Investigation of the Effects of Gas Metal Arc Welding and Friction Stir Welding Hybrid Process on AA6082-T6 and AA5083-H111 Aluminum Alloys

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

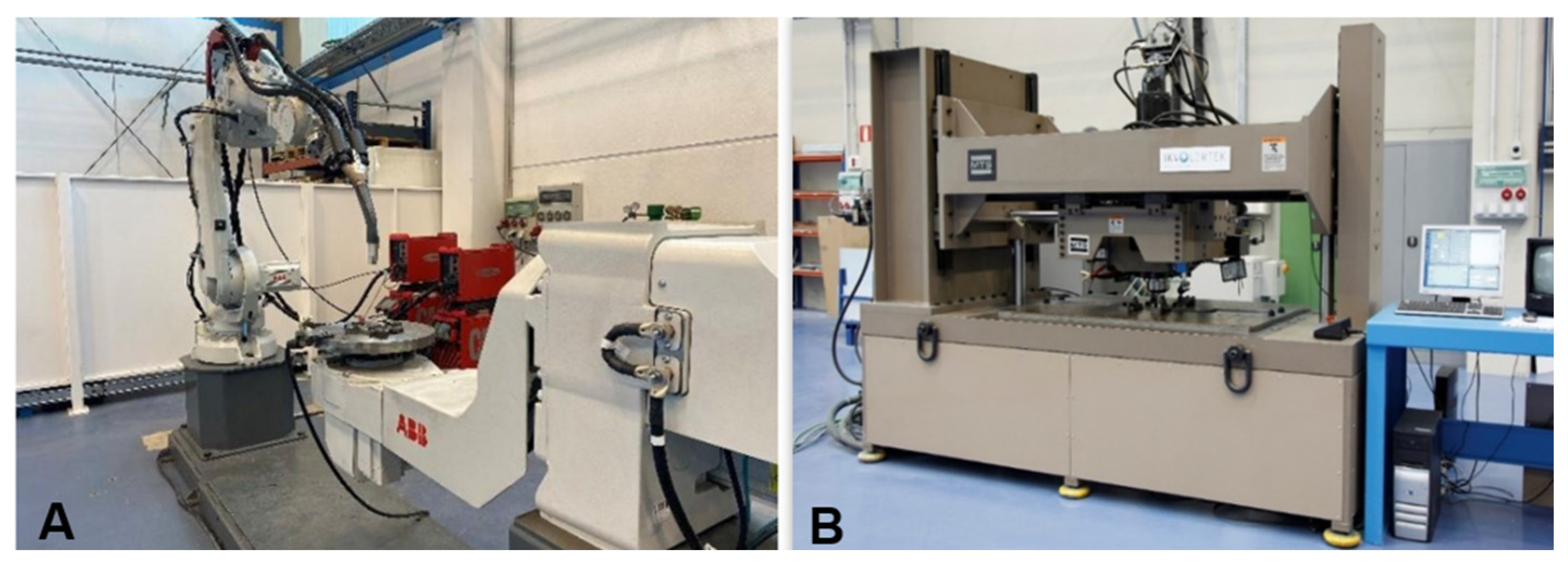

2.2. Welding Processes

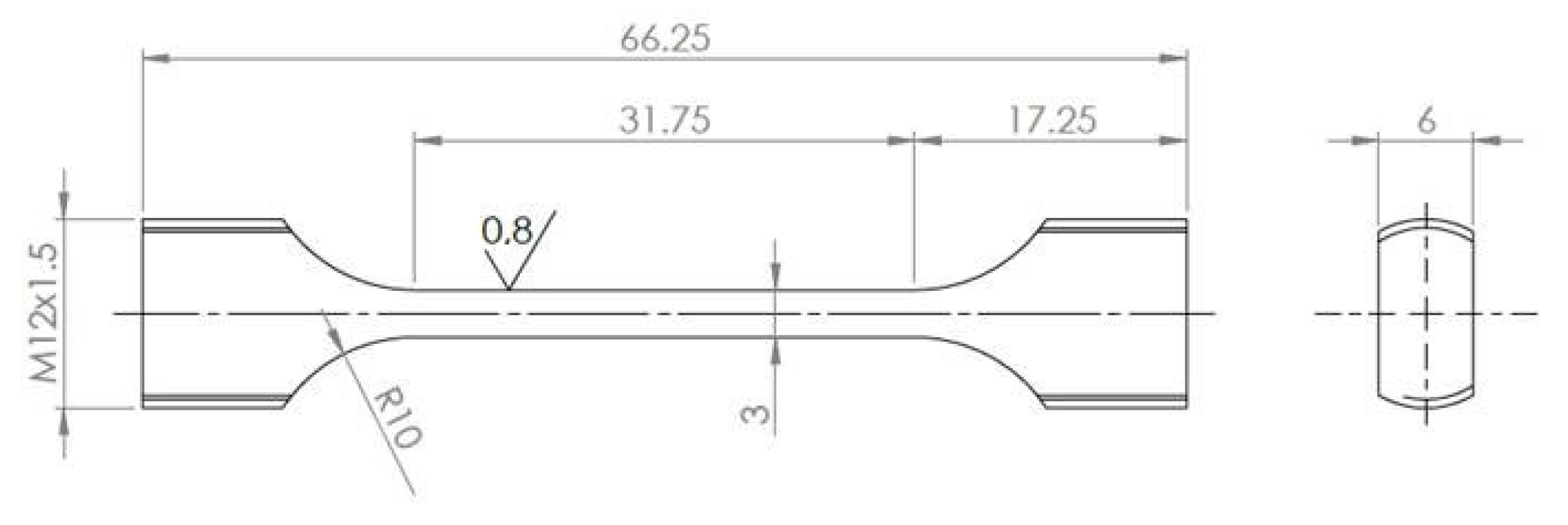

2.3. Joint Analysis

3. Results and Discussions

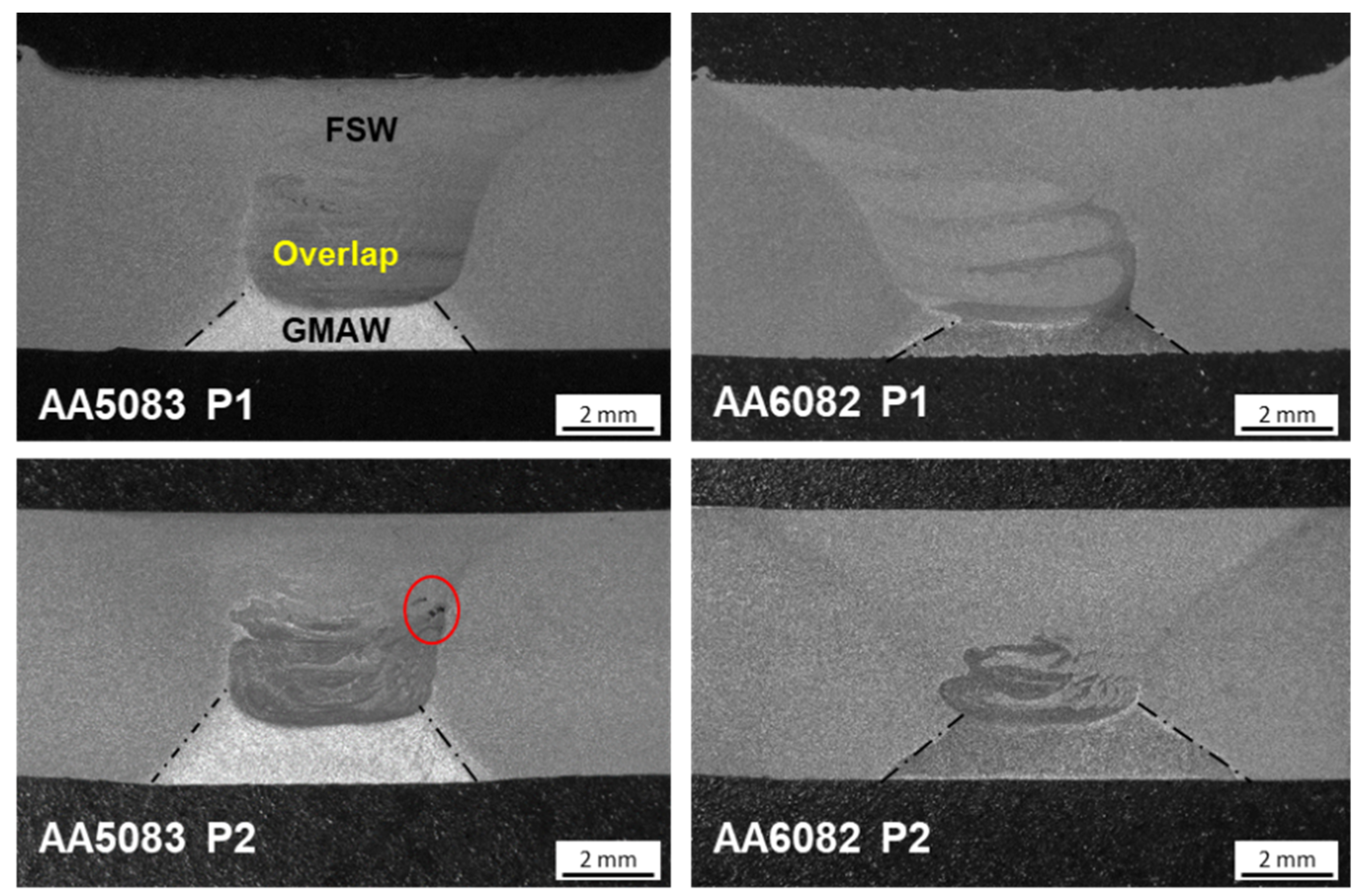

3.1. Weld Macrostructure

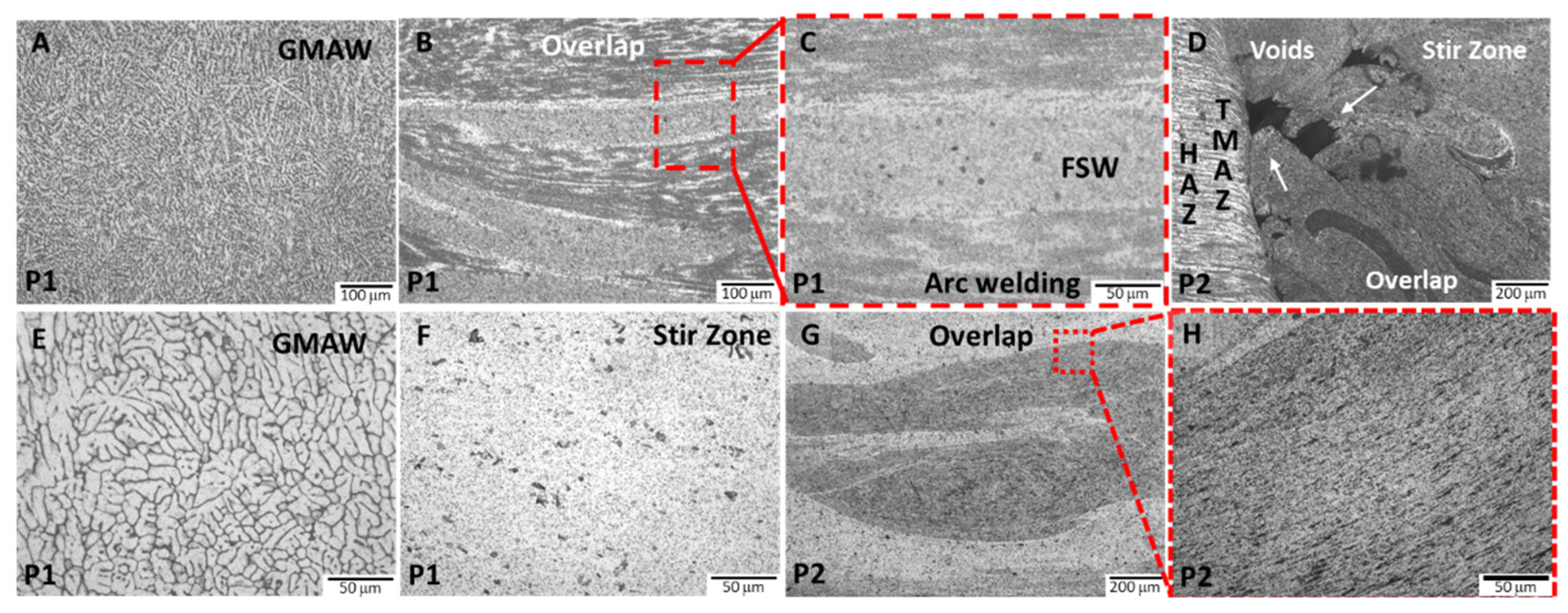

3.2. Weld Microstructure

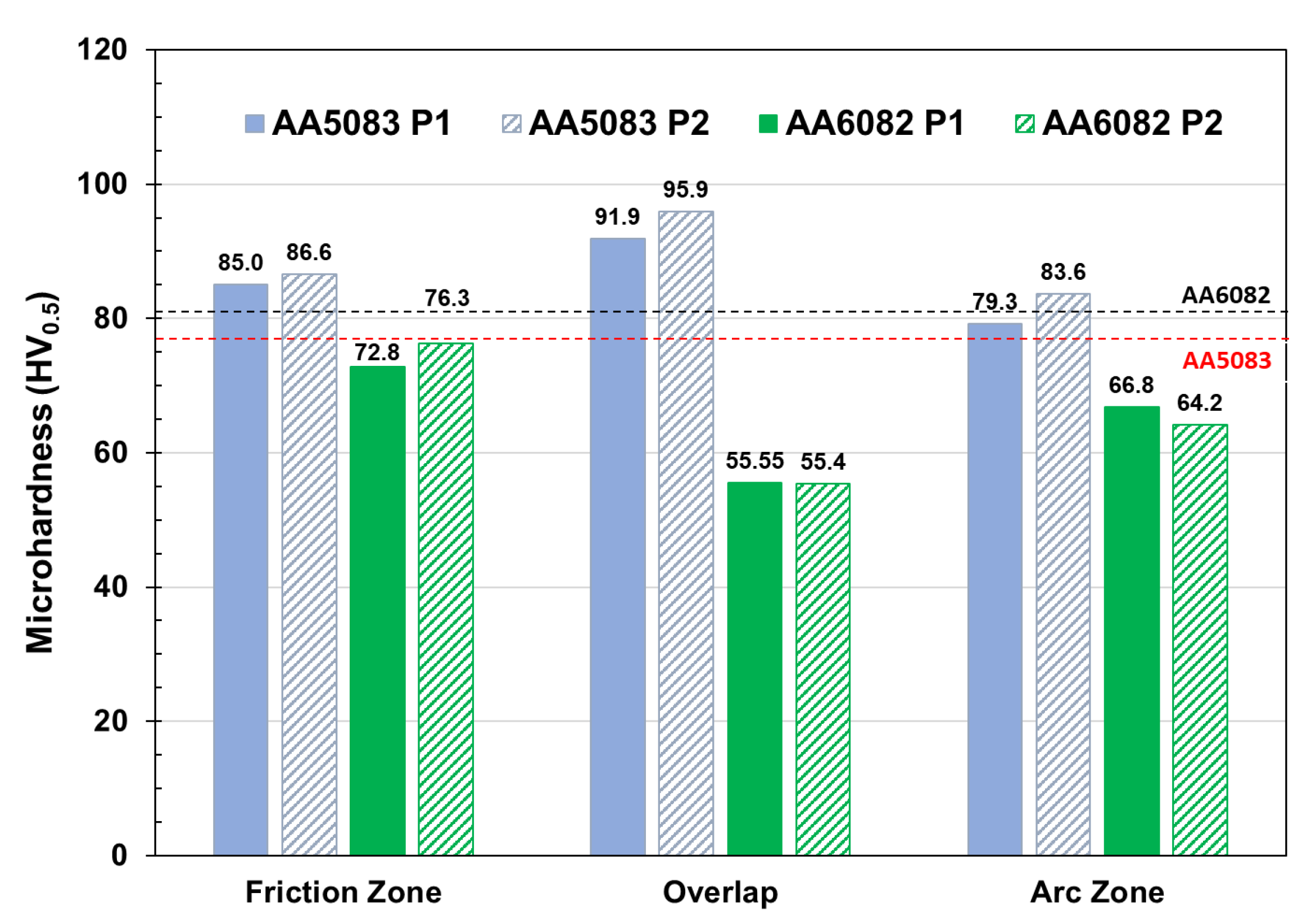

3.3. Microhardness

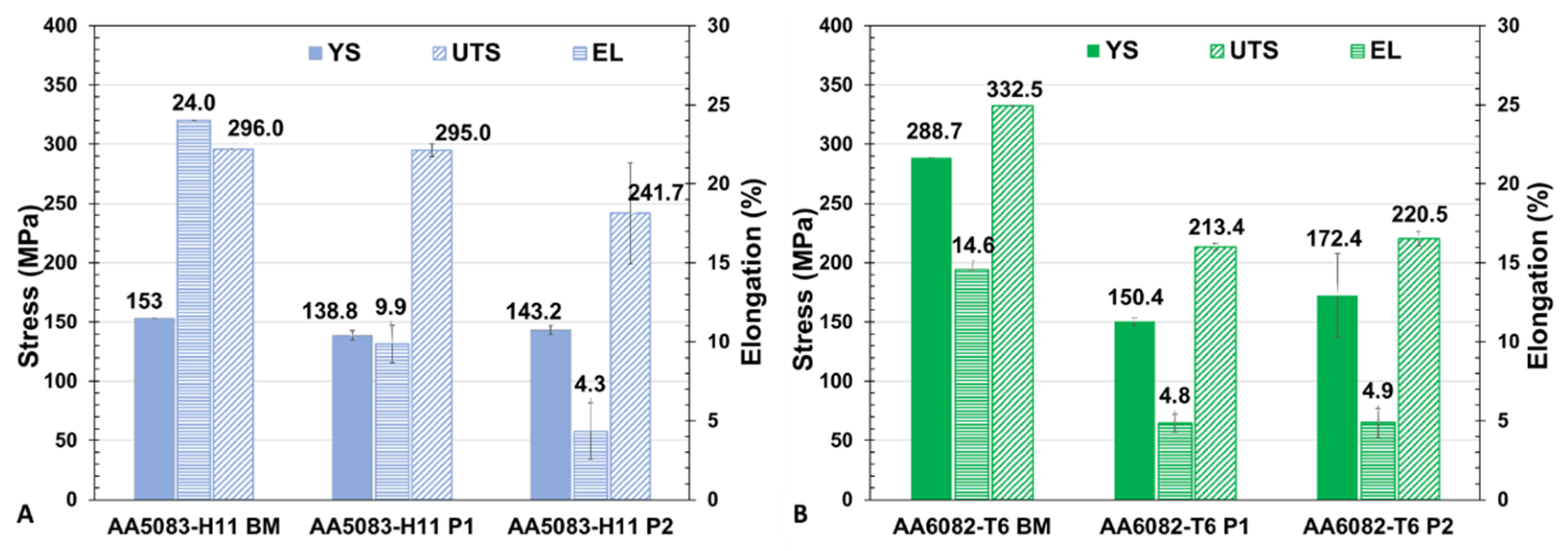

3.4. Tensile Testing

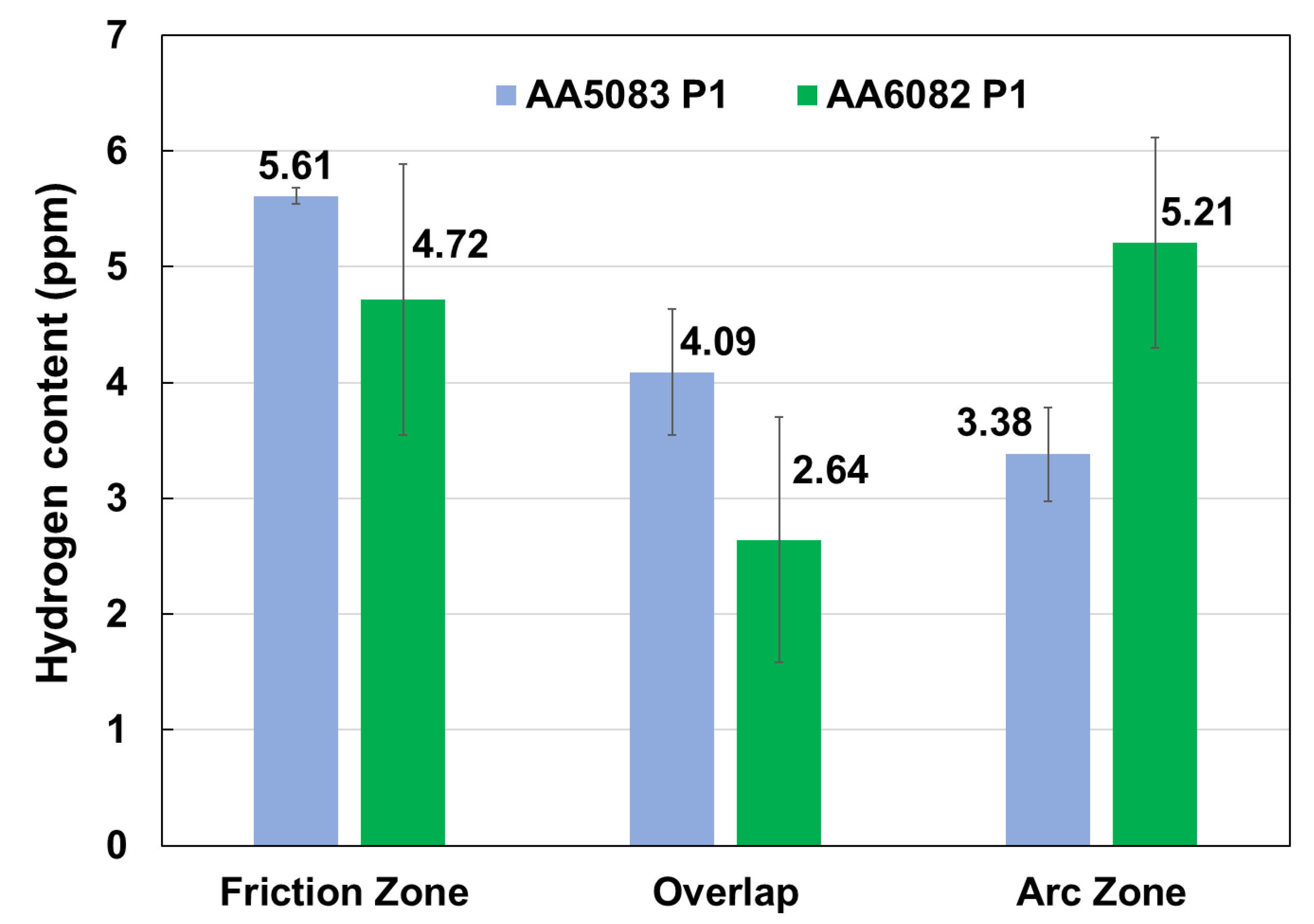

3.5. Mechanical Behavior in Hydrogen Environment

4. Conclusions

- Variations in welding parameters, such as rotation and travel speeds, resulted in similar performance in both alloys.

- The metallurgical examination revealed the characteristic microstructures associated with each welding process across all conditions. In the overlap zone, the cast structure originally produced by arc welding was altered by the friction-stirring action, resulting in a fine, equiaxed grain structure typical of friction stir welding.

- In the AA5083-H111 joints, the overlap zone exhibited the highest hardness values (95.9 HV), representing a notable 23% increase compared to the base material. Tensile testing revealed a joint efficiency of 99%, which was primarily attributed to the high strain rates and significant grain refinement induced by the friction stir welding process.

- The AA6082-T6 joints showed a reduction in hardness across all welded zones compared to the base material, with the overlap zone presenting the lowest value (55.6 HV). The highest joint efficiency achieved in tensile testing was 66.7%. This performance is associated with the dissolution of strengthening precipitates caused by the thermal and mechanical effects of the FSW process.

- Hydrogen absorption varied across weld zones and alloys, with the FSW zone of AA5083-H111 and the arc-welded zone of AA6082-T6 showing the highest hydrogen content. Nevertheless, hydrogen embrittlement indices remained within the “Negligible” classification for both alloys. Furthermore, SSRT tests revealed no significant differences in fracture location or ductility loss between specimens tested in inert and hydrogen-rich environments, confirming that the hybrid welds maintained their mechanical integrity under hydrogen exposure.

- The GMAW–FSW hybrid techniques applied to AA6082-T6 and AA5083-H111 successfully modified the microstructure and improved the mechanical properties, indicating the robustness of the hybrid welding approach.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AR | Area Reduction |

| BM | Base Material |

| CSA | Canadian Standards Association |

| CTWD | Contact-Tip-to-Workpiece Distance |

| FSW | Friction Stir Welding |

| GMAW | Gas Metal Arc Welding |

| GTAW | Gas Tungsten Arc Welding |

| HAZ | Heat-Affected Zone |

| NZ | Nugget Zone |

| OM | Optical Microscopy |

| SCC | Stress Corrosion Cracking |

| SSRT | Slow Strain Rate Testing |

| SZ | Stir Zone |

| TMAZ | Thermo-Mechanically–Affected Zone |

| UTS | Ultimate Tensile Strength |

| YS | Yield Strength |

References

- Kou, S. Welding Metallurgy; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2002. [Google Scholar] [CrossRef]

- O’Brien, A. Welding Handbook—Welding Processes Part I; American Welding Society: Doral, FL, USA, 2004; Volume 1. [Google Scholar]

- Verma, S.; Wu, C.S.; Thakur, L.; Muhammad, N.A.; Li, S. Effect of material position and tool offset on the microstructure and mechanical properties of friction stir welded AA7075/AZ31B with ultrasonic assistance. J. Manuf. Process. 2024, 118, 45–62. [Google Scholar] [CrossRef]

- Inácio, P.L.; Ferreira, F.B.; Vilaça, P.; Oliveira, J.P.; Santos, T.G. Assessment of the energetic efficiency of friction stir welding/processing. J. Manuf. Process. 2023, 103, 298–308. [Google Scholar] [CrossRef]

- Panagopoulos, C.N.; Georgiou, E.; Giannakopoulos, K.I.; Orfanos, P.G. Effect of pH on stress corrosion cracking of 6082 al alloy. Metals 2018, 8, 578. [Google Scholar] [CrossRef]

- Huang, L.; Hua, X.; Wu, D.; Jiang, Z.; Ye, Y. A study on the metallurgical and mechanical properties of a GMAW-welded al-mg alloy with different plate thicknesses. J. Manuf. Process. 2019, 37, 438–445. [Google Scholar] [CrossRef]

- Jesus, J.S.; Costa, J.M.; Loureiro, A.; Ferreira, J.M. Fatigue strength improvement of GMAW T-welds in AA 5083 by friction-stir processing. Int. J. Fatigue 2017, 97, 124–134. [Google Scholar] [CrossRef]

- Cong, S.; Wu, L.; Wang, Z.; Li, N.; Zhu, Z.; Wang, F.; Zhang, X.; Wang, K.; Xue, P.; Ni, D.; et al. Achieving superior mechanical and corrosion properties in medium-thickness Ti-6Al-4 V alloy joints by back heating assisted friction stir welding below β-phase transformation temperature. Mater. Charact. 2024, 217, 114391. [Google Scholar] [CrossRef]

- Chen, J.; Miura, T.; Ushioda, K.; Fujii, H. Effects of microstructure and phosphorus segregation on tensile properties of friction stir welded high phosphorus weathering steel. Mater. Sci. Eng. A 2024, 916, 147315. [Google Scholar] [CrossRef]

- Tong, Y.; Dong, B.; Cai, X.; Zhang, H.; Lin, S. Friction stir welding of 2195 Al-Li alloy: Effect of microstructure on joint failure. Mater. Charact. 2025, 224, 115077. [Google Scholar] [CrossRef]

- Yu, P.; Wu, C.S.; Shi, L. Analysis and characterization of dynamic recrystallization and grain structure evolution in friction stir welding of aluminum plates. Acta Mater. 2021, 207, 116692. [Google Scholar] [CrossRef]

- Akbari, M.; DebRoy, T.; Asadi, P.; Sadowski, T. Recent advances in friction stir welding/processing tools. J. Manuf. Process. 2025, 142, 99–156. [Google Scholar] [CrossRef]

- Chludzinski, M.; Vivas, J.; Vázquez-Martínez, J.M.; Del Sol, I.; Begiristain, E.A. Influence of TiC particles on the properties of AA2017 friction surfaced coatings. Adv. Compos. Hybrid Mater. 2025, 8, 222. [Google Scholar] [CrossRef]

- Dos Santos, R.E.; Chludzinski, M.; Nunes, R.M.; Marinho, R.R.; Paes, M.T.P.; Reguly, A. Investigation of Friction Hydro-Pillar Processing as a Repair Technique for Offshore Mooring Chain Links. J. Manuf. Mater. Process. 2023, 7, 200. [Google Scholar] [CrossRef]

- Lim, Y.C.; Sanderson, S.; Mahoney, M.; Wasson, A.J.; Fairchild, D.P.; Wang, Y.; Feng, Z. Study of mechanical properties and characterization of pipe steel welded by hybrid (friction stir weld + root arc weld) approach. In Friction Stir Welding and Processing VIII; Springer: Cham, Switzerland, 2016; pp. 55–68. [Google Scholar] [CrossRef]

- Mahone, M.; Sanderson, S.; Feng, Z.; Steel, R.; Packer, S.; Fleck, D. Friction Stir Welding of Pipeline Steels. In Friction Stir Welding and Proceesing Vll; Springer: Cham, Switzerland, 2013. [Google Scholar]

- El-Fahhar, H.H.; Gadallah, E.A.; Habba, M.I.A.; Seleman, M.M.E.-S.; Ahmed, M.M.Z.; Mohamed, A.Y.; Fouad, R.A. Effect of post-weld heat-treatment and solid-state thermomechanical treatment on the properties of the AA6082 MIG welded joints. Sci. Rep. 2024, 14, 4380. [Google Scholar] [CrossRef]

- Rao, K.P.; Ram, G.J.; Stucker, B.E. Effect of friction stir processing on corrosion resistance of aluminum–copper alloy gas tungsten arc welds. Mater. Des. 2010, 31, 1576–1580. [Google Scholar] [CrossRef]

- Zucchi, F.; Trabanelli, G.; Grassi, V. Pitting and stress corrosion cracking resistance of friction stir welded AA 5083. Werkst. Korros. 2001, 52, 853–859. [Google Scholar] [CrossRef]

- Bodaghi, F.; Atapour, M.; Shamanian, M. Assessment of Microstructure and Stress Corrosion Cracking Susceptibility of Multipass Gas Metal Arc Welded Al 5083-H321 Aluminum Alloy. Metallogr. Microstruct. Anal. 2021, 10, 246–256. [Google Scholar] [CrossRef]

- Costa, A.M.S.; Oliveira, J.P.; Pereira, V.F.; Nunes, C.A.; Ramirez, A.J.; Tschiptschin, A.P. Ni-based Mar-M247 superalloy as a friction stir processing tool. J. Mater. Process. Technol. 2018, 262, 605–614. [Google Scholar] [CrossRef]

- ASTM G129; Standard Practice for Slow Strain Rate Testing to Evaluate the Susceptibility of Metallic Materials to Environmentally Assisted Cracking. ASTM International: West Conshohocken, PA, USA, 2013.

- ISO 16573-2; Steel—Measurement Method for Hydrogen Embrittlement Resistance of High Strength Steels—Part 2: Constant Loading Method. ISO: Geneva, Switzerland, 2019.

- ASTM G142; Standard Test Method for Determination of Susceptibility of Metals to Embrittlement in Hydrogen Containing Environments at High Pressure, High Temperature, or Both. ASTM International: West Conshohocken, PA, USA, 2010.

- CSA (Canadian Standards Association). Standards on Hydrogen Embrittlement; CSA Group: Toronto, ON, Canada, 2014. [Google Scholar]

- NASA/TM—2016–218602; Hydrogen Embrittlement. NASA Technical Memorandum: Cleveland, OH, USA, 2016.

- Mishra, R.S.; De, P.S.; Kumar, N. Friction Stir Welding and Processing; Springer International Publishing: Cham, Switzerland, 2014. [Google Scholar] [CrossRef]

- Svensson, L.E.; Karlsson, L.; Larsson, H.; Karlsson, B.; Fazzini, M.; Karlsson, J. Microstructure and mechanical properties of friction stir welded aluminium alloys with special reference to AA 5083 and AA 6082. Sci. Technol. Weld. Join. 2000, 5, 285–296. [Google Scholar] [CrossRef]

- Noga, P.; Skrzekut, T.; Wędrychowicz, M.; Węglowski, M.S.; Węglowska, A. Research of Friction Stir Welding (FSW) and Electron Beam Welding (EBW) Process for 6082-T6 Aluminum Alloy. Materials 2023, 16, 4937. [Google Scholar] [CrossRef]

- Essa, A.R.S.; Aboud, A.R.K.; Ahmed, M.M.Z.; El-Nikhaily, A.E.; Easa, A.S.; Habba, M.I.A. Friction stir welding of aluminum alloy 6082-T6 using eccentric shoulder tools to eliminate the need for tool tilting. Sci. Rep. 2025, 15, 8801. [Google Scholar] [CrossRef]

- Habba, M.I.A.; Alsaleh, N.A.; Badran, T.E.; Seleman, M.M.E.-S.; Ataya, S.; El-Nikhaily, A.E.; Abdul-Latif, A.; Ahmed, M.M.Z. Comparative Study of FSW, MIG, and TIG Welding of AA5083-H111 Based on the Evaluation of Welded Joints and Economic Aspect. Materials 2023, 16, 5124. [Google Scholar] [CrossRef]

- Kundu, J.; Singh, H. Friction stir welding of AA5083 aluminium alloy: Multi-response optimization using Taguchi-based grey relational analysis. Adv. Mech. Eng. 2016, 8, 1687814016679277. [Google Scholar] [CrossRef]

- Da Silva, J.; Costa, J.M.; Loureiro, A.; Ferreira, J.M. Fatigue behaviour of AA6082-T6 MIG welded butt joints improved by friction stir processing. Mater. Des. 2013, 51, 315–322. [Google Scholar] [CrossRef]

- Chanakyan, C.; Sivasankar, S.; Meignanamoorthy, M.; Ravichandran, M.; Muralidharan, T. Experimental investigation on influence of process parameter on friction stir processing of AA6082 using response surface methodology. Mater. Today Proc. 2020, 21, 231–236. [Google Scholar] [CrossRef]

- Mroczka, K.; Pietras, A. FSW characterization of 6082 aluminium alloys sheets. Arch. Mater. Sci. Eng. 2009, 40, 104–109. [Google Scholar]

- Adamowski, J.; Gambaro, C.; Lertora, E.; Ponte, M.; Szkodo, M. Analysis of FSW welds made of aluminium alloy AW6082-T6. Arch. Mater. Sci. Eng. 2007, 28, 453–460. [Google Scholar]

- Sreenivas, P.; Anil Kumar, R.; Sreejith, P.S. Effect of applied axial force on FSW of AA 6082-T6 aluminium alloys. Int. J. Mech. Eng. Technol. 2017, 8, 88–99. [Google Scholar]

- Costa, M.I.; Rodrigues, D.M.; Leitão, C. Analysis of AA 6082-T6 welds strength mismatch: Stress versus hardness relationships. Int. J. Adv. Manuf. Technol. 2015, 79, 719–727. [Google Scholar] [CrossRef]

- Qu, G.; Guo, W.; Zhang, H.; Shen, Z.; Zhang, L.; Dai, W.; Xiao, J.; Xue, J.; Zhu, H.; Li, M.; et al. Stress Corrosion Behavior of MIG Welded Joints of 6082-T6 Aluminum Alloy at Different Temperatures. Chin. J. Mech. Eng. 2024, 37, 167. [Google Scholar] [CrossRef]

- Ghorani, A.; Itoh, G.; Ohbuchi, T.; Kiuchi, T. Effect of Sensitization on Hydrogen Embrittlement in a 5083 Aluminum Alloy. Mater. Trans. 2022, 63, 1425–1430. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, J.; Qin, Z.; Xia, D.-H.; Behnamian, Y.; Hu, W.; Tribollet, B. A mechanistic study on stress corrosion cracking of sensitized AA5083 in a simulated water level fluctuation zone: Combined impedance analysis and tensile tests. Corros. Sci. 2025, 245, 112701. [Google Scholar] [CrossRef]

- Papantoniou, I.G.; Karmiris-Obratański, P.; Leszczyńska-Madej, B.; Manolakos, D.E. Investigating the Impact of Friction Stir Processing on the Hydrogen Embrittlement in AA6082-T6 Heat-Treatable Aluminum Alloy. Met. Mater. Int. 2024, 30, 2668–2684. [Google Scholar] [CrossRef]

- Gao, W.; Gu, Y.; Chen, L.; Liang, H.; Wang, D.; Seifi, M.; Lewandowski, J.J. Effects of sensitization on environmentally assisted cracking of AA5083-H128 Al–Mg alloy. J. Mater. Res. Technol. 2023, 25, 681–697. [Google Scholar] [CrossRef]

- Georgiou, E.P.; Celis, J.P.; Panagopoulos, C.N. The effect of cold rolling on the hydrogen susceptibility of 5083 aluminum alloy. Metals 2017, 7, 451. [Google Scholar] [CrossRef]

- Kyriakopoulou, H.P.; Farantos, C.N.; Vazdirvanidis, A.; Markoulis, A.; Xanthis, C.A.; Chatzidouros, E.V.; Pantelis, D.I. Investigation of the Hydrogen Embrittlement Susceptibility of AA5083-H111 and AA6082-T6 Dissimilar Friction Stir Welds. J. Mater. Eng. Perform. 2019, 28, 7687–7701. [Google Scholar] [CrossRef]

- Qin, J.; Li, Z.; Ma, M.-Y.; Yi, D.-Q.; Wang, B. Diversity of intergranular corrosion and stress corrosion cracking for 5083 Al alloy with different grain sizes. Trans. Nonferrous Met. Soc. China 2022, 32, 765–777. [Google Scholar] [CrossRef]

- Chandra Muduli, R.; Kale, P. Silicon nanostructures for solid-state hydrogen storage: A review. Int. J. Hydrogen Energy 2023, 48, 1401–1439. [Google Scholar] [CrossRef]

- Chen, Y.-S.; Huang, C.; Liu, P.-Y.; Yen, H.-W.; Niu, R.; Burr, P.; Moore, K.L.; Martínez-Pañeda, E.; Atrens, A.; Cairney, J.M. Hydrogen trapping and embrittlement in metals—A review. Int. J. Hydrogen Energy 2024, 136, 789–821. [Google Scholar] [CrossRef]

| Element (wt.%) | Mn | Si | Cr | Cu | Zn | Fe | Ti | Mg |

|---|---|---|---|---|---|---|---|---|

| AA5083-H111 | 0.48 | 0.27 | 0.07 | 0.06 | 0.05 | 0.32 | 0.03 | 4.70 |

| AA6082-T6 | 0.51 | 0.88 | 0.01 | 0.04 | 0.02 | 0.36 | 0.01 | 0.90 |

| ER4043 | 0.05 | 4.50–6.00 | - | - | - | 0.80 | - | 0.05 |

| ER5183 | 0.50–1.00 | 0.40 | - | - | - | 0.40 | - | 4.30–5.20 |

| Properties | AA5083-H111 | AA6082-T6 |

|---|---|---|

| Ultimate tensile strength (MPa) | 296.00 | 332.50 |

| Yield strength (MPa) | 153.00 | 288.70 |

| Maximum elongation (%) | 24.00 | 14.56 |

| Alloy | AA6082-T6 | AA5083-H111 | ||

|---|---|---|---|---|

| Welding Parameter | 1 | 2 | 1 | 2 |

| Rotation speed (rpm) | 1000 | 800 | 600 | 700 |

| Transversal speed (mm/min) | 150 | 300 | 175 | 300 |

| Heat input (J/mm) | 711.7 | 351.7 | 473.7 | 278.4 |

| Alloy | Sample 1 | Initial Area (A0) (mm2) | Initial Length (L0) (mm) | UTS (MPa) | AR (%) | ε (%) |

|---|---|---|---|---|---|---|

| AA5083-H111 | T01_N2 | 17.6 | 30.1 | 311.7 | 42.3 | 21.8 |

| T02_H2 | 17.9 | 29.8 | 306.5 | 39.9 | 22.6 | |

| T03_H2 | 17.9 | 30.0 | 307.8 | 43.5 | 20.5 | |

| T04_H2 | 17.7 | 30.1 | 310.2 | 42.7 | 21.1 | |

| AA6082-T6 | T01_N2 | 18.2 | 30.0 | 215.9 | 41.5 | 11.0 |

| T02_H2 | 17.9 | 29.3 | 213.9 | 46.1 | 11.0 | |

| T03_H2 | 18.1 | 29.7 | 211.4 | 48.1 | 11.2 | |

| T04_H2 | 17.7 | 29.1 | 214.8 | 42.7 | 10.6 |

| Alloy | HEE σUTS | HEE σAR | HEEe |

|---|---|---|---|

| AA5083-H111 | 0.9887 | 0.9944 | 0.9795 |

| AA6082-T6 | 0.9881 | 1.1004 | 0.9908 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chludzinski, M.; Garcia-Sesma, L.; Zubiri, O.; Rodriguez, N.; Aldanondo, E. Investigation of the Effects of Gas Metal Arc Welding and Friction Stir Welding Hybrid Process on AA6082-T6 and AA5083-H111 Aluminum Alloys. Metals 2025, 15, 1005. https://doi.org/10.3390/met15091005

Chludzinski M, Garcia-Sesma L, Zubiri O, Rodriguez N, Aldanondo E. Investigation of the Effects of Gas Metal Arc Welding and Friction Stir Welding Hybrid Process on AA6082-T6 and AA5083-H111 Aluminum Alloys. Metals. 2025; 15(9):1005. https://doi.org/10.3390/met15091005

Chicago/Turabian StyleChludzinski, Mariane, Leire Garcia-Sesma, Oier Zubiri, Nieves Rodriguez, and Egoitz Aldanondo. 2025. "Investigation of the Effects of Gas Metal Arc Welding and Friction Stir Welding Hybrid Process on AA6082-T6 and AA5083-H111 Aluminum Alloys" Metals 15, no. 9: 1005. https://doi.org/10.3390/met15091005

APA StyleChludzinski, M., Garcia-Sesma, L., Zubiri, O., Rodriguez, N., & Aldanondo, E. (2025). Investigation of the Effects of Gas Metal Arc Welding and Friction Stir Welding Hybrid Process on AA6082-T6 and AA5083-H111 Aluminum Alloys. Metals, 15(9), 1005. https://doi.org/10.3390/met15091005