The Effect of Drag Finishing on Additively Manufactured Customized Dental Crowns

Abstract

:1. Introduction

2. Experimental Section

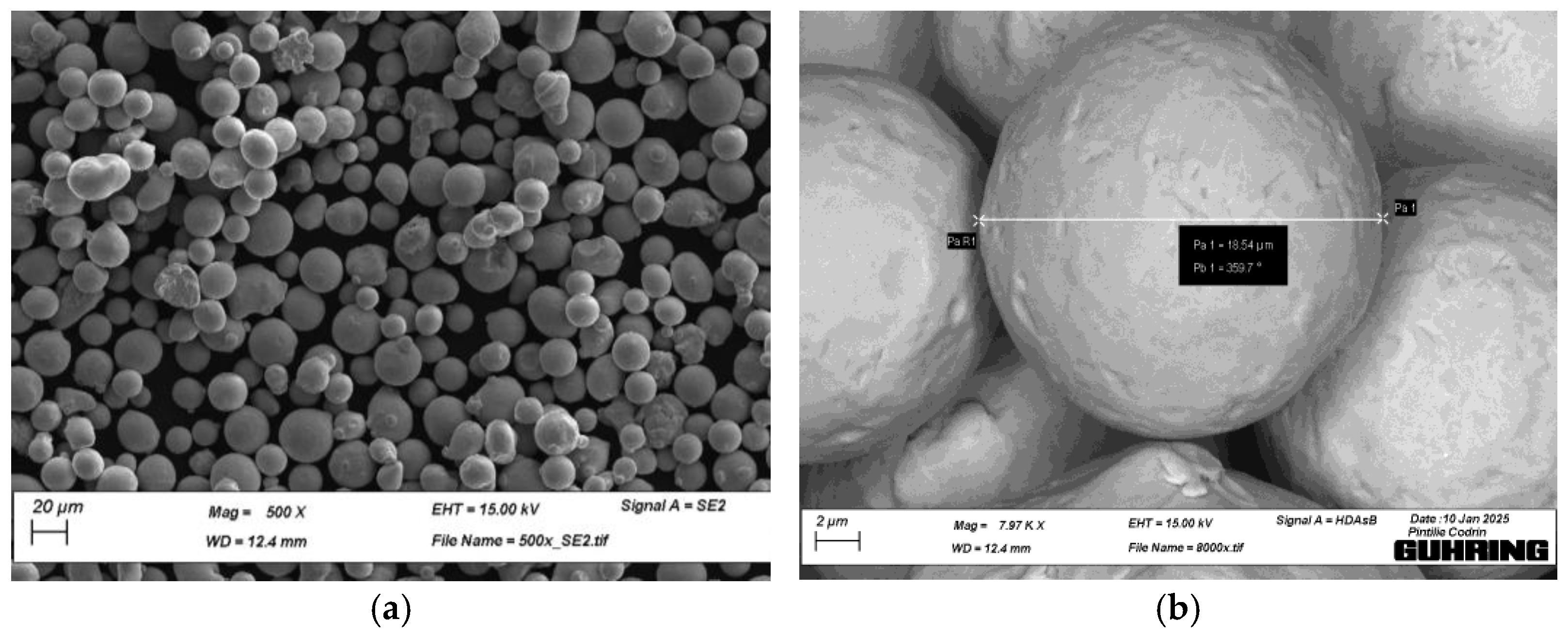

2.1. Material

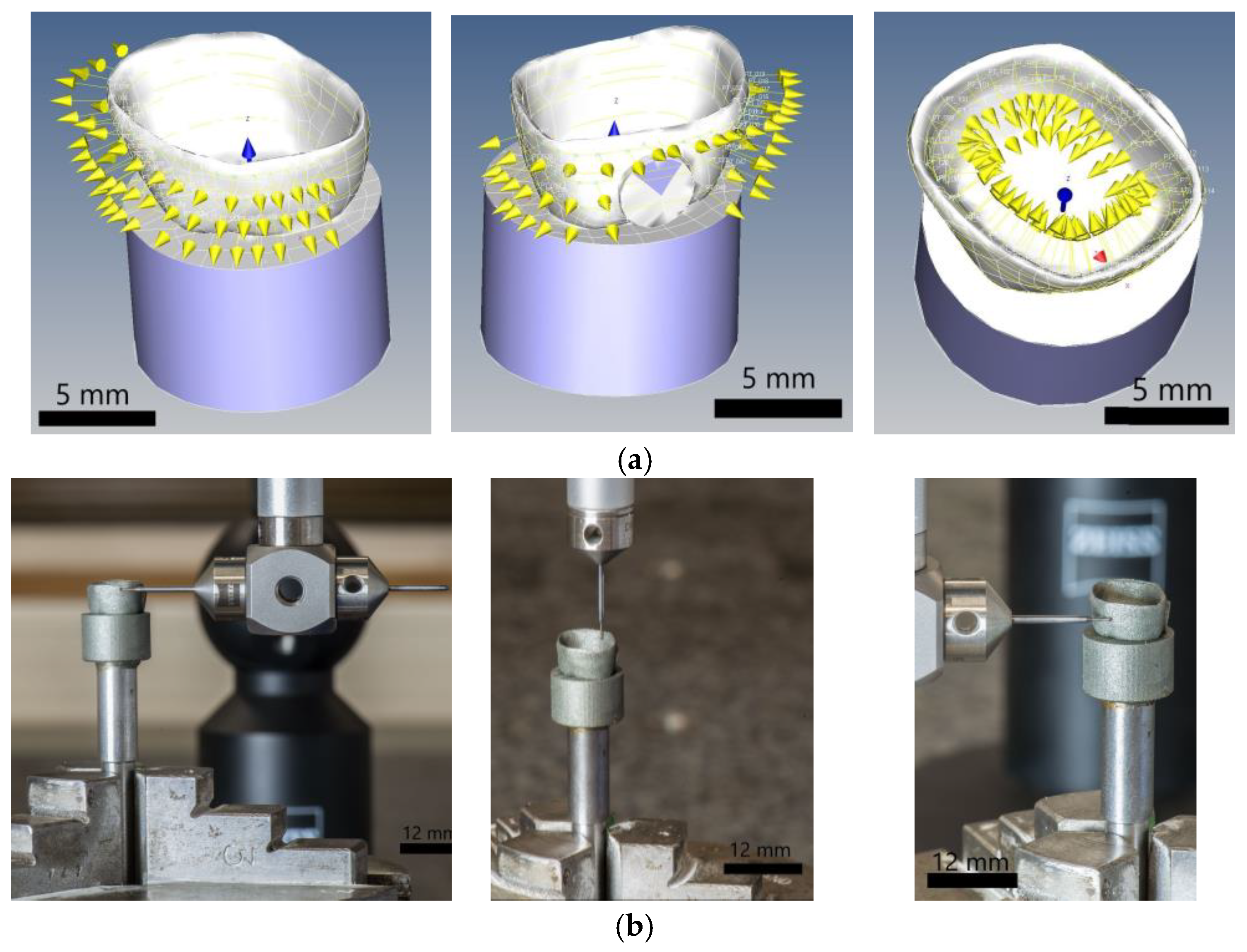

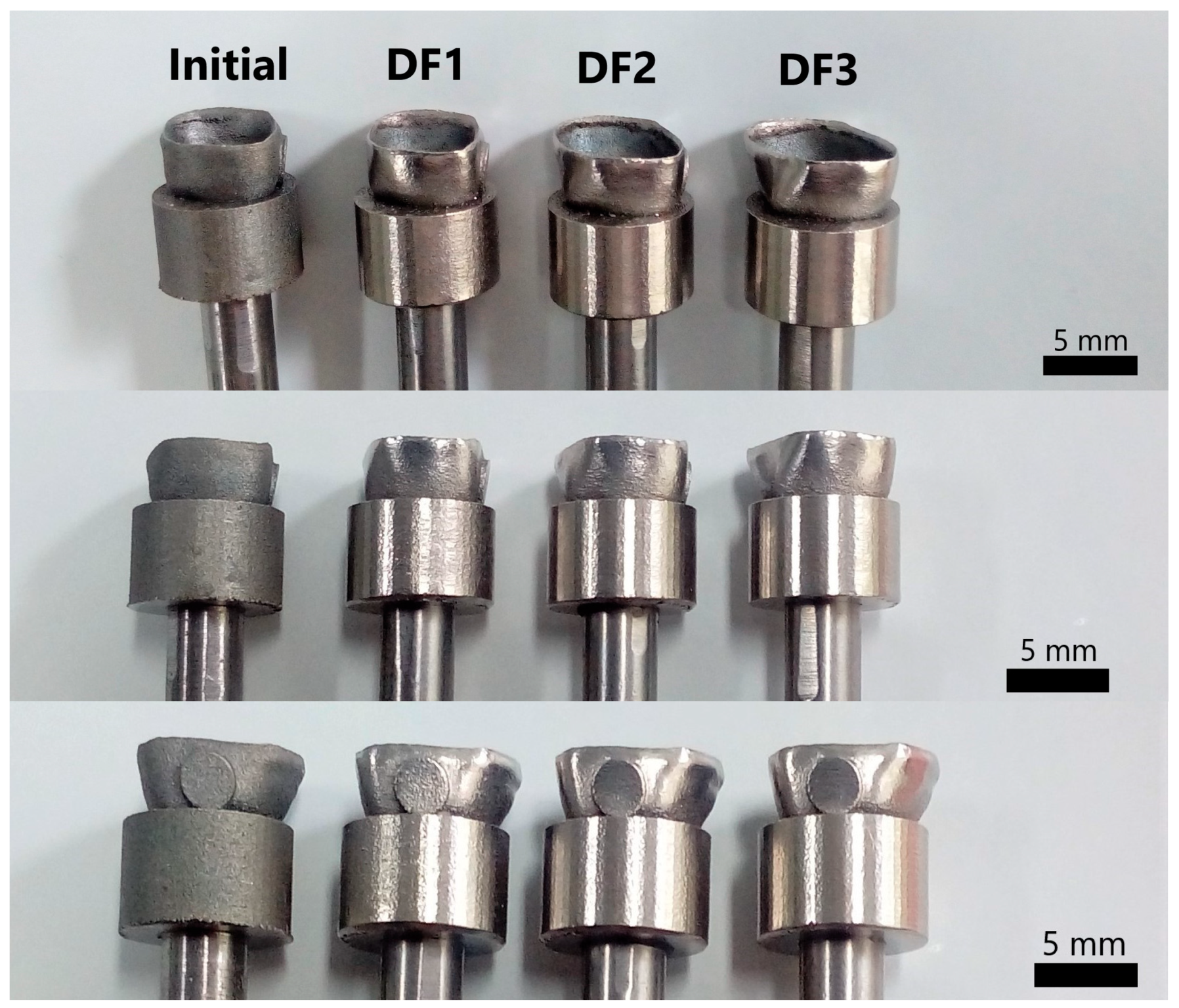

2.2. Specimen Design

2.3. PBF-LB/M Manufacturing

2.4. Drag Finishing Process

2.5. Examination Methods

2.6. Statistical Analysis

3. Results

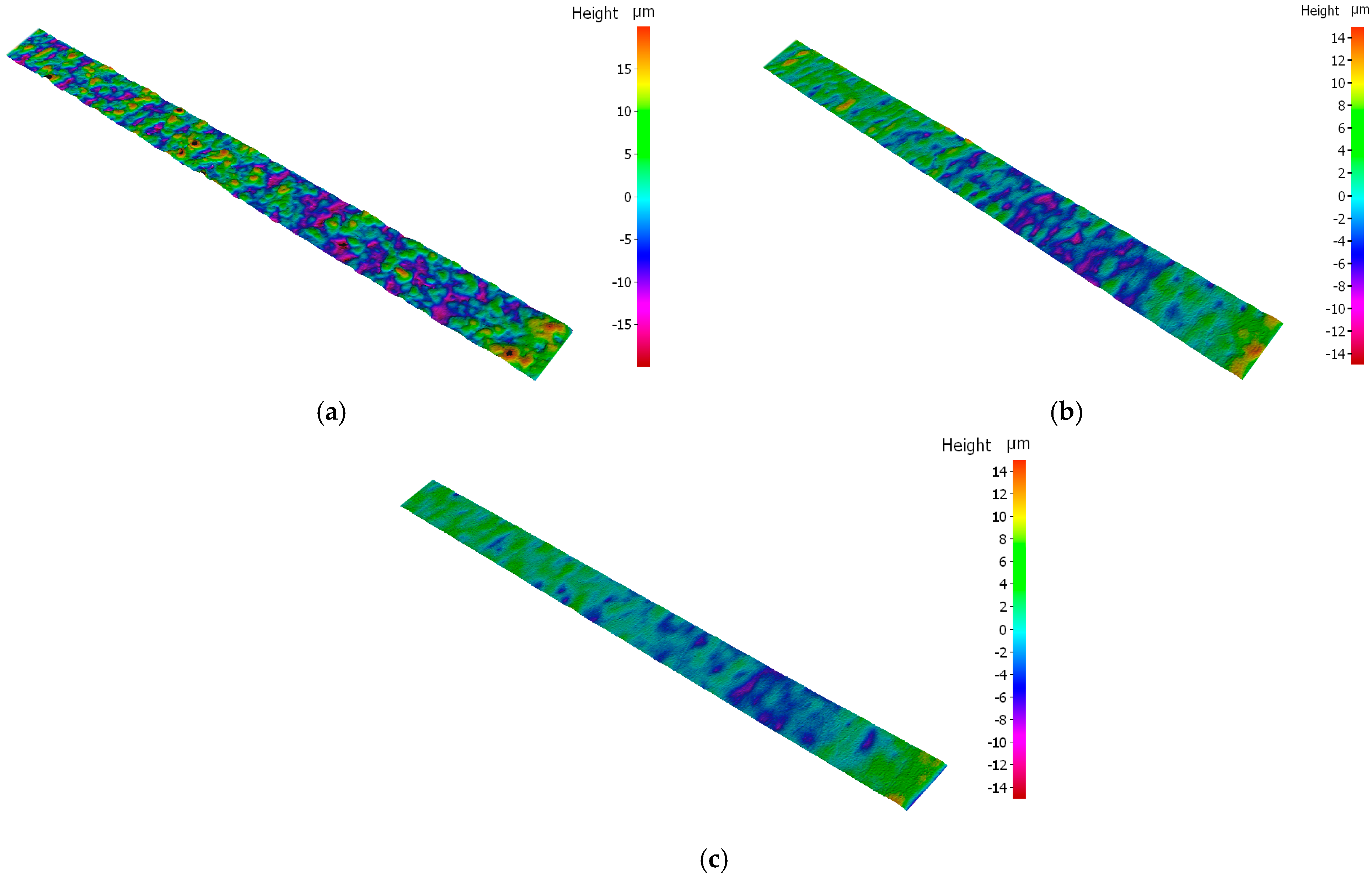

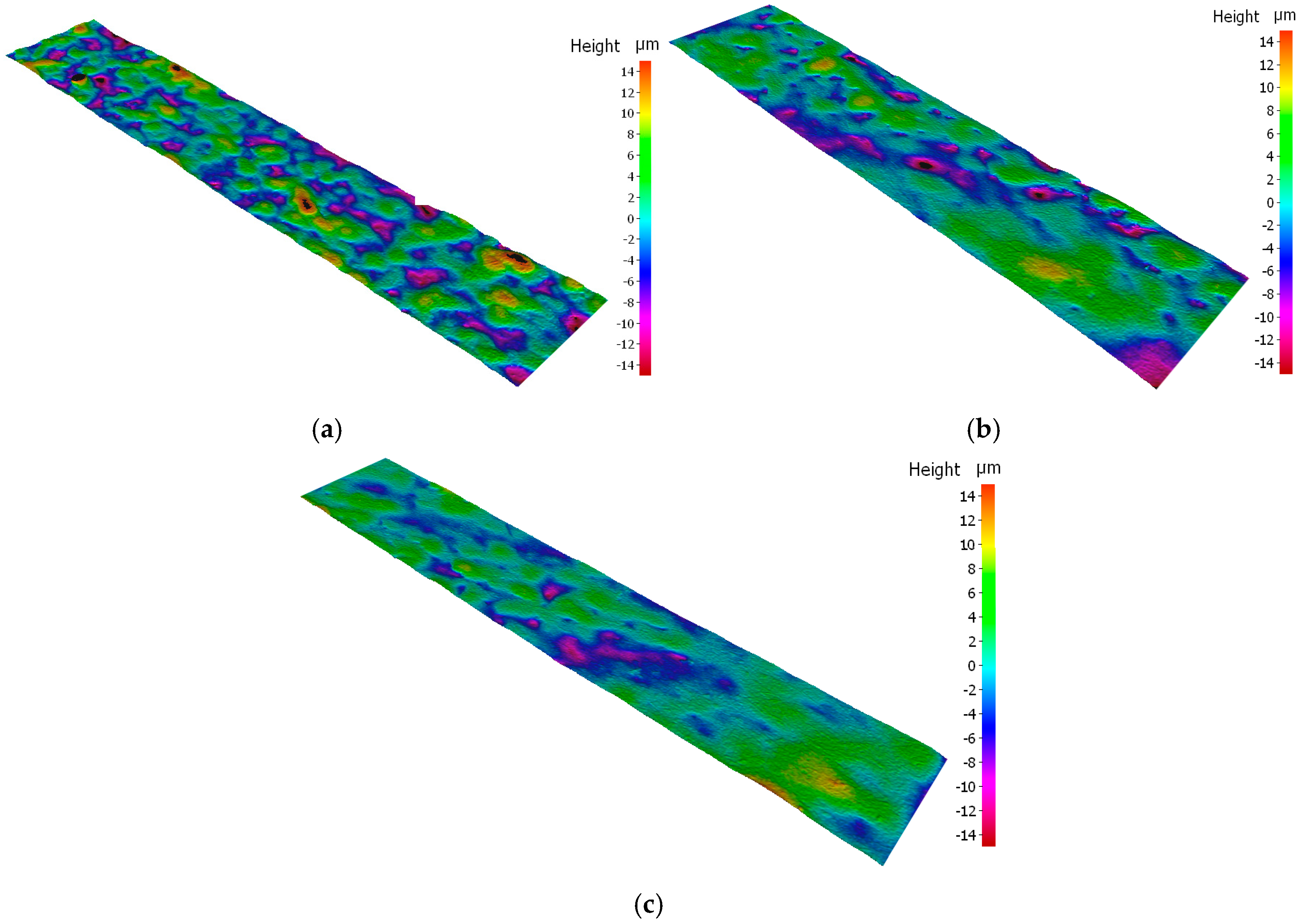

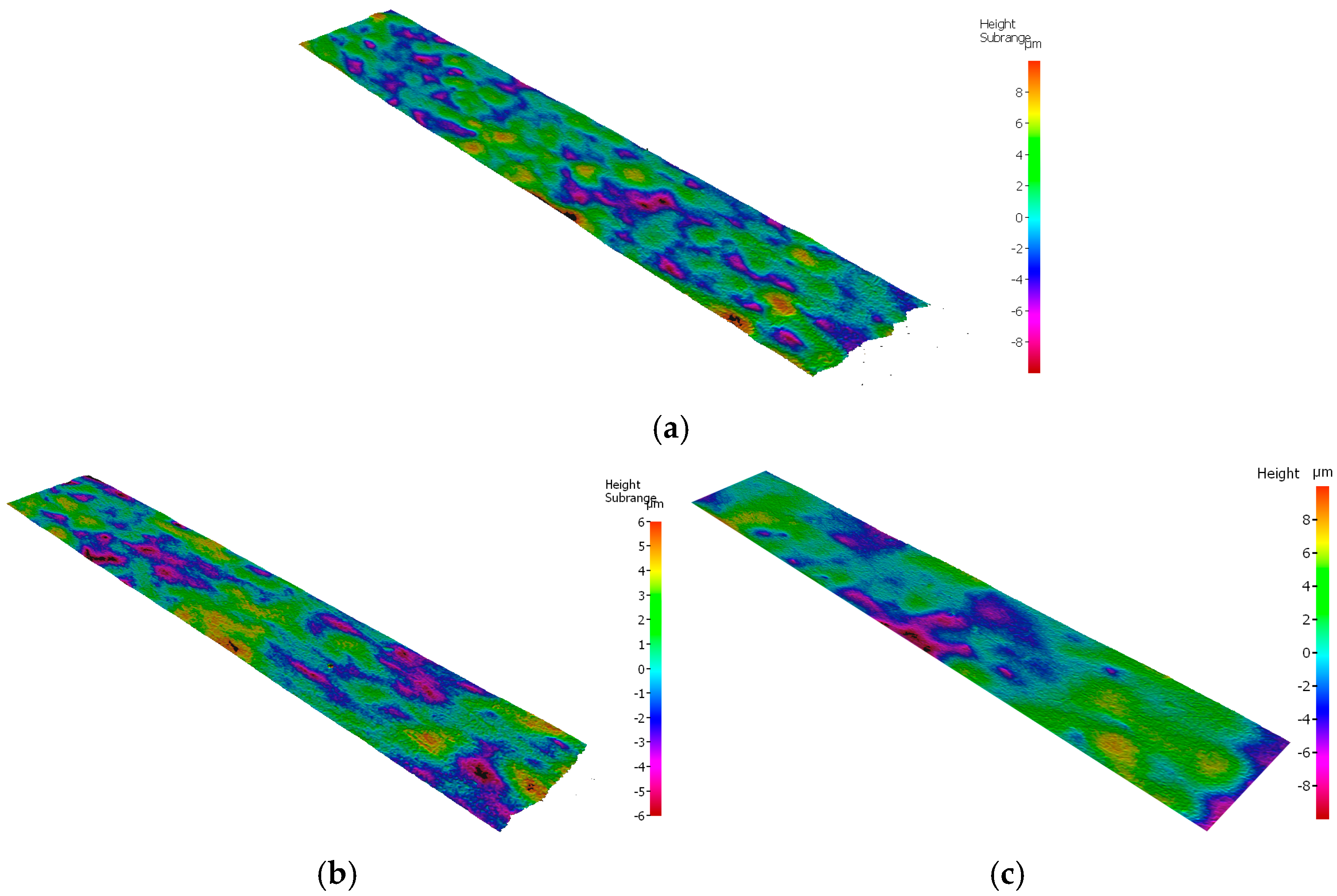

3.1. Surface Roughness

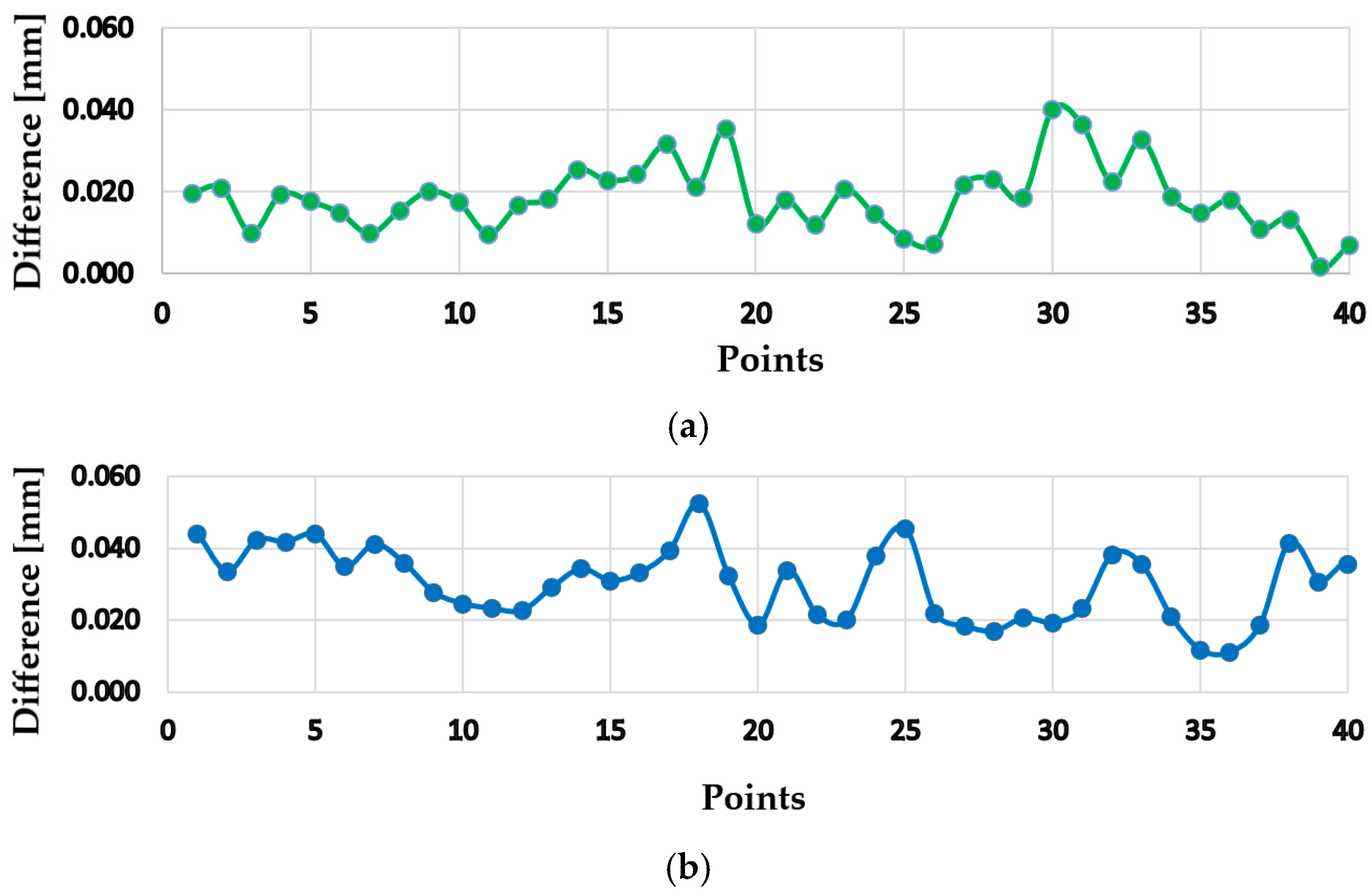

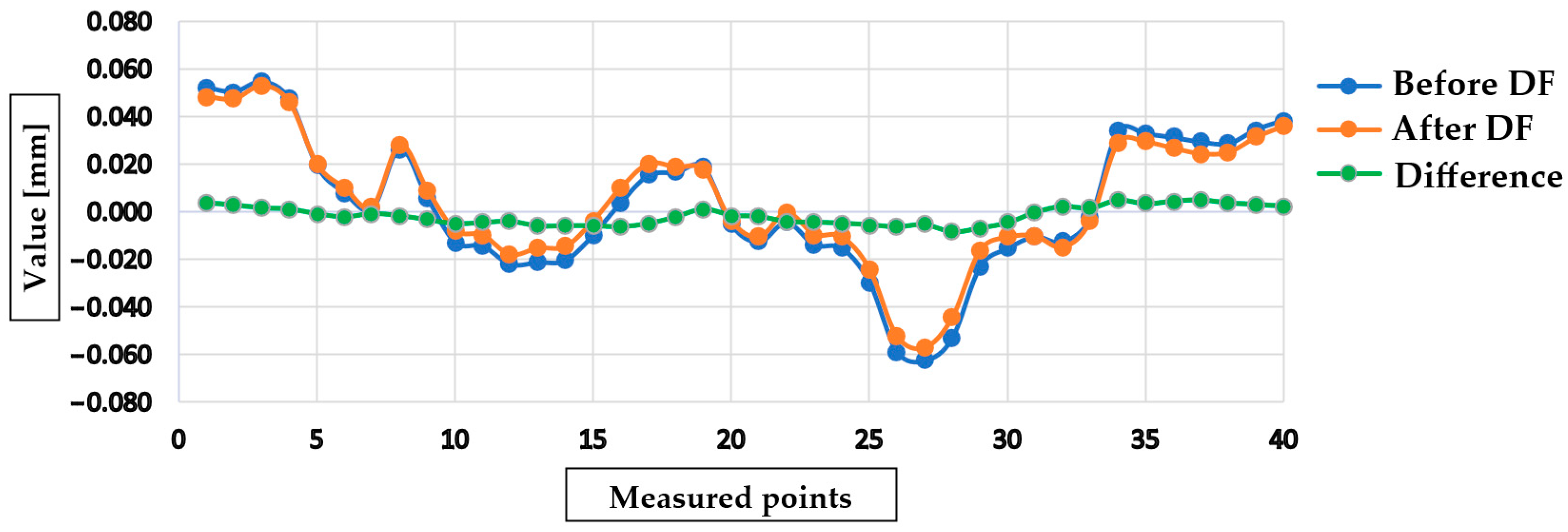

3.2. Dimensional Deviations—Accuracy

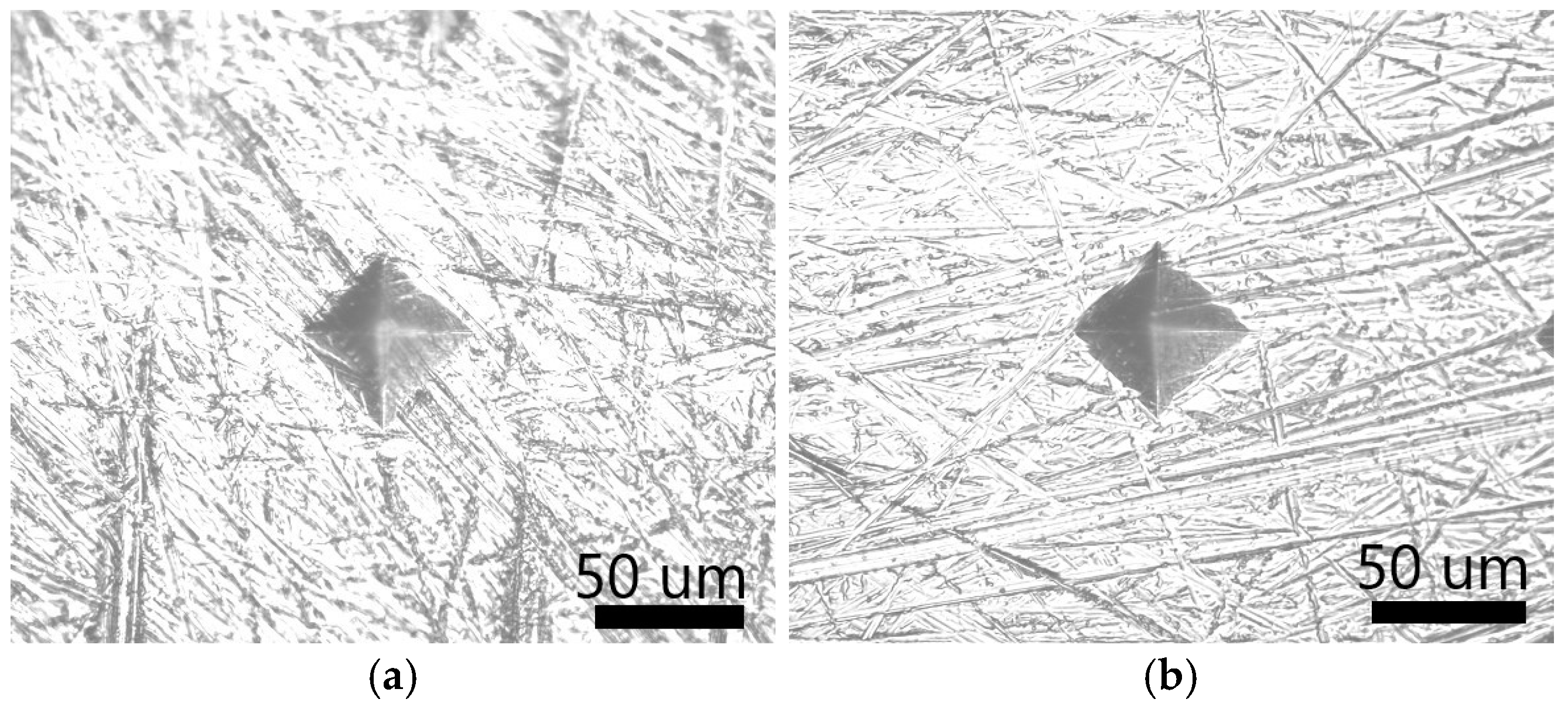

3.3. Surface Hardness

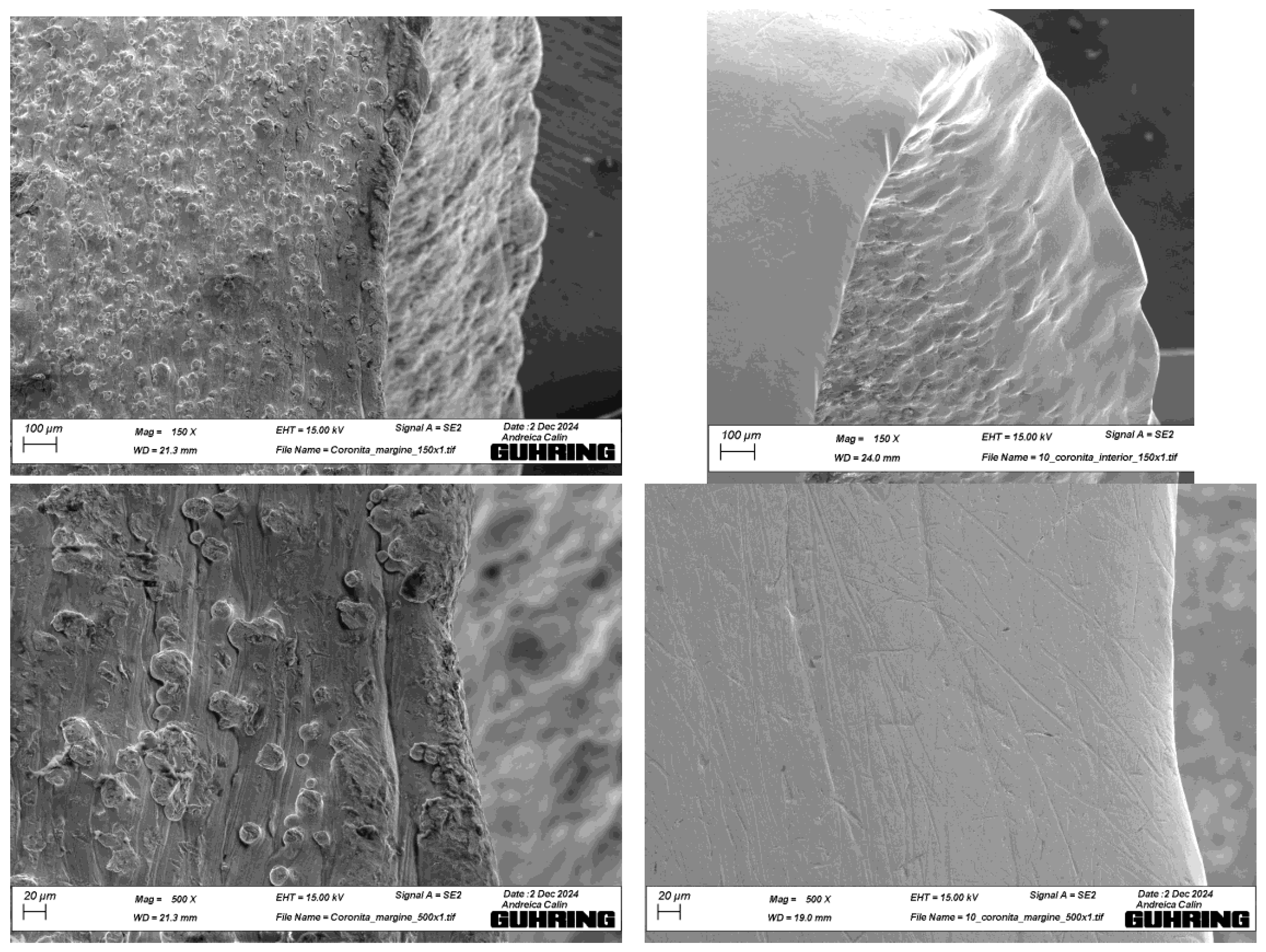

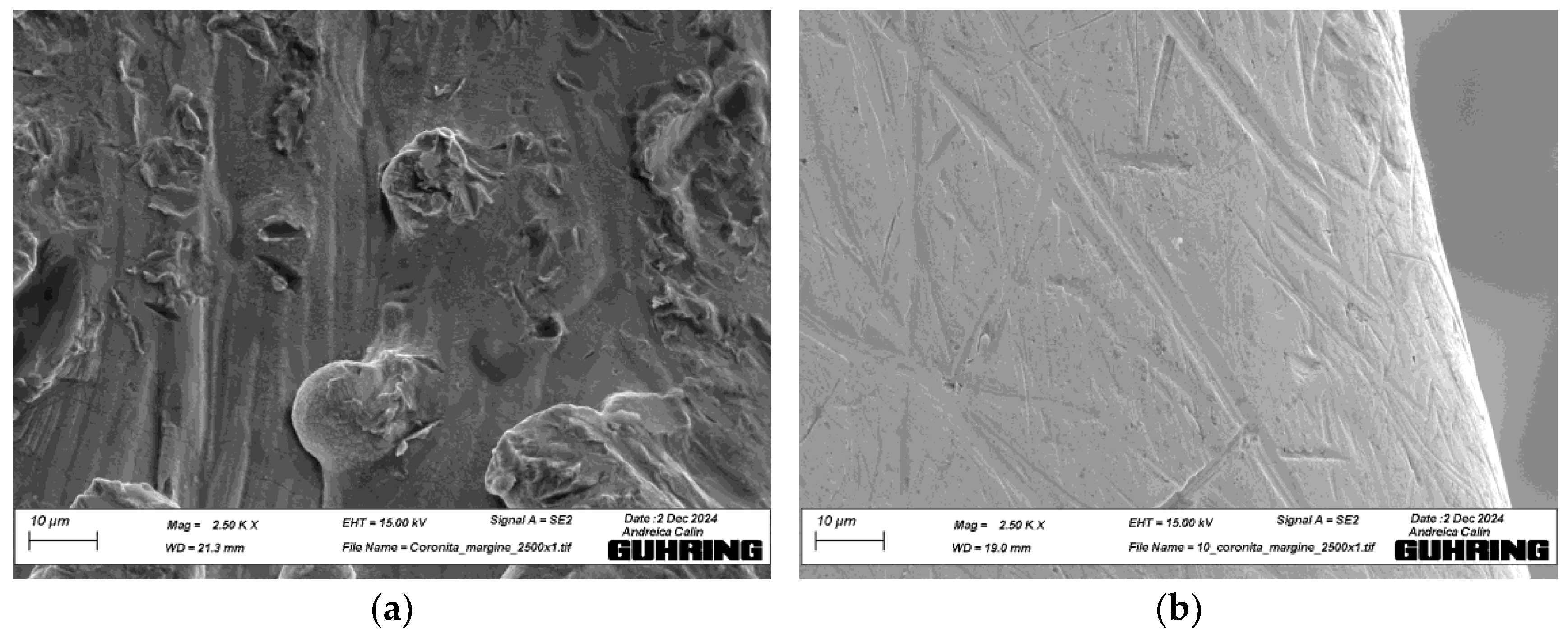

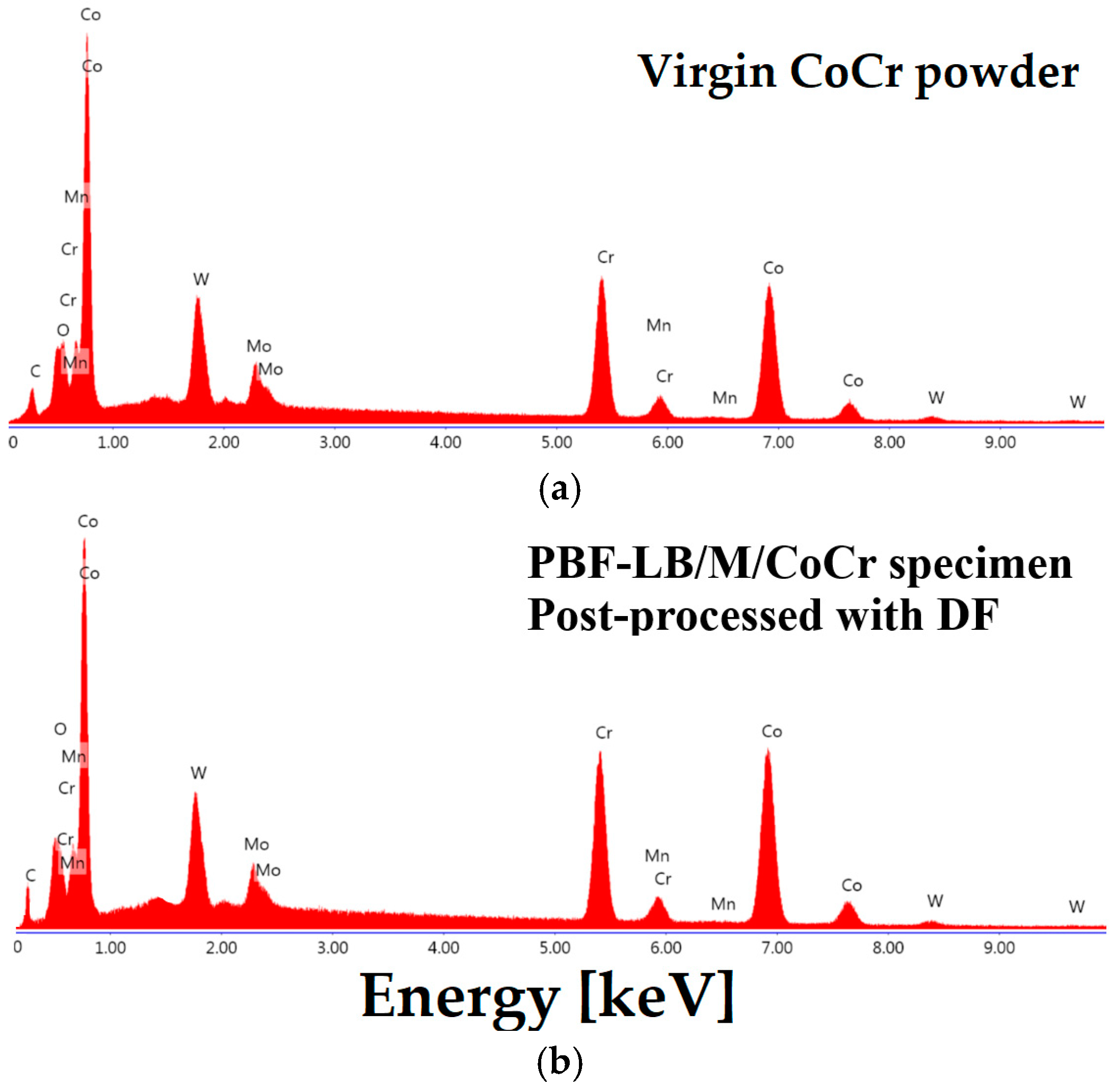

3.4. SEM Analysis of Microstructure

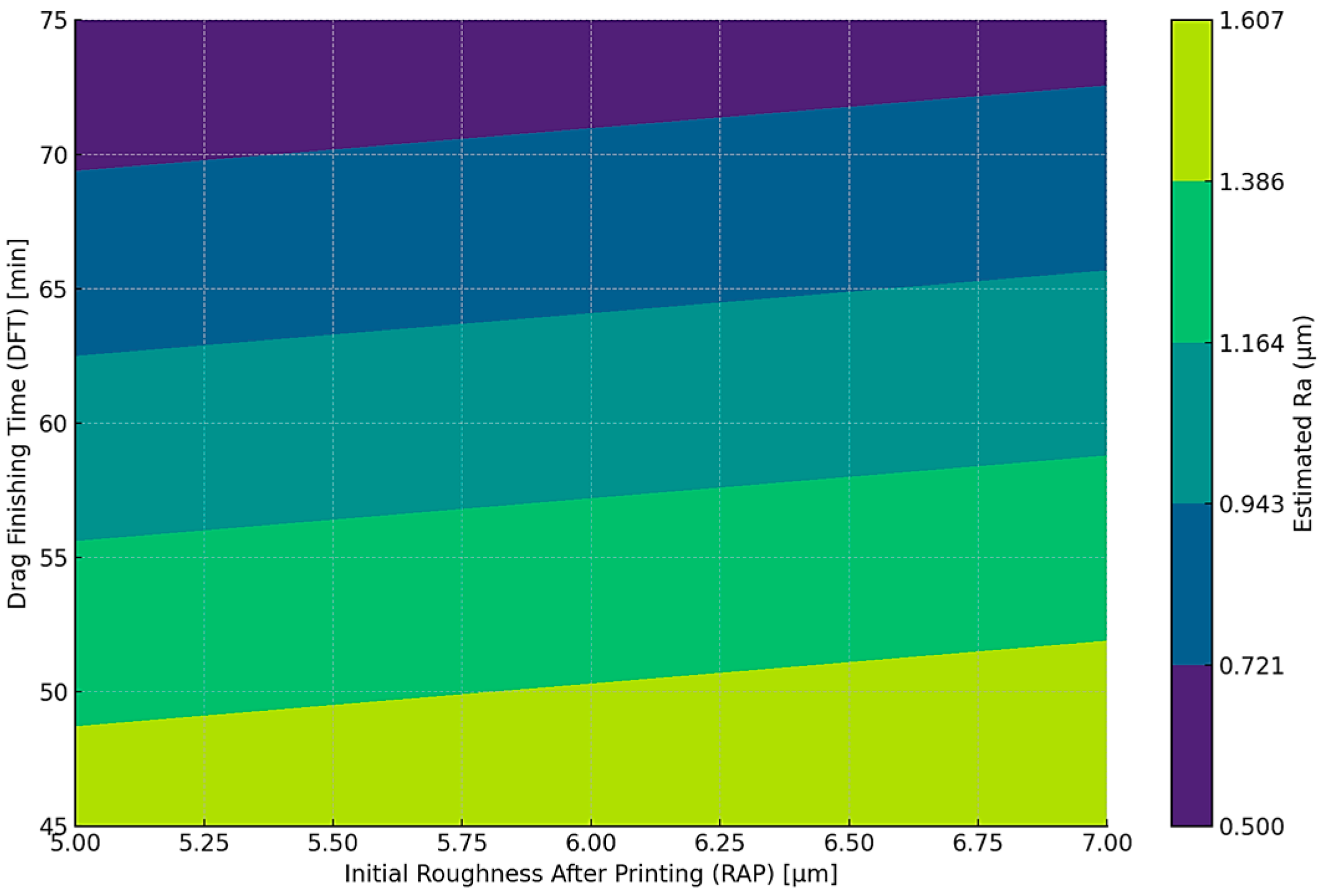

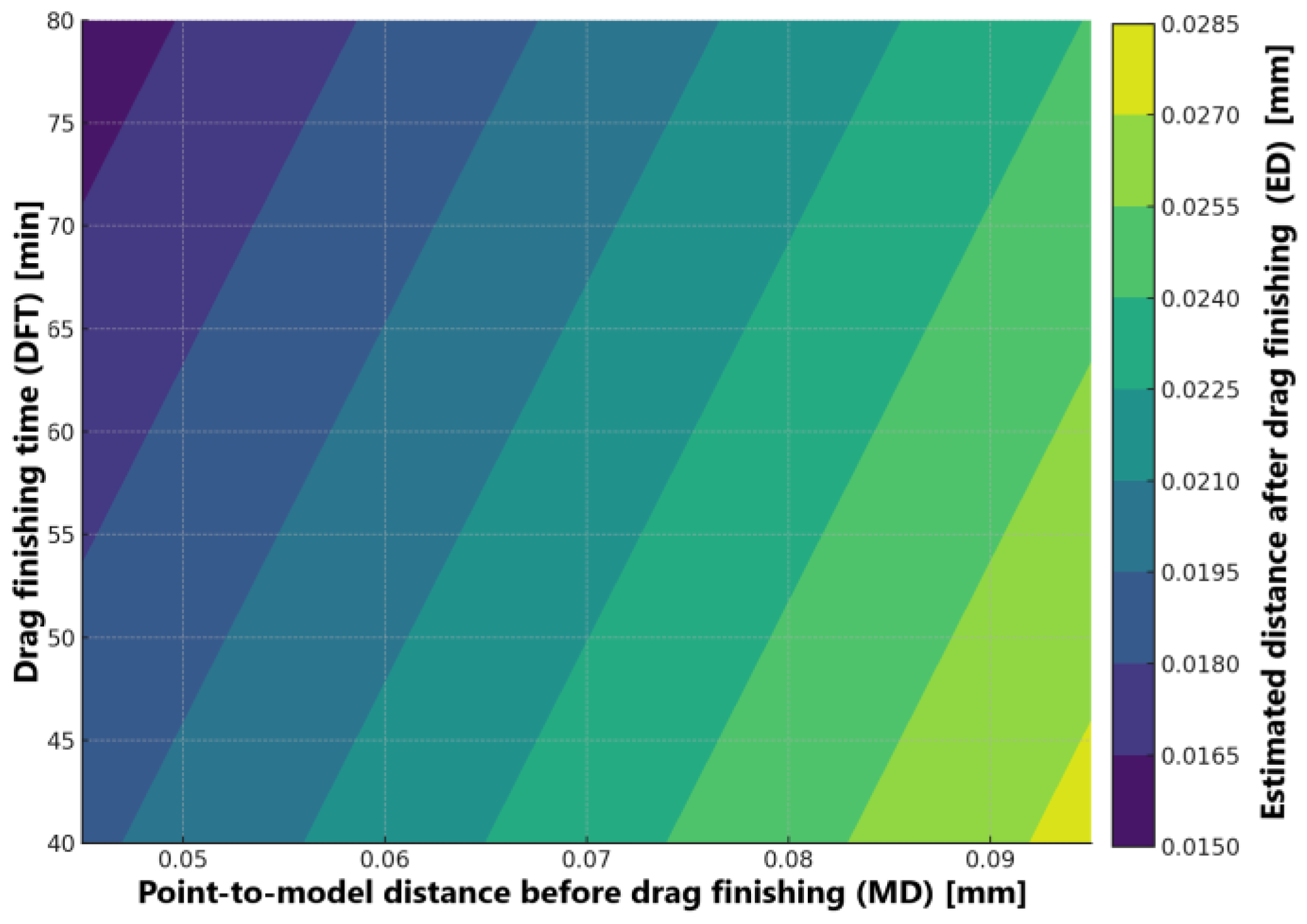

3.5. Statistical Analysis

4. Discussion

5. Conclusions

- DF is an effective and feasible method for improving both the surface quality and dimensional accuracy of CoCr dental crowns manufactured via PBF-LB/M, offering a viable pathway for automating post-processing procedures.

- The outer surface roughness of CoCr crowns could be reduced by up to 90% when the DF processing time was increased from 45 to 75 min, achieving values of Ra 0.6 µm, Rz 4.5 µm, and Rq 1.0 µm. However, the effectiveness of the post-processing was limited on the inner surfaces.

- Three-dimensional surface topography analyses after DF revealed a notable reduction in peak heights, resulting in smoother, more uniform surfaces and effective removal of residual particles.

- The DF method enhanced dimensional accuracy, with minimal deviations (+0.010 to +0.050 mm) observed on the outer surfaces, indicating that delicate features, such as thin crown walls, were preserved and not over-polished during the process.

- The empirical equations developed were validated through experimental results, demonstrating their ability to accurately predict both surface roughness and material loss following the DF process.

- Despite the high hardness of CoCr crowns (530 HV), the DF3 method produced high-quality surface finishes within a shorter processing time, offering a more time-efficient alternative compared to other DF works that recommend longer times.

- To fully understand the clinical significance of these results, further studies are necessary to evaluate the bonding strength between ceramic veneering materials applied to CoCr crowns that have undergone DF3 post-processing.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 15-5PH | Precipitation-hardening stainless steel alloy |

| 316L | Stainless steel alloy |

| AM | Additive manufacturing |

| ANOVA | Analysis of variance, statistical method |

| ASTM | American Society for Testing and Material standard |

| CMM | Coordinate measuring machine |

| CNC | Computer numerical control |

| CoCr | Cobalt–chromium alloy |

| DF | Drag finishing process |

| DF1, DF2, DF3 | Drag finishing process with different finishing times |

| DFT | Drag finishing total time |

| DWIO | Dental Wings IntraOral system |

| ED | Estimated distance between CMM point and 3D model after DF procedure |

| EDAX | Energy-dispersive X-ray spectroscopy (EDAX) |

| HRC | Rockwell hardness scale C |

| HSC | Mixture of 70% walnut shell granulates and 30% silicon carbide |

| HV | Vickers surface hardness |

| Inconel 718 | Nickel-based superalloy |

| ISO | International organization for standardization |

| MD | Point-to-model distance or measured distance between determinate CMM point and 3D model, measured before DF procedure |

| NiCr | Nickel–chromium alloy |

| Nd:YAG | Neodymium-doped Yttrium Aluminum Garnet, solid-state laser |

| R2 | R squared or coefficient of determination |

| Ra | Surface roughness parameter |

| Rp, Rv, Rc, Rt | Amplitude parameters, peak and valley |

| Rq, Rku, Rsk | Average amplitude parameters |

| Rsm, Rdq, Rmax | Other surface roughness parameters |

| Rz | Surface roughness parameter |

| PBF-LB/M | Scanning electron microscopy |

| SiC | Silicon carbide |

| Ti | Titanium |

| Ti6Al4V | Titanium alloy |

| W | Watts |

References

- Dawood, A.; Marti, B.; Sauret-Jackson, V.; Darwood, A. 3D printing in dentistry. Nat. Br. Dent. J. 2015, 219, 521–529. [Google Scholar] [CrossRef] [PubMed]

- Cosma, C.; Moldovan, M.; Simion, M.; Balc, N. Impact of laser parameters on additively manufactured cobalt-chromium restorations. J Prosthet. Dent. 2022, 128, 421–429. [Google Scholar] [CrossRef] [PubMed]

- Yager, S.; Ma, J.; Ozcan, H.; Kilinc, H.I.; Elwany, A.; Karaman, I. Mechanical Properties and Microstructure of Removable Partial Denture Clasps Manufactured Using Selective Laser Melting. Addit. Manuf. 2015, 8, 117–123. [Google Scholar] [CrossRef]

- Hedberg, Y.; Hedberg, Y.; Qian, B.; Shen, Z.; Virtanen, S.; Odnevall Wallinder, I. In Vitro Biocompatibility of CoCrMo Dental Alloys Fabricated by Selective Laser Melting. Dent. Mater. 2014, 30, 525–534. [Google Scholar] [CrossRef]

- Al Jabbari, Y.S. Physico-Mechanical Properties and Prosthodontic Applications of Co-Cr Dental Alloys: A Review of the Literature. J. Adv. Prosthodont. 2014, 6, 138–145. [Google Scholar] [CrossRef]

- Oltean-Dan, D.; Dogaru, G.-B.; Tomoaia-Cotisel, M.; Apostu, D.; Mester, A.; Benea, H.-R.-C.; Paiusan, M.-G.; Jianu, E.-M.; Mocanu, A.; Balint, R.; et al. Enhancement of Bone Consolidation Using High-Frequency Pulsed Electromagnetic Short-Waves and Titanium Implants Coated with Biomimetic Composite Embedded into PLA Matrix: In Vivo Evaluation. Int. J. Nanomed. 2019, 14, 5799–5816. [Google Scholar] [CrossRef]

- Munteanu, L.; Iancu, I.; Breazu, C.; Cioltean, C.; Brânzilă, S.; Odainii, A.; Furda, P.; Bocşe, H.; Herdean, A.; Bartoş, D.; et al. Rare Causes of Gastrointestinal Bleeding: Focus on Pancreatic Pathology and Visceral Artery Aneurysms. Chirurgia 2021, 116, S5–S15. [Google Scholar]

- Kassapidou, M.; Franke Stenport, V.; Hjalmarsson, L.; Johansson, C.B. Cobalt-Chromium Alloys in Fixed Prosthodontics in Sweden. Acta Biomater Odontol. Scand. 2017, 3, 53–62. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Li, J.; Zhao, C.; Zhuo, D.; Lin, J. Investigation on the microstructure, mechanical property and corrosion behavior of the selective laser melted CoCrW alloy for dental application. Mater. Sci. Eng. C Mater. Biol. Appl. 2015, 49, 517–525. [Google Scholar] [CrossRef]

- Soporan, V.S.; Lehene, T.R.; Pădureţu, S.; Gabor, T. Engineering of circular economy and good management of industrial material resources. IOP Conf. Ser. Mater. Sci. Eng. 2019, 572, 012086. [Google Scholar] [CrossRef]

- Mitić, J.; Vitković, N.; Trajanović, M.; Górski, F.; Păcurar, A.; Borzan, C.; Sabău, E.; Păcurar, R. Utilizing Artificial Neural Networks for Geometric Bone Model Reconstruction in Mandibular Prognathism Patients. Mathematics 2024, 12, 1577. [Google Scholar] [CrossRef]

- Charles, A.; Elkaseer, A.; Thijs, L.; Hagenmeyer, V.; Scholz, S. Effect of Process Parameters on the Generated Surface Roughness of Down-Facing Surfaces in Selective Laser Melting. Appl. Sci. 2019, 9, 1256. [Google Scholar] [CrossRef]

- Băilă, D.I.; Doicin, C.V.; Cotruț, C.M.; Ulmeanu, M.E.; Ghionea, I.G.; Tarbă, C.I. Sintering the beaks of the elevator manufactured by direct metal laser sintering (DMLS) process from Co-Cr alloy. Metalurgija 2016, 55, 663–666. [Google Scholar]

- Hong, M.-H.; Min, B.; Kwon, T.-Y. The Influence of Process Parameters on the Surface Roughness of a 3D-Printed Co–Cr Dental Alloy Produced via Selective Laser Melting. Appl. Sci. 2016, 6, 401. [Google Scholar] [CrossRef]

- Martin, A.A.; Calta, N.P.; Khairallah, S.A.; Wang, J.; Depond, P.J.; Fong, A.Y.; Thampy, V.; Guss, G.M.; Kiss, A.M.; Stone, K.H.; et al. Dynamics of pore formation during laser powder bed fusion additive manufacturing. Nat. Commun. 2019, 10, 1987. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Additive manufacturing of cardiovascular CoCr stents by selective laser melting. Mater. Des. 2017, 119, 338–350. [Google Scholar] [CrossRef]

- Löber, L.; Flache, C.; Petters, R.; Kühn, U.; Eckert, J. Comparison of different post processing technologies for SLM generated 316l steel parts. Rapid Prototyp. J. 2013, 19, 173–179. [Google Scholar] [CrossRef]

- Buican, G.R.; Oancea, G.; Martins, R.F. Study on SLM manufacturing of teeth used for dental tools testing. MATEC Web Conf. 2017, 94, 03002. [Google Scholar] [CrossRef]

- Luca, A.; Balc, N.; Popan, A.; Ceclan, V.; Panc, N. Improving the quality of the parts made by rapid metal casting process. Acad. J. Manuf. Eng. 2014, 12, 82–86. [Google Scholar]

- Selden, A.I.; Persson, B.; Bornberger-Dankvardt, S.I.; Winstrom, L.E.; Bodin, L.S. Exposure to cobalt chromium dust and lung disorders in dental technicians. Thorax 1995, 50, 769–772. [Google Scholar] [CrossRef]

- Kumbhar, N.N.; Mulay, A.V. Post Processing Methods used to Improve Surface Finish of Products which are Manufactured by Additive Manufacturing Technologies: A Review. J. Inst. Eng. (India) Ser. C 2016, 99, 481–487. [Google Scholar] [CrossRef]

- Gora, W.S.; Tian, Y.; Cabo, A.P.; Ardron, M.; Maier, R.R.J.; Prangnell, P.; Weston, N.J.; Hand, D.P. Enhancing Surface Finish of Additively Manufactured Titanium and Cobalt Chrome Elements Using Laser Based Finishing. Phys. Procedia 2016, 83, 258–263. [Google Scholar] [CrossRef]

- Duval-Chaneac; Han, S.; Claudin, C.; Salvatore, F.; Bajolet, J.; Rech, J. Experimental study on finishing of internal laser melting (SLM) surface with abrasive flow machining (AFM). Precis. Eng. 2018, 54, 1–6. [Google Scholar] [CrossRef]

- Conțiu, G.; Popa, M.S.; Socaciu, L.; Pop, G. Fuzzy analytical hierarchy process applied to determine the material machinability in EDM process. Acta Tech. Napoc. Ser. Appl. Math. Mech. Eng. 2015, 58, 385–394. [Google Scholar]

- Ma, C.P.; Guan, Y.C.; Zhou, W. Laser polishing of additive manufactured Ti alloys. Opt. Lasers Eng. 2017, 93, 171–177. [Google Scholar] [CrossRef]

- Mohammad, A.; Mohammed, M.K.; Alahmari, A.M. Effect of laser ablation parameters on surface improvement of electron beam melted parts. Int. J. Adv. Manuf. Technol. 2016, 87, 1033–1044. [Google Scholar] [CrossRef]

- Jamal, M.; Morgan, M. Design Process Control for Improved Surface Finish of Metal Additive Manufactured Parts of Complex Build Geometry. Inventions 2017, 2, 36. [Google Scholar] [CrossRef]

- Zanger, F.; Kacaras, A.; Neuenfeldt, P.; Schulze, V. Optimization of the stream finishing process for mechanical surface treatment by numerical and experimental process analysis. CIRP Ann. 2019, 68, 373–376. [Google Scholar] [CrossRef]

- Kaynak, Y.; Kitay, O. The effect of post-processing operations on surface characteristics of 316L stainless steel produced by selective laser melting. Addit. Manuf. 2018, 26, 84–93. [Google Scholar] [CrossRef]

- Koike, M.; Greer, P.; Owen, K.; Lilly, G.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Okabe, T. Evaluation of Titanium Alloys Fabricated Using Rapid Prototyping Technologies—Electron Beam Melting and Laser Beam Melting. Materials 2011, 4, 1776–1792. [Google Scholar] [CrossRef]

- Wang, X.; Gong, X.; Chou, K. Review on powder-bed laser additive manufacturing of Inconel 718 parts. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 231, 1890–1903. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Kuang, M.; Ma, W.; Kuang, T. Microstructural characterization and properties of selective laser melted maraging steel with different build directions. Sci. Technol. Adv. Mater. 2018, 19, 746–758. [Google Scholar] [CrossRef]

- ISO 22674:2022; Dentistry—Metallic Materials for Fixed and Removable Restorations and Appliances. ISO: Geneva, Switzerland, 2022.

- Cuc, S.; Burde, A.; Cosma, C.; Leordean, D.; Rusu, M.; Balc, N.; Prodan, D.; Moldovan, M.; Ene, R. Adhesion between Biocomposites and Different Metallic Structures Additive Manufactured. Coatings 2021, 11, 483. [Google Scholar] [CrossRef]

- Leordean, D.; Dudescu, C.; Marcu, T.; Berce, P.; Balc, N. Customized implants with specific properties, made by selective laser melting. Rapid Prototyp. J. 2015, 21, 98–104. [Google Scholar] [CrossRef]

- Ucar, Y.; Ekren, O. Effect of layered manufacturing techniques, alloy powders, and layer thickness on mechanical properties of Co-Cr dental alloys. J. Prosthet. Dent. 2018, 120, 762–770. [Google Scholar] [CrossRef]

- Cho, H.H.W.; Takaichi, A.; Kajima, Y.; Htat, H.L.; Kittikundecha, N.; Hanawa, T.; Wakabayashi, N. Effect of Post-Heat Treatment Cooling Conditions on Microstructures and Fatigue Properties of Cobalt Chromium Molybdenum Alloy Fabricated through Selective Laser Melting. Metals 2021, 11, 1005. [Google Scholar] [CrossRef]

- Roudnicka, M.; Bigas, J.; Molnarova, O.; Palousek, D.; Vojtech, D. Different Response of Cast and 3D-Printed Co-Cr-Mo Alloy to Heat Treatment: A Thorough Microstructure Characterization. Metals 2021, 11, 687. [Google Scholar] [CrossRef]

- Zhang, K.; Fu, G.; Zhang, P.; Ma, Z.; Mao, Z.; Zhang, D.Z. Study on the Geometric Design of Supports for Overhanging Structures Fabricated by Selective Laser Melting. Materials 2018, 12, 27. [Google Scholar] [CrossRef]

- Lee, S.; Shao, S.; Wells, D.N.; Zetek, M.; Kepka, M.; Shamsaei, N. Fatigue behavior and modeling of additively manufactured IN718: The effect of surface treatments and surface measurement techniques. J. Mater. Process. Technol. 2022, 302, 117475. [Google Scholar] [CrossRef]

- Pätoprstý, B.; Vozár, M.; Pokorný, P.; Vopát, T.; Buranský, I.; Zetek, M.; Cajthamlová, Š.; Laudát, V. Development of cutting edge radius size of solid carbide mills when drag finishing. In Lecture Notes in Mechanical Engineering; Springer: Singapore, 2020; pp. 95–100. [Google Scholar] [CrossRef]

- Cook, R.B.; Shearwood-Porter, N.R.; Latham, J.M.; Wood, R.J.K. Volumetric assessment of material loss from retrieved cemented metal hip replacement stems. Tribol. Int. 2015, 89, 105–108. [Google Scholar] [CrossRef]

- Panc, N.; Contiu, G.; Bocanet, V. Comparative Analysis of Surface Finishing for Different Cutting Strategies of Parts Made from POM C. In Lecture Notes in Mechanical Engineering; Springer: Singapore, 2018; pp. 324–332. [Google Scholar] [CrossRef]

- ISO 4278:1997; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 1997.

- ISO 10360:2000; Acceptance and Re-Verification Tests for Coordinate Measuring Machines. ISO: Geneva, Switzerland, 2000.

- ISO 6507-1:2018; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2018.

- Surface Roughness Measurement-Parameters, OLYMPUS, Tokyo, Japan. Available online: www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/ (accessed on 23 March 2024).

- Takaichi, A.; Kajima, Y.; Jialin, D.; Wakabayashi, N. Metal Additive Manufacturing Technology for Digital Dentistry. Health Care Curr Rev. 2024, 12, 407. Available online: https://www.walshmedicalmedia.com/open-access/metal-additive-manufacturing-technology-for-digital-dentistry.pdf (accessed on 4 February 2025).

- Wei, W.; Zhou, Y.; Sun, Q.; Li, N.; Yan, J.; Li, H.; Liu, W.; Huang, C. Microstructures and mechanical properties of dental Co-CR-MO-W alloys fabricated by selective laser melting at different subsequent heat treatment temperatures. Metall. Mater. Trans. A 2020, 51, 3205–3214. [Google Scholar] [CrossRef]

- Herrero-Climent, M.; Lázaro, P.; Rios, J.V.; Lluch, S.; Marqués, M.; Guillem-Martí, J.; Gil, F.J. Influence of acid-etching after grit-blasted on osseointegration of titanium dental implants: In vitro and in vivo studies. J. Mater. Sci. Mater. Med. 2013, 24, 2047–2055. [Google Scholar] [CrossRef] [PubMed]

- Behjat, A.; Lannunziata, E.; Gadalińska, E.; Iuliano, L.; Saboori, A. Improving the surface quality and mechanical properties of additively manufactured AISI 316L stainless steel by different surface post-treatment. Procedia CIRP 2023, 118, 771–776. [Google Scholar] [CrossRef]

- Valentinčič, J.; Koroth, J.E.; Zeidler, H. Advancements in surface finish for additive manufacturing of metal parts: A comprehensive review of plasma electrolytic polishing (PEP). Virtual Phys. Prototyp. 2024, 19, e2364222. [Google Scholar] [CrossRef]

- Shen, L.; Ross, I. Implant Manufacture out of CoCr by Means of SLM and Laser Polishing. Annual Report Fraunhofer Institute for Laser Technology ILT 2014. Available online: www.ilt.fraunhofer.de (accessed on 19 May 2020).

- Gisario, A.; Barletta, M.; Veniali, F. Laser polishing: A review of a constantly growing technology in the surface finishing of components made by additive manufacturing. Int. J. Adv. Manuf. Technol. 2022, 120, 1433–1472. [Google Scholar] [CrossRef]

- Mizokoshi, N.; Sakurai, T.; Shimpo, H.; Kawamura, N.; Ohkubo, C. Finishing efficiencies of additive-manufactured Co-Cr alloy and Ti alloy clasps. Dent. Mater. J. 2025, 2024-356. [Google Scholar] [CrossRef]

- Monroy, K.P.; Delgado, J.; Sereno, L.; Ciurana, J.; Hendrichs, N.J. Effects of the Selective Laser Melting manufacturing process on the properties of CoCrMo single tracks. Met. Mater. Int. 2014, 20, 873–884. [Google Scholar] [CrossRef]

- Ayyıldız, S.; Soylu, E.H.; İde, S.; Kılıç, S.; Sipahi, C.; Pişkin, B.; Gökçe, H.S. Annealing of Co-Cr dental alloy: Effects on nanostructure and Rockwell hardness. J. Adv. Prosthodont. 2013, 5, 471. [Google Scholar] [CrossRef]

- ASTM F75-18; Standard Specification for Cobalt-28 Chromium-6 Molybdenum Alloy Castings and Casting Alloy for Surgical Implants (UNS R30075). ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM F90-14; Standard Specification for Wrought Cobalt-20Chromium-15Tungsten-10Nickel Alloy for Surgical Implant Applications (UNS R30605). ASTM International: West Conshohocken, PA, USA, 2014.

- Kotila, J.; Syvänen, T.; Hänninen, J.; Latikka, M.; Nyrhilä, O. Direct Metal Laser Sintering—New Possibilities in Biomedical Part Manufacturing. Mater. Sci. Forum 2007, 534–536, 461–464. [Google Scholar] [CrossRef]

- Lapcevic, A.R.; Jevremovic, D.P.; Puskar, T.M.; Williams, R.J.; Eggbeer, D. Comparative analysis of structure and hardness of cast and direct metal laser sintering produced Co-Cr alloys used for dental devices. Rapid Prototyp. J. 2016, 22, 144–151. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, N.; Yan, J.; Zeng, Q. Comparative analysis of the microstructures and mechanical properties of Co-Cr dental alloys fabricated by different methods. J. Prosthet. Dent. 2018, 120, 617–623. [Google Scholar] [CrossRef] [PubMed]

- Tunthawiroon, P.; Chiba, A. Effects of Si concentrations on microstructure and mechanical properties of as-cast CoCrMo alloys. IOP Conf. Ser. Mater. Sci. Eng. 2019, 635, 012006. [Google Scholar] [CrossRef]

- Monkova, K.; Monka, P.P.; Pantazopoulos, G.A.; Toulfatzis, A.I.; Šmeringaiová, A.; Török, J.; Papadopoulou, S. Effect of Crosshead Speed and Volume Ratio on Compressive Mechanical Properties of Mono- and Double-Gyroid Structures Made of Inconel 718. Materials 2023, 16, 4973. [Google Scholar] [CrossRef]

- Ibrahim, M.; Hulme, C.; Grasmo, G.; Aune, R.E. Preliminary Evaluation of Nickel Silicide (NiSi12-wt%) Laser Cladding for Enhancing Microhardness and Corrosion Resistance of S355 Steel. Metals 2024, 14, 1389. [Google Scholar] [CrossRef]

- Grobelny, P.; Legutko, S.; Habrat, W.; Furmanski, L. Investigations of surface topography of titanium alloy manufactured with the use of 3D print. IOP Conf. Ser. Mater. Sci. Eng. 2018, 393, 012108. [Google Scholar] [CrossRef]

- Fratila, A.; Jimenez-Marcos, C.; Mirza-Rosca, J.C.; Saceleanu, A. Mechanical properties and biocompatibility of various cobalt chromium dental alloys. Mater. Chem. Phys. 2023, 304, 127867. [Google Scholar] [CrossRef]

- ISO 9693:2019; Dentistry—Compatibility Testing for Metal-Ceramic and Ceramic-Ceramic Systems. ISO: Geneva, Switzerland, 2019.

| Chemical Element | Co | Cr | W | Mo | Si | Mn | O | Other Elements (C, Fe, N) |

|---|---|---|---|---|---|---|---|---|

| Maximum weight percentage [%] | 59.3 | 25.1 | 9.4 | 3.4 | 1.2 | 0.9 | 0.5 | Max. 1 |

| Laser Power (W) | Laser Scanning Speed (mm/s) | Hatch Spacing (μm) | Layer Thickness (μm) | Laser Spot Diameter (μm) | Scanning Strategy |

|---|---|---|---|---|---|

| 85 | 960 | 60 | 25 | 30 | Chessboard |

| Code of DF Condition | Main Heat Speed [rpm] | Spindle Speed [rpm] | Immersion Depth [mm] | Clockwise Rotation [min] | Counter-Clockwise Rotation [min] | Total Finishing Time [min] |

|---|---|---|---|---|---|---|

| DF1 | 35 | 60 | 420 | 22.5 | 22.5 | 45 |

| DF2 | 30 | 30 | 60 | |||

| DF3 | 37.5 | 37.5 | 75 |

| Code of DF Condition | Ra Surface Roughness [µm] | Rz Surface Roughness [µm] | ||||

|---|---|---|---|---|---|---|

| As-Built | After DF | Difference [%] | As-Built | After DF | Difference [%] | |

| DF1 | 5.20 | 1.52 | 73.19 | 23.80 | 7.65 | 67.86 |

| DF2 | 5.54 | 1.05 | 82.84 | 34.09 | 5.38 | 84.22 |

| DF3 | 6.05 | 0.51 | 91.57 | 29.81 | 4.05 | 86.41 |

| Code of DF Condition | Ra Surface Roughness [µm] | Rz Surface Roughness [µm] | |||||

|---|---|---|---|---|---|---|---|

| As-Built | After DF | Difference [%] | As-Built | After DF | Difference [%] | ||

| Outer surfaces | DF1 | 5.95 | 1.60 | 70.45 | 27.83 | 8.20 | 70.54 |

| DF2 | 6.25 | 1.10 | 84.38 | 53.32 | 6.59 | 87.64 | |

| DF3 | 6.14 | 0.61 | 90.07 | 32.49 | 4.53 | 86.06 | |

| Chamfer | DF1 | 6.29 | 1.48 | 76.47 | 36.48 | 7.40 | 79.72 |

| DF2 | 6.01 | 0.98 | 83.69 | 35.46 | 5.39 | 84.80 | |

| DF3 | 6.67 | 0.49 | 92.65 | 40.02 | 2.79 | 93.02 | |

| Inner surfaces | DF1 | 6.95 | 5.24 | 24.60 | 40.31 | 31.65 | 21.48 |

| DF2 | 5.85 | 4.97 | 15.04 | 29.87 | 23.07 | 22.77 | |

| DF3 | 6.77 | 5.48 | 19.05 | 35.38 | 31.11 | 12.07 | |

| Code of DF Condition | Amplitude Average Parameters | Amplitude Parameters (Peak and Valley) | Others | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ra [µm] | Rq [µm] | Rsk [µm] | Rku [µm] | Rz [µm] | Rp [µm] | Rv [µm] | Rc [µm] | Rt [µm] | Rsm [µm] | Rmax [µm] | Rdq [µm] | Rt/Rz Ratio | |

| DF1 | 1.60 | 1.99 | −0.19 | 2.87 | 8.20 | 5.31 | 6.67 | 6.07 | 11.98 | 178.14 | 11.23 | 0.12 | 1.46 |

| DF2 | 1.10 | 1.52 | −0.68 | 6.57 | 6.59 | 4.71 | 7.76 | 5.75 | 12.47 | 280.08 | 12.47 | 0.11 | 1.89 |

| DF3 | 0.61 | 1.04 | −1.29 | 7.97 | 4.53 | 2.41 | 5.79 | 3.96 | 8.20 | 292.47 | 8.20 | 0.08 | 1.80 |

| Surface Condition | Initial | DF1 | DF2 | DF3 |

|---|---|---|---|---|

| Vickers hardness [HV1] | 520 ± 56 | 524 ± 42 | 527 ± 38 | 530 ± 27 |

| Sample No. | Ra After Printing (µm) | Drag Finishing Time (min) | Ra After DF, Estimated a (µm) | Ra After DF, Measured (µm) | Difference b (µm) | Point-to-Model Distance Before DF (mm) | ED After DF c (mm) | Measured Distance After DF (mm) | Difference (mm) d |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 5.92 | 45 | 1.55 | 1.59 | 0.04 | 0.070 | 0.023 | 0.025 | 0.002 |

| 2 | 5.75 | 45 | 1.54 | 1.58 | 0.04 | 0.081 | 0.025 | 0.028 | 0.003 |

| 3 | 6.34 | 60 | 1.09 | 1.12 | 0.03 | 0.052 | 0.018 | 0.022 | 0.004 |

| 4 | 6.18 | 75 | 0.60 | 0.64 | 0.04 | 0.062 | 0.019 | 0.024 | 0.005 |

| 5 | 5.97 | 75 | 0.59 | 0.64 | 0.05 | 0.091 | 0.024 | 0.027 | 0.003 |

| Material | Specimen Shape [Basic/Complex] | Post-Processing Method | Ra of as-Built Specimen [μm] | Ra After Post-Processing [μm] | Vickers Hardness [HV] | Source |

|---|---|---|---|---|---|---|

| CoCr | Complex | DF, 75 min. | 6.1 | 0.6 | 530 | This study |

| Ti6Al4V | Complex | DF, 90–120 min. | 7.5 | 0.6–0.8 | ~400 | Jamal et al. [27] |

| 316L | Basic | DF, 120–240 min. | 6 | 2–3 | 280 | Kaynak et al. [29] |

| 316L | Basic | DF, 180 min. | 12 | 5 | ~220 | Behjat et al. [51] |

| Inconel 718 | Basic | DF, 240 min. | 4.3 | 2.2 | - | Lee et al. [40] |

| Inconel 718 | Basic | Grinding + DF, 240 min. | 4.3 | 0.5 | - | Lee et al. [40] |

| 316L | Basic | Vibratory surface finishing | 6 | 4 | 280 | Kaynak et al. [29] |

| CoCr | Complex | Electro-polishing | 9.1 | 1.4 | - | Demir et al. [16] |

| CoCr | Basic | Electro-polishing | 20 | 0.02 | - | Valentinčič et al. [52] |

| 316L * | Basic | Electro-polishing | 15.1 | 9.2 | ~250 | Lober et al. [17] |

| 316L * | Basic | Plasma-polishing | 15.1 | 8.5 | ~250 | Lober et al. [17] |

| 316L * | Basic | Blasted with sand (90–250 μm) | 15.1 | 3.8 | ~250 | Lober et al. [17] |

| CoCr | Complex | Laser polishing | 7 | 0.3 | - | Fraunhofer Inst. Laser Tech. [53] |

| CoCr | Basic | Laser polishing | 12.8 | 0.6 | - | Gora et al. [22] |

| Ti6Al4V | Basic | Laser polishing | 5.2 | 0.4 | 345 | Ma et al. [25] |

| Inconel 718 | Basic | Laser polishing | 7.5 | 0.1 | 440 | Gisario et al. [54] |

| 316L * | Basic | Laser polishing | 4.6 | 0.3 | ~302 | Gisario et al. [54] |

| 15-5PH * | Complex | Abrasive flow machining (150 cycles) | 13.9 | 2.5 | 650 | Duval-Chaneac et al. [23] |

| Manufacturing Method | Vickers Hardness [HV] | Source |

|---|---|---|

| PBF-LB/M | 524–530 | Present study after DF post-processing |

| 400–460 | [60] | |

| 325–482 | [57] | |

| 440 | [61] | |

| 564–570 | [9] | |

| 498–618 * | [2] | |

| Casting | 280–385 | [5] |

| 323 | [62] | |

| 287–295 ** | [63] | |

| 266–345 | Standard of CoCr alloy for surgical implants [58] | |

| 300–400 | Standard of CoCr alloy for surgical implants [59] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cosma, C.; Melichar, M.; Libu, S.; Popan, A.; Contiu, G.; Teusan, C.; Berce, P.; Balc, N. The Effect of Drag Finishing on Additively Manufactured Customized Dental Crowns. Metals 2025, 15, 471. https://doi.org/10.3390/met15050471

Cosma C, Melichar M, Libu S, Popan A, Contiu G, Teusan C, Berce P, Balc N. The Effect of Drag Finishing on Additively Manufactured Customized Dental Crowns. Metals. 2025; 15(5):471. https://doi.org/10.3390/met15050471

Chicago/Turabian StyleCosma, Cosmin, Martin Melichar, Stelian Libu, Alexandru Popan, Glad Contiu, Cristina Teusan, Petru Berce, and Nicolae Balc. 2025. "The Effect of Drag Finishing on Additively Manufactured Customized Dental Crowns" Metals 15, no. 5: 471. https://doi.org/10.3390/met15050471

APA StyleCosma, C., Melichar, M., Libu, S., Popan, A., Contiu, G., Teusan, C., Berce, P., & Balc, N. (2025). The Effect of Drag Finishing on Additively Manufactured Customized Dental Crowns. Metals, 15(5), 471. https://doi.org/10.3390/met15050471