Characterization of the Carbides in Carburized CSS-42L Steel and Their Effect on the Fatigue Failure Mechanism

Abstract

1. Introduction

2. Material and Experimental Procedure

2.1. Material

2.2. Microstructure Characterization

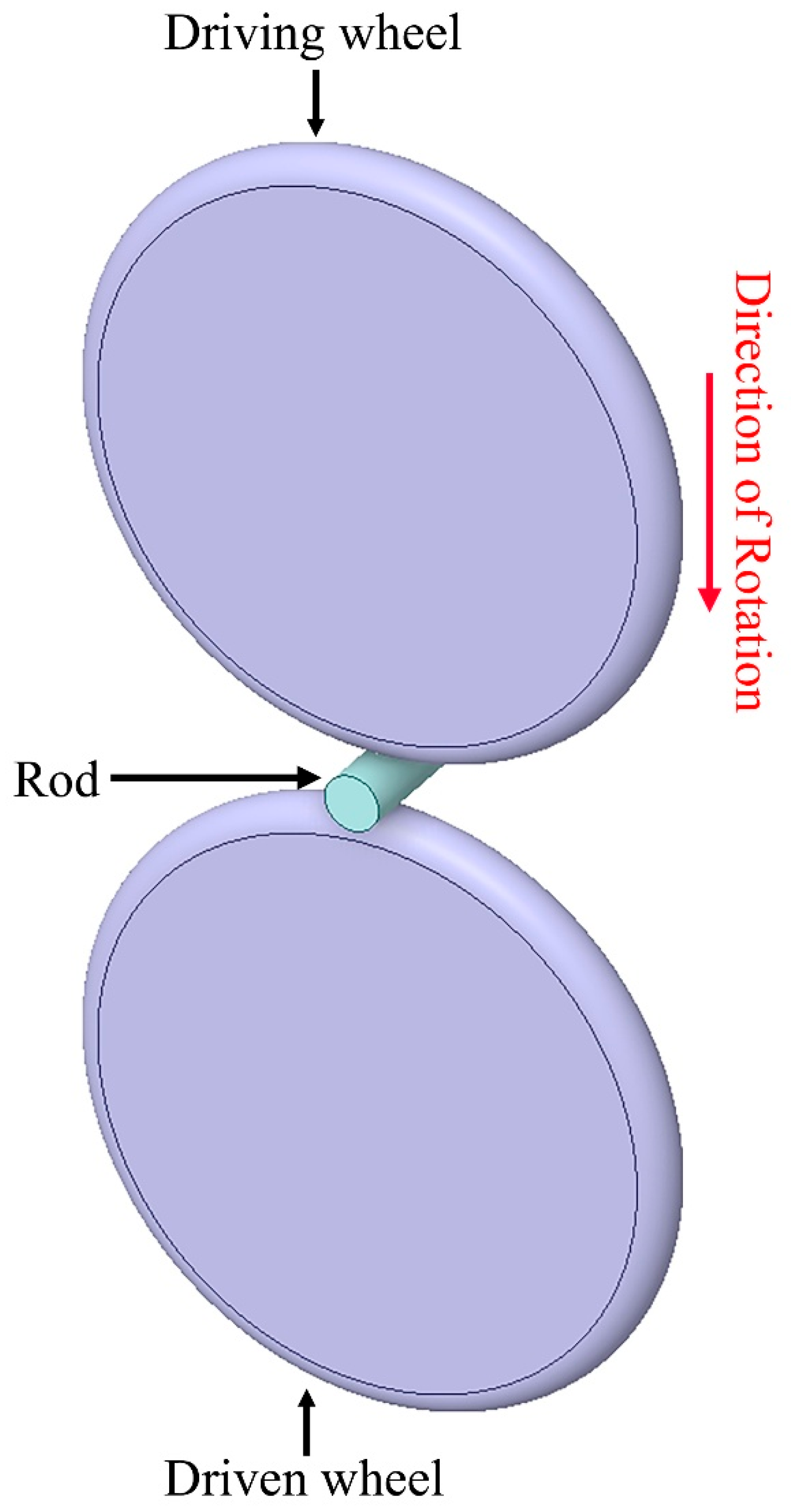

2.3. RCF Test

3. Results and Discussion

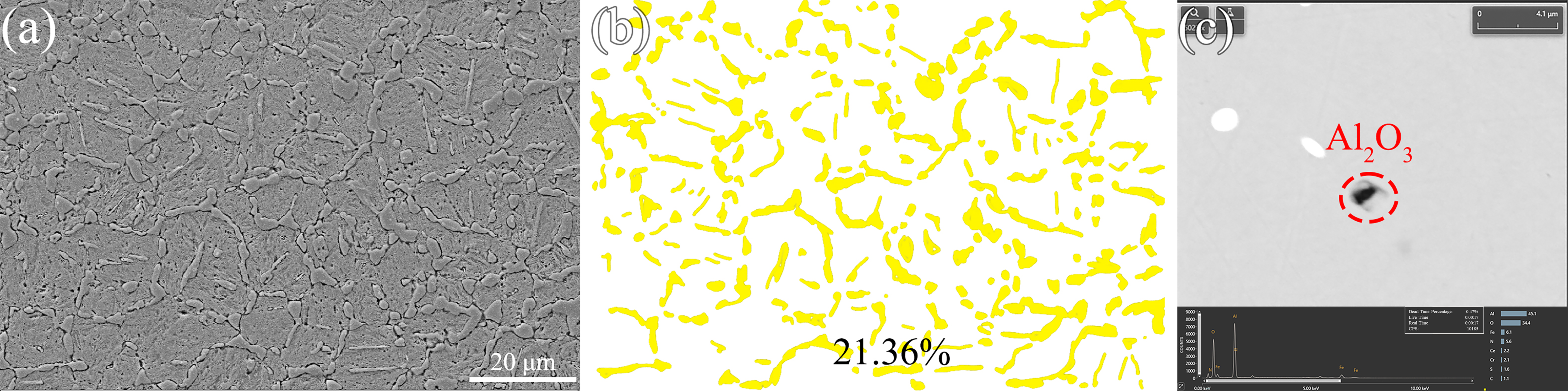

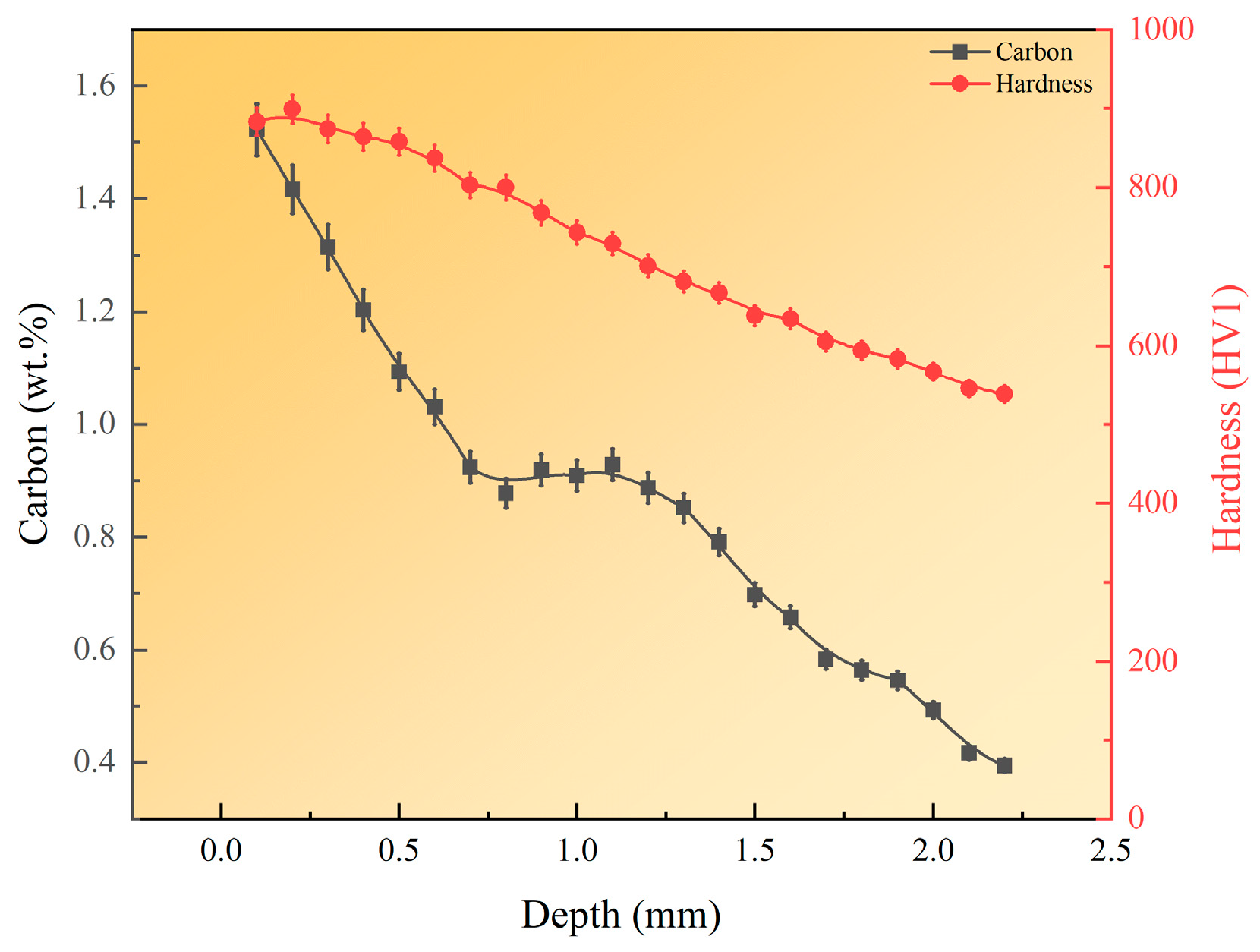

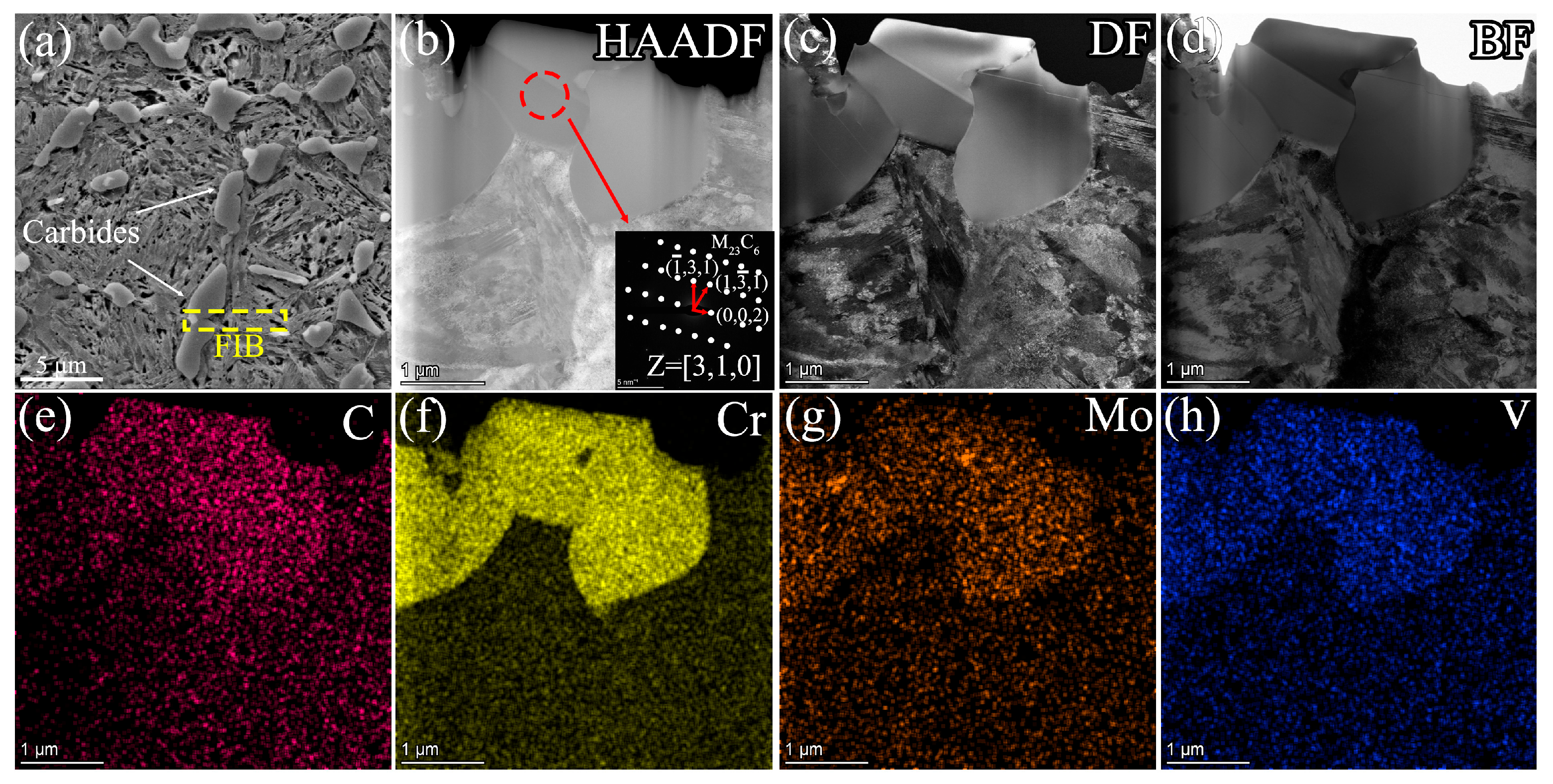

3.1. Characterization of the Microstructure and Carbides in Carburized CSS-42L Steel

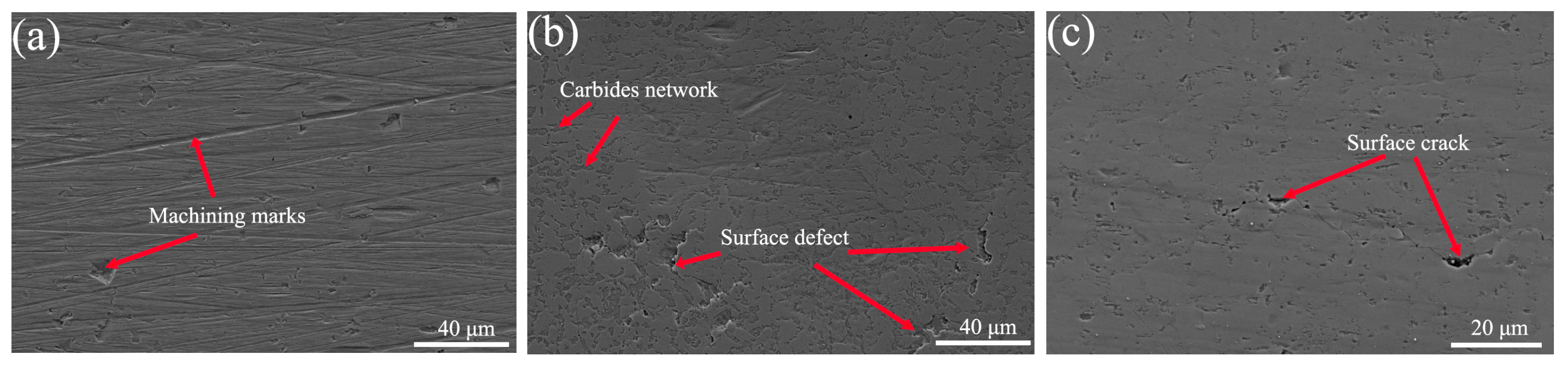

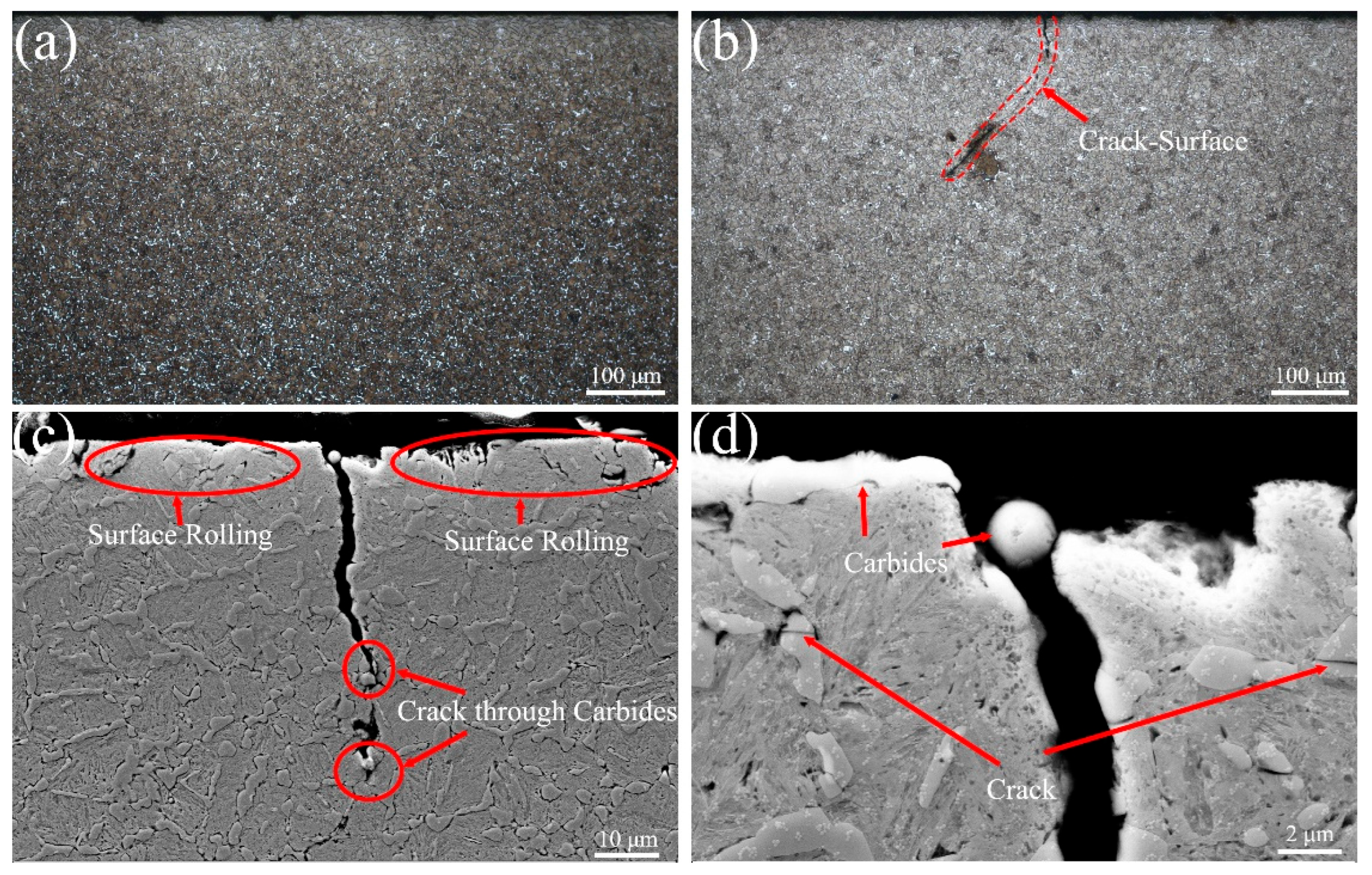

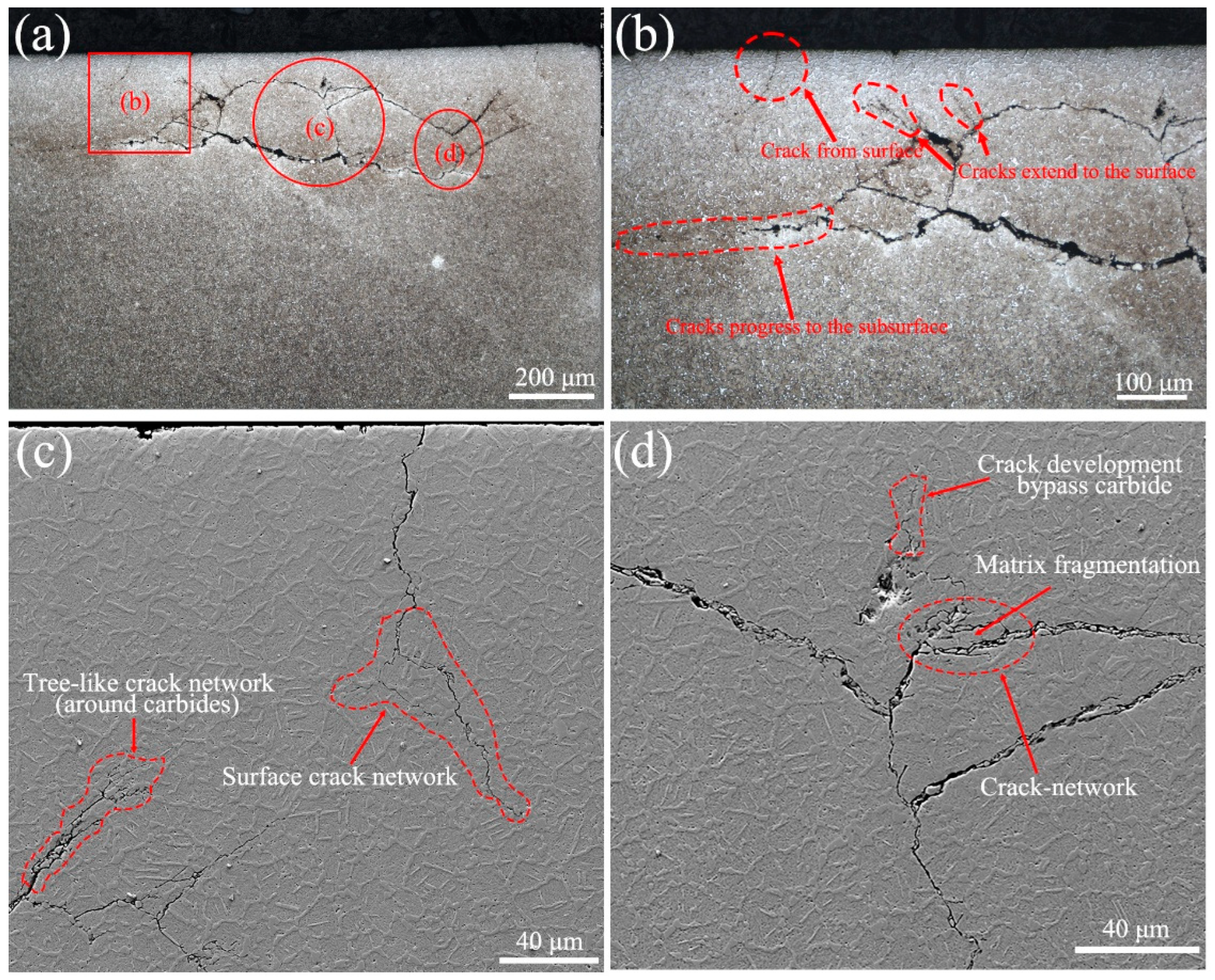

3.2. Fatigue Failure Mechanism Due to Surface Crack

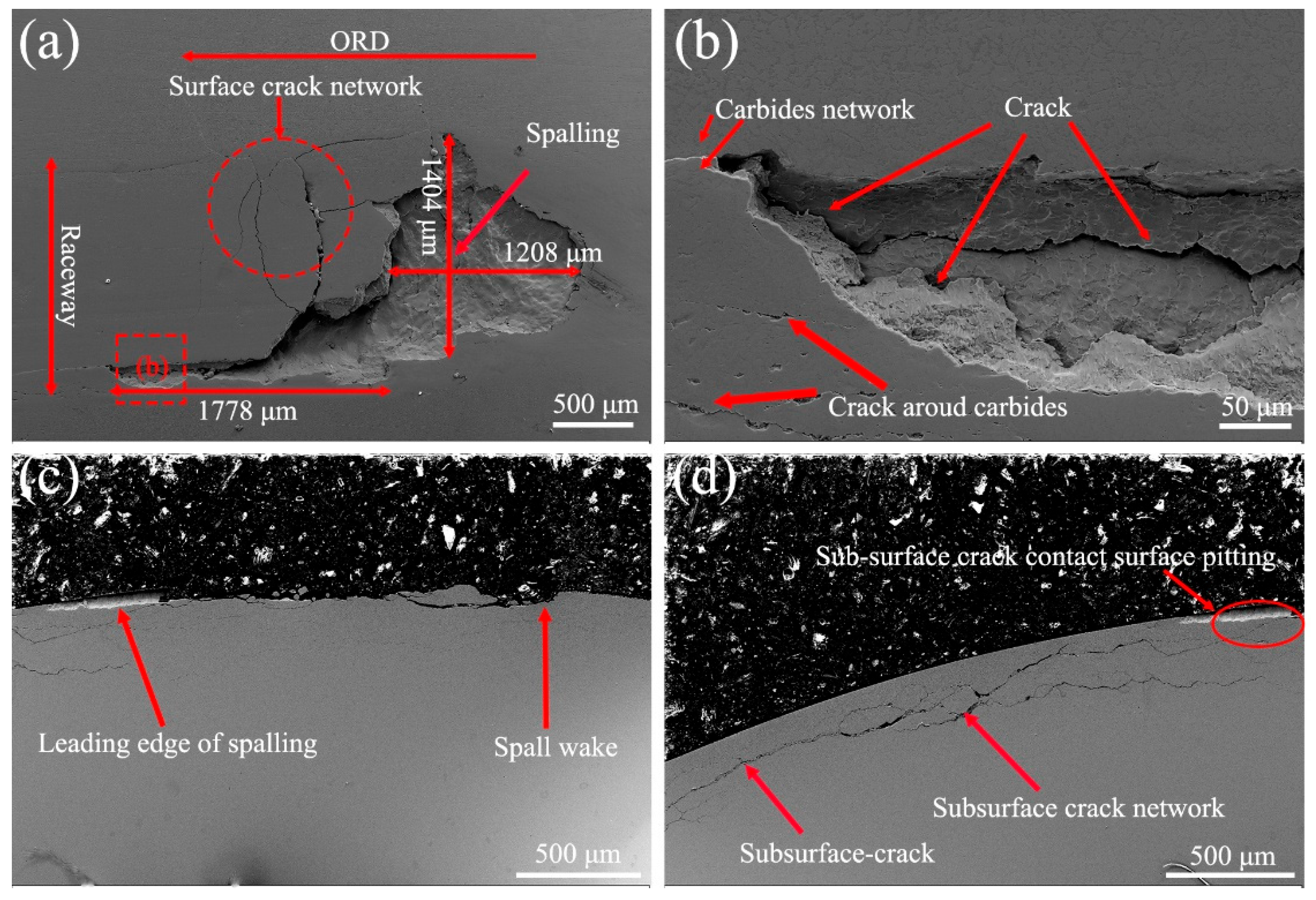

3.3. Subsurface-Spalling of Network Carbides in Rolling Contact

4. Conclusions

- (1)

- The carbides in CSS-42L steel after carburizing are mainly M23C6 and M6C. M23C6 carbides are Cr-rich carbides, and they exhibit irregular morphologies and relatively large sizes. The network carbides distributed along the grain boundaries are predominantly M23C6 carbides. M6C carbides are Mo-rich carbides, and they exhibit near-spherical morphologies.

- (2)

- The spalling of network M23C6 carbides forms micro-spalling pits on the contact surface during RCF, causing local stress concentration and thereby inducing cracks to initiate on the surface. Surface cracks initially propagate perpendicularly to the contact surface and then propagate parallelly to the contact surface under the influence of shear stress.

- (3)

- Subsurface cracks initiate approximately 100 μm below the surface, with their propagation direction being roughly parallel to the contact surface. Secondary cracks extend along the network carbides, forming a large number of grid-like cracks. Meanwhile, during the development of subsurface cracks may interact with micro-pitting initiating at the surface, which can lead to the expansion of surface micro-pitting.

- (4)

- During rolling contact fatigue, the size and morphology of networked carbides exacerbate the accumulation of subsurface cyclic shear stress. This stress accumulation subsequently accelerates the initiation and propagation of contact fatigue cracks.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Braza, J.F.; Pearson, P.K. Tribological and metallurgical evaluation of ferritic nitrocarburized M-50 and M-50 NiL steels. Creat. Use Bear. Steels 1993, 1195, 49. [Google Scholar]

- Braza, J.F.; Pearson, P.K.; Hannigan, C.J. The Performance of 52100, M-50, and M-50 NiL Steels in Radial Bearings. In International Off-Highway & Powerplant Congress & Exposition; SAE Transactions: Warrendale, PA, USA, 1993; pp. 437–449. [Google Scholar]

- Yu, X.F.; Zheng, D.Y.; Yang, X.F.; Wang, S.Y.; An, M.; Yan, G.B.; Xia, Y.Z.; Xing, F. Effect of carbide precipitation behavior at high temperatures on microstructure and mechanical properties of M50 steel. J. Mater. Res. Technol. 2022, 18, 1155–1165. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, F.; Yin, F.; Qian, D.; Liu, X.; Wu, M. Microstructure evolution and deformation behaviors of pulse electro-assisted deformation in M50 bearing steel. J. Mater. Res. Technol. 2023, 23, 4909–4921. [Google Scholar] [CrossRef]

- Wei, P.; Bai, P.; Yue, L.; Zhou, X.; Wen, X.; Zhao, H.; Meng, Y.; Tian, Y. Comparing friction behavior and mechanism of three generation bearing steel (GCr15, M50, CSS-42L) paired silicon nitride under ester oil lubrication from room temperature to 350 °C. J. Mater. Res. Technol. 2024, 30, 1354–1367. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Wang, Y.; Dai, Y.; Luo, J. Friction and wear performance of titanium alloy against tungsten carbide lubricated with phosphate ester. Tribol. Int. 2016, 95, 27–34. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.; Kannaki, P.S.; Srinivas, M.; Roy, M. Microstructural developments during abrasion of M50 bearing steel. Wear 2014, 315, 31–37. [Google Scholar] [CrossRef]

- Guetard, G.; Toda-Caraballo, I.; Rivera-Díaz-del-Castillo, P.E.J. Damage evolution around primary carbides under rolling contact fatigue in VIM–VAR M50. Int. J. Fatigue 2016, 91 Pt 1, 59–67. [Google Scholar] [CrossRef]

- Li, Y.J.; Herbig, M.; Goto, S.; Raabe, D. Atomic scale characterization of white etching area and its adjacent matrix in a martensitic 100Cr6 bearing steel. Mater. Charact. 2017, 123, 349–353. [Google Scholar] [CrossRef]

- Arakere, N.K.; Branch, N.; Levesque, G.; Svendsen, V.; Forster, N.H. Rolling Contact Fatigue Life and Spall Propagation of AISI M50, M50NiL, and AISI 52100, Part II: Stress Modeling. Tribol. Trans. 2009, 53, 42–51. [Google Scholar] [CrossRef]

- Oezel, M.; Schwedt, A.; Janitzky, T.; Kelley, R.; Bouchet-Marquis, C. Formation of white etching areas in SAE 52100 bearing steel under rolling contact fatigue—Influence of diffusible hydrogen. Wear 2018, 414–415, 352–365. [Google Scholar] [CrossRef]

- Liu, X.; Guo, Z.; Lu, Z.; Qin, L. Tribological behavior of the wear-resistant and self-lubrication integrated interface structure with ordered micro-pits. Surf. Coat. Technol. 2023, 454, 129159. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Qin, L.; Guo, Z.; Lu, Z.; Zhao, X.; Dong, H.; Xiao, Q. Friction and wear properties of a novel interface of ordered microporous Ni-based coating combined with MoS2 under complex working conditions. Tribol. Int. 2023, 189, 108970. [Google Scholar] [CrossRef]

- Tomasello, C.M.; Burrrier, H.I.; Knepper, R.A.; Balliett, S.; Maloney, J.L. Progress in the Evaluation of CSS-42L™: A High Performance Bearing Alloy. In Bearing Steel Technology; ASTM International: West Conshohocken, PA, USA, 2002; pp. 375–385. [Google Scholar]

- Burrier, H.I.; Tomasello, C.M.; Balliett, S.A.; Maloney, J.L.; Milam, D.L.; Ogden, W.P. Development of CSS-421™, A High Performance Carburizing Stainless Steel for High Temperature Aerospace Applications. In Bearing Steels: Into the 21st Century; ASTM International: West Conshohocken, PA, USA, 1998; pp. 374–390. [Google Scholar]

- Li, S.; Xiao, M.; Ye, G.; Zhao, K.; Yang, M. Effects of deep cryogenic treatment on microstructural evolution and alloy phases precipitation of a new low carbon martensitic stainless bearing steel during aging. Mater. Sci. Eng. A 2018, 732, 167–177. [Google Scholar] [CrossRef]

- Hetzner, D.W.; Van Geertruyden, W. Crystallography and metallography of carbides in high alloy steels. Mater. Charact. 2008, 59, 825–841. [Google Scholar] [CrossRef]

- Chen, X.; Zheng, L.; Feng, S.; Li, J.; Wang, F.; Zhang, H. Tempering influence on microstructural evolution and mechanical properties in a core of CSS-42L bearing steel. Mater. Sci. Eng. A 2022, 861, 144233. [Google Scholar] [CrossRef]

- Tai, S.; Bu, C.; Wang, Y.; Yue, T.; Liu, H.; Wang, L. Identification of aircraft longitudinal aerodynamic parameters using an online corrective test for wind tunnel virtual flight. Chin. J. Aeronaut. 2024, 37, 261–275. [Google Scholar] [CrossRef]

- Li, T.; Shi, H.; Bai, X.; Li, N.; Zhang, K. Rolling bearing performance assessment with degradation twin modeling considering interdependent fault evolution. Mech. Syst. Signal Process. 2025, 224, 112194. [Google Scholar] [CrossRef]

- Shi, J.; Zhao, B.; He, J.; Lu, X. The optimization design for the journal-thrust couple bearing surface texture based on particle swarm algorithm. Tribol. Int. 2024, 198, 109874. [Google Scholar] [CrossRef]

- Sadeghi, F.; Jalalahmadi, B.; Slack, T.S.; Raje, N.; Arakere, N.K. A Review of Rolling Contact Fatigue. J. Tribol. 2009, 131, 041403. [Google Scholar] [CrossRef]

- Voskamp, A.P. Material Response to Rolling Contact Loading. J. Tribol. 1985, 107, 359–366. [Google Scholar] [CrossRef]

- Warhadpande, A.; Sadeghi, F.; Evans, R.D. Microstructural Alterations in Bearing Steels under Rolling Contact Fatigue Part 1—Historical Overview. Tribol. Trans. 2013, 56, 349–358. [Google Scholar] [CrossRef]

- Maharjan, N.; Zhou, W.; Zhou, Y. Microstructural study of bearing material failure due to rolling contact fatigue in wind turbine gearbox. In Proceedings of the International Symposium on Current Research in Hydraulic Turbines, Dhulikhel, Nepal, 14 March 2016. [Google Scholar]

- Mitamura, N.; Hidaka, H.; Takaki, S. Microstructural Development in Bearing Steel during Rolling Contact Fatigue. Mater. Sci. Forum 2007, 539–543, 4255–4260. [Google Scholar] [CrossRef]

- Cai, X.; Hu, X.; Lu, X.; Liu, H.; Cao, Y.; Li, D. Exploring the ultrahigh rolling contact fatigue life of M50 bearing steel by adjusting the cryogenic sequence. J. Mater. Sci. Technol. 2024, 169, 243–250. [Google Scholar] [CrossRef]

- Olver, A.V. The Mechanism of Rolling Contact Fatigue: An Update. Proceedings of the Institution of Mechanical Engineers. Part J J. Eng. Tribol. 2005, 219, 313–330. [Google Scholar] [CrossRef]

- Grabulov, A.; Ziese, U.; Zandbergen, H.W. TEM/SEM investigation of microstructural changes within the white etching area under rolling contact fatigue and 3-D crack reconstruction by focused ion beam. Scr. Mater. 2007, 57, 635–638. [Google Scholar] [CrossRef]

- Evans, M.H.; Richardson, A.D.; Wang, L.; Wood, R.; Anderson, W.B. Confirming subsurface initiation at non-metallic inclusions as one mechanism for white etching crack (WEC) formation. Tribol. Int. 2014, 75, 87–97. [Google Scholar] [CrossRef]

- Morsdorf, L.; Mayweg, D.; Li, Y.; Diederichs, A.; Raabe, D.; Herbig, M. Moving cracks form white etching areas during rolling contact fatigue in bearings. Mater. Sci. Eng. A 2020, 771, 138659. [Google Scholar] [CrossRef]

- Kang, J.H.; Hosseinkhani, B.; Williams, C.A.; Moody, M.P.; Bagot, P.A.J.; Rivera-Díaz-del-Castillo, P.E.J. Solute redistribution in the nanocrystalline structure formed in bearing steels. Scr. Mater. 2013, 69, 630–633. [Google Scholar] [CrossRef]

- Zheng, C.; Dan, R.; Zhang, F.; Lv, B.; Yan, Z.; Shan, J.; Long, X. Effects of retained austenite and hydrogen on the rolling contact fatigue behaviours of carbide-free bainitic steel. Mater. Sci. Eng. A 2014, 594, 364–371. [Google Scholar] [CrossRef]

- Liang, X.Z.; Rivera-Díaz-del-Castillo, P.E.J. Hydrogen-accelerated white etching area formation in bearings under rolling contact fatigue. Int. J. Fatigue 2022, 159, 106753. [Google Scholar] [CrossRef]

- Grabulov, A. Fundamentals of Rolling Contact Fatigue. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2010. [Google Scholar]

- Bhadeshia, H.K.D.H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Pian, L.P.; Li, H.H.; Pang, X.D.; Sun, Y.; Chi, H.X.; Gu, J.B. Mechanical behavior and microstructural evolution of a modified CSS-42L steel during tempering. J. Iron Steel Res. Int. 2025. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Mo | Co | V | Ni | Nb |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.13 | 0.18 | 0.09 | 13.80 | 4.70 | 12.70 | 0.60 | 2.00 | 0.02 |

| Swept Area (μm2) | Count | Average Diameter (μm) | Maximum Diameter (μm) | Percentage of Area |

|---|---|---|---|---|

| 30.00 | 40 | 1.54 | 2.76 | 0.00001 |

| Number Density | 1–2 µm | 2–5 µm | 5–10 µm | >10 µm |

|---|---|---|---|---|

| 1.33 | 33 82.50% | 7 17.50% | 0 0% | 0 0% |

| Test Number | RCF Loading Cycles |

|---|---|

| 1 | 9.3 × 106 |

| 2 | 1.2 × 107 |

| 3 | 2.6 × 107 |

| 4 | 3.6 × 107 |

| 5 | 2.0 × 108 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Lu, X.; Lei, C.; Ma, X.; Liu, H. Characterization of the Carbides in Carburized CSS-42L Steel and Their Effect on the Fatigue Failure Mechanism. Metals 2025, 15, 1013. https://doi.org/10.3390/met15091013

Liu M, Lu X, Lei C, Ma X, Liu H. Characterization of the Carbides in Carburized CSS-42L Steel and Their Effect on the Fatigue Failure Mechanism. Metals. 2025; 15(9):1013. https://doi.org/10.3390/met15091013

Chicago/Turabian StyleLiu, Ming, Xingyu Lu, Chengshuai Lei, Xinxin Ma, and Hongwei Liu. 2025. "Characterization of the Carbides in Carburized CSS-42L Steel and Their Effect on the Fatigue Failure Mechanism" Metals 15, no. 9: 1013. https://doi.org/10.3390/met15091013

APA StyleLiu, M., Lu, X., Lei, C., Ma, X., & Liu, H. (2025). Characterization of the Carbides in Carburized CSS-42L Steel and Their Effect on the Fatigue Failure Mechanism. Metals, 15(9), 1013. https://doi.org/10.3390/met15091013