Formation Mechanisms for Entry and Exit Defects in Bobbin Friction Stir Welding

Abstract

:1. Introduction

1.1. Literature

1.2. Approach

2. Materials and Methods

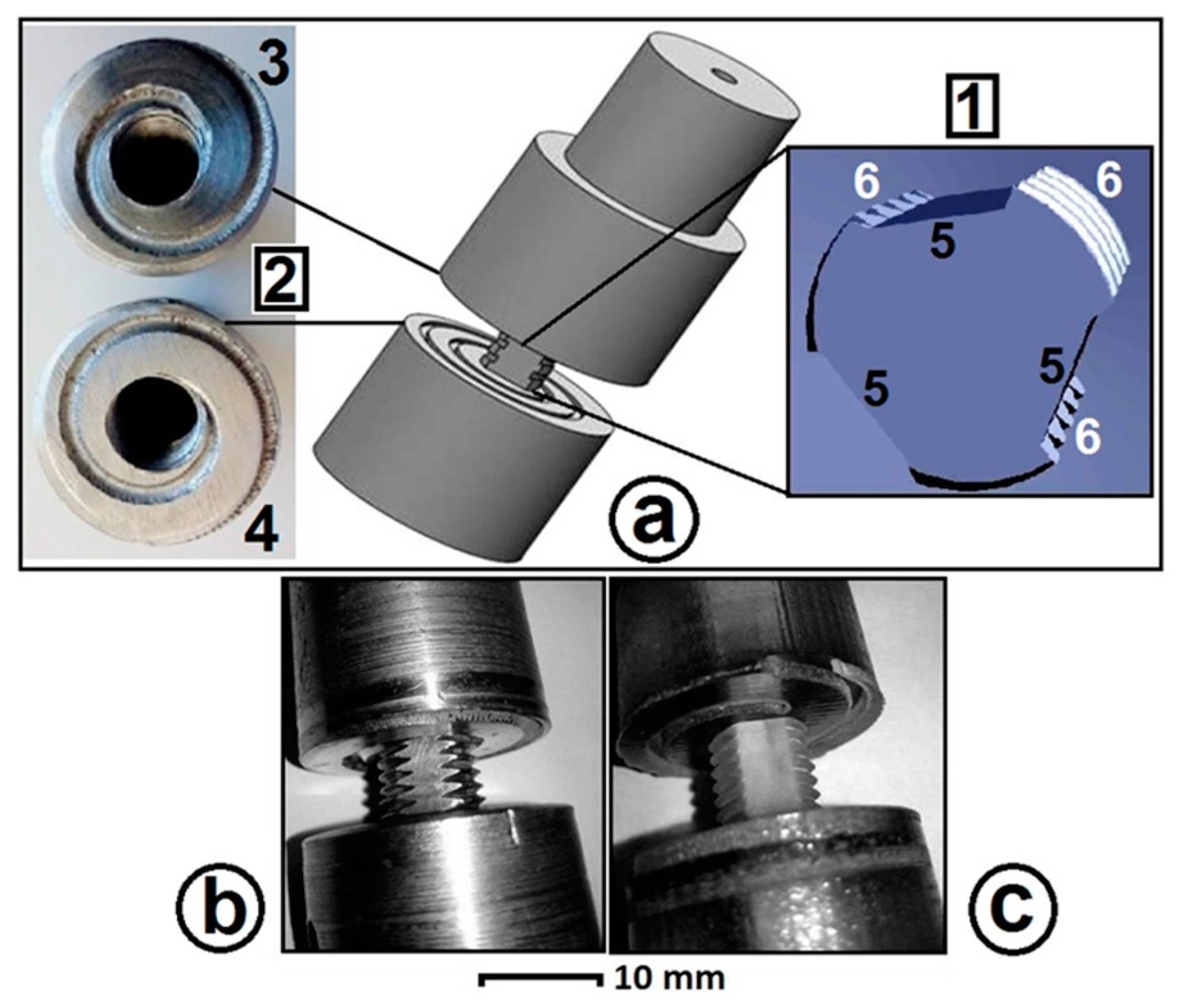

2.1. Tool Design Features

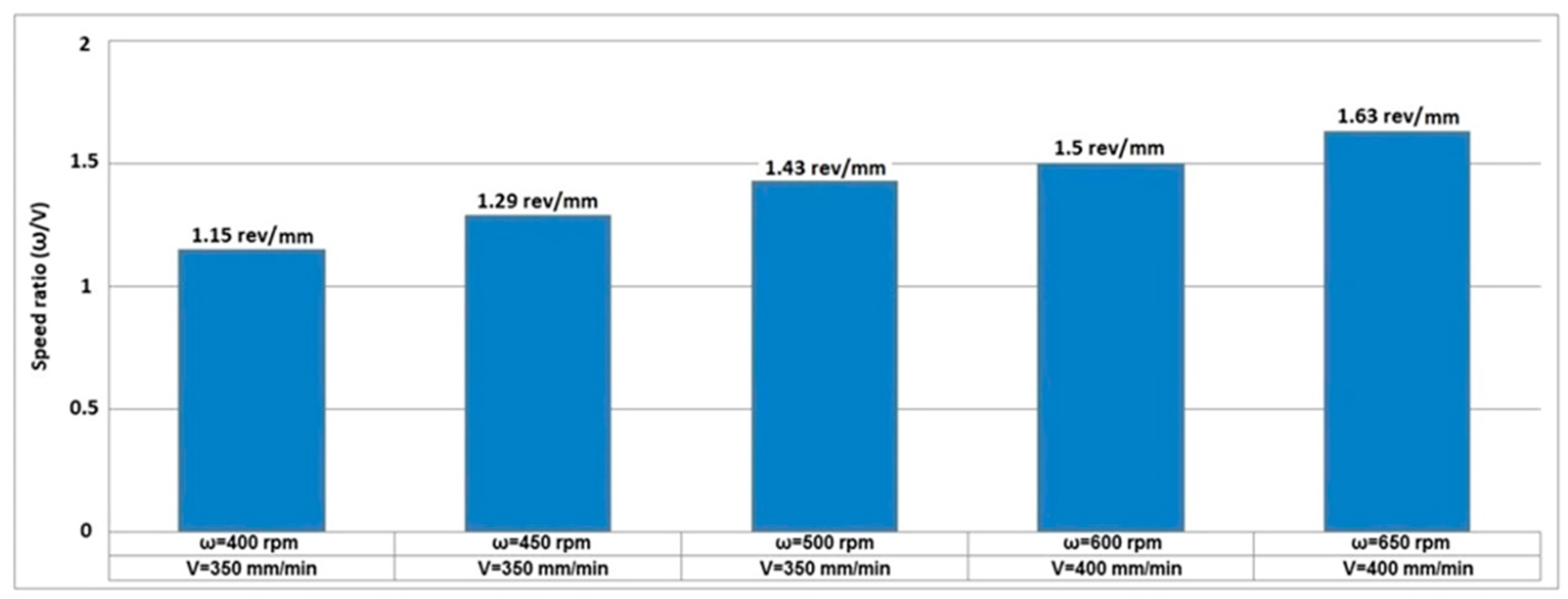

2.2. Welding Process Parameters

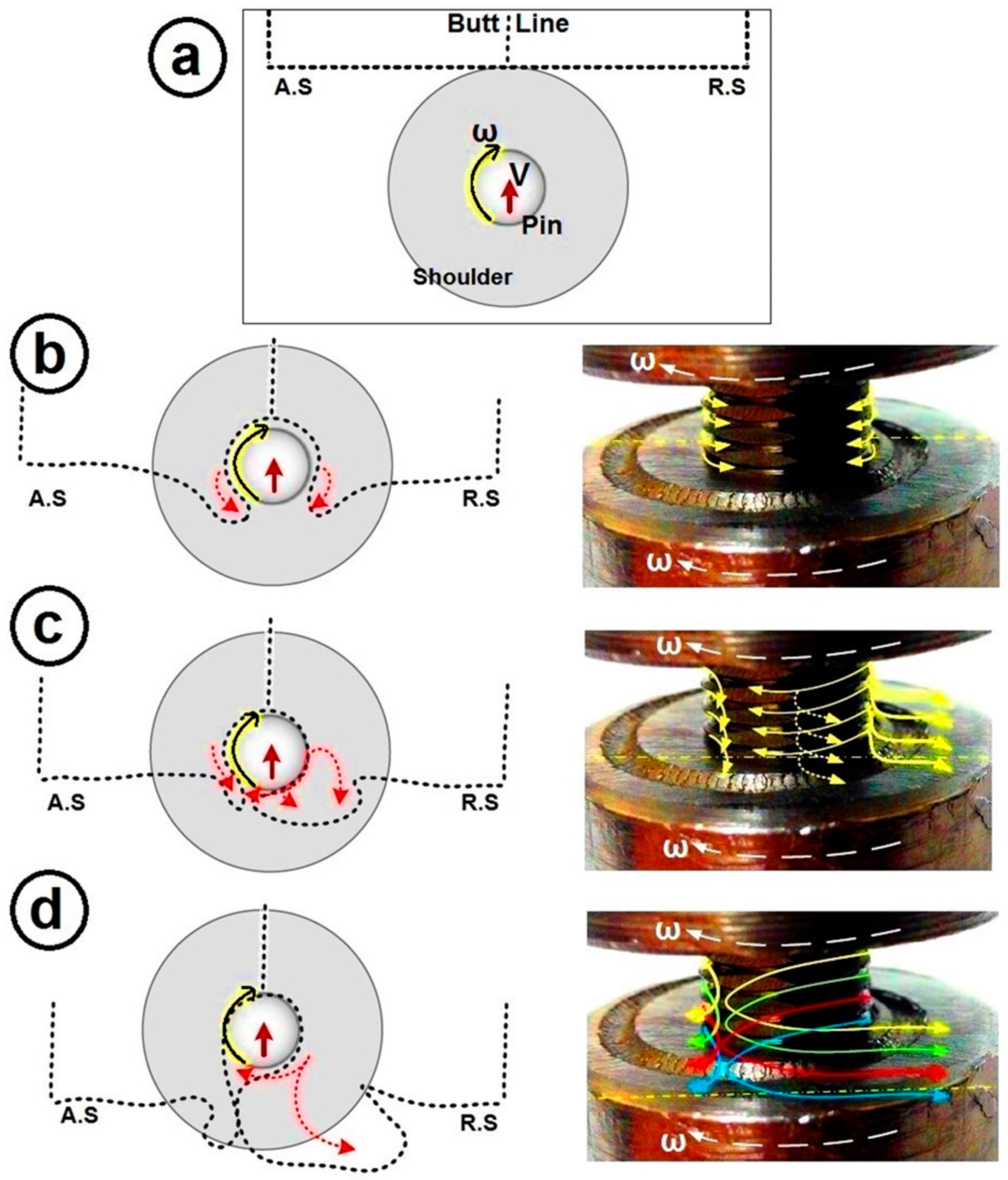

2.3. Methods for Conducting Plasticine Tests

2.3.1. Creating a Layered Plasticine Slab

2.3.2. Conducting Tests with Plasticine

2.4. Methods for Conducting Aluminium Tests

2.5. Characterization Methods

3. Results

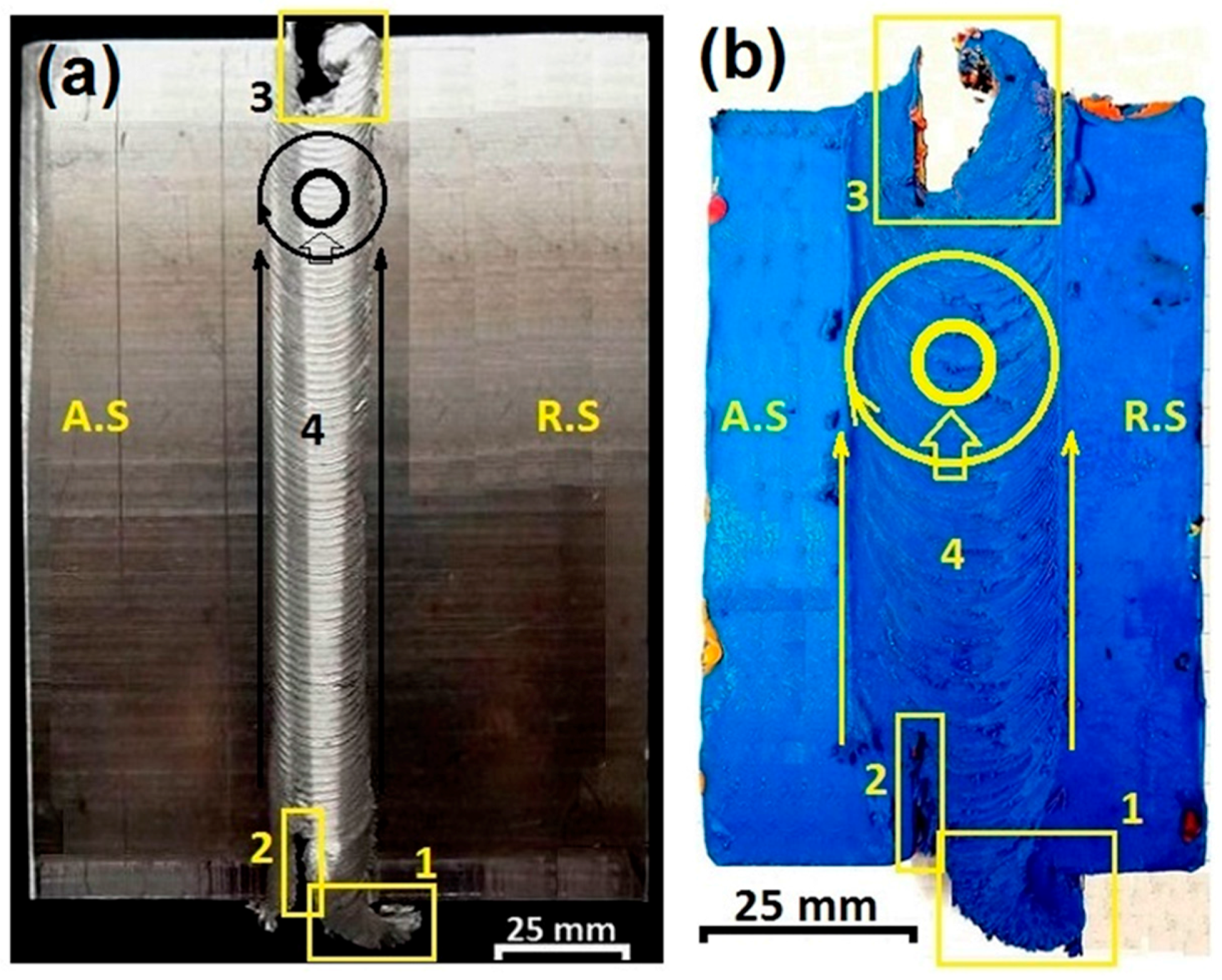

3.1. General Appearances of the BFSW Weld

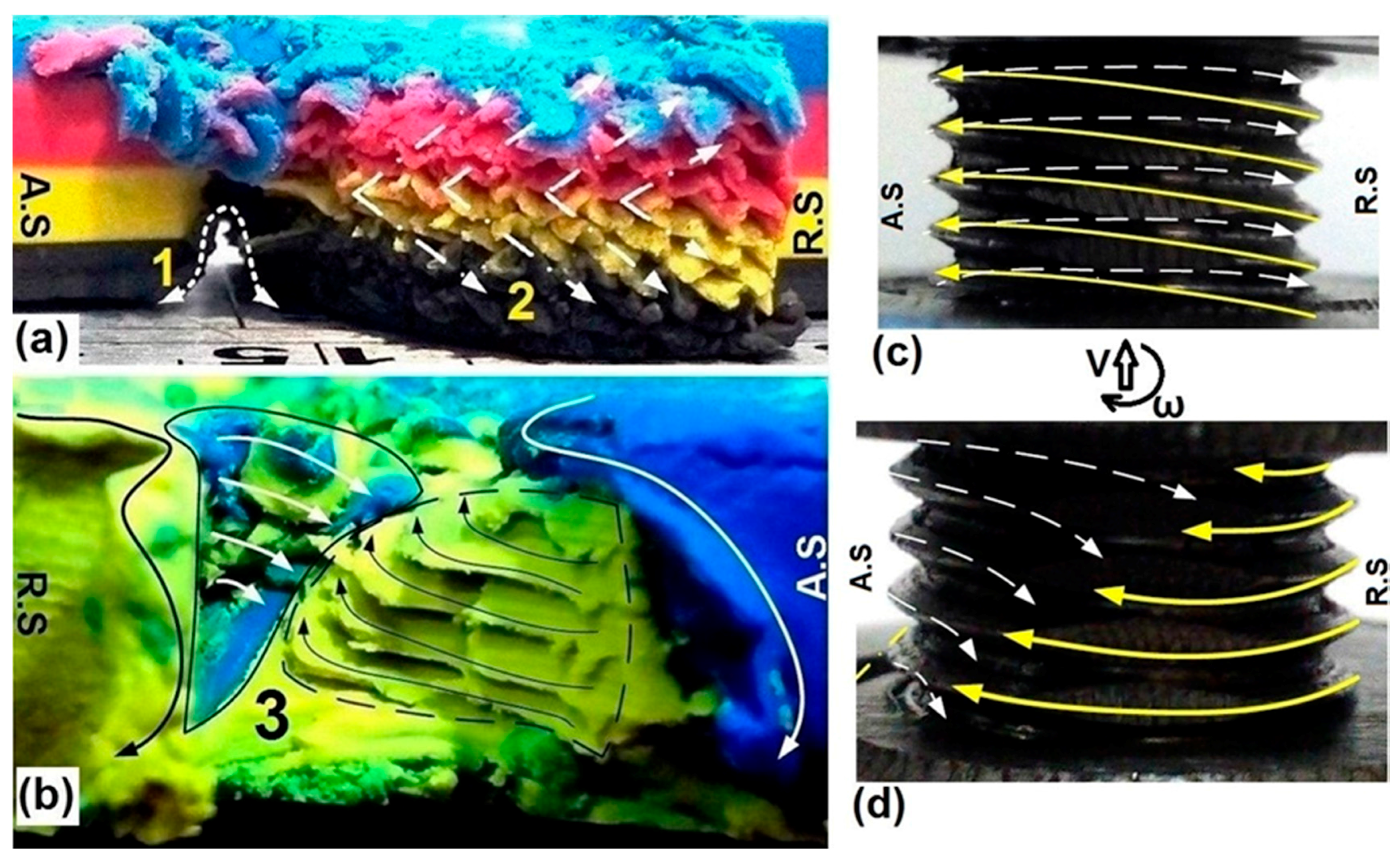

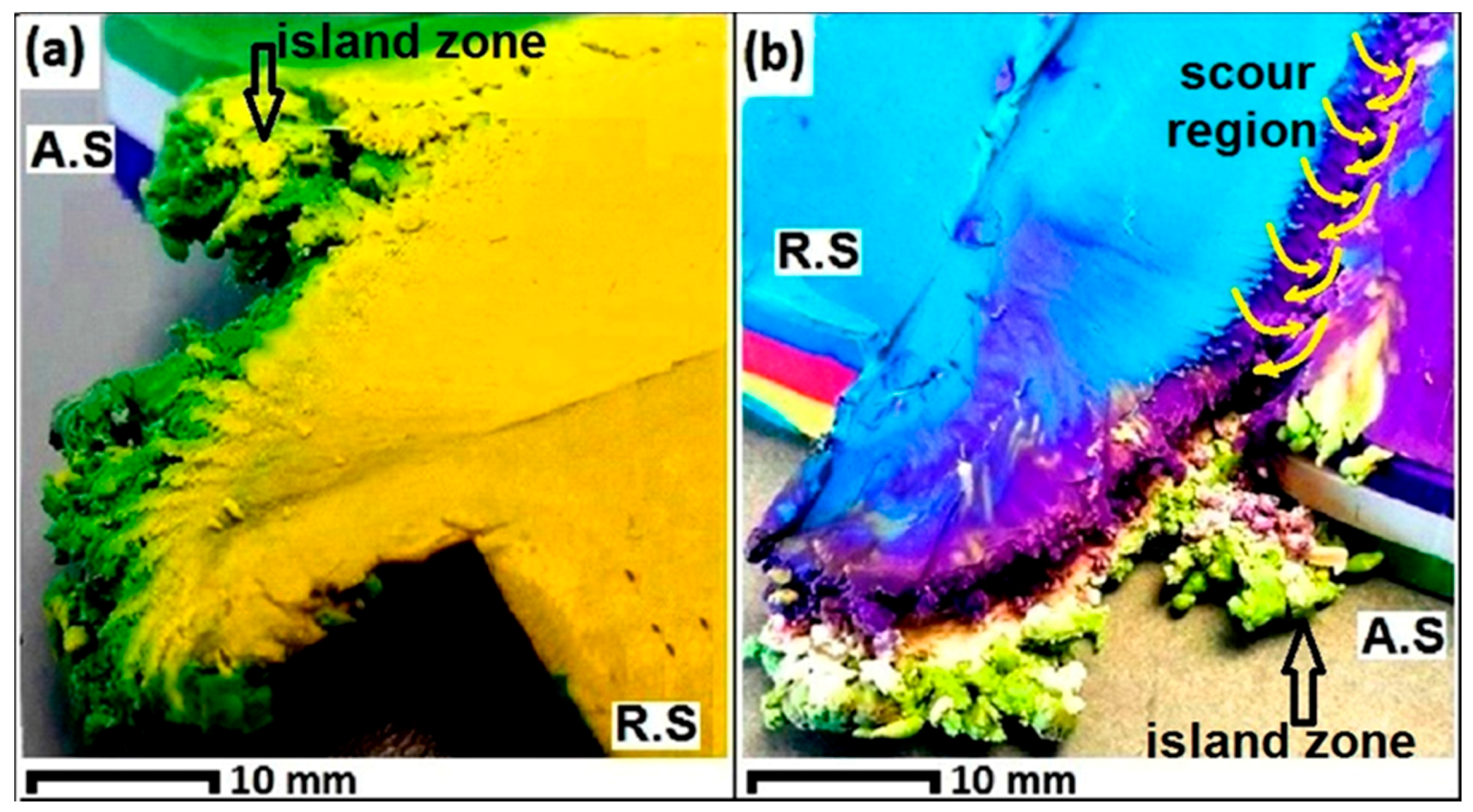

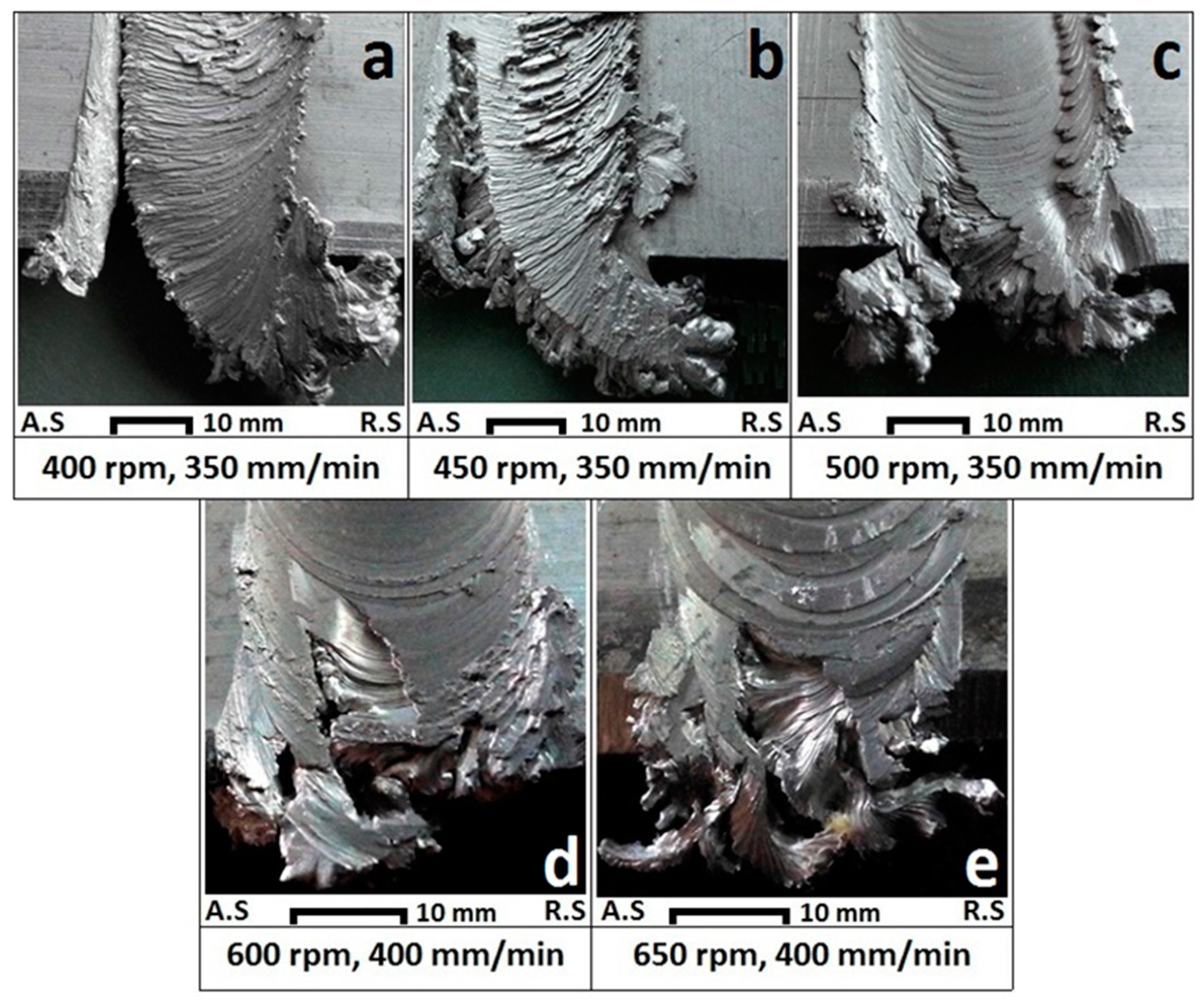

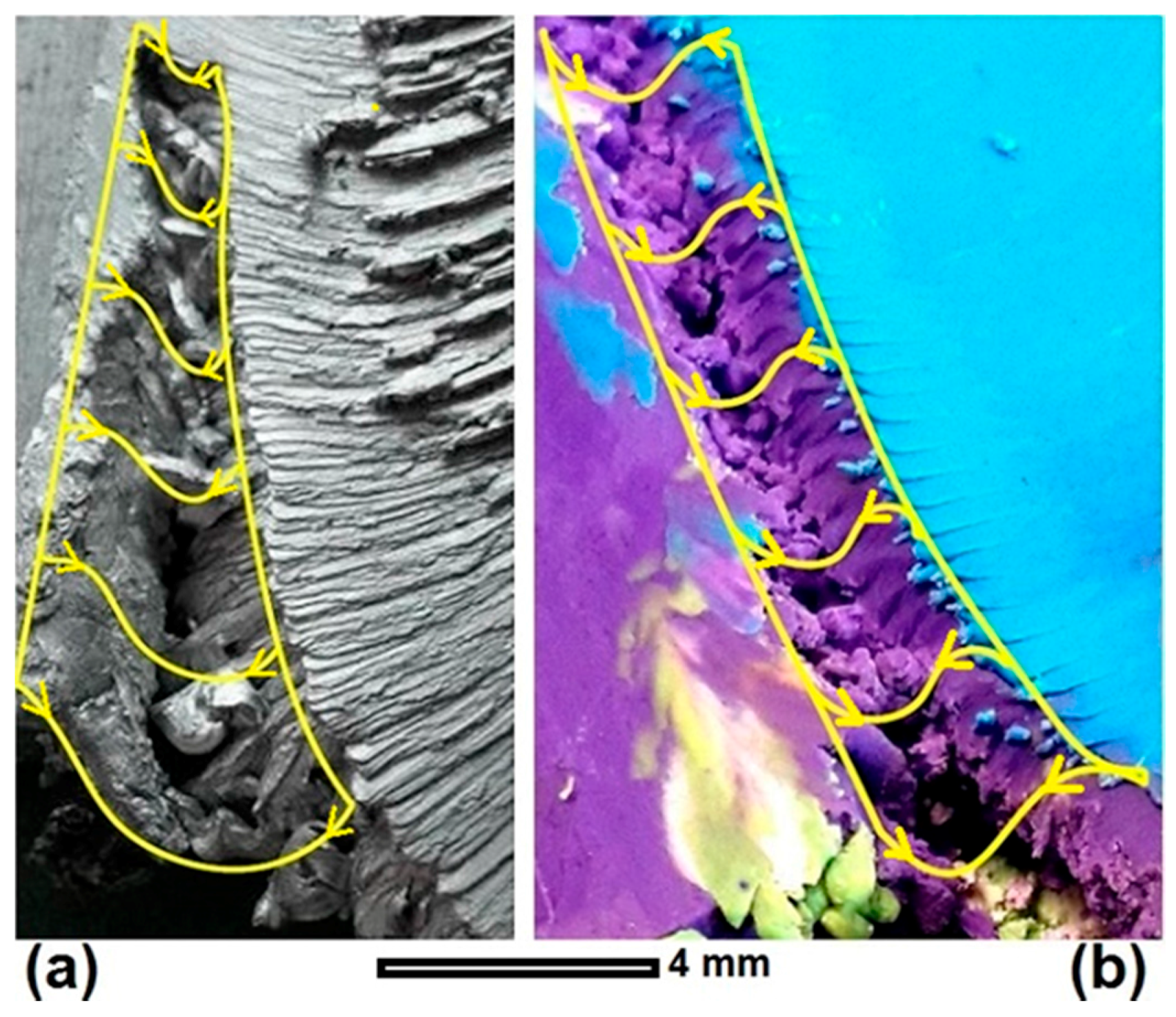

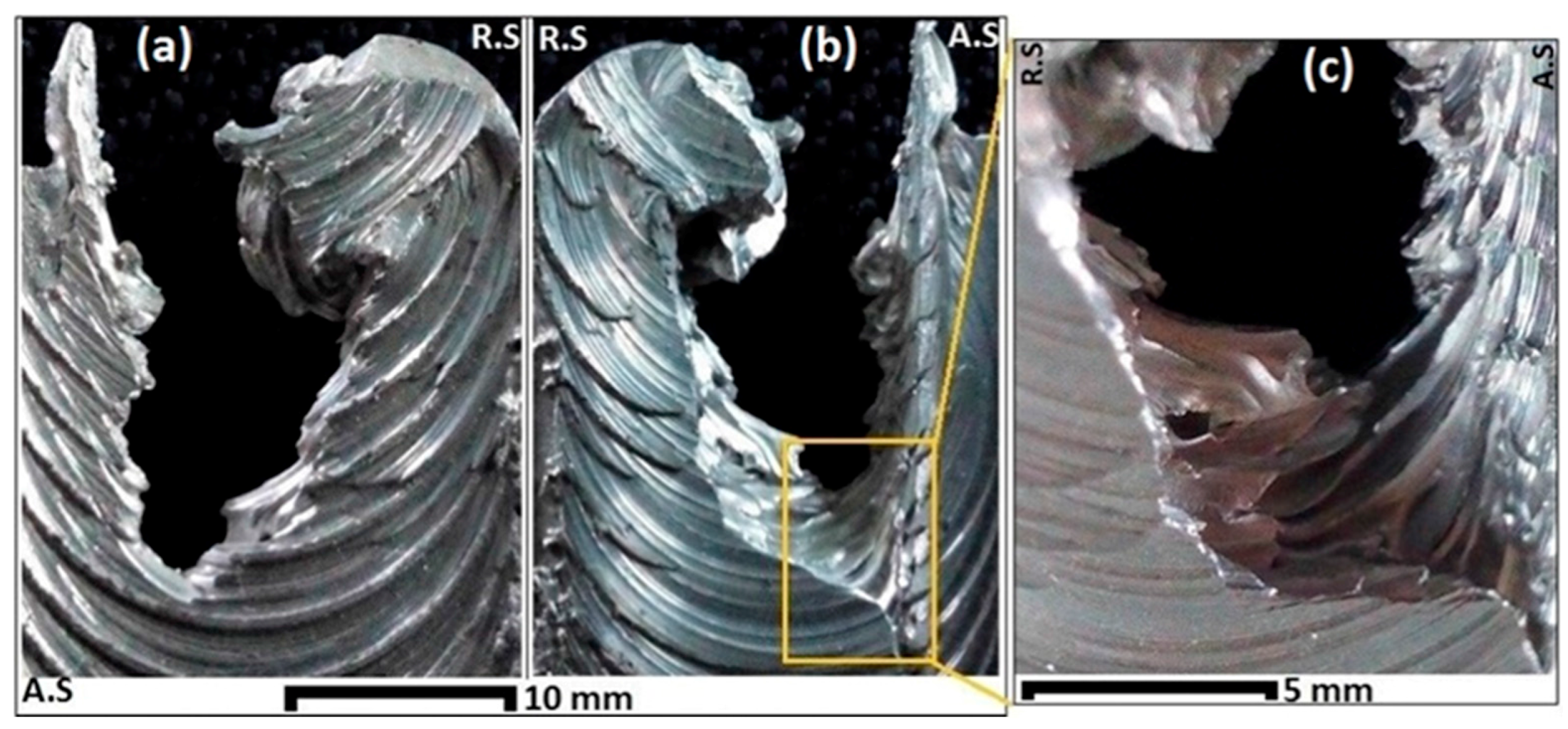

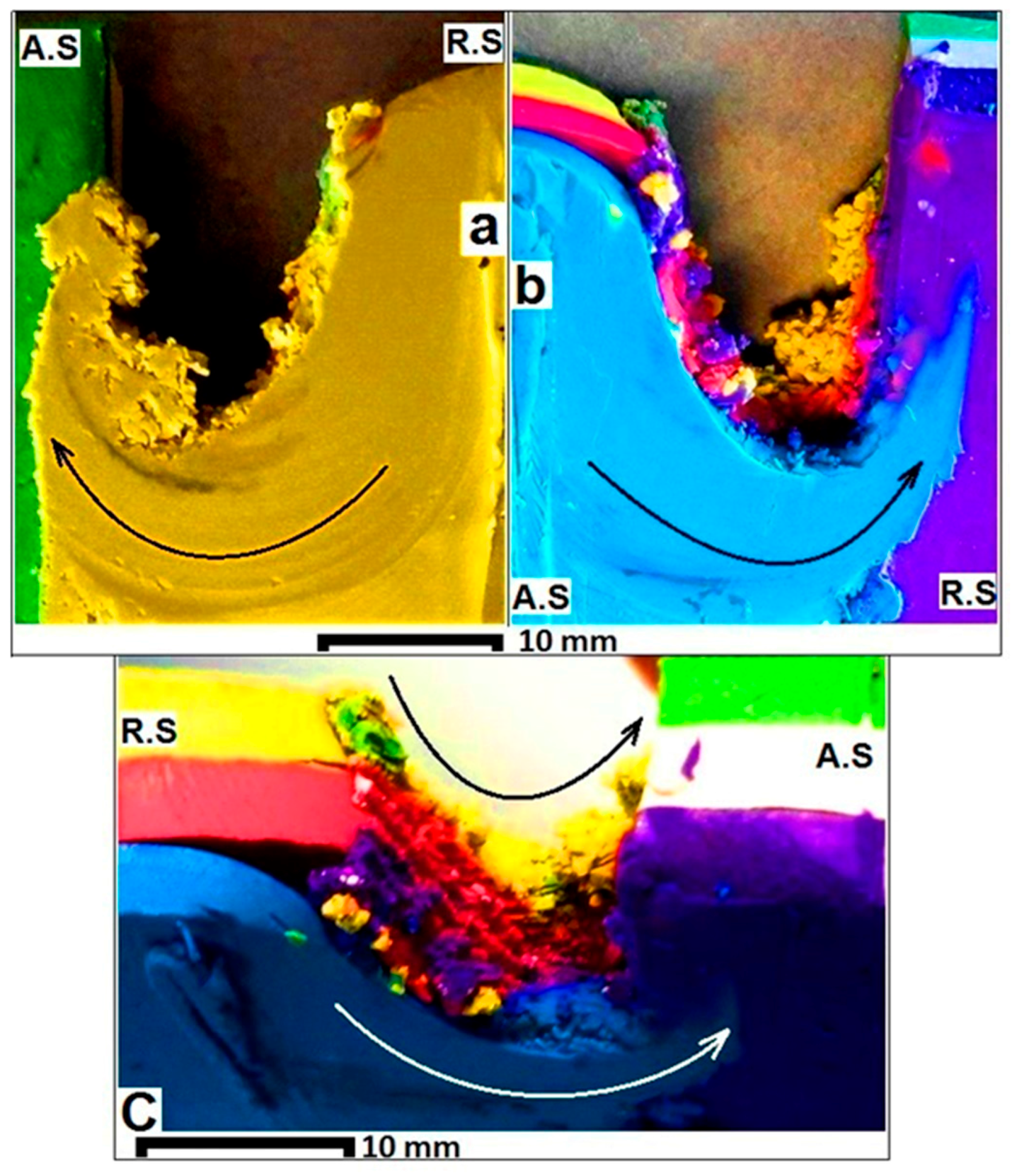

3.2. Entry Zone

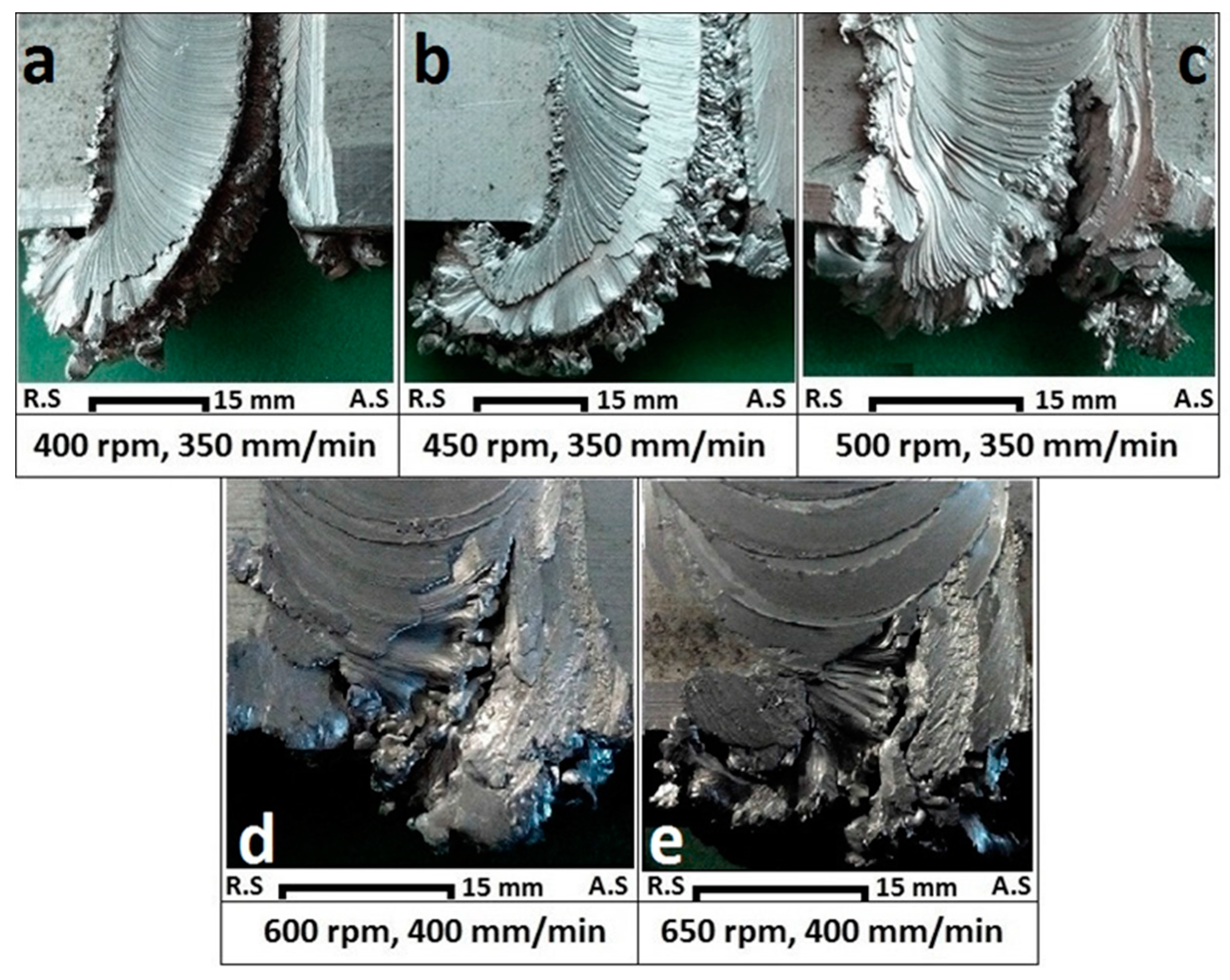

3.3. Exit Zone

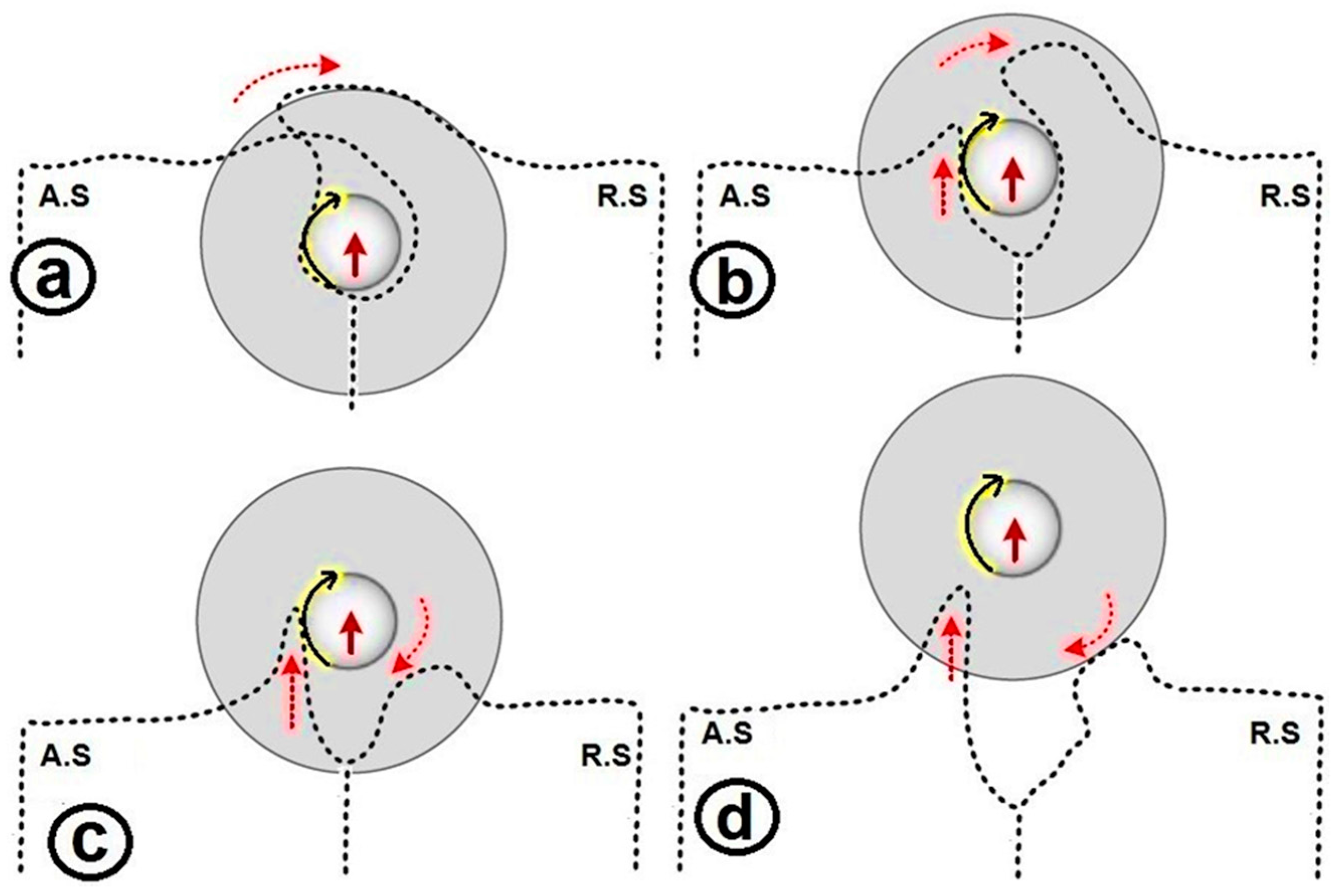

4. Discussion

4.1. Outcomes

4.2. Limitations of the Study

4.3. Implications for Future Research

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Thomas, W. Friction Stir Welding. International Patent Application No. PCT/GB92/02203, 6 December 1991. [Google Scholar]

- Arbegast, W.J. A flow-partitioned deformation zone model for defect formation during friction stir welding. Scr. Mater. 2008, 58, 372–376. [Google Scholar] [CrossRef]

- Morisada, Y.; Imaizumi, T.; Fujii, H. Clarification of material flow and defect formation during friction stir welding. Sci. Technol. Weld. Join. 2015, 20, 130–137. [Google Scholar] [CrossRef]

- Waldron, D.; Roberts, R.; Dawes, C.; Tubby, P. Friction Stir Welding-A Revolutionary New Joining Method; SAE Technical Paper; Society of Automotive Engineers: Warrendale, PA, USA, 1998; ISBN 0768005167. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H. Effect of welding parameters on mixing of materials in nugget zone of friction stir welds. Acta Metall. Sin.-Chin. Ed. 2007, 43, 321. [Google Scholar]

- Leonard, A.; Lockyer, S. Flaws in friction stir welds. In Proceedings of the 4th International Symposium on Friction Stir Welding, Park City, UT, USA, 14–16 May 2003. [Google Scholar]

- Leal, R.M.; Loureiro, A. Defects formation in friction stir welding of aluminium alloys. In Materials Science Forum; Trans Tech Publications: Zürich, Switzerland, 2004; pp. 299–302. [Google Scholar]

- Le Jolu, T.; Morgeneyer, T.F.; Denquin, A.; Gourgues-Lorenzon, A.-F. Effect of welding defects on plastic behaviour and fatigue lifetime of friction stir welded Al-Cu-Li alloy. In Proceedings of the 13th International Conference on Fracture, Beijing, China, 16–21 June 2013; p. 10. [Google Scholar]

- Dickerson, T.; Przydatek, J. Fatigue of friction stir welds in aluminium alloys that contain root flaws. Int. J. Fatigue 2003, 25, 1399–1409. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Ahmed, M.; Martin, J.P.; Perrett, J.G.; Wynne, B.P. The use of bobbin tools for friction stir welding of aluminium alloys. In Materials Science Forum; Trans Tech Publications: Zürich, Switzerland, 2010; pp. 1179–1184. [Google Scholar]

- Thomas, W.; Wiesner, C.; Marks, D.; Staines, D. Conventional and bobbin friction stir welding of 12% chromium alloy steel using composite refractory tool materials. Sci. Technol. Weld. Join. 2009, 14, 247–253. [Google Scholar] [CrossRef]

- Martin, J.; Wei, S. Friction stir welding technology for marine applications. In Friction Stir Welding and Processing VIII; Springer: Berlin, Germany, 2015; pp. 219–226. [Google Scholar]

- Neumann, T.; Zettler, R.; Vilaca, P.; Dos Santos, J.; Quintino, L. Analysis of self-reacting friction stir welds in a 2024-T351 alloy. In Friction Stir Welding and Processing IV; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 2007; pp. 55–72. [Google Scholar]

- Thomas, W.; Wiesner, C. Recent developments of fsw technologies: Evaluation of root defects, composite refractory tools for steel joining and one-pass welding of thick sections using self-reacting bobbin tools. In Proceedings of the Trends in Welding Research 8th International Conference, Callaway Gardens Resort, Pine Mountain, GA, USA, 1–6 June 2008; ASM International: Almere, The Netherlands, 2009; p. 25. [Google Scholar]

- Sued, M.K.; Pons, D.J. Dynamic interaction between machine, tool, and substrate in bobbin friction stir welding. Int. J. Manuf. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Chen, J.; Fujii, H.; Sun, Y.; Morisada, Y.; Ueji, R. Fine grained Mg-3Al-1Zn alloy with randomized texture in the double-sided friction stir welded joints. Mater. Sci. Eng. A 2013, 580, 83–91. [Google Scholar] [CrossRef]

- Hejazi, I.; Mirsalehi, S.E. Effect of pin penetration depth on double-sided friction stir welded joints of AA6061-T913 alloy. Trans. Nonferr. Met. Soc. China 2016, 26, 676–683. [Google Scholar] [CrossRef]

- Sued, M.; Pons, D.; Lavroff, J.; Wong, E.-H. Design features for bobbin friction stir welding tools: Development of a conceptual model linking the underlying physics to the production process. Mater. Des. (1980–2015) 2014, 54, 632–643. [Google Scholar] [CrossRef]

- Esmaily, M.; Mortazavi, N.; Osikowicz, W.; Hindsefelt, H.; Svensson, J.; Halvarsson, M.; Martin, J.; Johansson, L. Bobbin and conventional friction stir welding of thick extruded AA6005-T6 profiles. Mater. Des. 2016, 108, 114–125. [Google Scholar] [CrossRef]

- Dolby, R.; Sanderson, A.; Threadgill, P. Recent developments and applications in electron beam and friction technologies. In Proceedings of the 7th International Aachen Welding Conference, Kobe, Japan, 20–22 November 2001. [Google Scholar]

- Sued, M.K. Fixed Bobbin Friction Stir Welding of Marine Grade Aluminium. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2015. [Google Scholar]

- Zhang, H.; Wang, M.; Zhang, X.; Yang, G. Microstructural characteristics and mechanical properties of bobbin tool friction stir welded 2A14-T6 aluminum alloy. Mater. Des. (1980–2015) 2015, 65, 559–566. [Google Scholar] [CrossRef]

- Shen, J.; Wang, F.; Suhuddin, U.F.; Hu, S.; Li, W.; Dos Santos, J.F. Crystallographic texture in bobbin tool friction-stir-welded aluminum. Metall. Mater. Trans. A 2015, 46, 2809–2813. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Development of metallographic etchants for the microstructure evolution of A6082-T6 BFSW welds. Metals 2017, 7, 423. [Google Scholar] [CrossRef]

- Li, W.; Fu, T.; Hütsch, L.; Hilgert, J.; Wang, F.; Dos Santos, J.; Huber, N. Effects of tool rotational and welding speed on microstructure and mechanical properties of bobbin-tool friction-stir welded Mg AZ31. Mater. Des. 2014, 64, 714–720. [Google Scholar] [CrossRef]

- Sued, M.; Tamadon, A.; Pons, D. Material flow visualization in bobbin friction stir welding by analogue model. In Proceedings of Mechanical Engineering Research Day 2017; Centre for Advanced Research on Energy: Durian Tunggal, Melaka, Malaysia, 2017; pp. 368–369. [Google Scholar]

- Liu, H.; Hou, J.; Guo, H. Effect of welding speed on microstructure and mechanical properties of self-reacting friction stir welded 6061-T6 aluminum alloy. Mater. Des. 2013, 50, 872–878. [Google Scholar] [CrossRef]

- Wan, L.; Huang, Y.; Lv, Z.; Lv, S.; Feng, J. Effect of self-support friction stir welding on microstructure and microhardness of 6082-T6 aluminum alloy joint. Mater. Des. 2014, 55, 197–203. [Google Scholar] [CrossRef]

- Wan, L.; Huang, Y.; Guo, W.; Lv, S.; Feng, J. Mechanical properties and microstructure of 6082-T6 aluminum alloy joints by self-support friction stir welding. J. Mater. Sci. Technol. 2014, 30, 1243–1250. [Google Scholar] [CrossRef]

- He, X.; Gu, F.; Ball, A. A review of numerical analysis of friction stir welding. Prog. Mater. Sci. 2014, 65, 1–66. [Google Scholar] [CrossRef]

- Dialami, N.; Chiumenti, M.; Cervera, M.; de Saracibar, C.A.; Ponthot, J.-P.; Bussetta, P. Numerical simulation and visualization of material flow in friction stir welding via particle tracing. In Numerical Simulations of Coupled Problems in Engineering; Springer: Berlin, Germany, 2014; pp. 157–169. [Google Scholar]

- Buffa, G.; Donati, L.; Fratini, L.; Tomesani, L. Solid state bonding in extrusion and FSW: Process mechanics and analogies. J. Mater. Process. Technol. 2006, 177, 344–347. [Google Scholar] [CrossRef]

- Genevois, C.; Girard, M.; Huneau, B.; Sauvage, X.; Racineux, G. Interfacial reaction during friction stir welding of Al and Cu. Metall. Mater. Trans. A 2011, 42, 2290. [Google Scholar] [CrossRef]

- Hilgert, J.; Schmidt, H.; Dos Santos, J.; Huber, N. Thermal models for bobbin tool friction stir welding. J. Mater. Process. Technol. 2011, 211, 197–204. [Google Scholar] [CrossRef]

- Hilgert, J.; dos Santos, J.F.; Huber, N. Investigation of the material shear layer in bobbin tool friction stir welding. In Friction Stir Welding and Processing VI; Wiley: Hoboken, NJ, USA, 2011; pp. 187–193. [Google Scholar]

- Lin, S.-B.; Zhao, Y.-H.; He, Z.-Q.; Wu, L. Modeling of friction stir welding process for tools design. Front. Mater. Sci. 2011, 5, 236–245. [Google Scholar] [CrossRef]

- Sued, M.; Pons, D.; Lavroff, J. Compression ratio effects in bobbin friction stir welding. In Proceedings of the 10th International Friction Stir Welding Symposium, Beijing, China, 20–22 May 2014; pp. 1–19. [Google Scholar]

- Chouhan, D.; Pal, S.K.; Garg, S. Experimental study on the effect of welding parameters and tool pin profiles on mechanical properties of the FSW joints. Dimensions 2013, 806, 28. [Google Scholar]

- Ragupathy, V.; Bhat, M.; Prasad, M. An experimental study of discontinuities in friction stir welded joints through nondestructive testing. Mater. Eval. 2017, 75, 406–412. [Google Scholar]

- Conti, P.; De Paulis, A. A simple model to simulate the interlaminar stresses generated near the free edge of a composite laminate. In Delamination and Debonding of Materials; ASTM International: Almere, The Netherlands, 1985. [Google Scholar]

- Seidel, T.; Reynolds, A.P. Visualization of the material flow in AA2195 friction-stir welds using a marker insert technique. Metall. Mater. Trans. A 2001, 32, 2879–2884. [Google Scholar] [CrossRef]

- Reynolds, A.P. Flow visualization and simulation in FSW. Scr. Mater. 2008, 58, 338–342. [Google Scholar] [CrossRef]

- Chen, Z.; Pasang, T.; Qi, Y. Shear flow and formation of nugget zone during friction stir welding of aluminium alloy 5083-O. Mater. Sci. Eng. A 2008, 474, 312–316. [Google Scholar] [CrossRef]

- Liu, Z.; Xin, R.; Liu, D.; Shu, X.; Liu, Q. Textural variation in triple junction region of friction stir welded Mg alloys and its influence on twinning and fracture. Mater. Sci. Eng. A 2016, 658, 185–191. [Google Scholar] [CrossRef]

- Liu, D.; Xin, R.; Sun, L.; Zhou, Z.; Liu, Q. Influence of sampling design on tensile properties and fracture behavior of friction stir welded magnesium alloys. Mater. Sci. Eng. A 2013, 576, 207–216. [Google Scholar] [CrossRef]

- Liechty, B.; Webb, B. Modeling the frictional boundary condition in friction stir welding. Int. J. Mach. Tools Manuf. 2008, 48, 1474–1485. [Google Scholar] [CrossRef]

- Liechty, B.; Webb, B. Flow field characterization of friction stir processing using a particle-grid method. J. Mater. Process. Technol. 2008, 208, 431–443. [Google Scholar] [CrossRef]

- Liechty, B.; Webb, B. The use of plasticine as an analog to explore material flow in friction stir welding. J. Mater. Process. Technol. 2007, 184, 240–250. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, M.; Zhang, H.; Zhang, X.; Yu, T.; Wu, Z. A finite element model to simulate defect formation during friction stir welding. Metals 2017, 7, 256. [Google Scholar] [CrossRef]

- Gratecap, F.; Girard, M.; Marya, S.; Racineux, G. Exploring material flow in friction stir welding: Tool eccentricity and formation of banded structures. Int. J. Mater. Form. 2012, 5, 99–107. [Google Scholar] [CrossRef]

| Workpiece | Tool Material | Work Temp | DShoulder (mm) | DPin (mm) | DShoulder/DPin | Plate Thickness (mm) | Compression Ratio | Feed ω (rpm) | Speed V (mm/min) | Thread Pitch (mm) | Number of Threads |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AA6082-T6 | H13 Tool Steel | 18 °C | 25 | 5 | 5 | 6 | 3.75% | 400 | 350 | 1.2 | 5 |

| 450 | 350 | ||||||||||

| 500 | 350 | ||||||||||

| 600 | 400 | ||||||||||

| 650 | 400 | ||||||||||

| Multilayered Plasticine | VeroClear plastic | −4 °C | 30 | 6 | 5 | 10 | 3.75% | 75 | 50 | 1.43 | 7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Formation Mechanisms for Entry and Exit Defects in Bobbin Friction Stir Welding. Metals 2018, 8, 33. https://doi.org/10.3390/met8010033

Tamadon A, Pons DJ, Sued K, Clucas D. Formation Mechanisms for Entry and Exit Defects in Bobbin Friction Stir Welding. Metals. 2018; 8(1):33. https://doi.org/10.3390/met8010033

Chicago/Turabian StyleTamadon, Abbas, Dirk J. Pons, Kamil Sued, and Don Clucas. 2018. "Formation Mechanisms for Entry and Exit Defects in Bobbin Friction Stir Welding" Metals 8, no. 1: 33. https://doi.org/10.3390/met8010033

APA StyleTamadon, A., Pons, D. J., Sued, K., & Clucas, D. (2018). Formation Mechanisms for Entry and Exit Defects in Bobbin Friction Stir Welding. Metals, 8(1), 33. https://doi.org/10.3390/met8010033