Abstract

Global resource consumption continues to grow each year, exerting increasing pressure on their availability. This trend could lead to a shortage of raw materials in the coming years. Aware of the risks associated with this situation, the European Union has implemented policies and strategies aimed at diversifying its supply sources, including waste recycling. In this context, the present study was conducted with the objective of developing innovative processes to concentrate valuable metals present in the non-recovered fractions of waste electrical and electronic equipment (WEEE). Three types of samples were studied: washing table residues (WTRs), printed circuit boards (PCBs), and powders from cathode-ray tube screens (CRT powders). Several separation techniques, based on the physical properties of the elements, were implemented, including electrostatic separation, magnetic separation, and density and gravity-based separations. The results obtained are promising. For WTRs and PCBs, the recovery rates of targeted metals (Cu, Al, Pb, Zn, Sn) reached approximately 91% and 80%, respectively. In addition to these metals, other valuable metals, present in significant quantities, deserve further exploration. Regarding CRT powders, the performances are also encouraging, with recovery rates of 54.7% for zinc, 57.1% for yttrium, and approximately 71% for europium. Although these results are satisfactory, optimizations are possible to maximize the recovery of these critical elements. The techniques implemented have demonstrated their effectiveness in concentrating target metals in the treated fractions. These results confirm that recycling constitutes a viable alternative to address resource shortages and secure part of the supplies needed for the European Union’s industry.

1. Introduction

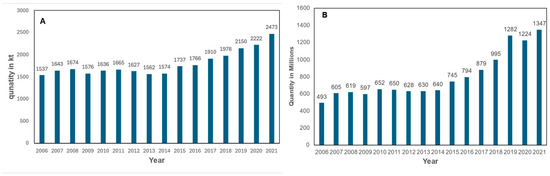

The global production of waste electrical and electronic equipment (WEEE) has nearly doubled since 2010, increasing from 33.8 million tons to approximately 62 million tons in 2022 [1,2,3]. WEEE is one of the fastest-growing waste streams, with global e-waste production expected to reach 82 million tons by 2030 [1]. China is by far the world’s largest producer of electronic waste, generating over 12 million tons in 2022 [1]. The United States followed, with approximately seven million tons produced. Global electronic waste production reached around 62 million tons in 2022 and is expected to continue increasing in the coming years [1,2,3]. In France, ADEME (French agency of ecological transition) report from 2022 on the WEEE sector in France provides a market study of electrical and electronic equipment (EEE) with all relevant organizations for the past year. This report presents key data on the WEEE sector in France (all data comes from ADEME’s 2022 annual report on EEE, based on 2021 figures): in 2021, 1.3 billion electrical and electronic devices of all categories were placed on the French market, representing a 10% increase compared to 2020. This accounted for 2,473,423 tons (+11%), equivalent to 244 times the weight of the Eiffel Tower. The following figure (Figure 1) illustrates the evolution of the total weight and number of devices placed on the market between 2006 and 2021.

Figure 1.

Evolution of the quantity of electronic equipment (A) and the weight in tonnes (B) from 2006 to 2021 (Reprinted form Refs. [4,5]).

This figure shows an increase in the total weight of equipment over the years, which has been further amplified by the inclusion of new devices in the sector. However, another trend that is not visible in the figure is emerging: the decline in the average unit weight of equipment. This trend has been continuously decreasing, with the average weight per device dropping from 2.7 kg in 2007 to 1.8 kg in 2021 (−33%). This decline can be explained by the miniaturization of consumer electronics (such as phones, computers, and cameras), the increasing demand for small connected and monitoring devices (such as smart surveillance cameras and Wi-Fi repeaters), and the use of lighter materials like plastic instead of metal. Among the 1.3 billion EEE of all categories placed on the market, 945 million were household electrical and electronic equipment (+8% compared to 2020), representing approximately 14 devices per inhabitant and a total weight of 2,089,273 tons. Figure 2 illustrates the distribution of household EEE tonnages placed on the market by category in 2021.

The quantity of professional EEE placed on the market in 2021 amounted to 409 million devices (+17% compared to 2020), totaling 384,150 tons.

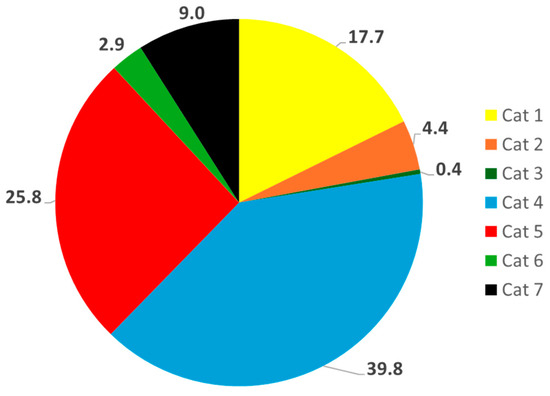

Figure 2.

Distribution of household EEE tonnage by category (Reprinted form Refs. [4,5]).

Cat 1: thermal exchange equipment, Cat 2: screens, monitors, and equipment with screens larger than 100 cm2, Cat 3: lamps, Cat 4: large equipment, Cat 5: small equipment, Cat 6: small IT and telecommunication equipment, Cat 7: photovoltaic panels.

From this figure, we observe that large equipment (Cat 4) and small equipment (Cat 5) dominate the number of devices sold, with respective shares of 39.8% and 25.8%.

1.1. Management of Waste Electrical and Electronic Equipment (WEEE)

Once EEE reaches the end of its life cycle, organizations known as “Waste Prevention and Management Operators”, established by Extended Producer Responsibility (EPR) schemes, handle WEEE management through service providers. Waste management within EPR schemes follows three main stages: collection, transport, and treatment.

- Collection involves gathering waste, including its sorting and preliminary storage, for transport to a waste-treatment facility [6,7,8].

- Treatment is defined as any recovery or disposal operation, including preparation before recovery or disposal [6,7,8].

In France, WEEE collection is organized into six waste streams, closely aligned with the category classification set by the directive [6]. This system is designed to facilitate the processing of WEEE after collection by grouping devices with similar characteristics or environmental treatment concerns, such as water, soil, and air pollution. The six streams are as follows:

- GEM F (Large Cold Household Appliances)—e.g., refrigerators, air conditioners.

- GEM HF (Large Non-Cold Household Appliances)—e.g., dishwashers, washing machines.

- Screens—e.g., cathode-ray tube screens, flat screens.

- PAM (Small Mixed Appliances)—e.g., toasters, printers, phones, computers.

- LAMPS.

- PP (Photovoltaic Panels)—included since 2015.

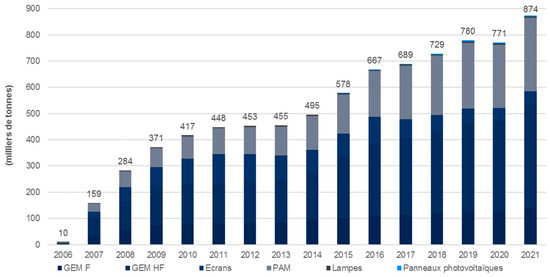

On average, 994,805 tons of WEEE from all categories were collected in France in 2021 (+17% compared to 2020). The share of collected household WEEE in 2021 was 873,974 tons (+13% compared to 2020), while the collected professional WEEE amounted to 120,831 tons (+14% compared to 2020). Figure 3 illustrates the evolution of collected household WEEE tonnage between 2006 and 2021.

Figure 3.

Quantity of WEEE collected by category (Reprinted form Refs. [4,5]).

1.2. Description of Samples and Study Objective

Given the challenges related to raw materials and the need for their supply, recycling and recovering waste electrical and electronic equipment (WEEE) is a way to partially meet the local demand while reducing dependence on external supplies and their associated risks. Although treatment processes already exist to extract valuable materials from WEEE, they generate several fine fractions that still contain metals to be recycled. Due to the technological limitations in processing fine particles (lack of adapted technologies), these fractions are untreated and often landfilled or incinerated. This study is part of the REVIWEEE project and aims to contribute to the development of treatment processes (physical separation) to concentrate metals and rare earth elements from untreated fine fractions from current WEEE treatment processes. In addition, it aims to transfer mineral-processing technologies for advanced applications in WEEE treatment.

To achieve this, some of the studied samples come from unrecovered fractions provided by the company “Environnement Recycling (ER)” [9]. Founded in 2003, Environnement Recycling is now a major French and European player in WEEE recycling.

As part of this article, three types of samples will be studied:

- CRT powders (cathode-ray tube powders)

- WTRs (washing table residues)

- Used printed circuit boards (PCBs)

- CRT (cathode-ray tube) powders: Specifically, phosphor powders found inside cathode-ray tubes. These powders are collected through dust extraction via cyclonic separation during the shredding of cathode-ray tubes. They are extremely fine (75% of the mass <20 microns) and contain significant concentrations of zinc and lead, as well as rare earth elements such as yttrium and europium.

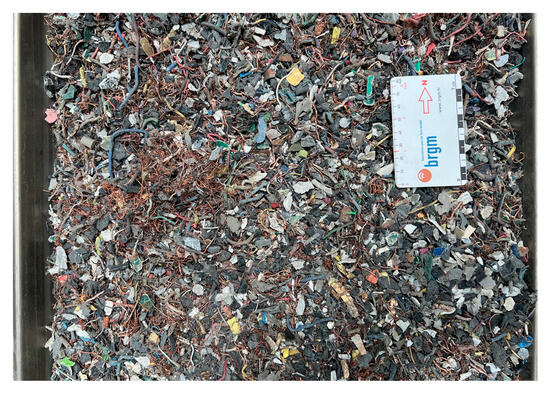

- WTRs (washing table residues): These are residues from the unrecovered fractions generated during the recycling of small mixed appliances (PAM) at Environnement Recycling. This fraction is rich in metals such as copper, aluminum, lead, zinc, tin, etc.

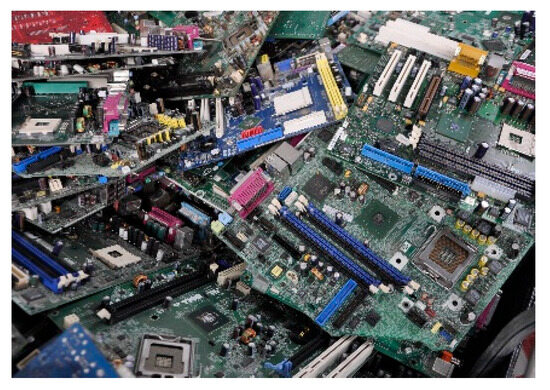

- Printed circuit boards (PCBs): These electronic circuit boards come from small mixed appliances. They are rich in base metals such as copper (Cu), zinc (Zn), lead (Pb), and tin (Sn), as well as precious metals like gold (Au), silver (Ag), and palladium (Pd).

2. Materials and Methods

This section is dedicated to both the sample-preparation methodology, as well as the presentation of the equipment used for this work. The various experimental techniques employed for the physical characterization of materials are also detailed.

2.1. Materials

The samples used in this study are CRT powders, washing table residues, and printed circuit boards. Since they have different physical and properties, WTR and PCBs will be treated differently from CRT powders. However, the separation techniques and equipment, primarily focused on physical sorting, will largely remain the same for all samples. This aligns with the main objective of this work: to develop efficient physical separation methods to concentrate valuable metals while removing non-economically valuable materials.

2.1.1. Cathode-Ray Tubes (CRTs)

CRT powders are extremely fine materials (75% of the mass <20 µm). Due to their small particle size, some processing steps, such as grinding, can be omitted. However, their fine granulometry presents challenges for certain separation techniques, as these methods are optimized for specific particle size ranges, making CRT powders too fine for efficient treatment. The valuable elements present in CRT powders include zinc (Zn), yttrium (Y), europium (Eu)

CRT powders are obtained through the suction (cyclone) of fine particles generated during the shredding of CRT tubes. First, cathode-ray tube screens are collected and stored. They are then shredded using a crusher equipped with a suction system, which allows for the recovery of fine particles produced during the shredding process.

2.1.2. Washing Table Residues (WTRs)

Washing table residues (WTR) are generated during the processing of small mixed appliances (PAMs). This fraction represents the unrecovered portion of the recycling process, which is typically sent to landfill or incinerated. PAMs belong to a category of small WEEE (Waste Electrical and Electronic Equipment), including microwaves, toasters, coffee makers, electric razors, hair dryers, irons, and vacuum cleaners. The heterogeneous nature of PAMs makes the treatment of unrecovered residues complex, as these residues contain a mix of various materials such as plastic, wood, ceramics, and glass, as well as ferrous and non-ferrous metals, including iron, copper, aluminum, gold, and silver.

2.1.3. Printed Circuit Boards (PCBs)

Printed circuit boards (PCBs) are substrates that interconnect various electronic components to form a functional circuit. They represent 4 to 7% of the total mass of WEEE and contain nearly 90% of the precious metals found in electronic waste [10]. PCBs are composed of the following: a non-metallic insulating polymer substrate (resin treated with flame retardants such as Br and Sb, impregnated with siliceous fibers); metallic foil layers, primarily copper and laminated layers and various electronic components. According to comparative studies in the literature, a typical PCB consists of 40% metals, 30% ceramics and glass, and 30% polymers [11,12]. The main metals present in PCBs are as follows: base metals such as copper (Cu), aluminum (Al), lead (Pb), zinc (Zn), tin (Sn), and nickel (Ni); precious metals, silver (Ag), gold (Au), and palladium (Pd). PCBs are recovered after the manual dismantling of end-of-life electronic equipment. Figure 4, Figure 5 and Figure 6 represent, respectively, photos of the investigated samples of WEEE (CRT, WTR, and PCBs).

Figure 4.

Image of CRT powder sample.

Figure 5.

Image of WTR sample.

Figure 6.

Image of PCB sample.

2.2. Methods

The mixed samples of WTRs and PCBs require some processing before being analyzed. That is why we proceeded with the shredding and grinding of these samples. Given the nature of the elements (copper wires, iron, glass, ceramics, etc.), we used the knife shredder-grinder “FRITSCH/RETSCH”. The initial particle size of these samples, which was centimeter-scale and heterogeneous, led us to carry out sequential grinding aimed at reducing the particle size from 10 mm to 0.75 mm, according to the following steps: 10 mm–8 mm–6 mm–4 mm–2 mm–1 mm–0.75 mm. Sequential grinding involves grinding a material in several successive stages (or sequences), each intended to further reduce the particle size and avoid the overproduction of fines, until the desired size is reached. This step is carried out in order to reach the particle liberation mesh and thus facilitate the subsequent separation techniques. After shredding and grinding, we used the planetary mill, as needed for analysis, to further reduce (micronize) the size of the investigated samples. The samples were homogenized and quartered for multiple batches.

Analysis Methods

The chemical composition analysis was performed by using the Niton XL3t GOLDD+ portable XRF from Thermon Fisher Scientific (Waltham, MA, USA). The distribution of chemical elements was determined based on a polished representative sample through scanning electron microscopy and energy dispersion spectroscopy (SEM EDS) mapping using TESCAN Mira3XMU equipment (TESCAN, Brno, Czech Republic) operated at 15–25 kV with an EDAX Apollo EDS detector. A laser scattering Granulo-meter (granulolaser) “Partica LA-960V2” from HORIBA (Kyoto, Japan) was used to characterize the particle size in CRT powders.

Thermogravimetric analysis determines the quantity of plastic present in WTR and PCB samples; for this work, the thermal analysis used was the high volume TG/DT analysis developed by BRGM (Orléans, France). We ran this technique to observe the behavior of the investigated samples from 20 to 1000 °C under a controlled atmosphere and to quantify the plastics contained. As the samples are heterogeneous materials, we ran several grams; instead, 100 mg can be used in conventional TG/DTA analysis.

3. Separation Techniques Used

Following sample preparation (sampling), various physical separation techniques were carried out on the three samples according to their physical properties, to observe their effects and gain insight into which ones effectively separate valuable metals from the gangue.

3.1. Classification

CRT powders are extremely fine (75% of the mass <20 µm). For the granulolaser analysis carried out on this sample and due to the fact that phosphor powders contain zinc and rare earth elements and have a fine particle size, we performed wet classification at 20 microns using an ultrasonic probe to prevent particle agglomeration on the sieve. The objective of this technique is to concentrate the targeted elements in the particle size class below 20 µm. The ultrasonic probe emits ultrasonic waves that cause water molecules to vibrate, thereby facilitating the disintegration of particles. This process reduces accumulation on the mesh and promotes the smooth passage of particles through it, particularly for the 20 µm sieve used in our study.

For the WTR and PCB samples, after grinding down to 0.75 mm, classification at 200 µm was carried out. The aim was to separate particles smaller than 200 µm from the rest (200 µm < d < 750 µm). This classification was performed using a 200 µm sieve.

3.2. Magnetic Separation

This separation technique relies on the magnetic properties of the materials. The principle is to use a magnetic field to separate magnetic and non-magnetic materials. The applied magnetic field can be low intensity (LIMS: Low Intensity Magnetic Separator), with a maximum magnetic flux of 3000 gauss, or high intensity (HIMS: High Intensity Magnetic Separator), with a magnetic flux of up to 20,000 gauss. LIMS separators are used to separate ferro magnetic materials (e.g., iron) from diamagnetic materials (e.g., copper, aluminum, lead) and non-magnetic elements (e.g., plastics). HIMS can be used to separate weak magnetic elements, such as copper and aluminum, for example.

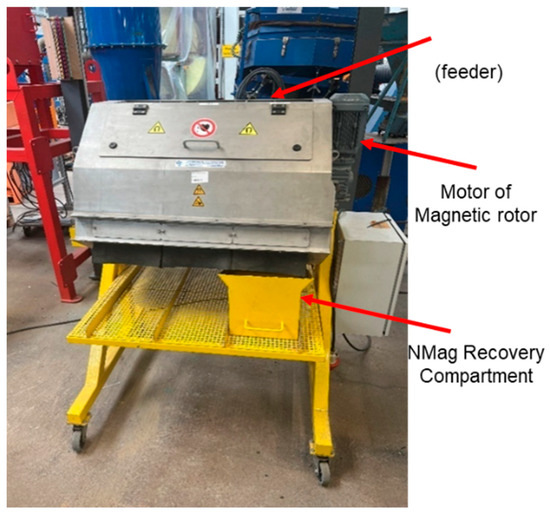

For WTR and PCB samples, we used a multipolar magnetic separator “GS magnet and separation (Longwy, France)” (Figure 7). The objective is to separate strongly magnetic particles, such as scrap metal, from other particles (copper, aluminum, lead, zinc, tin). The device consists of three drums containing Nd-type permanent magnets producing variable magnetic fields (1000, 1500, and 3000 gauss). The sample is fed from the top of the device. The ferromagnetic particles attracted by the magnetic field stick to the drum and adhere to it under the action of the magnetic force. Non-magnetic particles follow a normal fall trajectory under the action of gravity. The discharge of ferromagnetic particles occurs under the drum when they leave the field. The variable experimental parameters are the magnetic field intensity (3 possibilities), the rotation speed of the drums, and the sample casting rate, which depends on the user. The capacity of the device is several kilograms.

Figure 7.

Multipolar magnetic separator.

3.3. Electrostatic Separation

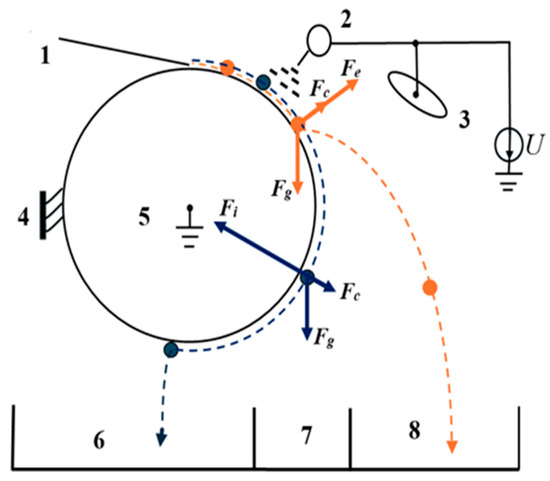

This separation method distinguishes between conductive and non-conductive (insulators) materials [13,14,15]. The device used is a laboratory-sized Carpco electrostatic drum separator (Figure 8), capable of processing a few hundred grams of material, with a particle size between 0.63 mm and 5 mm. It is composed of a rotating drum, two main electrodes (ionizing and static), a neutralizing electrode, a heating lamp, a brush, a dosing device, and three compartments corresponding to the three products (conductive, mixed, and non-conductive) recovered at the end of the process. The adjustable parameters include the voltage, distance from the ionizing and static electrodes to the drum, drum rotation speed, angle between the two electrodes (ionizing and static), electric current intensity, position of the field electrode, dosing flow rate (adjustable via the dosing vibration frequency), and the position of the separation valve between the mixed fraction and the conductive fraction. The separator’s operating principle can be described as follows: insulating and metallic particles are transported by the vibro-transporter and deposited on the grounded rotating cylinder. Electric charges are created by ionizing the air at the ionizing electrode, which is connected to a high-voltage DC source [16,17,18]. All particles acquire an electrical charge and behave differently depending on whether they are electrically conductive or insulating: insulating particles “stick” to the surface of the drum because of the electrical image force. They then fall into the left-hand part of the collector intended for them. Particles that do not fall off and still remain “stuck” are removed from the drum surface mechanically using a brush [16,17,18]. Conductive particles rapidly lose their charge as they pass through the earthed cylindrical drum, arriving in the zone of the electric field generated by the static electrode, where they acquire, through electrostatic induction, a charge of the opposite sign to the potential of the high DC voltage [16,17,18]. They are then electrically attracted by the static electrode and deposited in the right-hand part of the collector [16,17,18]. The sample is separated into three fractions collected in separate containers (conductors, mixed, insulating/non-conductors) for each test. After the tests, the mixed and non-conducting fractions are combined to form a single non-conducting sample, which ultimately results in two fractions: conductive and non-conductive. To properly carry out this separation and given the large number of parameters to consider, we used the design of the experimental method (DOE) in order to reduce the number of experiments to be carried out and to optimize the results.

Figure 8.

Schematic diagram of corona drum electrostatic separator (developed by Capco, Inc. New York, NY, USA) [18]. 1. vibrating chute; 2. Corona electrode 3. Static electrode 4. Brush 5. Rotating cylindrical electrode 6. Non-conductors compartment 7. Mixed compartment 8. Conductors compartment Fe: Electrostatic force. Fc: Centrifugal force. Fi: Electric image force. Fg: Gravitational force.

3.4. Density Separation

For WTR and PCBs, we used a dense NaCl solution (density 1.20 g/cm3) for separation. Metals thus end up in the downstream fraction, while plastics remain in the floating fraction. Table 1 shows the contents of different fractions after density separation.

Table 1.

Fractions generated from Density separation of the investigated samples.

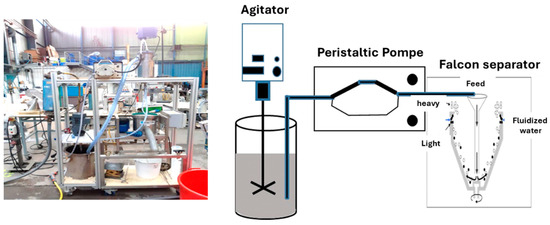

For CRT powders, this is a wet separation technique that uses centrifugal force to separate two particles of similar size based on their density. By increasing the centrifugal force, the separation of denser particles from less dense particles in a liquid medium can be accelerated [19,20]. The device used is a Falcon centrifugal density separator (Langley, Colombie-Britannique, Canada) (Figure 9). It consists of a Falcon bowl in which the particles are separated. This bowl is connected to a motor with adjustable rotation speed. A conduit evacuates the light particles, which are collected in a container. The heavier particles remain in the bowl and are collected at the end of the process. Several parameters are involved in this separation: the initial mass of the sample, the feed rate of the separator, the pulp percentage (solid/liquid ratio), and the rotation speed, expressed by the G-number. The G-number is a dimensionless unit used to express acceleration as a multiple of Earth’s gravitational acceleration, denoted g. On Earth, g has an average value of about 9.81 m/s2. The G number represents the number of times a given acceleration is equivalent to the gravitational acceleration g. The aim of this separation techniques is to concentrate dense elements such as sphalerite, yttrium and europium oxides in the case of CRT powders, and all metals in the case of WTR and PCBs in the Heavy and Sinking fractions respectively. And to concentrate light and/or floating elements such as silicates and glasses for CRT and plastics, wood, etc. for WTR and PCBs respectively.

Figure 9.

Schematic diagram of density separation using Falcon separator (Falcon Concentrators Inc., Langley, BC, Canada).

4. Result

4.1. Chemical Composition of the Studied Samples

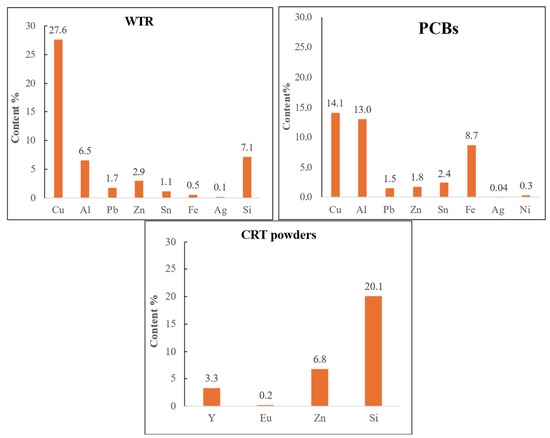

The sample collected from the WTR is very rich in metals. Figure 10 shows the initial composition of the main chemical elements contained. WTR sample contains more than 27% Cu, 7% Al, 1.7% Pb, and 1.1% Sn. However, it contains few amounts of iron (0.5%) and precious metals, with 0.1% of Ag. PCBs contain significant amounts of metals. Copper is the main one with over 14% and 13% Al. CRT powders are phosphor-containing powders derived from cathode-ray tube screens. They contain valuable elements such as rare earth oxides (Y2O3 and Eu2O3) and sphalerite (ZnS). The presence of silica (SiO2) comes from the glass of the cathode-ray tube. Figure 10 summarizes their chemical composition. From this figure, they contain more than 20% silica (glass), 7% Zn in the form of sphalerite, and more than 3% Y in the form of oxide, with Eu at 0.2%.

Figure 10.

Chemical composition of the studied samples.

It is important to note that WTR and PCB samples share some similarities, particularly in their matrix (metals and plastics). Additionally, both samples were crushed and sieved to 200 µm. The separation techniques and the equipment used for both are the same.

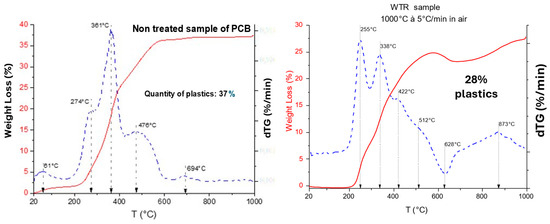

Thermal Analysis of Studied Samples

A thermogravimetric analysis was performed on the two studied samples of PCBs and WTRs, containing organic substances (plastics). This analysis aims to quantify the plastic content and can also be used to validate the efficiency of electrostatic separation. The tests were performed under an air atmosphere, in a temperature range from 20 to 1000 °C, with a temperature rise rate of 5 °C/min. The results obtained, presented in Figure 11, illustrate the evolution of mass loss as a function of temperature. It appears that all organic substances volatilize at 1000 °C. It is observed that approximately 37% of plastics are present in the PCB samples and 28% in the WTR samples. In addition, the different temperatures shown in both figures are related to different oxidation reactions of various metals and the degradation of plastics.

Figure 11.

Thermogravic analysis of non treated sample of PCBs (left) and WTRs (right).

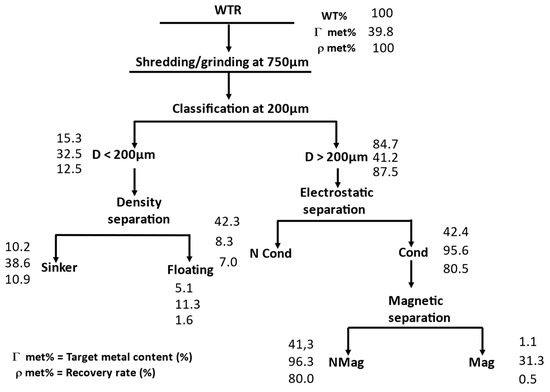

4.2. Classification

This technique allows the sample to be separated into two size fractions, improving and facilitating the application of subsequent separation techniques (WTRs and PCBs). Regarding WTRs, after a shredding/grinding process of the sample to 750 µm, classification was performed at 200 µm to separate the fraction smaller than 200 µm from the one between 200 µm and 750 µm (D > 200 µm). This step aims to eliminate the fraction smaller than 200 µm (D < 200 µm), considered a fin fraction, before applying separation techniques such as electrostatic and magnetic separation. In terms of the mass, the fraction between 200 µm and 750 µm is the most significant since the shredding/grinding stopped at the 750 µm sieve, although the mass of the fraction smaller than 200 µm is not negligible. This latter fraction is processed using treatment methods adapted to such a granulometric size.

4.3. Recovery of Metals from WTRs and PCBs

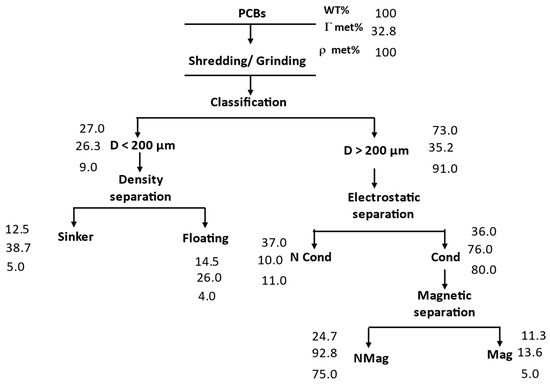

By examining this process diagram (Figure 12), it is evident that the percentage of the five target metals (Cu, Al, Pb, Zn, Sn) improves progressively through the separation stages. Starting at 39.8% in the raw sample, this percentage rises to approximately 41% in the fraction between 200 µm and 750 µm (D > 200 µm). Electrostatic separation further concentrates the target metals in their conductive fraction, reaching a percentage of 95.6% with a recovery rate of 80%. In this context, magnetic separation does not produce significant results, as the iron had already been removed during a previous treatment. However, a slight improvement in the percentage is observed, from 95.6% to 96.3%. Finally, a density separation applied to the fraction smaller than 200 µm (D < 200 µm) recovers about 11% of the target metals in the sinking fraction. This last separation recovers the target metals lost in the fraction below 200 µm (D < 200 µm). At the end of the separation, almost all the metals are lost in the sinker fraction, as they have a higher density than the dense solution used (NaCl solution with a density of 1.20 g/cm3). Plastics end up in the floating fraction, as they have a lower density than the dense solution.

Figure 12.

Schematic representing the physical process used to recover metals from the WTR.

Thus, this sequence of separation techniques allows for the recovery of approximately 91% of the target metals in the two useful fractions, namely the non-magnetic fraction of the magnetic separation and the sinking fraction of the density separation with a loss of about 9%. This result is therefore particularly satisfactory.

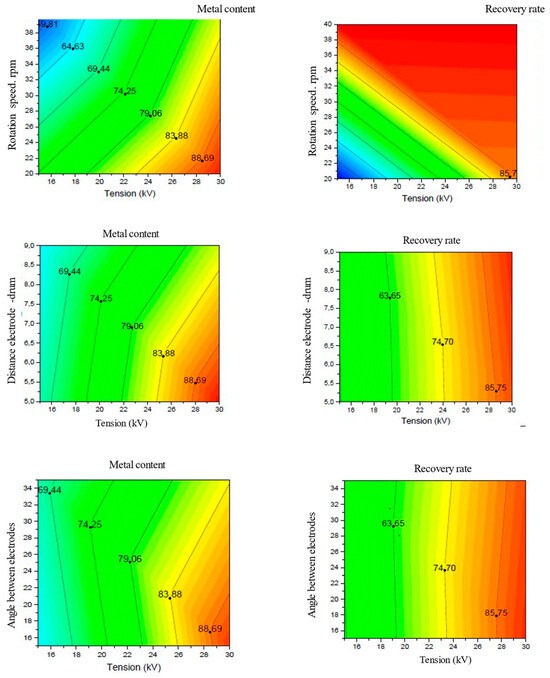

To optimize the electrostatic separation of WTRs, different parameters such as the drum rotation speed, the distance between the electrode and the drum, and the angle between the electrodes (static and ionizing) were evaluated as a function of the voltage (kV). The design of the experimental approach was taken into consideration, and the results are illustrated in Figure 13. It can be observed that at 28–30 kV and a drum rotation speed between 20 and 22 rpm, approximately 86% of the material can be recovered in the conductive fraction, accounting for 87% of the metal content. At a distance between the electrode and the drum of 5–5.5 cm and at 28 kV, the metal recovery rate is approximately 86%, with a metal content of 89%. For an angle of 17° between the electrodes and at 28 kV, the recovery rate is about 89%, with a metal content of 86%.

Figure 13.

Metal contents and recovery rates for different parameters of the electrostatic separation of WTRs.

The sequence of processes applied to treat the PCB sample is identical to that used for WTRs. First, a classification at 200 µm increases the percentage of target metals from 32.8% to 35.2% in the fraction greater than 200 µm (D > 200 µm). Then, electrostatic separation further increases the concentration of target metals, reaching 76% in the conductive fraction. Magnetic separation almost completely eliminates iron, raising the concentration of target metals (Cu, Al, Pb, Zn, Sn) from 76% to about 93% in the non-magnetic fraction. An overall recovery rate of 75% of the target metals is thus achieved. Then a density separation applied to the fraction smaller than 200 µm (D < 200 µm) recovers about 5% of the target metals in the sinking fraction. The latter separation recovers the target metals lost in the fraction below 200 µm (D < 200 µm). In this way, with this treatment scheme, we recovered 80% (Figure 14) of the target metals in the two useful fractions: the non-magnetic fraction from magnetic separation and the sinking fraction from density separation, with a loss of around 20%.

Figure 14.

Schematic representing the physical process used to recover metals from PCBs.

4.4. Recovery of Metals from CRT Powder

CRT (cathode-ray tube) powders represent a distinct sample compared to the two previous ones (WTRs and PCBs). These are ultra-fine powders originating from cathode-ray tube screens. The primary elements targeted for extraction from this sample are rare earth oxides (Y2O3 and Eu2O3), along with the zinc present in sphalerite.

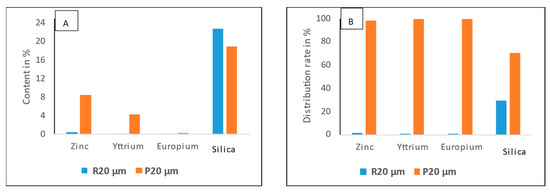

Due to the complexity of this sample, multiple analytical methods were employed to enhance its characterization. Various separation techniques were tested, some with success, others without. The extremely fine particle size, especially for the target elements (rare earth oxides and ZnS), with a d95 below 20 microns, presents a significant challenge as it nears the efficiency threshold of physical separation methods. The CRT sample was initially classified at 20 microns, enabling the removal of impurities in the coarser fraction and the concentration of target metals in particles smaller than 20 µm. The classification at 20 μm was performed via wet processing using an ultrasonic probe (Figure 15). The following figures show the results obtained. We can see that the fraction below 20 µm concentrates all the targeted elements (both in terms of content and distribution rate). The fraction above 20 µm (R20 µm) has been depleted of these various elements.

Figure 15.

Chemical compostion (A) and distribution rate (B) of different target elements in R20 µm and P20 µm.

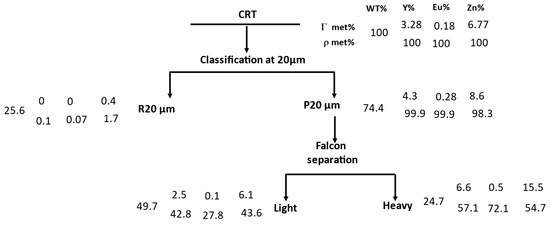

To recover the target elements contianed in the CRT powder, classification through density separation was used. The mass balance is shown in Figure 16. The fraction smaller than 20 μm (P20 μm) was subjected to density separation via centrifugation using the Falcon separator. As a result, over half of the three target elements were recovered in the heavy fraction: 54.7% of zinc and 57.1% of yttrium, along with about 72% of europium. However, silica remains present, as the current techniques are unable to effectively separate it from the other elements. While further optimization is needed to improve the recovery rates, these results demonstrate the technique’s effectiveness in concentrating the target elements.

Figure 16.

Schematic representing the physical process used to recover metals from CRTs.

5. Conclusions and Perpsectives

The study of the three samples produced promising results, achieving the initial objective of concentrating valuable metals from the WEEE fractions generated through physical separation processes.

For the WTR samples and printed circuit boards (PCBs), the targeted metals were copper (Cu), aluminum (Al), lead (Pb), zinc (Zn), and tin (Sn). The recovery rates achieved for these metals proved very promising. In the case of WTRs, around 91% of the targeted metals were recovered in the useful fractions, with 80% for the PCBs.

The efficient treatment process established for these two samples involved several steps as follows: a 200 µm classification that allowed the elimination of fractions smaller than this size. An electrostatic separation was used to isolate metals (conductors) from plastics (non-conductors). Finally, a magnetic separation was carried out to remove iron (a metal of lower economic value) from the other metals. This step produced very good results for the printed circuit boards (PCBs) but was less conclusive for the WTR samples, which had already undergone initial magnetic treatment at the industrial site. These separation processes applied to the WTR samples and PCBs proved both effective and relevant in concentrating the valuable metals present in these samples.

Despite these good results, some improvements can be considered for future perspectives:

- Optimization of grinding: reduce or avoid the overproduction of fine fractions (below 200 µm) by exploring new grinding techniques or adopting more suitable equipment to limit the generation of particles of this size.

- Improvement of density separation: in cases where the production of fine fractions is unavoidable, consider using denser solutions for density separation. This could help increase metal recovery during this stage and improve overall yields.

- Use of more sophisticated chemical analysis methods: implement advanced analytical techniques to quantify the precious metals such as gold and palladium in these samples.

For CRT powders, the targeted elements were rare earth oxides (yttrium oxide and europium oxide), as well as sphalerite (ZnS). Due to the fine nature of the sample, its treatment proved more complex than the other two samples studied, approaching the limits of physical separation techniques. Despite these challenges, separation techniques were applied, yielding overall satisfactory results and enabling the establishment of a treatment process. This process begins with a classification at 20 µm, followed by density separation through centrifugation using the Falcon separator. Through this sequence, we were able to recover 54.7% of zinc and 57.1% of yttrium, with a recovery rate exceeding 72% for europium. For this sample, several improvement prospects can be considered:

- Enhancing the performance of Falcon separation by adjusting its parameters (flow rate, rotation speed, etc.) to determine optimal values for maximizing the recovery of target elements.

Testing other physical separation methods adapted to this fine particle size, such as gravimetric separation uisng a shaking table or separation in dense media, which would enable us to better process this sample.

- Implementing processes such as flotation with the use of specific reagents to effectively separate the target elements from silica and then to separate rare earth oxides from sphalerite.

- Improving or changing shredding (grinding) and sample recovery techniques at the plant; grinding cathode ray tube (CRT) screens and then vacuuming the fine particles increases the likelihood of silica dust being recovered with phosphor powders. A possible solution would be to vacuum the phosphor powders before grinding.

Author Contributions

Conceptualization, N.-E.M. and A.T.; methodology, A.T. and N.-E.M.; validation, N.-E.M. and A.T.; formal analysis, A.T., investigation, N.-E.M. and A.T.; writing original draft preparation, N.-E.M. and A.T. writing and editing, N.-E.M. and A.T.; review, N.-E.M. and A.T.; visualization, N.-E.M. and A.T., supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This work was performed in the framework of the REVIWEEE project (PEPR Recyclage), financed by the ANR-France 2030.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the manuscript; further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Le Portail Statista.com: Production Mondiale de Déchets Électroniques 2010–2022|Statista. Available online: https://www.statista.com/ (accessed on 23 August 2024).

- Li, J.; Lopez, B.N.; Liu, L.; Zhao, N.; Yu, K.; Zheng, L. Regional or global WEEE recycling. Where to go? Waste Manag. 2013, 33, 923–934. [Google Scholar] [CrossRef]

- Baldé, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. Quantities, Flows and Resources, The Global E-waste Monitor 2017; United Nations University: Tokyo, Japan, 2017. [Google Scholar]

- ADEME, Octobre 2022. Equipements Électriques et Électroniques: Données 2021—Rapport Annuel. Available online: https://librairie.ademe.fr/ (accessed on 17 July 2025).

- La Gestion des Déchets Ménagers et Assimilés par les Collectivités, ADEME, 2021. Available online: https://optigede.ademe.fr/collecte-separee-deee (accessed on 17 July 2025).

- European Parliament and Council. Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE); European Parliament and Council: Strasbourg, France, 2012. [Google Scholar]

- European Parliament and Council. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Parliament and Council: Strasbourg, France, 2008. [Google Scholar]

- European Commission. Directorate-General for Internal Market Entrepreneurship and SMEs, Study on the Critical Raw Materials for the EU 2023—Final Report; Publications Office of the EU: Luxembourg, 2023. [Google Scholar]

- Environnement Recycling. Available online: https://www.environnement-recycling.com/ (accessed on 17 July 2025).

- Barnwal, A.; Dhawan, N. Recovery of Copper Values from Discarded Random Access Memory Cards via Fluidization and Thermal Exposure. J. Clean. Prod. 2020, 256, 120516. [Google Scholar] [CrossRef]

- Christian, T. Recyclage des cartes électroniques: Un aperçu de l’état de l’art. Ann. Des Mines-Responsab. Environ. 2016, 82, 57. [Google Scholar] [CrossRef]

- de Buzin, P.J.W.K.; Ambrós, W.M.; de Brum, I.A.S.; Tubino, R.M.C.; Sampaio, C.H.; Moncunill, J.O. Development of a physical separation route for the concentration of base metals from old wasted printed circuit boards. Minerals 2021, 11, 1014. [Google Scholar] [CrossRef]

- Franke, T.S.; Nuckowski, P.M.; Gołombek, K.; Hyra, K. Recovery of metals from PCB by means of electrostatic separation. Manag. Syst. Prod. Eng. 2020, 28, 213–219. [Google Scholar]

- de Souza, R.A.; Veit, H.M. Study of electrostatic separation to concentrate silver, aluminium, and silicon from solar panel scraps. Circ. Econ. 2023, 2, 100027. [Google Scholar]

- Zeghloul, T.; Touhami, S.; Richard, G.; Miloudi, M.; Dahou, O.; Dascalescu, L. Optimal operation of a plate-type corona-electrostatic separator for the recovery of metals and plastics from granular wastes. IEEE Trans. Ind. Appl. 2016, 52, 2506–2512. [Google Scholar] [CrossRef]

- Tilmatine, A. Synthèse sur Les Séparateurs Électrostatiques des Mélanges Granulaires et Leurs Composants. Ph.D. Thesis, Djilali Liabes University Sidi Bel Abbès, Algérie, North Africa, 2004. Available online: https://www.researchgate.net/publication/283516594 (accessed on 17 July 2025).

- Richard, G. Étude Expérimentale et Optimisation Fonctionnelle des Installations de Séparation Électrostatique de Mélanges de Matériaux Granulaires. Ph.D. Thesis, Université de Poitiers, Poitiers, France, 2018. Available online: https://theses.fr/2018POIT2260 (accessed on 17 July 2025).

- Moulai, H. Procède de Séparation Électrostatique Pour la Récupération des Métaux de Valeur Des Fractions Fines Issues du Traitement des Déchets D’équipements Électriques et Électroniques. Ph.D. Thesis, Université de Poitier, Poitier, France, 2024. [Google Scholar]

- Ambaye, T.G.; Vaccari, M.; Castro, F.D.; Prasad, S.; Rtimi, S. Emerging technologies for the recovery of rare earth elements (REEs) from the end-of-life electronic wastes: A review on progress, challenges, and perspectives. Environ. Sci. Pollut. Res. 2020, 27, 36052–36074. [Google Scholar] [CrossRef]

- Kroll-Rabotin, J.-S. Analyse Physique et Modélisation de la Séparation Centrifuge de Particules Ultrafines en Film Fluant: Application au Séparateur Industriel Falcon. Génie des Procédés; Institut National Polytechnique de Toulouse—INPT: Toulouse, France, 2010. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).