Analysis of Friction Stir Welding of Aluminum Alloys

Abstract

1. Introduction

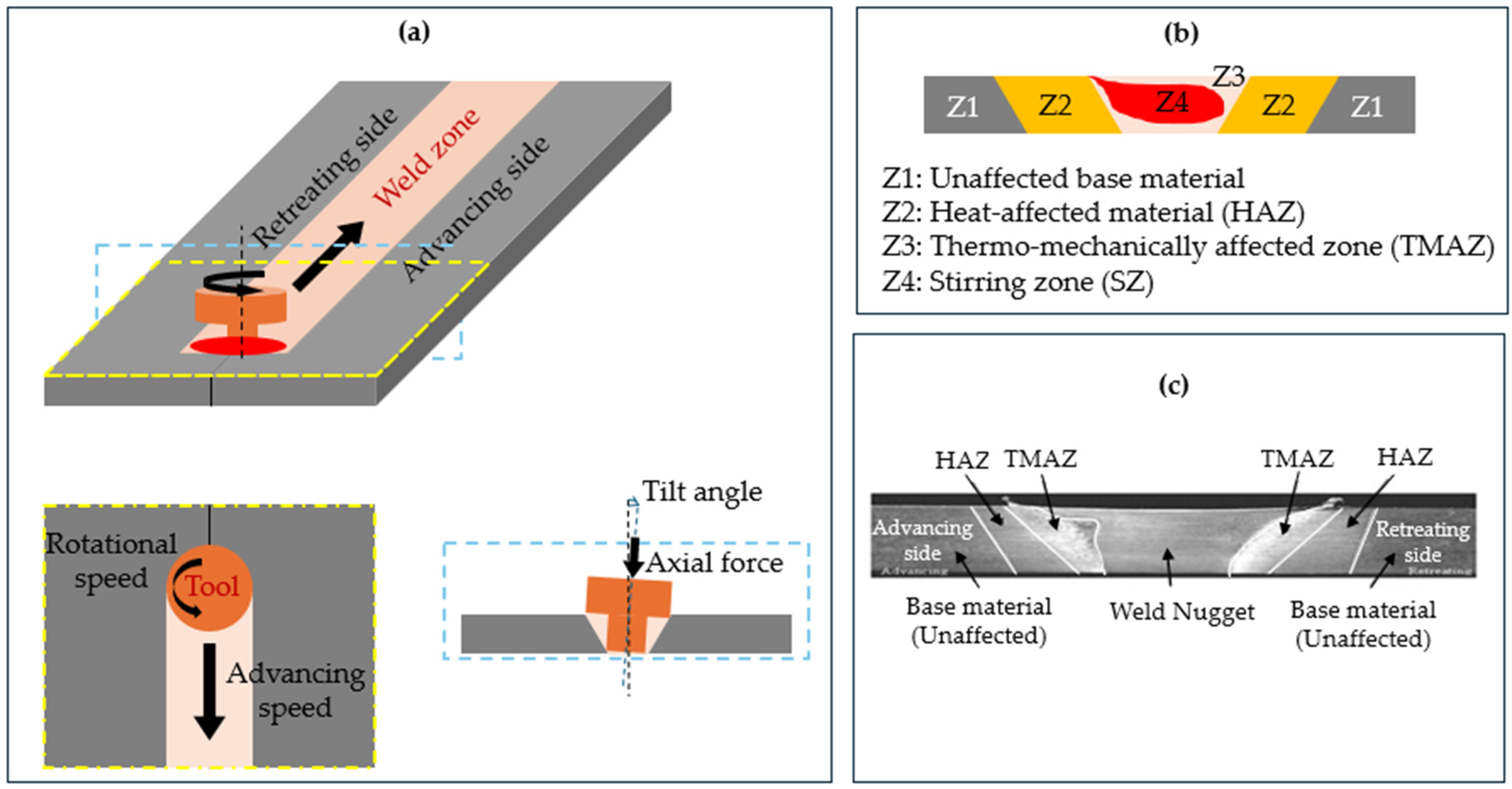

2. Historical Development of Friction Stir Welding

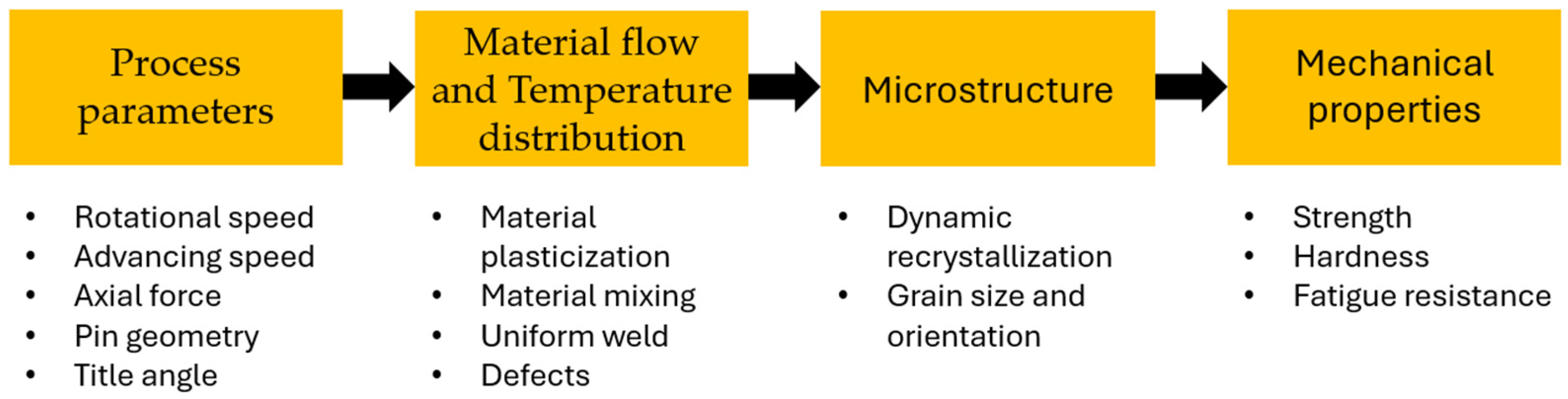

3. Principles and Mechanisms of Friction Stir Welding

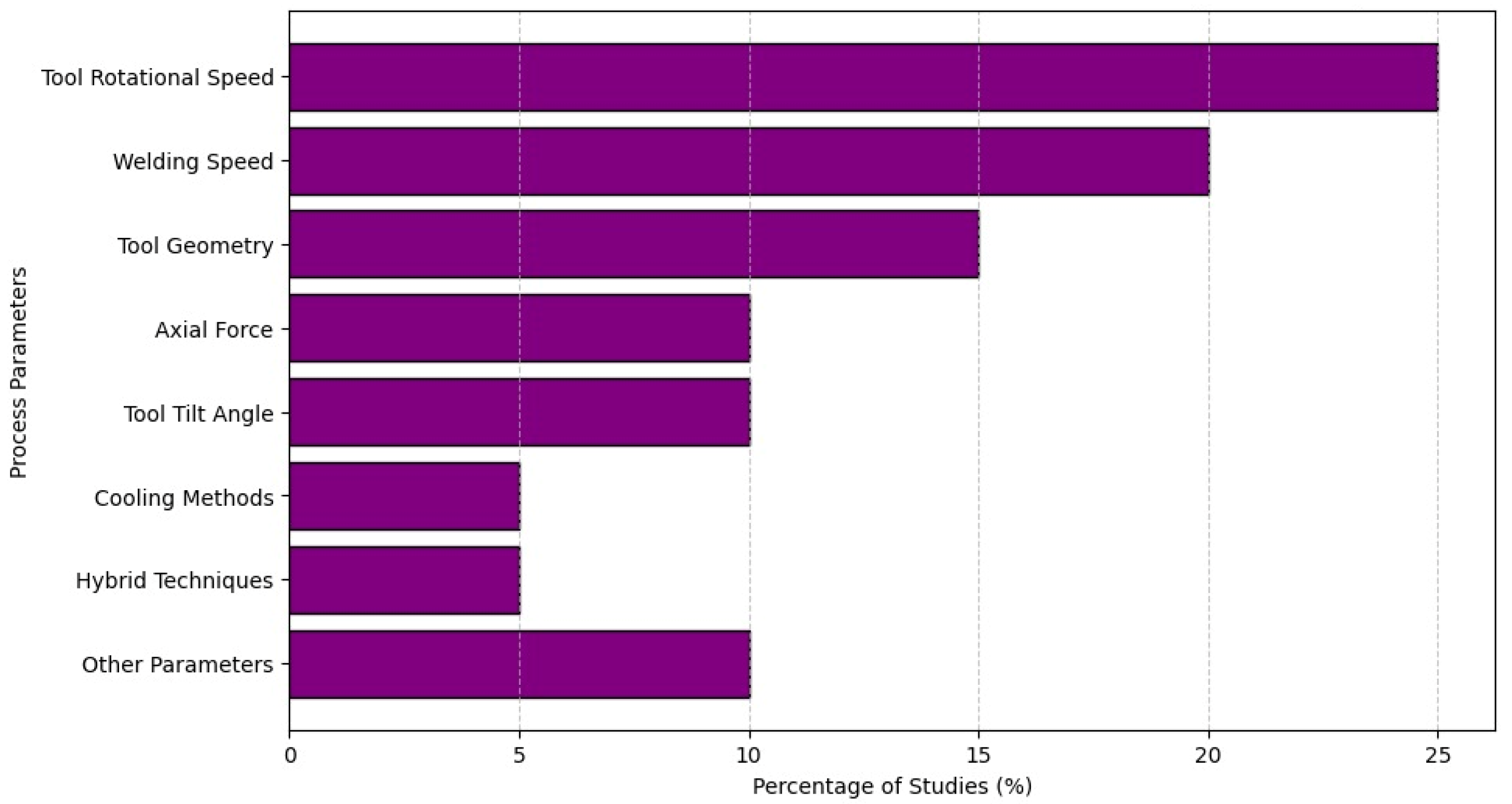

4. Friction Stir Welding Process Parameters

5. Discussion of Effects of Friction Stir Welding on Aluminum Alloys

5.1. Introduction to FSW and the Role of DRX

5.1.1. Dynamic Recrystallization (DRX) Mechanisms

- Accumulation of dislocations due to severe plastic deformation, generating dislocation tangles and sub-cell structures that increase stored deformation energy [51].

- Rearrangement of dislocation structures into low-angle grain boundaries (LAGBs), which progressively transform into high-angle grain boundaries (HAGBs).

- Progressive rotation and growth of subgrains, culminating in the formation of new, recrystallized grains.

5.1.2. Influence of Temperature on DRX

5.1.3. Influence of Strain Rate on DRX

5.1.4. Combined Thermomechanical Effects and Microstructural Zones

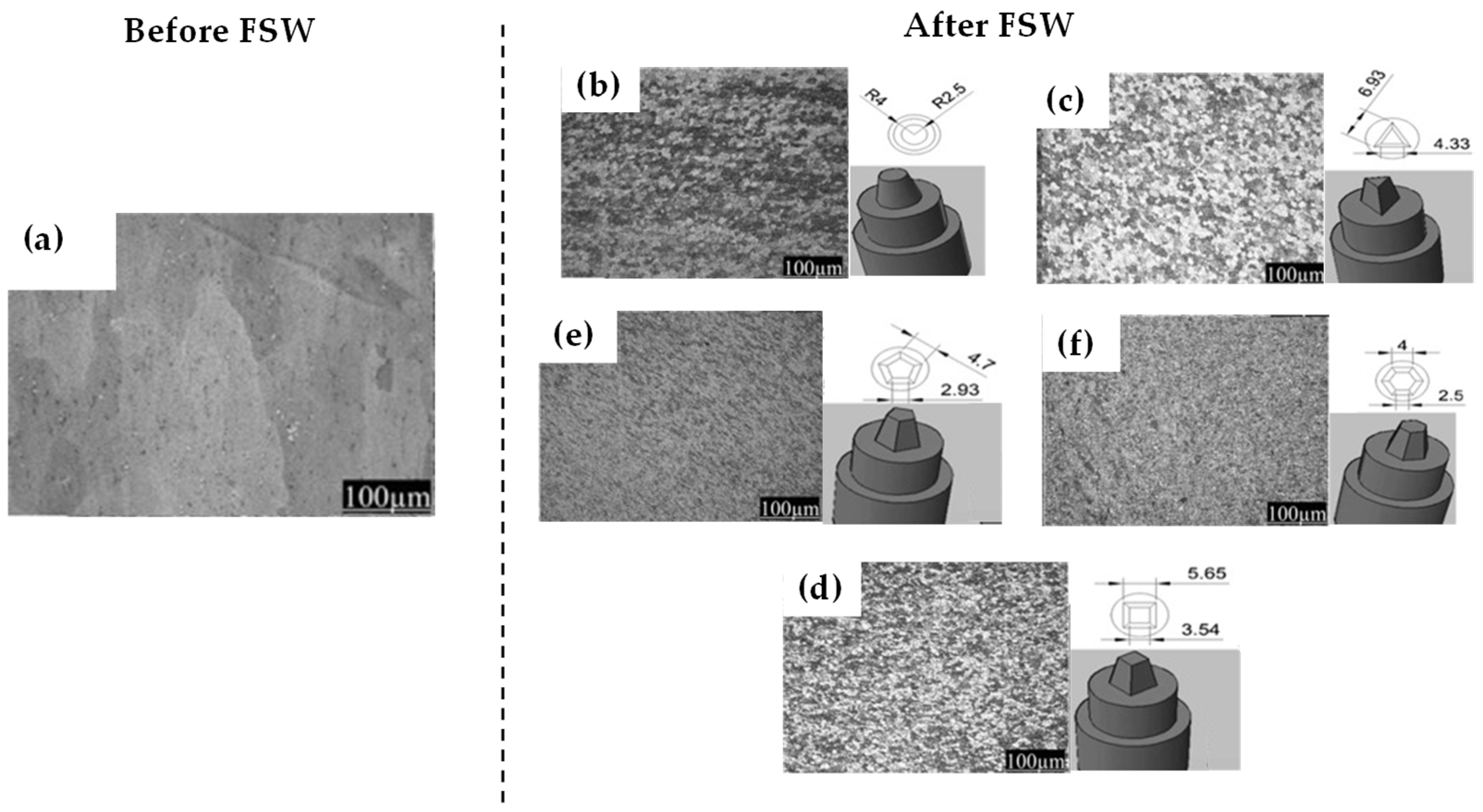

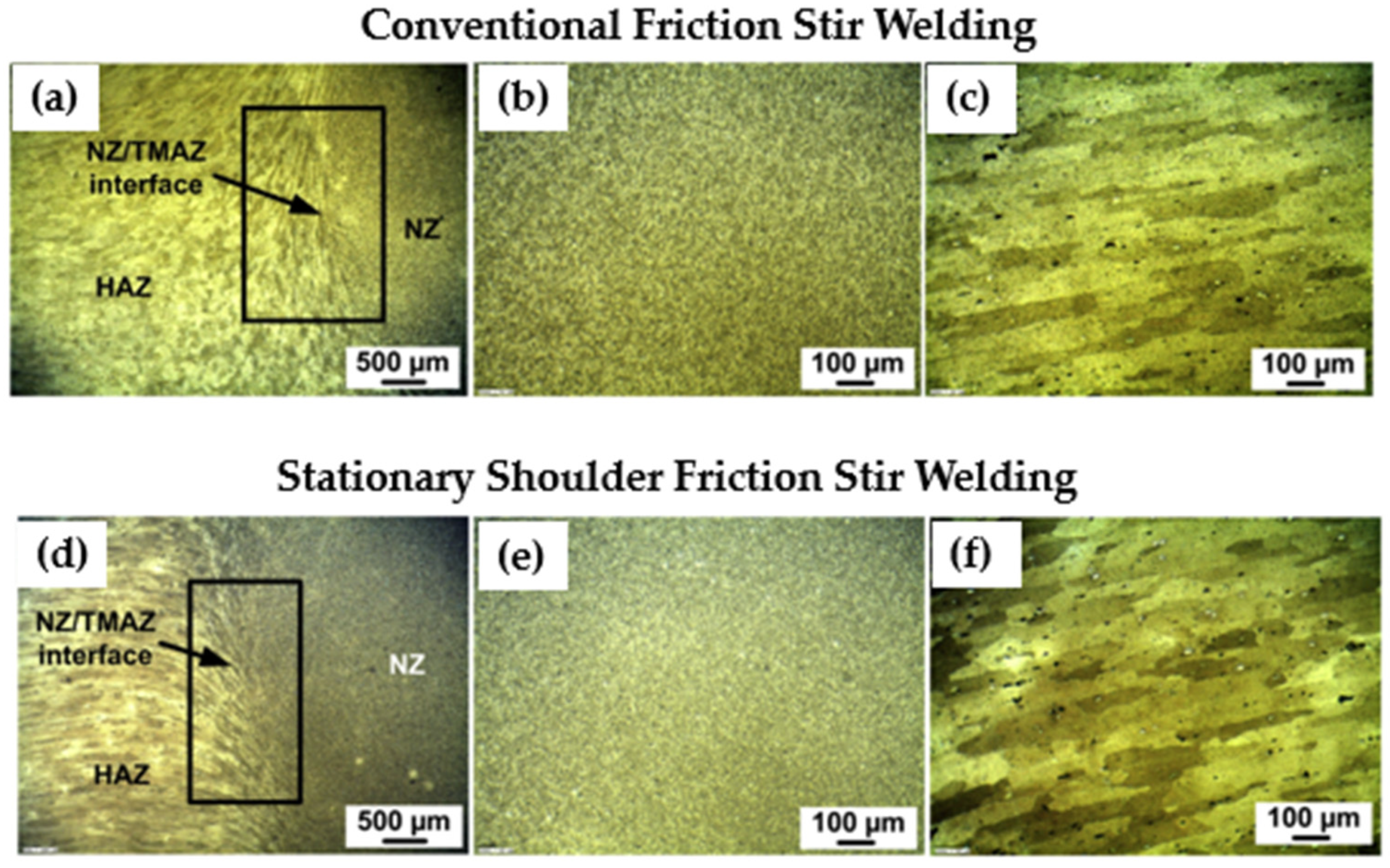

5.2. Microstructure Evolution

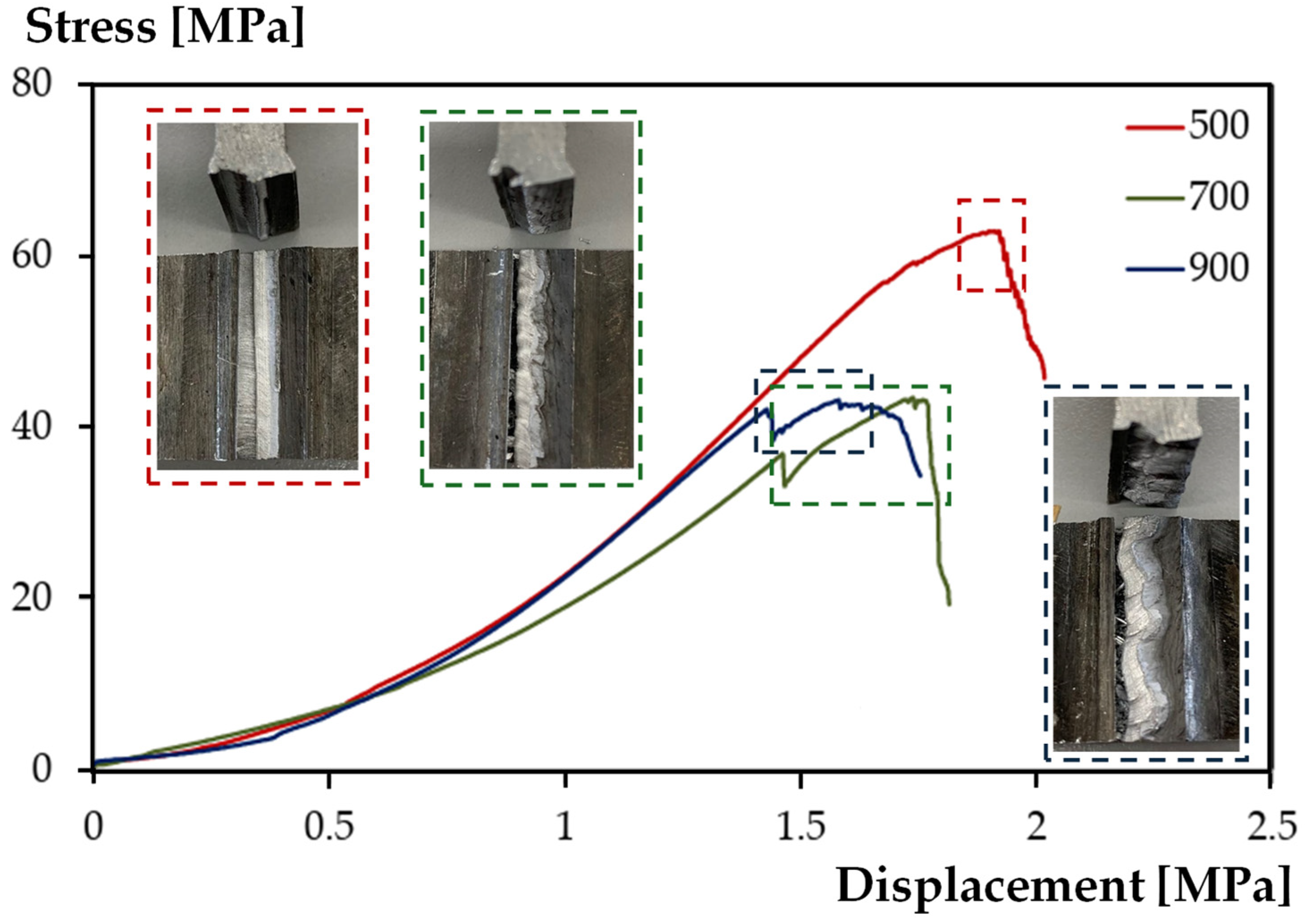

5.3. Mechanical Properties

5.4. Residual Stresses and Distortions

6. Advantages of Friction Stir Welding in Aluminum Alloys

6.1. Improved Mechanical Properties

6.2. Enhanced Corrosion Resistance

6.3. Environmental Benefits

7. Challenges and Limitations of Friction Stir Welding in Aluminum Alloys

7.1. Tool Wear and Maintenance

7.2. Process Control and Automation

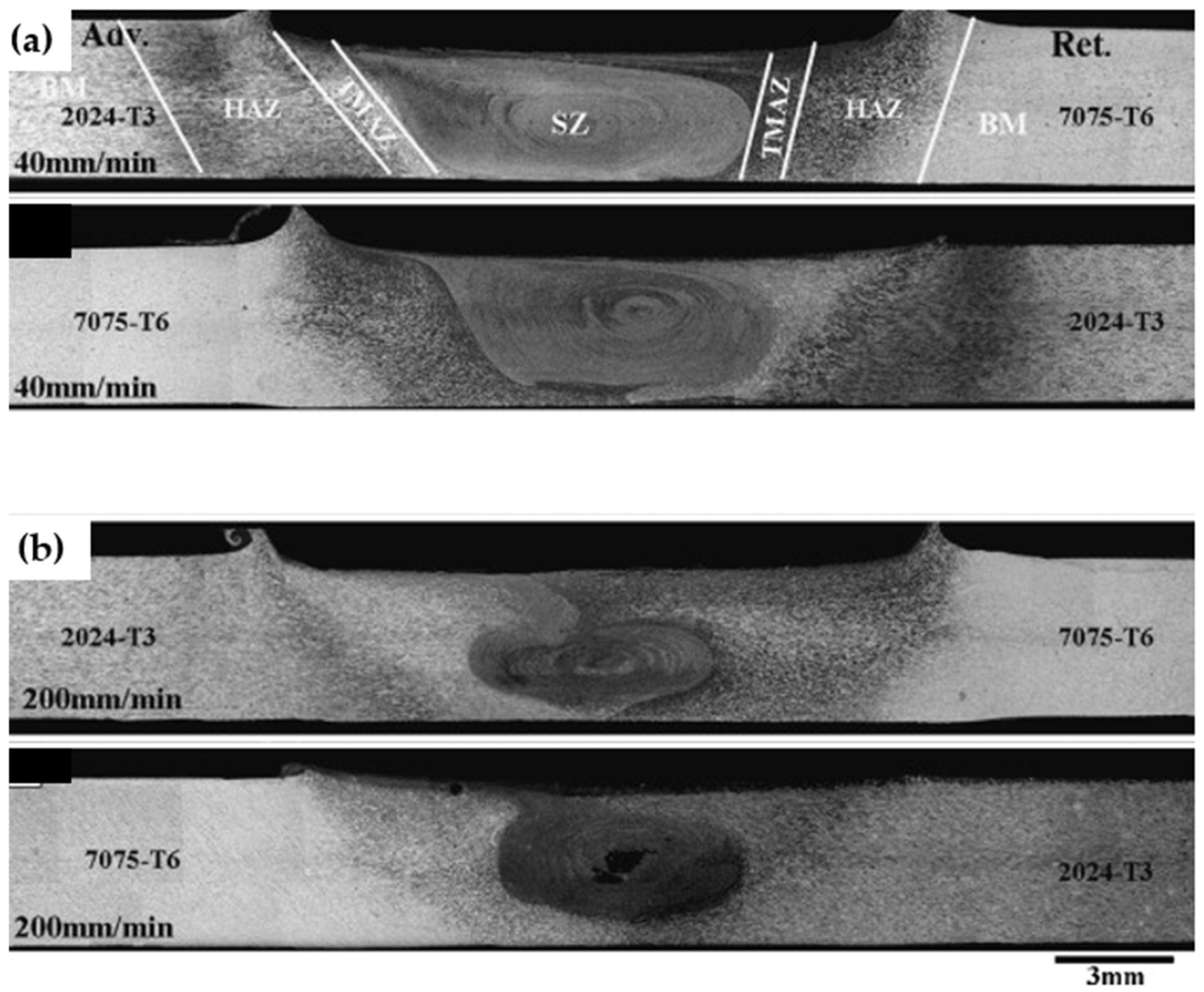

7.3. Joining Dissimilar Alloys

8. Applications of Friction Stir Welding in Aluminum Alloys

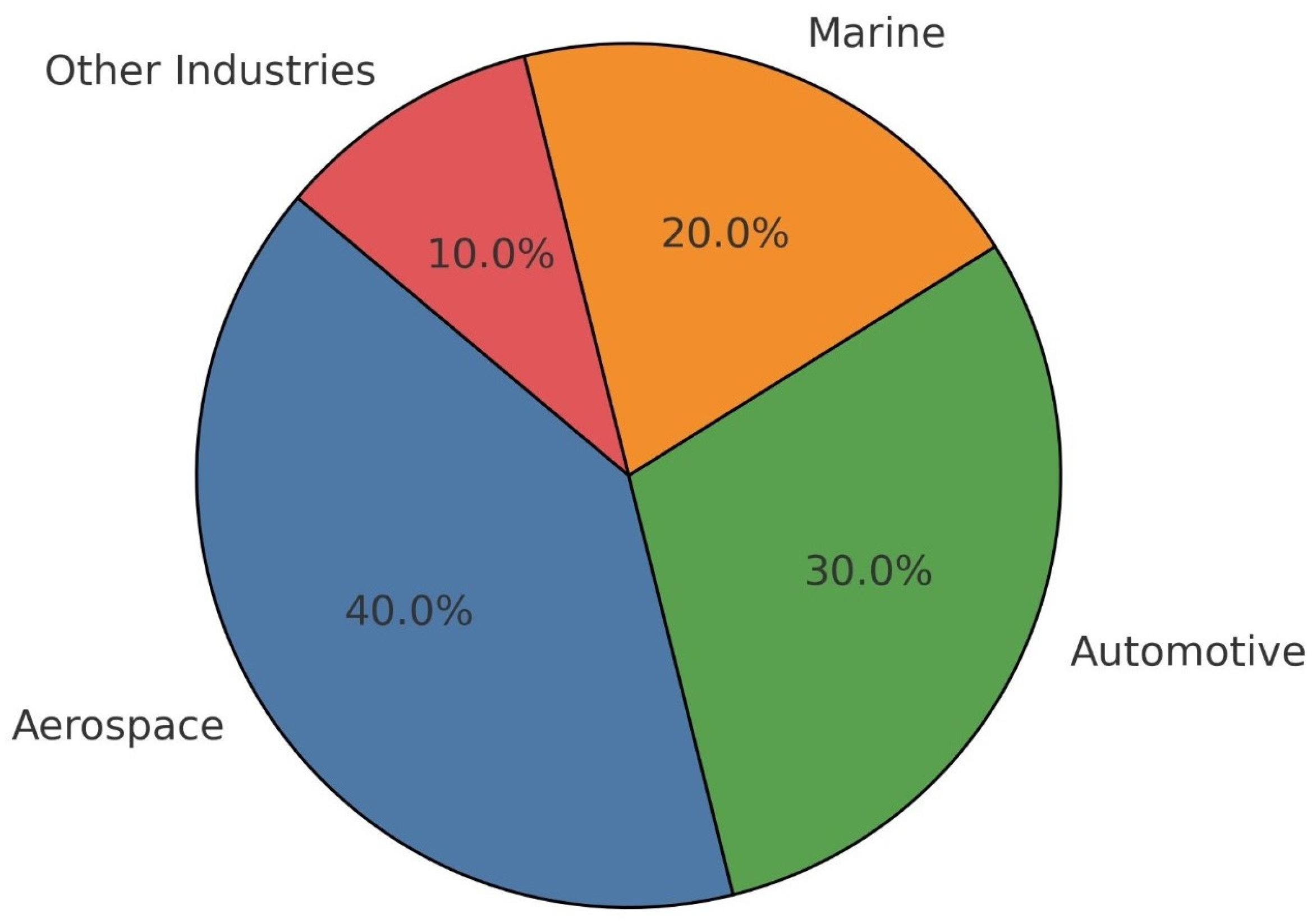

8.1. Aerospace Industry

8.2. Automotive Sector

8.3. Marine Applications

9. Comparative Analysis with Conventional Welding Techniques

9.1. Discussion of Existing Studies on FSW

- The FSW welding tool’s pin is consumable, and its size (diameter and length) must be adjusted to match the qualities of the plates to be joined.

- Due to the orientation of the FSW machine with the tool installed, the welding position is limited.

- The end-to-end connection is important, but there must be no obstructions in the vicinity of the FSW machine that might interfere with the rotation and transverse tool.

- Lap joints are important, but the size of the welding tool must be chosen carefully.

- After withdrawing the pin, a keyhole is produced at the end of each weld; this may be prevented by utilizing a retractable pin tool.

- In general, the pace of friction stir welding is slower than that of fusion welding.

9.2. Integration of AI in Welding Technologies

10. Future Research Directions

11. Summary and Conclusions

- Advanced multi-physics and numerical models: Using finite element or mesh-free techniques, build high-fidelity models combining thermomechanical coupling, dynamic recrystallization, and defect prediction. The simulation of dissimilar material flow and thick-section joints under changing boundary conditions should take center stage.

- Digital twin methodologies and artificial intelligence: Use neural networks, optimization techniques, and supervised learning to find ideal process settings and forecast weld quality. Zero-defect manufacturing and predictive maintenance are made possible by real-time data integration via digital twin models.

- Innovations in tool materials: To handle fast degradation in hard or dissimilar alloys, look at wear-resistant, thermally stable tool materials or coatings. Tools with functionally graded and adaptive geometry should also be taken into consideration for performance at varied thicknesses or complex contours.

- Hybrid and assisted strategies: To improve microstructural refinement in demanding alloy systems, combine FSW with auxiliary technologies (e.g., ultrasonic vibration, laser assistance, or induction heating) to enhance heat control, so lowering tool loads.

- Better joining of different materials: Invest methodically in the thermal metallurgical responses of different aluminum alloys and aluminum in other metal combinations. Intermetallic formation, tool offset techniques, and the application of new pin geometries or adaptive feed paths should take center stage.

- From laboratory optimization to real-world performance validation, service condition and durability testing takes center stage. Especially in aerospace and marine environments, long-term behavior under fatigue, corrosion, and thermal cycling remains understudied.

- Life-cycle assessment and sustainable measures: Using LCA tools, quantify energy efficiency, environmental impact, and economic trade-offs between FSW and fusion welding methods. For the sectors of automotive, aerospace, and renewable energy especially, this is extremely important.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cabibbo, M.; Forcellese, A.; Santecchia, E.; Paoletti, C.; Spigarelli, S.; Simoncini, M. New approaches to friction stir welding of aluminum light-alloys. Metals 2020, 10, 233. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Fydrych, D.; Çam, G. Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials 2023, 16, 2971. [Google Scholar] [CrossRef] [PubMed]

- Hassan, A.; Pedapati, S.R.; Awang, M.; Soomro, I.A. A Comprehensive Review of Friction Stir Additive Manufacturing (FSAM) of Non-Ferrous Alloys. Materials 2023, 16, 2723. [Google Scholar] [CrossRef] [PubMed]

- Mamgain, A.; Singh, V.; Singh, A.P. Influence of Welding parameters on Mechanical property during Friction Stir Welded joint on Aluminium Alloys: A Review. J. Kejuruter. 2023, 35, 13–28. [Google Scholar] [CrossRef]

- Mahakur, V.K.; Gouda, K.; Patowari, P.K.; Bhowmik, S. A Review on Advancement in Friction Stir Welding Considering the Tool and Material Parameters. Arab. J. Sci. Eng. 2021, 46, 7671–7697. [Google Scholar] [CrossRef]

- Lewise, K.A.S.; Dhas, J.E.R.; Pandiyarajan, R.; Sabarish, S. Metallurgical and mechanical investigation on FSSWed dissimilar aluminum alloy. J. Alloys Metall. Syst. 2023, 2, 100010. [Google Scholar] [CrossRef]

- Messler, R.W. Welding Principles of Processes, Physics, Chemistry, and Metallurgy; Materials Science and Engineering Department Rensselaer Polytechnic Institute Troy, British Library Cataloging; Wiley: New York, NY, USA, 2004. [Google Scholar]

- Zhang, Z.; Lv, J.; Tong, C.; Shi, Z.; Lin, J. Investigation of microstructure and mechanical properties of welds in wide stiffened panels from an innovative multi-container extrusion technology. J. Manuf. Process. 2025, 136, 305–315. [Google Scholar] [CrossRef]

- Kilic, S.; Ozturk, F.; Demirdogen, M.F. A comprehensive literature review on friction stir welding: Process parameters, joint integrity, and mechanical properties. J. Eng. Res. 2024, 13, 122–130. [Google Scholar] [CrossRef]

- Anand, R.; Sridhar, V.G. Studies on process parameters and tool geometry selecting aspects of friction stir welding—A review. Mater. Today Proc. 2020, 27, 576–583. [Google Scholar] [CrossRef]

- Kosturek, R.; Torzewski, J.; Wachowski, M.; Śnieżek, L. Effect of Welding Parameters on Mechanical Properties and Microstructure of Friction Stir Welded AA7075-T651 Aluminum Alloy Butt Joints. Materials 2022, 15, 5950. [Google Scholar] [CrossRef]

- Kumar, J.; Majumder, S.; Mondal, A.K.; Verma, R.K. Influence of rotation speed, transverse speed, and pin length during underwater friction stir welding (UW-FSW) on aluminum AA6063: A novel criterion for parametric control. Int. J. Lightweight Mater. Manuf. 2022, 5, 295–305. [Google Scholar] [CrossRef]

- Di Bella, G.; Favaloro, F.; Borsellino, C. Effect of Process Parameters on Friction Stir Welded Joints between Dissimilar Aluminum Alloys: A Review. Metals 2023, 13, 1176. [Google Scholar] [CrossRef]

- Ravi, B.; Naik, B.B.; Kumar, G.R. Influence of Tool Rotational Speed on the Mechanical and Microstructure Properties of Friction Stir Welded Al-B4C MMCs. Mater. Today Proc. 2018, 5, 1411–1417. [Google Scholar] [CrossRef]

- Lu, X.; Luan, Y.; Meng, X.; Zhou, Y.; Zhao, N.; Liang, S.Y. Temperature Distribution And Mechanical Properties of FSW Medium Thickness 2219 Aluminum Alloy. Int. J. Adv. Manuf. Technol. 2022, 119, 7229–7241. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.; Robson, J.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752. [Google Scholar]

- Singh, B.; Sharma, S.; Kumar, V.; Maheshwari, K.; Singhal, P. A Review on Heat Generation and Temperature Distribution Models in Friction stir Welding (FSW). In IOP Conference Series: Materials Science and Engineering, Proceedings of the International Conference on Futuristic and Sustainable Aspects in Engineering and Technology (FSAET 2020), Mathura, India, 18–19 December 2020; IOP Publishing: Bristol, UK, 2021; Volume 1116, p. 012080. [Google Scholar]

- Choudhary, A.K.; Jain, R. Numerical prediction of various defects and their formation mechanism during friction stir welding using coupled Euler Lagrangian technique. Mech. Adv. Mater. Struct. 2022, 30, 2371–2384. [Google Scholar] [CrossRef]

- Ni, Y.; Qin, D.Q.; Mao, Y.; Xiao, X.; Fu, L. Influences of welding parameters on axial force and deformations of micro pinless friction stir welding. Int. J. Adv. Manuf. Technol. 2020, 106, 3273–3283. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Andrews, A.; Akinlabi, S.A. Effects of processing parameters on corrosion properties of dissimilar friction stir welds of aluminium and copper. Trans. Nonferrous Met. Soc. China 2014, 24, 1323–1330. [Google Scholar] [CrossRef]

- Mallieswaran, K.; Padmanabhan, R. Effect of sheet thickness on the FSW parameters for dissimilar aluminium grades tailor welded blanks. Adv. Mater. Process. Technol. 2021, 7, 150–165. [Google Scholar] [CrossRef]

- Asmare, A.; Al-Sabur, R.; Messele, E. Experimental investigation of friction stir welding on 6061-t6 aluminum alloy using taguchi-based GRA. Metals 2020, 10, 1480. [Google Scholar] [CrossRef]

- Sabry, I. Exploring the effect of friction stir welding parameters on the strength of AA2024 and A356-T6 aluminum alloys. J. Alloys Metall. Syst. 2024, 8, 100124. [Google Scholar] [CrossRef]

- Di Bella, G.; Borsellino, C.; Chairi, M.; Campanella, D.; Buffa, G. Effect of Rotational Speed on Mechanical Properties of AA5083/AA6082 Friction Stir Welded T-Joints for Naval Applications. Metals 2024, 14, 1410. [Google Scholar] [CrossRef]

- Beygi, R.; Mehrizi, M.Z.; Akhavan-Safar, A.; Mohammadi, S.; da Silva, L.F.M. A Parametric Study on the Effect of FSW Parameters and the Tool Geometry on the Tensile Strength of AA2024–AA7075 Joints: Microstructure and Fracture. Lubricants 2023, 11, 59. [Google Scholar] [CrossRef]

- Venkat Ramana, G.; Sanke, N. Evaluation of tensile and microstructure properties of AA2014 and AA7075 FSW weldments developed by HSS-10%Co and WC tools. Mater. Today Proc. 2021, 46, 913–918. [Google Scholar]

- Milčić, M.; Milčić, D.; Vuherer, T.; Radović, L.; Radisavljević, I.; Đurić, A. Influence of welding speed on fracture toughness of friction stir welded AA2024-T351 joints. Materials 2021, 14, 1561. [Google Scholar] [CrossRef]

- Satish Kumar, P.; Shiva Chander, M. Effect of tool pin geometry on FSW dissimilar aluminum alloys—(AA5083 & AA6061). Mater. Today Proc. 2020, 39, 472–477. [Google Scholar]

- Elangovan, K.; Balasubramanian, V. Influences of tool pin profile and welding speed on the formation of friction stir processing zone in AA2219 aluminium alloy. J. Mater. Process. Technol. 2008, 200, 163–175. [Google Scholar] [CrossRef]

- Essa, A.R.; Aboud, A.R.; Ahmed, M.M.; E El-Nikhaily, A.; Easa, A.S.; Habba, M.I. Friction stir welding of aluminum alloy 6082-T6 using eccentric shoulder tools to eliminate the need for tool tilting. Sci. Rep. 2025, 15, 8801. [Google Scholar] [CrossRef]

- Di Bella, G.; Borsellino, C.; Khaskhoussi, A.; Proverbio, E. Effect of Tool Rotation Direction on Mechanical Strength of Single Lap Friction Stir Welded Joints between AA5083 Aluminum Alloy and S355J0 Steel for Maritime Applications. Metals 2023, 13, 411. [Google Scholar] [CrossRef]

- Saad, M.; Mahany, M.S.; Abbas, R.R.; Ahmed, M.M.Z.; Abdelkader, H. Influence Of Tool Rotational Speed And Axial Load In Friction Stir Welding (Fsw) Of High Strength Aluminum Alloys. Int. J. Res. Eng. Technol. 2017, 13, 411. Available online: https://www.researchgate.net/publication/318702531 (accessed on 10 April 2025).

- Akbari, M.; Esfandiar, M.; Abdollahzadeh, A. The role of force and torque in friction stir welding: A detailed review. J. Adv. Join. Process. 2025, 11, 100289. [Google Scholar] [CrossRef]

- Parasuraman, P.; Sonar, T.; Rajakumar, S. Microstructure, tensile properties and fracture toughness of friction stir welded AA7075-T651 aluminium alloy joints. Mater. Mater. Test. 2022, 64, 1843–1850. [Google Scholar] [CrossRef]

- Langari, J.; Kolahan, F.; Aliakbari, K. Effect of Tool Speed on Axial Force, Mechanical Properties and Weld Morphology of Friction Stir Welded Joints of A7075-T651. Int. J. Eng. 2016, 28, 403–410. [Google Scholar]

- Raman, K.; Senthil, S.K. Evaluation of process parameter of friction stir processing of AA2024-T351 Alloy using RSM and GRA. J. Adhes. Sci. Technol. 2023, 38, 1675–1701. [Google Scholar]

- Ghiasvand, A.; Noori, S.M.; Suksatan, W.; Tomków, J.; Memon, S.; Derazkola, H.A. Effect of Tool Positioning Factors on the Strength of Dissimilar Friction Stir Welded Joints of AA7075-T6 and AA6061-T6. Materials 2022, 15, 2463. [Google Scholar] [CrossRef]

- Rathinasuriyan, C.; Puviyarasan, M.; Sankar, R.; Selvakumar, V. Effect of process parameters on weld geometry and mechanical properties in friction stir welding of AA2024 and AA7075 alloys. J. Alloys Metall. Syst. 2024, 7, 100091. [Google Scholar] [CrossRef]

- Di Bella, G.; Alderucci, T.; Favaloro, F.; Borsellino, C. Effect of tool tilt angle on mechanical resistance of AA6082/AA5083 friction stir welded joints for marine applications. Procedia CIRP 2023, 118, 879–884. [Google Scholar] [CrossRef]

- Rajendran, C.; Srinivasan, K.; Balasubramanian, V.; Balaji, H.; Selvaraj, P. Effect of tool tilt angle on strength and microstructural characteristics of friction stir welded lap joints of AA2014-T6 aluminum alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 1824–1835. [Google Scholar] [CrossRef]

- Singh, K.; Singh, G.; Singh, H. Review on friction stir welding of magnesium alloy. J. Magnes. Alloys 2018, 6, 399–416. [Google Scholar] [CrossRef]

- Padhy, G.K.; Wu, C.S.; Gao, S. Friction stir based welding and processing technologies—Processes, parameters, microstructures and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38. [Google Scholar] [CrossRef]

- Martinez, N.; Kumar, N.; Mishra, R.S.; Doherty, K.J. Effect of tool dimensions and parameters on the microstructure of friction stir welded aluminum 7449 alloy of various thicknesses. Mater. Sci. Eng. A 2017, 684, 470–479. [Google Scholar] [CrossRef]

- Feddal, I.; Khamlichi, A.; Ameziane, K. Resistance to buckling of a stiffened panel under axial compression; Effect of imperfections resulting from welding process. Procedia Manuf. 2019, 32, 921–927. [Google Scholar] [CrossRef]

- Paik, J.K. Mechanical properties of friction stir welded aluminum alloys 5083 and 5383. Mater. Today Proc. 2018, 5, 39–49. [Google Scholar]

- Liu, X.; Ye, T.; Li, Y.; Pei, X.; Sun, Z. Quasi-in-situ characterization of microstructure evolution in friction stir welding of aluminum alloy. J. Mater. Res. Technol. 2023, 25, 6380–6394. [Google Scholar] [CrossRef]

- Eslami, N.; Hischer, Y.; Harms, A.; Lauterbach, D.; Böhm, S. Optimization of process parameters for friction stir welding of aluminum and copper using the taguchi method. Metals 2019, 9, 63. [Google Scholar] [CrossRef]

- Fu, M.W.; Wang, J.L. Size effects in multi-scale materials processing and manufacturing. Int. J. Mach. Tools Manuf. 2021, 167, 103755. [Google Scholar] [CrossRef]

- Lipińska, M.; Kooijman, A.; Śnieżek, L.; Szachogłuchowicz, I.; Torzewski, J.; Gonzalez-Garcia, Y.; Lewandowska, M. The Influence of Microstructure Evolution on the Mechanical and Electrochemical Properties of Dissimilar Welds from Aluminum Alloys Manufactured Via Friction Stir Welding. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2024, 55, 4373–4390. [Google Scholar] [CrossRef]

- Regev, M.; Spigarelli, S. On Dynamic Recrystallization during the Friction Stir Processing of Commercially Pure Ti and Its Influence on the Microstructure and Mechanical Properties. Metals 2024, 14, 644. [Google Scholar] [CrossRef]

- Mishra, D.; Gupta, A.; Raj, P.; Kumar, A.; Anwer, S.; Pal, S.K.; Chakravarty, D.; Pal, S.; Chakravarty, T.; Pal, A.; et al. Real time monitoring and control of friction stir welding process using multiple sensors. CIRP J. Manuf. Sci. Technol. 2020, 30, 1–11. [Google Scholar] [CrossRef]

- Jata, K.V.; Semiatin, S.L. Continuous Dynamic Recrystallization During Friction Stir Welding Of High Strength Aluminum Alloys. Scr. Mater. 2000, 43, 743–749. Available online: www.elsevier.com/locate/scriptamat (accessed on 10 April 2025). [CrossRef]

- Mo, S.; Hu, Y.; Huang, T.; Zhou, Y.; Zhang, J.; Zhang, W. Nonlinear dynamic of friction stir welding for aluminum alloy. Commun. Nonlinear Sci. Numer. Simul. 2025, 142, 108576. [Google Scholar] [CrossRef]

- Xing, W.; Yu, Z.; Zhou, J.; Zhang, Z.; Liu, C.; Zhao, H. Study of the friction stir welding process and mechanical behavior of 7075/6061 heterogeneous aluminum alloys based on in-situ EBSD/DIC testing. Mater. Today Commun. 2025, 44, 112000. [Google Scholar] [CrossRef]

- Xu, W.; Suo, H.; Lu, H.; Wang, C.; Wang, Y.; Wang, H. Influence of composite-shaped pins on microstructure and mechanical properties homogeneity of friction stir welding 7050-T7451 aluminum alloy long-thick plate joints. Mater. Charact. 2025, 221, 114776. [Google Scholar] [CrossRef]

- Gungor, B.; Kaluc, E.; Taban, E.; Sik, A. Mechanical, fatigue and microstructural properties of friction stir welded 5083-H111 and 6082-T651 aluminum alloys. Mater. Des. 2014, 56, 84–90. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, G.; Cao, Y.; Zhu, Y.; Liu, Q. On the microstructure and mechanical properties of similar and dissimilar AA7075 and AA2024 friction stir welding joints: Effect of rotational speed. J. Manuf. Process. 2019, 37, 470–487. [Google Scholar] [CrossRef]

- Shou, H.; Song, Y.; Zhang, C.; Zhang, P.; Zhao, W.; Zhu, X.; Shi, P.; Xing, S. Grain Structure and Texture Evolution in the Bottom Zone of Dissimilar Friction-Stir-Welded AA2024-T351 and AA7075-T651 Joints. Materials 2024, 17, 3750. [Google Scholar] [CrossRef]

- Chowdhury, I.; Sengupta, K.; Maji, K.K.; Roy, S.; Ghosal, S. Investigation of mechanical properties of dissimilar joint of Al6063 aluminium alloy and C26000 copper alloy by ultrasonic assisted friction stir welding. Mater. Today Proc. 2021, 50, 1527–1534. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, C.; Shi, L. Effect of ultrasonic field on microstructure evolution in friction stir welding of dissimilar Al/Mg alloys. J. Mater. Res. Technol. 2021, 17, 1–21. [Google Scholar] [CrossRef]

- Mallieswaran, K.; Rajendran, C.; Padmanabhan, R.; Rajasekaran, S. Evaluation of nickel shot peening process on strength of friction stir welded AA2014-T6 aluminum alloy joints. Prakt. Metallogr. Pract. Metallogr. 2023, 60, 442–460. [Google Scholar] [CrossRef]

- Rambabu, G.; Naik, D.B.; Rao, C.V.; Rao, K.S.; Reddy, G.M. Optimization of friction stir welding parameters for improved corrosion resistance of AA2219 aluminum alloy joints. Def. Technol. 2015, 11, 330–337. [Google Scholar] [CrossRef]

- Rambabu, G.; Peel, M.; Steuwer, A.; Preuss, M.; Withers, P.J. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds. Acta Mater. 2018, 51, 114–129. [Google Scholar]

- Li, H.; Gao, J.; Li, Q. Fatigue of friction stir welded aluminum alloy joints: A review. Appl. Sci. 2018, 14, 2626. [Google Scholar] [CrossRef]

- Gite, R.A.; Loharkar, P.K.; Shimpi, R. Friction stir welding parameters and application: A review. Mater. Today Proc. 2019, 19, 361–365. [Google Scholar] [CrossRef]

- Ogunsemi, B.; Abioye, T.; Ogedengbe, T.; Zuhailawati, H. A review of various improvement strategies for joint quality of AA 6061-T6 friction stir weldments. J. Mater. Res. Technol. 2021, 11, 1061–1089. [Google Scholar] [CrossRef]

- Lewise, K.A.S.; Dhas, J.E.R. FSSW process parameter optimization for AA2024 and AA7075 alloy. Mater. Manuf. Process 2021, 37, 34–42. [Google Scholar] [CrossRef]

- Guo, Y.; Li, P. Effect of Residual Stress and Microstructure on the Fatigue Crack Growth Behavior of Aluminum Friction Stir Welded Joints. Materials 2024, 17, 385. [Google Scholar] [CrossRef]

- Koilraj, M.; Kumar, A.S.; Paul, D.B.; Rao, S.K. Mechanical Properties and Corrosion Resistance of Friction Stir Welded Dissimilar Aluminum Alloys 2219 to 5083. Appl. Mech. Mater. 2015, 813–814, 203–207. [Google Scholar] [CrossRef]

- Sashank, J.S.; Sampath, P.; Krishna, P.S.; Sagar, R.; Venukumar, S.; Muthukumaran, S. Effects of friction stir welding on microstructure and mechanical properties of 6063 aluminium alloy. Mater. Today Proc. 2018, 5, 8348–8353. [Google Scholar] [CrossRef]

- Singh, R.P.; Dubey, S.; Singh, A.; Kumar, S. A review paper on friction stir welding process. Mater. Today Proc. 2020, 38, 6–11. [Google Scholar] [CrossRef]

- Zapata, J.; Toro, M.; López, D. Journal of Materials Processing Technology Residual stresses in friction stir dissimilar welding of aluminum alloys. J. Mater. Process. Technol. 2016, 229, 121–127. [Google Scholar] [CrossRef]

- Zhang, X.X.; Wu, L.H.; Andrae, H.; Gan, W.M.; Hofmann, M.; Wang, D.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y. Effects of welding speed on the multiscale residual stresses in friction stir welded metal matrix composites. J. Mater. Sci. Technol. 2019, 35, 824–832. [Google Scholar] [CrossRef]

- Battina, N.M.; Vanthala, V.S.P.; Chirala, H.K. Influence of tool pin profile on mechanical and metallurgical behavior of friction stir welded AA6061-T6 and AA2017-T6 tailored blanks. Eng. Res. Express 2021, 3, 035026. [Google Scholar] [CrossRef]

- Dharmalingam, S.; Lenin, K. Effect of friction stir welding parameters on microstructure and mechanical properties of the dissimilar (AA7475-AA8011) joints. Mater. Today Proc. 2020, 39, 105–109. [Google Scholar] [CrossRef]

- Sucharitha, M.; Sankar, B.R.; Umamaheswarrao, P. Experimental investigations on the effect of tool rotational speed on mechanical properties and microstructure of friction stir welded AZ31 Mg alloy. Mater. Today Proc. 2021, 46, 3455–3459. [Google Scholar] [CrossRef]

- Chen, P.; Zou, S.; Chen, J.; Qin, S.; Yang, Q.; Zhang, Z.; Jia, Z.; Zhang, L.; Jiang, T.; Liu, Q. Effect of rotation speed on microstructure evolution and mechanical properties of nugget zone in 2195-T8 Al-Li alloy friction stir welding joints. Mater. Charact. 2021, 176, 111079. [Google Scholar] [CrossRef]

- Deore, H.; Bhardwaj, A.; Rao, A.; Mishra, J.; Hiwarkar, V. Consequence of reinforced SiC particles and post process artificial ageing on microstructure and mechanical properties of friction stir processed AA7075. Def. Technol. 2020, 16, 1039–1050. [Google Scholar] [CrossRef]

- Kumar, S.; Srivastava, A.K.; Singh, R.K.; Dwivedi, S.P. Experimental study on hardness and fatigue behavior in joining of AA5083 and AA6063 by friction stir welding. Mater. Today Proc. 2019, 25, 646–648. [Google Scholar] [CrossRef]

- Tra, T.H.; Okazaki, M.; Suzuki, K. Fatigue crack propagation behavior in friction stir welding of AA6063-T5: Roles of residual stress and microstructure. Int. J. Fatigue 2012, 43, 23–29. [Google Scholar] [CrossRef]

- Seleman, M.M.E.-S.; Ahmed, M.M.Z.; Ramadan, R.M.; Zaki, B.A. Effect of FSW Parameters on the Microstructure and Mechanical Properties of T-joints between Dissimilar Al-Alloys. Int. J. Integr. Eng. 2022, 14, 1–12. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Azizieh, M.; Alavijeh, A.S.; Abbasi, M.; Balak, Z.; Kim, H. Mechanical properties and microstructural evaluation of AA1100 to AZ31 dissimilar friction stir welds. Mater. Chem. Phys. 2016, 170, 251–260. [Google Scholar] [CrossRef]

- Yuan, Y.; Wu, Z.; Chen, K.; Liu, H.; Huang, H.; Li, Y. Effects of plunge depth on macro-/microstructure and mechanical properties of refill friction stir spot welded 2195-T6 Al–Li alloy. J. Mater. Res. Technol. 2025, 35, 6026–6041. [Google Scholar] [CrossRef]

- Dawood, H.; Mohammed, K.S.; Rahmat, A.; Uday, M. Effect of small tool pin profiles on microstructures and mechanical properties of 6061 aluminum alloy by friction stir welding. Trans. Nonferrous Met. Soc. China 2015, 25, 2856–2865. [Google Scholar] [CrossRef]

- Fathi, J.; Ebrahimzadeh, P.; Farasati, R.; Teimouri, R. Friction stir welding of aluminum 6061-T6 in presence of watercooling: Analyzing mechanical properties and residual stress distribution. Int. J. Lightweight Mater. Manuf. 2019, 2, 107–115. [Google Scholar] [CrossRef]

- Boz, M.; Kurt, A. The influence of stirrer geometry on bonding and mechanical properties in friction stir welding process. Mater. Des. 2004, 25, 343–347. [Google Scholar] [CrossRef]

- Rajakumar, S.; Muralidharan, C.; Balasubramanian, V. Influence of friction stir welding process and tool parameters on strength properties of AA7075-T6 aluminium alloy joints. Mater. Des. 2011, 32, 535–549. [Google Scholar] [CrossRef]

- Prasad, K.; Krishnaswamy, H.; Jain, J. Leveraging transient mechanical effects during stress relaxation for ductility improvement in aluminium AA 8011 alloy. J. Mech. Work. Technol. 2018, 255, 1–7. [Google Scholar] [CrossRef]

- Yuvaraj, K.; Varthanan, P.A.; Haribabu, L.; Madhubalan, R.; Boopathiraja, K. Optimization of FSW tool parameters for joining dissimilar AA7075-T651 and AA6061 aluminium alloys using Taguchi Technique. Mater. Today Proc. 2021, 45, 919–925. [Google Scholar] [CrossRef]

- Mishra, A.; Sefene, E.M.; Tsegaw, A.A. Process parameter optimization of Friction Stir Welding on 6061AA using Supervised Machine Learning Regression-based Algorithms. arXiv 2021, arXiv:2109.00570. [Google Scholar] [CrossRef]

- Threadgilll, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Qiao, Q.; Tang, C.; Lam, W.; Pu, J.; Shi, H.; Qian, H.; Li, Z.; Guo, D.; Zhang, D.; Kwok, C.; et al. Effect of heat input on microstructure and mechanical properties of AA6061 alloys fabricated by additive friction stir deposition. J. Mater. Res. Technol. 2024, 33, 6182–6195. [Google Scholar] [CrossRef]

- Luo, L.; Yang, B.H.; Yang, X.R.; Yan, W.W.; Gan, C.; Liu, X.Y.; Wang, J.Z. Effects of different cooling conditions on microstructure and precipitation behavior of fine-grained Al–Zn–Mg–Cu alloy friction stir welding joint. J. Mater. Res. Technol. 2023, 24, 4534–4550. [Google Scholar] [CrossRef]

- Węglowski, M.S. Friction stir processing—State of the art. Arch. Civ. Mech. Eng. 2018, 18, 114–129. [Google Scholar] [CrossRef]

- Soni, N.; Chandrashekhar, S.; Kumar, A.; Chary, V.R. Defects Formation during Friction Stir Welding: A Review. Int. J. Eng. Manag. Res. 2017, 7, 121–125. [Google Scholar]

- Shaik, B.; Gowd, G.H.; Prasad, B.D. Experimental and parametric studies with friction stir welding on aluminium alloys. Mater. Today Proc. 2019, 19, 372–379. [Google Scholar] [CrossRef]

- Kumar, R.; Salah, A.N.; Kant, N.; Singh, P.; Hashmi, A.W.; Malla, C. Effect of FSW process parameters on mechanical properties and microstructure of dissimilar welded joints of AA2024 and AA6082. Mater. Today Proc. 2021, 50, 1435–1441. [Google Scholar] [CrossRef]

- Sibalic, N.; Vukcevic, M. Numerical simulation for FSW process at welding aluminium alloy aa6082-t6. Metals 2019, 9, 747. [Google Scholar] [CrossRef]

- El-Sayed, M.M.; Shash, A.; Abd-Rabou, M.; ElSherbiny, M.G. Welding and processing of metallic materials by using friction stir technique: A review. J. Adv. Join. Process. 2021, 3, 100059. [Google Scholar] [CrossRef]

- Zhang, Q.-Z.; Gong, W.-B.; Liu, W. Microstructure and mechanical properties of dissimilar Al-Cu joints by friction stir welding. Trans. Nonferrous Met. Soc. China 2015, 25, 1779–1786. [Google Scholar] [CrossRef]

- de Souza Carvalho Machado, C.; Donatus, U.; Milagre, M.X.; Araujo, J.V.d.S.; de Viveiros, B.V.G.; Klumpp, R.E.; Pereira, V.F.; Costa, I. How microstructure affects localized corrosion resistance of stir zone of the AA2198-T8 alloy after friction stir welding. Mater. Charact. 2021, 174, 111025. [Google Scholar] [CrossRef]

- Zhai, W.; Bai, L.; Zhou, R.; Fan, X.; Kang, G.; Liu, Y.; Zhou, K. Recent Progress on Wear-Resistant Materials: Designs, Properties, and Applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhu, Z.; Zhu, Y.; Sun, L.; Guo, Y. Solid-State Welding of Aluminum to Magnesium Alloys: A Review. Metals 2023, 13, 1410. [Google Scholar] [CrossRef]

- Khaled, B.; Salih, O.S.; Ou, H.; Sun, W.; McCartney, D.G. A review of friction stir welding of aluminium matrix composites. J. Constr. Steel Res. 2015, 11, 323–330. [Google Scholar]

- Sinhmar, S.; Dwivedi, D.K. Mechanical behavior of FSW joint welded by a novel designed stationary shoulder tool. J. Mater. Process. Technol. 2020, 277, 116482. [Google Scholar] [CrossRef]

- Yadav, R.; Dwivedi, V.K.; Kishore, C.; Bansal, G. Differentiate mechanical properties of the metal joining process through FCW, FSW and FSP: A review. Mater. Today Proc. 2021, 46, 10252–10256. [Google Scholar] [CrossRef]

- Terra, C.S.; Silveira, J.L.L. Models for FSW forces using a square pin profile tool. J. Manuf. Process. 2021, 68, 1395–1404. [Google Scholar] [CrossRef]

- Sunnapu, C.; Kolli, M. Tool shoulder and pin geometry’s effect on friction stir welding: A study of literature. Mater. Today Proc. 2020, 39, 1565–1569. [Google Scholar] [CrossRef]

- Naveen, G.; Goel, S.; Gupta, A.; Gulati, P. Effect of various tool pin profiles on temperature rise and mechanical properties of friction stir processed AZ31Mg alloy. Mater. Today Proc. 2018, 5, 4384–4391. [Google Scholar] [CrossRef]

- Raturi, M.; Garg, A.; Bhattacharya, A. Joint strength and failure studies of dissimilar AA6061-AA7075 friction stir welds: E ff ects of tool pin, process parameters and preheating. Eng. Fail. Anal. 2019, 96, 570–588. [Google Scholar] [CrossRef]

- Lunetto, V.; De Maddis, M.; Lombardi, F.; Spena, P.R. A Review of Friction Stir Welding of Industrial Alloys: Tool Design and Process Parameters. J. Manuf. Mater. Process. 2025, 9, 36. [Google Scholar] [CrossRef]

- Guo, N.; Fu, Y.; Wang, Y.; Meng, Q.; Zhu, Y. Microstructure and mechanical properties in friction stir welded 5A06 aluminum alloy thick plate. Mater. Des. 2017, 113, 273–283. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, Y.; Jiang, J.; Liu, Z.; Miao, S.; Lin, Z.; Wang, C.; Dong, C.; Zhen, L. Investigation of microstructure and properties in an aged ultra-high strength Al alloy and its friction stir welded joints. J. Mater. Res. Technol. 2022, 21, 2338–2351. [Google Scholar] [CrossRef]

- Gurdal, O.; Rae, B.; Zonuzi, A.; Ozturk, E. Vision-assisted robotic finishing of friction stir-welded corner joints. Procedia Manuf. 2019, 40, 70–76. [Google Scholar] [CrossRef]

- Shultz, E.F.; Fehrenbacher, A.; Pfefferkorn, F.E.; Zinn, M.R.; Ferrier, N.J. Shared control of robotic friction stir welding in the presence of imperfect joint fit-up. J. Manuf. Process. 2013, 15, 25–33. [Google Scholar] [CrossRef]

- Jabraeili, R.; Jafarian, H.R.; Khajeh, R.; Park, N.; Kim, Y.; Heidarzadeh, A.; Eivani, A.R. Effect of FSW process parameters on microstructure and mechanical properties of the dissimilar AA2024 Al alloy and 304 stainless steel joints. Mater. Sci. Eng. A 2021, 814, 140981. [Google Scholar] [CrossRef]

- Mazzeschi, M.; Sanz, M.; Monge, J.C.; Cañibano, E.; Rodriguez-Juan, C.P.; Núñez, K.C. Electrical conductivity field analysis: A prognostic instrument for real time monitoring of friction stir welding process. J. Manuf. Process. 2024, 131, 93–110. [Google Scholar] [CrossRef]

- Khodir, S.A.; Shibayanagi, T. Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys. Mater. Sci. Eng. B 2008, 148, 82–87. [Google Scholar] [CrossRef]

- Harisha, P.; Nanjundaswamy, H.; Divakar, H.; Krishnan, D. Tensile properties of aluminium and copper alloys friction stir welded joints. Mater. Today Proc. 2021, 54, 223–227. [Google Scholar] [CrossRef]

- Gan, W.; Okamoto, K.; Hirano, S.; Chung, K.; Kim, C.; Wagoner, R.H. Properties of friction-stir welded aluminum alloys 6111 and 5083. J. Eng. Mater. Technol. Trans. ASME 2008, 130, 0310071–03100715. [Google Scholar] [CrossRef]

- Chen, W.J.; Chen, H.; Wu, B.X. Mechanical Properties of Friction Stir-Welded Joints of Aluminum Alloys. Strength Mater. 2015, 47, 74–79. [Google Scholar] [CrossRef]

- El-Zathry, N.E.; Akinlabi, S.; Woo, W.L.; Patel, V.; Mahamood, R.M. Taguchi-based optimisation of FSW parameters for advancement in aerospace materials: Al-Li 2060 alloy. Heliyon 2024, 10, e41048. [Google Scholar] [CrossRef] [PubMed]

- Choudhury, B.; Chandrasekaran, M. Investigation on welding characteristics of aerospace materials—A review. Mater. Today Proc. 2017, 4, 7519–7526. [Google Scholar] [CrossRef]

- Gao, Y.; Zuo, Y.; Liu, H.; Li, D.; Li, X. Microstructure and Mechanical Properties of Mg-Li/Al Dissimilar Joints via Dynamic Support Friction Stir Lap Welding. Materials 2024, 17, 2883. [Google Scholar] [CrossRef]

- Ayad, M.; Lapostolle, L.; Rondepierre, A.; Le Bras, C.; Ünaldi, S.; Donik, Č.; Klobčar, D.; Berthe, L.; Trdan, U. New methodology of dynamical material response of dissimilar FSWed Al alloy joint under high strain rate laser shock loading. Mater. Des. 2022, 222, 111080. [Google Scholar] [CrossRef]

- Wciślik, W. Selected Microstructural Phenomena In Fsw Joints. Struct. Environ. 2024, 16, 97–110. [Google Scholar] [CrossRef]

- Bai, Y.; Jin, W. Marine Structural Design, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Jebaraj, A.V.; Ajaykumar, L.; Deepak, C.R.; Aditya, K.V.V. Weldability, machinability and surfacing of commercial duplex stainless steel AISI2205 for marine applications—A recent review. J. Adv. Res. 2017, 8, 183–199. [Google Scholar] [CrossRef]

- Paik, J.K.; Andrieu, C.; Cojeen, H.P. Mechanical Collapse Testing on Aluminum Stiffened Plate Structures for Marine Applications. In Proceedings of the 10th International Symposium on Practical Design of Ships and Other Floating Structures, Houston, TX, USA, 30 September–5 October 2007. [Google Scholar]

- Chen, X.; Lei, Z.; Chen, Y.; Han, Y.; Jiang, M.; Tian, Z.; Bi, J.; Lin, S.; Jiang, N. Effect of Laser Beam Oscillation on Laser Welding–Brazing of Ti/Al Dissimilar Metals. Materials 2019, 12, 4165. [Google Scholar] [CrossRef]

- Ranjan, R.; Khan, A.R.; Parikh, C.; Jain, R.; Mahto, R.P.; Pal, S.; Pal, S.K.; Chakravarty, D. Classification and identification of surface defects in friction stir welding: An image processing approach. J. Manuf. Process. 2016, 22, 237–253. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Chen, F.; Yang, Z.; He, J. Characteristics of resistance spot welded Ti6Al4V titanium alloy sheets. Metals 2017, 7, 424. [Google Scholar] [CrossRef]

- Park, G.-W.; Jo, H.; Park, M.; Shin, S.; Ko, W.-S.; Park, N.; Kim, B.-J.; Ahn, Y.-S.; Jeon, J.B. Microstructure and mechanical properties of gas tungsten arcwelded high manganese steel sheet. Metals 2019, 9, 1167. [Google Scholar] [CrossRef]

- Fadaeifard, F.; Matori, K.A.; Abd Aziz, S.; Zolkarnain, L.; Abdul Rahim, M.A.Z.B. Effect of the welding speed on the macrostructure, microstructure and mechanical properties of AA6061-T6 friction stir butt welds. Metals 2017, 7, 48. [Google Scholar] [CrossRef]

- Señorís-Puentes, S.; Serrano, R.F.; González-Doncel, G.; Hattel, J.H.; Mishin, O.V. Microstructure and mechanical properties of friction stir welded AA6061/AA6061 + 40 vol% SiC plates. Metals 2021, 11, 206. [Google Scholar] [CrossRef]

- Chiara, B.; Favaloro, F.; Di Bella, G. Effect of Accelerated Aging Tests in Salt Spray of Single Lap Friction Stir Welded Joints Between S355-J0 Steel—AA5083 Aluminum Alloy—Part 1—Mechanical Tests. 2023. Available online: https://www.preprints.org/manuscript/202312.1196/v1 (accessed on 10 April 2025).

- Colligan, K. Material Flow Behavior during Friction Stir Welding of Aluminum. Weld J. 1999, 78, 229–237. [Google Scholar]

- Balasubramanian, V. Relationship between base metal properties and friction stir welding process parameters. Mater. Sci. Eng. A 2008, 480, 397–403. [Google Scholar] [CrossRef]

- Kalaiselvan, K.; Murugan, N. Role of friction stir welding parameters on tensile strength of AA6061 − B 4 C composite joints. Trans. Nonferrous Met. Soc. China 2013, 23, 616–624. [Google Scholar] [CrossRef]

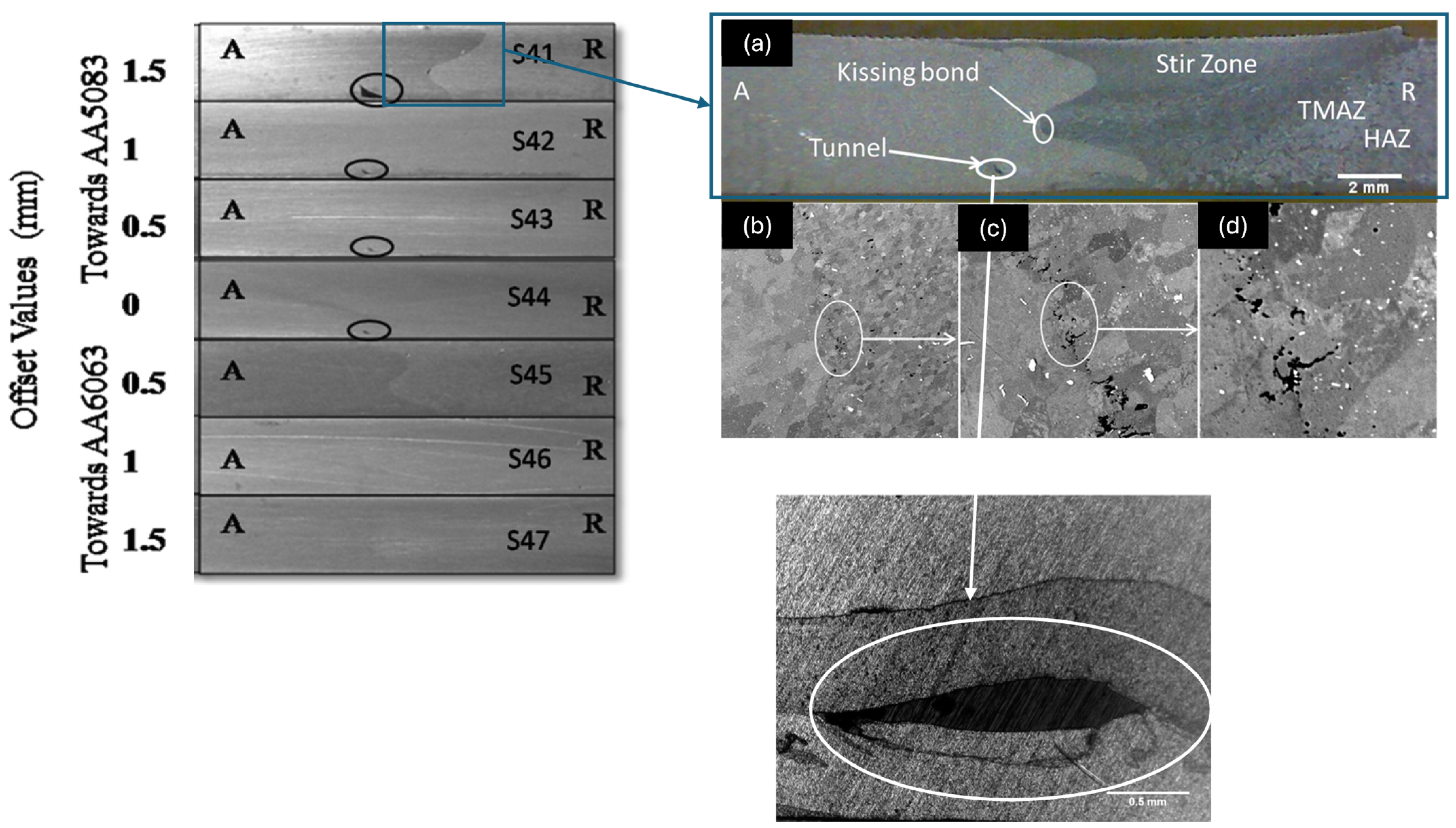

- Khan, N.Z.; Siddiquee, A.N.; Khan, Z.A.; Shihab, S.K. Investigations on tunneling and kissing bond defects in FSW joints for dissimilar aluminum alloys. J. Alloy. Compd. 2015, 648, 360–367. [Google Scholar] [CrossRef]

- Kumar, J.P.; Raj, A.; Arul, K.; Mohanavel, V. A literature review on friction stir welding of dissimilar materials. Mater. Today Proc. 2021, 47, 286–291. [Google Scholar] [CrossRef]

- Khaled, B.; Ben Salem, S. Modélisation expérimentale et optimisation des conditions de soudage par friction et malaxage cas d’alliage d’aluminium 2017. In Proceedings of the 5ième Congrès International Conception et Modélisation des Systèmes Mécaniques CMSM’2013 1, Djerba, Tunisie, 25–27 March 2013. [Google Scholar]

- Kalemba-Rec, I.; Hamilton, C.; Kopyściański, M.; Miara, D.; Krasnowski, K. Microstructure and Mechanical Properties of Friction Stir Welded 5083 and 7075 Aluminum Alloys. J. Mater. Eng. Perform. 2017, 26, 1032–1043. [Google Scholar] [CrossRef]

- Chiara, B.; Favaloro, F.; Di Bella, G. Durability of Single Lap Friction Stir Welded Joints between S355-J0 Steel and AA5083 Aluminum Alloy–Mechanical Tests. Metals 2024, 14, 137. [Google Scholar] [CrossRef]

- Datta, A.; Shrivastava, A.; Chakraborty, S.S.; Pal, S.K. Effect of work material combination and welding speed in dissimilar friction stir welding of aluminium to steel. Mater. Today Proc. 2022, 66, 3729–3737. [Google Scholar] [CrossRef]

- Khedmati, M.R.; Zareei, M.R.; Rigo, P. Sensitivity analysis on the elastic buckling and ultimate strength of continuous stiffened aluminium plates under combined in-plane compression and lateral pressure. Thin-Walled Struct. 2009, 47, 1232–1245. [Google Scholar] [CrossRef]

- Al-Sabur, R. Tensile strength prediction of aluminium alloys welded by FSW using response surface methodology—Comparative review. Mater. Today Proc. 2021, 45, 4504–4510. [Google Scholar] [CrossRef]

- Ajayi, O.O.; Lorenzo-Martin, C. Friction Stir Processing and Surfacing. In Friction, Lubrication, and Wear Technology; Totten, G.E., Ed.; ASM International: Almere, The Netherlands, 2018; pp. 696–705. [Google Scholar]

- Mishra, R.S.; De, P.S.; Kumar, N.; Mishra, R.S.; De, P.S.; Kumar, N. Friction Stir Processing. In Friction Stir Welding and Processing; Springer: Berlin/Heidelberg, Germany, 2014; pp. 259–296. [Google Scholar]

- Soto-Diaz, R.; Vásquez-Carbonell, M.; Escorcia-Gutierrez, J. A review of artificial intelligence techniques for optimizing friction stir welding processes and predicting mechanical properties. Eng. Sci. Technol. Int. J. 2025, 62, 101949. [Google Scholar] [CrossRef]

- Patil, S.; Nagamadhu, M.; Malyadri, T. A critical review on microstructure and hardness of aluminum alloy 6061 joints obtained by friction stir welding-past, present, and its prospects. Mater. Today Proc. 2023, 82, 75–78. [Google Scholar] [CrossRef]

- Biradar, R.; Patil, S. Tensile, microhardness and microstructural characteristics of friction stir welded/processed AA7075 alloy: A review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Bai, Y.; Xie, C.; Zhou, X. AI-based macro model learning for high cycle fatigue assessment of welded joints in large-span steel structures. Int. J. Fatigue 2024, 184, 108321. [Google Scholar] [CrossRef]

- Kahnamouei, J.T.; Moallem, M. Advancements in control systems and integration of artificial intelligence in welding robots: A review. Ocean Eng. 2024, 312, 119294. [Google Scholar] [CrossRef]

- Habibkhah, F.; Moallem, M. Application of machine learning for seam profile identification in robotic welding. Mach. Learn. Appl. 2025, 20, 100633. [Google Scholar] [CrossRef]

- Gyasi, E.A.; Handroos, H.; Kah, P. Survey on artificial intelligence (AI) applied in welding: A future scenario of the influence of AI on technological, economic, educational and social changes. Procedia Manuf. 2019, 38, 702–714. [Google Scholar] [CrossRef]

| Parameter | Conclusions | Ref. |

|---|---|---|

| Rotational speed | Rotation speed of 500 rpm establishes an optimal balance between heat input and material flow, leading to improved joint performance with better mechanical properties and fewer defects. | [24] |

| Tool rotational speed of 1600 rpm produces better metallurgical and mechanical properties. | [74] | |

| When the tool rotational speed is high, defect-free welded joints are obtained. | [75] | |

| 1120 rpm and 900 rpm tool rotational speeds produce welded joints with enhanced tensile strength and hardness. | [76] | |

| When increasing the rotational speed, grain refinement strengthening is reduced. | [77] | |

| Welding speed | Mechanical properties are significantly improved when increasing welding speed. | [19] |

| Rotational speed and Welding speed | Both tool rotation speed and welding speed provided significant improvement in the wear resistance, impact toughness, and microhardness. | [78] |

| The hardness of the joint lay between the baseplate of both materials. | [79] | |

| The microstructure of this material was enhanced with increased rotational speed and reduced welding speed | [80] | |

| Defect-free T-joints of high quality were achieved through the application of a D/d ratio of 4.31, utilizing rotational rates of 800 and 1000 rpm, alongside travel speeds of 50, 75, and 100 mm/min. As a result, a tool with a large shoulder diameter was favored for this type of joint. | [81] | |

| All produced joints exhibited no defects, regardless of the different combinations of welding speeds and varying tool rotation speeds employed. Nonetheless, the parameters employed had significant impacts on the microstructure of the resulting joints. | [11] | |

| Increased rotation velocity and reduced welding speed enhanced material flow and joint strength. | [82] | |

| The degree of intermetallic formation was directly associated with the ratio of rotational speed to travel speed, as well as the peak temperature during Friction Stir Welding. Because the peak temperature was higher during Friction Stir Welding, the hardness of the stir zone went up as the rotational speed went up. This made it easier for intermetallics to form. | [83] | |

| Rotational speed and plunge depth | Defects in 2195-T6 Al–Li alloy welds got better when the rotational speeds were increased and the plunge depth was fine-tuned. Increasing the plunge depth caused the tensile shear load to rise at first, then drop. The fracture mode changed from shear to shear-plug and finally to plug mode. | [84] |

| Tool rotation direction | When advancing or retreating the rotational tool, it led to changes in the mechanical properties: the joints on the advancing side exhibited superior joint strength compared to those on the receding side. This process parameter influenced temperatures, deformations, residual stresses, interlocking at the interface (i.e., hooking effect), and, as a result, the mechanical properties. | [31] |

| Tool geometry | The threaded cylindrical pin enhanced microhardness and strength in AA6061-T6 welds. | [85] |

| Tool geometry and rotational speed | The square pin profile combined with a moderate rotation speed resulted in improved mechanical properties for AA6061-T6. | [86] |

| Conical pins operating at elevated rotation speeds and improved material integrating and joint performance in AA6065. | [87] | |

| The joint created with the FSW process parameters of 1400 rpm (tool rotational speed), 60 mm/min (welding speed), and 8 kN (axial force), along with tool specifications of 15 mm (shoulder diameter), 5 mm (pin diameter), and 45 HRc (tool hardness), demonstrated superior strength properties in comparison to other joints. | [88] | |

| Welding speed and tilt angle | Significant enhancement in ductility was achieved when AA8011 samples underwent single-step stress relaxation. The enhancement in ductility was influenced by factors such as pre-strain, strain rate, and holding time, consistent with previous findings on various material grades. | [89] |

| Tool offset: The intentional lateral displacement of the tool from the weld centerline | Optimized weld strength in dissimilar Al alloys (AA2024-AA7075) was achieved with a 1–2 mm tool offset. | [90] |

| Rotation speed and welding speed and tilt angle | The ultimate tensile strength, tool wear, temperature distribution, residual stress, and hardness of the AA2024-T3 and AA356-T3 aluminum alloy joints exhibited a significant correlation with the rotation speed of the tool employed, particularly when assessed in conjunction with other parameters pertinent to Friction Stir Welding (FSW). | [23] |

| Rotation speed and welding speed and axial force | Supervised machine learning based regression algorithms were used to boost FSW parameters for AA6061 alloy, resulting in a joint strength efficiency of 94.2%. | [91] |

| Heat input and tool geometry | High levels of heat input resulted in grain coarsening, while an optimized tool design effectively reduced defects. | [92] |

| Heat generation and rotational speed | The improved distribution of heat input led to an improvement in the plasticity of the stir zone in AA6061-T6. | [93] |

| Cooling rate and rotational speed | Water-cooled FSW improved strength through the refinement of microstructure in AA7075. | [94] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feddal, I.; Chairi, M.; Di Bella, G. Analysis of Friction Stir Welding of Aluminum Alloys. Metals 2025, 15, 532. https://doi.org/10.3390/met15050532

Feddal I, Chairi M, Di Bella G. Analysis of Friction Stir Welding of Aluminum Alloys. Metals. 2025; 15(5):532. https://doi.org/10.3390/met15050532

Chicago/Turabian StyleFeddal, Ikram, Mohamed Chairi, and Guido Di Bella. 2025. "Analysis of Friction Stir Welding of Aluminum Alloys" Metals 15, no. 5: 532. https://doi.org/10.3390/met15050532

APA StyleFeddal, I., Chairi, M., & Di Bella, G. (2025). Analysis of Friction Stir Welding of Aluminum Alloys. Metals, 15(5), 532. https://doi.org/10.3390/met15050532