Investigation of High-Temperature Tensile Properties and Fracture Mechanisms of GH3536 Alloy Fabricated by Selective Laser Melting

Abstract

1. Introduction

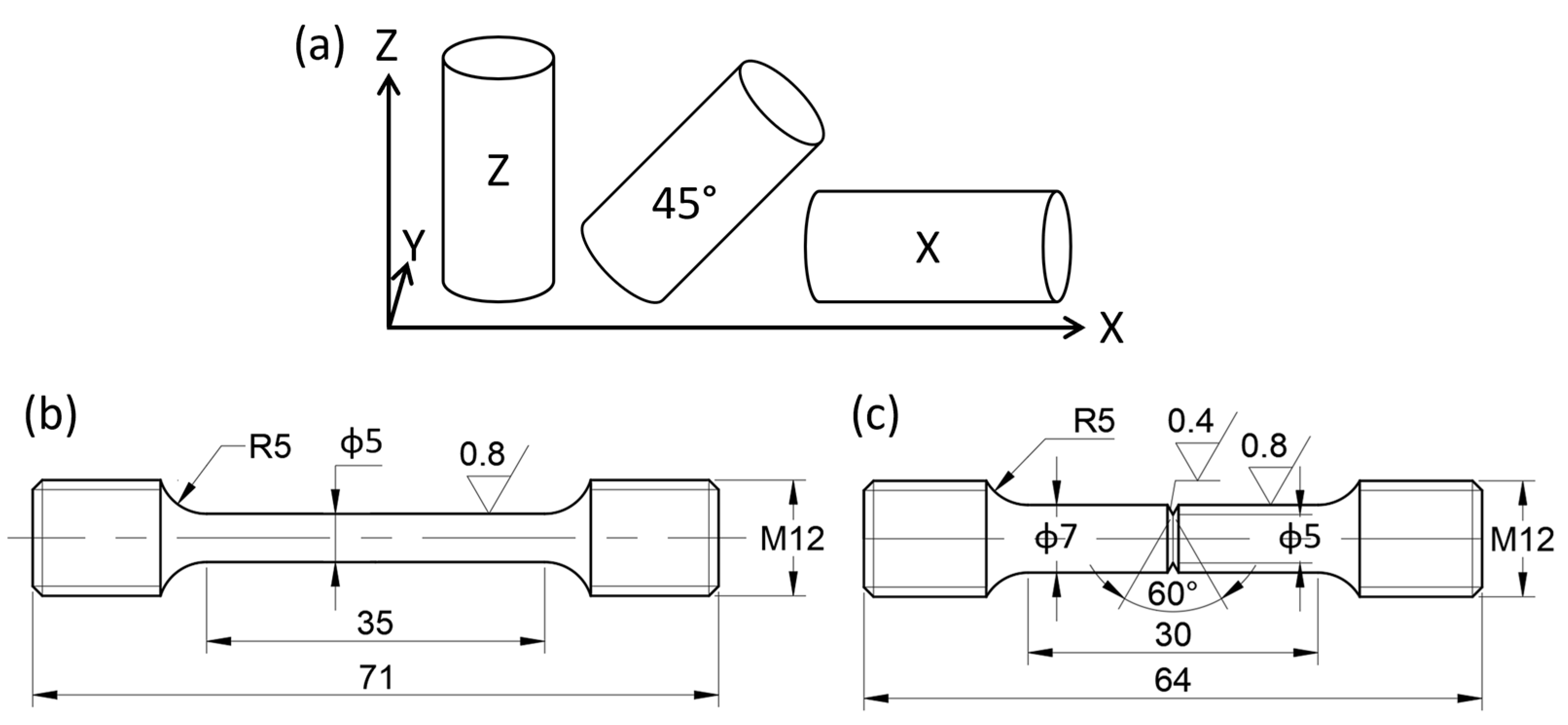

2. Experimental Section

3. Results and Discussion

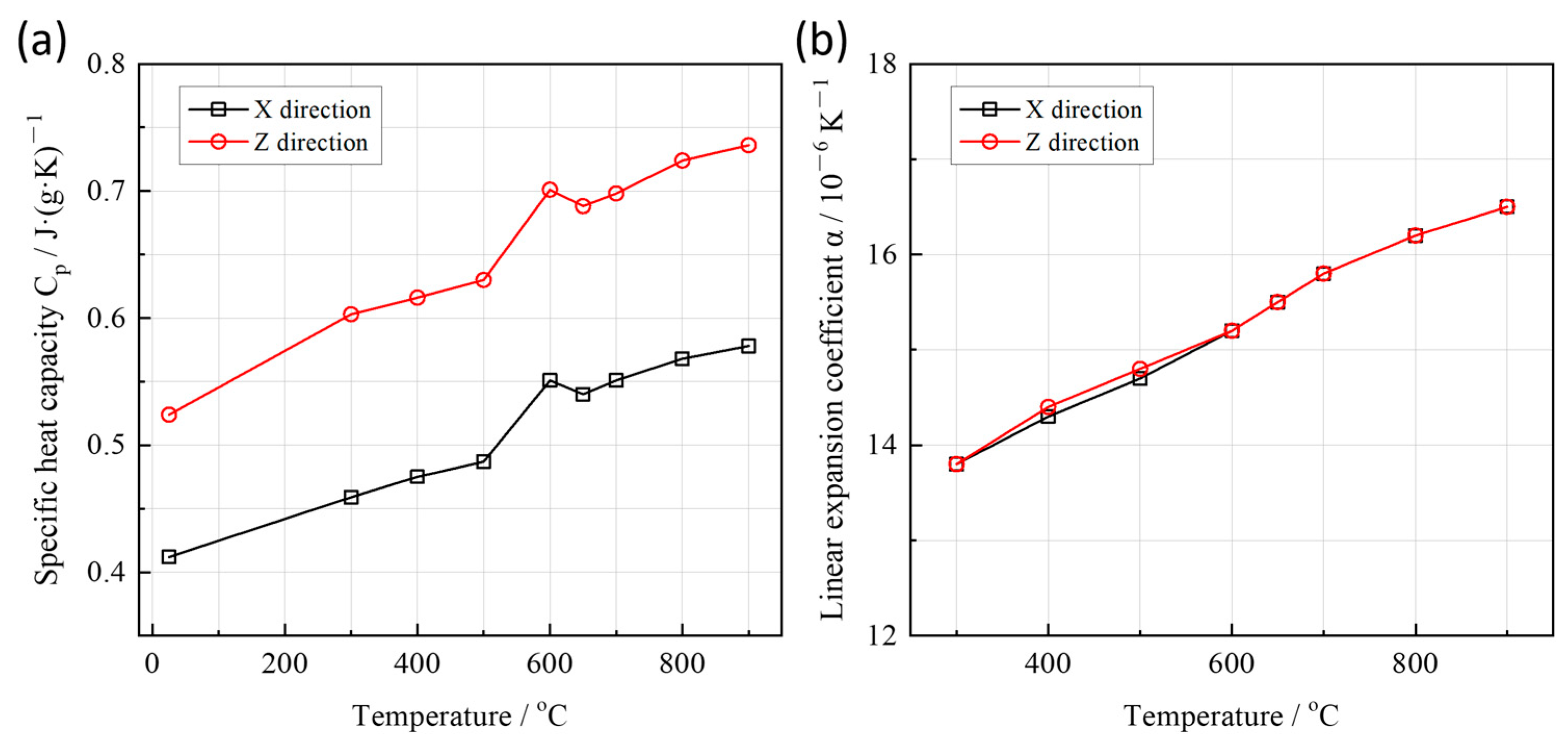

3.1. Thermophysical Properties

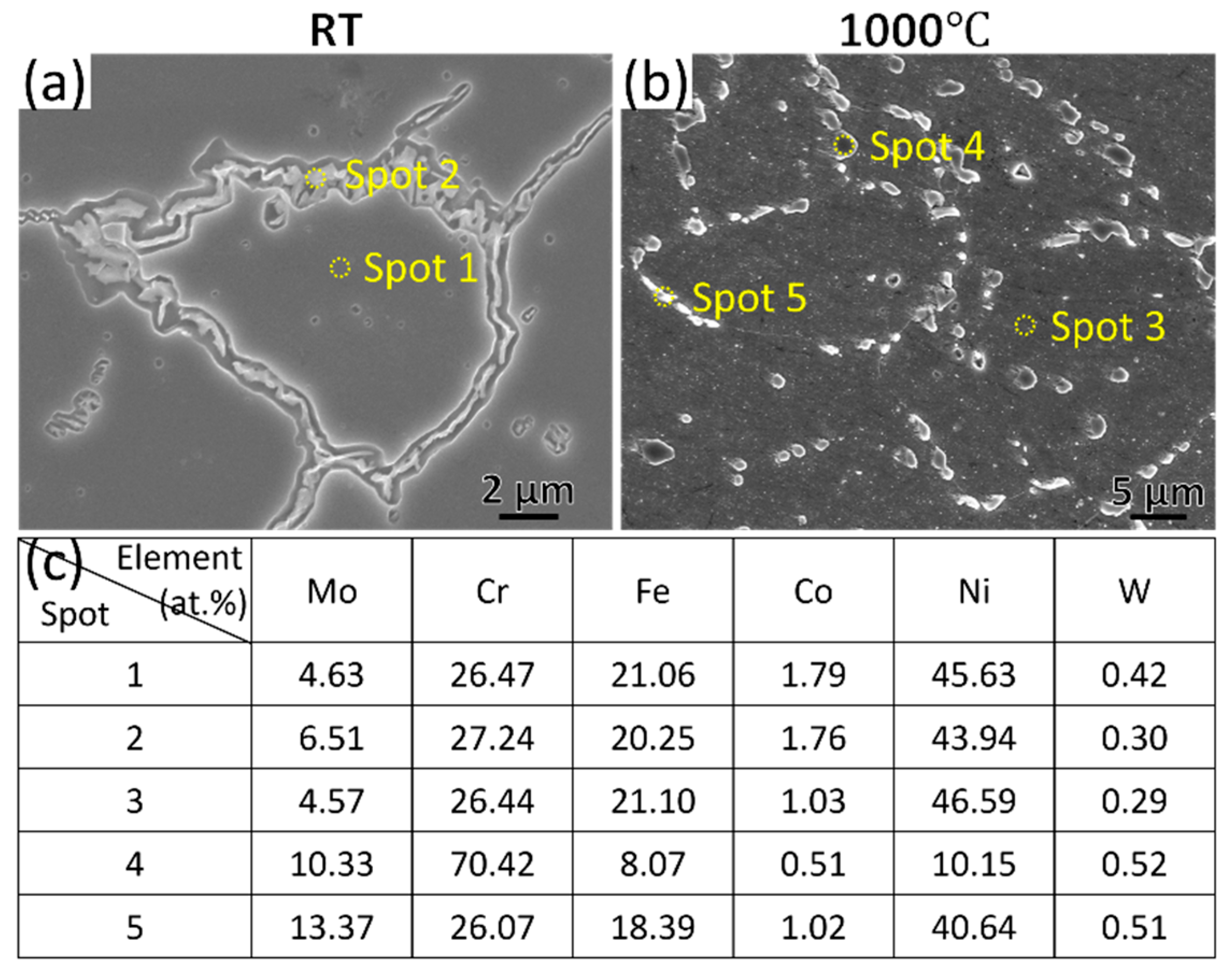

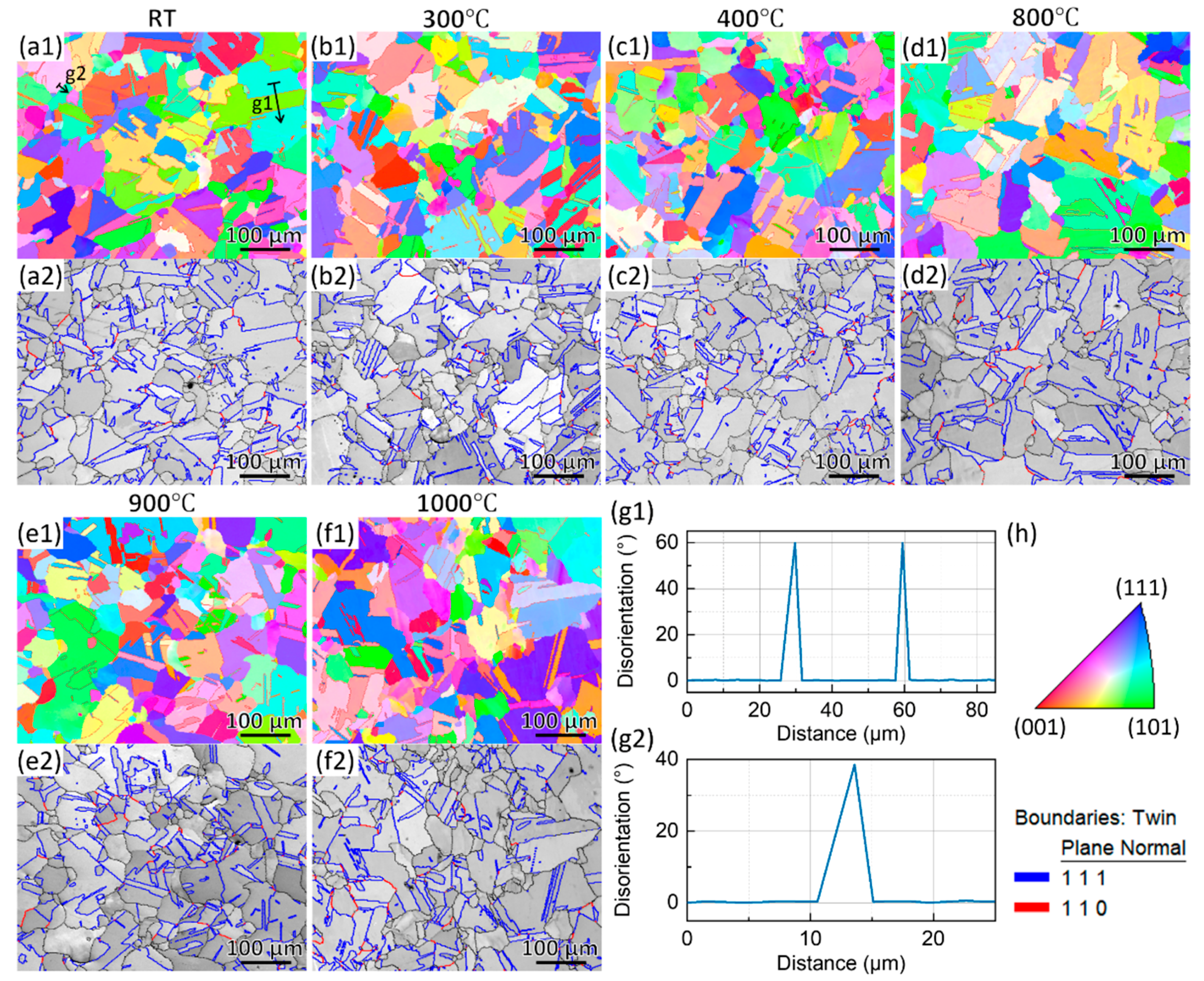

3.2. Microstructure Characterization

3.3. Tensile Properties

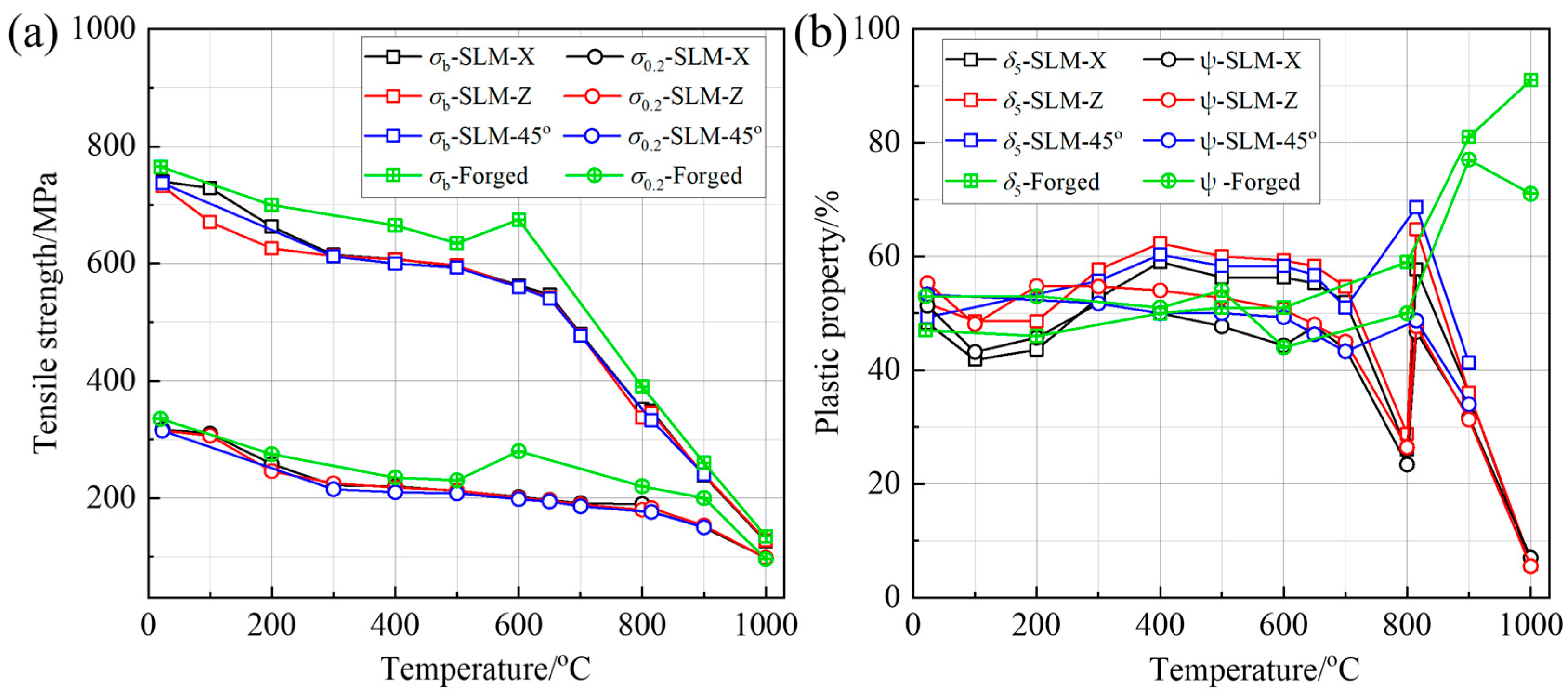

3.3.1. Tensile Properties of Smooth Specimens

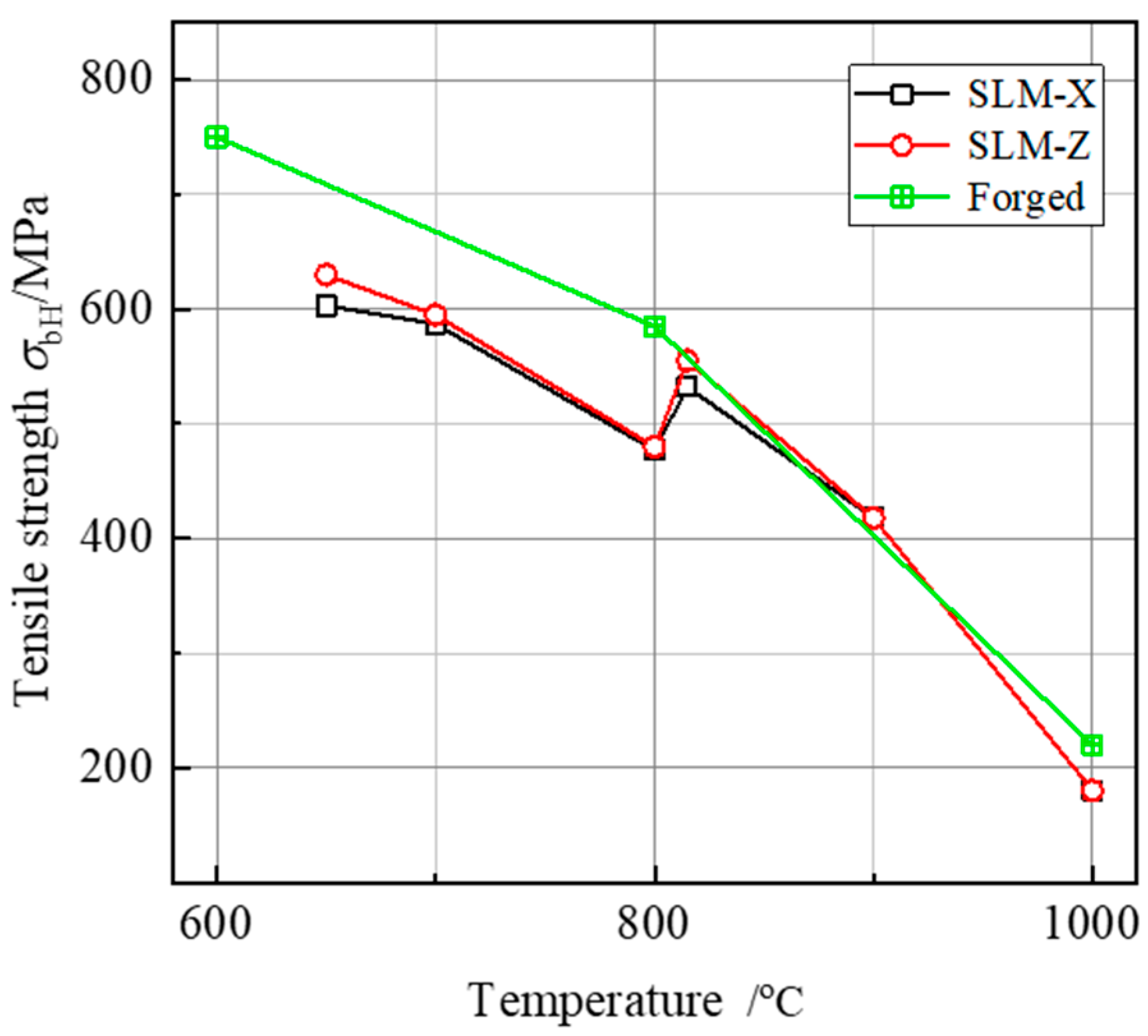

3.3.2. Tensile Properties of Notched Specimens

4. Conclusions

- The tensile strength of the two types of specimens and the elongation of the smooth specimens decreased gradually with the increase in ambient temperature. Among them, the smooth specimens exhibited isotropy along X, Z, and 45° directions.

- Compared to conventional forged materials, SLM GH3536 alloy exhibited a similar tensile strength, but the elongation gap increased at temperatures above 900 °C.

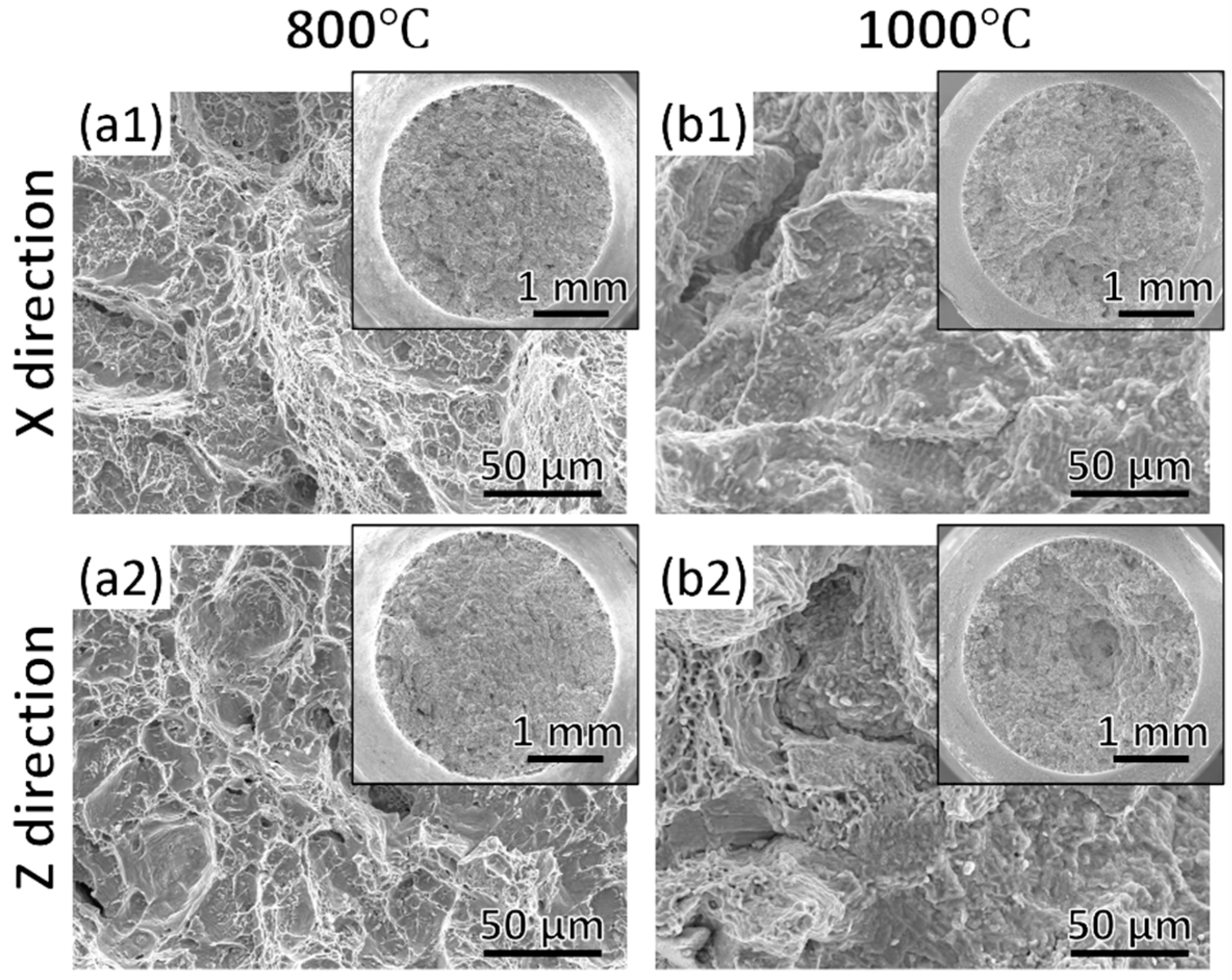

- At elevated temperatures, the continuous carbides gradually disappeared, while a significant number of granular carbides precipitated at the grain boundaries and within the grains.

- Above 815 °C, the tensile fracture mode changed from mixed fracture to intergranular fracture, and the coarse carbide particles at the grain boundary promoted intergranular cracking.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Geddes, B.; Leon, H.; Huang, X. Superalloys: Alloying and Performance; ASM International: Materials Park, OH, USA, 2010. [Google Scholar] [CrossRef]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.-T.; Strayer, S.; Chang, K.-C.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.-C.; Tin, S.; et al. Additive manufacturing of nickel-based superalloys: A state-of-the-art review on process-structure-defect-property relationship. Prog. Mater. Sci. 2023, 136, 101108. [Google Scholar] [CrossRef]

- Wu, S.; Song, H.; Peng, H.; Hodgson, P.; Wang, H.; Wu, X.; Zhu, Y.; Lam, M.; Huang, A. A microstructure-based creep model for additively manufactured nickel-based superalloys. Acta Mater. 2022, 224, 117528. [Google Scholar] [CrossRef]

- Sanchez, S.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ashcroft, I.A.; Chen, H.; Clare, A.T. Powder Bed Fusion of nickel-based superalloys: A review. Int. J. Mach. Tools Manuf. 2021, 165, 103729. [Google Scholar] [CrossRef]

- Zhou, Y.; Qi, Z.; Cong, B.; Zhao, Y.; Guo, W.; Jiang, Z.; Li, H.; Dong, C.; Ji, Y.; He, X.; et al. Influence of in-situ precipitation on corrosion behaviors of wire arc directed energy deposited Al-Mg(-Sc-Zr). J. Mater. Sci. Technol. 2025, 228, 172–188. [Google Scholar] [CrossRef]

- Zhang, K.; Li, J.; Anousheh, A.; Li, J.; Parniani, F.; Zang, C.; Tang, X.S.; Zhou, Y.N.; Peng, P. Interfacial liquid control to realize superior comprehensive properties of microwelded NiTi-stainless steel joints for multifunctional biomedical device fabrication. J. Mater. Sci. Technol. 2025; in press. [Google Scholar] [CrossRef]

- Jinoop, A.N.; Paul, C.P.; Ganesh Kumar, J.; Anilkumar, V.; Singh, R.; Rao, S.; Bindra, K.S. Influence of heat treatment on the microstructure evolution and elevated temperature mechanical properties of Hastelloy-X processed by laser directed energy deposition. J. Alloys Compd. 2021, 868, 159207. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Y.; Liu, F.; Wang, D.; Liu, F.; Huang, C.; Li, Q.; Lin, X.; Huang, W. Huang, Effect of solution temperature on the microstructure and mechanical properties of Hastelloy X superalloy fabricated by laser directed energy deposition. Mater. Sci. Eng. A 2021, 820, 141537. [Google Scholar] [CrossRef]

- Guo, B.; Zhang, Y.; He, F.; Ma, J.; Li, J.; Wang, Z.; Wang, J.; Feng, J.; Wang, W.; Gao, L. Origins of the mechanical property heterogeneity in a hybrid additive manufactured Hastelloy X. Mater. Sci. Eng. A 2021, 823, 141716. [Google Scholar] [CrossRef]

- Kangazian, J.; Shamanian, M.; Kermanpur, A.; Foroozmehr, E.; Badrossamay, M. Investigation of microstructure-tensile behavior relationship in Hastelloy X Ni-based superalloy processed by laser powder-bed fusion: Insights into the elevated temperature ductility loss. Mater. Sci. Eng. A 2021, 823, 141742. [Google Scholar] [CrossRef]

- Cheng, X.; Zhao, Y.; Qian, Z.; Wu, J.; Dong, J.; Ma, Z.; Liu, Y. Crack elimination and mechanical properties enhancement in additive manufactured Hastelloy X via in-situ chemical doping of Y2O3. Mater. Sci. Eng. A 2021, 824, 141867. [Google Scholar] [CrossRef]

- Yin, Y.; Zhang, J.; Gao, J.; Zhang, Z.; Han, Q.; Zan, Z. Laser powder bed fusion of Ni-based Hastelloy X superalloy: Microstructure, anisotropic mechanical properties and strengthening mechanisms. Mater. Sci. Eng. A 2021, 827, 142076. [Google Scholar] [CrossRef]

- Sanchez-Mata, O.; Wang, X.; Muñiz-Lerma, J.A.; Atabay, S.E.; Shandiz, M.A.; Brochu, M. Dependence of mechanical properties on crystallographic orientation in nickel-based superalloy Hastelloy X fabricated by laser powder bed fusion. J. Alloys Compd. 2021, 865, 158868. [Google Scholar] [CrossRef]

- Zhao, Y.; Gong, B.; Wang, Y.; Gu, Y. Effects of microstructure anisotropy on dynamic fracture behaviors of a selective laser melting nickel-based superalloy. Mater. Sci. Eng. A 2022, 858, 144133. [Google Scholar] [CrossRef]

- Wu, S.; Dai, S.; Heilmaier, M.; Peng, H.; Zhang, G.; Huang, S.; Zhang, X.; Tian, Y.; Zhu, Y.; Huang, A. The effect of carbides on the creep performance of Hastelloy X fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2023, 875, 145116. [Google Scholar] [CrossRef]

- Keshavarzkermani, A.; Esmaeilizadeh, R.; Enrique, P.D.; Asgari, H.; Zhou, N.Y.; Bonakdar, A.; Toyserkani, E. Static recrystallization impact on grain structure and mechanical properties of heat-treated Hastelloy X produced via laser powder-bed fusion. Mater. Charact. 2021, 173, 110969. [Google Scholar] [CrossRef]

- Karapuzha, A.S.; Fraser, D.; Schliephake, D.; Dietrich, S.; Zhu, Y.; Wu, X.; Huang, A. Microstructure, mechanical behaviour and strengthening mechanisms in Hastelloy X manufactured by electron beam and laser beam powder bed fusion. J. Alloys Compd. 2021, 862, 158034. [Google Scholar] [CrossRef]

- Tomus, D.; Jarvis, T.; Wu, X.; Mei, J.; Rometsch, P.; Herny, E.; Rideau, J.-F.; Vaillant, S. Controlling the Microstructure of Hastelloy-X Components Manufactured by Selective Laser Melting. Phys. Procedia 2013, 41, 823–827. [Google Scholar] [CrossRef]

- Wu, S.; Peng, H.; Gao, X.; Hodgson, P.; Song, H.; Zhu, Y.; Tian, Y.; Huang, A. Improving creep property of additively manufactured Inconel 718 through specifically-designed post heat treatments. Mater. Sci. Eng. A 2022, 857, 144047. [Google Scholar] [CrossRef]

- Zheng, Y.; He, Y.; Chen, X.; Lei, L. Elevated-temperature tensile properties and fracture behavior of GH3536 alloy formed via selective laser melting. Chin. J. Lasers 2020, 47, 106–115. [Google Scholar] [CrossRef]

- Ma, R.; Liu, L.; Wang, Y.; Bai, J.; Tan, C.; Song, X. Effect of solution temperature on the microstructure evolution and mechanical properties of laser powder bed melting GH3536 alloy. Trans. China Weld. Inst. 2022, 43, 73–79. [Google Scholar] [CrossRef]

- Geng, S.; Zhang, D.; Li, J.; Yi, D.; Chi, Y.; Huang, S.; Zhang, X. Effect of homogenizing treatment on microstructure and microhardness of GH3536 and GH4169 alloy by selective laser melting. J. Aeronaut. Mater. 2024, 44, 72–83. [Google Scholar] [CrossRef]

- Sun, Y. Process and Microstructure and Property Control of GH3536 Alloy; Harbin Institute of Technology: Harbin, China, 2024. [Google Scholar]

- Montero-Sistiaga, M.L.; Liu, Z.; Bautmans, L.; Nardone, S.; Ji, G.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Effect of temperature on the microstructure and tensile properties of micro-crack free hastelloy X produced by selective laser melting. Addit. Manuf. 2020, 31, 100995. [Google Scholar] [CrossRef]

| Direction | θ/°C | 25 | 300 | 400 | 500 | 600 | 650 | 700 | 800 | 900 |

|---|---|---|---|---|---|---|---|---|---|---|

| X | Cp/J·(g·K)−1 | 0.412 | 0.459 | 0.475 | 0.487 | 0.551 | 0.540 | 0.551 | 0.568 | 0.578 |

| Z | 0.524 | 0.603 | 0.616 | 0.630 | 0.701 | 0.688 | 0.698 | 0.724 | 0.736 |

| Direction | Heating Range θ/°C | 20~300 | 20~400 | 20~500 | 20~600 | 20~650 | 20~700 | 20~800 | 20~900 |

|---|---|---|---|---|---|---|---|---|---|

| X | α/10−6 K−1 | 13.8 | 14.3 | 14.7 | 15.2 | 15.5 | 15.8 | 16.2 | 16.5 |

| Z | 13.8 | 14.4 | 14.8 | 15.2 | 15.5 | 15.8 | 16.2 | 16.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, B.; Huang, S.; Wang, T.; Wang, C.; Chen, B. Investigation of High-Temperature Tensile Properties and Fracture Mechanisms of GH3536 Alloy Fabricated by Selective Laser Melting. Metals 2025, 15, 381. https://doi.org/10.3390/met15040381

Zhou B, Huang S, Wang T, Wang C, Chen B. Investigation of High-Temperature Tensile Properties and Fracture Mechanisms of GH3536 Alloy Fabricated by Selective Laser Melting. Metals. 2025; 15(4):381. https://doi.org/10.3390/met15040381

Chicago/Turabian StyleZhou, Biao, Shuai Huang, Tianyuan Wang, Cheng Wang, and Bingqing Chen. 2025. "Investigation of High-Temperature Tensile Properties and Fracture Mechanisms of GH3536 Alloy Fabricated by Selective Laser Melting" Metals 15, no. 4: 381. https://doi.org/10.3390/met15040381

APA StyleZhou, B., Huang, S., Wang, T., Wang, C., & Chen, B. (2025). Investigation of High-Temperature Tensile Properties and Fracture Mechanisms of GH3536 Alloy Fabricated by Selective Laser Melting. Metals, 15(4), 381. https://doi.org/10.3390/met15040381