Stiffness and Damping Properties of LPBF-Fabricated TC4 Alloy Beams Incorporating Self-Sealing Powder and Lattice Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Beam Structure Design

2.2. LPBF Manufacturing

2.3. Characterization and Testing

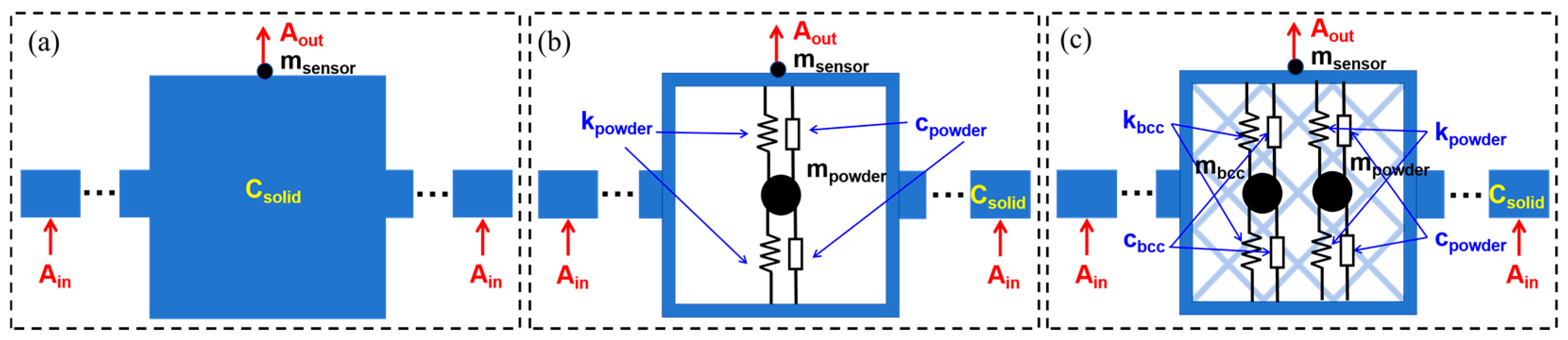

3. Modeling and Simulation

3.1. Static Simulation

3.2. Dynamic Simulation

4. Results

4.1. Forming Quality

4.2. Stiffness

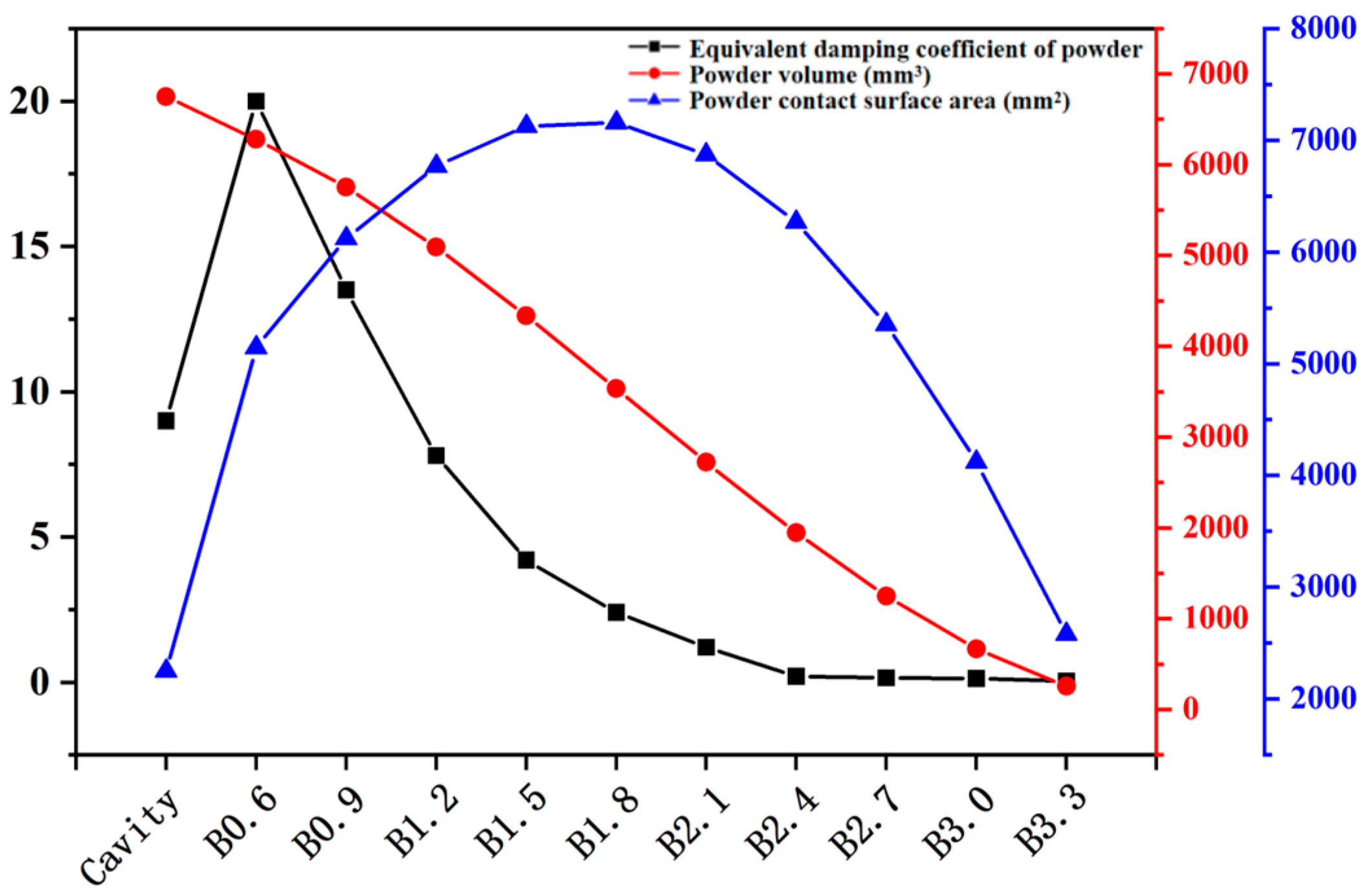

4.3. Damping Performance

5. Discussion

5.1. The Effect of Lattice Structure on Bending Stiffness

5.2. The Effect of Lattice Structure on Damping Performance

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mottershead, J.E.; Ram, Y.M. Inverse eigenvalue problems in vibration absorption: Passive modification and active control. Mech. Syst. Signal Process. 2006, 20, 5–44. [Google Scholar] [CrossRef]

- Bosia, F.; Dal Poggetto, V.F.; Gliozzi, A.S.; Greco, G.; Lott, M.; Miniaci, M.; Ongaro, F.; Onorato, M.; Seyyedizadeh, S.F.; Tortello, M.; et al. Optimized structures for vibration attenuation and sound control in nature: A review. Matter 2022, 5, 3311–3340. [Google Scholar] [CrossRef]

- Xing, W.; Tuo, W.; Li, X.; Wang, T.; Yang, C. Micro-vibration suppression and compensation techniques for in-orbit satellite: A review. Chin. J. Aeronaut. 2024, 37, 1–19. [Google Scholar] [CrossRef]

- Chapain, S.; Aly, A. Vibration attenuation in high-rise buildings to achieve system-level performance under multiple hazards. Eng. Struct. 2019, 197, 109352. [Google Scholar] [CrossRef]

- Friend, R.D.; Kinra, V.K. Particle Impact Damping. J. Sound Vib. 2000, 233, 93–118. [Google Scholar] [CrossRef]

- Gagnon, L.; Morandini, M.; Ghiringhelli, G.L. A review of particle damping modeling and testing. J. Sound Vib. 2019, 459, 114865. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, M.Y.; Chen, T. Particle damping for passive vibration suppression: Numerical modelling and experimental investigation. J. Sound Vib. 2005, 279, 1097–1120. [Google Scholar] [CrossRef]

- Xiao, W.; Li, J.; Pan, T.; Zhang, X.; Huang, Y. Investigation into the influence of particles’ friction coefficient on vibration suppression in gear transmission. Mech. Mach. Theory 2017, 108, 217–230. [Google Scholar] [CrossRef]

- Xiao, W.; Xu, Z.; Bian, H.; Li, Z. Lightweight heavy-duty CNC horizontal lathe based on particle damping materials. Mech. Syst. Signal Process. 2021, 147, 107127. [Google Scholar] [CrossRef]

- Zhang, K.; Xi, Y.; Chen, T.; Ma, Z. Experimental studies of tuned particle damper: Design and characterization. Mech. Syst. Signal Process. 2018, 99, 219–228. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, Z.; Masri, S.F.; Lu, X. Particle impact dampers: Past, present, and future. Struct. Control Health Monit. 2018, 25, e2058. [Google Scholar] [CrossRef]

- Guo, H.; Ichikawa, K.; Sakai, H.; Zhang, H.; Zhang, X.; Tsuruta, K.; Makihara, K.; Takezawa, A. Numerical and experimental analysis of additively manufactured particle dampers at low frequencies. Powder Technol. 2022, 396, 696–709. [Google Scholar] [CrossRef]

- Guo, H.; Yoneoka, R.; Takezawa, A. Influence of cavity partition on the damping performance of additively manufactured particle dampers. Powder Technol. 2024, 439, 119675. [Google Scholar] [CrossRef]

- Harduf, Y.; Setter, E.; Feldman, M.; Bucher, I. Modeling additively-manufactured particle dampers as a 2DOF frictional system. Mech. Syst. Signal Process. 2023, 187, 109928. [Google Scholar] [CrossRef]

- Scott-Emuakpor, O.; Beck, J.; Runyon, B.; George, T. Determining unfused powder threshold for optimal inherent damping with additive manufacturing. Addit. Manuf. 2021, 38, 101739. [Google Scholar] [CrossRef]

- Ehlers, T.; Lachmayer, R. Design Rules for Laser Beam Melted Particle Dampers. Proc. Des. Soc. 2022, 2, 2443–2452. [Google Scholar] [CrossRef]

- Hollkamp, J.P.; Scott-Emuakpor, O.; Celli, D. Analyses of Damping Sustainability of Additively Manufactured Nickel Alloy Components Subjected to High Strain Loading Cycles. J. Eng. Gas Turbines Power 2023, 145, 031011. [Google Scholar] [CrossRef]

- Ehlers, T.; Tatzko, S.; Wallaschek, J.; Lachmayer, R. Design of particle dampers for additive manufacturing. Addit. Manuf. 2021, 38, 101752. [Google Scholar] [CrossRef]

- Ozcevik, B.; Soylemez, E.; Bediz, B.; Simsek, U. Effects of particle damper design parameters on the damping performance of laser powder bed fused structures. Int. J. Adv. Manuf. Technol. 2024, 130, 3917–3928. [Google Scholar] [CrossRef]

- Ashby, M.F. The properties of foams and lattices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2005, 364, 15–30. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Chen, D.; Gao, K.; Yang, J.; Zhang, L. Functionally graded porous structures: Analyses, performances, and applications—A Review. Thin-Walled Struct. 2023, 191, 111046. [Google Scholar] [CrossRef]

- Miao, X.; Hu, J.; Xu, Y.; Su, J.; Jing, Y. Review on mechanical properties of metal lattice structures. Compos. Struct. 2024, 342, 118267. [Google Scholar] [CrossRef]

- Vogela, F.; Berger, S.; Özkaya, E.; Biermann, D. Vibration Suppression in Turning TiAl6V4 Using Additively ManufacturedTool Holders with Specially Structured, Particle Filled Hollow Elements. Procedia Manuf. 2019, 40, 32–37. [Google Scholar] [CrossRef]

- Werkle, K.T.; Menze, C.; Stehle, T.; Möhring, H.C. Additively manufactured, particle-filled damping structures withmagnetorheological fluids. Procedia CIRP 2021, 104, 1418–1423. [Google Scholar] [CrossRef]

- Corson, G.; Compton, B.; Gomez, M.; Schmitz, T. Internal feature design for increased damping by captured powder. In Proceedings of the ASPE 36th Annual Meeting, Minneapolis, MN, USA, 1–5 November 2021. [Google Scholar]

- Mohanraj, J.; Sahu, J. Numerical prediction of residual stress and distortion for laser powder bed fusion (LPBF) AM process of Ti-6Al-4V. Simul. Model. Pract. Theory 2025, 140, 103094. [Google Scholar] [CrossRef]

- Westbeld, J.; von Coburg, F.; Höfer, P. Forced-response characterization of PBF-LB/AlSi10Mg particle dampers with thin and flat cavities. Prog. Addit. Manuf. 2023, 8, 745–757. [Google Scholar] [CrossRef]

- Schmitz, T.; Gomez, M.; Ray, B.; Heikkenen, E.; Sisco, K.; Haines, M.; Osborne, J.S. Damping and mode shape modification for additively manufactured walls with captured powder. Precis. Eng. 2020, 66, 110–124. [Google Scholar] [CrossRef]

- Scott-Emuakpor, O.; Schoening, A.; Goldin, A.; Beck, J.; Runyon, B.; George, T. Internal Geometry Effects on Inherent Damping Performance of Additively Manufactured Components. AIAA J. 2021, 59, 379–385. [Google Scholar] [CrossRef]

- Rehmet, R.; Lorenz, S.; Hahn, V.; Lohrengel, A. Investigation on the Acoustical Transmission Path of Additively Printed Metals. Appl. Sci. 2022, 13, 180. [Google Scholar] [CrossRef]

- Ehlers, T.; Lachmayer, R. Design of Particle Dampers for Laser Powder Bed Fusion. Appl. Sci. 2022, 12, 2237. [Google Scholar] [CrossRef]

| Samples | Strut Diameter (mm) | Theoretical Powder Volume (mm3) | Theoretical Inner Surface Area (mm2) | Actual Sample Mass (g) |

|---|---|---|---|---|

| Cavity | - | 6750.00 | 2250.00 | 157.4 |

| B0.6 | 0.6 | 6278.26 | 5145.81 | 159.8 |

| B0.9 | 0.9 | 5752.86 | 6121.10 | 160.0 |

| B1.2 | 1.2 | 5091.59 | 6770.26 | 161.1 |

| B1.5 | 1.5 | 4337.29 | 7126.41 | 163.6 |

| B1.8 | 1.8 | 3532.83 | 7156.44 | 166.4 |

| B2.1 | 2.1 | 2721.07 | 6871.38 | 166.0 |

| B2.4 | 2.4 | 1945.4 | 6268.29 | 166.8 |

| B2.7 | 2.7 | 1247.7 | 5352.45 | 169.2 |

| B3.0 | 3.0 | 668.44 | 4121.47 | 167.8 |

| B3.3 | 3.3 | 257.96 | 2580.30 | 167.8 |

| Solid | - | - | - | 171.4 |

| Element | C | Al | V | Fe | H | Ti |

|---|---|---|---|---|---|---|

| Wt.% | 0.011 | 6.11 | 3.93 | 0.044 | 0.0034 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Xu, Y.; Xiang, Z.; Zhang, C.; Tang, J.; Ge, X.; Zhang, T.; Sun, M.; Xia, Z.; Chen, J.; Huang, S. Stiffness and Damping Properties of LPBF-Fabricated TC4 Alloy Beams Incorporating Self-Sealing Powder and Lattice Structures. Metals 2026, 16, 40. https://doi.org/10.3390/met16010040

Xu Y, Xiang Z, Zhang C, Tang J, Ge X, Zhang T, Sun M, Xia Z, Chen J, Huang S. Stiffness and Damping Properties of LPBF-Fabricated TC4 Alloy Beams Incorporating Self-Sealing Powder and Lattice Structures. Metals. 2026; 16(1):40. https://doi.org/10.3390/met16010040

Chicago/Turabian StyleXu, Yong, Zheng Xiang, Chenyu Zhang, Jingang Tang, Xiaohui Ge, Tianhao Zhang, Mingyan Sun, Zhihui Xia, Jie Chen, and Shuke Huang. 2026. "Stiffness and Damping Properties of LPBF-Fabricated TC4 Alloy Beams Incorporating Self-Sealing Powder and Lattice Structures" Metals 16, no. 1: 40. https://doi.org/10.3390/met16010040

APA StyleXu, Y., Xiang, Z., Zhang, C., Tang, J., Ge, X., Zhang, T., Sun, M., Xia, Z., Chen, J., & Huang, S. (2026). Stiffness and Damping Properties of LPBF-Fabricated TC4 Alloy Beams Incorporating Self-Sealing Powder and Lattice Structures. Metals, 16(1), 40. https://doi.org/10.3390/met16010040