Effect of Friction Stir Welding Parameters on the Mechanical and Microstructure Properties of the Al-Cu Butt Joint

Abstract

:1. Introduction

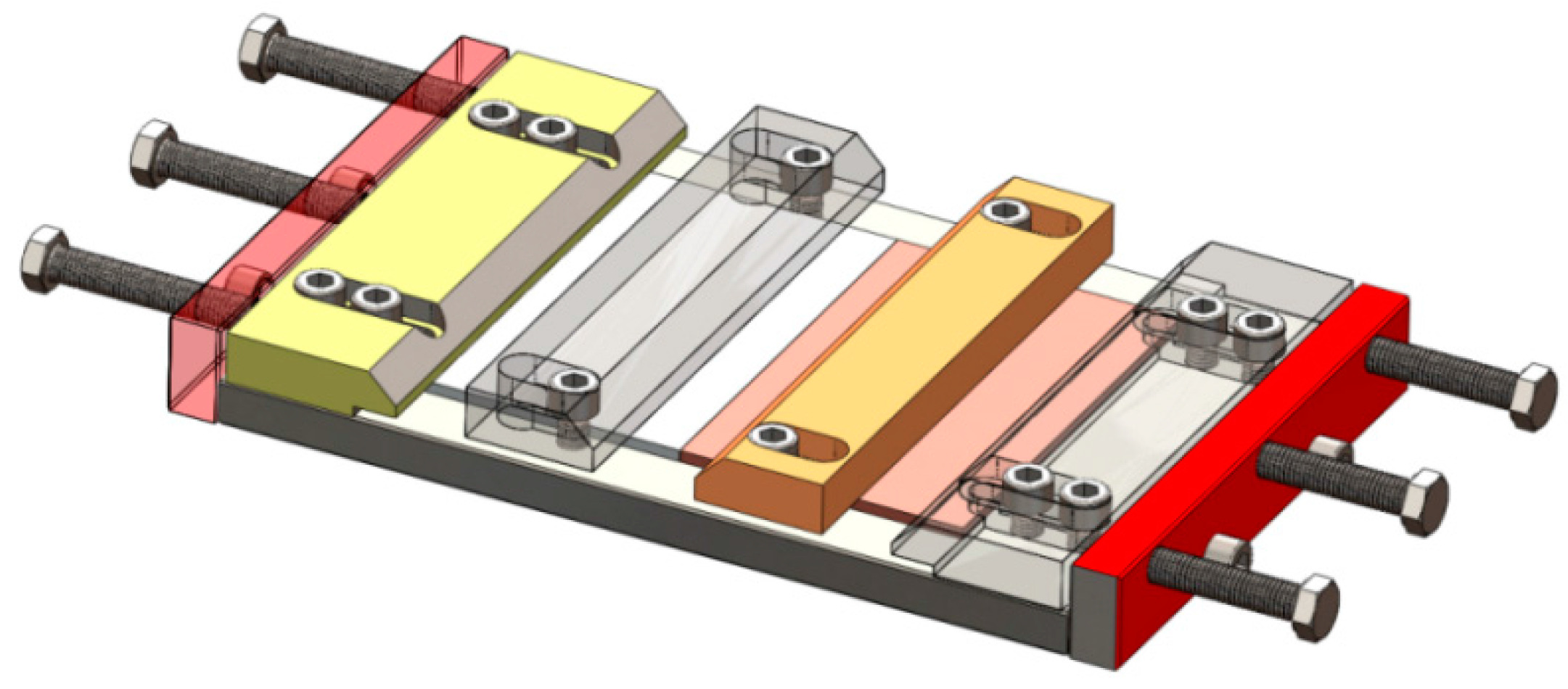

2. Materials and Methods

- Direction of rotation of the tool: Clockwise

- Tilt Angle: 1.5°

- Standby Time: 60 s.

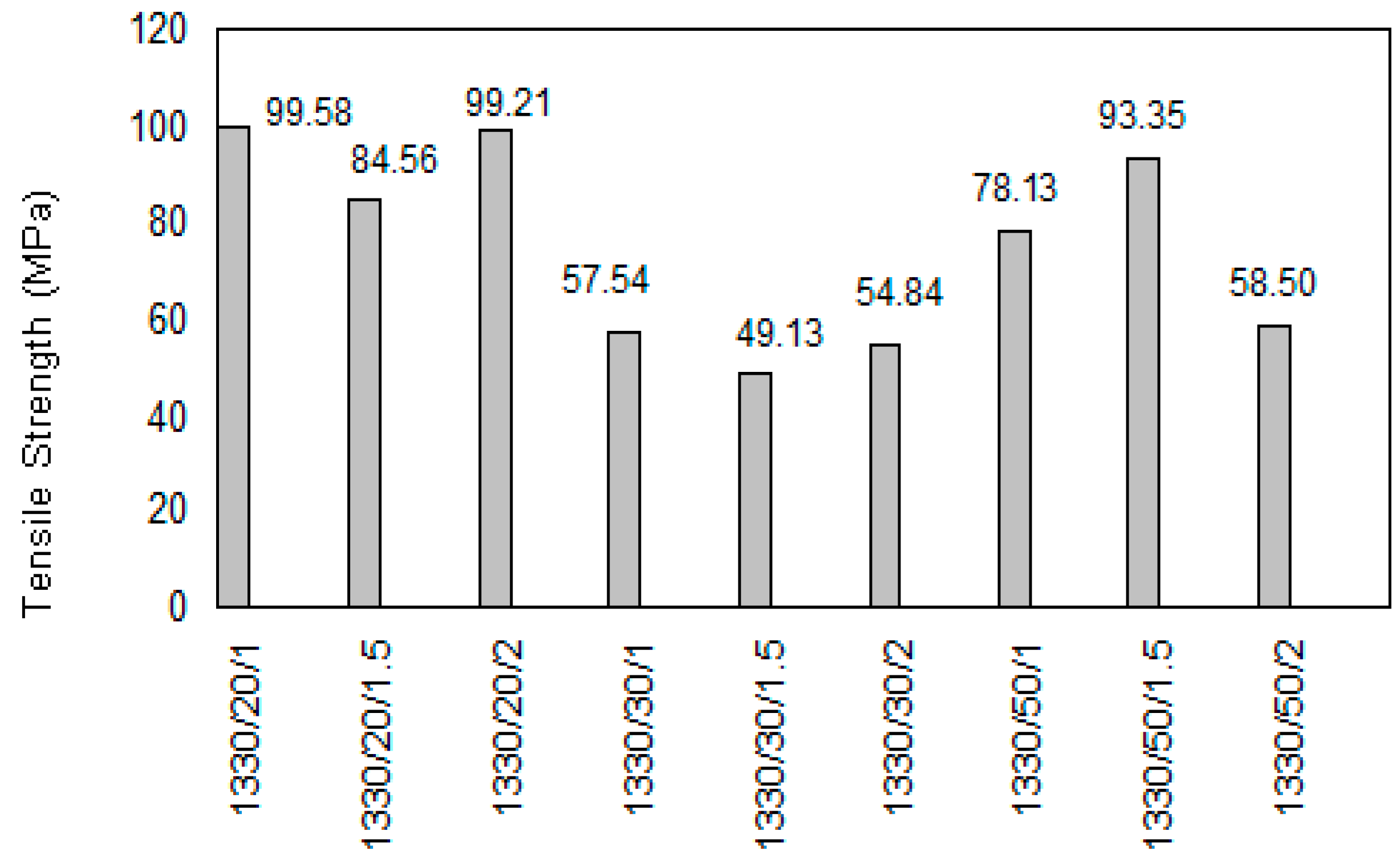

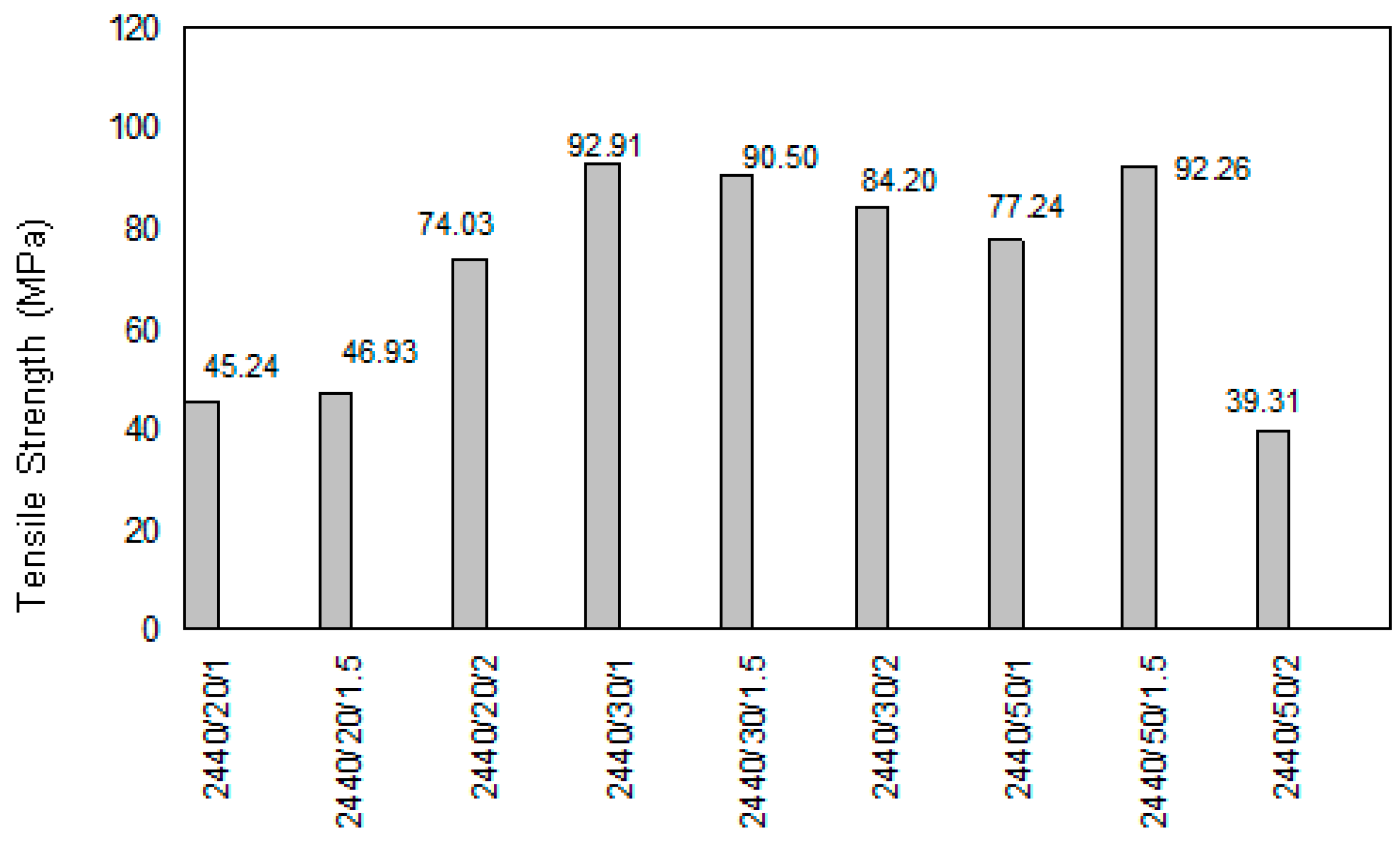

3. Results and Discussions

4. Conclusions

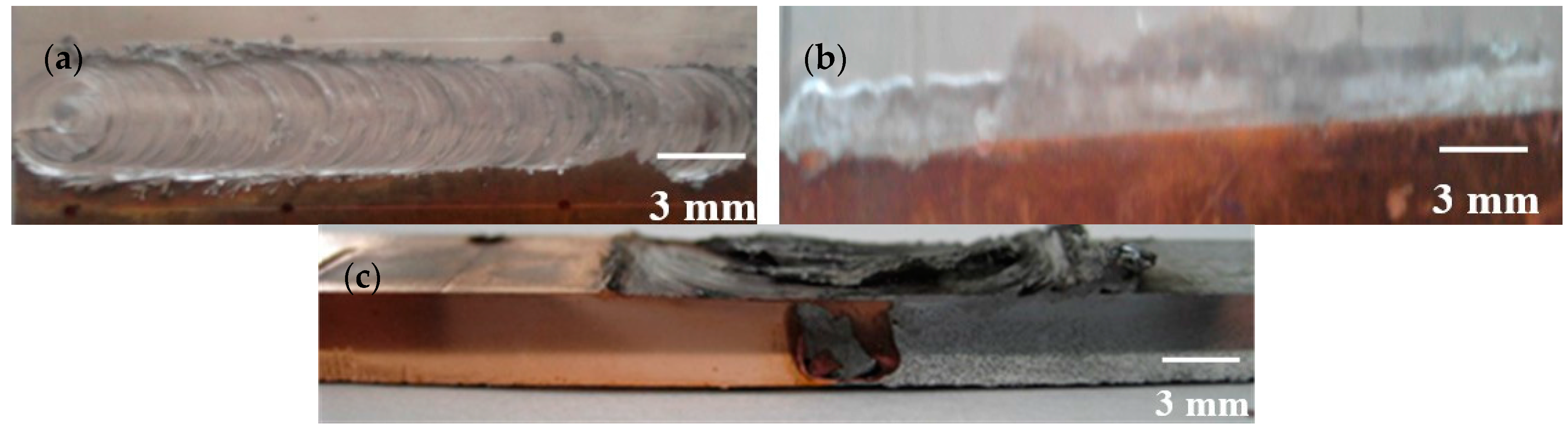

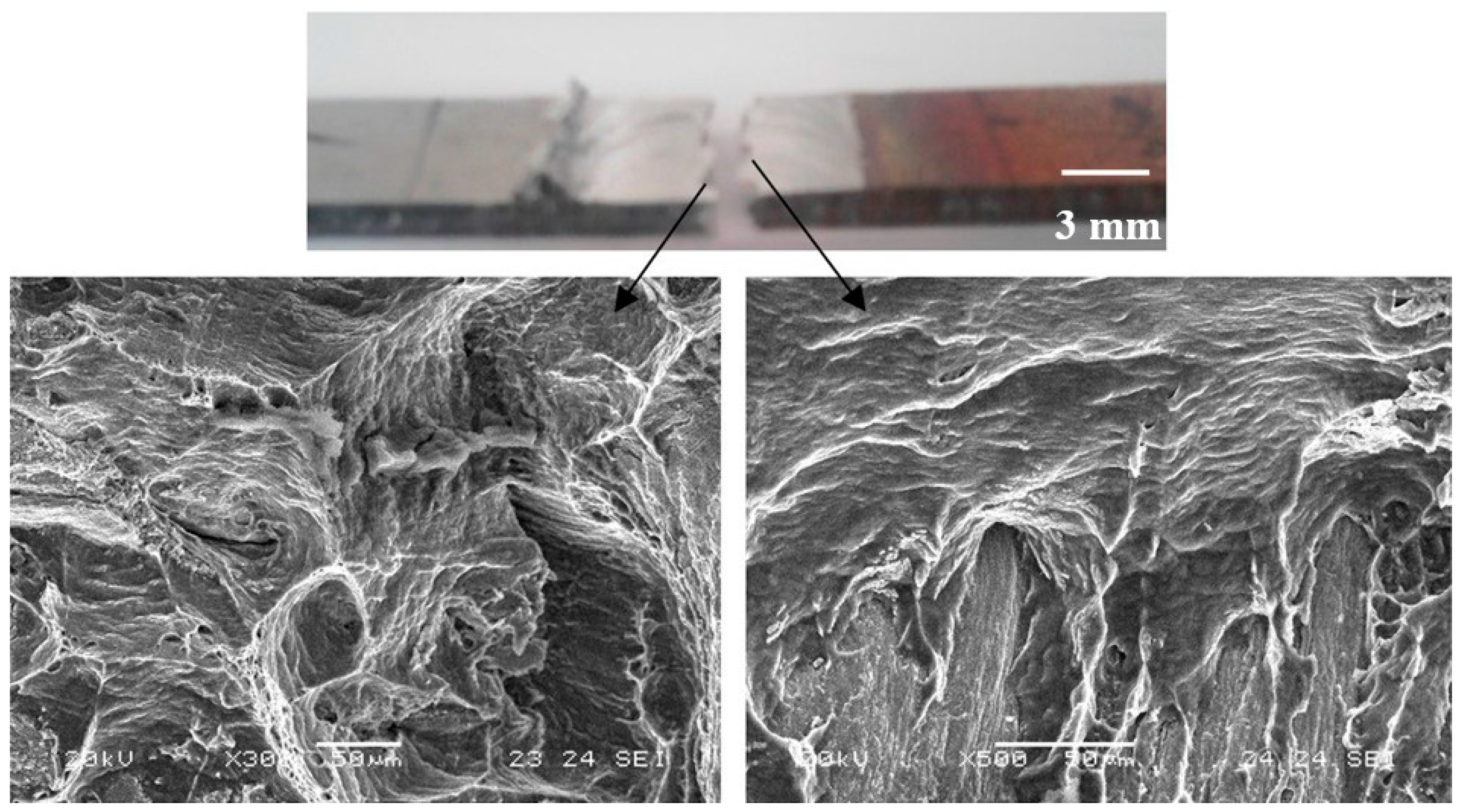

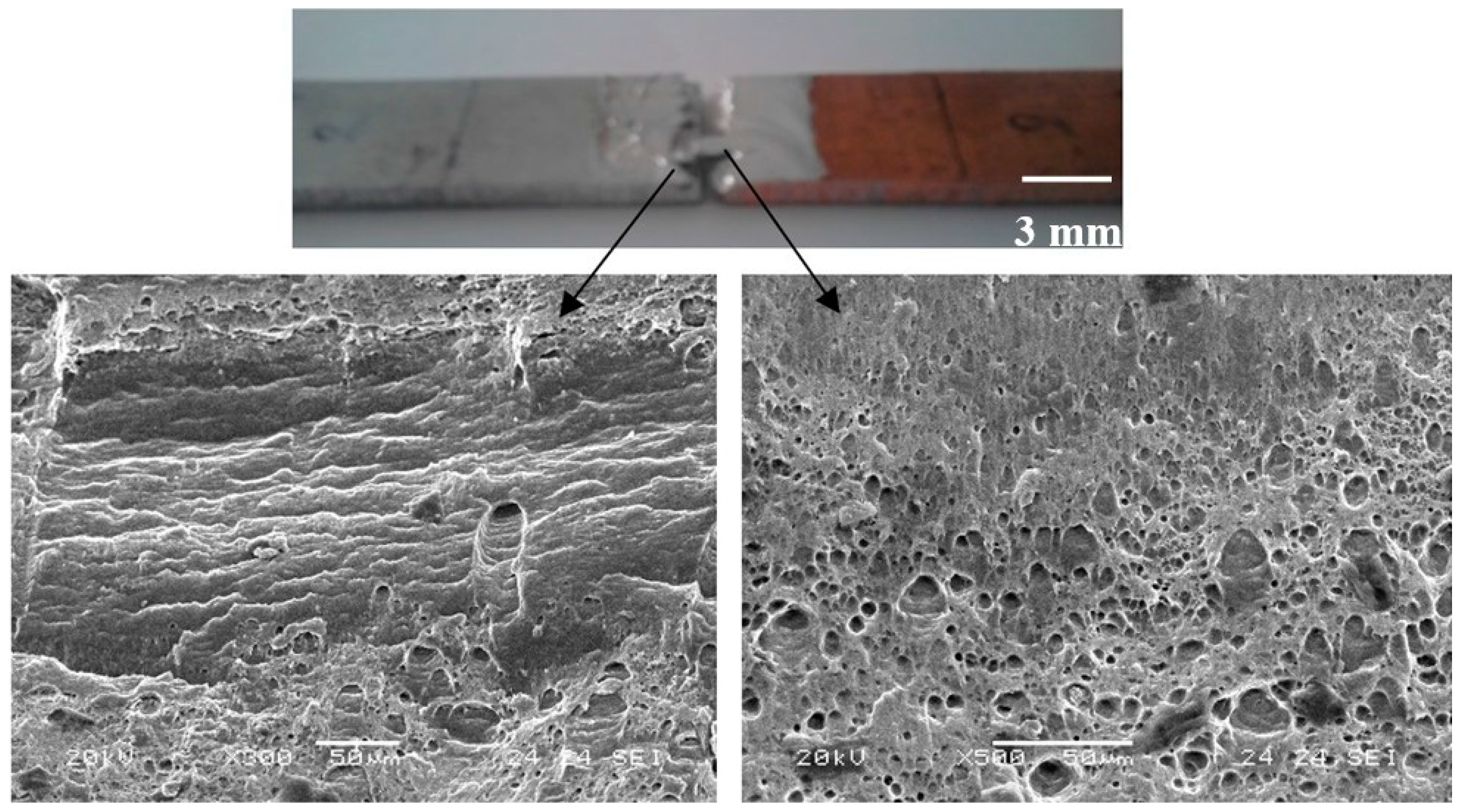

- In this study, the friction stir butt weldability of pure Cu and 1050 Al alloy was examined, and it was successfully accomplished under different parameters by using a cylindrical pin tool. Failures were observed in the weldings that has none tool shifting (zero positioned tool). Macro-level welding defects were not observed on the welded surfaces in the case of joints for which the stir pin was positioned at 1, 1.5 and 2 mm to the Al side. However, micro-level gaps were observed in low tensile strength specimens.

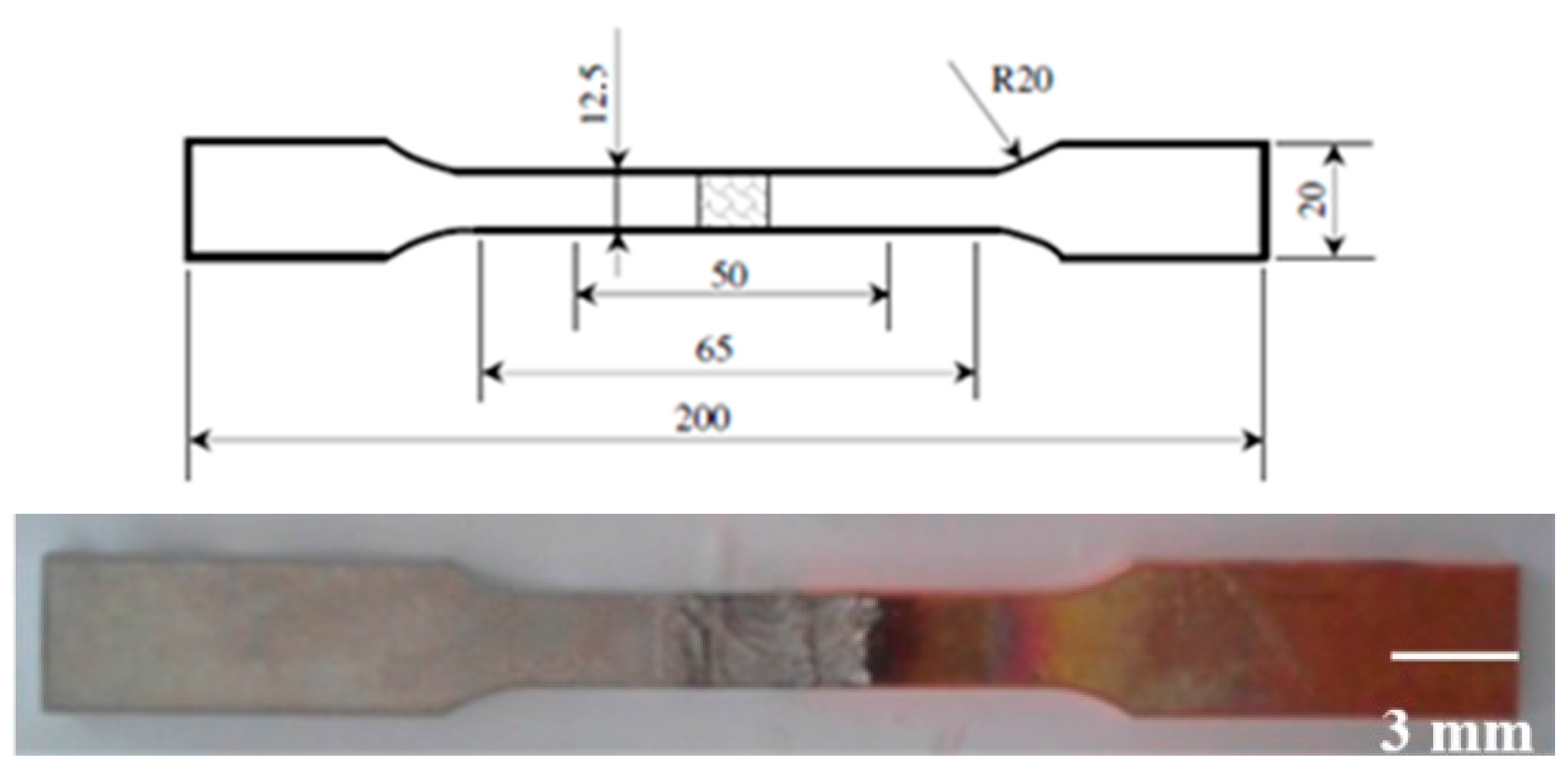

- Tensile and bending tests, as well as hardness measurements were made in order to determine the mechanical properties of joints. When the welding performance of joints was evaluated, the maximum value was found to be 89.5% with a 1330 rpm tool rotational speed, a 20 mm/min traverse speed and a 1 mm tool position configuration. As a result of the tensile test it was observed that ruptures usually occurred in joint zones and heat-affected zones of aluminum.

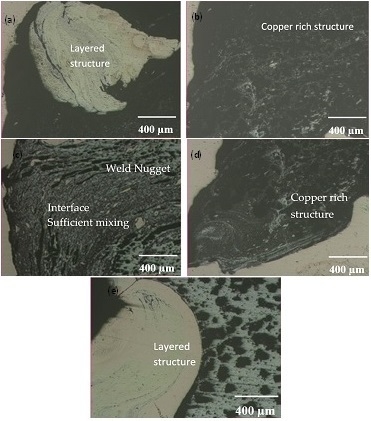

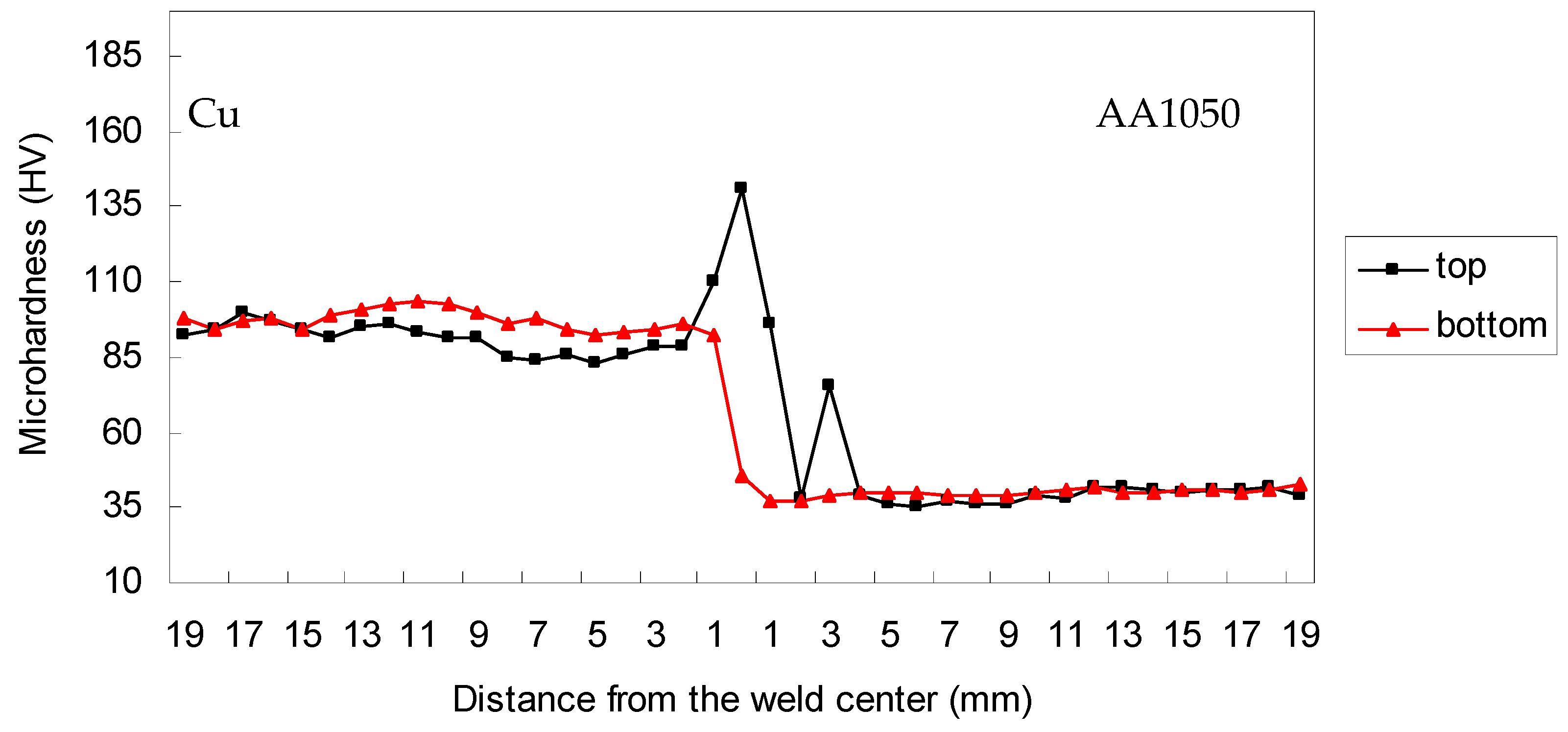

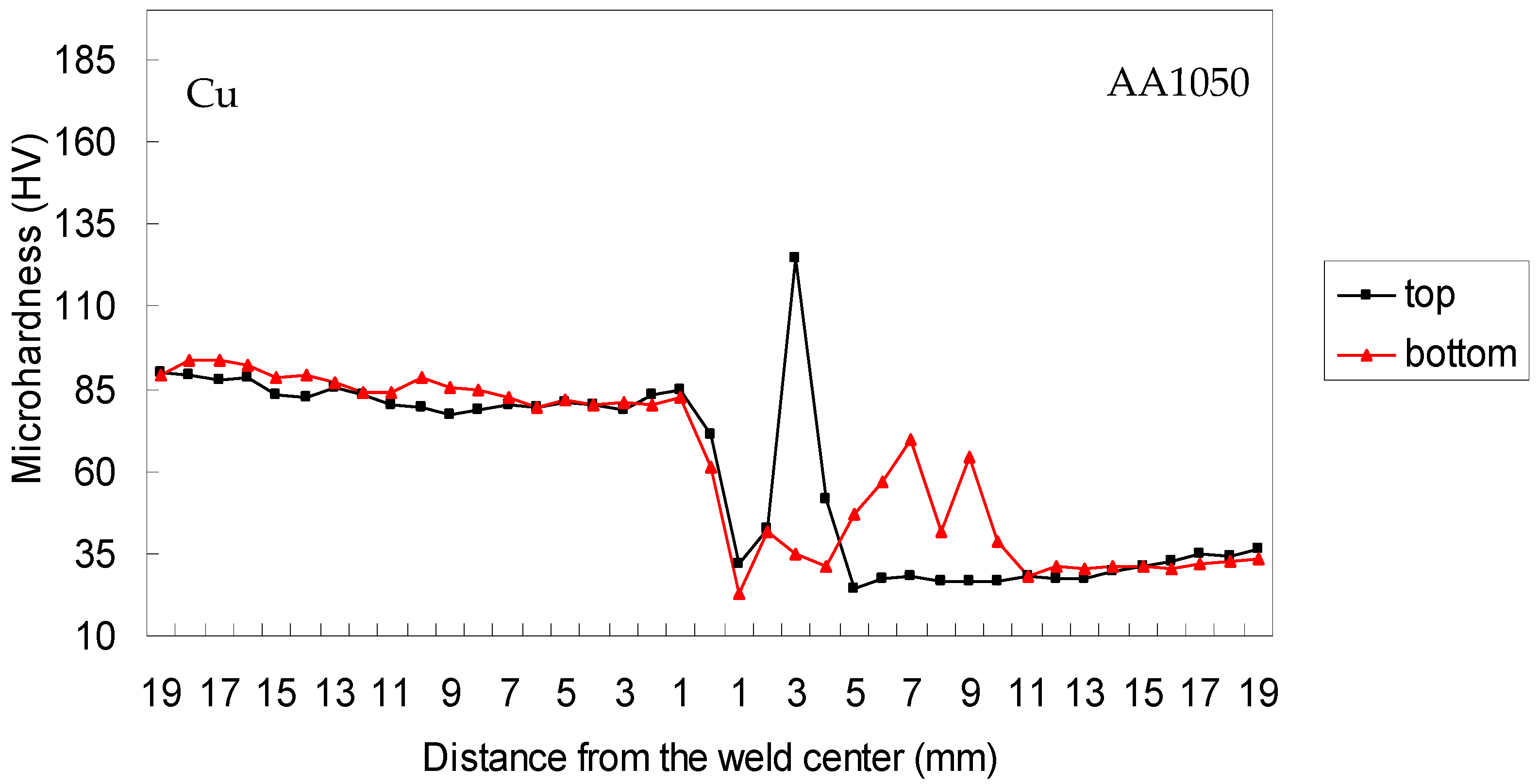

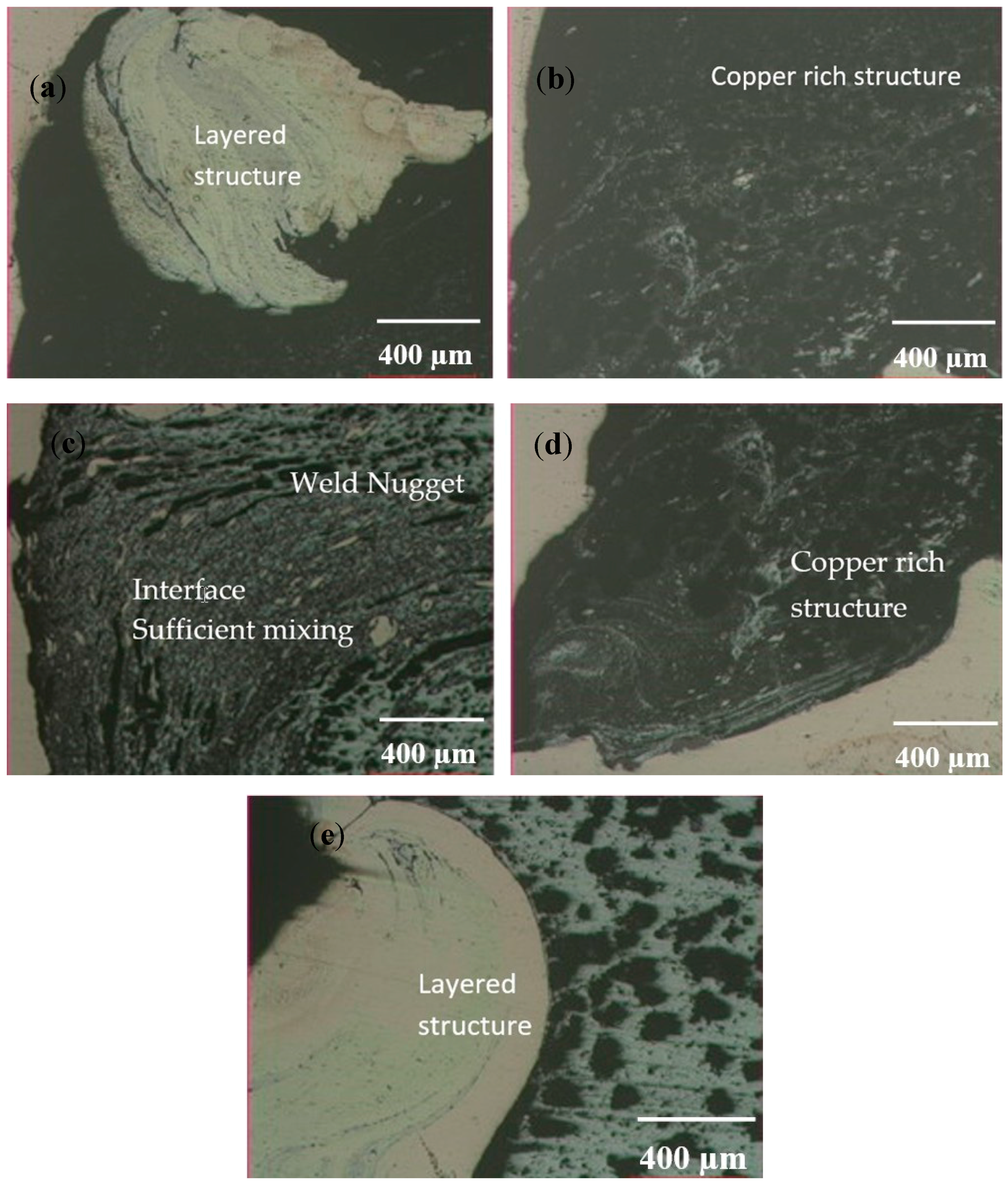

- Due to the Al-Cu layered structure in the weld center and intermetallic phases, a hardness increase in weld zone was observed. This had the effect of mixing particles that break off from the copper in the advancing side being moved into the aluminum matrix in the retreating side. Since the weld zone was formed on the Al side, the Cu bulk in the Al matrix and intermetallic phases increased in hardness. In high tensile strength specimens, the weld zones were observed to be larger.

- Microstructural analysis showed that the blending area happened to be on the Al side since the end of the stir pin was shifted to the Al side in proper values (1, 1.5, 2 mm). Higher strength values were obtained in a homogeneous composite structure.

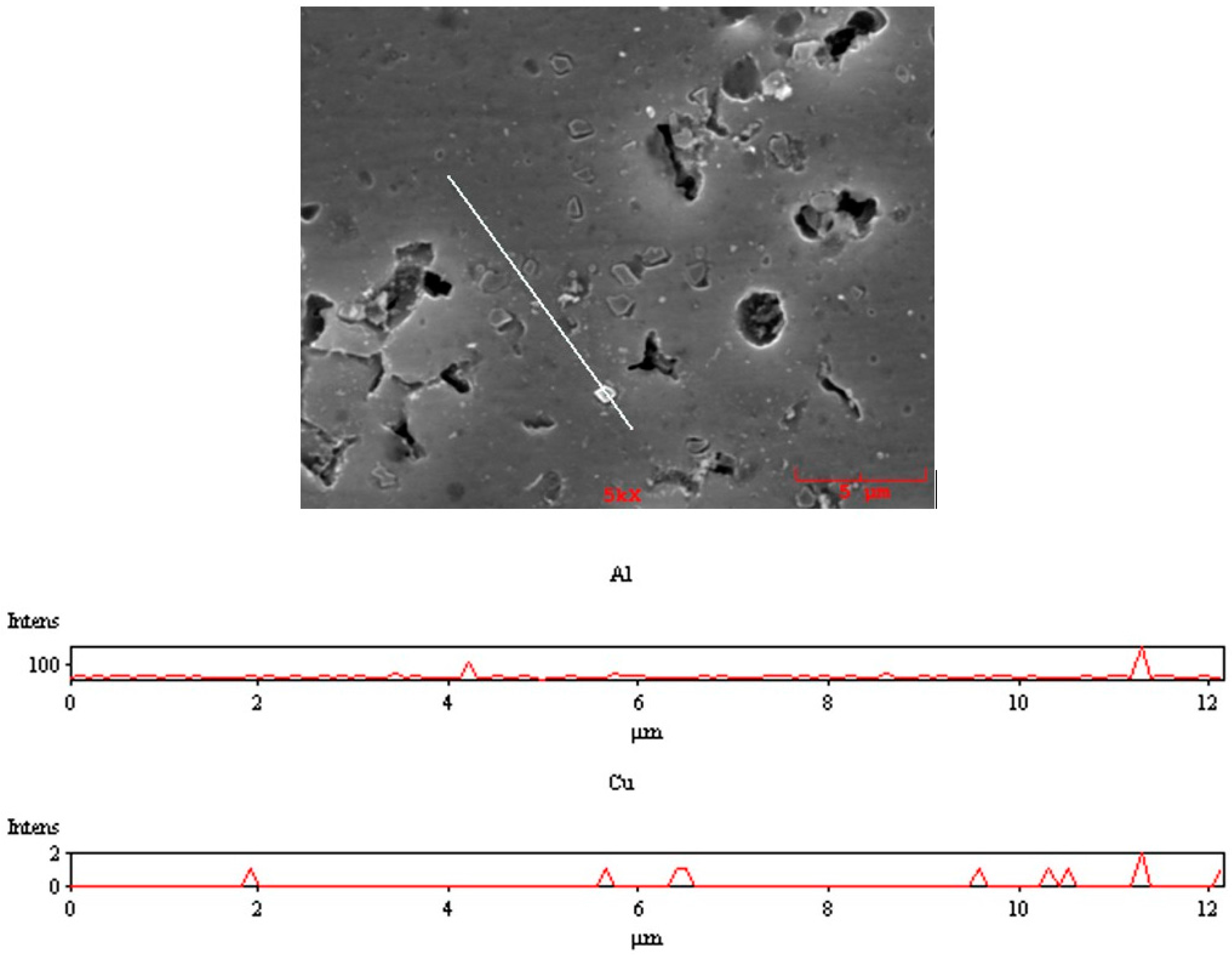

- According to linear and point EDS analysis, Al and Cu were detected on the cross sections and fracture surfaces of joints that were obtained after tensile tests. It was observed that the Cu content in the weld zones was less in specimens with a low tensile strength compared to high tensile strength specimens.

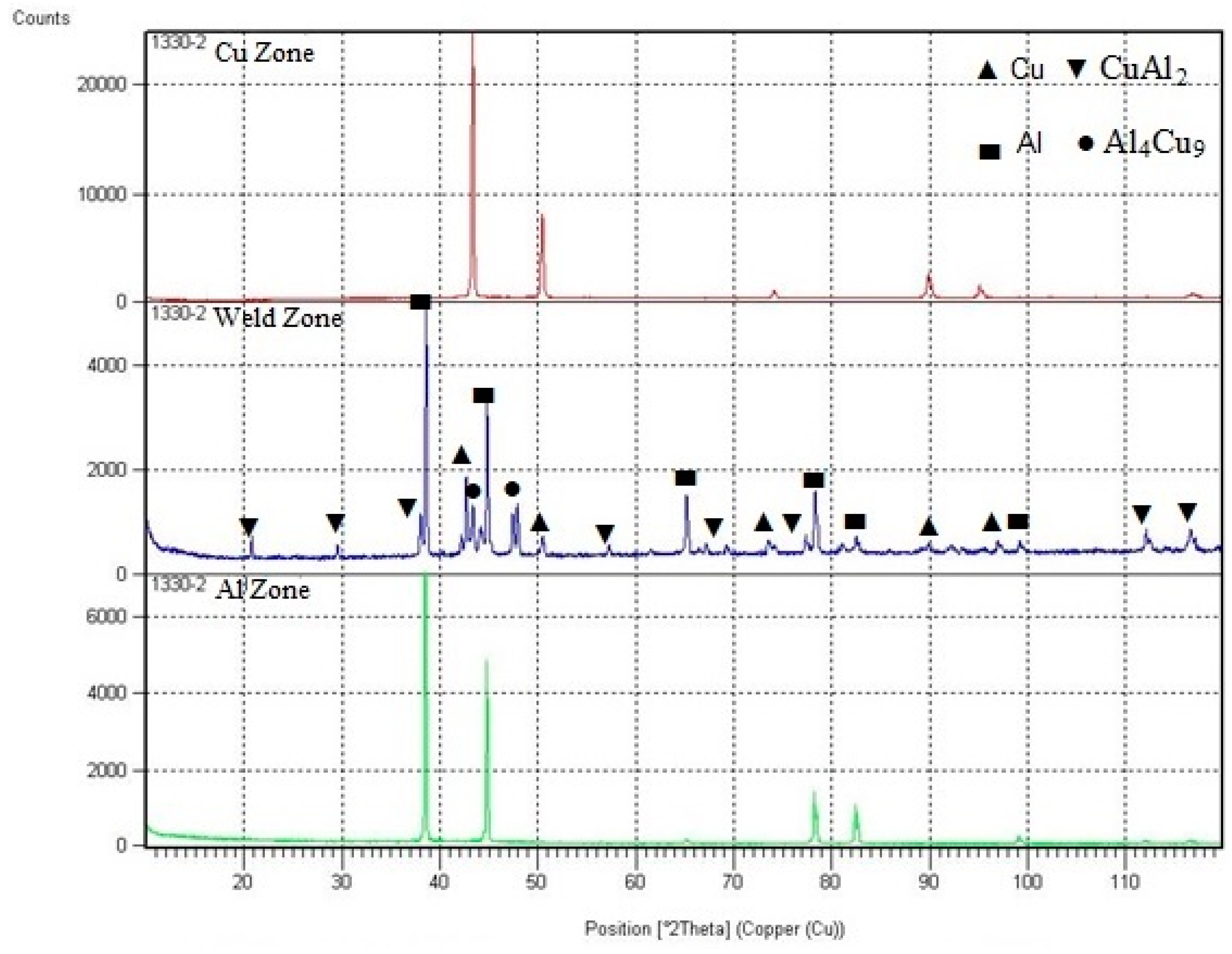

- CuAl2 and Al4Cu9 intermetallic phases were determined in the phase analysis that was performed using X-ray diffraction (XRD). The increase of the intermetallic phase had a lowering effect on the fragility and strength.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| FSW | Friction Stir Welding |

| EDS | Energy Dispersed Spectrometer |

| SEM | Scanning Electron Microscope |

| XRD | X-ray Diffractometer |

| IMCs | Intermetallic Compounds |

| HAZ | Heat Affected Zone |

References

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; TempleSmith, P.; Dawes, C.J. International Patent Application No. PCT/GB92/02203 and GB Patent Application No. 9125978.8, 6 December 1991.

- Lee, W.B.; Jung, S.B. The joint properties of copper by friction stir welding. Mater. Lett. 2004, 58, 1041–1046. [Google Scholar] [CrossRef]

- Jata, K.V.; Semiatin, S.L. Continuous Dynamic Recrystallization during Friction Stir Welding of High Strength Aluminum Alloys. Scr. Mater. 2000, 43, 743–749. [Google Scholar] [CrossRef]

- Hwang, Y.M.; Fan, P.L.; Lin, C.H. Experimental study on Friction Stir Welding of copper metals. J. Mater. Process. Technol. 2010, 210, 1667–1672. [Google Scholar] [CrossRef]

- Muthu, M.F.X.; Jayabalan, V. Tool travel speed effects on the microstructure of friction stir welded aluminum–copper joints. J. Mater. Process. Technol. 2015, 217, 105–113. [Google Scholar] [CrossRef]

- Abdollah-Zadeh, A.; Saeid, T.; Sazgari, B. Microstructural and mechanical properties of friction stir welded aluminum/copper lap joints. J. Alloy. Compd. 2008, 460, 535–538. [Google Scholar] [CrossRef]

- Mubiayi, M.P.; Akinlabi, E.T. Friction Stir Welding of Dissimilar Materials between Aluminium Alloys and Copper—An Overview. In Proceedings of the World Congress on Engineering 2013 Vol III, WCE 2013, London, UK, 3–5 July 2013.

- Galvão, I.; Verdera, D.; Gesto, D.; Loureiro, A.; Rodrigues, D.M. Influence of aluminium alloy type on dissimilar friction stir lap welding of aluminium to copper. J. Mater. Process. Technol. 2013, 213, 1920–1928. [Google Scholar] [CrossRef]

- Saeid, T.; Abdollah-zadeh, A.; Sazgari, B. Weldability and mechanical properties of dissimilar aluminum-copper lap joints made by friction stir welding. J. Alloy. Compd. 2010, 490, 652–655. [Google Scholar] [CrossRef]

- Scialpi, A.; de Filippis, L.A.C.; Cavaliere, P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminium alloy. Mater. Des. 2007, 28, 1124–1129. [Google Scholar] [CrossRef]

- Barlas, Z.; Uzun, H. Sürtünme karıştırma kaynağı yapılmış Cu/Al-1050 alın birleştirmesinin mikroyapı ve mekanik özelliklerinin incelenmesi. Gazi Üniversity Mühendislik Mimarlik Fakkülltes Dergisi 2010, 25, 857–865. [Google Scholar]

- Xue, P.; Xiao, B.L.; Wang, D.; Ma, Z.Y. Achieving high property friction stir welded aluminium/copper lap joint at low heat input. Sci. Technol. Weld. Join. 2011, 16. [Google Scholar] [CrossRef]

- Xue, P.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al-Cu joints. Mater. Sci. Eng. A 2011, 528, 4683–4689. [Google Scholar] [CrossRef]

- Ouyang, J.; Yarrapareddy, E.; Kovacevic, R. Microstructural evolution in the friction stir welded 6061 aluminum alloy (T6-temper condition) to copper. J. Mater. Process. Technol. 2006, 172, 110–122. [Google Scholar] [CrossRef]

- Liu, P.; Shi, Q.; Wang, W.; Wang, X.; Zhang, Z. Microstructure and XRD analysis of FSW joints for copper T2/aluminium 5A06 dissimilar materials. Mater. Lett. 2008, 62, 4106–4108. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. Enhanced mechanical properties of friction stir welded dissimilar Al-Cu joint by intermetallic compounds. Mater. Sci. Eng. A 2010, 527, 5723–5727. [Google Scholar] [CrossRef]

- Genevois, C.; Girard, M.; Huneau, B.; Sauvage, X.; Racineux, G. Interfacial Reaction during Friction Stir Welding of Al and Cu. Miner. Met. Mater. Soc. ASM Int. 2011, 42. [Google Scholar] [CrossRef]

- Leitão, C.; Loureiro, A.; Rodrigues, D.M. Influence of Base Material Properties and Process Parameters on Defect Formation during FSW. In Proceedings of the International Congress on Advances in Welding Science and Technology for Construction, Energy & Transportation Systems, Antalya, Turkey, 24–25 October 2011; pp. 177–184.

- Venkateswaran, P.; Reynolds, A.P. Factors affecting the properties of frictionstir welds between aluminum and magnesium alloys. Mater. Sci. Eng. A 2012, 545, 26–37. [Google Scholar] [CrossRef]

- Çelik, S. An Investigation of Diffusion Welding Parameters for Pure Aluminum and Copper in Inert Gas. Ph.D. Thesis, Balikesir University, Balikesir, Turkey, 1996. [Google Scholar]

- Kim, H.G.; Kim, S.M.; Lee, J.Y.; Choi, M.R.; Choe, S.C.; Kim, K.H.; Ryu, J.S.; Kim, S.; Han, S.Z.; Kim, W.Y.; et al. Microstructural evaluation of interfacial intermetallic compounds in Cu wire bonding with Al and Au pads. Acta Mater. 2014, 64, 356–366. [Google Scholar] [CrossRef]

| Properties | Aluminum (Al) | Copper (Cu) |

|---|---|---|

| Tensile Strength (MPa) | 111.20 | 231.38 |

| Elongation (%) | 14.98 | 41.03 |

| Hardness (HV) | 41 | 88 |

| Tool Rotational Speed (rpm) | Tool Traverse Speed (mm/min) | Tool Positioning (to the Al Side (mm)) |

|---|---|---|

| 630–1330–2440 | 20 | 1 |

| 1.5 | ||

| 2 | ||

| 30 | 1 | |

| 1.5 | ||

| 2 | ||

| 50 | 1 | |

| 1.5 | ||

| 2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Celik, S.; Cakir, R. Effect of Friction Stir Welding Parameters on the Mechanical and Microstructure Properties of the Al-Cu Butt Joint. Metals 2016, 6, 133. https://doi.org/10.3390/met6060133

Celik S, Cakir R. Effect of Friction Stir Welding Parameters on the Mechanical and Microstructure Properties of the Al-Cu Butt Joint. Metals. 2016; 6(6):133. https://doi.org/10.3390/met6060133

Chicago/Turabian StyleCelik, Sare, and Recep Cakir. 2016. "Effect of Friction Stir Welding Parameters on the Mechanical and Microstructure Properties of the Al-Cu Butt Joint" Metals 6, no. 6: 133. https://doi.org/10.3390/met6060133

APA StyleCelik, S., & Cakir, R. (2016). Effect of Friction Stir Welding Parameters on the Mechanical and Microstructure Properties of the Al-Cu Butt Joint. Metals, 6(6), 133. https://doi.org/10.3390/met6060133