Effects of TiC Addition on Mechanical Behavior and Cutting Performance of Powder Extrusion Printed Cemented Carbides

Abstract

1. Introduction

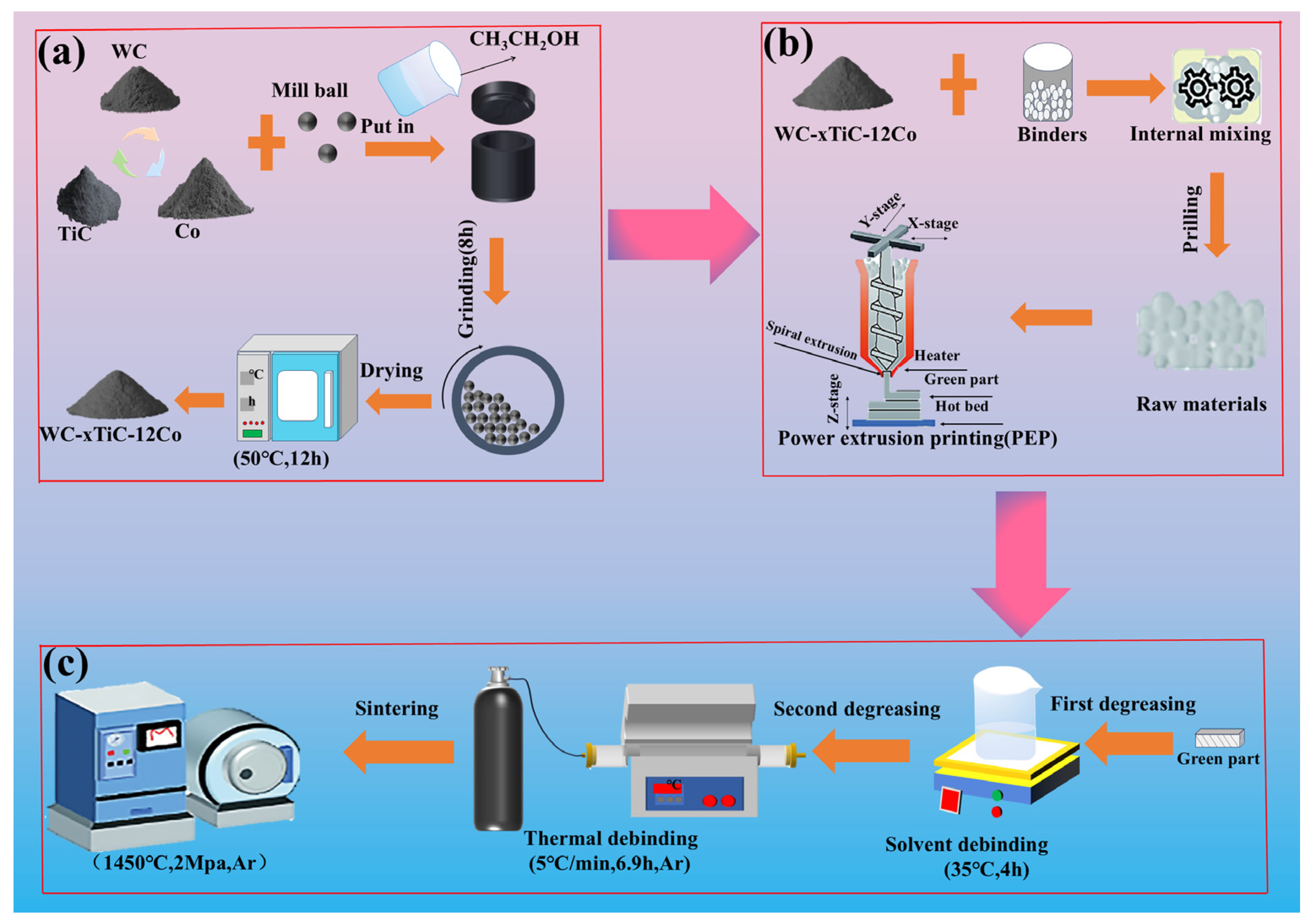

2. Materials and Methods

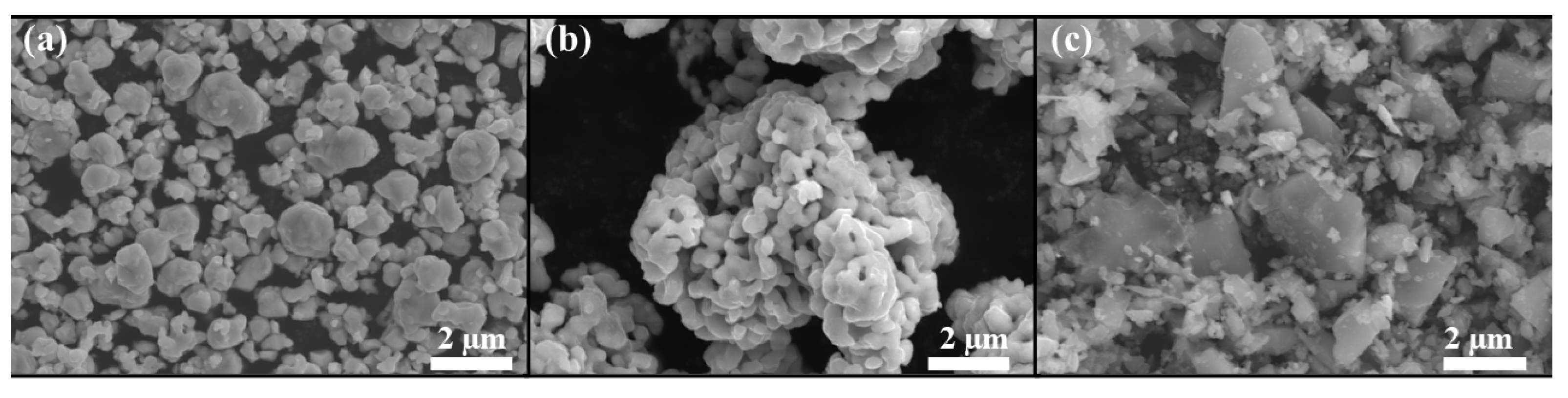

2.1. Materials

2.2. PEP and Post-Processes

2.3. Characterization Methods

3. Results and Discussion

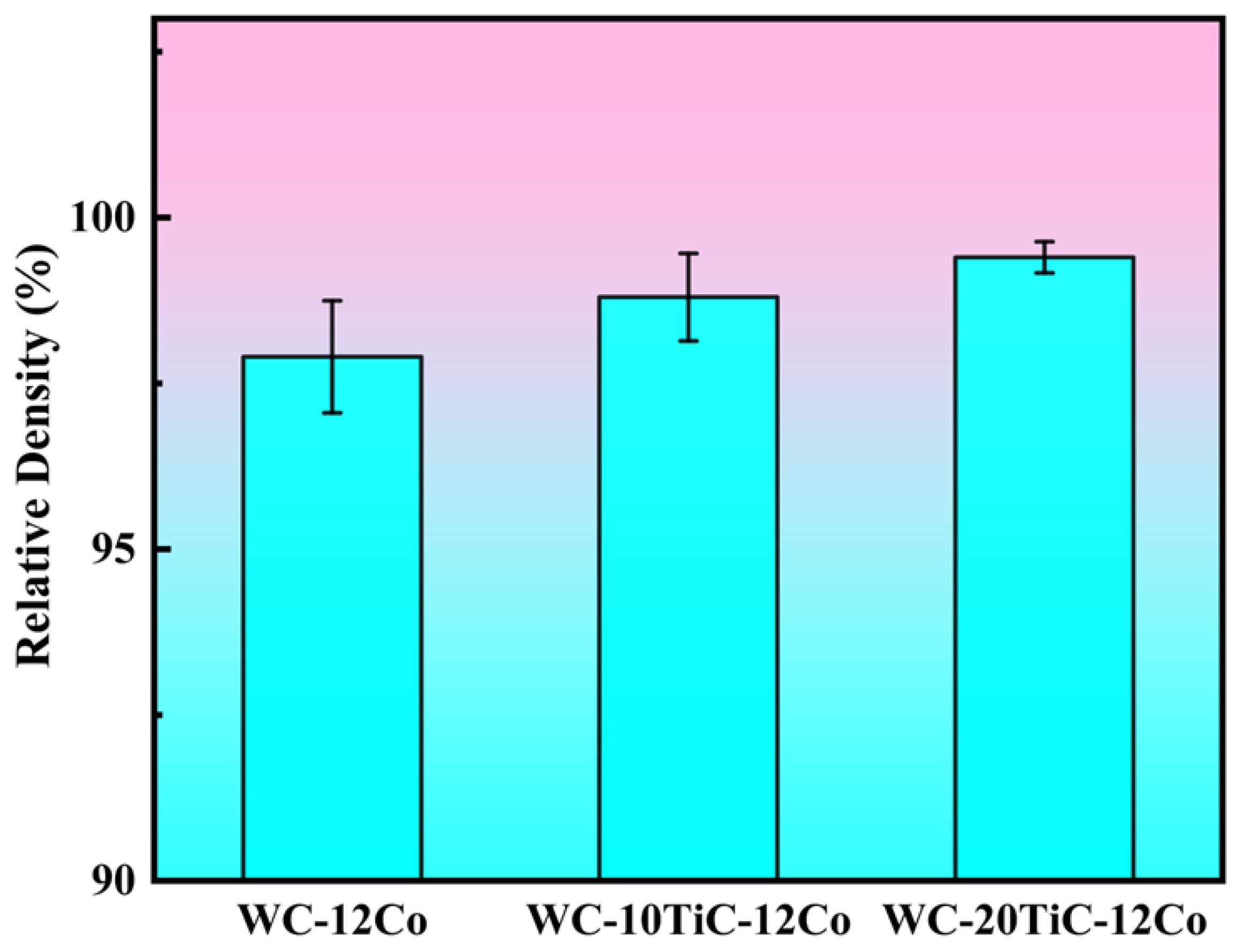

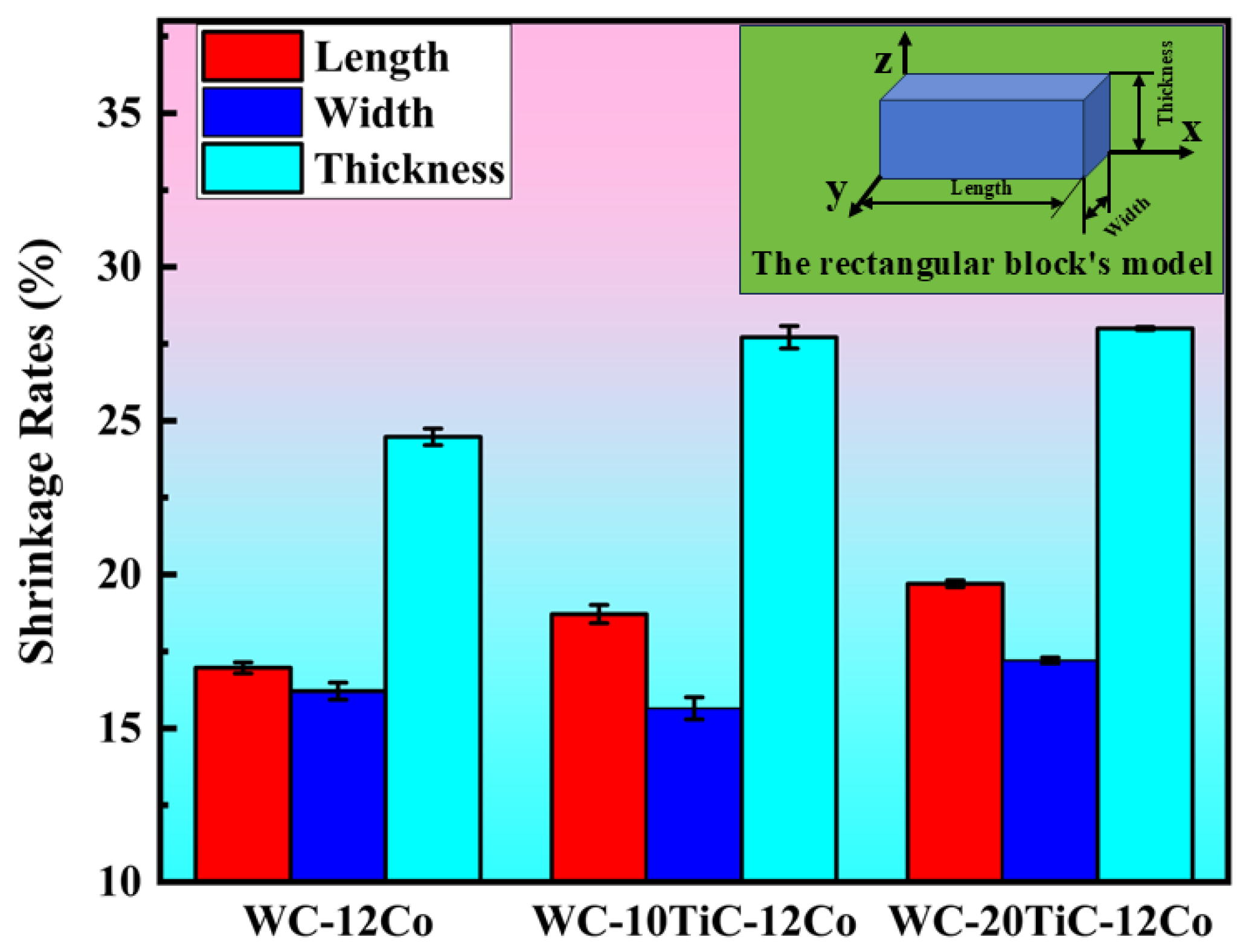

3.1. Relative Density and Dimensional Shrinkage

3.2. Microstructure Analysis

3.3. Mechanical Properties

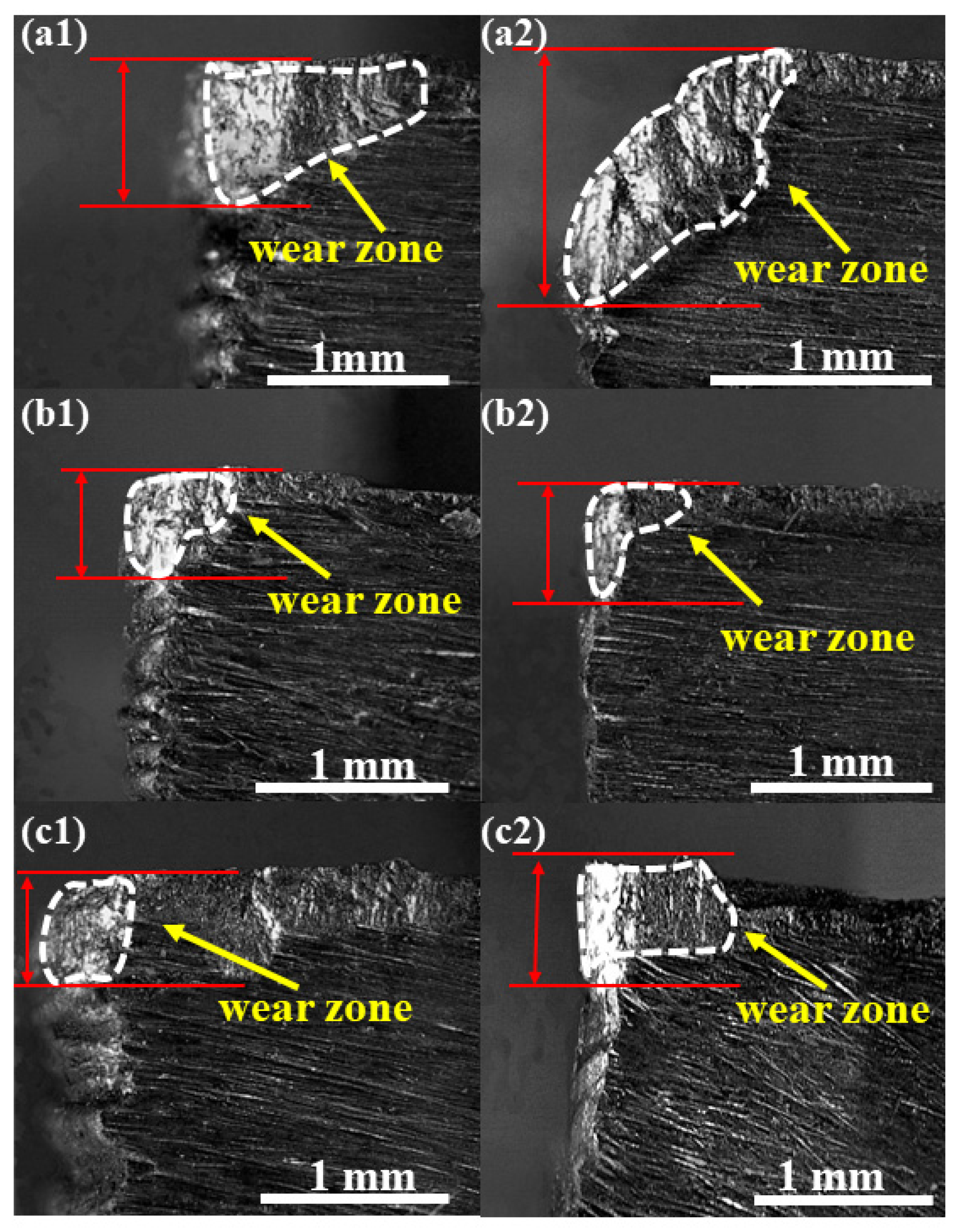

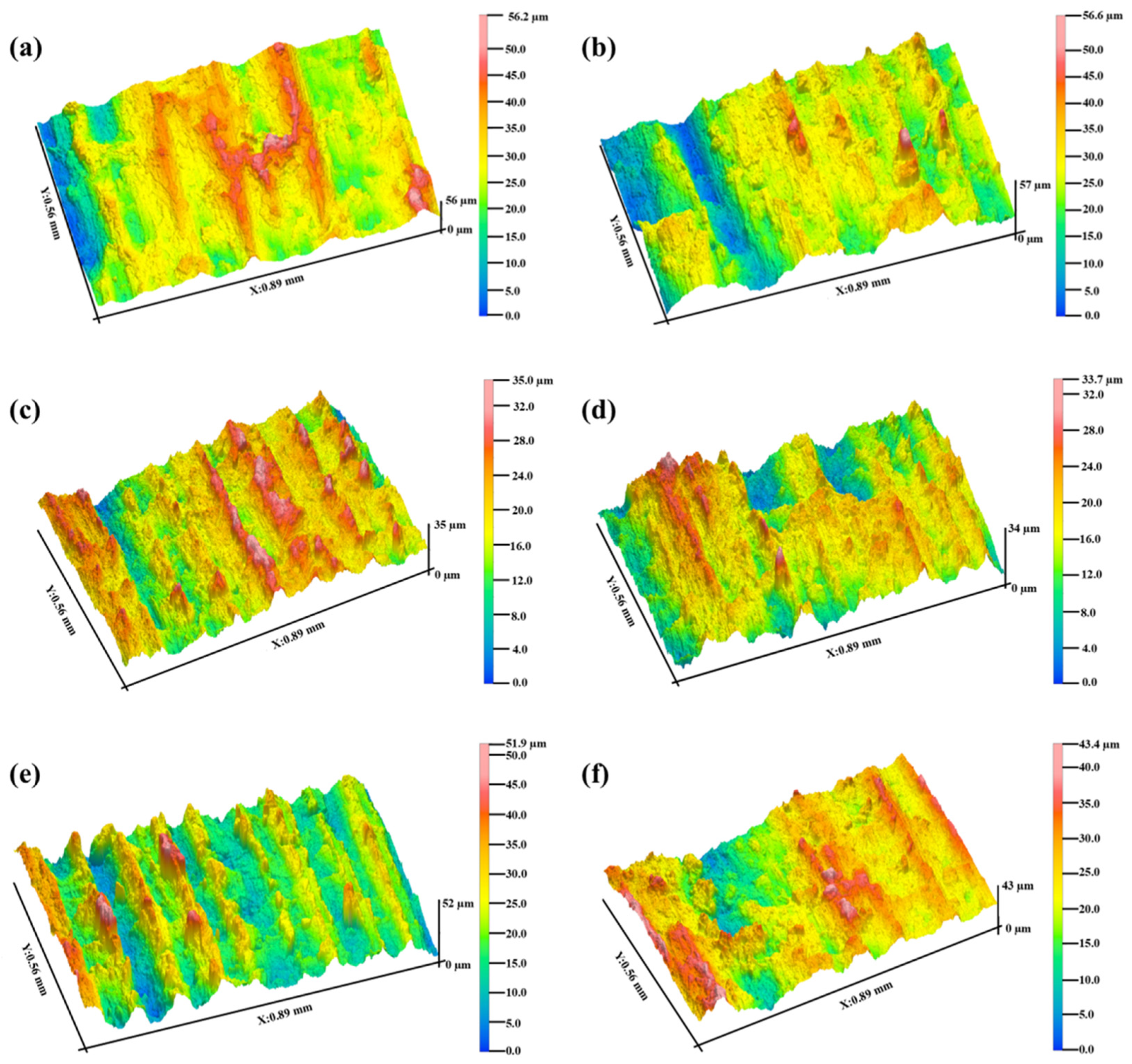

3.4. Cutting Performance

4. Conclusions

- (1)

- The PEP additive manufacturing process has been successfully utilized to fabricate high-density cemented carbides with high TiC contents. The PEP-processed WC-12Co, WC-10TiC-12Co, and WC-20TiC-12Co achieves relative densities of 97.9%, 98.8%, and 99.4%, respectively. The average linear shrinkage rates upon sintering are 14.9–19.7%, 13.1–17.2%, and 24.4–28.0% along the x, y, and z axes, respectively, indicating controllable dimensional changes.

- (2)

- The addition of TiC refines the WC grain size. The average WC grain size for WC-12Co carbides with 10 wt.% and 20 wt.% TiC are 0.88 μm and 0.87 μm, respectively, compared to 0.98 μm for TiC-free WC-12Co.

- (3)

- The hardness of the PEP processed carbides increases with TiC content, with the maximum Vickers hardness augmented by approximately 13.6% for WC-20TiC-12Co over WC-12Co. However, TiC addition decreases flexural strength apparently. Tribological testing reveals the friction coefficient decreases while wear resistance increases with TiC content.

- (4)

- The TiC addition significantly enhances wear resistance of PEP processed carbides during HT250 cutting test and reduces the workpiece surface roughness. The beneficial role of TiC in improving cutting performance is more evident for longer cutting durations.

- (5)

- Overall, PEP-processed TiC-containing carbides show promising properties, indicating significant industrial potential in metal cutting, milling, and molding. Future research on PEP-processed cemented carbides could focus on optimizing carbide particle size, designing organic binder materials, developing TaC/NbC-containing carbides, and exploring advanced sintering techniques like microwave sintering. Additionally, creating cutting tools with more complex geometries is another potential research direction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Petersson, A.; Ågren, J. Rearrangement and Pore Size Evolution during WC–Co Sintering below the Eutectic Temperature. Acta Mater. 2005, 53, 1673–1683. [Google Scholar] [CrossRef]

- Liu, X.; Song, X.; Wang, H.; Liu, X.; Tang, F.; Lu, H. Complexions in WC–Co Cemented Carbides. Acta Mater. 2018, 149, 164–178. [Google Scholar] [CrossRef]

- Miao, H.U.; Tang, J.; Chen, X.; Nan, Y.E.; Zhao, X.Y.; Xu, M.M. Microstructure and Properties of WC-12Co Composite Coatings Prepared by Laser Cladding. Trans. Nonferrous Met. Soc. China 2020, 30, 1017–1030. [Google Scholar]

- Yang, Q.; Deng, D.; Li, J.; Chen, L.; Guo, S.; Liu, J.; Chen, H. Fabrication and Mechanical Properties of WC–10Co Cemented Carbides with Plate-Like WC Grains. J. Alloys Compd. 2019, 803, 860–865. [Google Scholar] [CrossRef]

- Ma, M.; Diao, Y.; Wang, K.; Zhou, X.; Li, G.; Wang, Q. Nanocrystalline Microstructure Enhanced Mechanical Properties and Cutting Performance of WC–10Co–Ti (C, N) Gradient Cemented Carbides. Mater. Charact. 2024, 209, 113708. [Google Scholar] [CrossRef]

- Heydari, L.; Lietor, P.F.; Corpas-Iglesias, F.A.; Laguna, O.H. Ti (C,N) and WC-Based Cermets: A Review of Synthesis, Properties, and Applications in Additive Manufacturing. Materials 2021, 14, 6786. [Google Scholar] [CrossRef]

- Xiong, J.; Guo, Z.; Yang, M.; Wan, W.; Dong, G. Tool Life and Wear of WC–TiC–Co Ultrafine Cemented Carbide during Dry Cutting of AISI H13 Steel. Ceram. Int. 2013, 39, 337–346. [Google Scholar] [CrossRef]

- Petersson, A. Sintering Shrinkage of WC–Co and WC–(Ti, W)C–Co Materials with Different Carbon Contents. Int. J. Refract. Met. Hard Mater. 2004, 22, 211–217. [Google Scholar] [CrossRef]

- Lee, K.H.; Cha, S.I.; Kim, B.K.; Hong, S.H. Effect of WC/TiC Grain Size Ratio on Microstructure and Mechanical Properties of WC–TiC–Co Cemented Carbides. Int. J. Refract. Met. Hard Mater. 2006, 24, 109–114. [Google Scholar] [CrossRef]

- Chen, C.; Huang, B.; Liu, Z.; Li, Y.; Zou, D.; Liu, T.; Chang, Y.; Chen, L. Additive Manufacturing of WC–Co Cemented Carbides: Process, Microstructure, and Mechanical Properties. Addit. Manuf. 2023, 63, 103410. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive Manufacturing of Advanced Ceramic Materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Domashenkov, A.; Borbély, A.; Smurov, I. Structural Modifications of WC–Co Nanophased and Conventional Powders Processed by Selective Laser Melting. Mater. Manuf. Processes 2017, 32, 93–100. [Google Scholar] [CrossRef]

- Liu, J.; Chen, J.; Zhou, L.; Liu, B.; Lu, Y.; Wu, S.; Deng, X.; Lu, Z.; Xie, Z.; Liu, W.; et al. Role of Co Content on Densification and Microstructure of WC–Co Cemented Carbides Prepared by Selective Laser Melting. Acta Metall. Sin. (Engl. Lett.) 2021, 34, 1245–1254. [Google Scholar] [CrossRef]

- Konyashina, I.; Hinnersa, H.; Riesa, B.; Kirchner, A.; Kloeden, B.; Kieback, B.; Nilen, R.W.N.; Sidorenko, D. Additive Manufacturing of WC–13%Co by Selective Electron Beam Melting: Achievements and Challenges. Int. J. Refract. Met. Hard Mater. 2019, 84, 105028. [Google Scholar] [CrossRef]

- Wang, J.; Han, Y.; Zhao, Y.; Li, X.; Yi, D.; Guo, Z.; Cao, Y.; Liu, B.; Tang, H.P. Microstructure and Properties of WC–12Co Cemented Carbide Fabricated via Selective Electron Beam Melting. Int. J. Refract. Met. Hard Mater. 2022, 106, 105847. [Google Scholar] [CrossRef]

- Wang, X.C.; Laoui, T.; Bonse, J.; Kruth, J.P.; Lauwers, B.; Froyen, L. Direct Selective Laser Sintering of Hard Metal Powders: Experimental Study and Simulation. Int. J. Adv. Manuf. Technol. 2002, 19, 351–357. [Google Scholar] [CrossRef]

- Kruth, J.P.; Wang, X.; Laoui, T.; Froyen, L. Lasers and Materials in Selective Laser Sintering. Assem. Autom. 2003, 23, 357–371. [Google Scholar] [CrossRef]

- Kumar, S. Manufacturing of WC–Co Moulds Using SLS Machine. J. Mater. Process. Technol. 2009, 209, 3840–3848. [Google Scholar] [CrossRef]

- Kumar, S.; Czekanski, A. Optimization of Parameters for SLS of WC–Co. Rapid Prototyp. J. 2017, 23, 1202–1211. [Google Scholar] [CrossRef]

- Enneti, R.K.; Prough, K.C.; Wolfe, T.A.; Klein, A.; Studley, N.; Trasorras, J.L. Sintering of WC–12%Co Processed by Binder Jet 3D Printing (BJ3DP) Technology. Int. J. Refract. Met. Hard Mater. 2018, 71, 28–35. [Google Scholar] [CrossRef]

- Ren, X.; Shao, H.; Lin, T.; Zheng, H. 3D Gel-Printing—An Additive Manufacturing Method for Producing Complex Shape Parts. Mater. Des. 2016, 101, 80–87. [Google Scholar] [CrossRef]

- Kim, H.; Kim, J.I.; Kim, Y.D.; Jeong, H.; Ryu, S.S. Material Extrusion-Based Three-Dimensional Printing of WC–Co Alloy with a Paste Prepared by Powder Coating. Addit. Manuf. 2022, 52, 102679. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A Comprehensive Review of the Photopolymerization of Ceramic Resins Used in Stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Yakubov, V.; Ostergaard, H.; Bhagavath, S.; Leung, C.L.A.; Hughes, J.; Yasa, E.; Khezri, M.; Löschke, S.M.; Li, Q.; Paradowska, A.M. Recycled Aluminium Feedstock in Metal Additive Manufacturing: A State of the Art Review. Heliyon 2024, 10, e25252. [Google Scholar] [CrossRef] [PubMed]

- Morshed-Behbahani, K.; Aliyu, A.; Bishop, D.P.; Nasiri, A. Additive Manufacturing of Copper-Based Alloys for High-Temperature Aerospace Applications: A Review. Mater. Today Commun. 2024, 38, 108395. [Google Scholar] [CrossRef]

- Sun, H.; Zou, B.; Wang, X.; Chen, W.; Zhang, G.; Quan, T.; Huang, C. Advancements in Multi-Material Additive Manufacturing of Advanced Ceramics: A Review of Strategies, Techniques and Equipment. Mater. Chem. Phys. 2024, 314, 129337. [Google Scholar] [CrossRef]

- Li, X.; Su, H.; Dong, D.; Zhao, D.; Liu, Y.; Shen, Z.; Jiang, H.; Guo, Y.; Liu, H.; Fan, G.; et al. Enhanced Comprehensive Properties of Stereolithography 3D Printed Alumina Ceramic Cores with High Porosities by a Powder Gradation Design. J. Mater. Sci. Technol. 2022, 131, 264–275. [Google Scholar] [CrossRef]

- An, S.; Foest, R.; Fricke, K.; Riemer, H.; Fröhlich, M.; Quade, A.; Schäfer, J.; Weltmann, K.; Kersten, H. Pretreatment of Cutting Tools by Plasma Electrolytic Polishing (PEP) for Enhanced Adhesion of Hard Coatings. Surf. Coat. Technol. 2021, 405, 126504. [Google Scholar] [CrossRef]

- Chen, C.; Huang, B.; Liu, Z.; Chen, L.; Li, Y.; Zou, D.; Chang, Y.; Cheng, X.; Zhou, R.; Liu, Y. Material Extrusion Additive Manufacturing of WC–9Co Cemented Carbide. Addit. Manuf. 2024, 86, 104203. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, R.T.; Chen, J.; Xiong, X. Carbon Control and Densification of WC–8%Co Fabricated by Extrusion-Based Additive Manufacturing under Pressureless Sintering. Mater. Today Commun. 2023, 36, 106866. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, R.T.; Chen, J.; Xiong, X. Material Extrusion Printing of WC–8%Co Cemented Carbide Based on Partly Water-Soluble Binder and Post-Processing. J. Mater. Res. Technol. 2024, 29, 4394–4405. [Google Scholar] [CrossRef]

- Lu, T.X.; Meng, X.Y.; Li, S.D.; Deng, X. Additive Manufacturing Process and Microstructure during Powder Extrusion Printing of Cemented Carbides. J. Mater. Eng. 2022, 50, 147–155. [Google Scholar]

- ASTM C373-18; Standard Test Methods for Determination of Water Absorption and Associated Properties by Vacuum Method for Pressed Ceramic Tiles and Glass Tiles and Boil Method for Extruded Ceramic Tiles and Non-tile Fired Ceramic Whiteware Products. ASTM International: West Conshohocken, PA, USA, 2018.

- ISO 25178:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal. International Organization for Standardization: Geneva, Switzerland, 2012.

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM A370-24a; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2024.

- Zhang, W.; Liu, Y.; Wu, J.; Liu, Y.; Zhu, X.; Luo, Y.; Li, L.; Huang, L. Control Morphology and Properties in Additive Manufacturing of Functional Gradient Cemented Carbides for Polycrystalline Diamond Substrates. Int. J. Refract. Met. Hard Mater. 2024, 118, 106445. [Google Scholar] [CrossRef]

- Ait-Mansour, I.; Kretzschmar, N.; Chekurov, S.; Salmi, M.; Rech, J. Design-Dependent Shrinkage Compensation Modeling and Mechanical Property Targeting of Metal FFF. Prog. Addit. Manuf. 2020, 5, 51–57. [Google Scholar] [CrossRef]

- Mariani, M.; Goncharov, I.; Mariani, D.; De Gaudenzi, G.P.; Popovich, A.; Lecis, N.; Vedani, M. Mechanical and Microstructural Characterization of WC–Co Consolidated by Binder Jetting Additive Manufacturing. Int. J. Refract. Met. Hard Mater. 2021, 100, 105639. [Google Scholar] [CrossRef]

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented Carbide Microstructures: A Review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Sun, L.; Jia, C.C.; Xian, M. A Research on the Grain Growth of WC–Co Cemented Carbide. Int. J. Refract. Met. Hard Mater. 2007, 25, 121–124. [Google Scholar] [CrossRef]

- Luo, R.; Chen, N.; Xiong, H.; Li, Z. Microhomogeneous WC–TiC–Co Composite Powders with Enhanced Sinterability via a Two-Step Carburization Method. Int. J. Refract. Met. Hard Mater. 2021, 95, 105413. [Google Scholar] [CrossRef]

- Lamim, J.D.; de Oliveira, H.C.P.; Batista, A.C.; Guimarães, R.S.; Filgueira, M. Use of Ti in Hard Metal Alloys–Part II: Mechanical Properties. Mater. Wiss. Werkst. 2010, 41, 666–669. [Google Scholar] [CrossRef]

- Diniz, A.E.; Machado, Á.R.; Corrêa, J.G. Tool Wear Mechanisms in the Machining of Steels and Stainless Steels. Int. J. Adv. Manuf. Technol. 2016, 87, 3157–3168. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, H.; Li, X.; Yang, Z.; Zhang, D.; Liu, Z. Effect of Pore Structure on the Thermophysical and Frictional Properties of High-Density Graphite. Microporous Mesoporous Mater. 2022, 330, 111613. [Google Scholar] [CrossRef]

| Sample | WC-12Co | WC-10TiC-12Co | WC-20TiC-12Co |

|---|---|---|---|

| WC (wt.%) | 88 | 78 | 68 |

| TiC (wt.%) | 0 | 10 | 20 |

| Co (wt.%) | 12 | 12 | 12 |

| Nozzle Temperature (°C) | Build Plate Temperature (°C) | Printing Speed (mm/s) | Layer Thickness (mm) | Layer Thickness (mm) | Flow Rate (%) |

|---|---|---|---|---|---|

| 165 | 90 | 10 | 0.2 | 0.6 | 85 |

| Sample | WC-12Co | WC-10TiC-12Co | WC-20TiC-12Co |

|---|---|---|---|

| d50 (μm) | 0.98 | 0.88 | 0.87 |

| Main Cutting Parameters | Cutting Speed (m/min) | Cutting Speed (mm) | Feed Rate (mm/min) |

|---|---|---|---|

| Values | 47.1 | 1.6 | 50 |

| Sample | Unit | WC-12Co | WC-10TiC-12Co | WC-20TiC-12Co |

|---|---|---|---|---|

| Relative density | % | 97.9 | 98.8 | 99.4 |

| Hardness | HV30 | 1317 | 1403 | 1496 |

| Flexural strength | MPa | 2025 | 1434 | 915 |

| Friction coefficient | 0.56 | 0.51 | 0.47 | |

| Tribological Test: Wear rate | mm3/(N·m) | 91.828 × 10−6 | 77.843 × 10−6 | 43.034 × 10−6 |

| Cutting Test: Wear value/4 min | mm | 0.783 | 0.524 | 0.311 |

| Cutting Test: Wear value/8 min | mm | 1.104 | 0.574 | 0.367 |

| Parameter | Unit | WC-12Co | WC-10TiC-12Co | WC-20TiC-12Co | |||

|---|---|---|---|---|---|---|---|

| 4 min | 8 min | 4 min | 8 min | 4 min | 8 min | ||

| Ra | µm | 0.847 | 0.736 | 0.789 | 0.644 | 0.846 | 0.638 |

| Rz | µm | 5.323 | 5.040 | 4.402 | 3.838 | 5.612 | 4.187 |

| Rsk | −0.066 | 0.029 | 0.152 | −0.013 | −0.058 | 0.083 | |

| Rku | 3.993 | 2.804 | 2.878 | 3.082 | 3.056 | 3.714 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, B.; He, D.; Deng, X.; Ni, P. Effects of TiC Addition on Mechanical Behavior and Cutting Performance of Powder Extrusion Printed Cemented Carbides. Metals 2025, 15, 561. https://doi.org/10.3390/met15050561

Zhong B, He D, Deng X, Ni P. Effects of TiC Addition on Mechanical Behavior and Cutting Performance of Powder Extrusion Printed Cemented Carbides. Metals. 2025; 15(5):561. https://doi.org/10.3390/met15050561

Chicago/Turabian StyleZhong, Bisheng, Dezhi He, Xin Deng, and Peishen Ni. 2025. "Effects of TiC Addition on Mechanical Behavior and Cutting Performance of Powder Extrusion Printed Cemented Carbides" Metals 15, no. 5: 561. https://doi.org/10.3390/met15050561

APA StyleZhong, B., He, D., Deng, X., & Ni, P. (2025). Effects of TiC Addition on Mechanical Behavior and Cutting Performance of Powder Extrusion Printed Cemented Carbides. Metals, 15(5), 561. https://doi.org/10.3390/met15050561