Evaluation of Chill Cast Co-Cr Alloys for Biomedical Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Preparation

2.2. Materials Characterization

2.3. Electrochemical Techniques

3. Results

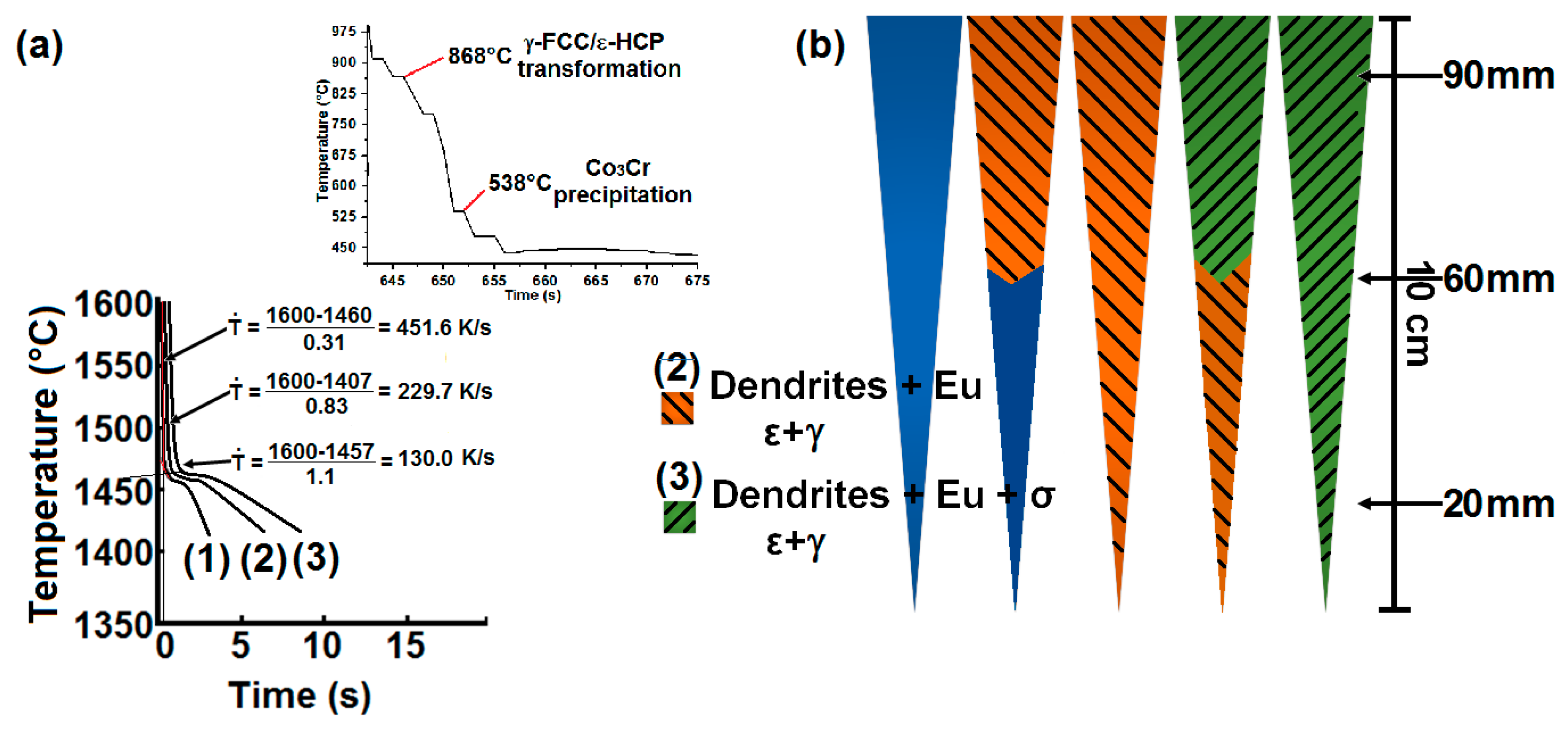

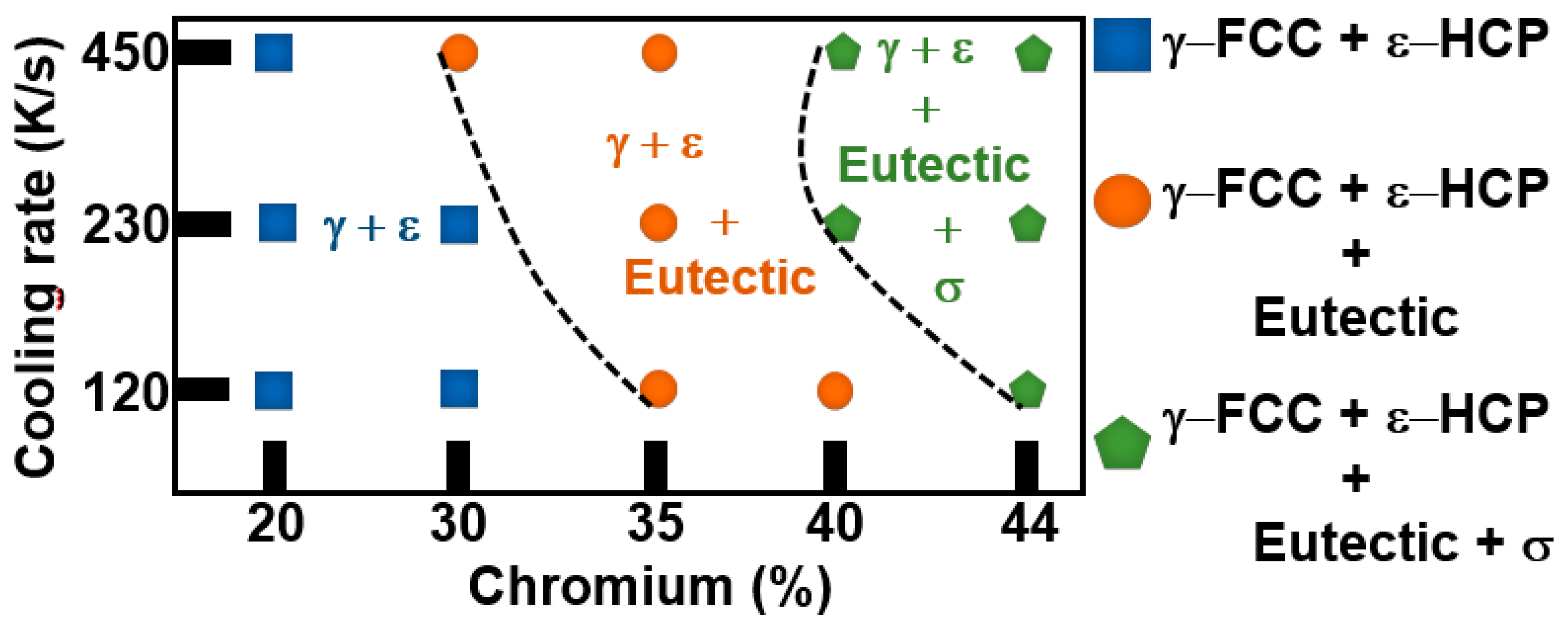

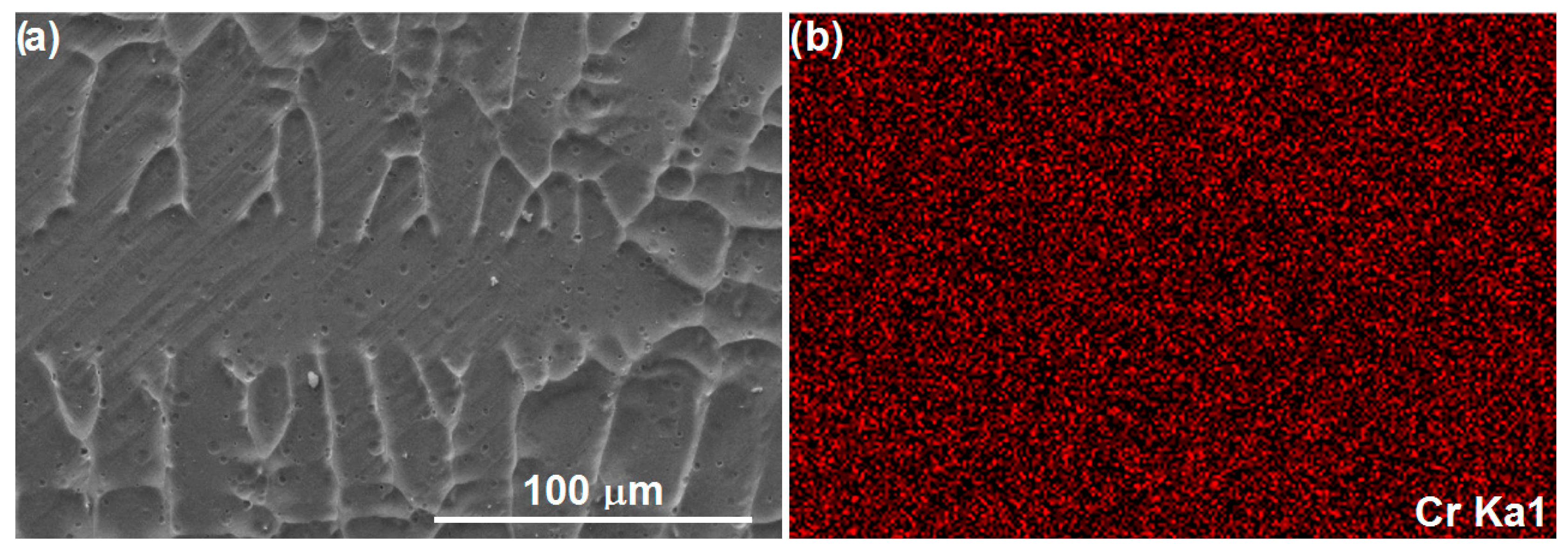

3.1. Cooling Rates and Microstructure

3.2. Mechanical and Corrosion Properties

4. Discussion

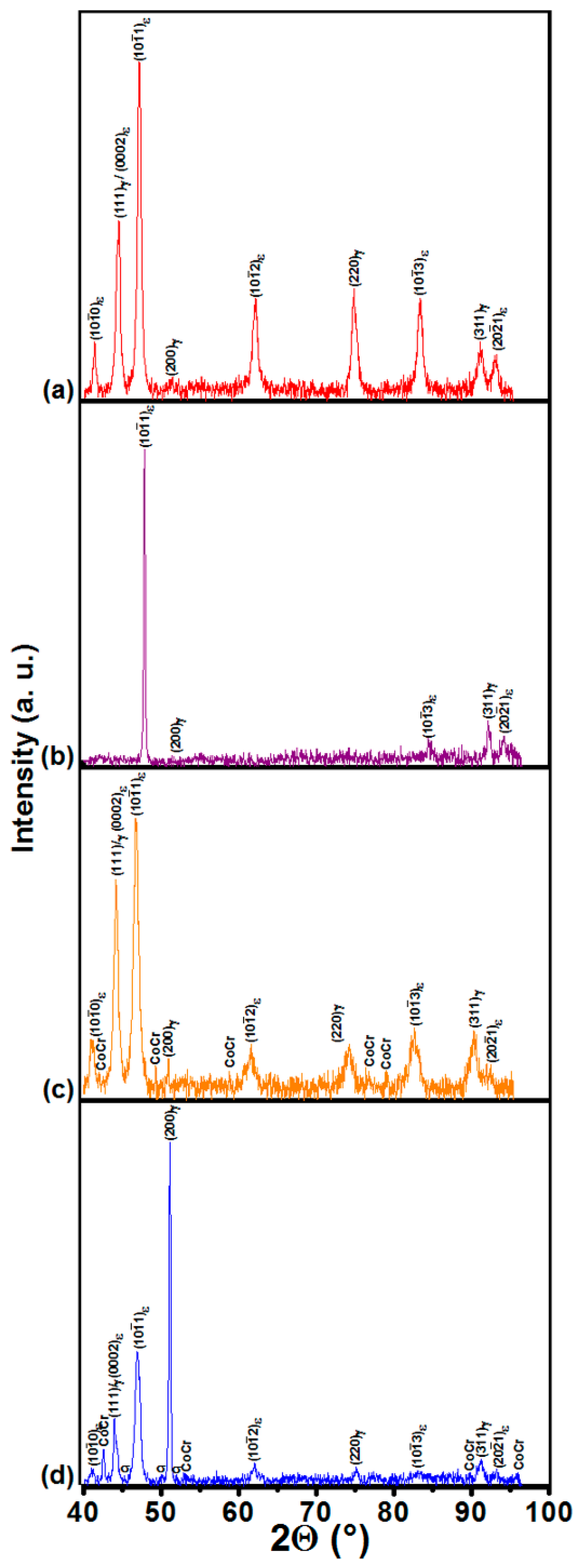

4.1. Phases

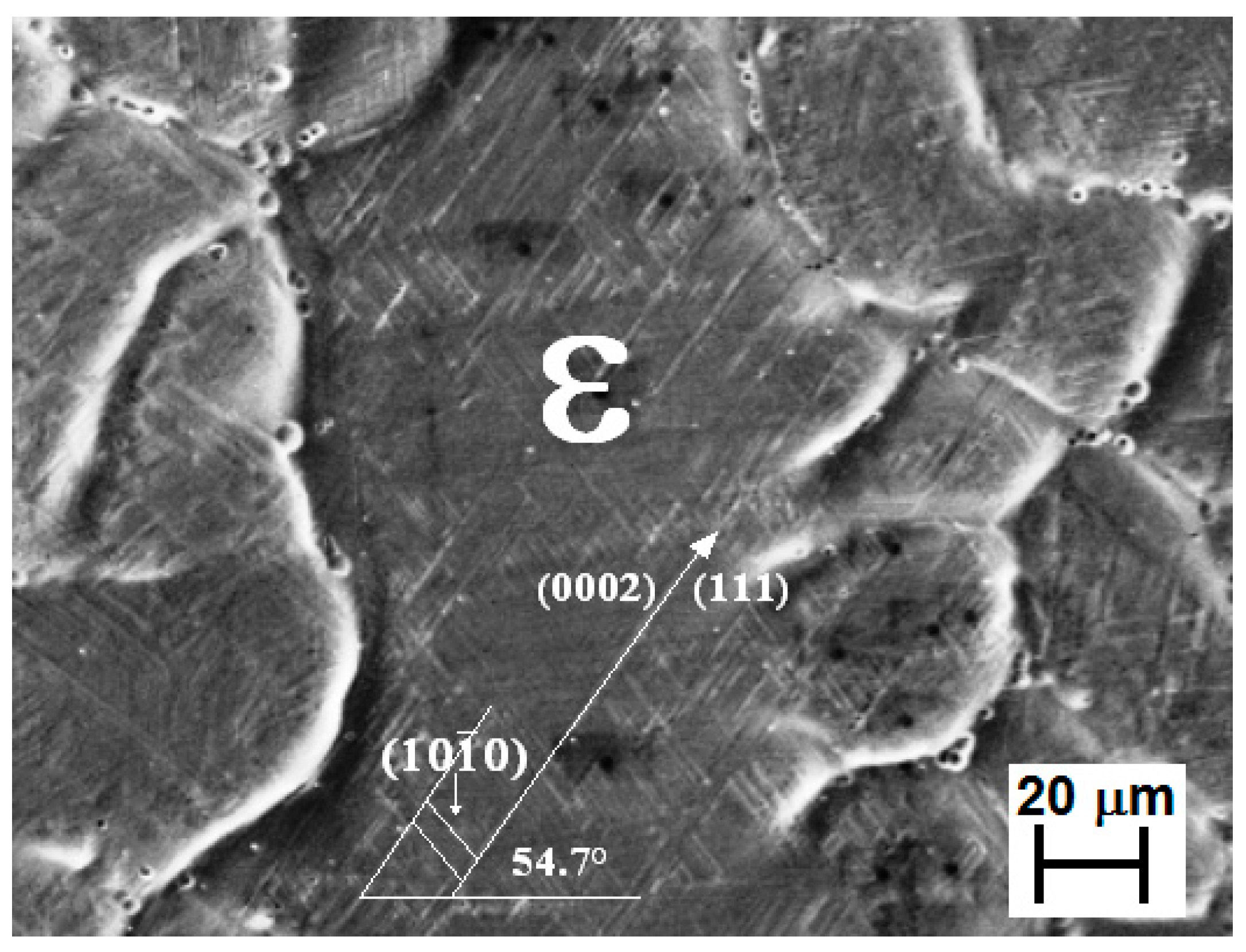

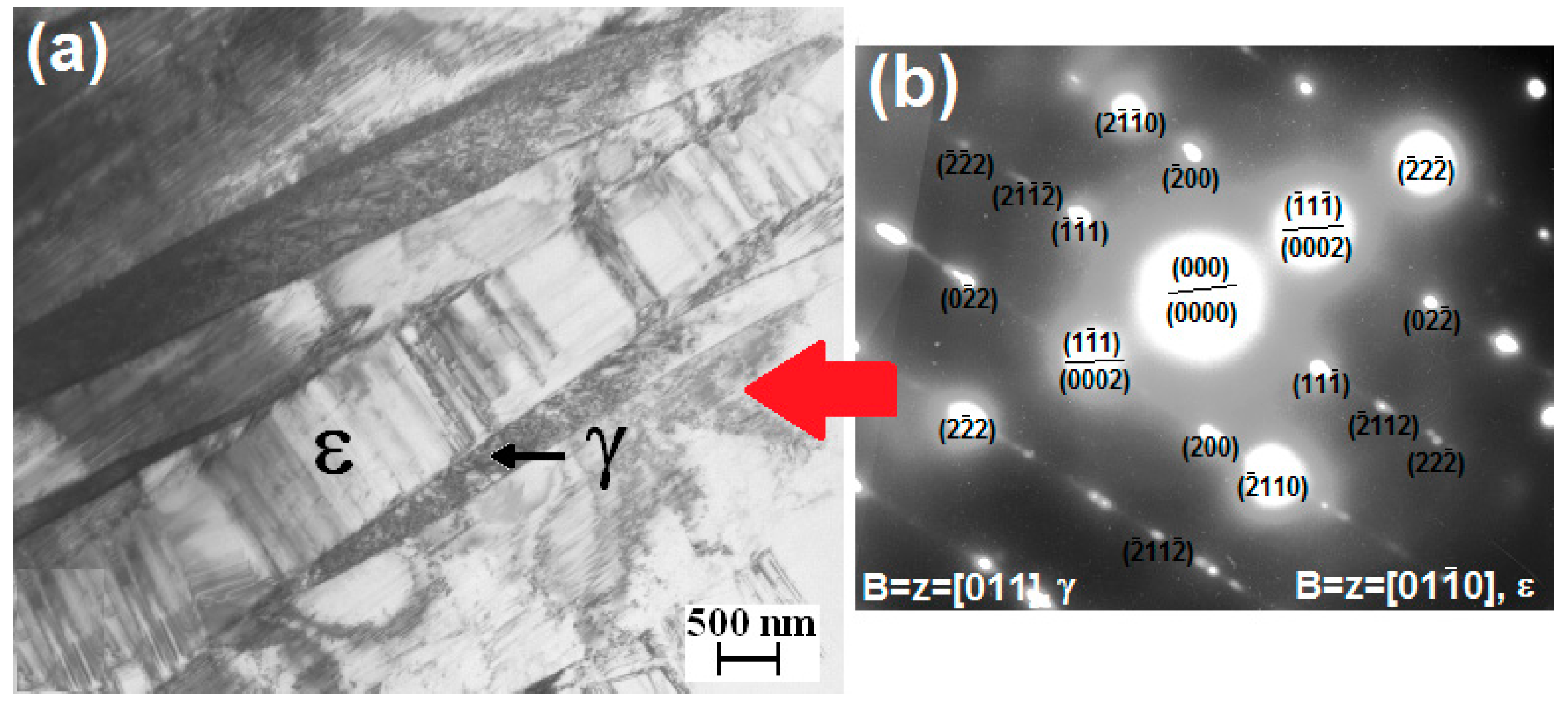

4.2. HCP and FCC Phases

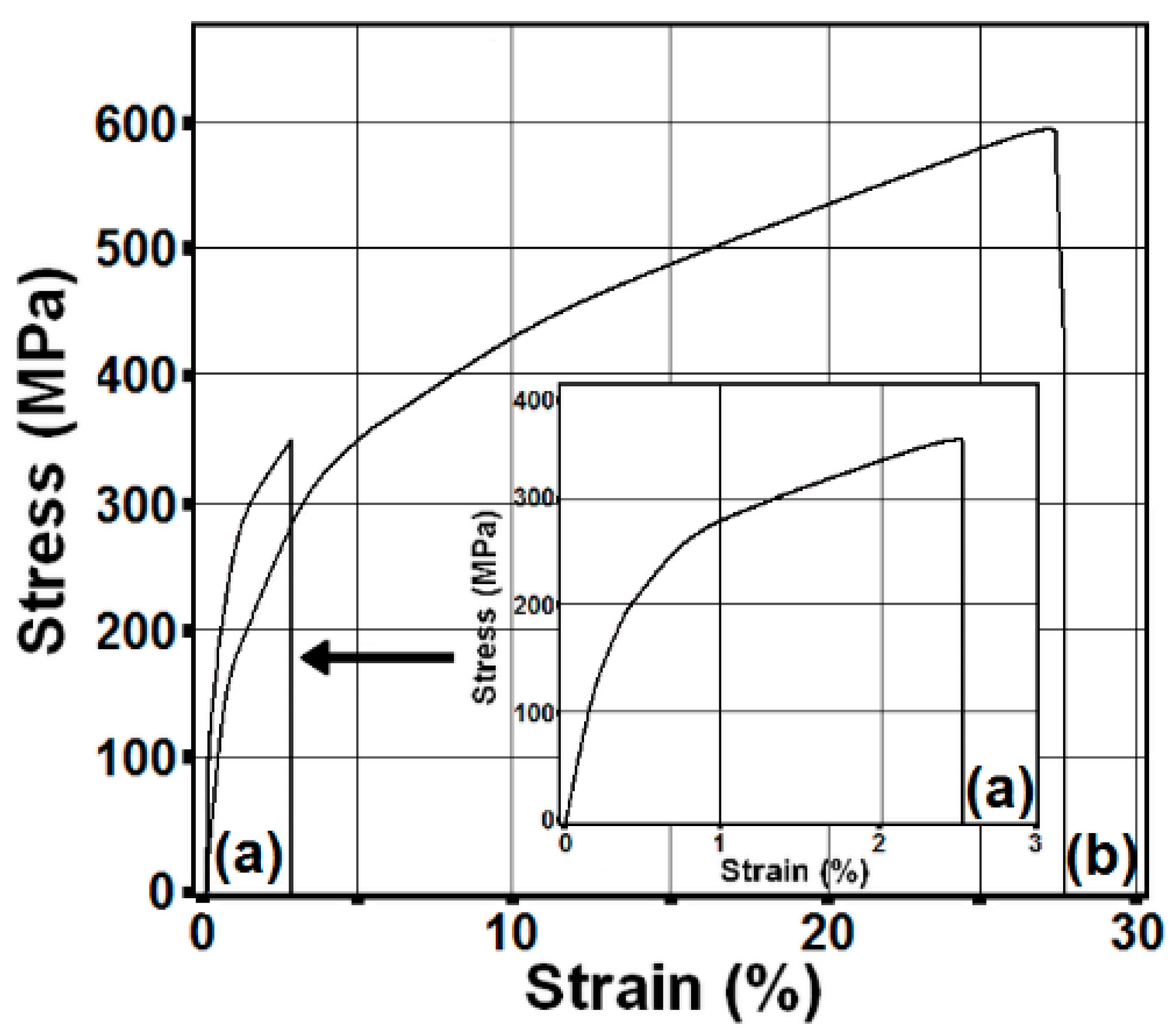

4.3. Mechanical Properties

4.4. Corrosion Properties

5. Conclusions

- (1)

- In this work an alternative solidification process is proposed that can be used to produce Co-Cr alloys with unique microstructures.

- (2)

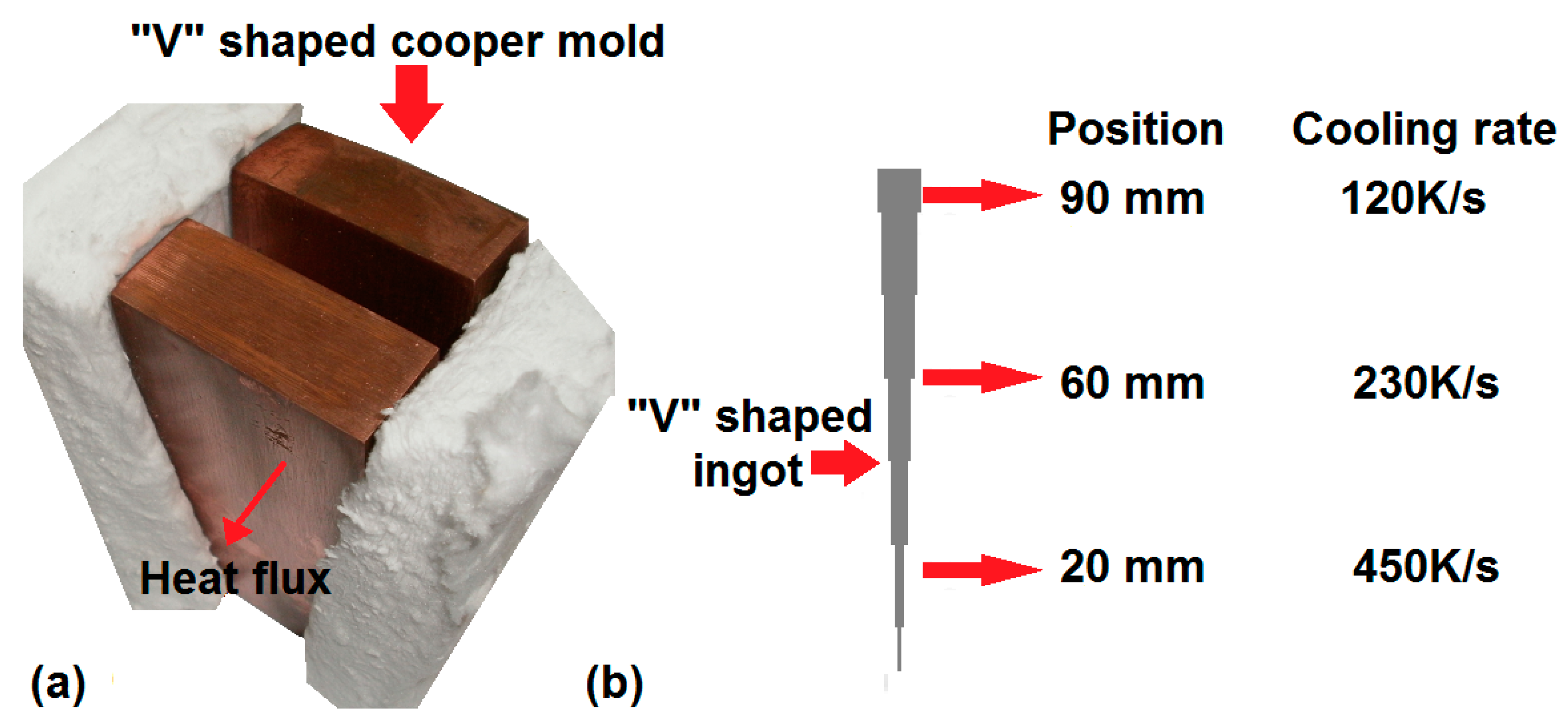

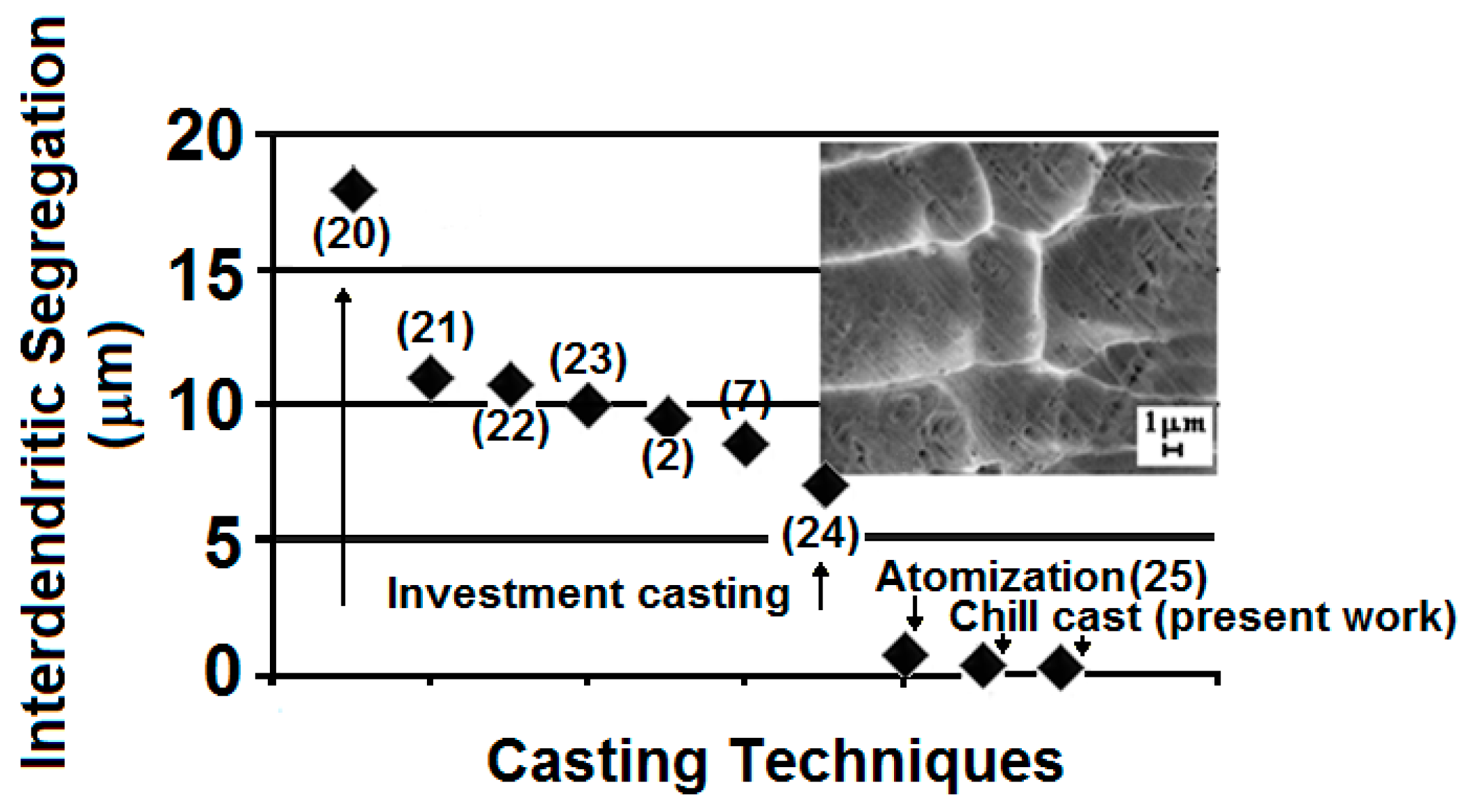

- Through the use of wedge-shaped copper molds, rapid solidification regimes were achieved in the solidified alloys.

- (3)

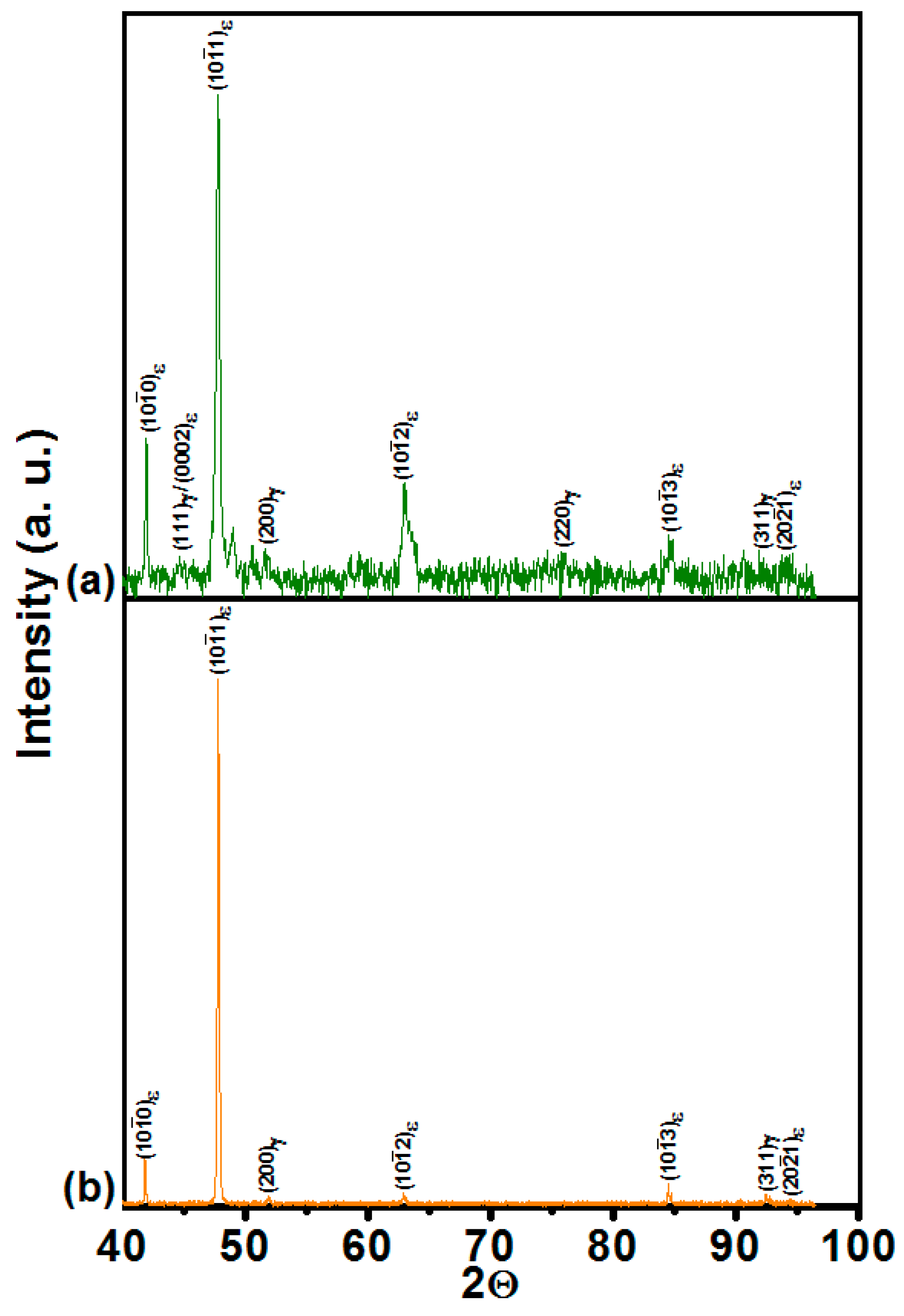

- In the eutectic composition (Co-44 wt. % Cr alloy) there were some constitutional changes; as a result of rapid solidification, the FCC γ-Co and HCP ε-Co solid solution phases were able to form outside their equilibrium limits (solid solubility extension). In addition, dendrite refinement and elimination or reduction of interdendritic segregation for Co-20, 30, 35, 40, and 44 wt. % Cr alloys was observed, which can be considered as one of the microstructural effects due to rapid solidification.

- (4)

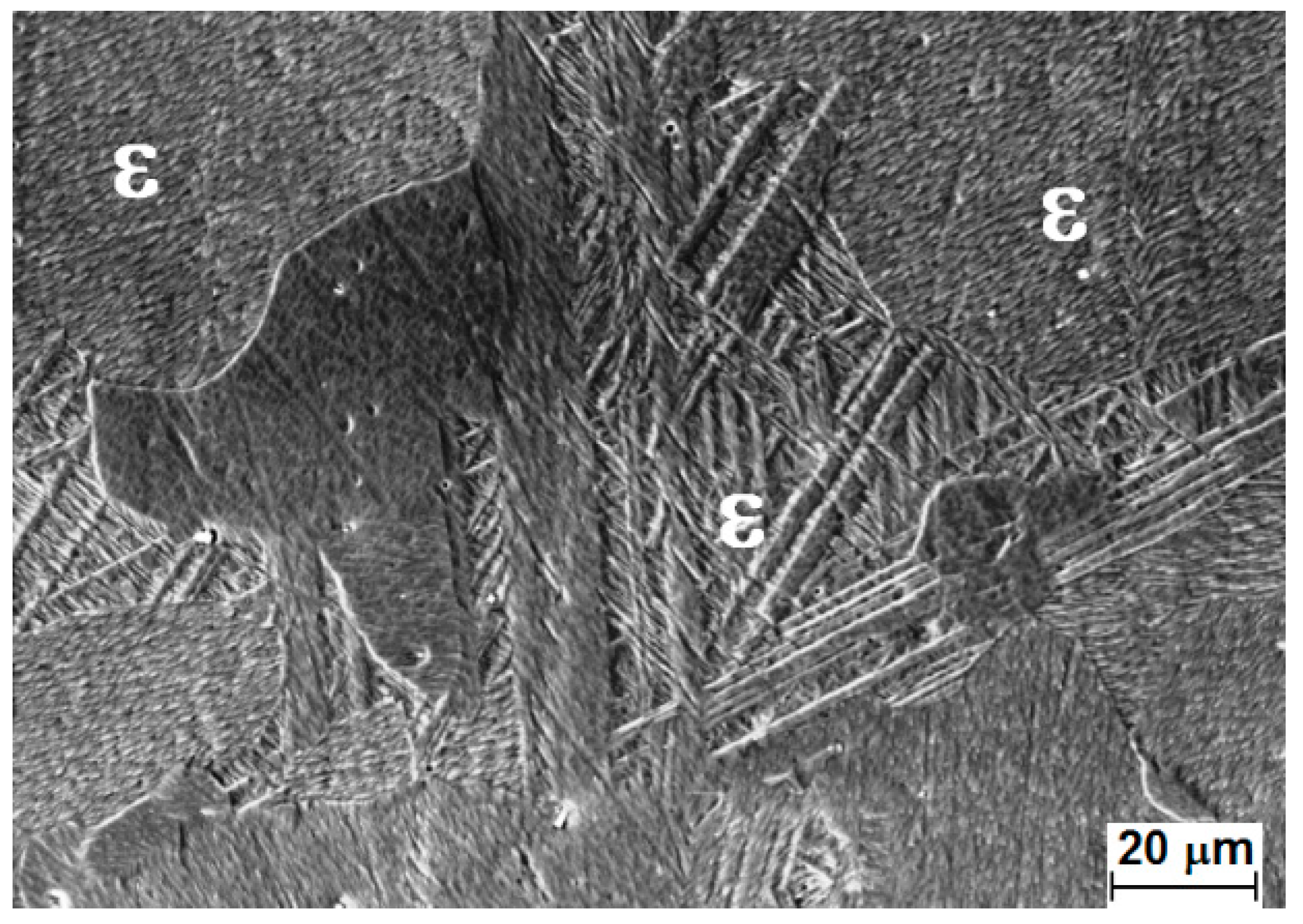

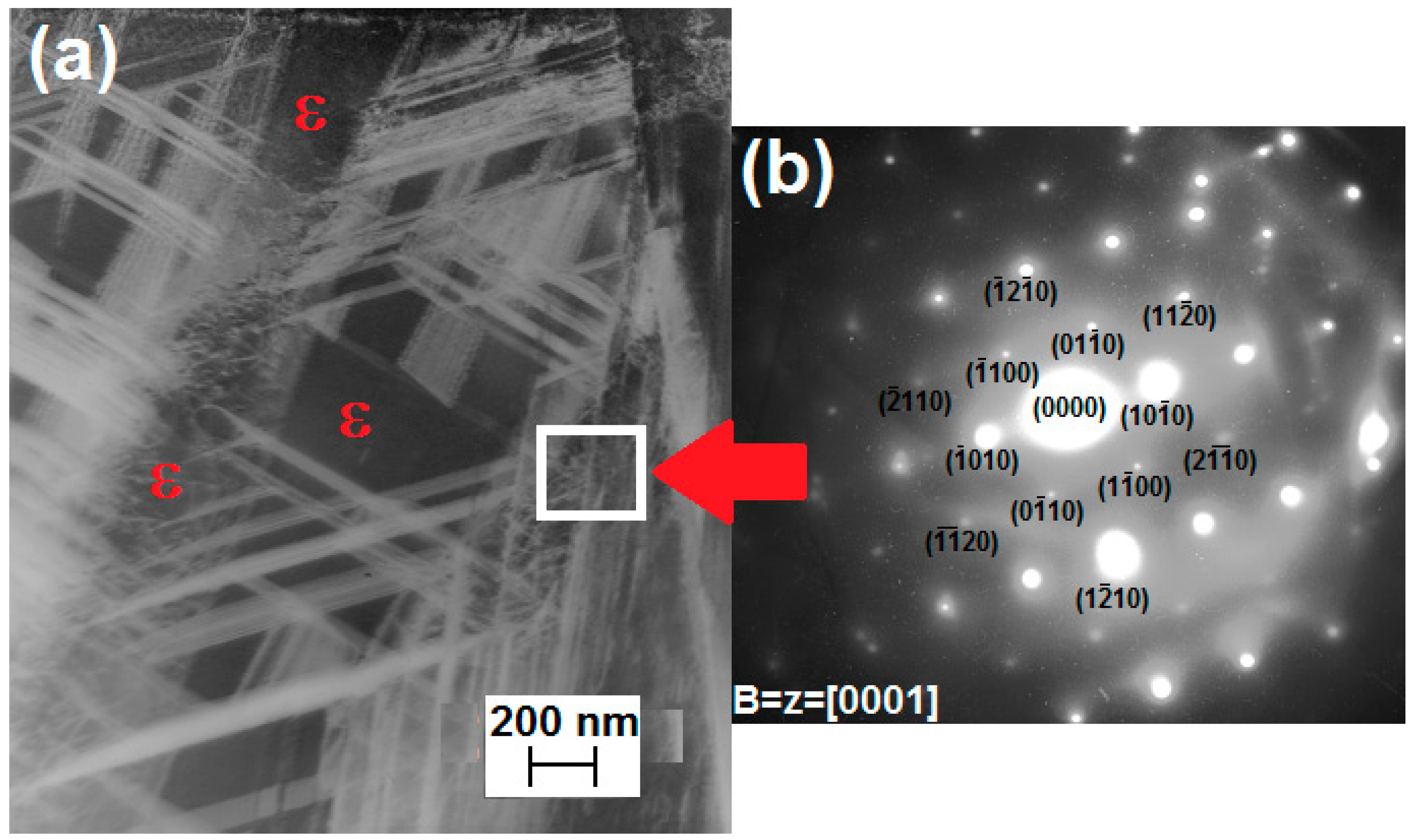

- Rapid solidification effects, such as excess vacancies and the development of numerous stacking faults and corresponding intersections, strongly favored the athermal ε-martensite transformation. Amounts of athermal ε-martensite exceeding 80 vol. % were induced at all of the cooling rates imposed on most of the alloys in the as-cast condition.

- (5)

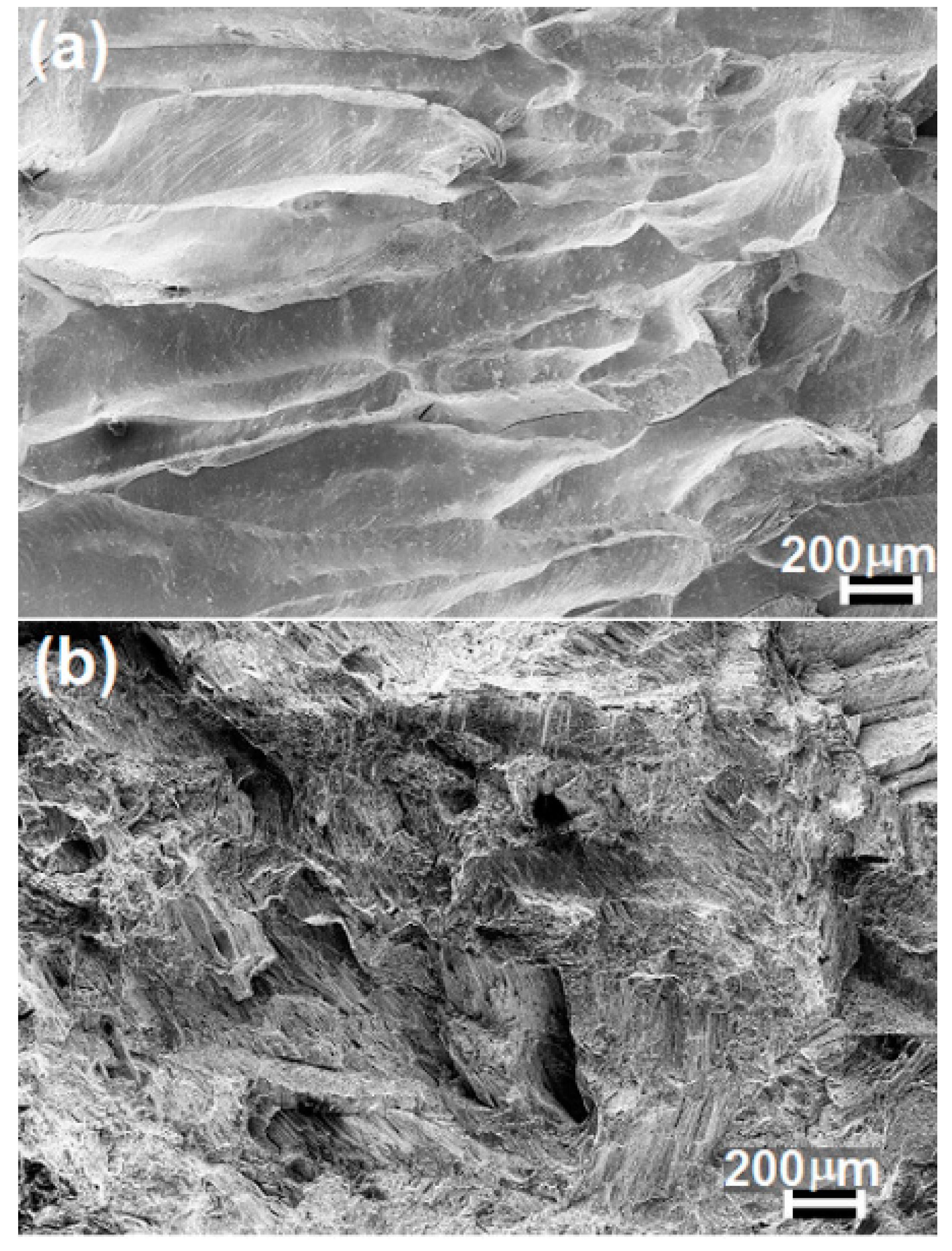

- An isothermal heat treatment below the γ-ε phase transformation temperature was implemented in the Co-20 wt. % Cr alloy. In turn, the mechanical strength was found to improve by over 40% whereas the alloy ductility exhibited over a 10-fold increase when compared with the alloy in as-cast condition. SEM and TEM characterization revealed that in the as-cast condition the resultant microstructure is composed of fine athermal ε-martensite plates inside directionally solidified columnar dendrites. After aging, the morphology undergoes a change due to the isothermal transformation of HCP ε-martensite as confirmed by X-ray diffraction data.

- (6)

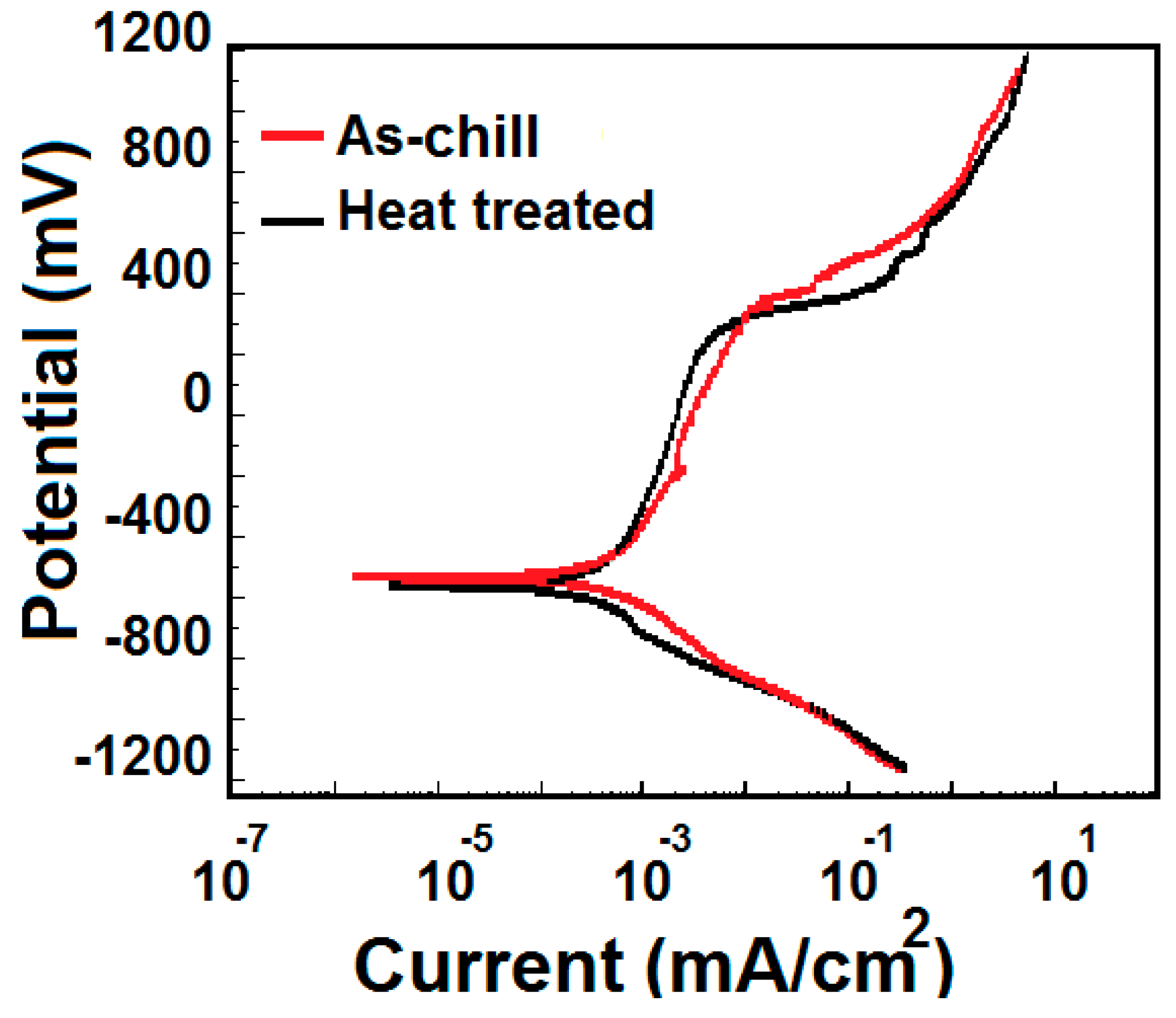

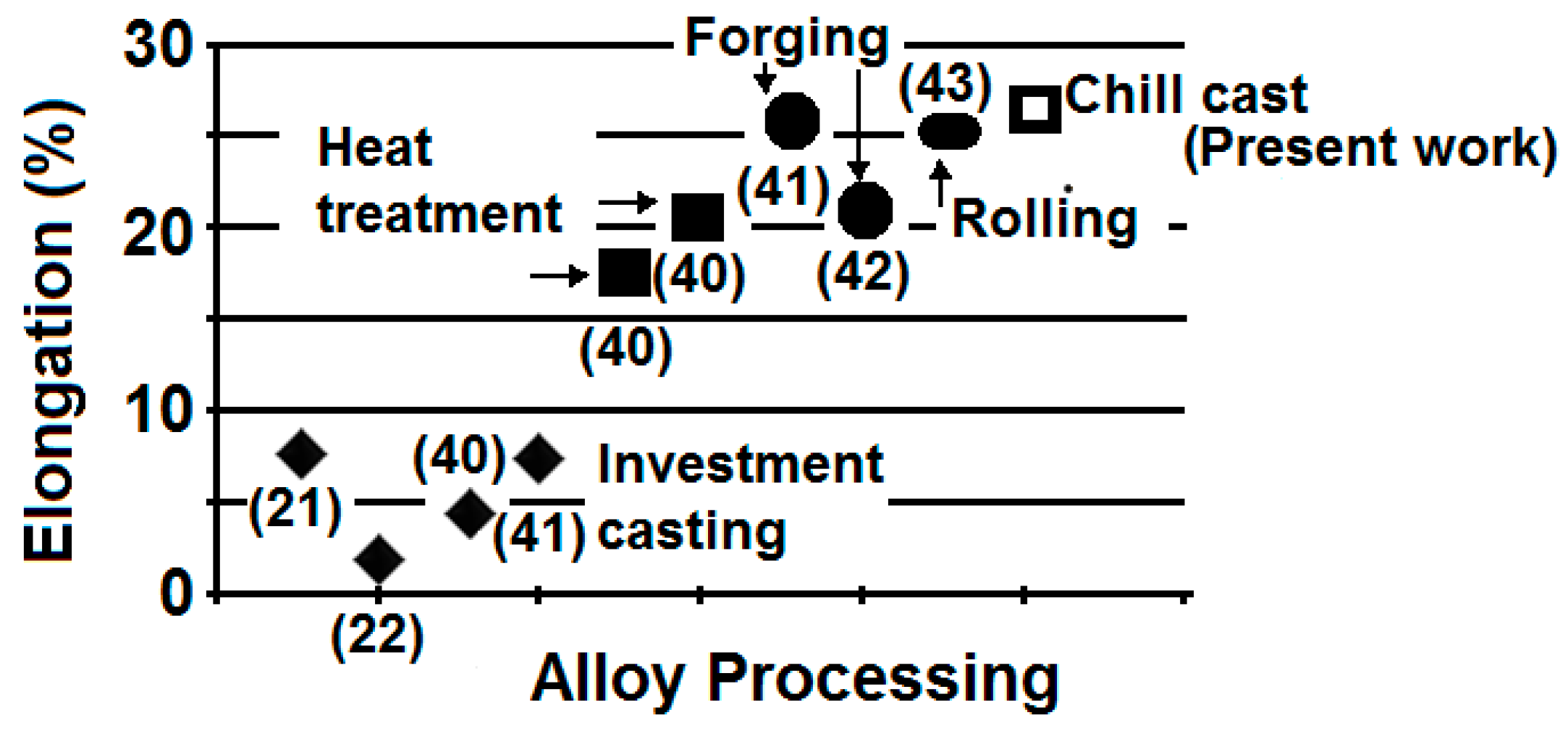

- Potentiodynamic polarization curves indicated that the Co-20 wt. % Cr alloy exhibited the lowest corrosion rates when compared with other Co-based alloys currently in use. In turn, preliminary results indicate that the combination of mechanical strength and corrosion resistance exhibited by this alloy processed by rapid solidification makes it attractive for potential applications as a biomaterial.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vandamme, N.S.; Topoleski, L.D.T. Control of surface morphology of carbide coating on Co-Cr-Mo implant alloy. J. Mater. Sci. Mater. Med. 2005, 16, 647–654. [Google Scholar] [CrossRef] [PubMed]

- Podrez-Radziszewska, M.; Haimann, K.; Dudziński, W.; Morawska-Sołtysik, M. Characteristic of intermetallic phases in cast dental CoCrMo alloy. Arch. Foundry Eng. 2010, 10, 51–56. [Google Scholar]

- Lee, S.H.; Nomura, N.; Chiba, A. Significant improvement in mechanical properties of biomedical Co-Cr-Mo alloys with combination of N addition and Cr-enrichment. Mater. Trans. JIM 2008, 49, 260–264. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef] [PubMed]

- Hedberg, Y.S.; Qian, B.; Shen, Z.; Virtanen, S.; Odnevall-Wallinder, I. In vitro biocompatibility of CoCrMo dental alloys fabricated by selective laser melting. Dent. Mater. 2014, 30, 525–534. [Google Scholar] [CrossRef] [PubMed]

- Berlin, R.M.; Gustavson, L.J.; Wang, K.K. Influence of post processing on the mechanical properties of investment cast and wrought Co-Cr-Mo alloys. In Cobalt Base Alloys for Biomedical Applications; Disegi, J.A., Kennedy, R.L., Pilliar, R., Eds.; ASTM International: West Conshohocken, PA, USA, 1999; pp. 62–70. [Google Scholar]

- Kaiser, R.; Williamson, K.; O’Brien, C.; Browne, D.J. Effects of section size, surface cooling conditions, and crucible material on microstructure and as-cast properties of investment cast Co-Cr biomedical alloy. Metall. Mater. Trans. A 2013, 44A, 5333–5342. [Google Scholar] [CrossRef]

- Lee, S.H.; Takahashi, E.; Nomura, N.; Chiba, A. Effect of carbon addition on microstructure and mechanical properties of a wrought Co-Cr-Mo implant alloy. Mater. Trans. JIM 2006, 47, 287–290. [Google Scholar] [CrossRef]

- Salinas-Rodriguez, A.; Rodriguez-Galicia, J.L. Deformation behavior of low-carbon Co-Cr-Mo alloys for low-friction implant applications. J. Biomed. Mater. Res. 1996, 31, 409–419. [Google Scholar] [CrossRef]

- Mani, A.; Salinas-Rodriguez, A.; Lopez, H.F. Deformation induced FCC to HCP transformation in a Co-27Cr-5Mo-0.05C alloy. Mater. Sci. Eng. A 2011, 528A, 3037–3043. [Google Scholar] [CrossRef]

- Lee, S.H.; Takahashi, E.; Nomura, N.; Chiba, A. Effect of heat treatment on microstructure and mechanical properties of Ni- and C-free Co-Cr-Mo alloys for medical applications. Mater. Trans. JIM 2005, 46, 1790–1793. [Google Scholar] [CrossRef]

- Paul, B.; Kapoor, R.; Chakravartty, J.K.; Bidaye, A.C.; Sharma, I.G.; Suri, A.K. Hot working characteristics of cobalt in the temperature range 600–950 °C. Scr. Mater. 2009, 60, 104–107. [Google Scholar] [CrossRef]

- Mori, M.; Yamanaka, K.; Sato, S.; Wagatsuma, K.; Chiba, A. Microstructures and mechanical properties of biomedical Co-29Cr-6Mo-0.14N alloys processed by hot rolling. Metall. Mater. Trans. A 2012, 42A, 3108–3119. [Google Scholar] [CrossRef]

- ASTM F562-13. Standard Specification for Wrought 35Cobalt-35Nickel-20Chromium-10Molybdenum Alloy for Surgical Implant Applications (UNS R30035); ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Niinomi, M. Recent research and development in titanium alloys for biomedical applications and healthcare goods. Sci. Technol. Adv. Mater. 2003, 4, 445–454. [Google Scholar] [CrossRef]

- Roach, M. Base metal alloys used for dental restorations and implants. Dent. Clin. N. Am. 2007, 51, 603–627. [Google Scholar] [CrossRef] [PubMed]

- Saravanan, G.; Mohan, S. Structure, composition and corrosion resistance studies of Co-Cr alloy electrodeposited from deep eutectic solvent (DES). J. Alloy. Compd. 2012, 522, 162–166. [Google Scholar] [CrossRef]

- Taylor, R.N.J.; Waterhouse, R.B. A study of the ageing behaviour of a cobalt based implant alloy. J. Mater. Sci. 1983, 18, 3265–3280. [Google Scholar] [CrossRef]

- Giancchi, J.V.; Morando, C.N.; Fornaro, O.; Palacio, H.A. Microstructural characterization of as-cast biocompatible Co-Cr-Mo alloys. Mater. Charact. 2011, 62, 53–61. [Google Scholar] [CrossRef]

- Zhuang, L.Z.; Langer, E.W. Effects of alloy additions on the microstructures and tensile properties of cast Co-Cr-Mo alloy used for surgical implants. J. Mater. Sci. 1989, 24, 4324–4330. [Google Scholar] [CrossRef]

- Zhuang, L.Z.; Langer, E.W. Effects of cooling rate control during the solidification process on the microstructure and mechanical properties of cast Co-Cr-Mo alloy used for surgical implants. J. Mater. Sci. 1989, 24, 381–388. [Google Scholar] [CrossRef]

- Montero-Ocampo, C.; Talavera, M.; Lopez, H. Effect of alloy preheating on the mechanical properties of as-cast Co-Cr-Mo-C alloys. Metall. Mater. Trans. A 1999, 30A, 611–620. [Google Scholar] [CrossRef]

- Mineta, S.; Alfirano; Namba, S.; Yoneda, T.; Ueda, K. Phase and formation/dissolution of precipitates in biomedical Co-Cr-Mo alloys with nitrogen addition. Metall. Mater. Trans. A 2013, 44A, 494–503. [Google Scholar] [CrossRef]

- Pilliar, R.M. Metallic biomaterials. In Biomedical Materials; Narayan, R., Ed.; Springer: New York, NY, USA, 2009; pp. 41–82. [Google Scholar]

- Song, C.; Park, H.; Lopez, H.F. Development of athermal and isothermal ε-martensite in atomized Co-Cr-Mo-C implant alloy powders. Metall. Mater. Trans. A 2006, 37A, 3197–3204. [Google Scholar] [CrossRef]

- Sage, M.; Guillaud, C. Méthode d'analyse quantitative des variétés allotropiques du cobalt pre les Rayons X. Rev. Metall. 1950, 49, 139–145. [Google Scholar]

- Shi, L.; Northwood, D.O.; Cao, Z. Alloy design and microstructure of a biomedical Co-Cr alloy. J. Mater. Sci. 1993, 28, 1312–1315. [Google Scholar] [CrossRef]

- Huang, P.; Lopez, H.F. Strain induced ε-martensite in a Co-Cr-Mo alloy: Grain size effects. Mater. Lett. 1999, 39, 244–248. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Chiba, A. Enhanced Mechanical Properties of As-Forged Co-Cr-Mo-N Alloys with Ultrafine-Grained Structures. Metall. Mater. Trans. A 2012, 43A, 5243–5257. [Google Scholar] [CrossRef]

- Sharma, M.; Ramesh-Kumar, A.V.; Singh, N.; Adya, N.; Saluja, B. Electrochemical corrosion behavior of dental/implant alloys in artificial saliva. J. Mater. Eng. Perform. 2008, 17, 695–701. [Google Scholar] [CrossRef]

- Angelini, E.; Zucchi, F. In vitro corrosion of some Co-Cr and Ni-Cr alloys used for removable partial dentures: Influence of heat treatments. J. Mater. Sci. Mater. Med. 1991, 2, 27–35. [Google Scholar] [CrossRef]

- Tomas, H.; Freire, A.P.; Abrantes, L.M. Cast Co-Cr alloy and pure chromium in proteinaceous media: An electrochemical characterization. J. Mater. Sci. Mater. Med. 1994, 5, 446–451. [Google Scholar] [CrossRef]

- Lawrence-Kats, J. Orthopedic applications. In Biomaterials Science: An Introduction to Materials in Medicine; Ratner, B.D., Hoffman, A.S., Schoen, F.J., Lemons, J.E., Eds.; Elsevier: London, UK, 2004; pp. 335–346. [Google Scholar]

- Bogno, A.; Nguyen-Thi, H.; Reinhart, G.; Billia, B.; Baruchel, J. Growth and interaction of dendritic equiaxed grains: In situ characterization by synchrotron X-ray radiography. Acta Mater. 2013, 61, 1302–1315. [Google Scholar] [CrossRef]

- Lopez, H.F.; Saldivar, A.; Huang, P. Development and properties of ε-martensite in Co-Cr-Mo alloys for biomedical applications. In Properties of Complex Inorganic Solids 2; Meike, A., Gonis, A., Turchi, P., Rajan, K., Eds.; Kluwer Academic/Plenum Publishers: New York, NY, USA, 1999; pp. 307–325. [Google Scholar]

- Huang, P.; Salinas-Rodriguez, A.; Lopez, H.F. Tribological behaviour of cast and wrought Co-Cr-Mo implant alloys. Mater. Sci. Technol. 1999, 15, 1324–1330. [Google Scholar]

- Saldivar-Garcia, A.; Mani-Medrano, A.; Salinas-Rodriguez, A. Effect of solution treatments on the fcc/hcp isothermal martensitic transformation in Co-27Cr-5Mo-0.05C aged at 800 °C. Scr. Mater. 1999, 40, 717–722. [Google Scholar] [CrossRef]

- Rajan, K. Phase Transformations in a Wrought Co-Cr-Mo-C Alloy. Metall. Mater. Trans. A 1982, 13A, 1161–1166. [Google Scholar] [CrossRef]

- Jones, H. Rapid Solidification of Metals and Alloys; The Institution of Metallurgists: London, UK, 1982; pp. 1–80. [Google Scholar]

- Saldivar, A.J.; Lopez, H.F. Role of aging on the martensitic transformation in a cast cobalt alloy. Scr. Mater. 2001, 45, 427–433. [Google Scholar] [CrossRef]

- Saldivar-Garcia, A.J.; Mani-Medrano, A.; Salinas-Rodriguez, A. Formation of Hcp martensite during the isothermal aging of an Fcc Co-27Cr-5Mo-0.05C orthopedic implant alloy. Metall. Mater. Trans. A 1999, 30A, 1177–1184. [Google Scholar] [CrossRef]

- Vander-Sande, J.B.; Coke, J.R.; Wulff, J. A transmission electron microscopy the mechanisms of strengthening in heat-treated Co-Cr-Mo-C alloys. Metall. Mater. Trans. A 1976, 7A, 389–397. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Zangeneh, S.; Hasanabadi, F.; Saghafi, M. Microstructural evolution during isothermal aging and strain-induced transformation followed by isothermal aging in Co-Cr-Mo-C alloy: A comparative study. Mater. Sci. Eng. A 2010, 527A, 4082–4091. [Google Scholar] [CrossRef]

- Chiba, A.; Kumagai, K.; Takeda, H.; Nomura, N. Mechanical properties of forged low Ni and C-containing Co-Cr-Mo. Mater. Sci. Forum 2005, 475–479, 2317–2322. [Google Scholar] [CrossRef]

| Compound | Quantity (g/L) |

|---|---|

| KH2PO4 | 0.34 |

| Na2HPO4·2H2O | 0.445 |

| KHCO3 | 1.5 |

| NaCl | 0.585 |

| MgCl2·6H2O | 0.0305 |

| Citric acid | 0.0315 |

| CaCl2 | 0.0166 |

| Cr (wt. %) | Cooling Rate (K/s) | HCP (wt. %) | I(l0Īl)HCP | I (200)FCC |

|---|---|---|---|---|

| 20 | 450 | 82.3 | 184.22 | 26.32 |

| 230 | 89.6 | 277.92 | 21.32 | |

| 120 | 92.6 | 481.82 | 25.32 | |

| 30 | 450 | 61.6 | 38.372 | 15.92 |

| 230 | 90.1 | 77.32 | 5.62 | |

| 120 | 81.1 | 92.92 | 14.32 | |

| 35 | 450 | 79.0 | 90.32 | 15.92 |

| 230 | 92.1 | 200.52 | 11.32 | |

| 120 | 81.9 | 145.52 | 21.32 | |

| 40 | 450 | 81.9 | 51.32 | 7.52 |

| 230 | 43.8 | 166.72 | 142.22 | |

| 120 | 51.5 | 25.12 | 15.72 |

| Co-20 wt. % Cr (Condition) | Ecorr (mV) | Icorr (mA/cm2) | Epit (mV) | Ipit (mA/m2) | Vcorr (mm/year) |

|---|---|---|---|---|---|

| As-cast (present work) | −554.2 | 1 × 10−4 | 298.2 | 0.006 | 0.00084 |

| Heat treated | −524.19 | 4.22 × 10−4 | 384.16 | 0.014 | 0.00356 |

| (present work) | |||||

| Co-Cr as-cast [17] | 1.26 | ||||

| Co-Cr as-cast [29] | 5.43 | ||||

| Co-Cr Heat treated [29] | 0.061 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramirez-Ledesma, A.L.; Lopez, H.F.; Juarez-Islas, J.A. Evaluation of Chill Cast Co-Cr Alloys for Biomedical Applications. Metals 2016, 6, 188. https://doi.org/10.3390/met6080188

Ramirez-Ledesma AL, Lopez HF, Juarez-Islas JA. Evaluation of Chill Cast Co-Cr Alloys for Biomedical Applications. Metals. 2016; 6(8):188. https://doi.org/10.3390/met6080188

Chicago/Turabian StyleRamirez-Ledesma, Ana Laura, Hugo F. Lopez, and Julio Alberto Juarez-Islas. 2016. "Evaluation of Chill Cast Co-Cr Alloys for Biomedical Applications" Metals 6, no. 8: 188. https://doi.org/10.3390/met6080188

APA StyleRamirez-Ledesma, A. L., Lopez, H. F., & Juarez-Islas, J. A. (2016). Evaluation of Chill Cast Co-Cr Alloys for Biomedical Applications. Metals, 6(8), 188. https://doi.org/10.3390/met6080188