Mechanical and Tribological Properties of Al2O3-TiC Composite Fabricated by Spark Plasma Sintering Process with Metallic (Ni, Nb) Binders

Abstract

:1. Introduction

2. Materials and Methods

3. Results

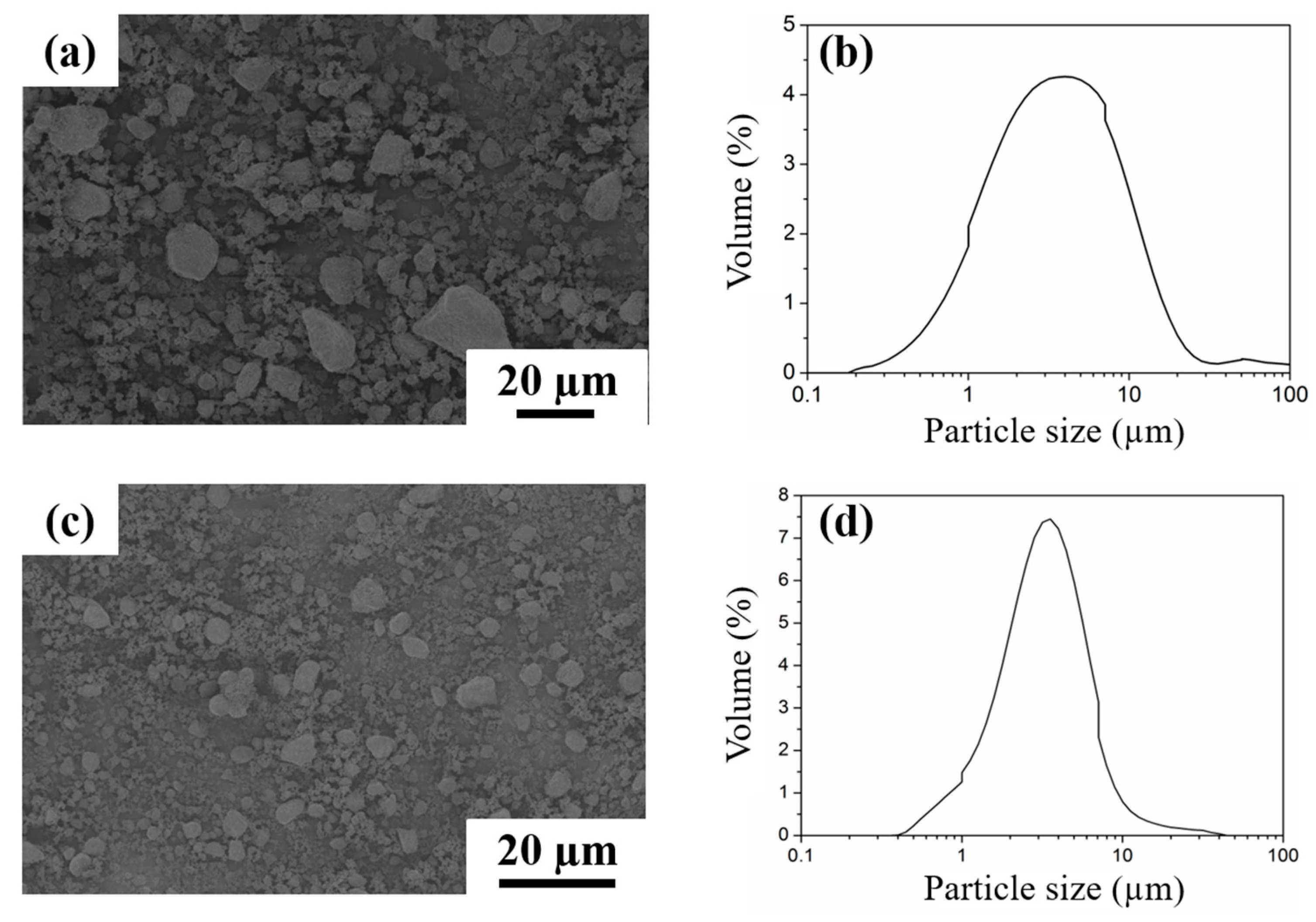

3.1. Power Characterization

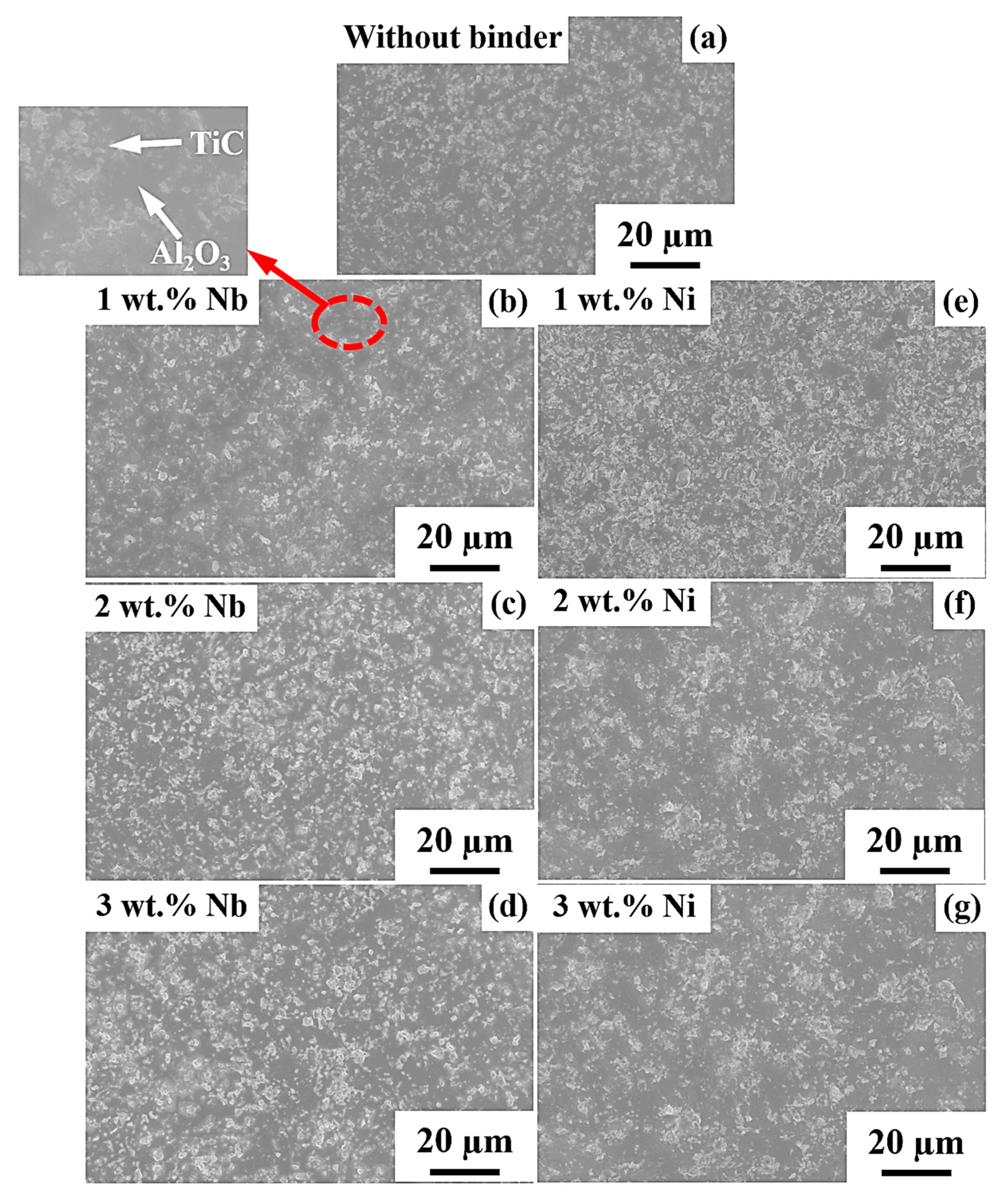

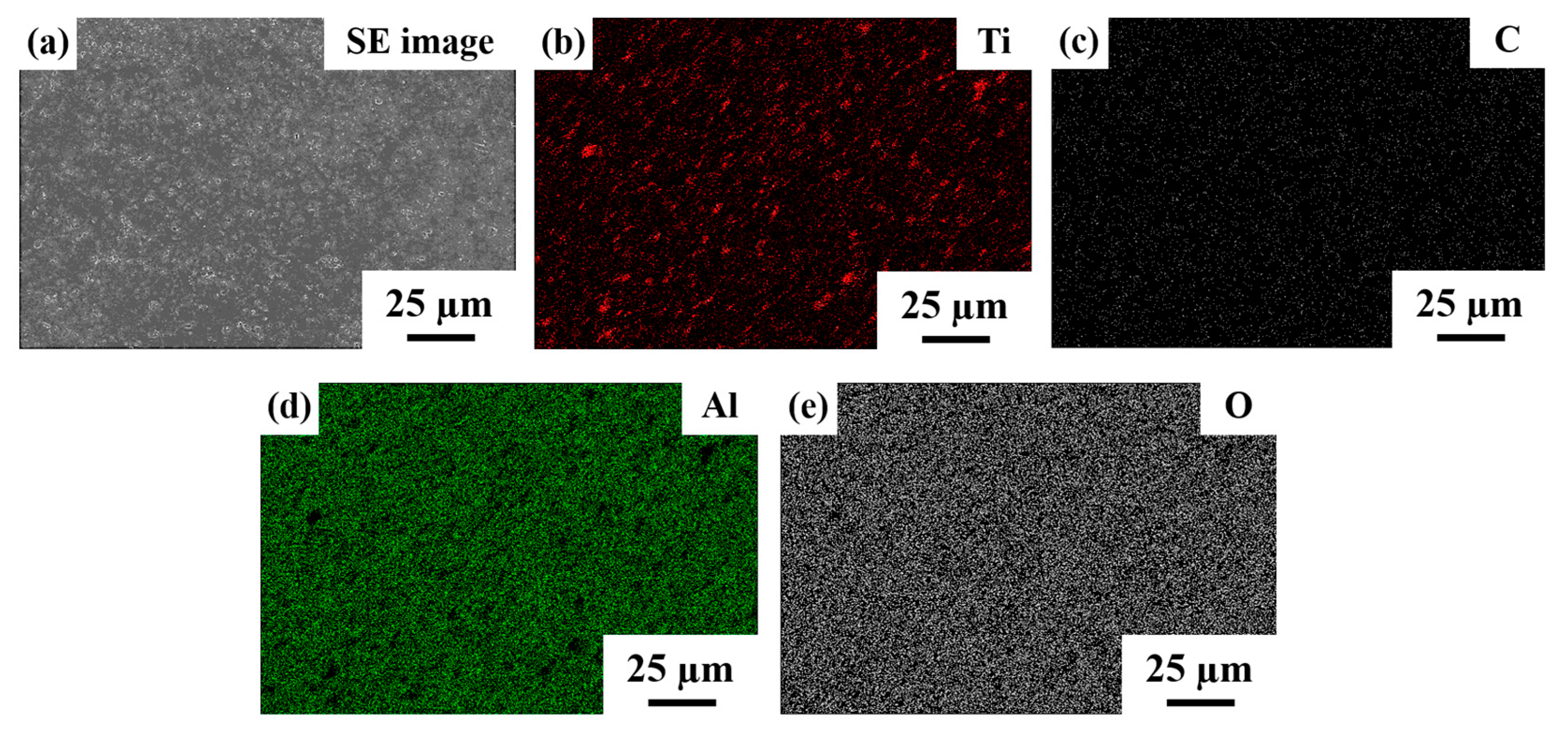

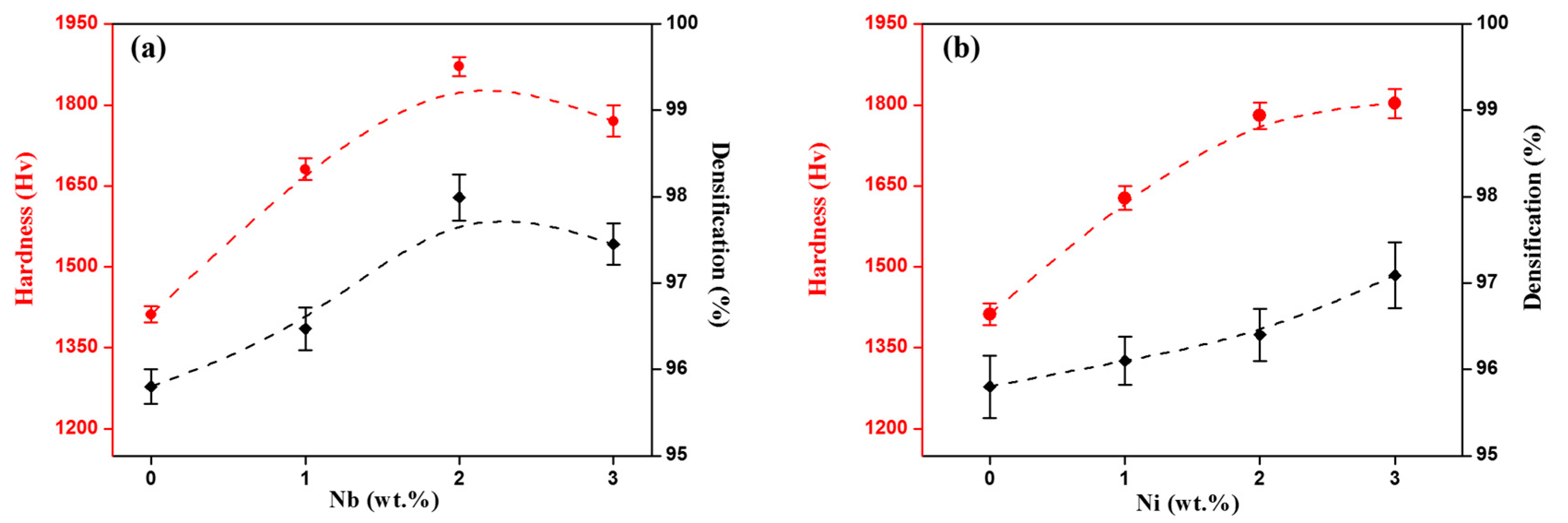

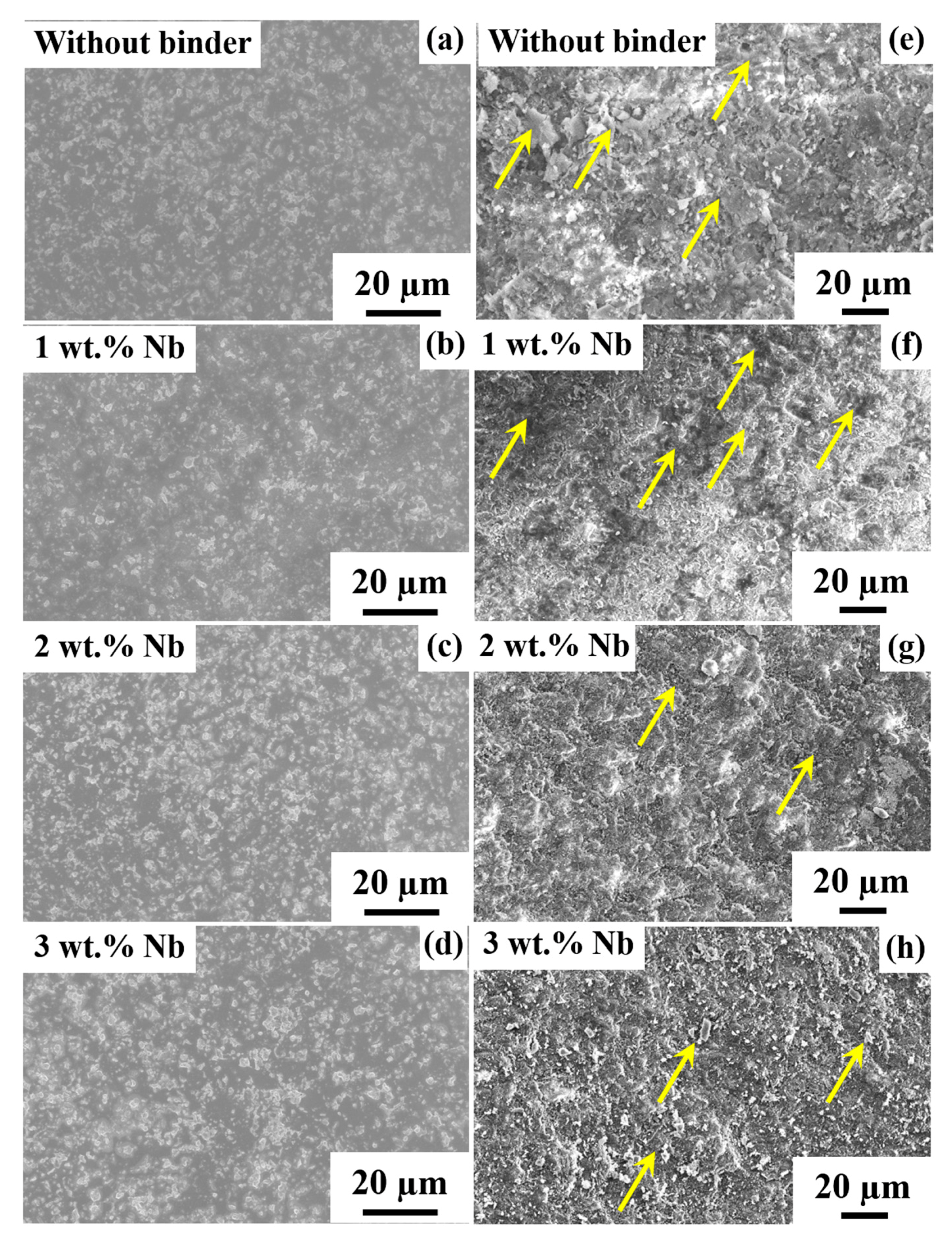

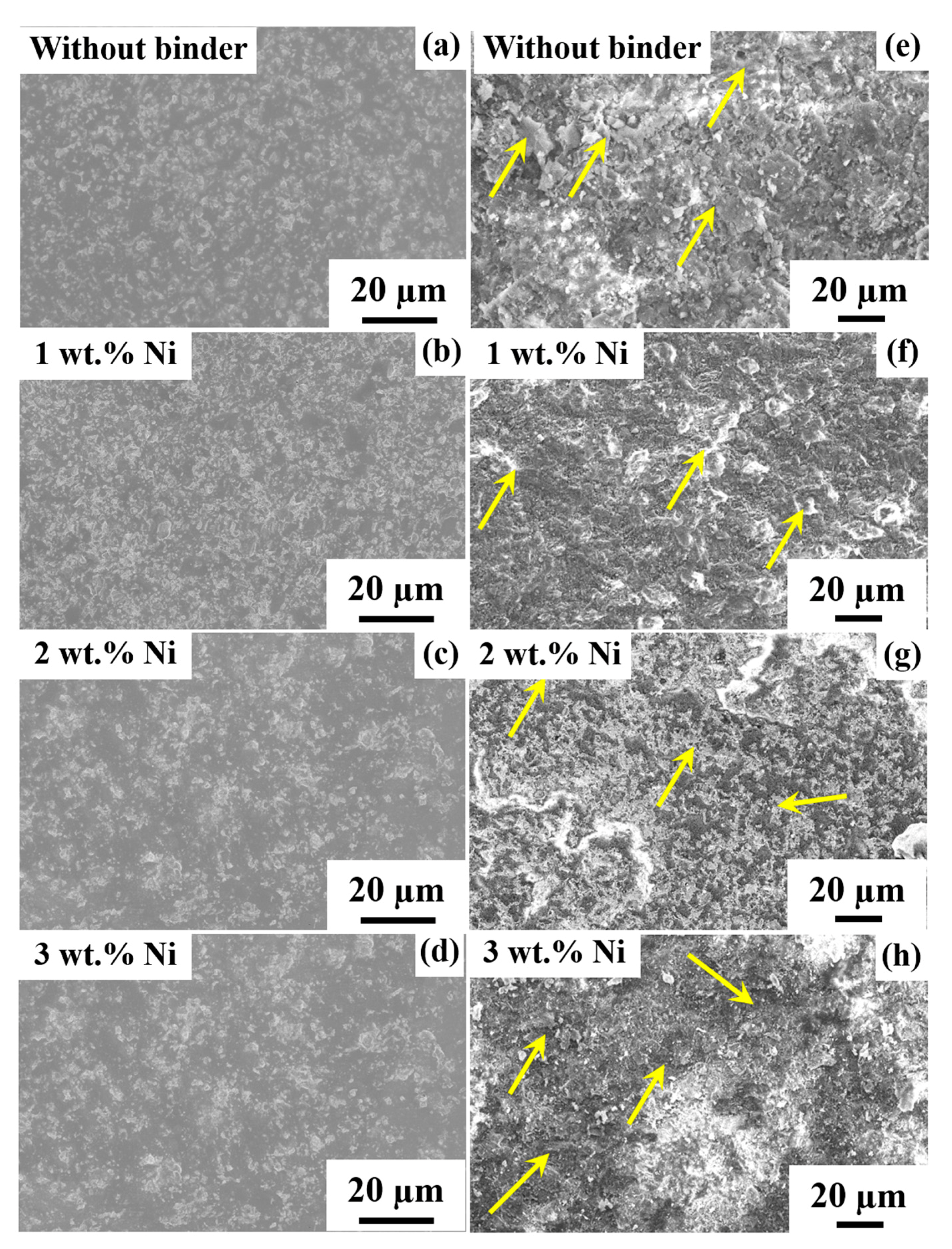

3.2. Microstructure and Mechanical Property of Bulk Sample

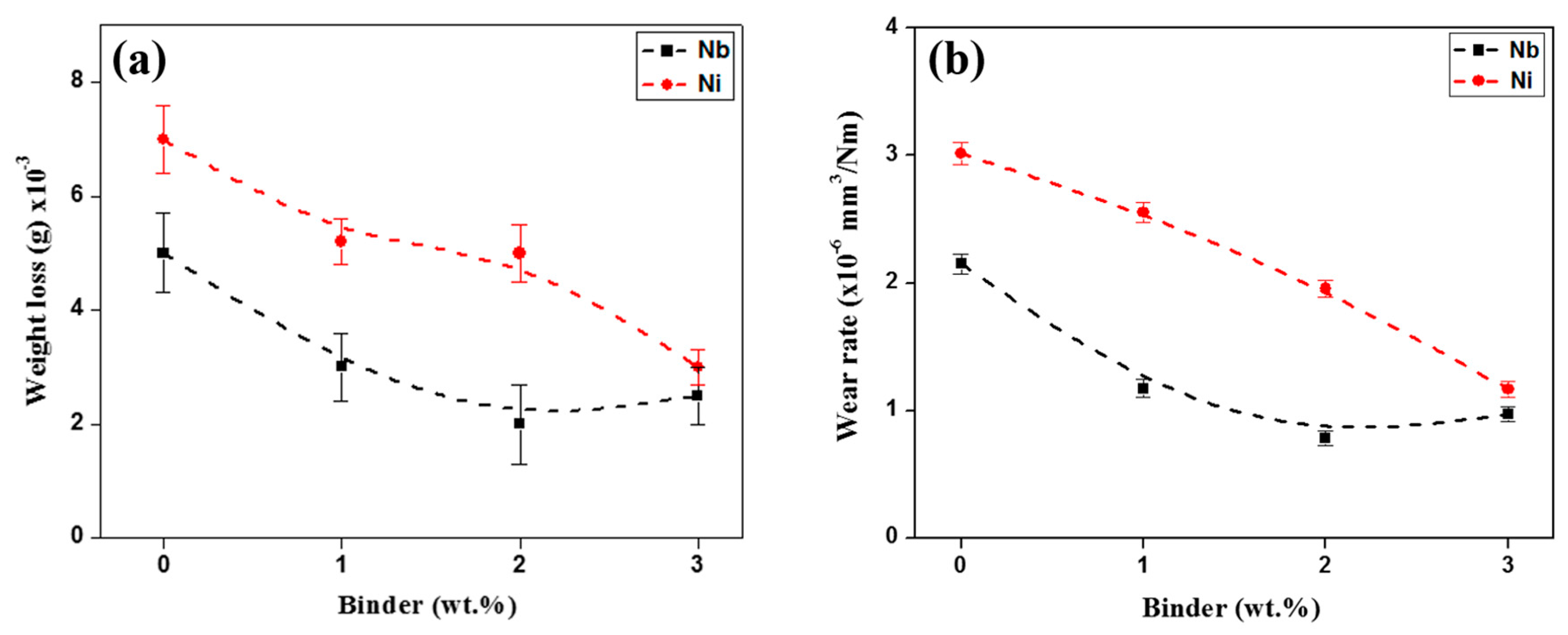

3.3. Abrasive Wear Study

4. Summary

- ➢

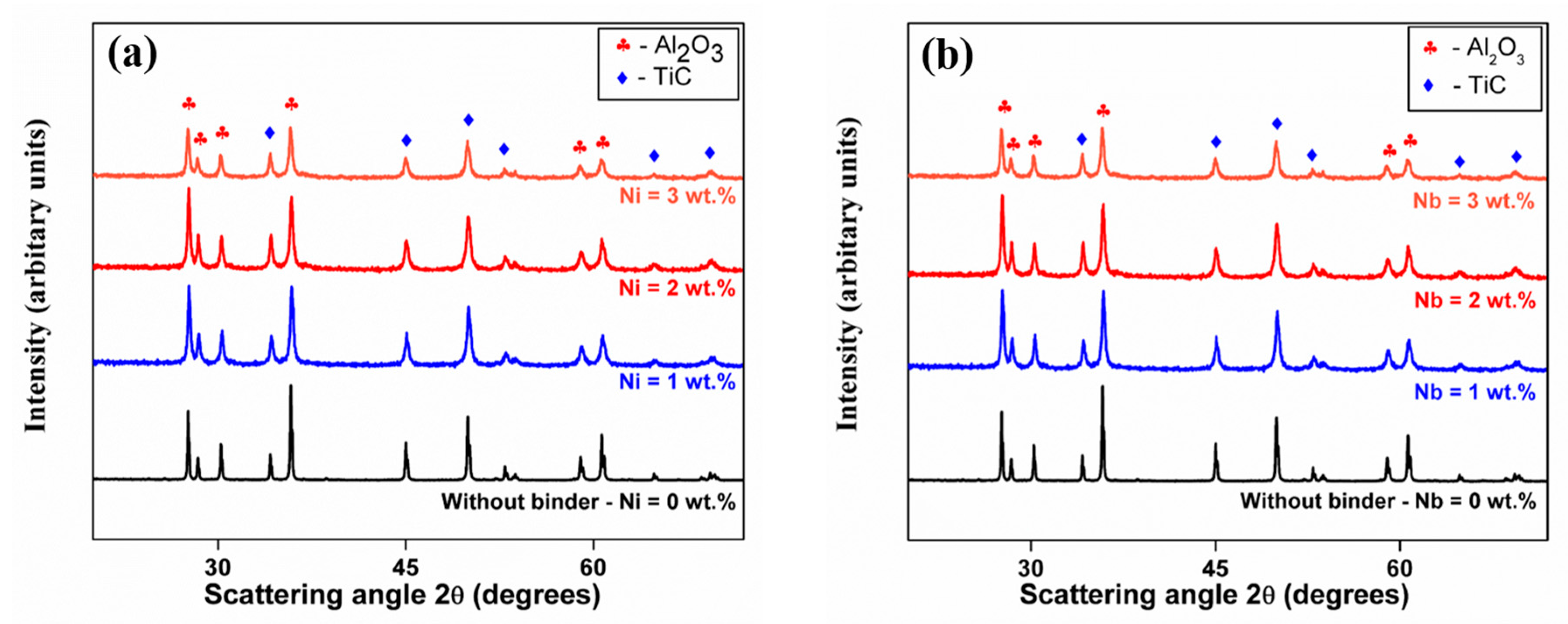

- XRD data shows the presence of two phases Al2O3 and TiC, confirming no reaction between the matrix, reinforcement, and metallic binders during the mechanical milling and subsequent spark plasma sintering processes. However, no peaks of Ni/Nb are observed owing to the small amounts of Ni/Nb addition, which is below the deductible limits of the XRD setup.

- ➢

- The microstructure of the composite reveals homogeneous distribution of the TiC particles within the Al2O3 matrix. The relative density, hardness, and the wear resistance of the composites increase with the addition of Nb until 2 wt. %. Any addition of Nb beyond 2 wt. % (3 wt. % addition of Nb) hampers their properties, due to relatively poor wettability of Nb with the Al2O3 matrix. Nevertheless, the properties of composites with 3 wt. % addition of Nb are better than the samples without the addition of Nb.

- ➢

- On the other hand, with the addition of Ni, the relative density, hardness, and wear resistance increases with increase in the Ni content. In general, the samples with the addition of Nb as binder show more improved properties than the composites with Ni addition, which is attributed to the marginal increase in the hardness of Nb compared to Ni.

- ➢

- Overall results show that the addition of metallic binders improve the relative density, hardness, and wear resistance of the Al2O3-10TiC composite samples.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ruehle, M.; Evans, A.G. High toughness ceramics and ceramic composites. Prog. Mater. Sci. 1989, 33, 85–167. [Google Scholar] [CrossRef]

- Moya, J.S.; Lopez-Esteban, S.; Pecharroman, C. The challenge of ceramic/metal microcomposites and nanocomposites. Prog. Mater. Sci. 2007, 52, 1017–1090. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Mitterer, C.; Hultman, L.; Clemens, H. Microstructural design of hard coatings. Prog. Mater. Sci. 2006, 51, 1032–1114. [Google Scholar] [CrossRef]

- Zhao, J.; Yuan, X.L.; Zhou, Y.H. Cutting performance and failure mechanisms of an Al2O3/WC/TiC micro–nano-composite ceramic tool. Int. J. Refract. Met. Hard Mater. 2010, 28, 330–337. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, J.; Sun, J.; Zhang, X. Tribological properties of pressureless sintered alumina matrix ceramic materials improved by diopside. J. Eur. Ceram. Soc. 2008, 28, 199–204. [Google Scholar] [CrossRef]

- Meybodi, S.M.; Bafrooei, H.B.; Ebadzadeh, T.; Tazike, M. Microstructure and mechanical properties of Al2O3–20 wt% Al2TiO5 composite prepared from alumina and titania nano powders. Ceram. Int. 2013, 39, 977–982. [Google Scholar] [CrossRef]

- Chaubey, A.K.; Prashanth, K.G.; Ray, N.; Wang, Z. Study on in-situ synthesis of Al-TiC composite by self propagating high temperature synthesis process. Mater. Sci. Indian J. 2015, 12, 454–461. [Google Scholar]

- Acchar, W.; Silva, Y.B.F.; Cairo, C.A. Mechanical properties of hot-pressed ZrO2 reinforced with (W, Ti)C and Al2O3 additions. Mater. Sci. Eng. A 2010, 527, 480–484. [Google Scholar] [CrossRef]

- Xu, L.; Huang, C.; Liu, H.L.; Zou, B.; Zhu, H.; Zhao, G.; Wang, J. Study on in-situ synthesis of ZrB2 whiskers in ZrB2–ZrC matrix powder for ceramic cutting tools. Int. J. Refract. Met. Hard Mater. 2013, 37, 98–105. [Google Scholar] [CrossRef]

- Sktani, Z.D.I.; Azhar, A.Z.A.; Ratnam, M.M.; Ahmad, Z.A. The influence of in-situ formation of hibonite on the properties of zirconia toughened alumina (ZTA) composites. Ceram. Int. 2014, 40, 6211–6217. [Google Scholar] [CrossRef]

- Gong, J.; Miao, H.; Zhao, Z. The influence of TiC-particle-size on the fracture toughness of Al2O3–30 wt. % TiC composites. J. Eur. Ceram. Soc. 2001, 21, 2377–2381. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Zhao, J.; Zhang, G.; Zhang, K. Cutting performance and wear mechanism of nanoscale and microscale textured Al2O3/TiC ceramic tools in dry cutting of hardened steel. Int. J. Refract. Met. Hard Mater. 2014, 43, 46–58. [Google Scholar] [CrossRef]

- Wang, H.; Wang, B.; Li, S.; Xue, Q.; Huang, F. Toughening magnetron sputtered TiB2 coatings by Ni addition. Surf. Coat. Technol. 2013, 232, 767–774. [Google Scholar] [CrossRef]

- Zawrah, M.F.; Abdel-kader, H.; Elbaly, N.E. Fabrication of Al2O3–20 vol.% Al nanocomposite powders using high energy milling and their sinterability. Mater. Res. Bull. 2012, 47, 655–661. [Google Scholar] [CrossRef]

- Sun, X.; Han, W.; Hu, P.; Wang, Z.; Zhang, X. Microstructure and mechanical properties of ZrB2–Nb composite. Int. J. Refract. Met. Hard Mater. 2010, 28, 472–474. [Google Scholar] [CrossRef]

- Mohammadpour, M.; Abachi, P.; Pourazarang, K. Effect of cobalt replacement by nickel on functionally graded cemented carbonitrides. Int. J. Refract. Met. Hard Mater. 2012, 30, 42–47. [Google Scholar] [CrossRef]

- Song, W.; Hu, J.; Zhao, Y.; Shao, D.; Li, J. Efficient removal of cobalt from aqueous solution using β-cyclodextrin modified graphene oxide. RSC Adv. 2013, 3, 9514–9521. [Google Scholar] [CrossRef]

- Tucker, M.C.; Cheng, L.; DeJonghe, L.C. Inorganic binder-containing composite cathode contact materials for solid oxide fuel cells. J. Power Sourc. 2013, 224, 174–179. [Google Scholar] [CrossRef]

- Kakade, M.B.; Ramanathan, S.; Das, D. Gel-combustion, characterization and processing of porous Ni–YSZ cermet for anodes of solid oxide fuel cells (SOFCs). Ceram. Int. 2011, 37, 195–200. [Google Scholar] [CrossRef]

- Kumar, B.V.M.; Kumar, J.R.; Basu, B. Crater wear mechanisms of TiCN–Ni–WC cermets during dry machining. Int. J. Refract. Met. Hard Mater. 2007, 25, 392–399. [Google Scholar] [CrossRef]

- Özer, A.; Kriven, W.M.; Tür, Y.K. The effect of 3 mol.% Y2O3 stabilized ZrO2 produced by a steric entrapment method on the mechanical and sintering properties of Cr3C2 based cermets. Mater. Sci. Eng. A 2012, 556, 878–884. [Google Scholar] [CrossRef]

- Yang, F.; Guo, Z.M.; Hao, J.J.; Shi, Y.L. Self-Propagating High-Temperature Synthesis of TiB2-Ti(C,N) Cermets Composite Powder. Adv. Mater. Res. 2012, 468, 1247–1250. [Google Scholar] [CrossRef]

- Saidi, A.; Barati, M. Production of (W, Ti)C reinforced Ni–Ti matrix composites. J. Mater. Process. Technol. 2002, 124, 166–170. [Google Scholar] [CrossRef]

- Hussainova, I. Effect of microstructure on the erosive wear of titanium carbide-based cermets. Wear 2003, 255, 121–128. [Google Scholar] [CrossRef]

- Rodriguez-Barrero, S.; Fernandez-Larrinoa, J.; Azkona, I.; Lopez de Lacalle, L.N.; Polvorosa, R. Enhanced performance of nanostructured coatings for drilling by droplet elimination. Mater. Manuf. Process. 2016, 31, 593–602. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suarez, A.; Lopez de Lacalle, L.N.; Cerrillo, I.; Wertland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Li, Y.; Liu, N.; Zhang, X.; Rong, C. Effect of Mo addition on the microstructure and mechanical properties of ultra-fine grade TiC–TiN–WC–Mo2C–Co cermets. Int. J. Refract. Met. Hard Mater. 2008, 26, 190–196. [Google Scholar] [CrossRef]

- Guo, X.; Niu, Y.; Huang, L.; Ji, H.; Zheng, X. Microstructure and Tribological Property of TiC-Mo Composite Coating Prepared by Vacuum Plasma Spraying. J. Therm. Spray Technol. 2012, 21, 1083–1090. [Google Scholar] [CrossRef]

- Wang, Y.; Shu, S.; Qiu, F.; Zhou, D.; Wang, J.; Jiang, Q. Effect of W content on the compression properties and abrasive wear behavior of the (TiB2–TiCxNy)/(Ni + W) composites. Mater. Des. 2013, 45, 286–291. [Google Scholar] [CrossRef]

- Chen, X.; Xiong, W.; Qu, J.; Yang, Q.; Yao, Z.; Huang, Y. Microstructure and mechanical properties of (Ti, W, Ta)C-xMo-Ni cermets. Int. J. Refract. Met. Hard Mater. 2012, 31, 56–61. [Google Scholar] [CrossRef]

- Chaubey, A.K.; Scudino, S.; Mukhopadhyay, N.K.; Khoshkhoo, M.S.; Mishra, B.K.; Eckert, J. Effect of particle dispersion on the mechanical behavior of Al-based metal matrix composites reinforced with nanocrystalline Al–Ca intermetallics. J. Alloys Compd. 2012, 536, 134–137. [Google Scholar] [CrossRef]

- Wang, Z.; Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Sordelet, D.J.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Tensile properties of Al matrix composites reinforced with in situ devitrified Al84Gd6Ni7Co3 glassy particles. J. Alloys Compd. 2014, 589, 419–422. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Surreddi, K.B.; Sakaliysla, M.; Murty, B.S.; Eckert, J. Crystallization of Zr65Ag5Cu12.5Ni10Al7.5 glassy powders produced by ball milling of pre-alloyed ingots. Mater. Sci. Eng. A 2009, 513–514, 279–285. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, J.; Sun, B.A.; Scudino, S.; Prashanth, K.G.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Fabrication and mechanical properties of Al-based matrix composites reinforced with Mg65Cu20Zn5Y10 metallic glass particles. Mater Sci. Eng. A 2014, 600, 53–58. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Kumar, S.; Scudino, S.; Murty, B.S.; Eckert, J. Fabrication and response of Al70Y16Ni10Co4 glass reinforced metal matrix composites. Mater. Manuf. Proc. 2011, 26, 1242–1247. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Murty, B.S. Production, kinetic study and properties of Fe-based glass and its composites. Mater. Manuf. Proc. 2010, 25, 592–597. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, J.; Scudino, S.; Sun, B.A.; Qu, R.T.; He, J.; Prashanth, K.G.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Mechanical behavior of Al-based matrix composites reinforced with Mg58Cu28.5Gd11Ag2.5 metallic glass. Adv. Powder Technol. 2014, 25, 635–639. [Google Scholar] [CrossRef]

- Radhika, N.; Raghu, R. Three body abrasion wear behaviour of functionally graded aluminium/B4C metal matrix composite using design of experiments. Proc. Eng. 2014, 97, 713–722. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Loeber, L.; Wang, P.; Attar, H.; Schimansky, F.; Pyczak, F.; Eckert, J. Processing of Al-12Si–TNM composites by selective laser melting and evaluation of compressive and wear properties. J. Mater. Res. 2016, 31, 55–65. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.C.; Zhang, L.-C. Evaluation of mechanical and wear properties of Ti-xNb-7Fe designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

- Murthy, T.S.; Subramanian, C.; Fotedar, R.K.; Gonal, M.R.; Sengupta, P.; Kumar, S.; Suri, A.K. Preparation and property evaluation of TiB2 + TiSi2 composite. Int. J. Refract. Met. Hard Mater. 2009, 27, 629–636. [Google Scholar] [CrossRef]

- Kumar, R.; Chaubey, A.K.; Bathula, S.; Jha, B.B.; Dhar, A. Synthesis and characterization of Al2O3-TiC nano-composite by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2016, 54, 304–308. [Google Scholar] [CrossRef]

- Wang, Z.; Georgarakis, K.; Zhang, W.W.; Prashanth, K.G.; Eckert, J.; Scudino, S. Reciprocating sliding wear behavior of high-strength nanocrystalline AL84Ni7Gd6Co3 alloys. Wear 2017, 383, 78–84. [Google Scholar] [CrossRef]

- Wang, Z.; Qu, R.T.; Scudino, S.; Sun, B.A.; Prashanth, K.G.; Louzguine-Luzgin, D.V.; Chen, M.W.; Zhang, Z.F.; Eckert, J. Hybrid nanostructured aluminum alloys with high strength. NPG Asia Mater. 2015, 7, e229. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Eckert, J.; Prakash, O.; Ramamurty, U. Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Mao, D.S.; Li, J.; Guo, S.Y.; Mao, Z.Y. Study of abrasion behavior of an advanced Al2O3-TiC-Co ceramic. Wear 1997, 209, 153–159. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, R.; Chaubey, A.K.; Maity, T.; Prashanth, K.G. Mechanical and Tribological Properties of Al2O3-TiC Composite Fabricated by Spark Plasma Sintering Process with Metallic (Ni, Nb) Binders. Metals 2018, 8, 50. https://doi.org/10.3390/met8010050

Kumar R, Chaubey AK, Maity T, Prashanth KG. Mechanical and Tribological Properties of Al2O3-TiC Composite Fabricated by Spark Plasma Sintering Process with Metallic (Ni, Nb) Binders. Metals. 2018; 8(1):50. https://doi.org/10.3390/met8010050

Chicago/Turabian StyleKumar, Rohit, Anil K. Chaubey, Tapabrata Maity, and Konda Gokuldoss Prashanth. 2018. "Mechanical and Tribological Properties of Al2O3-TiC Composite Fabricated by Spark Plasma Sintering Process with Metallic (Ni, Nb) Binders" Metals 8, no. 1: 50. https://doi.org/10.3390/met8010050

APA StyleKumar, R., Chaubey, A. K., Maity, T., & Prashanth, K. G. (2018). Mechanical and Tribological Properties of Al2O3-TiC Composite Fabricated by Spark Plasma Sintering Process with Metallic (Ni, Nb) Binders. Metals, 8(1), 50. https://doi.org/10.3390/met8010050