Effect of Ausforming Temperature on the Microstructure of G91 Steel

Abstract

:1. Introduction

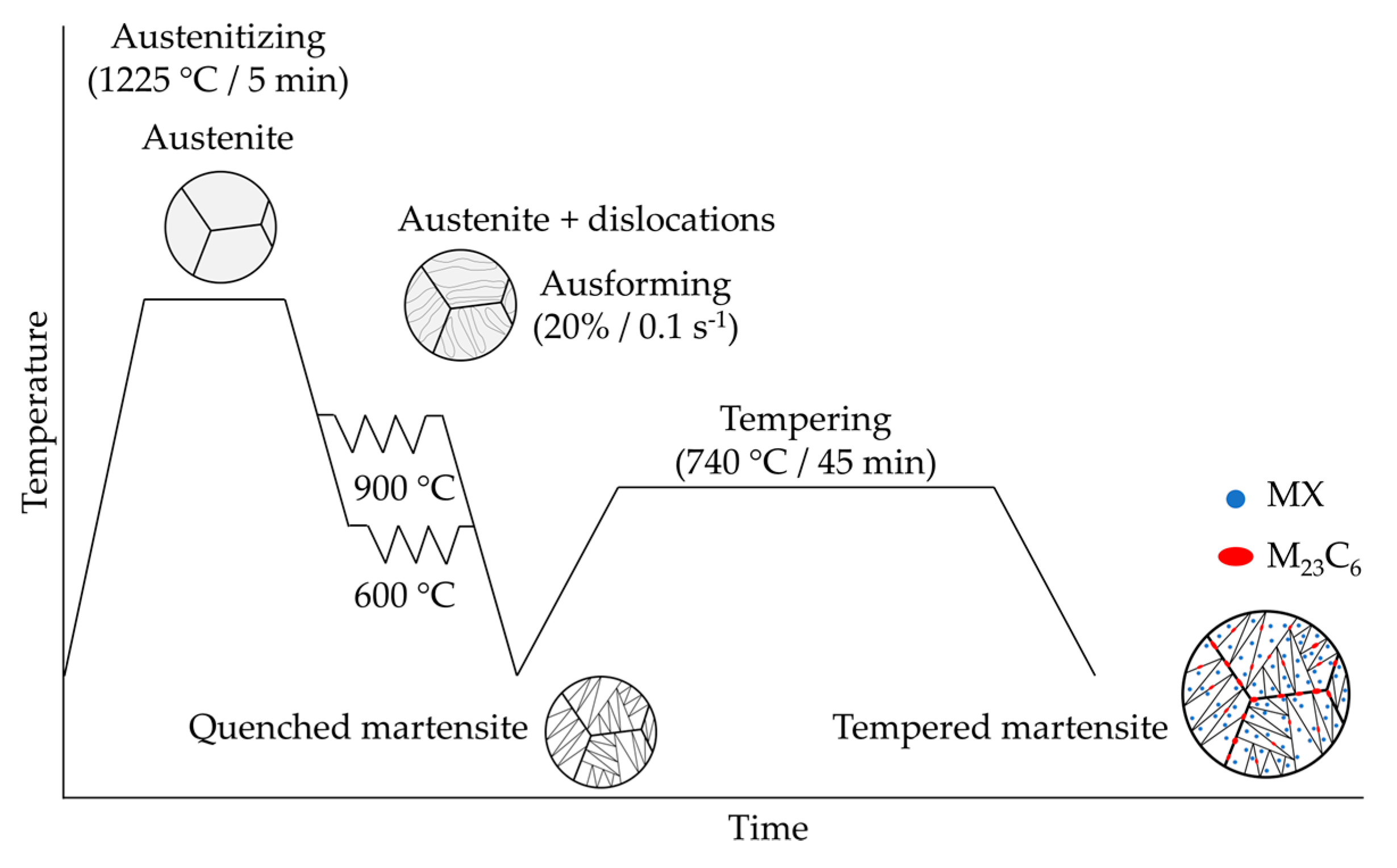

2. Materials and Methods

3. Results and Discussion

3.1. Thermodynamic Calculations

3.2. Microstructural Characterization

4. Conclusions

- 1.

- Microstructures containing three orders of magnitude higher number density and four times smaller size of MX precipitates.

- 2.

- Microstructures contain M23C6 precipitates with very similar values of size and number density.

- 3.

- An increase in hardness of 50 HV5, which is attributable to the increase in the number density and the reduction in the size of MX nanoprecipitates and the lath width refinement.

- 4.

- The martensitic microstructure reduces its lath width due to the strengthening of austenite produced by ausforming. However, ausforming at 600 °C results in a higher block width as compared to ausfoming at 900 °C because of the variant selection that takes place during the martensitic transformation in the sample ausformed at 600 °C.

- 5.

- The ausforming temperature does not affect M23C6 distribution and size, but ausforming at 600 °C leads to a slightly smaller size of MX.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mayer, K.H.; Masuyama, F. The development of creep-resistant steels. In Creep-Resistant Steels; Woodhead Publishing: Cambridge, UK, 2008; pp. 15–77. [Google Scholar]

- Klueh, R.L.; Gelles, D.S.; Jitsukawa, S.; Kimura, A.; Odette, G.R.; van der Schaaf, B.; Victoria, M. Ferritic/martensitic steels—Overview of recent results. J. Nucl. Mater. 2002, 307, 455–465. [Google Scholar] [CrossRef]

- Klueh, R.L.; Ehrlich, K.; Abe, F. Ferritic/martensitic steels: Promises and problems. J. Nucl. Mater. 1992, 191, 116–124. [Google Scholar]

- Helis, L.; Toda, Y.; Hara, T.; Miyazaki, H.; Abe, F. Effect of cobalt on the microstructure of tempered martensitic 9Cr steel for ultra-supercritical power plants. Mater. Sci. Eng. A 2009, 510, 88–94. [Google Scholar] [CrossRef]

- Kipelova, A.; Kaibyshev, R.; Belyakov, A.; Molodov, D. Microstructure evolution in a 3% co modified P911 heat resistant steel under tempering and creep conditions. Mater. Sci. Eng. A 2011, 528, 1280–1286. [Google Scholar] [CrossRef]

- Knežević, V.; Balun, J.; Sauthoff, G.; Inden, G.; Schneider, A. Design of martensitic/ferritic heat-resistant steels for application at 650 °C with supporting thermodynamic modelling. Mater. Sci. Eng. A 2008, 477, 334–343. [Google Scholar] [CrossRef]

- Rojas, D.; Garcia, J.; Prat, O.; Sauthoff, G.; Kaysser-Pyzalla, A.R. 9%Cr heat resistant steels: Alloy design, microstructure evolution and creep response at 650 °C. Mater. Sci. Eng. A 2011, 528, 5164–5176. [Google Scholar] [CrossRef]

- Klueh, R.L.; Hashimoto, N.; Maziasz, P.J. Development of new nano-particle-strengthened martensitic steels. Scr. Mater. 2005, 53, 275–280. [Google Scholar] [CrossRef]

- Hollner, S.; Fournier, B.; Le Pendu, J.; Cozzika, T.; Tournié, I.; Brachet, J.C.; Pineau, A. High-temperature mechanical properties improvement on modified 9Cr–1mo martensitic steel through thermomechanical treatments. J. Nucl. Mater. 2010, 405, 101–108. [Google Scholar] [CrossRef]

- Tan, L.; Busby, J.T.; Maziasz, P.J.; Yamamoto, Y. Effect of thermomechanical treatment on 9Cr ferritic–martensitic steels. J. Nucl. Mater. 2013, 441, 713–717. [Google Scholar] [CrossRef]

- Hollner, S.; Piozin, E.; Mayr, P.; Caës, C.; Tournié, I.; Pineau, A.; Fournier, B. Characterization of a boron alloyed 9Cr3W3CoVNbBN steel and further improvement of its high-temperature mechanical properties by thermomechanical treatments. J. Nucl. Mater. 2013, 441, 15–23. [Google Scholar] [CrossRef]

- Abe, F. Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants. Sci. Technol. Adv. Mater. 2008, 9, 013002. [Google Scholar] [CrossRef] [PubMed]

- Maruyama, K.; Sawada, K.; Koike, J.I. Strengthening mechanisms of creep resistant tempered martensitic steel. ISIJ Int. 2001, 41, 641–653. [Google Scholar] [CrossRef]

- Klueh, R.L.; Hashimoto, N.; Maziasz, P.J. New nano-particle-strengthened ferritic/martensitic steels by conventional thermo-mechanical treatment. J. Nucl. Mater. 2007, 367, 48–53. [Google Scholar] [CrossRef]

- Li, S.; Eliniyaz, Z.; Sun, F.; Shen, Y.; Zhang, L.; Shan, A. Effect of thermo-mechanical treatment on microstructure and mechanical properties of p92 heat resistant steel. Mater. Sci. Eng. A 2013, 559, 882–888. [Google Scholar] [CrossRef]

- Abe, F. Coarsening behavior of lath and its effect on creep rates in tempered martensitic 9Cr-W steels. Mater. Sci. Eng. A 2004, 387, 565–569. [Google Scholar] [CrossRef]

- Tamura, M.; Sakasegawa, H.; Kohyama, A.; Esaka, H.; Shinozuka, K. Effect of mx type particles on creep strength of ferritic steel. J. Nucl. Mater. 2003, 321, 288–293. [Google Scholar] [CrossRef]

- Tan, L.; Byun, T.S.; Katoh, Y.; Snead, L.L. Stability of mx-type strengthening nanoprecipitates in ferritic steels under thermal aging, stress and ion irradiation. Acta Mater. 2014, 71, 11–19. [Google Scholar] [CrossRef]

- Kimura, K.; Sawada, K.; Kushima, H.; Toda, Y. Influence of chemical composition and heat treatment on long-term creep strength of grade 91 steel. Procedia Eng. 2013, 55, 2–9. [Google Scholar] [CrossRef]

- Klueh, R.L. Elevated temperature ferritic and martensitic steels and their application to future nuclear reactors. Int. Mater. Rev. 2005, 50, 287–310. [Google Scholar] [CrossRef]

- Caballero, F.G.; Roelofs, H.; Hasler, S.; Capdevila, C.; Chao, J.; Cornide, J.; Garcia-Mateo, C. Influence of bainite morphology on impact toughness of continuously cooled cementite free bainitic steels. Mater. Sci. Technol. 2012, 28, 95–102. [Google Scholar] [CrossRef]

- Shi, Z.; liu, K.; Wang, M.; Shi, J.; Dong, H.; Pu, J.; Chi, B.; Zhang, Y.; Jian, L. Effect of tensile deformation of austenite on the morphology and strength of lath martensite. Met. Mater. Int. 2012, 18, 317–320. [Google Scholar] [CrossRef]

- Miyamoto, G.; Iwata, N.; Takayama, N.; Furuhara, T. Variant selection of lath martensite and bainite transformation in low carbon steel by ausforming. J. Alloys Compd. 2013, 577, S528–S532. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Y.H.; Zheng, C.L.; Zhang, F.C.; Wang, T.S. Austenite deformation behavior and the effect of ausforming process on martensite starting temperature and ausformed martensite microstructure in medium-carbon si–al-rich alloy steel. Mater. Sci. Eng. A 2014, 596, 9–14. [Google Scholar] [CrossRef]

- Chatterjee, S.; Wang, H.S.; Yang, J.R.; Bhadeshia, H.K.D.H. Mechanical stabilisation of austenite. Mater. Sci. Technol. 2006, 22, 641–644. [Google Scholar] [CrossRef]

- Prat, O.; García, J.; Rojas, D.; Sanhueza, J.P.; Camurri, C. Study of nucleation, growth and coarsening of precipitates in a novel 9%Cr heat resistant steel: Experimental and modeling. Mater. Chem. Phys. 2014, 143, 754–764. [Google Scholar] [CrossRef]

- Seo, S.W.; Jung, G.S.; Lee, J.S.; Bae, C.M.; Bhadeshia, H.K.D.H.; Suh, D.W. Ausforming of medium carbon steel. Mater. Sci. Technol. 2015, 31, 436–442. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | Cr | Mo | V | Nb | N | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Wt % | 0.1 | 0.4 | 0.4 | 9.0 | 1.0 | 0.2 | 0.07 | 0.038 | balance |

| Sample | Block Width (µm) | Lath Width (nm) |

|---|---|---|

| G91 as-received | 2.71 ± 0.23 | 356 ± 35 |

| Def. at 900 °C | 3.23 ± 0.26 | 285 ± 26 |

| Def. at 600 °C | 3.91 ± 0.36 | 212 ± 59 |

| No Def. | Def. at 900 °C | Def. at 600 °C |

|---|---|---|

| 426 ± 3 | 434 ± 5 | 465 ± 10 |

| Sample | Ms (°C) | Mf (°C) | ΔM (°C) |

|---|---|---|---|

| Austenitized | 385 | 220 | 165 |

| Def. at 900 °C | 374 | 195 | 179 |

| Def. at 600 °C | 338 | 145 | 193 |

| Sample | Precipitate | Diameter (nm) | Number Density (m−3) |

|---|---|---|---|

| G91 as-received | M23C6 | 141 ± 4 | 6.2019 |

| MX | 25 ± 0.6 | 8.141019 | |

| Def. at 900 °C | M23C6 | 125 ± 3 | 8.501019 |

| MX | 7.4 ± 0.3 | 6.41022 | |

| Def. at 600 °C | M23C6 | 136 ± 5 | 3.781019 |

| MX | 5.59 ± 0.4 | 9.391022 |

| G91 as-Received | Def. at 900 °C | Def. at 600 °C |

|---|---|---|

| 260 ± 2 | 310 ± 9 | 307 ± 8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vivas, J.; Capdevila, C.; Jimenez, J.A.; Benito-Alfonso, M.; San-Martin, D. Effect of Ausforming Temperature on the Microstructure of G91 Steel. Metals 2017, 7, 236. https://doi.org/10.3390/met7070236

Vivas J, Capdevila C, Jimenez JA, Benito-Alfonso M, San-Martin D. Effect of Ausforming Temperature on the Microstructure of G91 Steel. Metals. 2017; 7(7):236. https://doi.org/10.3390/met7070236

Chicago/Turabian StyleVivas, Javier, Carlos Capdevila, José Antonio Jimenez, Miguel Benito-Alfonso, and David San-Martin. 2017. "Effect of Ausforming Temperature on the Microstructure of G91 Steel" Metals 7, no. 7: 236. https://doi.org/10.3390/met7070236

APA StyleVivas, J., Capdevila, C., Jimenez, J. A., Benito-Alfonso, M., & San-Martin, D. (2017). Effect of Ausforming Temperature on the Microstructure of G91 Steel. Metals, 7(7), 236. https://doi.org/10.3390/met7070236