Effect of Interval Time Between Pre-Deformation and Artificial Aging on Mechanical Properties of Er-Containing 7075 Aluminum Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. The Starting Materials

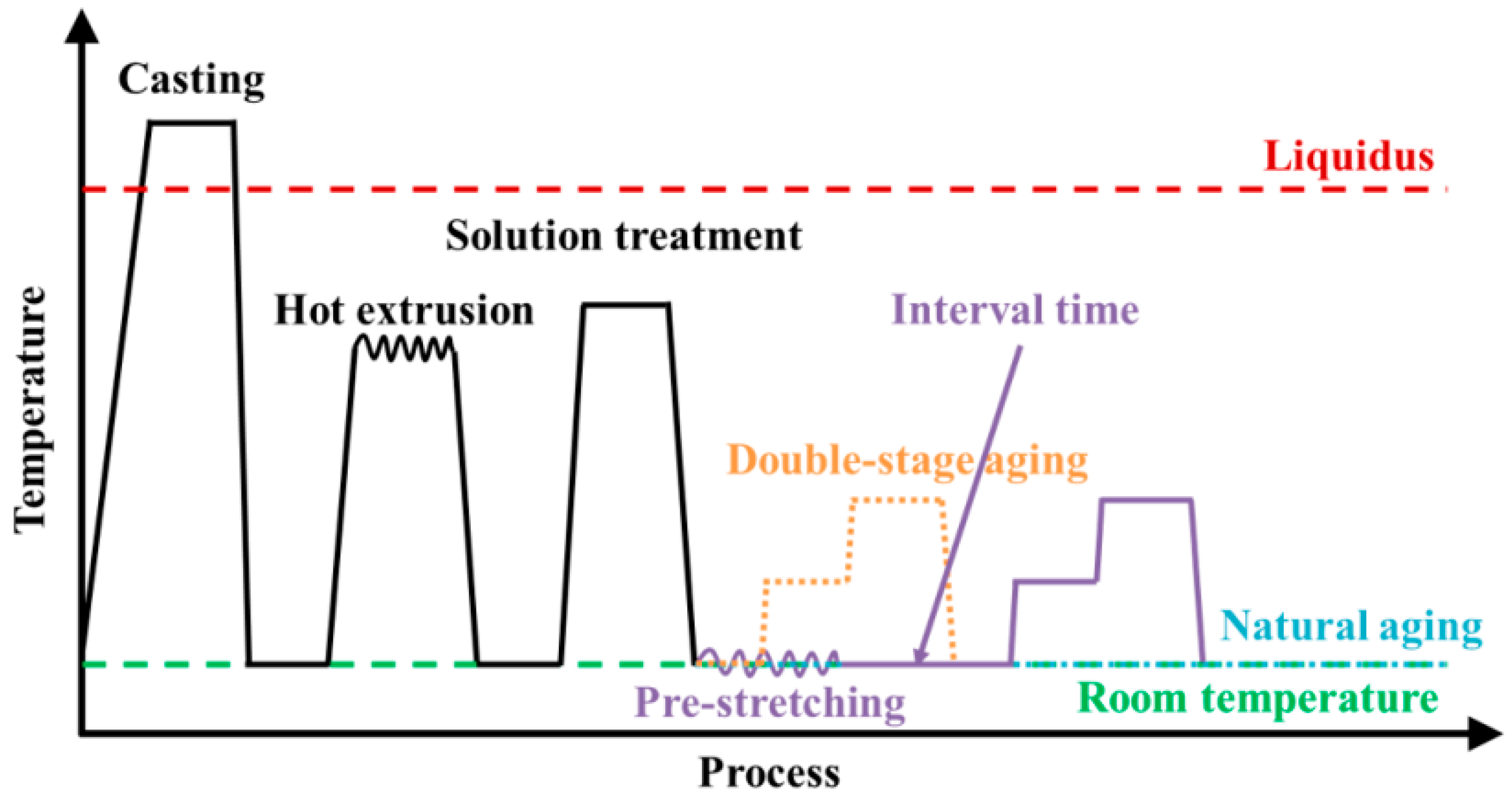

2.2. Heat Treatment

2.3. Mechanical Properties and Microstructure Test

3. Results and Discussion

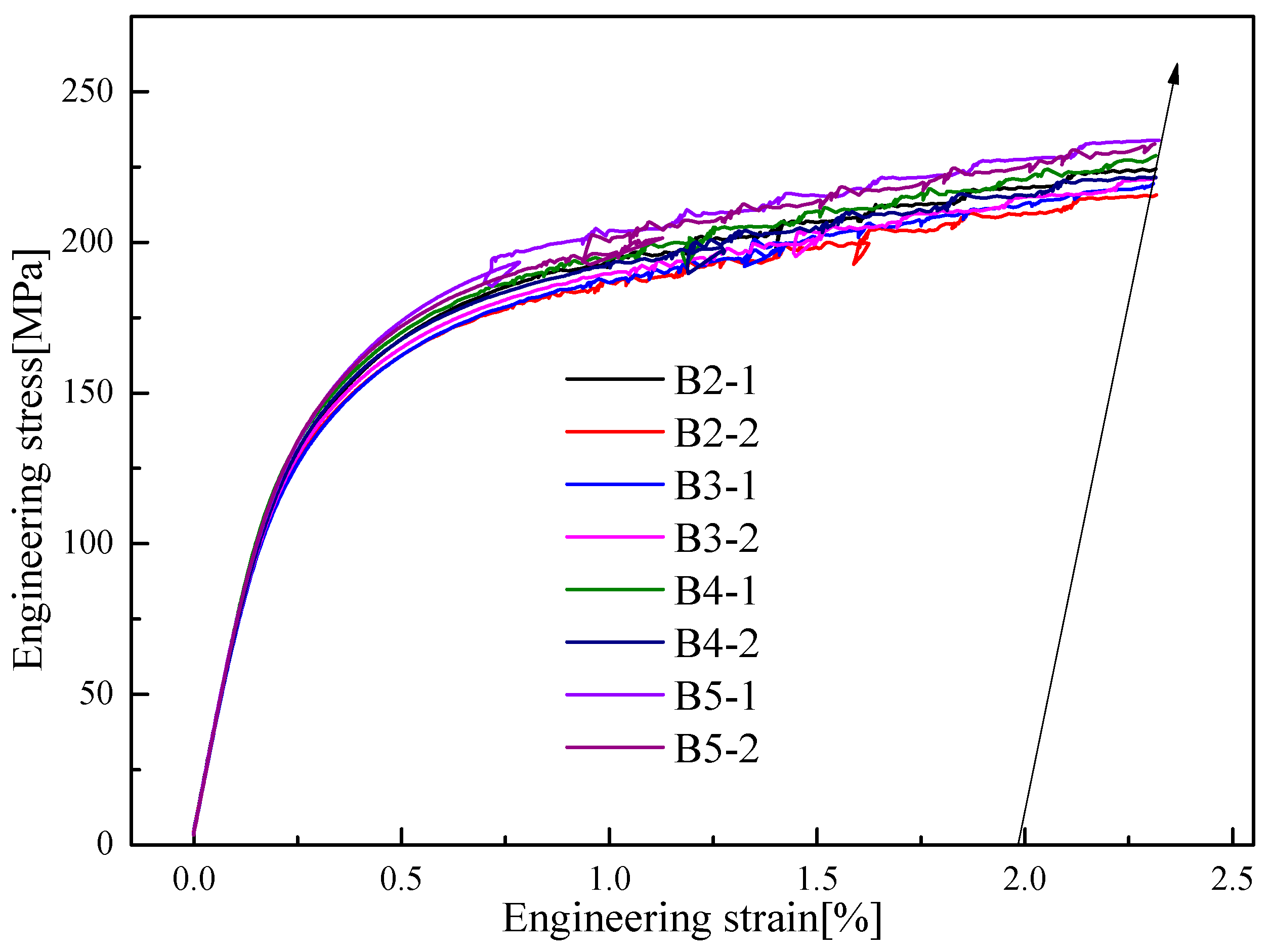

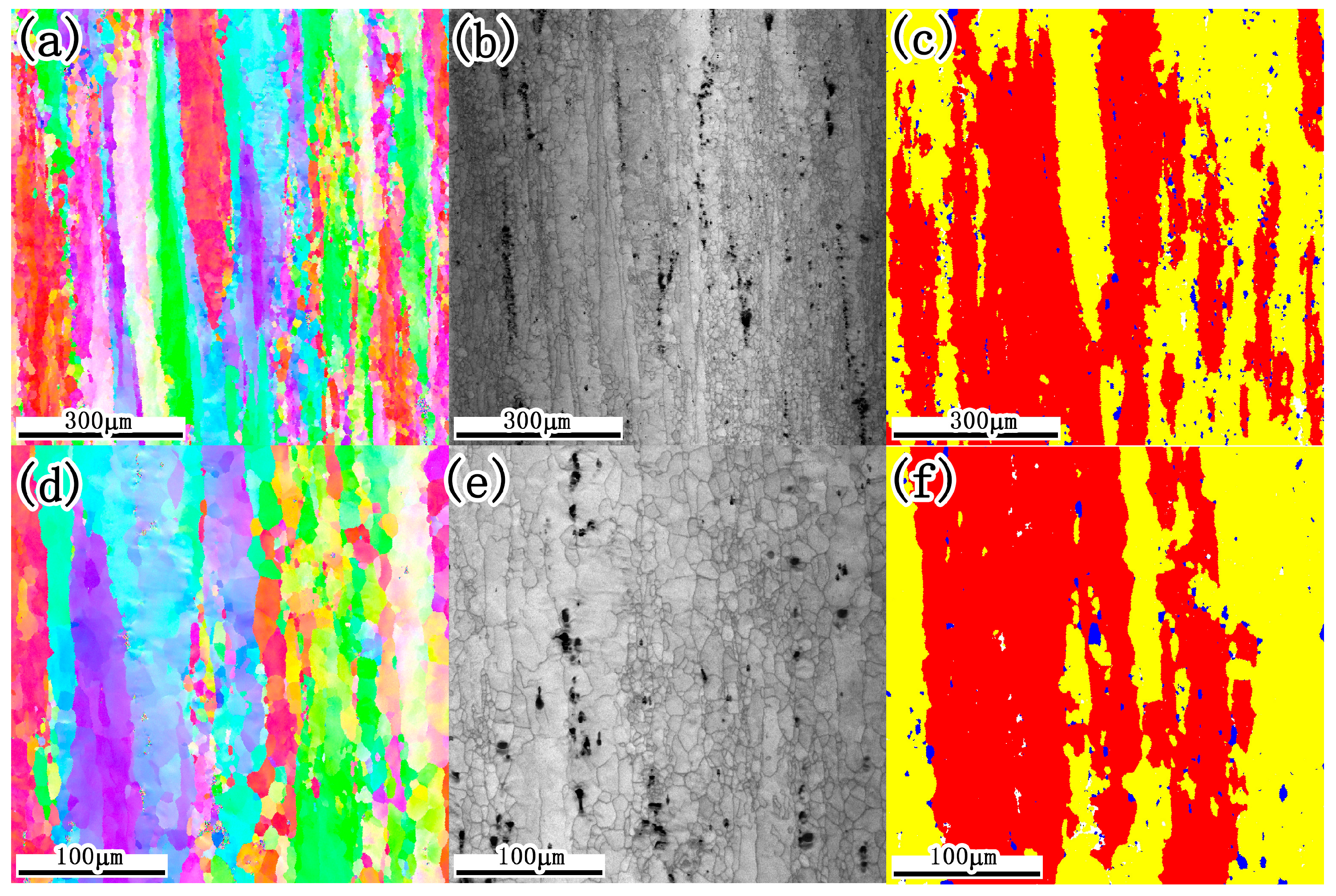

3.1. Pre-Stretching Treatment

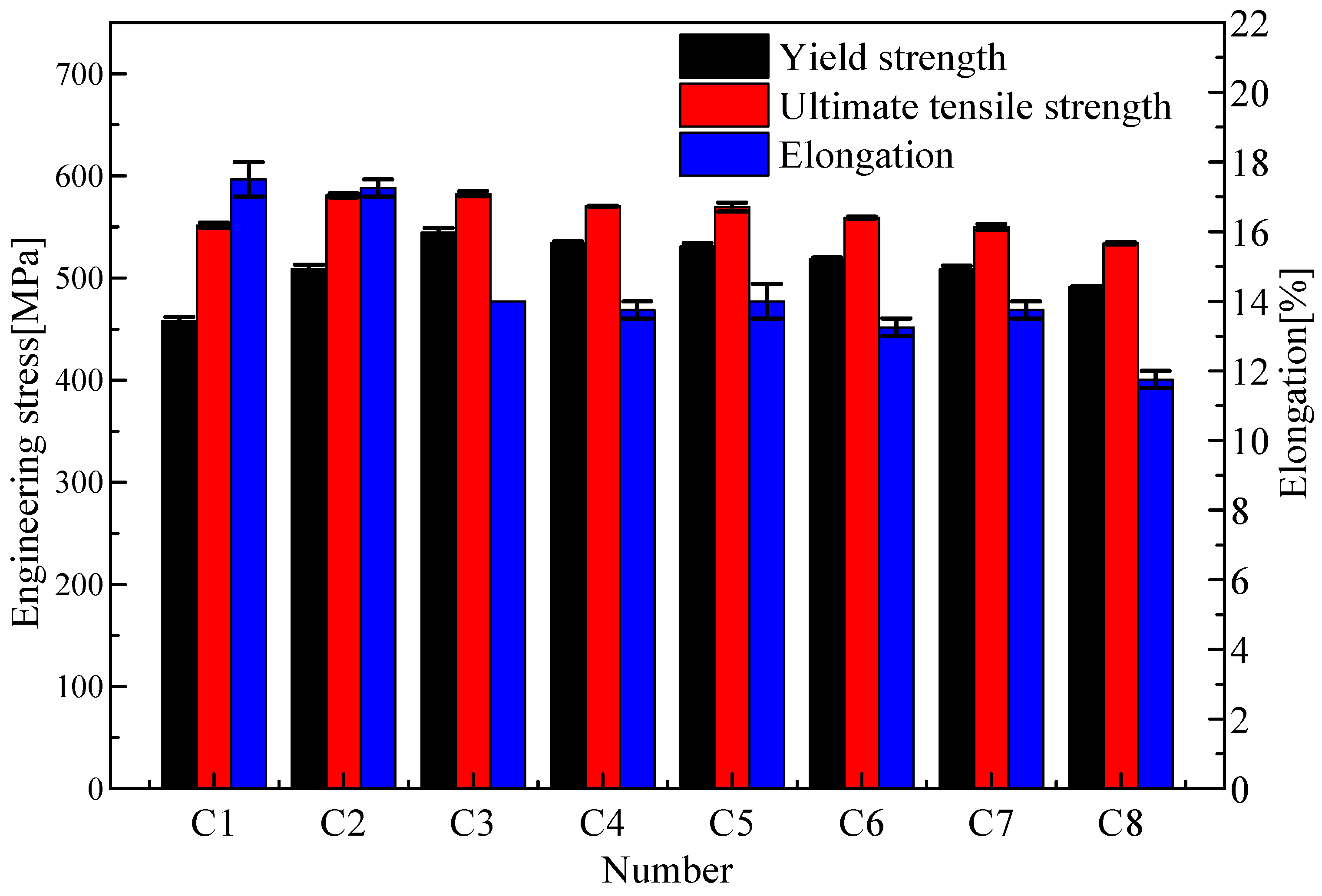

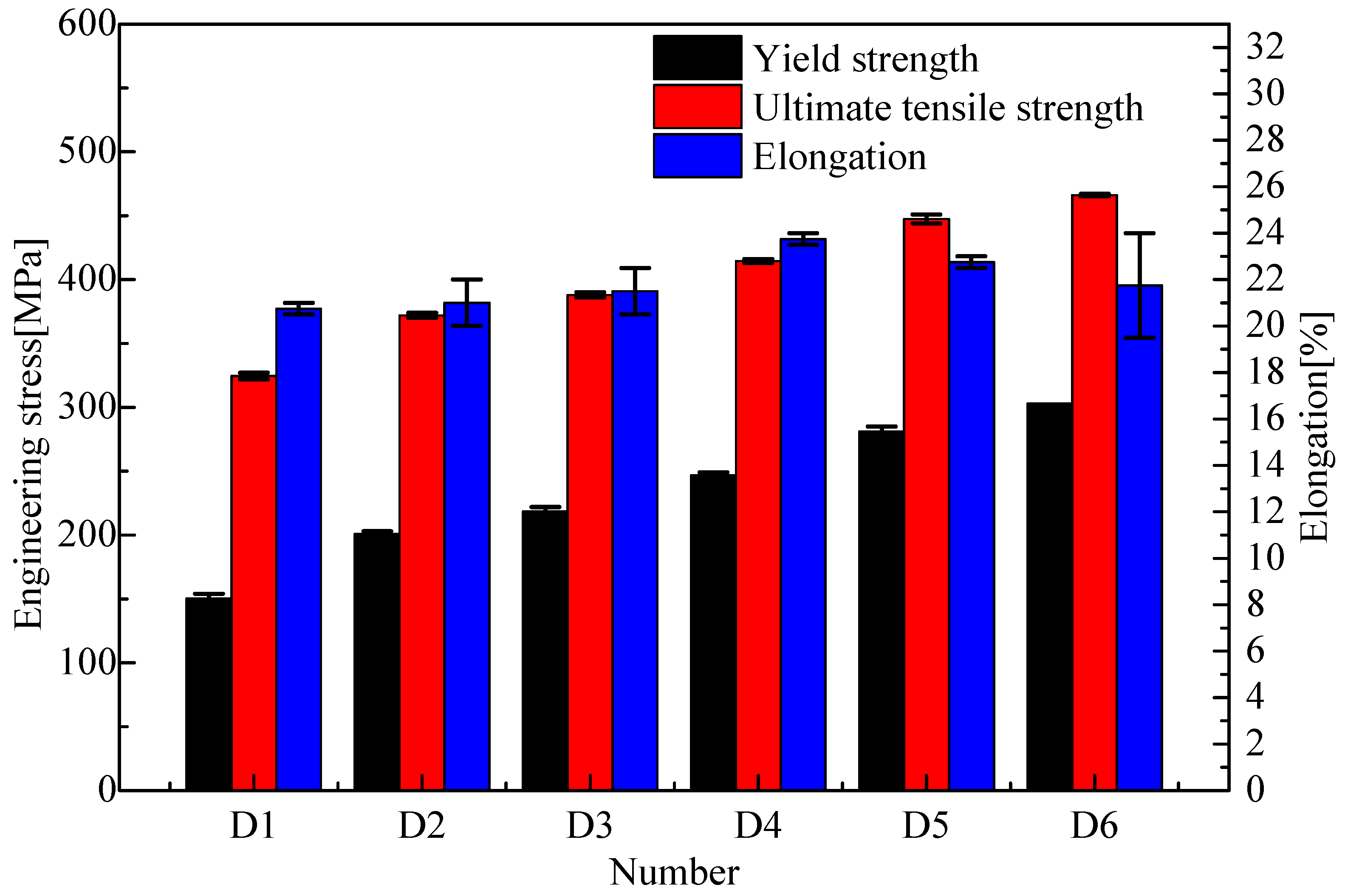

3.2. Mechanical Properties

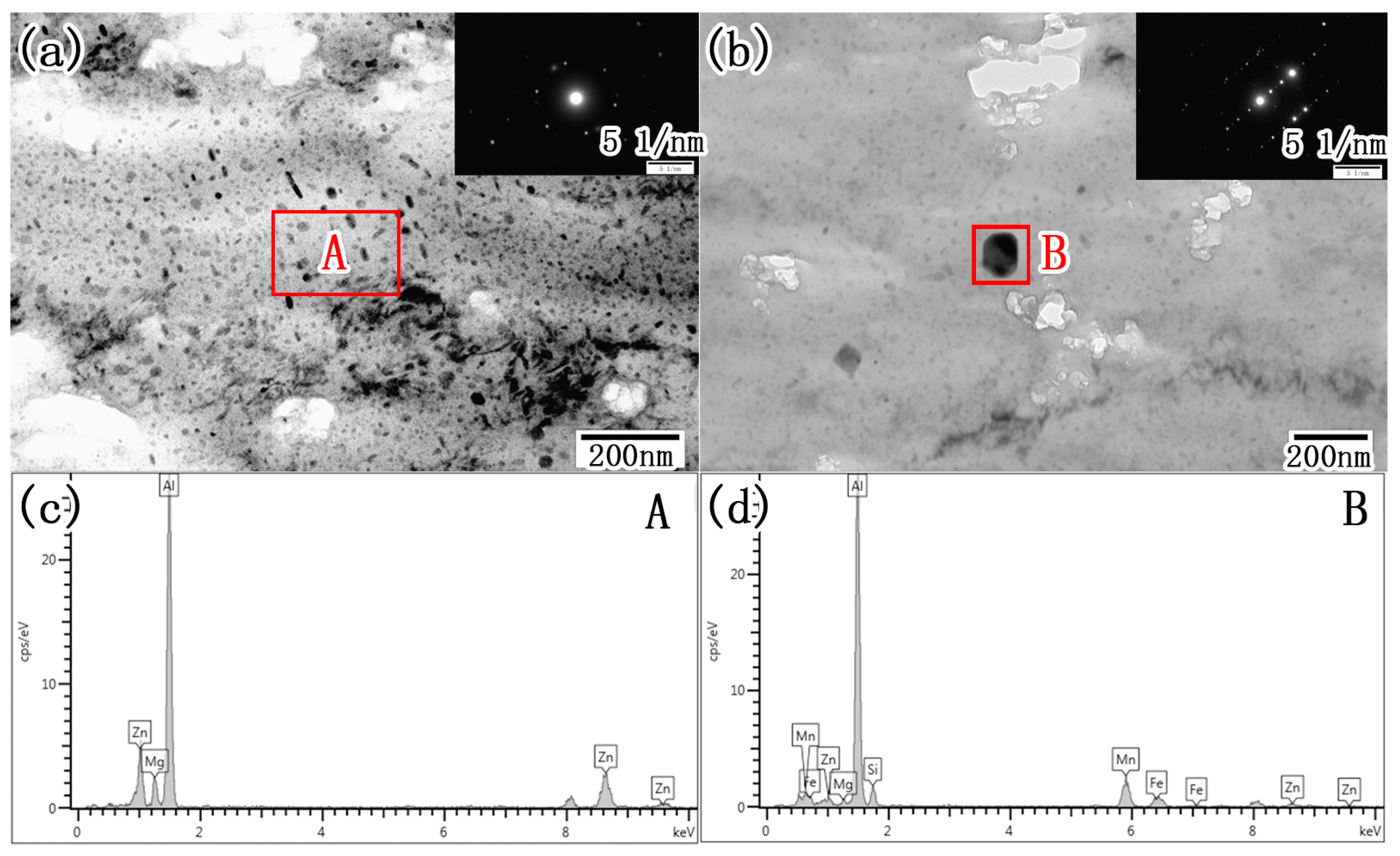

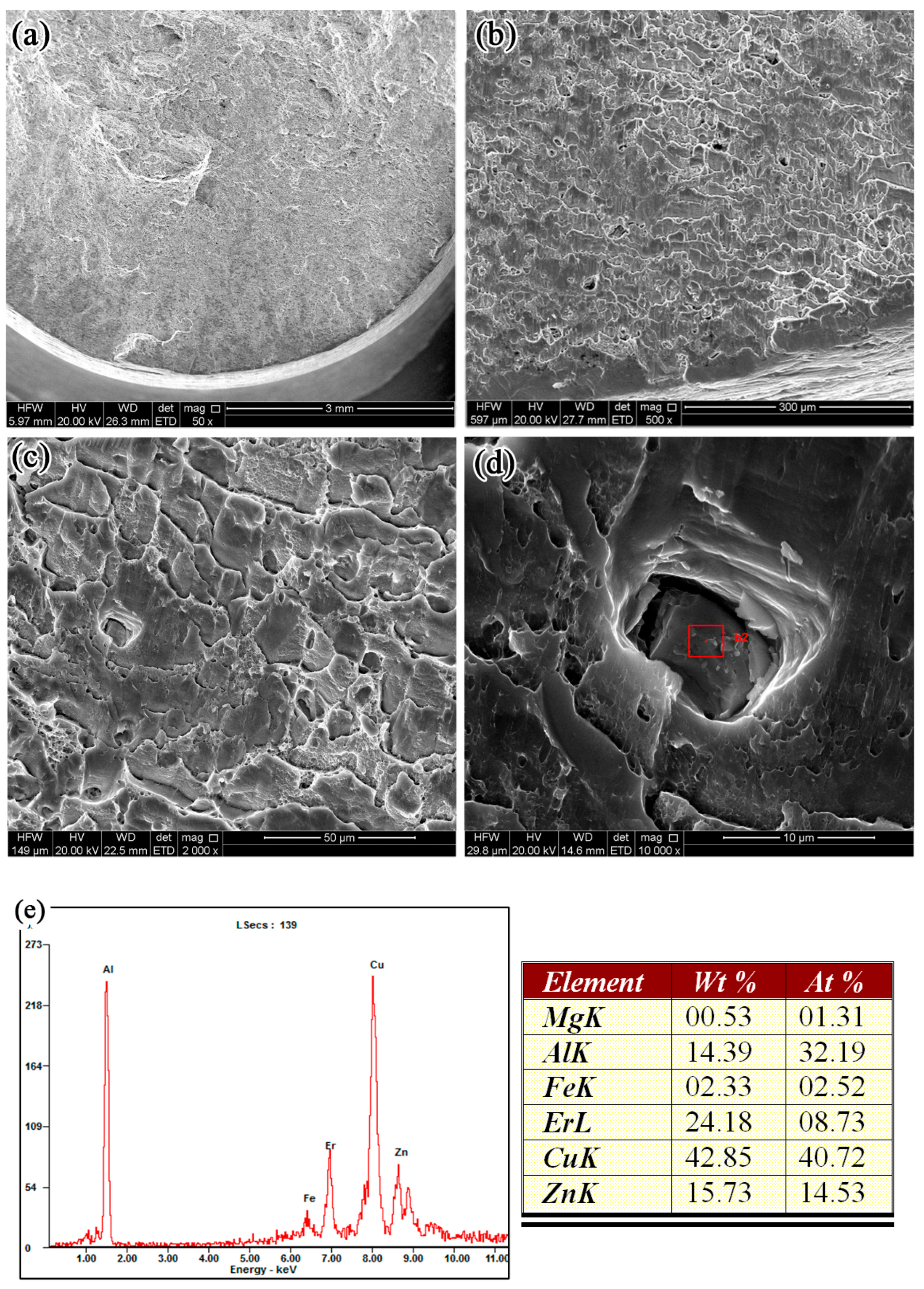

3.3. Microstructure and Fracture Behavior

4. Conclusions

- (1)

- Increasing the extrusion ratio during the hot extrusion process can significantly enhance the mechanical properties of Er-containing 7075 aluminum alloy.

- (2)

- Pre-stretching can provide nucleation sites for the precipitation of reinforcing phases, accelerate the aging strengthening process, and shorten the peak aging time.

- (3)

- The crack source of fracture in Er-containing 7075 aluminum alloy is the segregated second phases containing Cu and Er in the alloy, with the size of these alloy phases being around 10 micrometers.

- (4)

- The optimal heat treatment process for the Er-7075 alloy is 470 °C × 1 h + 500 °C × 2 h, with water quenching, a pre-stretching deformation of 2%, and double-stage aging at 110 °C × 5 h + 150 °C × 12 h.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, L.; He, L.; Chen, S.; Chen, K.; Li, J.; Li, S.; Liu, W. Effects of non-isothermal aging on microstructure, mechanical properties and corrosion resistance of 2A14 aluminum alloy. J. Alloys Compd. 2020, 842, 155542. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Y.; Mao, D.; Fan, G. Effect of Ultrasonic Bending Vibration Introduced by the L-shaped Ultrasonic Rod on Solidification Structure and Segregation of Large 2A14 Ingots. Materials 2020, 13, 807. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Zhan, L.; Xu, Y.; Chen, K.; Yang, Y.; Xu, L.; Peng, N.; Ma, B.; Liu, C.; Chen, Z. Temperature-dependent creep aging behavior of 2A14 aluminum alloy. J. Mater. Res. Technol. 2022, 19, 1343–1354. [Google Scholar] [CrossRef]

- Wang, B.; Yi, Y.; He, H.; Huang, S. Effects of deformation temperature on second-phase particles and mechanical properties of multidirectionally-forged 2A14 aluminum alloy. J. Alloys Compd. 2021, 871, 159459. [Google Scholar] [CrossRef]

- Lan, J.; Shen, X.; Liu, J.; Hua, L. Strengthening mechanisms of 2A14 aluminum alloy with cold deformation prior to artificial aging. Mater. Sci. Eng. A 2019, 745, 517–535. [Google Scholar] [CrossRef]

- Zinong, T.; Bing, Z.; Jun, J.; Zhiqiang, L.; Jianguo, L. A study on the hot roll bonding of aluminum alloys. Procedia Manuf. 2020, 50, 56–62. [Google Scholar] [CrossRef]

- Qian, X.; Li, X.; Li, Y.; Xu, G.; Wang, Z. Microstructure evolution during homogenization and hot workability of 7055 aluminum alloy produced by twin-roll casting. J. Mater. Res. Technol. 2021, 13, 2536–2550. [Google Scholar] [CrossRef]

- Zhu, Z.; Hu, Z.; Seet, H.L.; Liu, T.; Liao, W.; Ramamurty, U.; Ling Nai, S.M. Recent progress on the additive manufacturing of aluminum alloys and aluminum matrix composites: Microstructure, properties, and applications. Int. J. Mach. Tools Manuf. 2023, 190, 104047. [Google Scholar] [CrossRef]

- Honarmand, M.; Salehi, M.; Shabestari, S.G.; Saghafian, H. Impact strength and structural refinement of A380 aluminum alloy produced through gas-induced semi-solid process and Sr addition. Trans. Nonferrous Met. Soc. China 2022, 32, 1405–1415. [Google Scholar] [CrossRef]

- Li, G.; Qu, W.; Luo, M.; Cheng, L.; Guo, C.; Li, X.; Xu, Z.; Hu, X.; Li, D.; Lu, H.; et al. Semi-solid processing of aluminum and magnesium alloys: Status, opportunity, and challenge in China. Trans. Nonferrous Met. Soc. China 2021, 31, 3255–3280. [Google Scholar] [CrossRef]

- Qi, M.; Kang, Y.; Li, J.; Wulabieke, Z.; Xu, Y.; Li, Y.; Liu, A.; Chen, J. Microstructures refinement and mechanical properties enhancement of aluminum and magnesium alloys by combining distributary-confluence channel process for semisolid slurry preparation with high pressure die-casting. J. Mater. Process. Technol. 2020, 285, 116800. [Google Scholar] [CrossRef]

- Liu, F.; Dong, P.; Khan, A.S.; Zhang, Y.; Cheng, R.; Taub, A.; Ma, Z. 3D printing of fine-grained aluminum alloys through extrusion-based additive manufacturing: Microstructure and property characterization. J. Mater. Sci. Technol. 2023, 139, 126–136. [Google Scholar] [CrossRef]

- Tang, S.; Yang, Y.; Yang, L.; Fan, Z. A green extrusion-based 3D printing of hierarchically porous aluminum. Powder Technol. 2022, 399, 117198. [Google Scholar] [CrossRef]

- Faster 3D printing of aluminum. Met. Powder Rep. 2021, 76, 215. [CrossRef]

- Zhang, P.; Liu, J.; Gao, Y.; Liu, Z.; Mai, Q. Effect of heat treatment process on the micro machinability of 7075 aluminum alloy. Vacuum 2023, 207, 111574. [Google Scholar] [CrossRef]

- El Garchani, F.E.; Lgaz, H.; Kaya, S.; Lee, H.-S.; Ibrahim, S.M.; Chafiq, M.; Ko, Y.G.; Kabiri, M.R. Effects of Heat Treatment on the Corrosion Behavior and Mechanical Properties of Aluminum Alloy 2024. J. Mater. Res. Technol. 2023, 25, 1355–1363. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, W.; Jiang, J.; Huang, M.; Li, M.; Wang, Y.; Ding, C.; Zou, D. Effect of T6 heat treatment on microstructure and mechanical properties of large-weight aluminum alloy flywheel housing parts formed by local-loading squeeze casting. J. Mater. Res. Technol. 2023, 24, 1612–1625. [Google Scholar] [CrossRef]

- Xiao, A.; Lin, Y.; Huang, C.; Cui, X.; Yan, Z.; Du, Z. Effect of electromagnetic forming–heat treatment process on mechanical and corrosion properties of 2024 aluminum alloy. J. Mater. Res. Technol. 2023, 23, 1027–1038. [Google Scholar] [CrossRef]

- Singh, S.P.; George, D.T.; Xavier, A.A.J.; Raja, G.A. Effect of heat treatment on the hardness behaviour of the aluminium 6061 alloy. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Chen, Q.; Chen, G.; Ji, X.; Han, F.; Zhao, Z.; Wan, J.; Xiao, X. Compound forming of 7075 aluminum alloy based on functional integration of plastic deformation and thixoformation. J. Mater. Process. Technol. 2017, 246, 167–175. [Google Scholar] [CrossRef]

- Lin, B.; Fan, T.; Li, H.; Zhao, Y.; Zhang, W.; Liu, K. Microstructure and high temperature tensile properties of Al–Si–Cu–Mn–Fe alloys prepared by semi-solid thixoforming. Trans. Nonferrous Met. Soc. China 2021, 31, 2232–2249. [Google Scholar] [CrossRef]

- Li, G.F.; Zhang, X.M.; Zhu, H.F. Effect of minor er and y additions to Al-Zn-Mg-Cu-Zr alloy on homogenizing behavior. J. Aeronaut. Mater. 2010, 30, 1–6. [Google Scholar]

- Wu, H.; Wen, S.P.; Lu, J.T.; Mi, Z.P.; Zeng, X.L.; Huang, H. Microstructural evolution of new type Al–Zn–Mg–Cu alloy with Er and Zr additions during homogenization. Trans. Nonferrous Met. Soc. China 2017, 27, 1476–1482. [Google Scholar] [CrossRef]

- Shuai, Y.; Lina, J.; Hu, Z. Effects of Er on the Microstructure and Eutectic Phase Morphology of Directionally Solidified Al-Zn-Mg-Cu-Zr Alloys. Rare Met. Mater. Eng. 2021, 50, 3477–3484. [Google Scholar] [CrossRef]

- Chen, G.; Chen, Q.; Qin, J.; Du, Z. Effect of compound loading on microstructures and mechanical properties of 7075 aluminum alloy after severe thixoformation. J. Mater. Process. Technol. 2016, 229, 467–474. [Google Scholar] [CrossRef]

- Zhang, Y.; Yi, Y.; Huang, S.; Dong, F.; Wang, H. Investigation of the quenching sensitivity of forged 2A14 aluminum alloy by time-temperature-tensile properties diagrams. J. Alloys Compd. 2017, 728, 1239–1247. [Google Scholar] [CrossRef]

- Menargues, S.; Martín, E.; Baile, M.T.; Picas, J.A. New short T6 heat treatments for aluminium silicon alloys obtained by semisolid forming. Mater. Sci. Eng. A 2015, 621, 236–242. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, X.; Gao, M.; Guan, R. Enhanced strength-ductility synergy in a rheo-diecasting semi-solid aluminum alloy. Mater. Lett. 2021, 305, 130756. [Google Scholar] [CrossRef]

- Ragheb, Z.D.; Shabestari, S.G.; Najafi, Y. Effect of strain-induced melt activation process and thixoforming on microstructure and mechanical properties of 319 aluminum alloy. J. Alloys Compd. 2023, 954, 170152. [Google Scholar] [CrossRef]

| Element | Zn | Mg | Cu | Mn | Zr | Er | Fe | Si | Al |

|---|---|---|---|---|---|---|---|---|---|

| Content range | 5.5~6.6 | 1.8~2.6 | 1.0~1.6 | 0.08~0.12 | 0.06~0.12 | 0.08~0.12 | ≤0.15 | ≤0.10 | Balanced |

| Number | Solution Treatment | Pre-Tensile | Interval Time | Aging Treatment |

|---|---|---|---|---|

| A1 | 470 °C × 1 h + 500 °C × 2 h | 2.0% | None | Natural aging 180 d |

| A2 | / | Natural aging 180 d + 110 °C × 5 h + 150 °C × 12 h | ||

| B1 | None | Natural aging 180 d | ||

| B2 | 24 h | 110 °C × 5 h + 150 °C × 12 h | ||

| B3 | 15 d | |||

| B4 | 30 d | |||

| B5 | / | None | ||

| B6 | None | / | Natural aging 180 d + 110 °C × 5 h + 150 °C × 12 h | |

| C1 | None | None | 110 °C × 3 h | |

| C2 | None | None | 110 °C × 5 h | |

| C3 | None | None | 120 °C × 5 h + 163 × 3 h | |

| C4 | None | None | 120 °C × 5 h + 163 × 6 h | |

| C5 | None | None | 120 °C × 5 h + 163 × 9 h | |

| C6 | None | None | 120 °C × 5 h + 163 × 12 h | |

| C7 | None | None | 120 °C × 5 h + 163 × 15 h | |

| C8 | None | None | 120 °C × 5 h + 163 × 18 h | |

| D1 | None | None | Natural aging 0.5 h | |

| D2 | None | None | Natural aging 2 h | |

| D3 | None | None | Natural aging 4 h | |

| D4 | None | None | Natural aging 8 h | |

| D5 | None | None | Natural aging 24 h | |

| D6 | None | None | Natural aging 48 h |

| Number | PQ/kN | Pmax/kN | Pmax/PQ | KQ/MPa·m1/2 | KIC/MPa·m1/2 |

|---|---|---|---|---|---|

| C2 | 5.87 | 5.87 | 1.00 | 31.89 | 31.89 |

| C4 | 5.04 | 5.04 | 1.00 | 28.86 | 28.86 |

| C6 | 4.73 | 4.73 | 1.00 | 26.76 | 26.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Liao, Z.; Wang, D.; Liu, G.; Ren, J.; Li, W.; Yang, Y.; Chen, L.; Wang, Y. Effect of Interval Time Between Pre-Deformation and Artificial Aging on Mechanical Properties of Er-Containing 7075 Aluminum Alloy. Metals 2025, 15, 841. https://doi.org/10.3390/met15080841

Liu Y, Liao Z, Wang D, Liu G, Ren J, Li W, Yang Y, Chen L, Wang Y. Effect of Interval Time Between Pre-Deformation and Artificial Aging on Mechanical Properties of Er-Containing 7075 Aluminum Alloy. Metals. 2025; 15(8):841. https://doi.org/10.3390/met15080841

Chicago/Turabian StyleLiu, Yingze, Zhiqian Liao, Desheng Wang, Guoyuan Liu, Jiangyi Ren, Wenfu Li, Yunao Yang, Lingjie Chen, and Yue Wang. 2025. "Effect of Interval Time Between Pre-Deformation and Artificial Aging on Mechanical Properties of Er-Containing 7075 Aluminum Alloy" Metals 15, no. 8: 841. https://doi.org/10.3390/met15080841

APA StyleLiu, Y., Liao, Z., Wang, D., Liu, G., Ren, J., Li, W., Yang, Y., Chen, L., & Wang, Y. (2025). Effect of Interval Time Between Pre-Deformation and Artificial Aging on Mechanical Properties of Er-Containing 7075 Aluminum Alloy. Metals, 15(8), 841. https://doi.org/10.3390/met15080841