Effects of In Situ Electrical Pulse Treatment on the Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloy Resistance Spot Welds

Abstract

1. Introduction

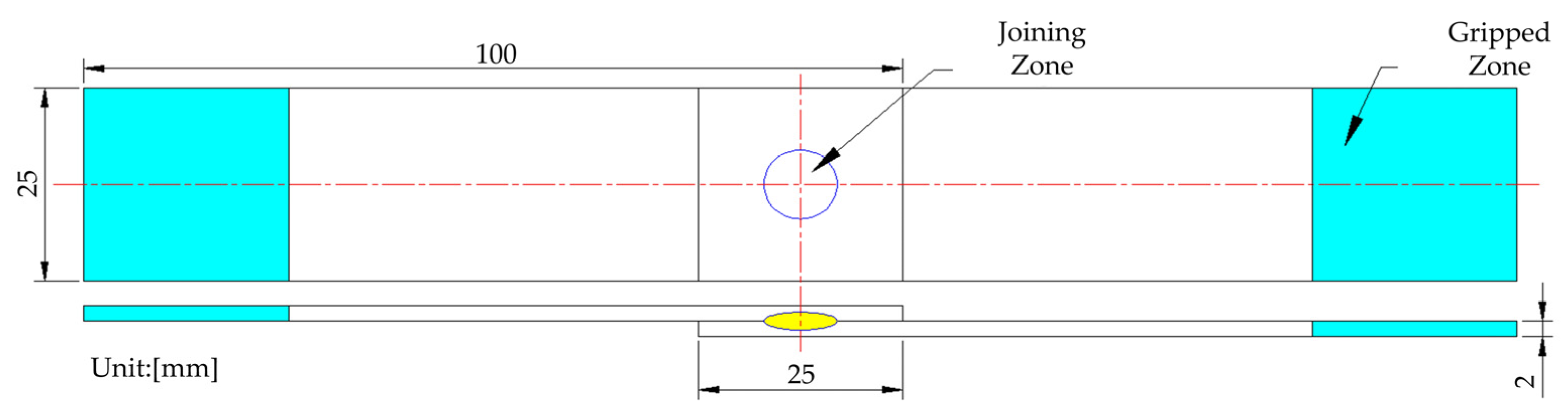

2. Materials and Methods

2.1. Materials

2.2. Experimental Parameters

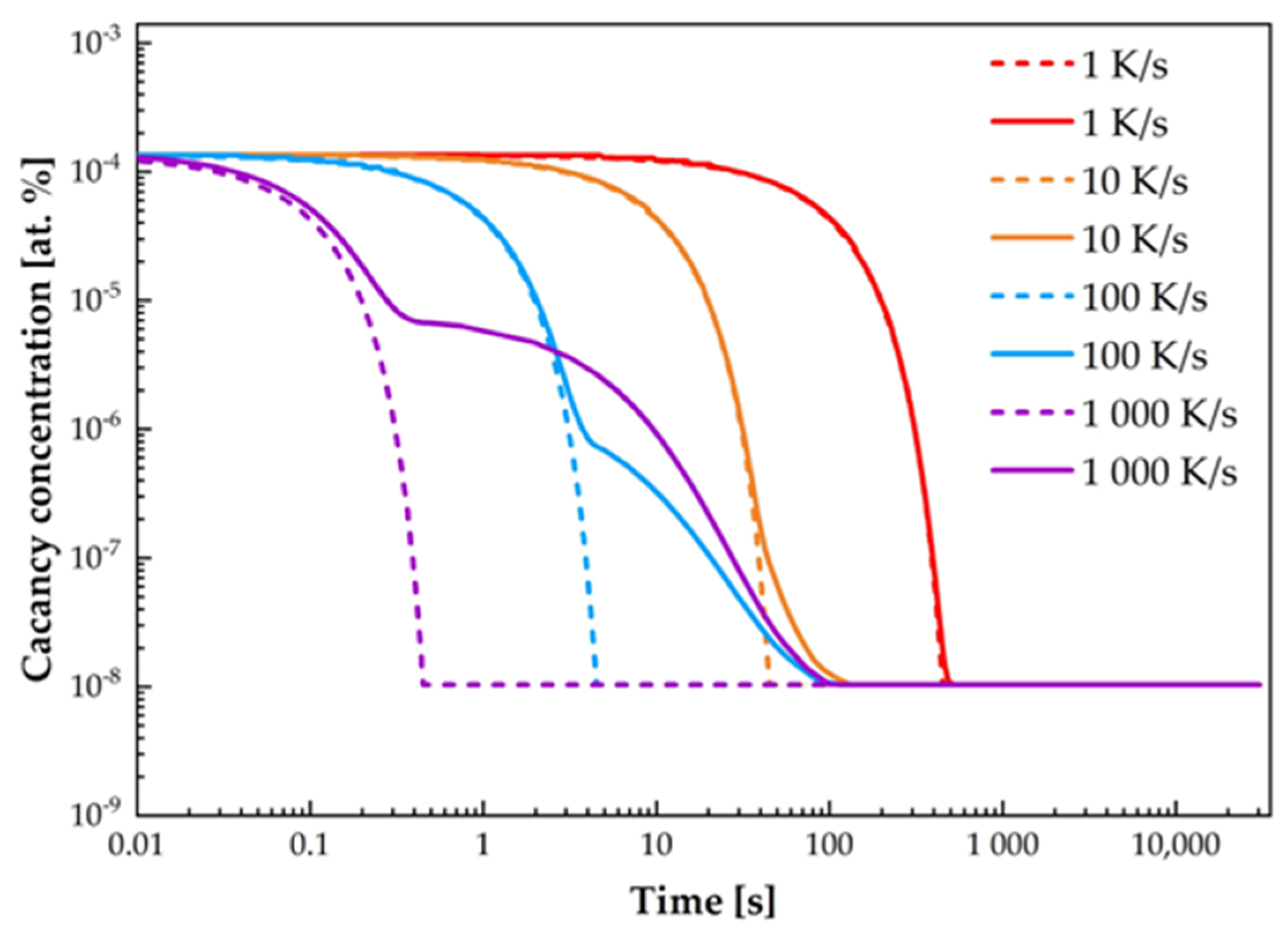

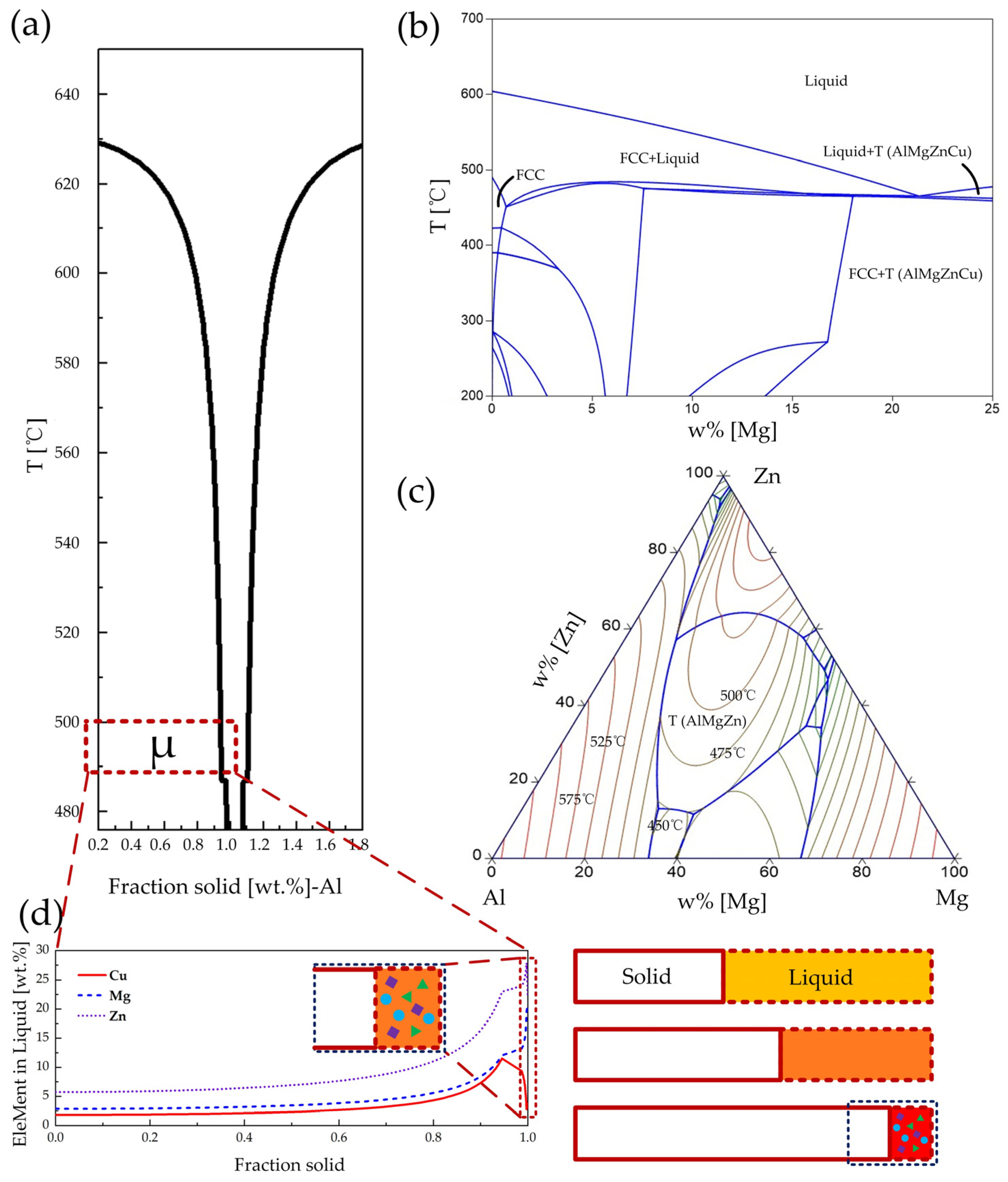

2.3. Vacancy Modeling and Phase Diagram Calculations

3. Results and Discussion

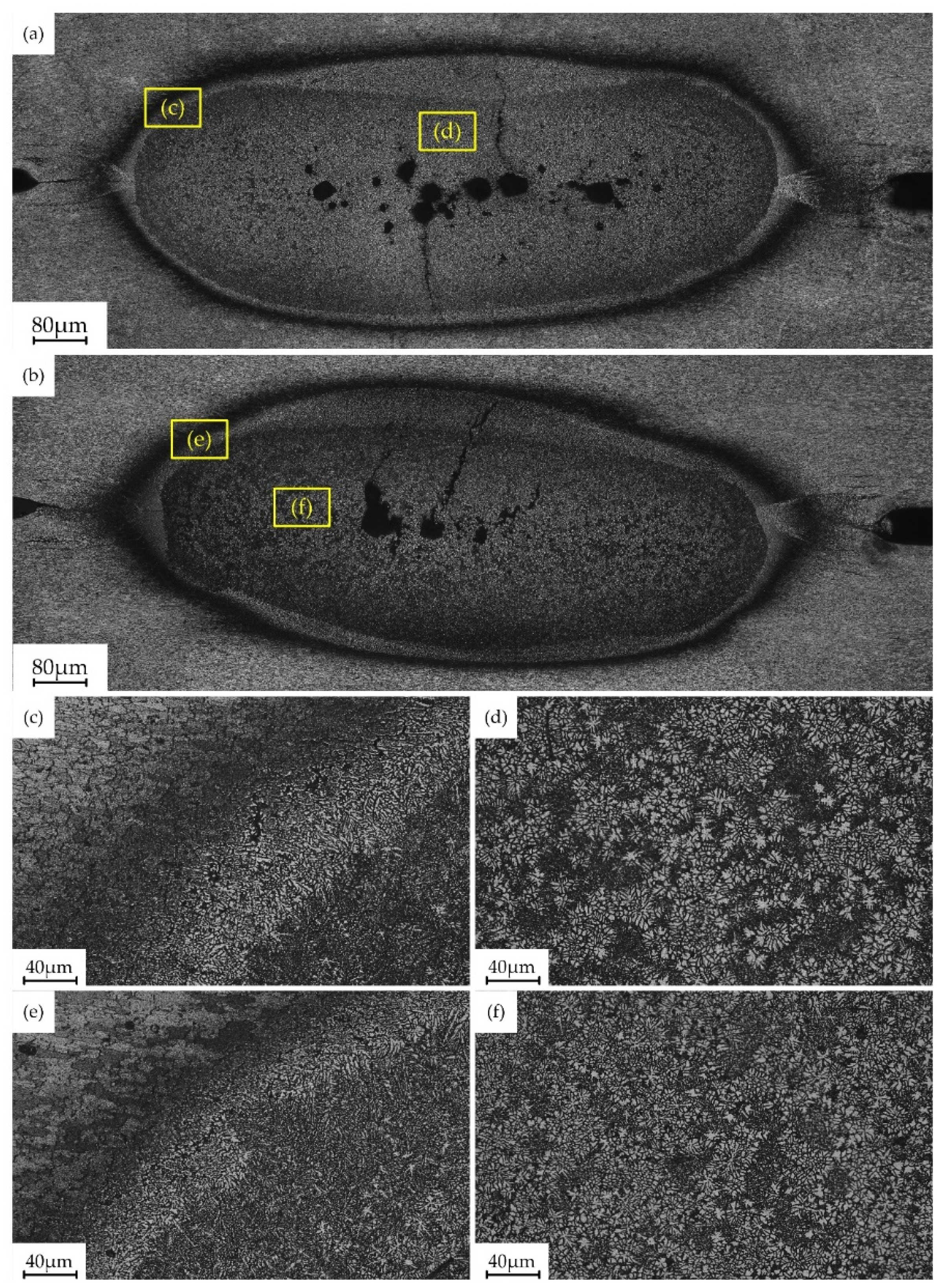

3.1. Microstructural Characteristics

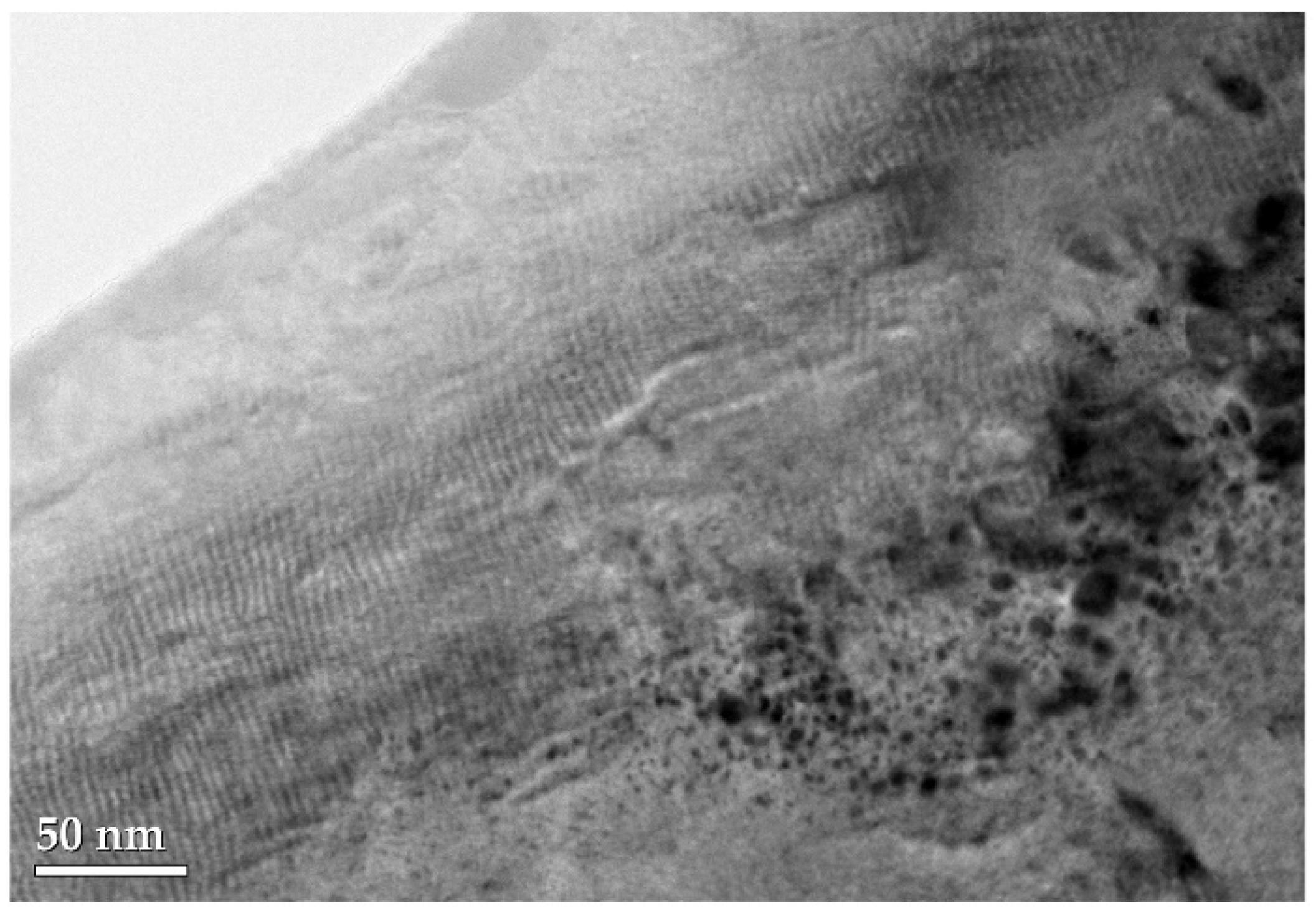

3.2. Formation and Dissolution of Quasicrystalline Phases

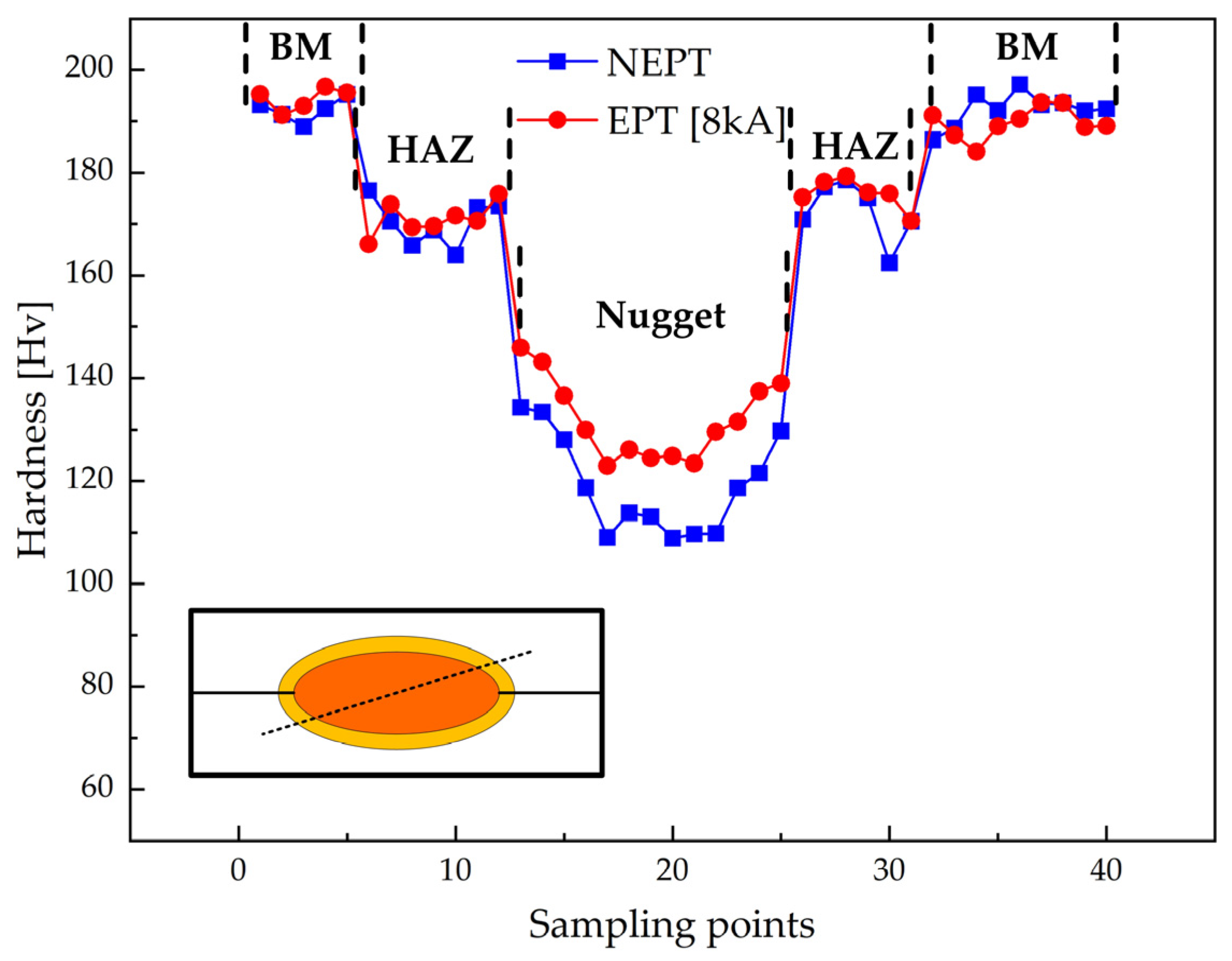

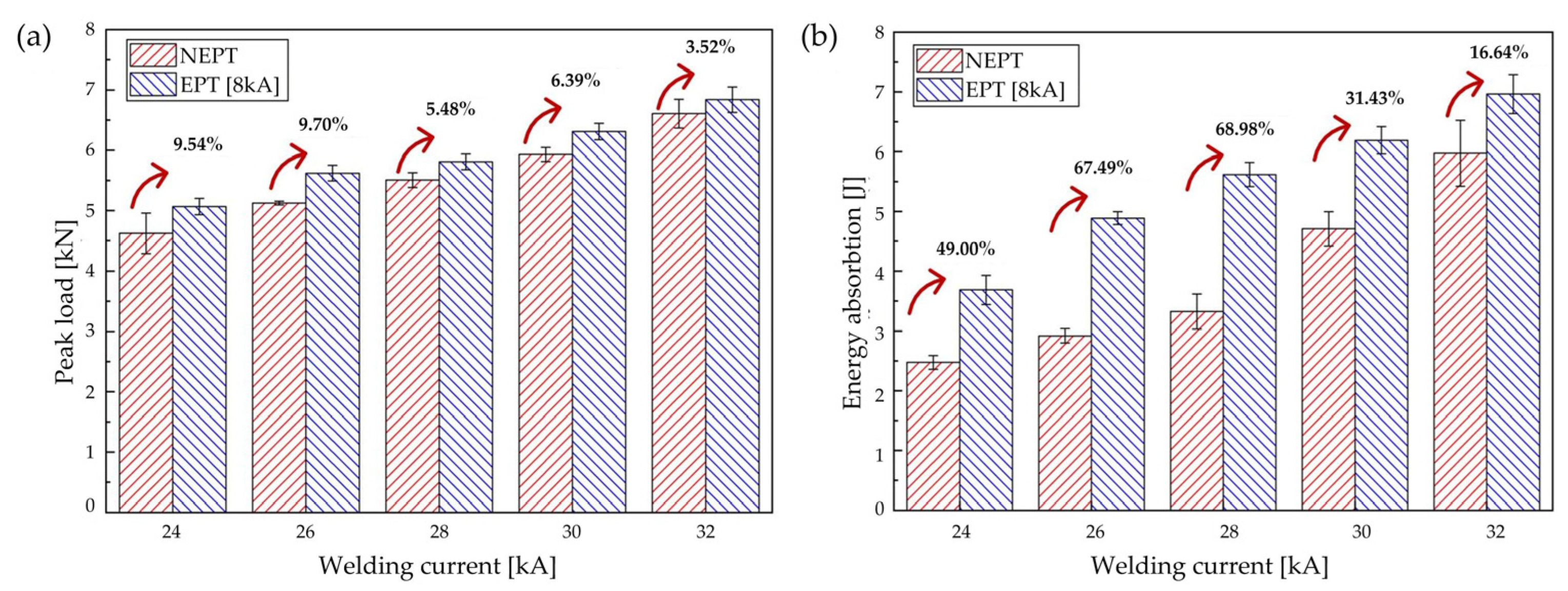

3.3. Mechanical Performance of the Joints

4. Conclusions

- (1)

- A resistance spot welding strategy incorporating in situ electrical pulsing under a high excess vacancy concentration (EVC) condition was proposed in this study. This method effectively triggered early-stage precipitation within the weld, promoting the rapid formation of band-like clusters. The observed cluster formation aligns with the classical precipitation sequence of Al-Zn-Mg-Cu alloys, providing a favorable structural basis for the subsequent development of strengthening phases.

- (2)

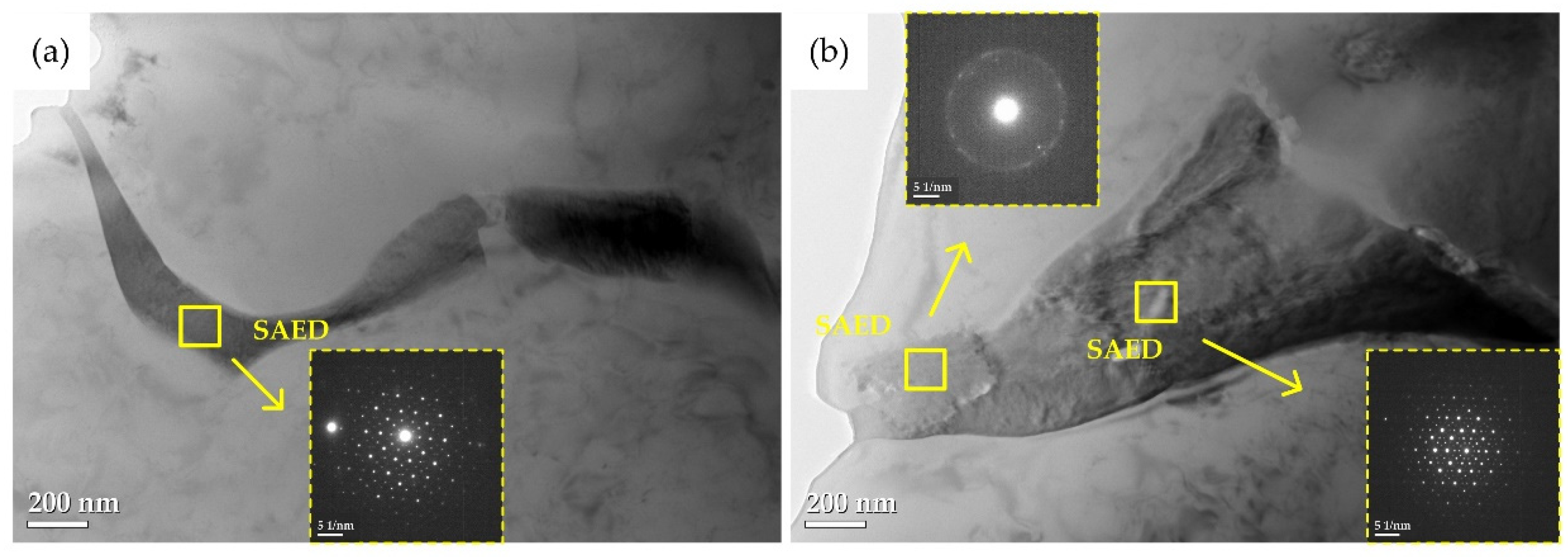

- Further TEM analysis revealed fivefold symmetric diffraction patterns in the interdendritic regions of both the NEPT and EPT specimens, confirming the formation of quasicrystals. In the EPT specimens, additional diffuse diffraction rings were observed, indicating the partial dissolution of quasicrystalline phases caused by local heating from the electrical pulses. These structures subsequently transformed into disordered cluster states and were retained in the matrix under rapid cooling conditions.

- (3)

- Mechanical testing showed that the EPT specimens exhibited significantly higher peak loads and energy absorption than the NEPT specimens across all the welding currents, with maximum improvements of 9.70% and 68.98%, respectively. Nugget size measurements demonstrated no significant difference between the two groups under the same current, ruling out size effects as the dominant factor. Therefore, the performance enhancement is primarily attributed to microstructural evolution induced by electrical pulse treatment within the weld.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation | Description |

| RSW | Resistance Spot Welding |

| EPT | Electrical Pulse-Treated |

| NEPT | Non-Electrical Pulse-Treated |

| EVC | Excess Vacancy Concentration |

| BM | Base Metal |

| HAZ | Heat-Affected Zone |

| TEM | Transmission Electron Microscopy |

| SAED | Selected Area Electron Diffraction |

References

- Won, S.J.; So, H.; Kang, L.; Oh, S.J.; Kim, K.H. Development of a high-strength Al-Zn-Mg-Cu-based alloy via multi-strengthening mechanisms. Scr. Mater. 2021, 205, 114216. [Google Scholar] [CrossRef]

- Wei, S.; Zhang, R.; Liu, X.; Zhang, Y. Comparative Study on the Effect of External Magnetic Field on Aluminum Alloy 6061 and 7075 Resistance Spot-Welding Joints. Metals 2024, 14, 1196. [Google Scholar] [CrossRef]

- Guo, X.; Li, H.; Pan, Z.; Zhou, S. Microstructure and mechanical properties of ultra-high strength Al-Zn-Mg-Cu-Sc aluminum alloy fabricated by wire+ arc additive manufacturing. J. Manuf. Process. 2022, 79, 576–586. [Google Scholar] [CrossRef]

- Park, H.-G.; Han, S.-C.; Park, C.; Jung, Y.; Jun, T.-S.; Lee, T. Effects of Paint Baking Heat Treatments on Mechanical Properties and Microstructure of Resistance Spot-Welded A5022-O and A6014-T4 Alloys. Metals 2023, 13, 1697. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Zhu, Z.; Luo, Z.; Manladan, S.M. Bake-strengthening of resistance spot welded aluminum alloy 6061. Weld. J. 2019, 98, 337S–350S. [Google Scholar]

- Gáspár, M.; Dobosy, Á.; Tisza, M.; Török, I.; Dong, Y.; Zheng, K. Improving the properties of AA7075 resistance spot-welded joints by chemical oxide removal and post weld heat treating. Weld. World 2020, 64, 2119–2128. [Google Scholar] [CrossRef]

- Fu, S.; Zhang, Y.; Liu, H.; Yi, D.; Wang, B.; Jiang, Y.; Chen, Z.; Qi, N. Influence of electric field on the quenched-in vacancy and solute clustering during early stage ageing of Al-Cu alloy. J. Mater. Sci. Technol. 2018, 34, 335–343. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, K.; Wu, W.; Wang, W.; Wang, J. Effect of electrical pulse treatment on the retrogression and re-aging behavior of 6061 aluminum alloy. Mater. Sci. Eng. A 2017, 703, 559–566. [Google Scholar] [CrossRef]

- Xiao, A.; Huang, C.; Wang, S.; Yang, J.; Cui, X. Effects of induced electro-pulsing and aging process on properties and microstructure of 7075 aluminum alloy. Mater. Charact. 2022, 192, 112222. [Google Scholar] [CrossRef]

- Dong, H.; Li, X.; Li, Y.; Zhao, S.; Wang, H.; Liu, X.; Meng, B.; Du, K. The anomalous negative electric current sensitivity of a precipitation hardened Al alloy during electrically-assisted forming. J. Mater. Res. Technol. 2023, 24, 9356–9368. [Google Scholar] [CrossRef]

- Sahoo, J.R.; Bharti, P.; Tripathi, A.; Mishra, S. An experimental and theoretical framework for comprehending the correlation between free vacancy concentration and natural aging susceptibility in Al-Mg-Si alloys. J. Alloys Compd. 2025, 1010, 177939. [Google Scholar] [CrossRef]

- Siegel, R.W. Vacancy concentrations in metals. J. Nucl. Mater. 1978, 69, 117–146. [Google Scholar] [CrossRef]

- Wolverton, C. Solute-vacancy binding in aluminum. Acta Mater. 2007, 55, 5867–5872. [Google Scholar] [CrossRef]

- Fischer, F.; Svoboda, J.; Appel, F.; Kozeschnik, E. Modeling of excess vacancy annihilation at different types of sinks. Acta Mater. 2011, 59, 3463–3472. [Google Scholar] [CrossRef]

- Du, Q.; Tang, K.; Marioara, C.D.; Andersen, S.J.; Holmedal, B.; Holmestad, R. Modeling over-ageing in Al-Mg-Si alloys by a multi-phase CALPHAD-coupled Kampmann-Wagner Numerical model. Acta Mater. 2017, 122, 178–186. [Google Scholar] [CrossRef]

- Miesenberger, B.; Kozeschnik, E.; Milkereit, B.; Warczok, P.; Povoden-Karadeniz, E. Computational analysis of heterogeneous nucleation and precipitation in AA6005 Al-alloy during continuous cooling DSC experiments. Materialia 2022, 25, 101538. [Google Scholar] [CrossRef]

- Li, S.S.; Qiu, F.; Yang, H.Y.; Liu, S.; Liu, T.S.; Chen, L.Y.; Jiang, Q.C. Strengthening of dislocation and precipitation for high strength and toughness casting Al-Zn-Mg-Cu alloy via trace TiB2+ TiC particles. Mater. Sci. Eng. A 2022, 857, 144107. [Google Scholar] [CrossRef]

- Du, Y.; Chang, Y.A.; Huang, B.; Gong, W.; Jin, Z.; Xu, H.; Yuan, Z.; Liu, Y.; He, Y.; Xie, F.Y. Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation. Mater. Sci. Eng. A 2003, 363, 140–151. [Google Scholar] [CrossRef]

- Geng, Y.; Zhang, D.; Zhang, J.; Zhuang, L. Early-stage clustering and precipitation behavior in the age-hardened Al-Mg-Zn(-Cu) alloys. Mater. Sci. Eng. A 2022, 856, 144015. [Google Scholar] [CrossRef]

- Yang, Y.; Bi, Y.; Su, J.; Luo, Z. Precipitate characteristic and nanoindentation analysis of resistance element welded DP780 steel and 6061 aluminum alloy joint. Mater. Lett. 2023, 347, 134571. [Google Scholar] [CrossRef]

- Shou, W.; Yi, D.; Yi, R.; Liu, H.; Bao, Z.; Wang, B. Influence of electric field on microstructure and mechanical properties of an Al-Cu-Li alloy during ageing. Mater. Des. 2016, 98, 79–87. [Google Scholar] [CrossRef]

- Sun, Q.; Yu, Y.; Wang, F. A novel electromagnetic shock treatment to selectively modify grain boundary and improve the corrosion resistance of aluminium alloy. Mater. Lett. 2023, 334, 133703. [Google Scholar] [CrossRef]

- Shechtman, D.; Blech, I.; Gratias, D.; Cahn, J.W. Metallic phase with long-range orientational order and no translational symmetry. Phys. Rev. Lett. 1984, 53, 1951. [Google Scholar] [CrossRef]

- AP, T.; Inoue, A.; Yokoyama, Y.; Masumoto, T. Stable icosahedral Al-Pd-Mn and Al-Pd-Re alloys. Mater. Trans. JIM 1990, 31, 98–103. [Google Scholar]

- Han, F.; Han, H.; Zhang, Y.; Yuan, T.; Wang, C. Formation mechanism of the quasicrystal in Al-Cu-Mg-Zn aluminum alloy resistance spot weld. Mater. Lett. 2023, 350, 134949. [Google Scholar] [CrossRef]

- Grushko, B.; Velikanova, T.Y. Stable and metastable quasicrystals in Al-based alloy systems with transition metals. J. Alloys Compd. 2004, 367, 58–63. [Google Scholar] [CrossRef]

- Singh, A.; Hiroto, T.; Ode, M.; Takakura, H.; Tesař, K.; Somekawa, H.; Hara, T. Precipitation of stable icosahedral quasicrystal phase in a Mg-Zn-Al alloy. Acta Mater. 2022, 225, 117563. [Google Scholar] [CrossRef]

- Turlo, V.; Rupert, T.J. Grain boundary complexions and the strength of nanocrystalline metals: Dislocation emission and propagation. Acta Mater. 2018, 151, 100–111. [Google Scholar] [CrossRef]

| Welding Current (kA) | Welding Time (ms) | Electrode Pressure (kN) | Electrical Pulse 8 kA |

|---|---|---|---|

| 24 | 120 | 4 | With/Without |

| 26 | 120 | 4 | With/Without |

| 28 | 120 | 4 | With/Without |

| 30 | 120 | 4 | With/Without |

| 32 | 120 | 4 | With/Without |

| No. | Notation | Variables | Value | Reference |

|---|---|---|---|---|

| 1 | Vacancy formation energy [eV/atom] | 0.66 | [12] | |

| 2 | Binding energy of vacancy and trap: i [eV/atom] | ; | [13] | |

| 3 | Coordination number | 12 | [14] | |

| 4 | Geometric correlation factor for FCC | 0.7815 | [14] | |

| 5 | Molar volume of Al matrix [m3/mol] | 1 × 10−5 | [15] | |

| 6 | Grain boundary energy [eV/m2] | 3.12 × 1018 | [16] | |

| 7 | Gas constant [eV/atom-K] | 8.63 × 10−5 | ||

| 8 | Average grain radius [um] | 13.05 | ||

| 9 | Dislocation density [m−2] | 7.4 × 1014 | [17] | |

| 10 | Jog spacing number | 50 | [15] | |

| 11 | Activation energy for diffusion of Mg, Cu [eV] | Mg—1.19; Cu—1.37 | [18] | |

| 12 | Diffusion prefactor [in m/s] | 1.39 × 10−5 | [18] |

| EPT Specimens | NEPT Specimens | |||

|---|---|---|---|---|

| Welding Current (kA) | Nugget Diameter (mm) | Standard Deviation | Nugget Diameter (mm) | Standard Deviation |

| 24 | 7.35 | 0 | 7.44 | 0.09 |

| 26 | 7.86 | 0.21 | 7.85 | 0.09 |

| 28 | 8.28 | 0.05 | 8.23 | 0.06 |

| 30 | 8.44 | 0.10 | 8.63 | 0.12 |

| 32 | 9.01 | 0.11 | 9.02 | 0.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, S.; Ma, X.; Xie, J.; Xie, Y.; Zhang, Y. Effects of In Situ Electrical Pulse Treatment on the Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloy Resistance Spot Welds. Metals 2025, 15, 703. https://doi.org/10.3390/met15070703

Wei S, Ma X, Xie J, Xie Y, Zhang Y. Effects of In Situ Electrical Pulse Treatment on the Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloy Resistance Spot Welds. Metals. 2025; 15(7):703. https://doi.org/10.3390/met15070703

Chicago/Turabian StyleWei, Shitian, Xiaoyu Ma, Jiarui Xie, Yali Xie, and Yu Zhang. 2025. "Effects of In Situ Electrical Pulse Treatment on the Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloy Resistance Spot Welds" Metals 15, no. 7: 703. https://doi.org/10.3390/met15070703

APA StyleWei, S., Ma, X., Xie, J., Xie, Y., & Zhang, Y. (2025). Effects of In Situ Electrical Pulse Treatment on the Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloy Resistance Spot Welds. Metals, 15(7), 703. https://doi.org/10.3390/met15070703