1. Introduction

The PIM (powder injection molding) process is somewhat similar to plastic injection molding. It combines the well-known polymer injection molding and powder metallurgy techniques. It consists of the following stages: feedstock preparation, injection molding, debinding of the green parts, and sintering of the brown parts [

1]. The PIM process is stated in

Figure 1.

With the development of injection molding techniques, the shape of the parts is increasingly complex [

3]. Due to the constraints in physical experiments and the availability of measurements for micro-scale factors, the accurate numerical simulation becomes more and more important in designing and manufacturing [

4]. Some studies on 3D simulation of the polymer injection molding can also be retrieved in recent years [

5,

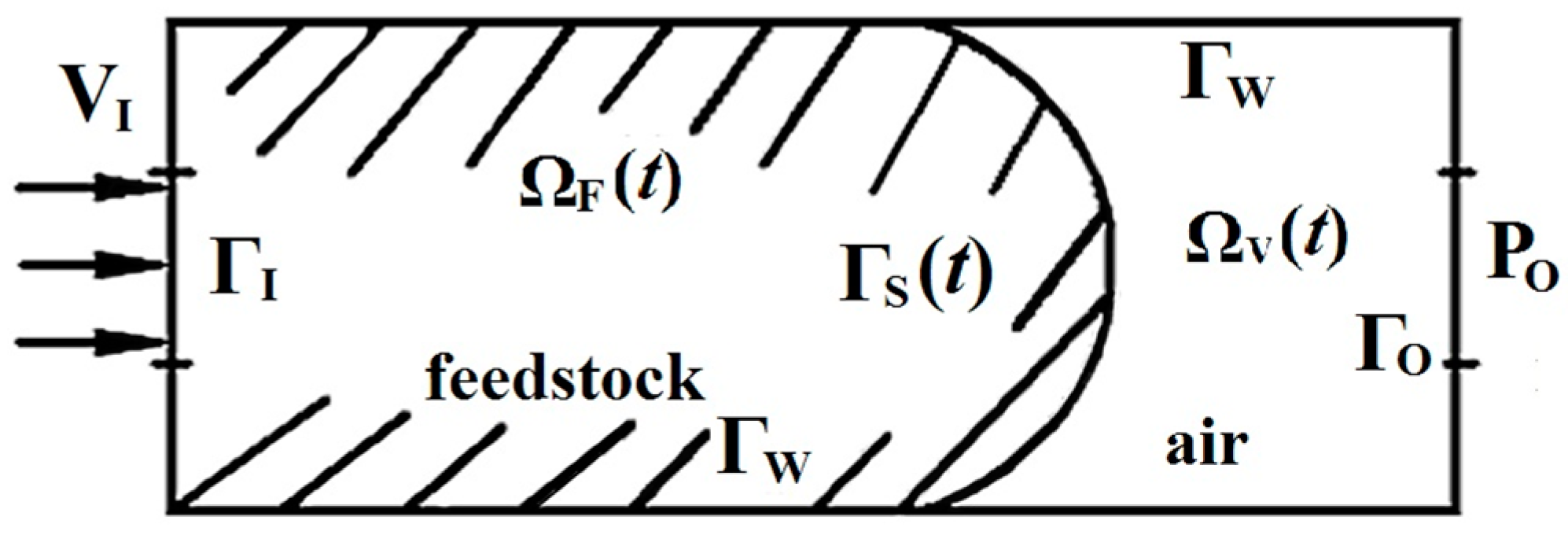

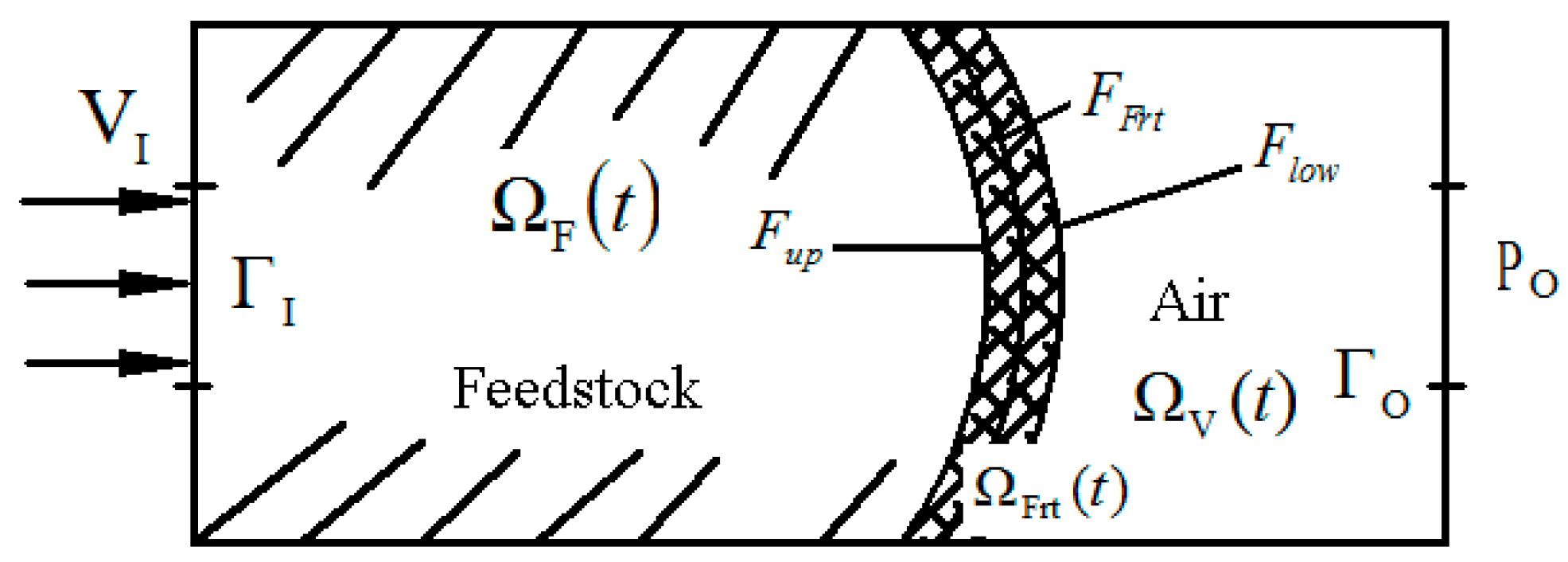

6]. In general, Eulerian description is used for simulation of the filling flow problems [

7,

8]. The mold cavity is assumed occupied by two different flow substances, viscous feedstock in the filled portion and air in the remained void part. A filling state variable

F(

x,t) is used to describe the evolution of the filling process. The evolution of the filling state is governed by the velocity field in the whole mold cavity. In most cases, the filling flow direction does not change dramatically. The velocity field in the void portion closest to the filling front is similar to that of the feedstock behind the filling front. So, according to the traditional mechanical model of the injection filling process, it will often result in a good and real simulation. However for some cases, it is observed that the filling patterns predicted by simulation are not the realistic ones, especially when the phenomena of opposite joining and bypass are involved, such as channels in shapes like

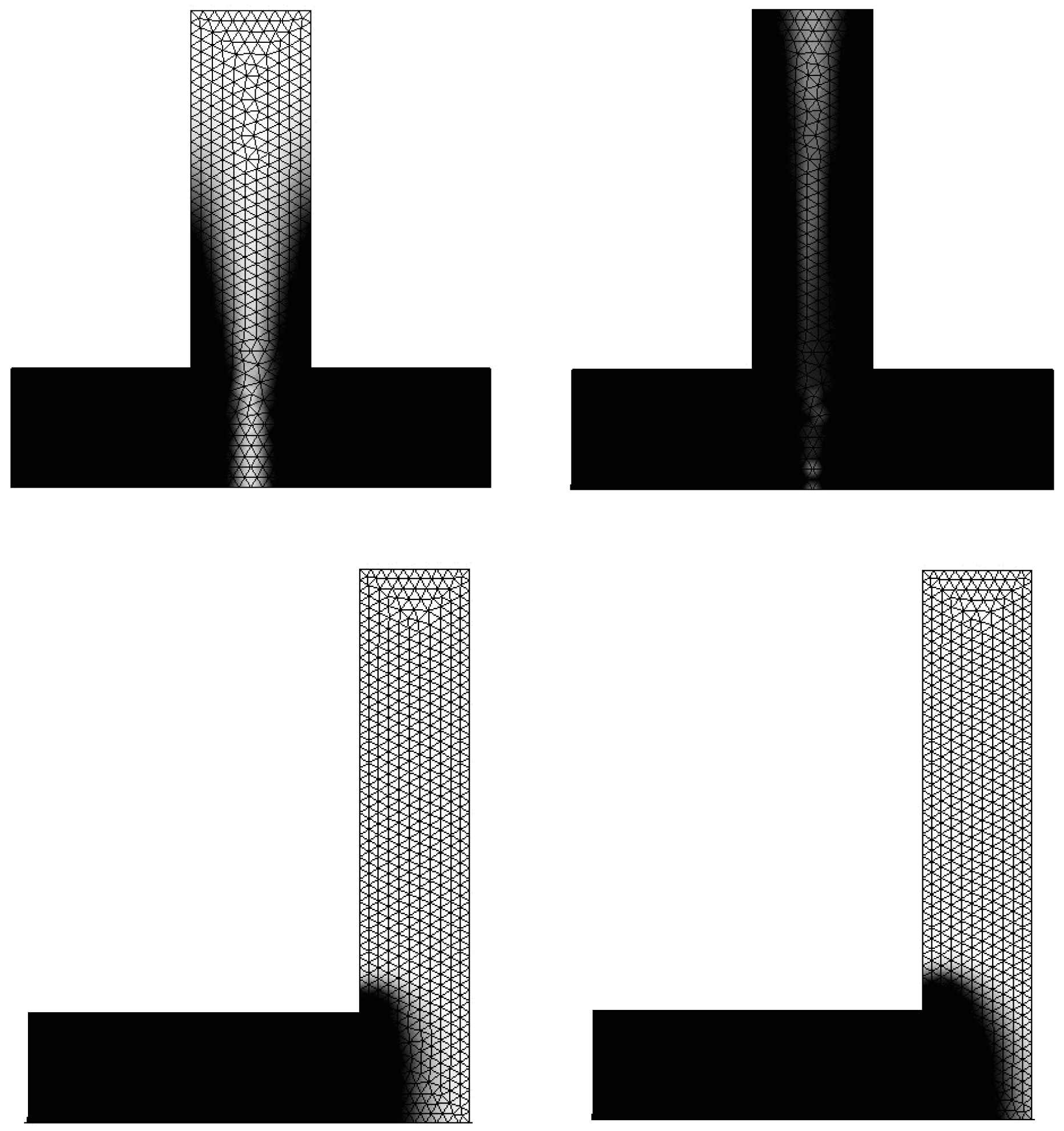

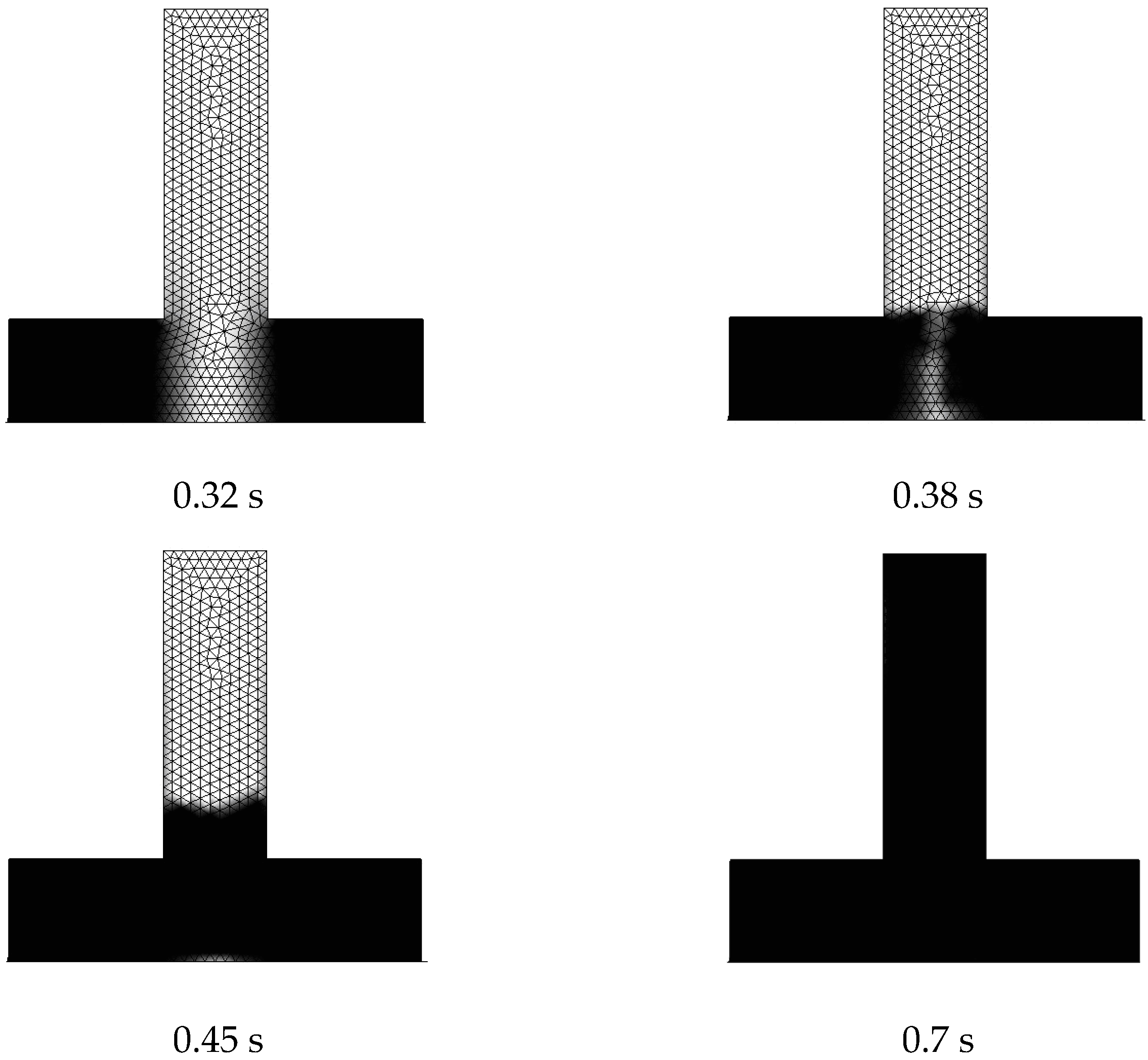

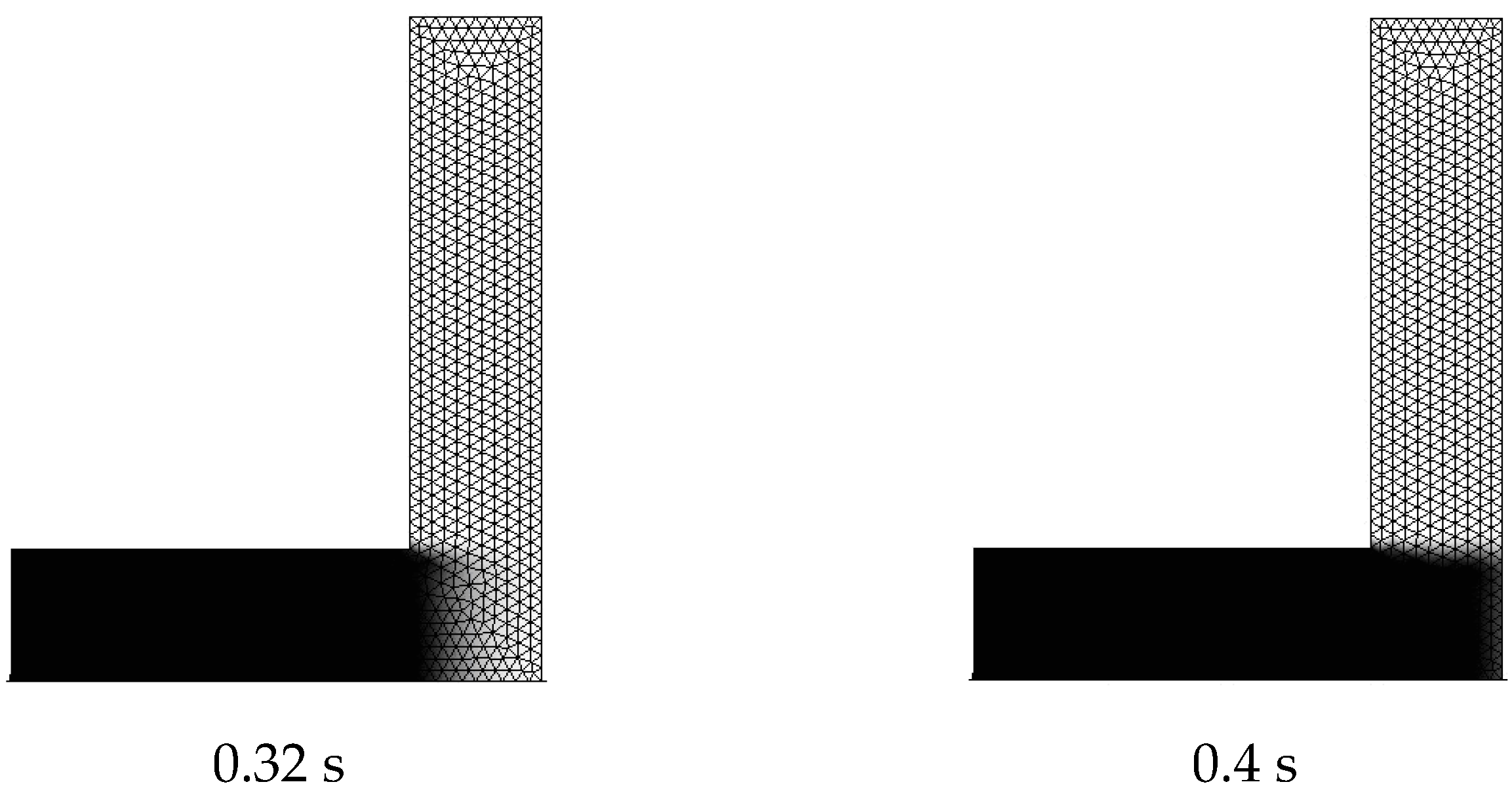

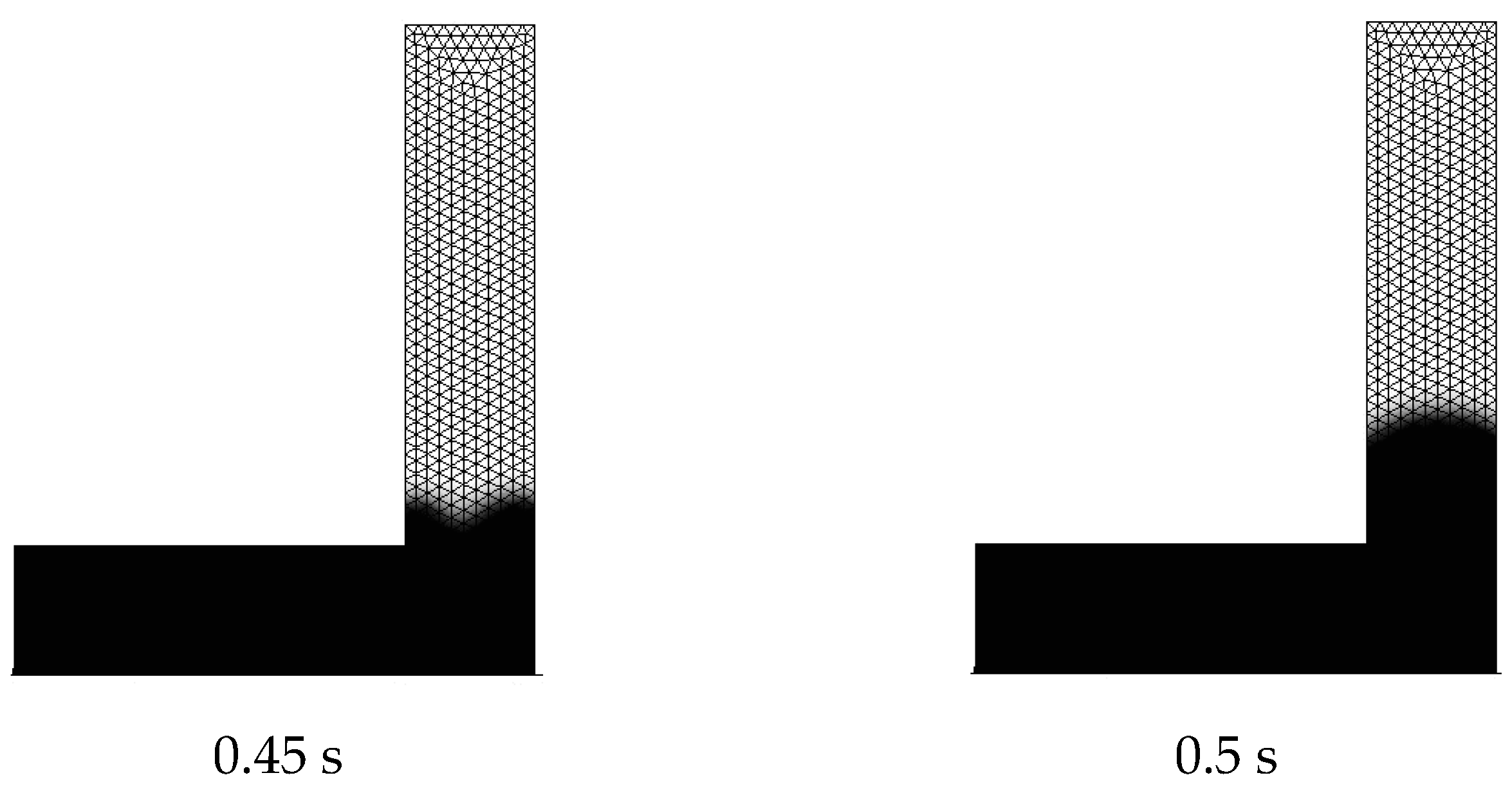

and L. The flow directions will be subject to the sudden changes when filling in these channels. Then, the untrue results may be produced, as shown in

Figure 2.

For the case of channel in shape

, the feedstock is injected from two inlets on opposite sides of the cavity. The same injected velocity was loaded in both inlets. The two different filling fronts with the same speed should independently progress in the mold cavities, and then meet to each other to reach a common outlet. However, in

Figure 2, it is observed that the filling fronts arrive at bypass before merging together at the middle of bottom area in

cavity. There exists an air gap between the two evolving fluid fronts that is not completely filled at the end of the simulation. For the case of channel in shape L, after the feedstock is horizontally injected into the mold cavity, it should arrive mainly at the right-hand side wall first, and then be extruded into the vertical part of the cavity. However, the same untrue phenomenon happens.

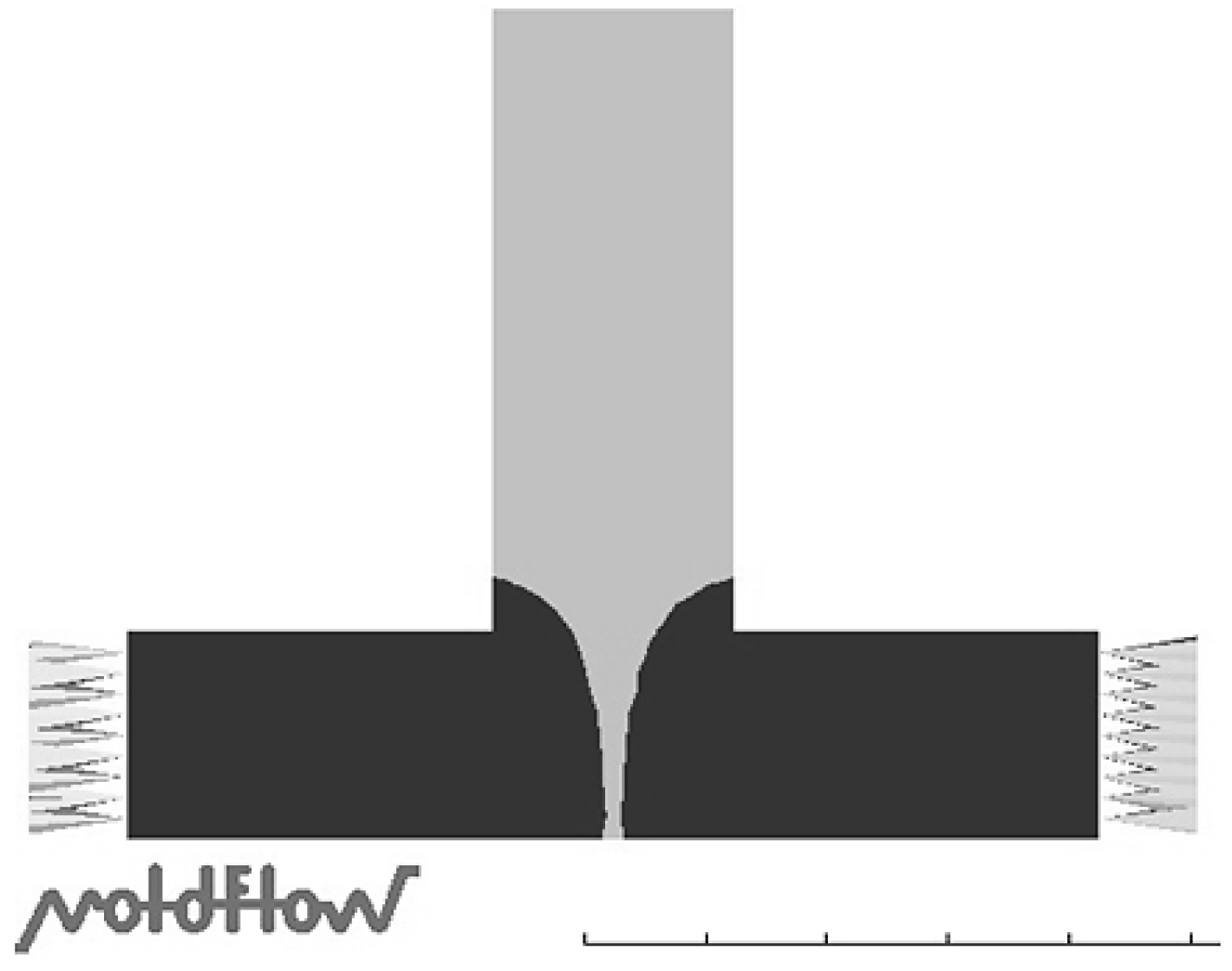

As another example, the simulation result made by commercial software MoldFlow® (Moldflow Corporation, Wayland, MA, USA) is introduced, as shown in

Figure 3. It can be found that in the filling of a typical channel in shape

, the filling fronts from two opposite inlets arrived at the middle bypass before they joined together. Evidently this result does not match the real physical phenomenon. Although the software uses some strategy to modify this problem in post-processing steps, the filling patterns are not yet the true ones for the two opposite filling fronts to join together.

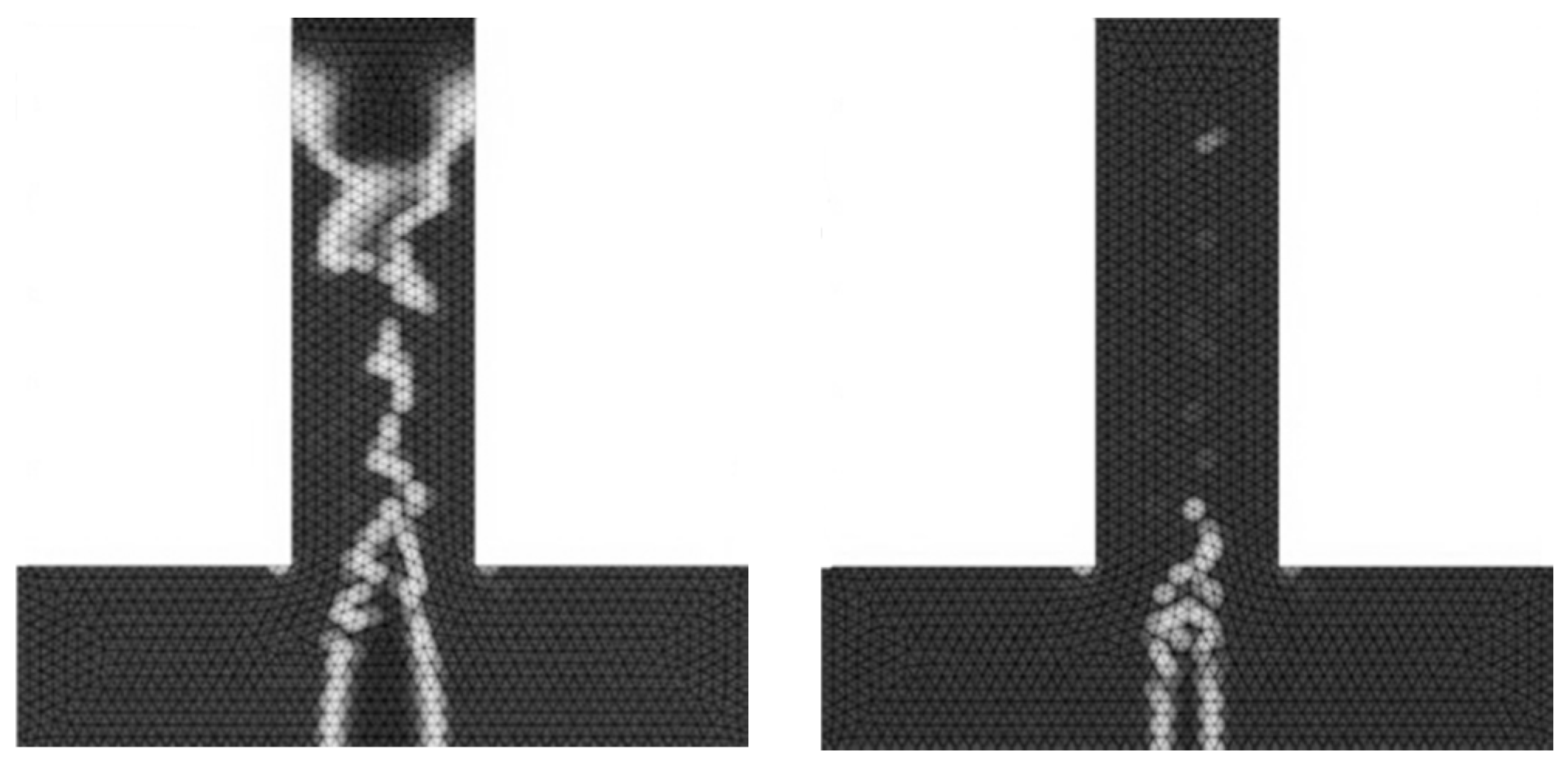

G. Larsen

et al. [

9] used the Streamline Upwind Petrov-Galerkin method (SUPG) to improve this filling problem, and confirmed that the simulation results are closer to the real situation than the ones by the Taylor-Galerkin method, which used previously by Barriere [

10] and Cheng [

11]. However, the real pattern of front joining in injection molding had not been exactly predicted, as shown in

Figure 4.

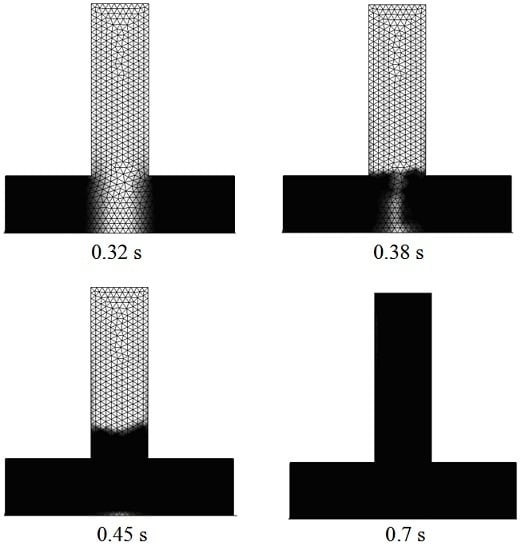

The objective of the present study is to analyze the source for the untrue simulation results and find an effective way to settle the problem. A modified algorithm, which is similar to the upwind method [

12,

13], is proposed to trace the filling front. This proposed method makes the advection of the filling state to be mainly affected by the filling flow behind the filling front. Based on the finite element method and the efficient vectorial explicit algorithm developed by Cheng

et al. [

14], a systematic operation was proposed for modifying the velocity field ahead of the filling front, making the advance pattern of the flow front to be guided more on the flow of the feedstock instead of the fictive air flow. The simulation results in shapes like

and L show that the proposed algorithm can effectively improve the untrue filling patterns in simulation.

4. Modification of the Solution Procedure

Based on the mechanical model and the notion of upwind method to strengthen the influences of the feedstock flow located behind the filling front, a notion similar to upwind method was introduced. A corresponding correction method was proposed to settle the distortion of filling front mentioned above. A feasible way to make the filling pattern more realistic is to modify the velocity field near the filling front. The advance of the filling front can be made to follow the guidance of the feedstock flow behind it, if the velocity just before the front is set to be similar to that behind the front. By means of a systematic operation to modify the velocity field for the filling simulation, the untrue impact of air flow, represented by the velocity field ahead of the filling fronts, can be reduced. To implement such method, there exist two key issues to be solved:

Firstly, how can we determine the band to be modified, ahead of the filling front?

The selection can be made by the unit of element, judging, and selecting element by element. In fact, according to the definition of field variable

F(

x,

t), it takes the value

F = 0 to indicate the void portion while

F = 1 represents the filled one inside the mold cavity. Then the nodes located in the band close to filling front should represent the values between 0 and 1, note that

FFrt, 0 <

FFrt < 1. One can prescribe two values

Flow and

Fup to define the range of band before the front.

By example, for the 2D triangle elements with three nodes, an element can be regarded in the band if there exists at least one node for its F value to locate between

Flow and

Fup. Let Ω

Frt represent the band region (neighbor to the filling front). Assuming e being any one element in the model,

i is the node number belong to this element:

as shown by the grey area in

Figure 6.

Secondly, how do we modify the velocity field for computation of the filling state?

It is evident that the modified velocity fields are used only for the solution of the filling states. The modified velocity fields should be smooth and continuous ones. Otherwise, the solution of the advection equation will become unstable and produce spurious results.

A general smoothed procedure is proposed as follows:

where {

V}

F is the velocity field, expressed in a discretized way at each node, for the solution of the filling state. Note that it is a modified and smoothed one to make the simulation of the front progress more realistic. {

Ve}

F represents the column of velocity values at all nodes of an element. It initially takes the velocity values obtained by the solution of the Stokes equations, but these values are modified when the elements locate in the band ahead of the filling front. First, one node with a maximal F value will be determined as the upwind node, then the velocity value of the rest of the nodes in the same element will be replaced by the velocity value of the upwind node.

For an element in the band, element number e, and the node number i:

where

k is the upwind-stream node number, indicating that the node is of a maximum

F value (

Fi)max in the element.

By this treatment to the velocity values of the elements located in the band, the velocity in thin layer elements ahead of the filling front is modified to be the values of elements behind. This operation reinforces the effect of the feedstock behind the flow front, while reducing the unrealistic guidance of the air flow. It represents more the real physical phenomenon, and it is more consistent with the true flow process.

For the details of different operators, let us take the triangle element of three nodes as a simpler example. These types of elements include three linear interpolation functions N1, N2, N3.

The values of

V at element level {

Ve} take the following form:

The matrix of the interpolation function [

Ñ] for velocity should be arranged in the corresponding form as:

Acknowledgments

This work is financially supported by the National Natural Science Foundation of China (Grant No. 11502219) and Doctoral Research Foundation of Southwest University of Science and Technology (Grant No. 14zx7139). The authors also wish to thank Femto-ST Institute on experiment and simulation support.

Author Contributions

All authors conceived, designed the study. Baosheng Liu and Jianjun Shi proposed the new modified algorithm. Thierry Barriere and Zhiqiang Cheng provide the efficient vectorial explicit finite element solver. Jianjun Shi performed and provided the modified simulation results. Jianjun Shi wrote the paper. All authors reviewed, edited, read and approved the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Abdullahi, A.A.; Choudhury, I.A.; Azuddin, M. Process Development and Product Quality of Micro-Metal Powder Injection Molding. Mater. Manuf. Process. 2015, 30, 1377–1390. [Google Scholar] [CrossRef]

- Sahli, M.; Millot, C.; Gelin, J.C.; Barriere, T. The manufacturing and replication of microfluidic mould inserts by the hot embossing process. J. Mater. Process. Technol. 2013, 213, 913–925. [Google Scholar] [CrossRef]

- Piotter, V.; Hanemann, T.; Heldele, R.; Mueller, M.; Mueller, T.; Plewa, K.; Ruh, A. Metal and ceramic parts fabricated by microminiature powder injection molding. Int. J. Powder Metall. 2010, 46, 21–28. [Google Scholar]

- Greiner, A.; Kauzlaric, D.; Korvink, J.G. Simulation of micro powder injection moulding: Powder segregation and yield stress effects during form filling. J. Eur. Ceram. Soc. 2011, 31, 2525–2534. [Google Scholar] [CrossRef]

- Liu, Q.S.; Jie, O.Y.; Liu, Z.J.; Li, W.M. Visualization and simulation of filling process of simultaneous co-injection molding based on level set method. J. Polym. Eng. 2015, 35, 813–827. [Google Scholar] [CrossRef]

- Hu, Z.X.; Zhang, Y.; Liang, J.J.; Shi, S.X.; Zhou, H.M. An efficient parallel algebraic multigrid method for 3D injection moulding simulation based on finite volume method. Int. J. Comput. Fluid Dyn. 2014, 28, 316–328. [Google Scholar] [CrossRef]

- Rokkam, R.G.; Fox, R.O.; Muhle, M.E. Computational fluid dynamics and electrostatic modeling of polymerization fluidized-bed reactors. Powder Technol. 2010, 203, 109–124. [Google Scholar] [CrossRef]

- Du, J.; Chong, X.Y.; Jiang, Y.H.; Feng, J. Numerical simulation of mold filling process for high chromium cast iron matrix composite reinforced by ZTA ceramic particles. Int. J. Heat Mass Transf. 2015, 89, 872–883. [Google Scholar] [CrossRef]

- Larsen, G.; Cheng, Z.Q.; Barriere, T.; Liu, B.S. A streamline-upwind model for filling front advection in powder injection moulding. In Proceedings of the 10th International Conference on Numerical Methods in Industrial Forming Processes Dedicated to Pro, Pohang, Korea, 13 June 2010; pp. 545–552.

- Barriere, T. Expérimentations, Modélisation et Simulation Numérique du Moulage par Injection de Poudres Métalliques. Ph.D. Thesis, Université de Franche-Comté, Besancon, France, December 2000. [Google Scholar]

- Cheng, Z.Q. Numerical Simulation on Metal Injection Moulding. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, December 2005. [Google Scholar]

- Burman, E. A monotonicity preserving, nonlinear, finite element upwind method for the transport equation. Appl. Math. Lett. 2015, 49, 141–146. [Google Scholar] [CrossRef]

- Kao, N.S.C.; Sheu, T.W.H.; Tsai, S.F. On a Wavenumber Optimized Streamline Upwinding Method for Solving Steady Incompressible Navier-Stokes Equations. Numer. Heat Transf. Part B Fundam. 2015, 67, 75–99. [Google Scholar] [CrossRef]

- Cheng, Z.Q.; Barriere, T.; Liu, B.S.; Gelin, J.C. A new explicit simulation for injection molding and its validation. Polym. Eng. Sci. 2009, 49, 1243–1252. [Google Scholar] [CrossRef]

- Abdullah, S.; Li, Y.; Aftab, K. Upwind compact finite difference scheme for time-accurate solution of the incompressible Navier–Stokes equations. Appl. Math. Comput. 2010, 215, 3201–3213. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).