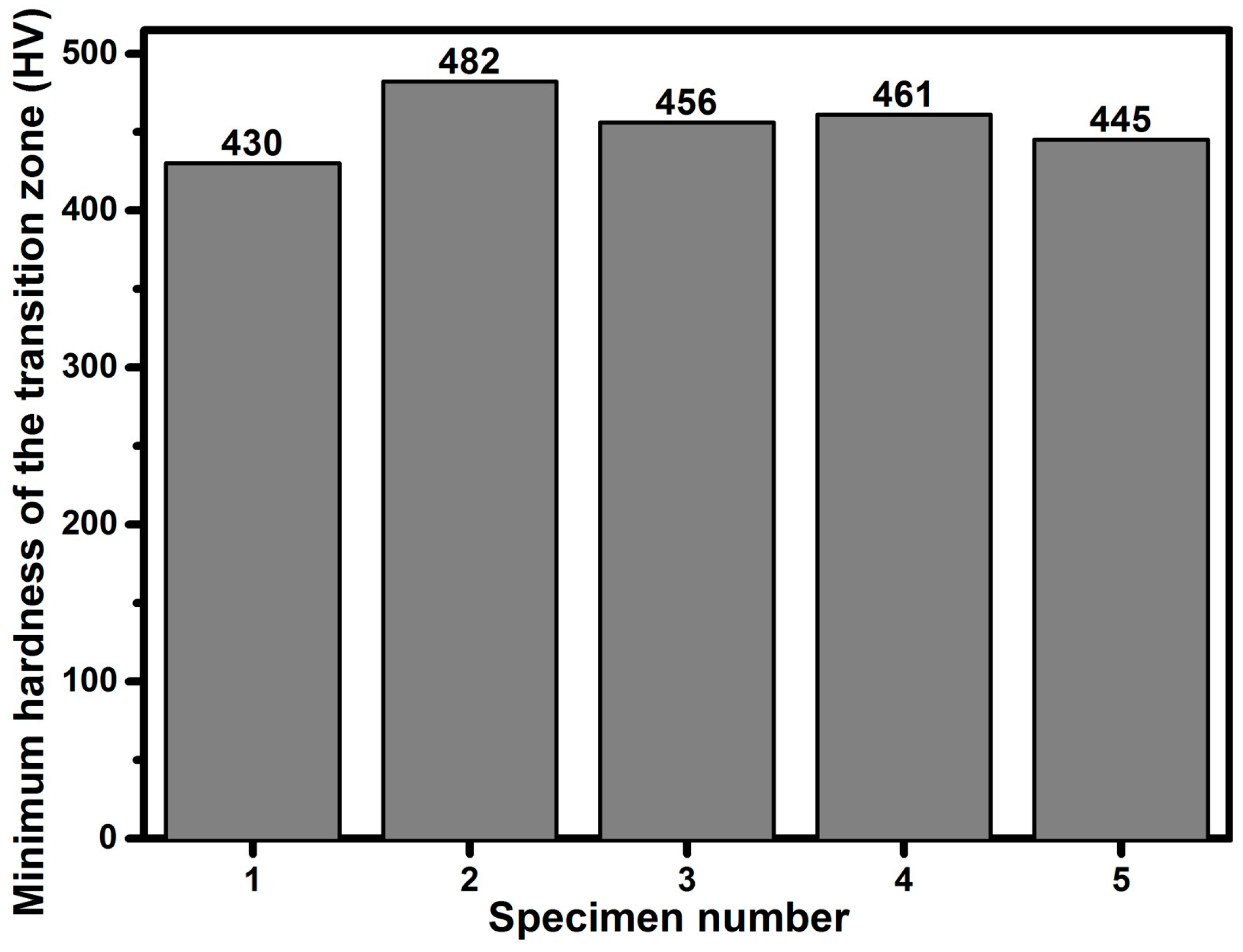

4.1. Microhardness Distribution

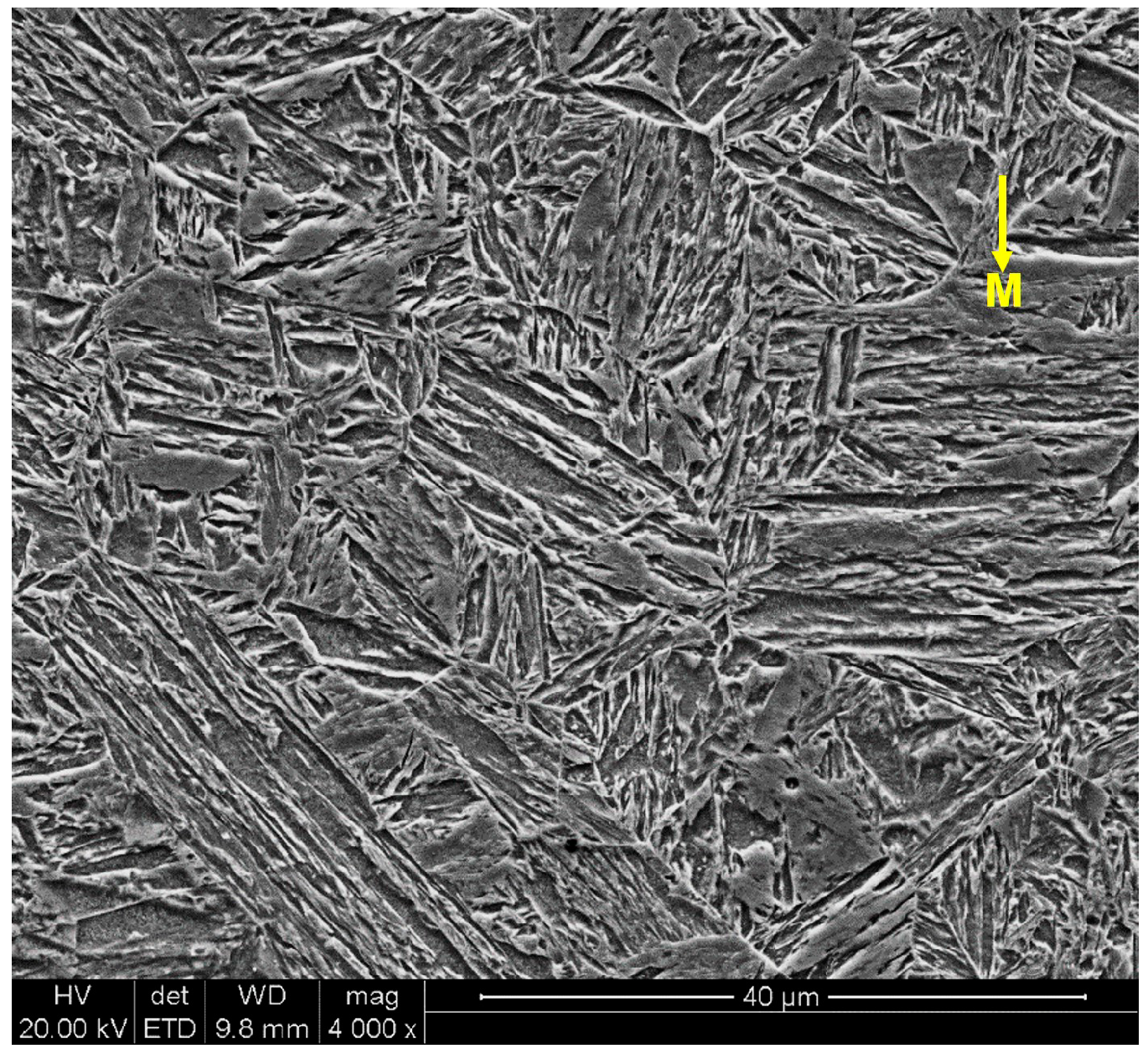

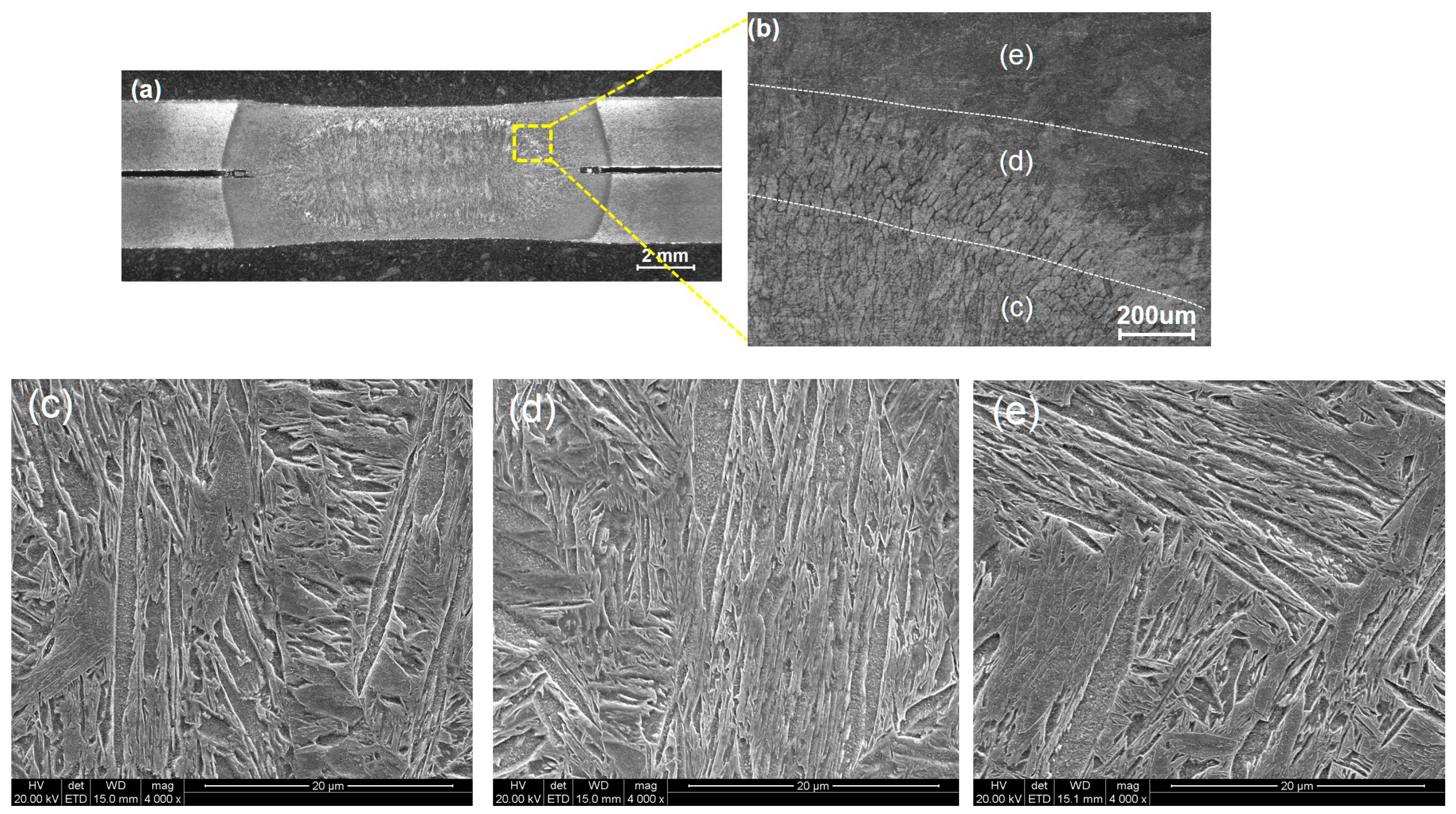

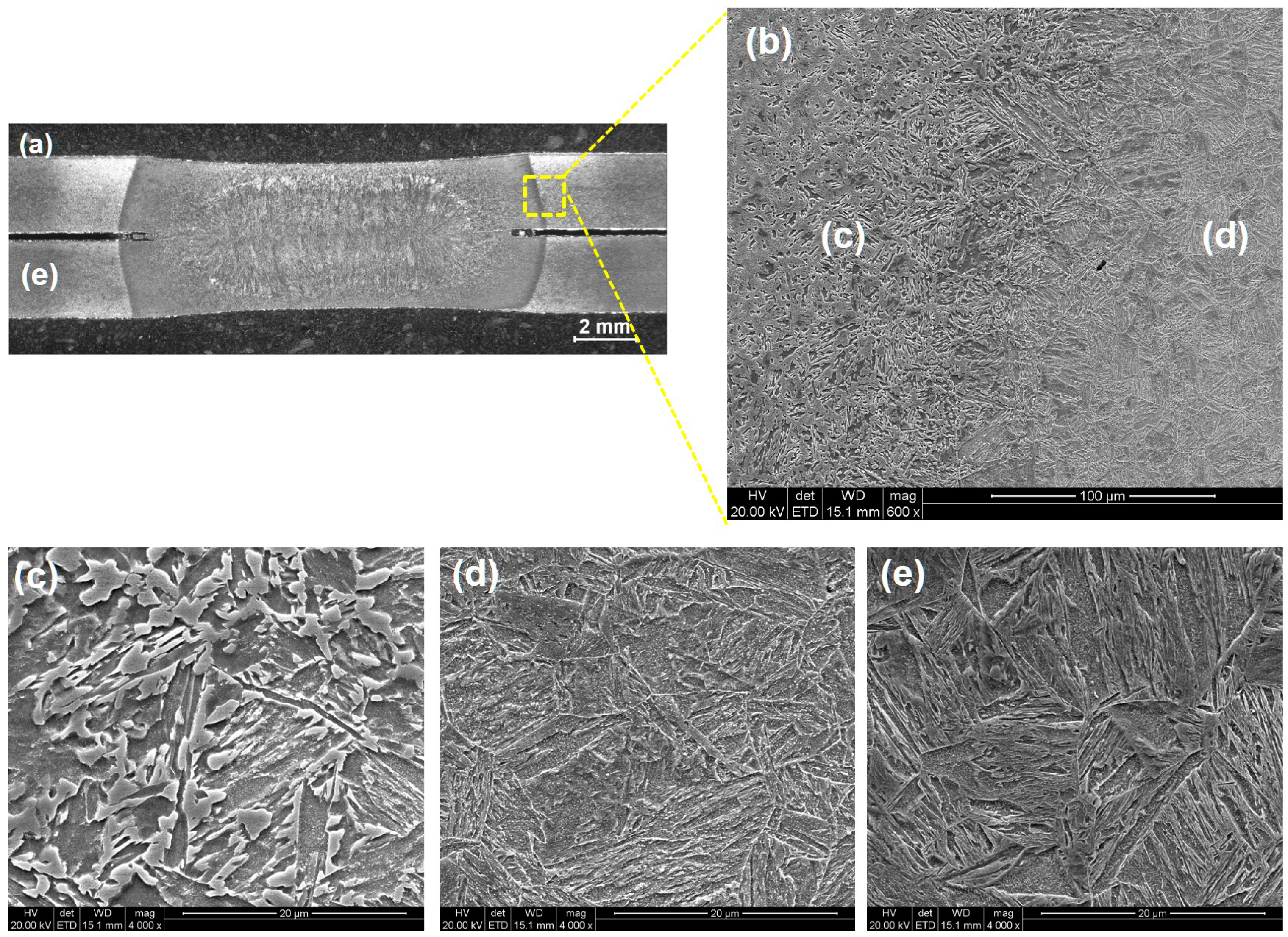

4.2. Microstructure

5. Conclusions

- (1)

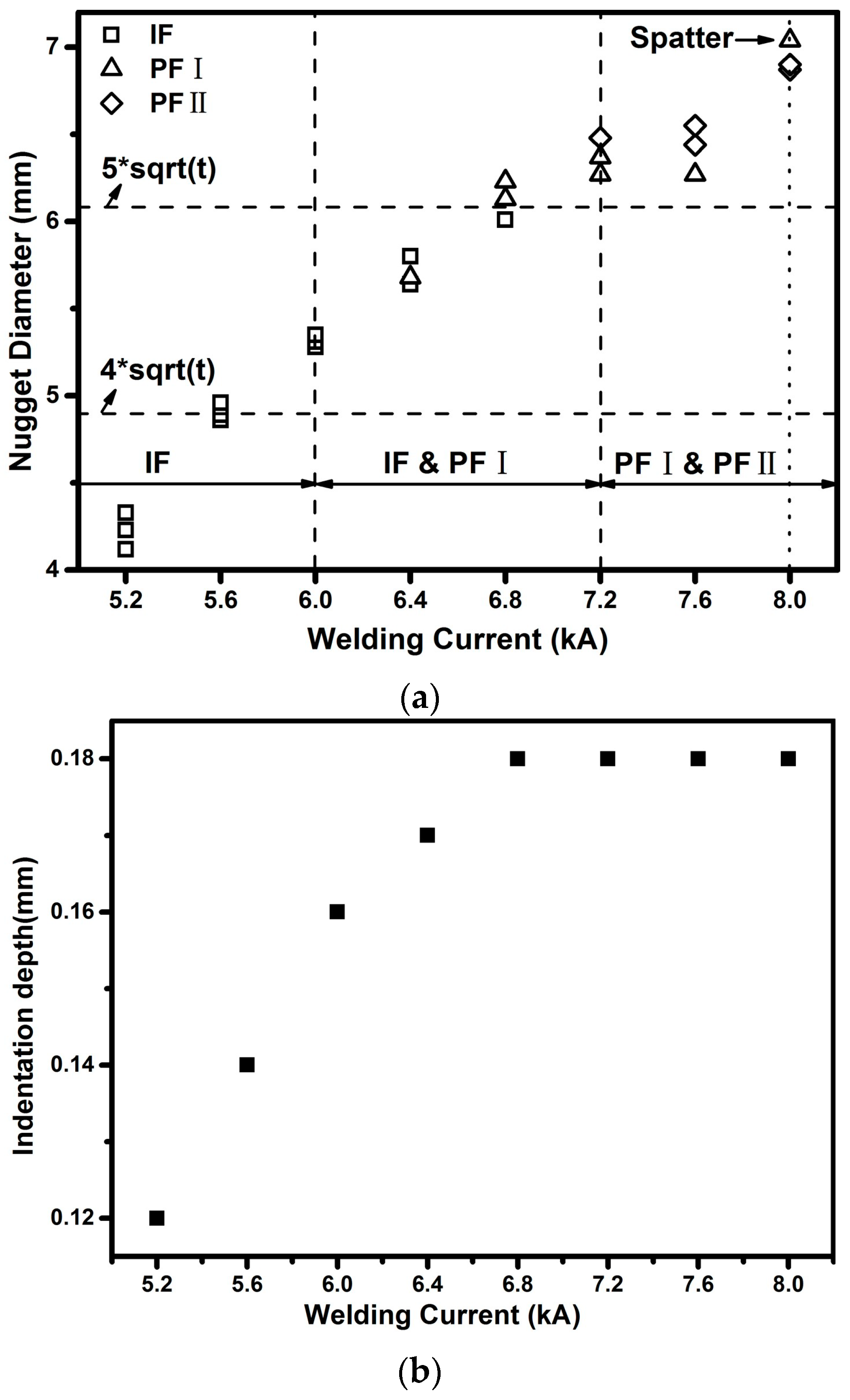

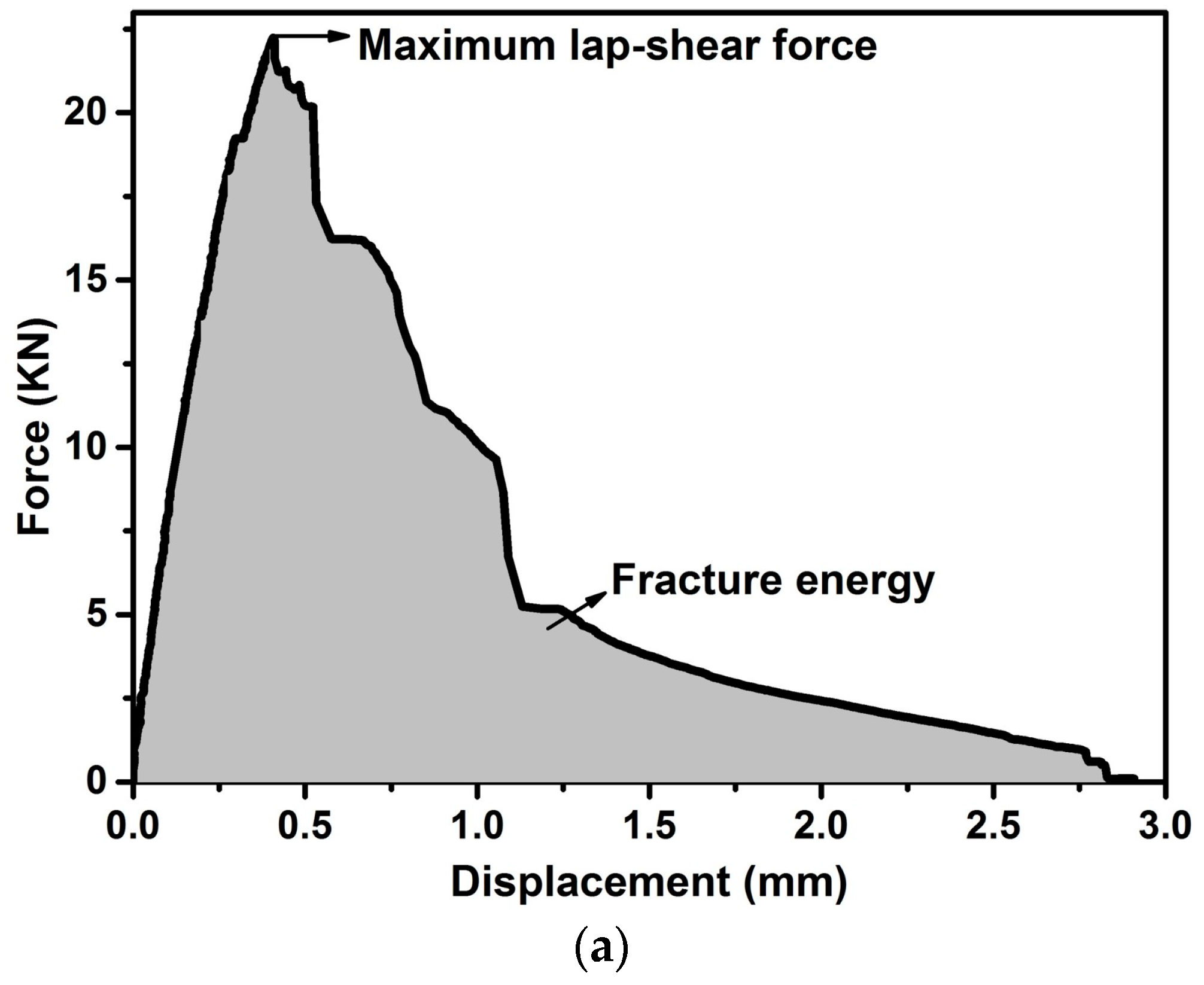

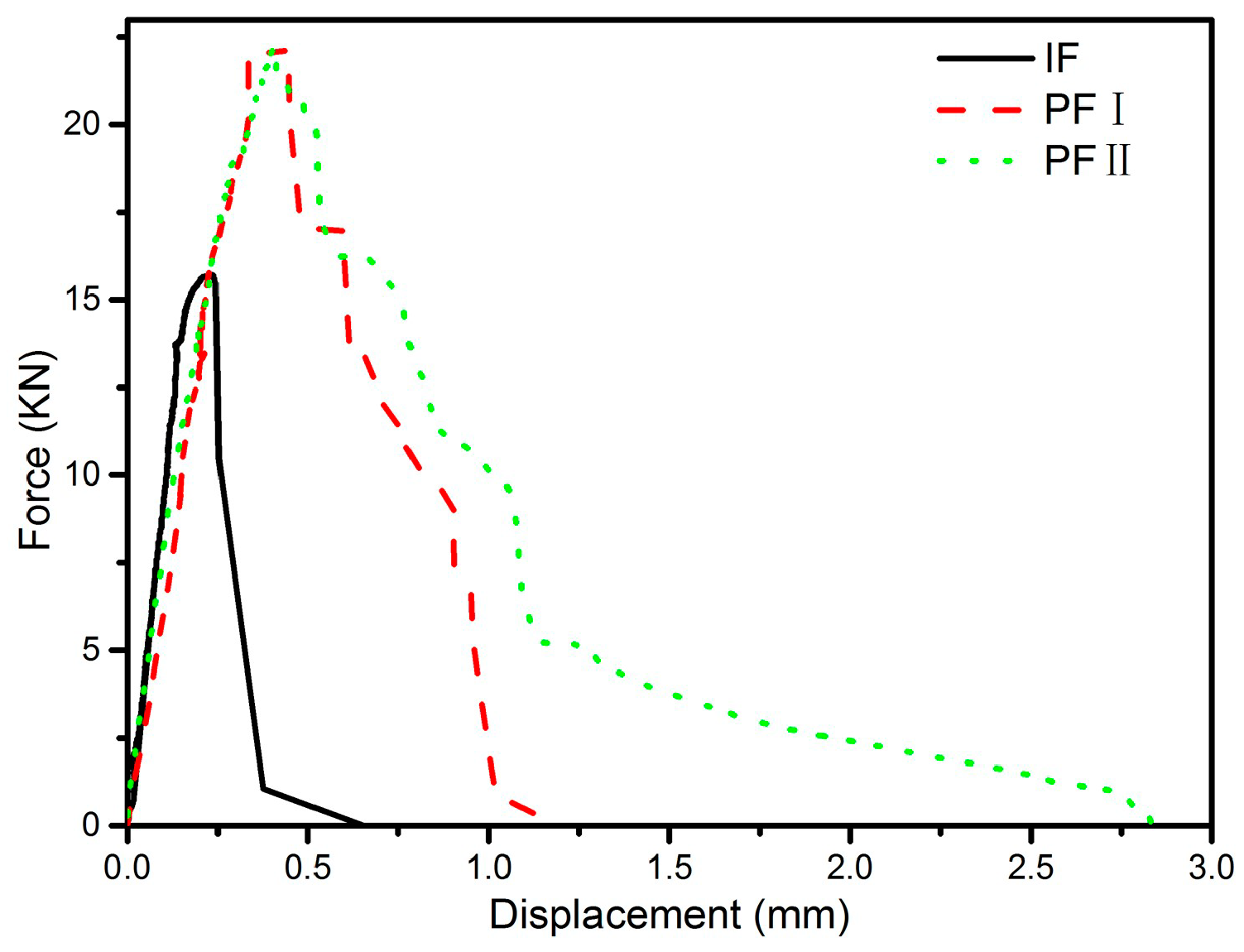

- Three fracture modes (IF, PF I and PF II) were found in lap-shear test of resistance spot welded B1500 joint. With the increase of nugget diameter, the fracture mode tended to change from IF to PF. Fracture route of IF extended along the interface of the nugget, while route of PF extended along the transition zone between nugget and upper critical zone. The PF II mode had the maximum lap shear force and fracture energy.

- (2)

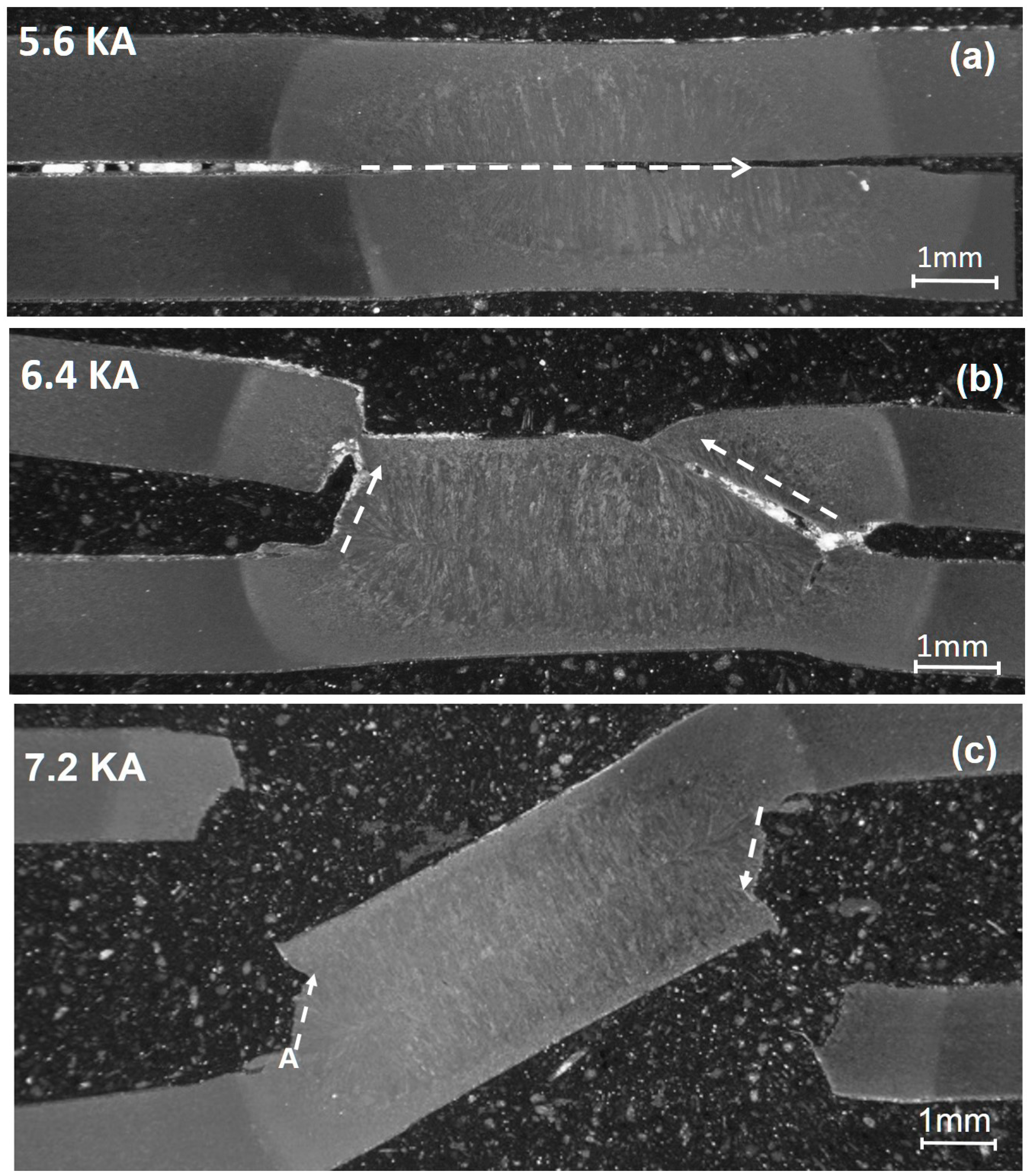

- At the welding current of 5.6 KA, IF mode initiated at the sheet interface and propagated towards the FZ and failed through the sheet. At higher welding currents and thus larger nugget size, a fracture mode will transit from IF to PF mode. For PF I mode, the fracture initiated at the FZ/UC zone and propagated along the thickness of the nugget, thus the nugget was pulled out from one sheet. For PF II mode, during which the failure initiated at the SCHAZ where the softest zone occurred and propagated to the BM side, indicating more reliability of the welds.

- (3)

- Obvious hardness decrease was observed in the transition zone of B1500 joint, which could provide the reason for route of PF I extending along this zone. This phenomenon can be explained with the formation of the delta ferrite at the fusion boundary due to the relatively high amount of alloying element in the hot-stamped boron steel. Fluctuation of the hardness in the transition zone led to the existence of both PF I and PF II at the same welding current.

Author Contributions

Funding

Conflicts of Interest

References

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H. Critical review of automotive steels spot welding: Process, structure and properties. Sci. Technol. Weld. Join. 2013, 18, 361–403. [Google Scholar] [CrossRef]

- Shaw, J.R.; Zuidema, B.K. New High Strength Steels Help Automakers Reach Future Goals for Safety, Affordability, Fuel Efficiency and Environmental Responsibility. SAE Trans. J. Mater. Manuf. 2001, 110, 976–983. [Google Scholar]

- Ighodaro, O.L.; Biro, E.; Zhou, Y.N. Comparative effects of Al-Si and galvannealed coatings on the properties of resistance spot welded hot stamping steel joints. J. Mater. Process. Technol. 2016, 236, 64–72. [Google Scholar] [CrossRef]

- Chabok, A.; van der Aa, E.; De Hosson, J.T.M.; Pei, Y.T. Mechanical behavior and failure mechanism of resistance spot welded DP1000 dual phase steel. Mater. Des. 2017, 124, 171–182. [Google Scholar] [CrossRef]

- Pouranvari, M.; Sobhani, S.; Goodarzi, F. Resistance spot welding of MS1200 martensitic advanced high strength: Microstructure-properties relationship. J. Mater. Process. 2018, 31, 867–874. [Google Scholar] [CrossRef]

- Chung, K.; Noh, W.; Yang, X.; Han, H.N.; Lee, M. Practical failure analysis of resistance spot welded advanced high-strength steel sheets. Int. J. Plast. 2017, 94, 122–147. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H. Failure mode transition in AISI 304 resistance spot welds. Weld. J. 2012, 91, 303s–309s. [Google Scholar]

- Eller, T.K.; Greve, L.; Andres, M.T.; Medricky, M.; Hatscher, A.; Meinders, V.T.; Boogaard, A.H.V.D. Plasticity and fracture modeling of quench-hardenable boron steel with tailored properties. J. Mater. Process. Technol. 2014, 214, 1211–1227. [Google Scholar] [CrossRef]

- Ma, C.; Chen, D.L.; Bhole, S.D.; Boudreau, G.; Lee, A.; Biro, E. Microstructure and Fracture Characteristics of Spot-Welded DP600 Steel. Mater. Sci. Eng. A 2008, 485, 334–346. [Google Scholar] [CrossRef]

- Emre, H.E.; Kaçar, R. Development of weld lobe for resistance spot-welded TRIP800 steel and evaluation of fracture mode of its weldment. Int. J. Adv. Manuf. Technol. 2015, 83, 1737–1747. [Google Scholar] [CrossRef]

- Safanama, D.S.; Marashi, S.P.H.; Pouranvari, M. Similar and dissimilar resistance spot welding of martensitic advanced high strength steel and low carbon steel: Metallurgical characteristics and failure mode transition. Sci. Technol. Weld. Join. 2012, 17, 288–294. [Google Scholar] [CrossRef]

- Ashiri, R.; Marashi, S.P.H.; Park, Y.D. Weld Processing and Mechanical Responses of 1-GPa TRIP Steel Resistance Spot Welds. Weld. J. 2018, 97, 157s–169s. [Google Scholar]

- Tamizi, M.; Pouranvari, M.; Movahedi, M. Welding metallurgy of martensitic advanced high strength steels during resistance spot welding. Sci. Technol. Weld. Join. 2017, 22, 327–335. [Google Scholar] [CrossRef]

- American Society for Testing Materials. Standard Test Methods for Tension Testing of Metallic Materials; ASTM E8/E8M-09; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Sun, X.; Stephens, E.V.; Khaleel, M.A. Effects of fusion zone size and failure mode on peak load and energy absorption of advanced high strength steel spot welds. Weld. J. 2007, 86, 18s–25s. [Google Scholar]

- Eller, T.K.; Greve, L.; Andres, M.; Medricky, M.; Geijselaers, H.J.M.; Meinders, V.T.; Boogaard, A.H.V.D. Plasticity and fracture modeling of the heat-affected zone in resistance spot welded tailor hardened boron steel. J. Mater. Process. Technol. 2016, 234, 309–322. [Google Scholar] [CrossRef]

- Lu, Y.; Peer, A.; Abke, T.; Kimchi, M.; Zhang, W. Subcritical heat affected zone softening in hot-stamped boron steel during resistance spot welding. Mater. Des. 2018, 155, 170–184. [Google Scholar] [CrossRef]

- Marya, M.; Gayden, X.Q. Development of Requirements for Resistance Spot Welding Dual-Phase (DP600) Steels Part 1—The Causes of Interfacial Fracture. Weld. J. 2005, 84, 172s–182s. [Google Scholar]

- Gould, J.E.; Khurana, S.P.; Li, T. Predictions of microstructures when welding automotive advanced high-strength steels. Weld. J. 2006, 85, 111s–116s. [Google Scholar]

- Inoue, H.; Koseki, T.; Okita, S.; Fuji, M. Epitaxial growth and phase formation of austenitic stainless steel weld metals near fusion boundaries: Study of solidification and transformation of Cr-Ni stainless steel weld metals (3rd Report). Weld. Int. 1998, 12, 195–206. [Google Scholar] [CrossRef]

- Yang, Z.; Sista, S.; Elmer, J.W.; Debroy, T. Three dimensional Monte Carlo simulation of grain growth during GTA welding of titanium. Acta Mater. 2000, 48, 4813–4825. [Google Scholar] [CrossRef]

- Ma, G.; Wu, D.; Guo, D. Segregation Characteristics of Pulsed Laser Butt Welding of Hastelloy C-276. Metall. Mater. Trans. A 2011, 42, 3853–3857. [Google Scholar] [CrossRef]

- Vignier, S.; Biro, E.; Hervé, M. Predicting the hardness profile across resistance spotwelds in martensitic steels. Weld World 2014, 58, 297–305. [Google Scholar] [CrossRef]

- Xia, M.; Biro, E.; Tian, Z.; Zhou, Y.N. Effects of Heat Input and Martensite on HAZ Softening in Laser Welding of Dual Phase Steels. ISIJ Int. 2008, 48, 809–814. [Google Scholar] [CrossRef]

| Steel | Chemical Composition in wt. % | ||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Ti | Al | B | |

| B1500 | 0.23 | 0.24 | 1.19 | 0.18 | 0.04 | 0.03 | 0.0023 |

| Steel | Mechanical Properties | ||

|---|---|---|---|

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | |

| B1500 | 1250 | 1530 | 7 |

| Parameters | Electrode Force (kN) | Welding Current (KA) | Squeeze Time (ms) | Weld Time (ms) | Hold Time (ms) |

|---|---|---|---|---|---|

| Value | 6.0 | 5.2~8.0 | 1000 | 580 | 200 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhang, Y.; Lai, X. Analysis of Fracture Modes of Resistance Spot Welded Hot-Stamped Boron Steel. Metals 2018, 8, 764. https://doi.org/10.3390/met8100764

Zhao Y, Zhang Y, Lai X. Analysis of Fracture Modes of Resistance Spot Welded Hot-Stamped Boron Steel. Metals. 2018; 8(10):764. https://doi.org/10.3390/met8100764

Chicago/Turabian StyleZhao, Yixi, Yansong Zhang, and Xinmin Lai. 2018. "Analysis of Fracture Modes of Resistance Spot Welded Hot-Stamped Boron Steel" Metals 8, no. 10: 764. https://doi.org/10.3390/met8100764

APA StyleZhao, Y., Zhang, Y., & Lai, X. (2018). Analysis of Fracture Modes of Resistance Spot Welded Hot-Stamped Boron Steel. Metals, 8(10), 764. https://doi.org/10.3390/met8100764