3D Microstructure Modeling of Porous Metal Filters

Abstract

:1. Introduction

2. Results and Discussion

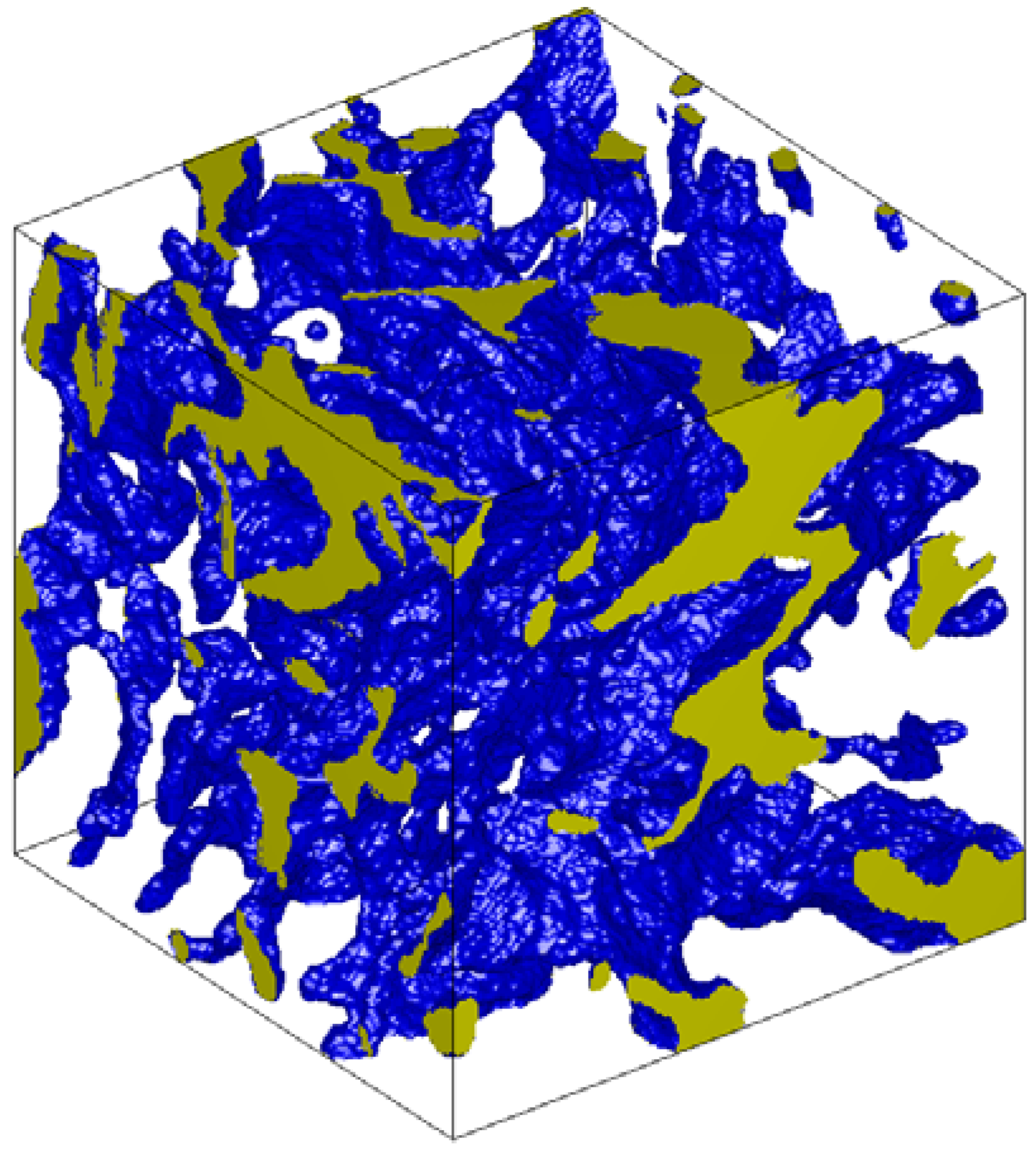

2.1. Reconstructed Microstructure (3D Replicas) of Porous Metal Filters

2.2. Transport Properties of Porous Metal Filters

| Sample | κexp (nm) | βexp (µm2) | κcal (nm) | βcal (µm2) |

|---|---|---|---|---|

| F1 media grade 0.5 | 67 ± 8 | 0.0527 ± 0.0008 | 67.1 | 0.0533 |

| F2 media grade 0.2 | 51 ± 2 | 0.0241 ± 0.0004 | 55.1 | 0.0324 |

3. Experimental Section

3.1. Materials

| Sample | Porosity | Bulk density (g·mL−1) | Specific surface area (μm−1) | Median pore diameter (μm) |

|---|---|---|---|---|

| F1 media grade 0.5 | 0.178 | 6.377 | 0.089 | 3.55 |

| F2 media grade 0.2 | 0.201 | 6.255 | 0.110 | 2.70 |

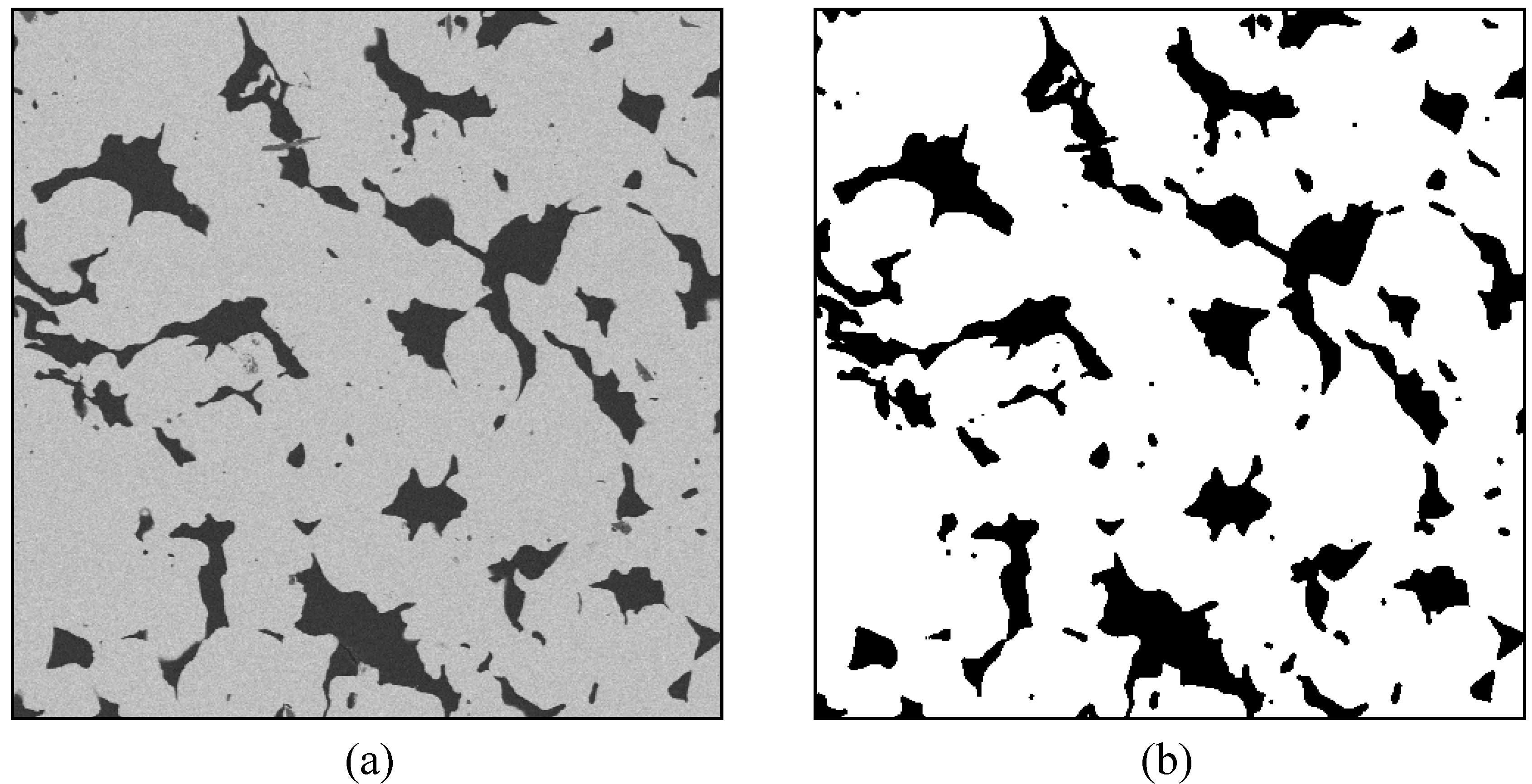

3.2. Imaging and Image Processing

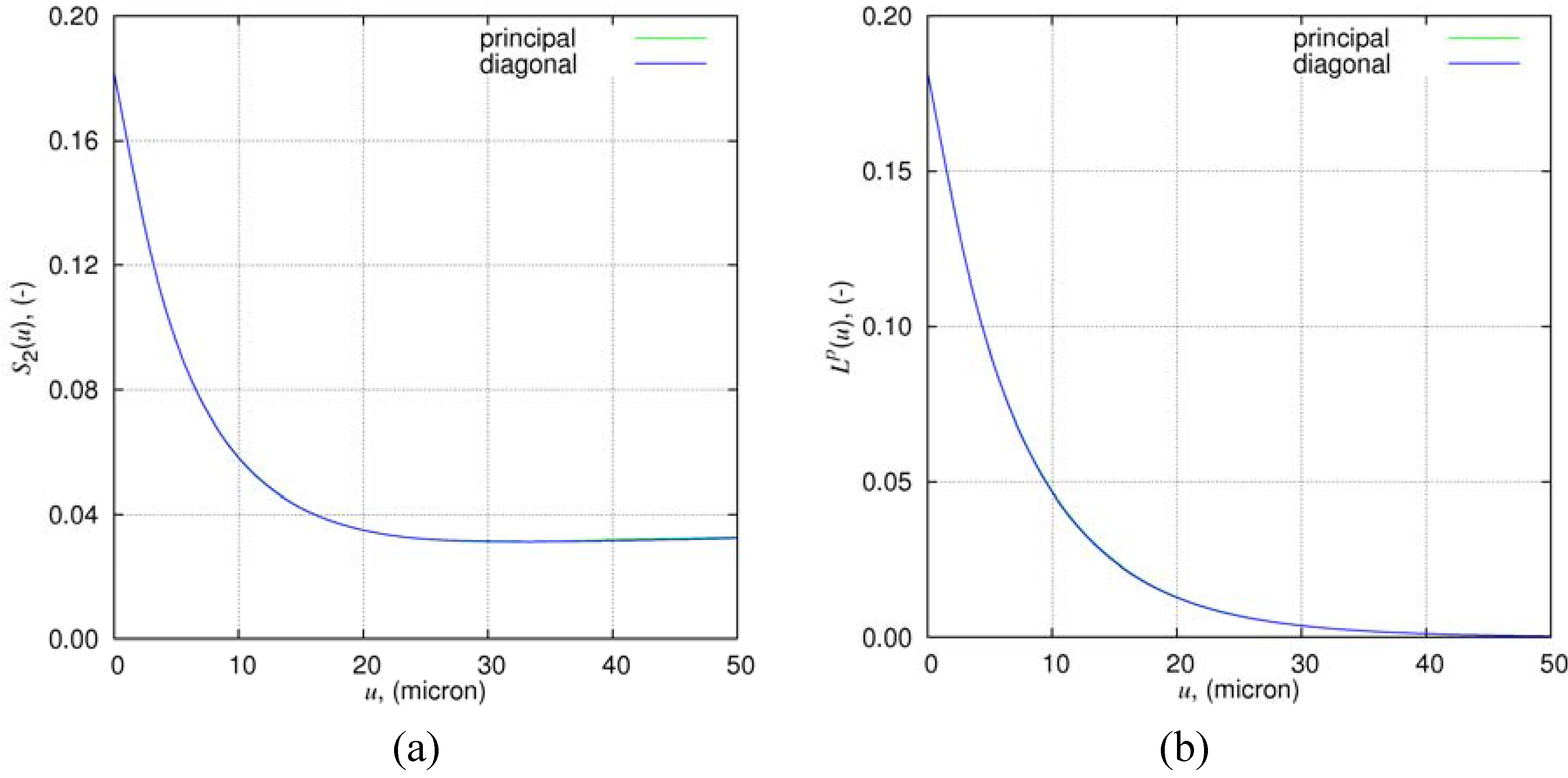

3.3. Microstructural Descriptors

3.4. Stochastic Reconstruction of Porous Metallic Filters

3.5. Calculation of Effective Permeability

of a walker and time t was used

of a walker and time t was used

is the effective diffusivity of the walker in an isotropic porous medium. To eliminate the dependence on temperature and gas and to get the quantity directly compared with experimental results,

is the effective diffusivity of the walker in an isotropic porous medium. To eliminate the dependence on temperature and gas and to get the quantity directly compared with experimental results,  was multiplied by ratio of the total porosity and the mean arithmetic velocity w. Thus, the effective pore size, κcal, represents the permeability of the porous metal filter.

was multiplied by ratio of the total porosity and the mean arithmetic velocity w. Thus, the effective pore size, κcal, represents the permeability of the porous metal filter.3.6. Measurement of Effective Permeability

4. Conclusions

Acknowledgments

Conflict of Interest

References

- Lymberopoulos, D.P.; Payatakes, A.C. Derivation of topological geometrical and correlation properties of porous media from pore-chart analysis of serial tomography data. J. Colloid Interface Sci. 1992, 150, 61–80. [Google Scholar] [CrossRef]

- Spanne, P.; Thovert, J.F.; Jacquin, C.J.; Lindquist, W.B.; Jones, K.W.; Adler, P.M. Synchrotron computed microtomography of porous media: Topology and transports. Phys. Rev. Lett. 1994, 73, 2001–2004. [Google Scholar] [CrossRef]

- Čapek, P.; Hejtmánek, V.; Brabec, L.; Zikánová, A.; Kočiřík, M. Stochastic reconstruction of particulate media using simulated annealing. Transp. Porous Med. 2009, 76, 179–198. [Google Scholar] [CrossRef]

- Čapek, P.; Hejtmánek, V.; Kolafa, J.; Brabec, L. Transport properties of stochastically reconstructed porous media with improved pore connectivity. Transp. Porous Med. 2011, 88, 87–106. [Google Scholar] [CrossRef]

- Biswal, B.; Manwart, C.; Hilfer, R. Three-dimensional local porosity analysis of porous media. Physica A 1998, 255, 221–241. [Google Scholar] [CrossRef]

- Hilfer, R. Local porosity theory and stochastic reconstruction for porous media. In Statistical Physics and Spatial Statistics, Lecture Notes in Physics; Mecke, K., Stoyan, D., Eds.; Springer-Verlag: Heidelberg, Germany, 2000; Volume 254, pp. 203–241. [Google Scholar]

- Gonzales, R.C.; Woods, R.E. Digital Image Processing, 2nd ed; Prentice Hall: New Jersey, NJ, USA, 2002. [Google Scholar]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, SMC−9, 62–66. [Google Scholar]

- Torquato, S. Random Heterogeneous Materials: Microstructure and Macroscopic Properties; Springer Verlag: New York, NY, USA, 2002. [Google Scholar]

- Rintoul, M.D.; Torquato, S. Reconstruction of the structure of dispersions. J. Colloid Interface Sci. 1997, 186, 467–476. [Google Scholar] [CrossRef]

- Yeong, C.L.Y.; Torquato, S. Reconstructing random media. Phys. Rev. E 1998, 58, 495–506. [Google Scholar]

- Yeong, C.L.Y.; Torquato, S. Reconstructing random media II. Three-dimensional media from two-dimensional cuts. Phys. Rev. E 1998, 58, 224–233. [Google Scholar] [CrossRef]

- Bentz, D.P.; Martys, N.S. A Stokes Permeability Solver for Three-Dimensional Porous Media; U.S. Department of Commerce, Technology Administration, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2007. [Google Scholar]

- Fott, P.; Petrini, G. Determination of transport parameters of porous catalysts from permeation measurements. Appl. Catal. 1982, 2, 367–378. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Hejtmánek, V.; Čapek, P. 3D Microstructure Modeling of Porous Metal Filters. Metals 2012, 2, 344-352. https://doi.org/10.3390/met2030344

Hejtmánek V, Čapek P. 3D Microstructure Modeling of Porous Metal Filters. Metals. 2012; 2(3):344-352. https://doi.org/10.3390/met2030344

Chicago/Turabian StyleHejtmánek, Vladimír, and Pavel Čapek. 2012. "3D Microstructure Modeling of Porous Metal Filters" Metals 2, no. 3: 344-352. https://doi.org/10.3390/met2030344

APA StyleHejtmánek, V., & Čapek, P. (2012). 3D Microstructure Modeling of Porous Metal Filters. Metals, 2(3), 344-352. https://doi.org/10.3390/met2030344