Fatigue Behavior of an Ultrafine-Grained Al-Mg-Si Alloy Processed by High-Pressure Torsion

Abstract

:1. Introduction

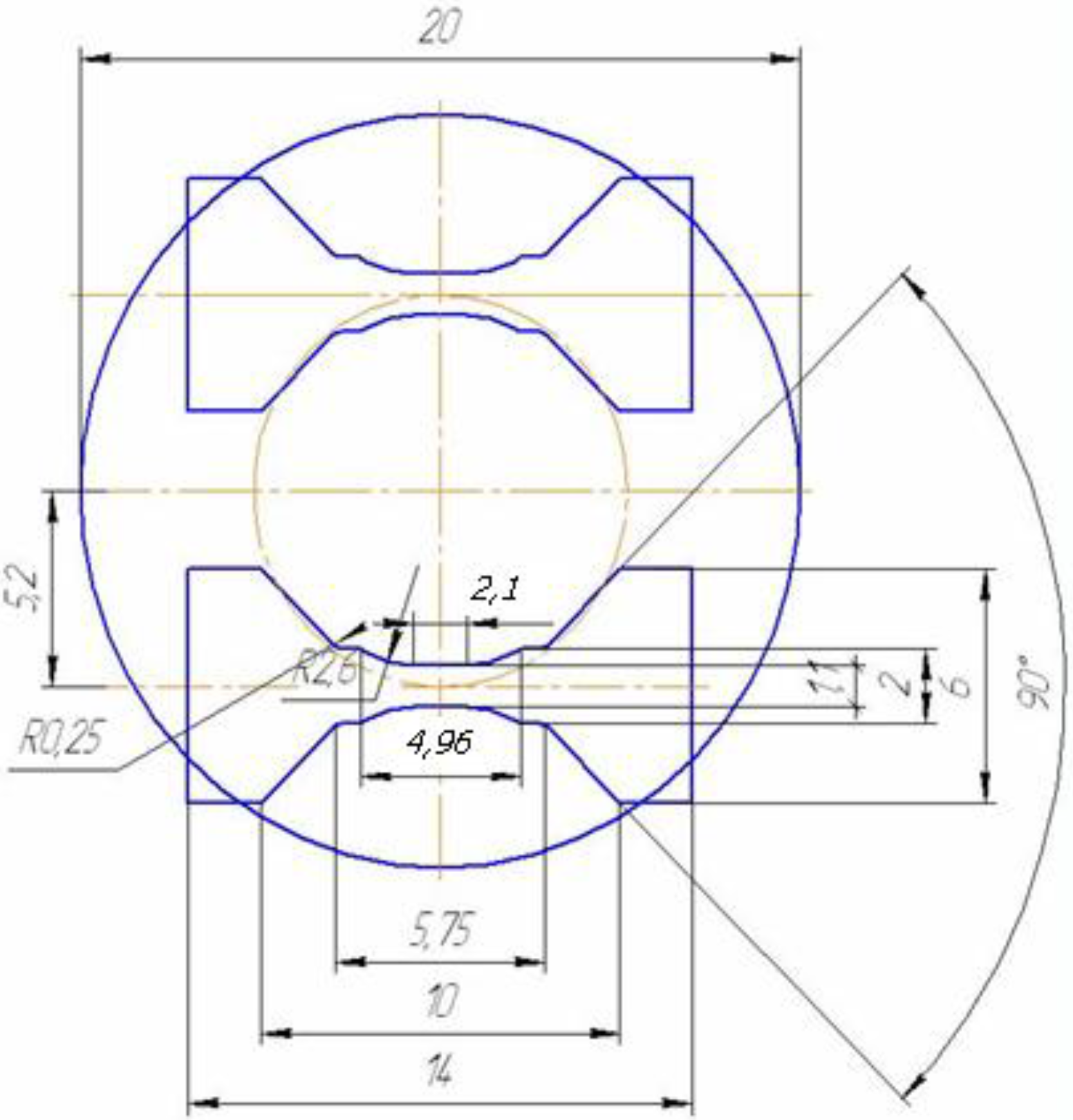

2. Experimental Section

3. Results and Discussion

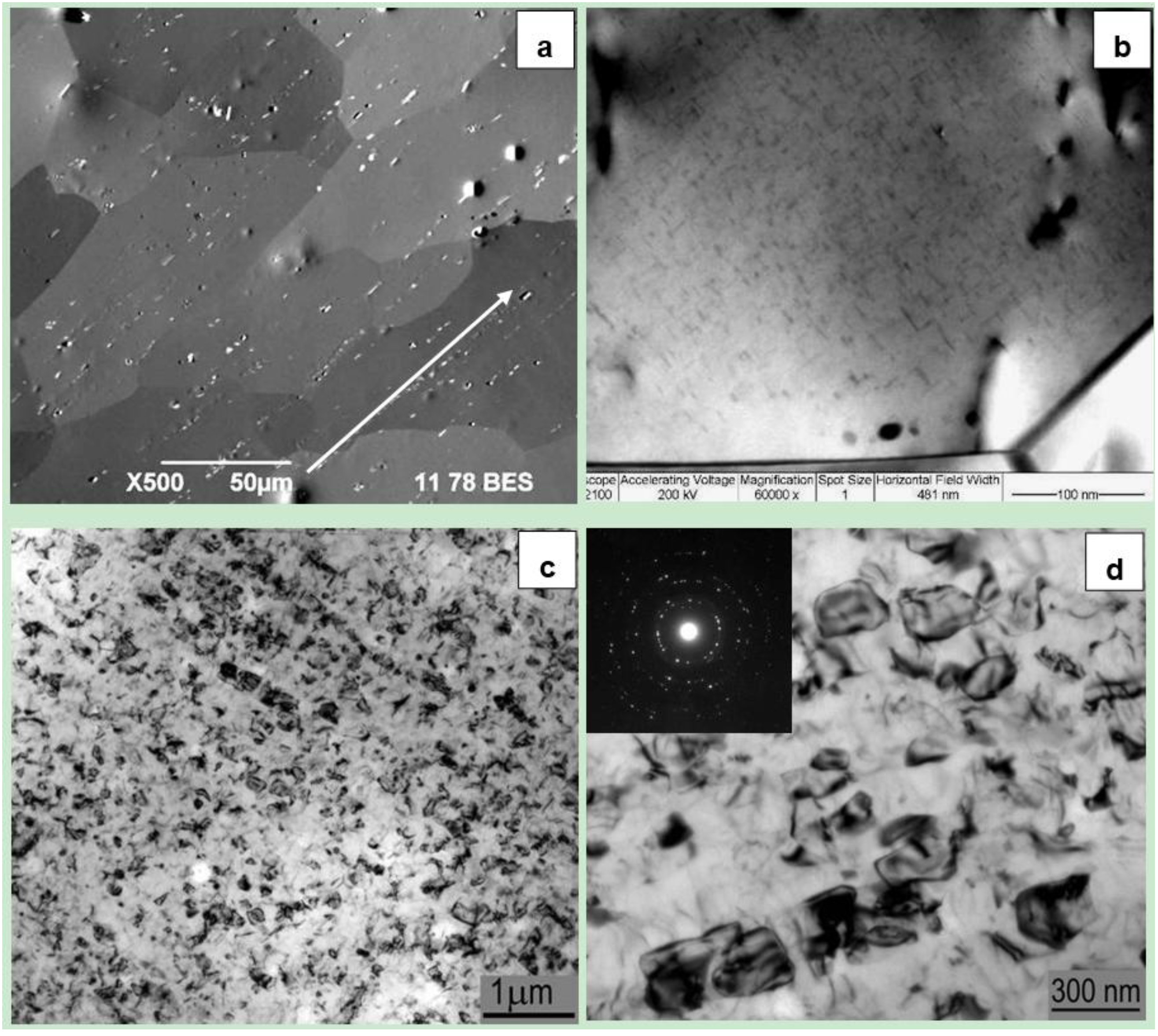

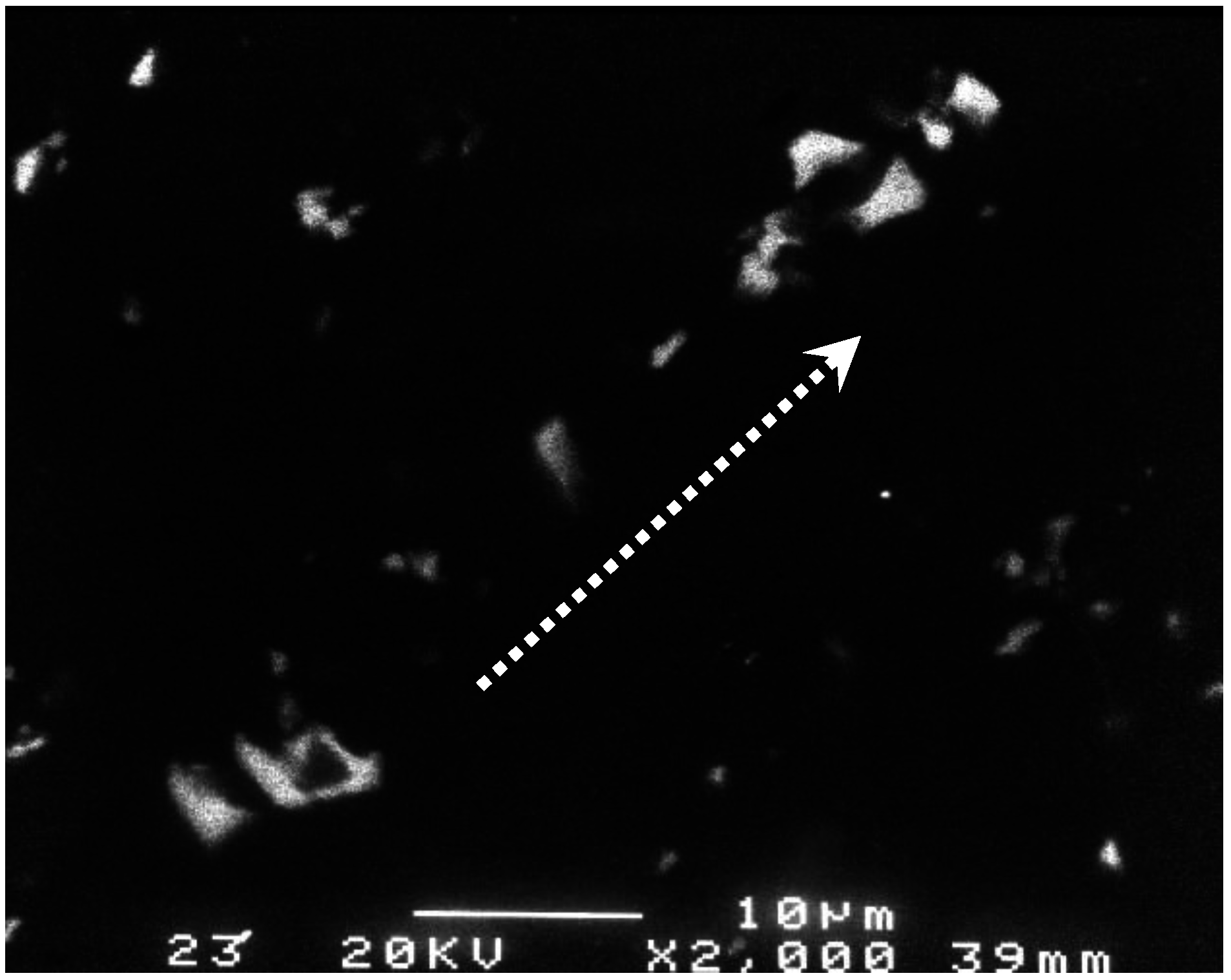

3.1. Effect of HPT Processing on Microstructure of the Al 6061 Alloy

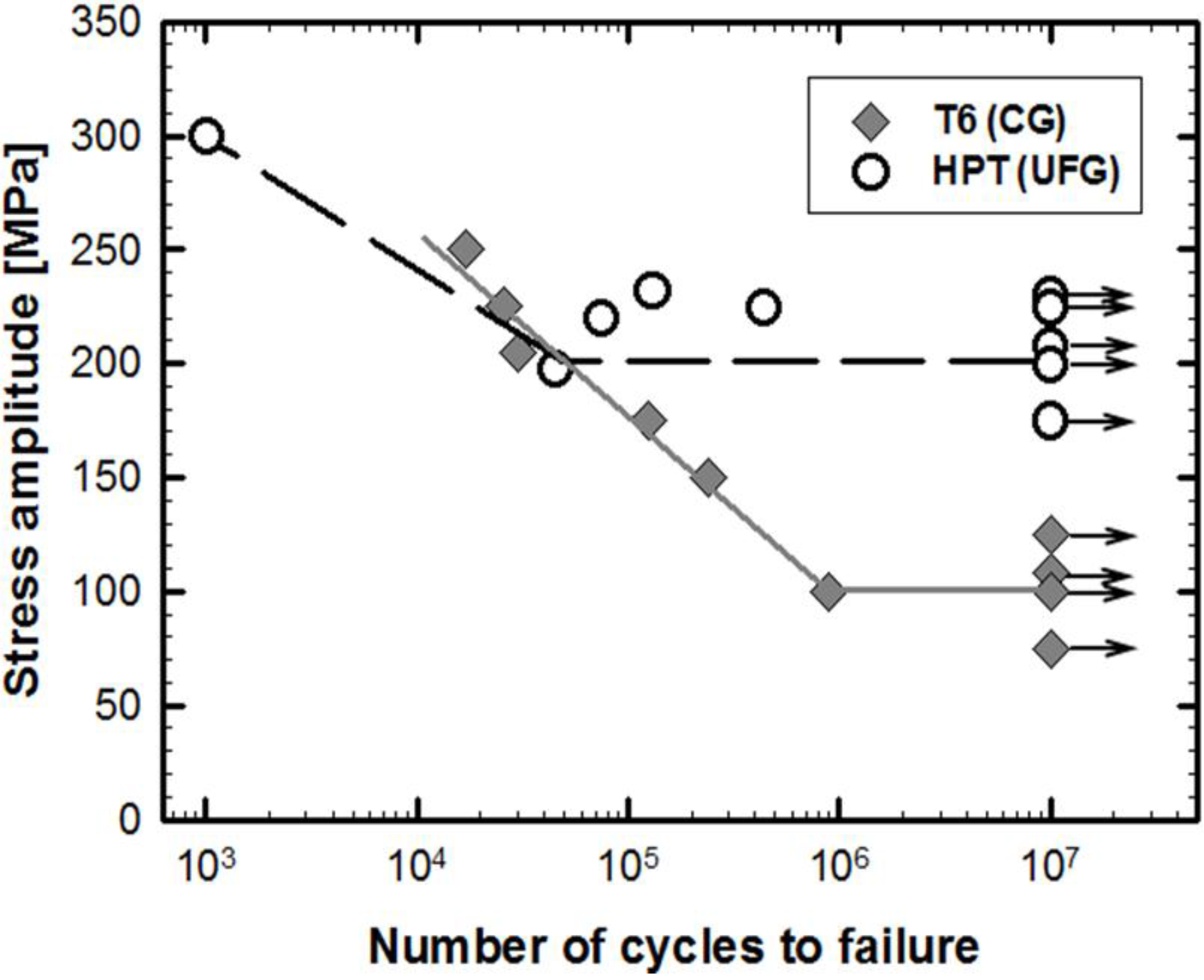

3.2. Effect of HPT Processing on Tensile and Fatigue Behavior of the Al 6061 Alloy

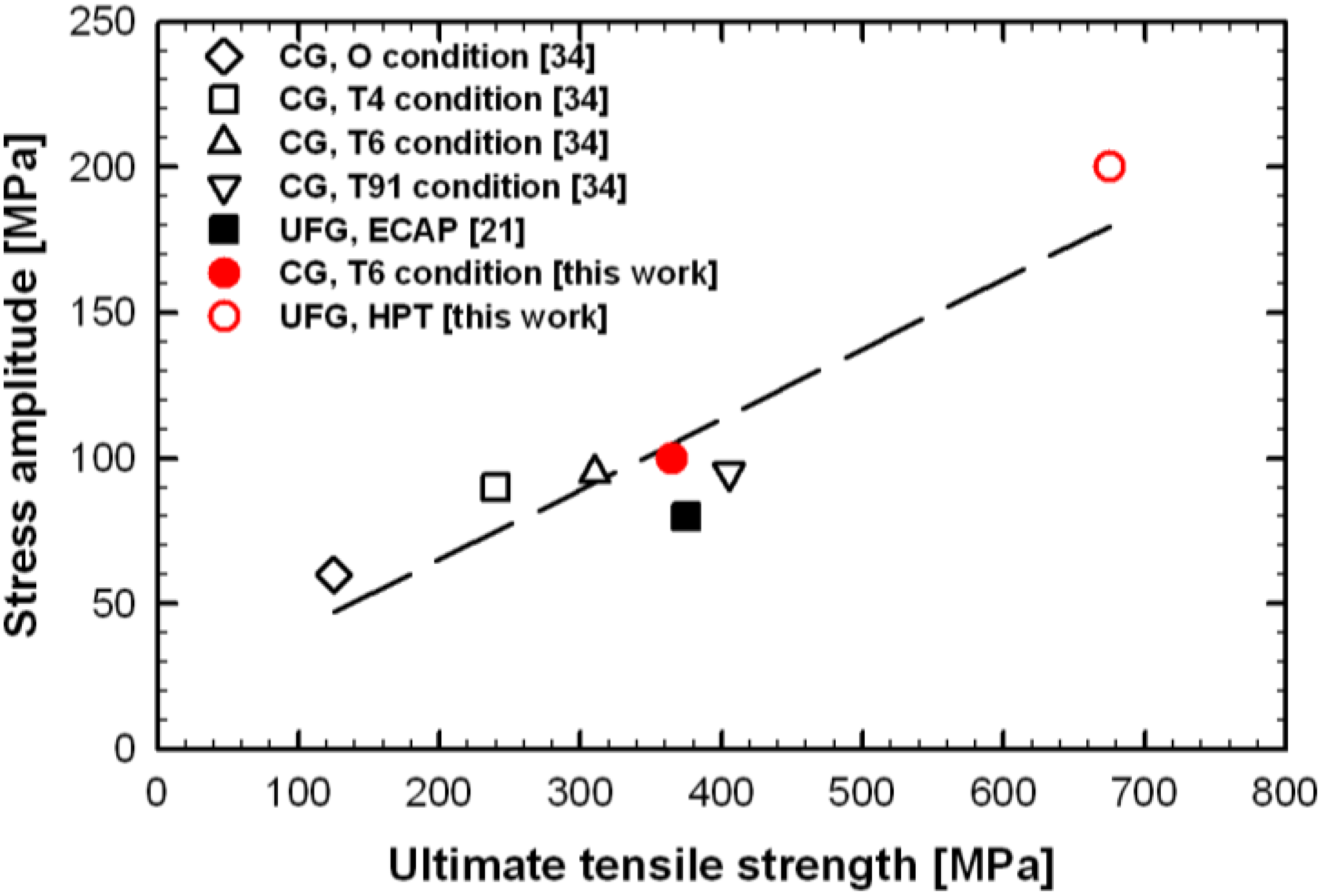

| Processing | State | σ0.2 (MPa) | σUTS (MPa) | δ (%) | σf (MPa) | σf/σUTS | Reference |

|---|---|---|---|---|---|---|---|

| T6 | CG | 276 | 365 | 14 | 100 | 0.27 | present work |

| HPT for 10 turns at RT | UFG | 605 | 675 | 5.5 | 200 | 0.30 | |

| Т6 | CG | 275 | 310 | 12 | 97 | 0.31 | [34] |

| ECAP at 125 °C for 1 pass | UFG | 310 | 375 | 20 | 80 | 0.21 | [21] |

| ECAP at 100 °C, 4 passes | UFG | 386 | 434 | 11 | - | - | [33] |

| ECAP + AA (130 °C for 24 h) | UFG | 434 | 470 | 10 | - | - | |

| ECAP + CR (15%) | UFG | 470 | 500 | 8 | - | - |

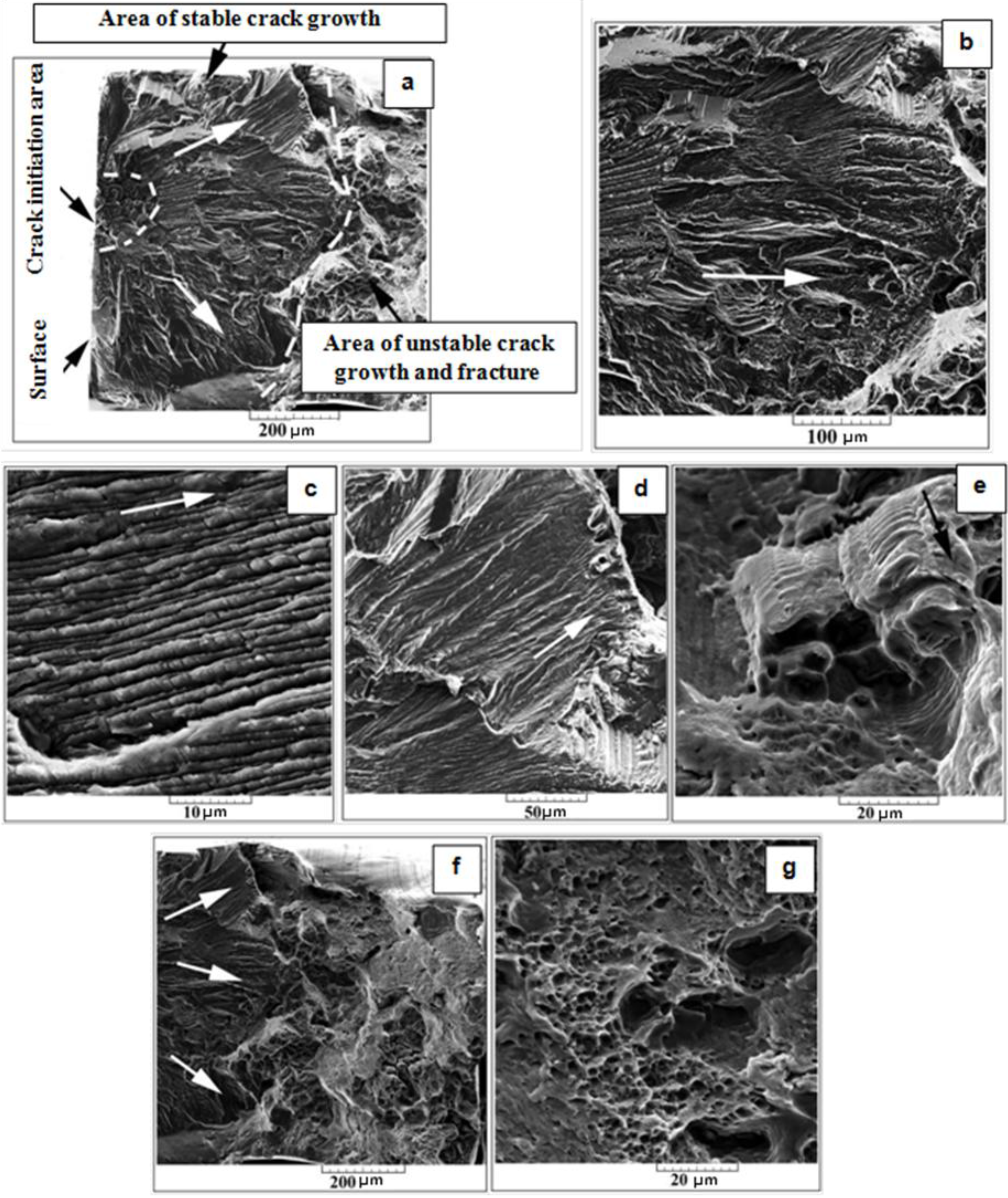

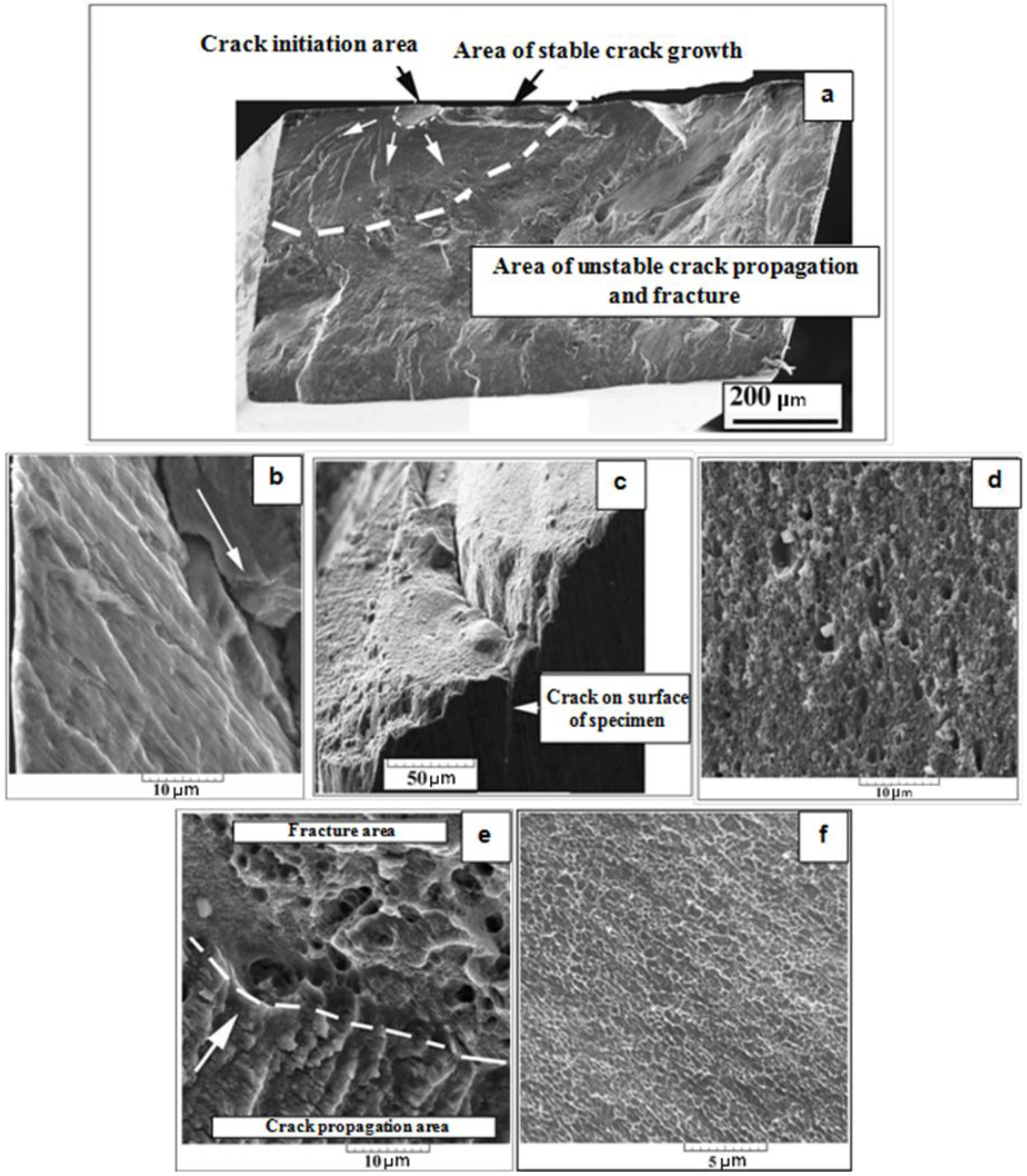

3.3. Analysis of Fatigue Fracture Surfaces

4. Conclusions

- High-pressure torsion (HPT) of the Al 6061 alloy at room temperature leads to the formation of a very homogeneous ultrafine-grained (UFG) microstructure with an average grain size of 170 nm. The yield strength and ultimate tensile strength of the HPT processed alloy are increased as compared to the CG counterpart subjected to the conventional Т6 heat treatment from 276 MPa to 605 MPa and from 365 MPa to 675 MPa, correspondingly.

- HPT processing of the Al 6061 alloy improves its endurance limit by a factor of two (from 100 MPa after Т6 treatment to 200 MPa after HPT). This is related to the formation of a very homogeneous UFG microstructure with homogeneous resistance to fatigue crack initiation in the HCF regime. In the LCF regime, the UFG alloy shows somewhat lower fatigue resistance due to its lower strain hardening ability.

- Classical stages of fatigue crack initiation and propagation are clearly observed on the fatigue fracture surfaces of the CG T6-treated alloy and UFG alloy. Ductile striations are observed in the stage of stable crack propagation in the CG T6-treated alloy, whereas brittle striations seem to dominate on the fatigue fracture surface of the UFG alloy. The dimpled fracture surface is observed at the final stage of crack propagation in both material conditions, with dimples having a smaller size in the UFG alloy.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Valiev, R.Z.; Zhilyaev, A.P.; Langdon, T.G. Bulk Nanostructured Materials: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2014; p. 456. [Google Scholar]

- Sabirov, I.; Murashkin, M.Y.; Valiev, R.Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development. Mater. Sci. Eng. A 2013, 560, 1–24. [Google Scholar] [CrossRef]

- Markushev, M.V.; Murashkin, M.Y. Mechanical properties of submicrocrystalline Al alloys processed by equal-channel angular pressing. Phys. Met. Metall. 2000, 90, 506–515. [Google Scholar]

- Roven, H.J.; Nesboe, H.; Werenskiold, J.C.; Seibert, T. Mechanical properties of aluminum alloys processed by SPD: Comparison of different alloy systems and possible product areas. Mater. Sci. Eng. A 2005, 410–411, 426–429. [Google Scholar]

- Lyakishev, N.P.; Alymov, M.I.; Dobatkin, S.V. Structural bulk nanomaterials. Russ. Metall. 2003, 3, 191–202. [Google Scholar]

- Dobatkin, S.V.; Zakharov, V.V.; Vinogradov, A.Y.; Kitagava, N.; Krasilnikov, N.A.; Rostova, T.D.; Bastrash, E.N. Nanocrystalline structure in Al-Mg-Sc alloys by severe plastic deformation. Russ. Metall. 2006, 6, 533–540. [Google Scholar] [CrossRef]

- Zhao, Y.; Liao, X.; Cheng, S.; Ma, E.; Zhu, Y. Simultaneously increasing the ductility and strength of nanostructured alloys. Adv. Mater. 2006, 18, 2280–2283. [Google Scholar] [CrossRef]

- Horita, Z.; Ohashi, K.; Fujita, T.; Kaneko, K.; Langdon, T.G. Achieving high strength and high ductility in precipitation-hardened alloys. Adv. Mater. 2005, 17, 1599–1603. [Google Scholar] [CrossRef]

- Markushev, M.V.; Bampton, C.C.; Murashkin, M.Y.; Hardwick, D.A. Structure and properties of ultra-fine grained Al alloys produced by severe plastic deformation. Mater. Sci. Eng. A. 1997, 234–236, 927–931. [Google Scholar]

- Murashkin, M.; Sabirov, I.; Kazykhanov, V.; Bobruk, E.; Dubravina, A.; Valiev, R.Z. Enhanced mechanical properties and electrical conductivity in ultra-fine grained Al alloy processed via ECAP-PC. J. Mater. Sci. 2013, 48, 4501–4509. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Murashkin, M.Y.; Sabirov, I. A nanostructural design to produce high-strength Al alloys with enhanced electrical conductivity. Scr. Mater. 2014, 76, 13–16. [Google Scholar] [CrossRef]

- Vinogradov, A.Y.; Khasimoto, S. Fatigue in ultrafine-grained materials processed by equal-channel angular pressing. Russ. Metall. 2004, 1, 42–51. [Google Scholar]

- Estrin, Y.; Vinogradov, A. Fatigue behaviour of light alloys with ultrafine grain structure produced by severe plastic deformation: An overview. Int. J. Fatigue 2010, 32, 898–907. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Höppel, W.; Kautz, M.; Murashkin, M.Y.; Xu, C.; Langdon, T.G.; Valiev, R.Z.; Mughrabi, H. An overview: Fatigue Behavior of Ultrafine-Grained Metals and Alloys. Int. J. Fatigue 2006, 28, 1001–1010. [Google Scholar] [CrossRef]

- Höpel, H.W.; Göken, M. Fatigue Behavior in Nanostructured Metals. In Nanostructured Metals and Alloys: Processing, Microstructure, Mechanical Properties and Applications; Whang, S.H., Ed.; Woodhead Publishing Limited: Suite, PA, USA, 2011; pp. 507–541. [Google Scholar]

- Mughrabi, H.; Höppel, H.W.; Kautz, M. Fatigue and microstructure of ultra-fine grained metals produced by severe plastic deformation. Scr. Mater. 2004, 51, 807–812. [Google Scholar] [CrossRef]

- Malekjani, S.; Hodgson, P.D.; Cizek, P.; Sabirov, I.; Hilditch, T.B. Cyclic deformation response of UFG 2024 Al alloy. Int. J. Fatigue 2011, 33, 700–709. [Google Scholar] [CrossRef]

- Canadinc, D.; Maier, H.J.; Gabor, P.; May, J. On the cyclic deformation response of ultrafine-grained Al–Mg alloys at elevated temperatures. Mater. Sci. Eng. A 2008, 496, 114–120. [Google Scholar] [CrossRef]

- Vinogradov, A.; Washikita, A.; Kitagawa, K.; Kopylov, V.I. Fatigue life of fine-grain Al-Mg-Sc alloys produced by equal-channel angular pressing. Mater. Sci. Eng. A 2003, 349, 318–326. [Google Scholar] [CrossRef]

- Chung, C.S.; Kim, J.K.; Kim, H.K.; Kim, W.J. Improvement of high-cycle fatigue life in a 6061 Al alloy produced by equal channel angular pressing. Mater. Sci. Eng. A 2002, 337, 39–44. [Google Scholar] [CrossRef]

- Lapovok, R.; Loader, C.; Dalla Torre, F.H.; Semiatin, S.L. Microstructure evolution and fatigue behavior of 2124 aluminum processed by ECAE with back pressure. Mater. Sci. Eng. A 2006, 425, 36–46. [Google Scholar] [CrossRef]

- Malekjani, S.; Hodgson, P.D.; Cizek, P.; Hilditch, T.B. Cyclic deformation response of ultra-fine pure Al. Acta Mater. 2011, 59, 5358–5367. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Enikeev, N.A.; Murashkin, M.Y.; Kazykhanov, V.U.; Sauvage, X. On the origin of the extremely high strength of ultra-fine grained Al alloys. Scr. Mater. 2010, 63, 949–952. [Google Scholar] [CrossRef]

- Liddicoat, P.V.; Liao, X.Z.; Zhao, Y.; Zhu, Y.; Murashkin, M.Y.; Lavernia, E.J.; Valiev, R.Z.; Ringer, S.P. Nanostructural hierarchy increases the strength of aluminium alloys. Nat. Comm. 2010, 1, 63–70. [Google Scholar] [CrossRef]

- Ruffing, C.; Ivanisenko, Y.; Kerscher, E. Fatigue behavior of ultrafine grained medium Carbon steel processed by severe plastic deformation. IOP Conf. Series: Mater. Sci. Eng. 2014, 63, 012163. [Google Scholar] [CrossRef]

- Polmear, I.J. Light Alloys. In From Traditional Alloys to Nanocrystals; Butterworth-Heinemann: Oxford, UK, 2006; p. 417. [Google Scholar]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Butterworth: Oxford, UK, 1976; p. 971. [Google Scholar]

- Murayama, M.; Hono, K. Pre-precipitate clusters and precipitation processes in Al-Mg-Si alloys. Acta Mater. 1999, 47, 1537–1548. [Google Scholar] [CrossRef]

- Nurislamova, G.; Sauvage, X.; Murashkin, M.; Islamgaliev, R.; Valiev, R. Nanostructure and related mechanical properties of an Al-Mg-Si alloy processed by severe plastic deformation. Phil. Mag. Lett. 2008, 88, 459–466. [Google Scholar] [CrossRef]

- Moreno-Valle, E.C.; Sabirov, I.; Perez-Prado, M.T.; Murashkin, M.Y.; Bobruk, E.V.; Valiev, R.Z. Effect of the grain refinement via severe plastic deformation on strength properties and deformation behavior of an Al 6061 alloy at room and cryogenic temperatures. Mater. Lett. 2011, 65, 2917–2919. [Google Scholar] [CrossRef]

- Sha, G.; Tugcu, K.; Liao, X.Z.; Trimby, P.W.; Murashkin, M.Y.; Valiev, R.Z.; Ringer, S.P. Strength, grain refinement and solute nanostructures of an Al-Mg-Si alloy (AA6060) processed by high-pressure torsion. Acta Mater. 2014, 63, 169–179. [Google Scholar] [CrossRef]

- Murashkin, M.Y.; Markushev, M.V.; Ivanisenko, Y.V.; Valiev, R.Z. Strength of commercial aluminum alloys after equal channel angular pressing and post-ECAP processing. Solid State Phen. 2006, 114, 91–96. [Google Scholar] [CrossRef]

- Hatch, J.E. Aluminium: Properties and Physical Metallurgy; ASM International: Materials Park, OH, USA, 1984; p. 636. [Google Scholar]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998; p. 679. [Google Scholar]

- Milella, P.P. Fatigue and Corrosion in Metals; Springer: Berlin, Germany, 2013; p. 763. [Google Scholar]

- Dalla Torre, F.; van Swygenhoven, H.; Victoria, M. Nanocrystalline electrodeposited Ni: Microstructure and tensile properties. Acta Mater. 2002, 50, 3957–3970. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murashkin, M.; Sabirov, I.; Prosvirnin, D.; Ovid'ko, I.; Terentiev, V.; Valiev, R.; Dobatkin, S. Fatigue Behavior of an Ultrafine-Grained Al-Mg-Si Alloy Processed by High-Pressure Torsion. Metals 2015, 5, 578-590. https://doi.org/10.3390/met5020578

Murashkin M, Sabirov I, Prosvirnin D, Ovid'ko I, Terentiev V, Valiev R, Dobatkin S. Fatigue Behavior of an Ultrafine-Grained Al-Mg-Si Alloy Processed by High-Pressure Torsion. Metals. 2015; 5(2):578-590. https://doi.org/10.3390/met5020578

Chicago/Turabian StyleMurashkin, Maxim, Ilchat Sabirov, Dmitriy Prosvirnin, Ilya Ovid'ko, Vladimir Terentiev, Ruslan Valiev, and Sergey Dobatkin. 2015. "Fatigue Behavior of an Ultrafine-Grained Al-Mg-Si Alloy Processed by High-Pressure Torsion" Metals 5, no. 2: 578-590. https://doi.org/10.3390/met5020578

APA StyleMurashkin, M., Sabirov, I., Prosvirnin, D., Ovid'ko, I., Terentiev, V., Valiev, R., & Dobatkin, S. (2015). Fatigue Behavior of an Ultrafine-Grained Al-Mg-Si Alloy Processed by High-Pressure Torsion. Metals, 5(2), 578-590. https://doi.org/10.3390/met5020578