Influence of Friction Stir Processing Post-Treatment on the Microstructure and Mechanical Properties of 205A Aluminum Alloy Produced by Wire Arc-Directed Energy Deposition

Abstract

1. Introduction

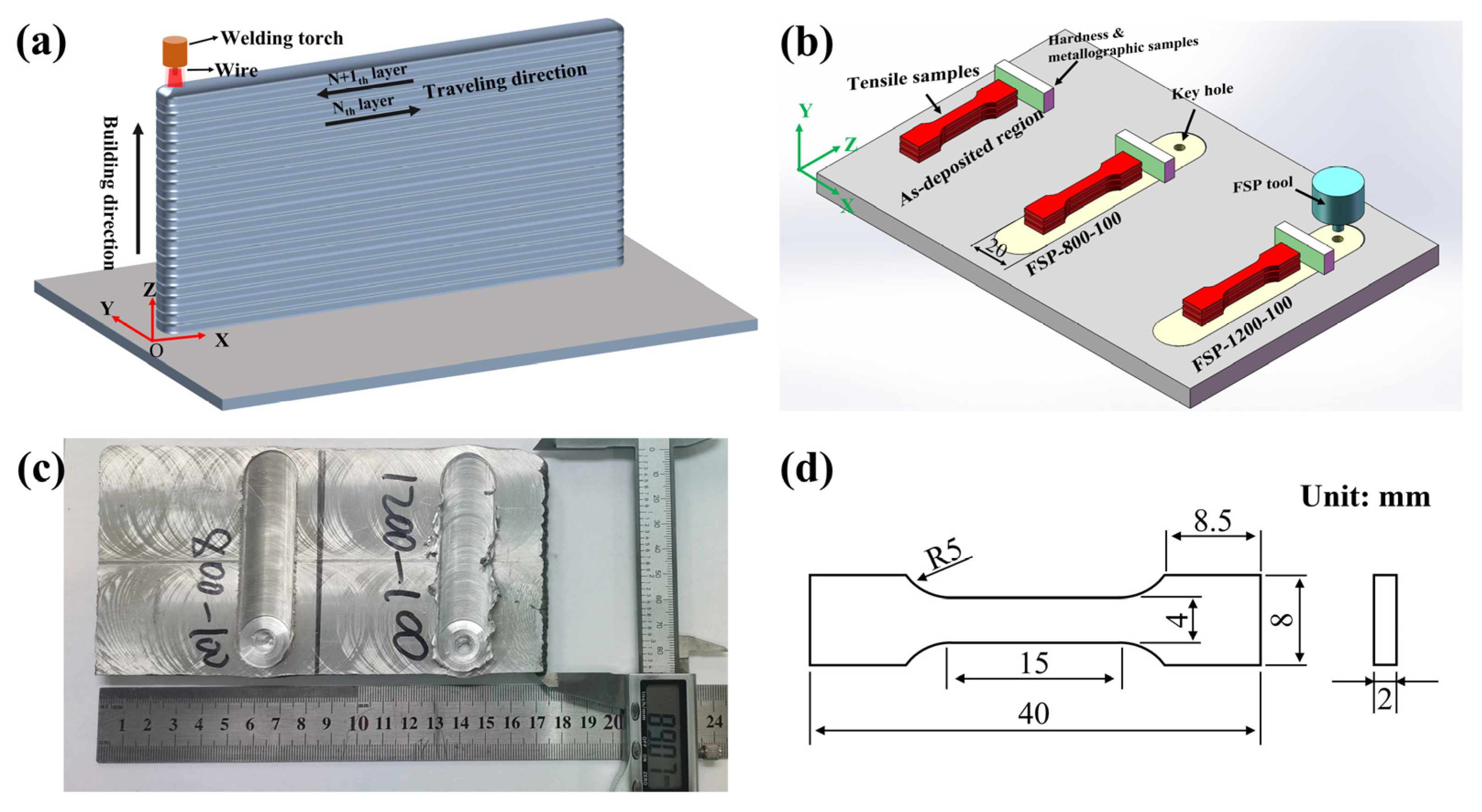

2. Materials and Methods

3. Results and Discussion

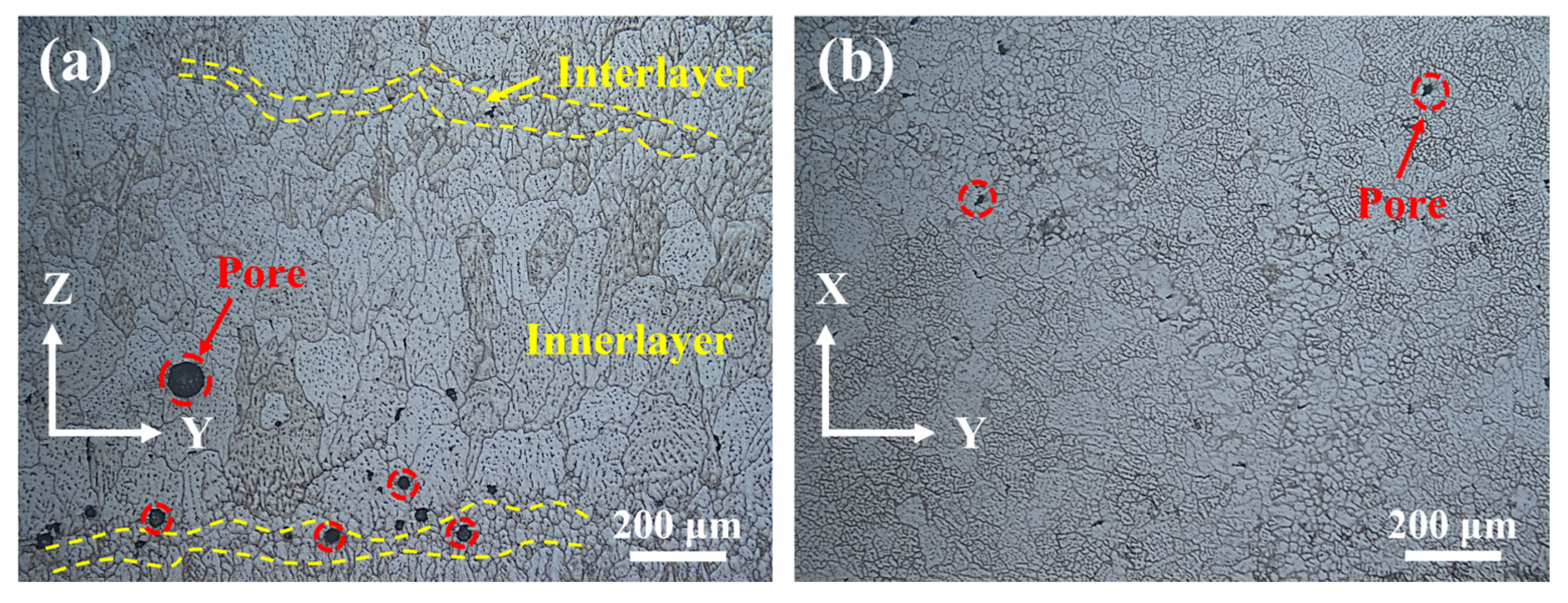

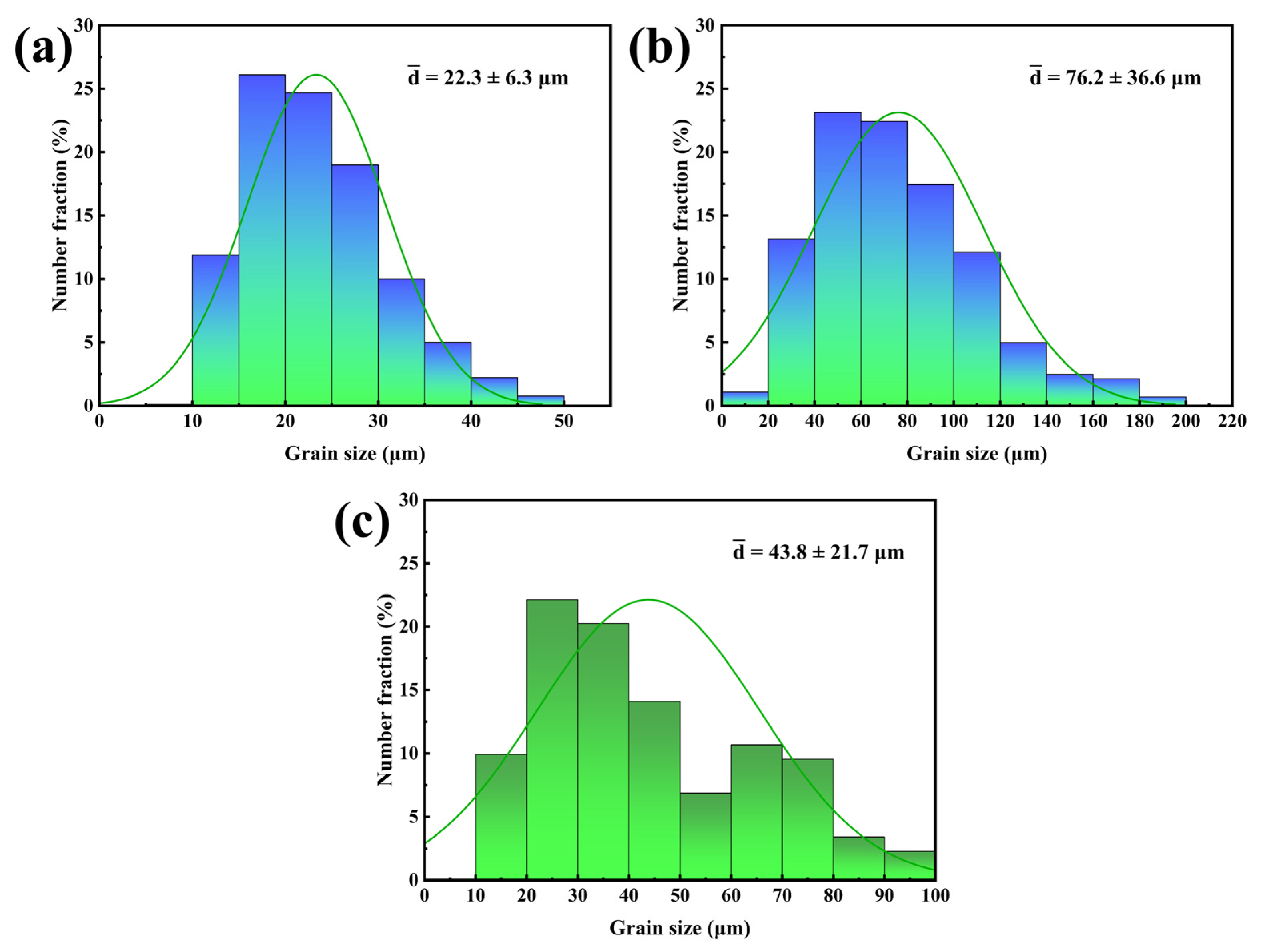

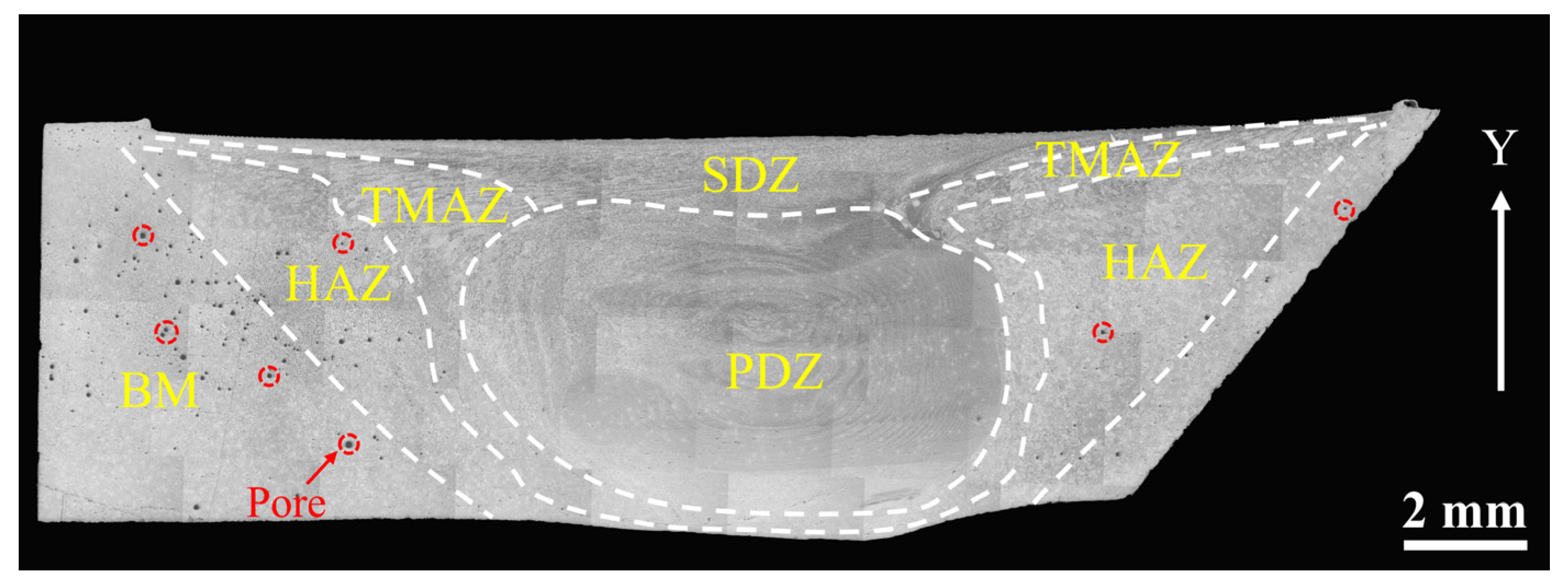

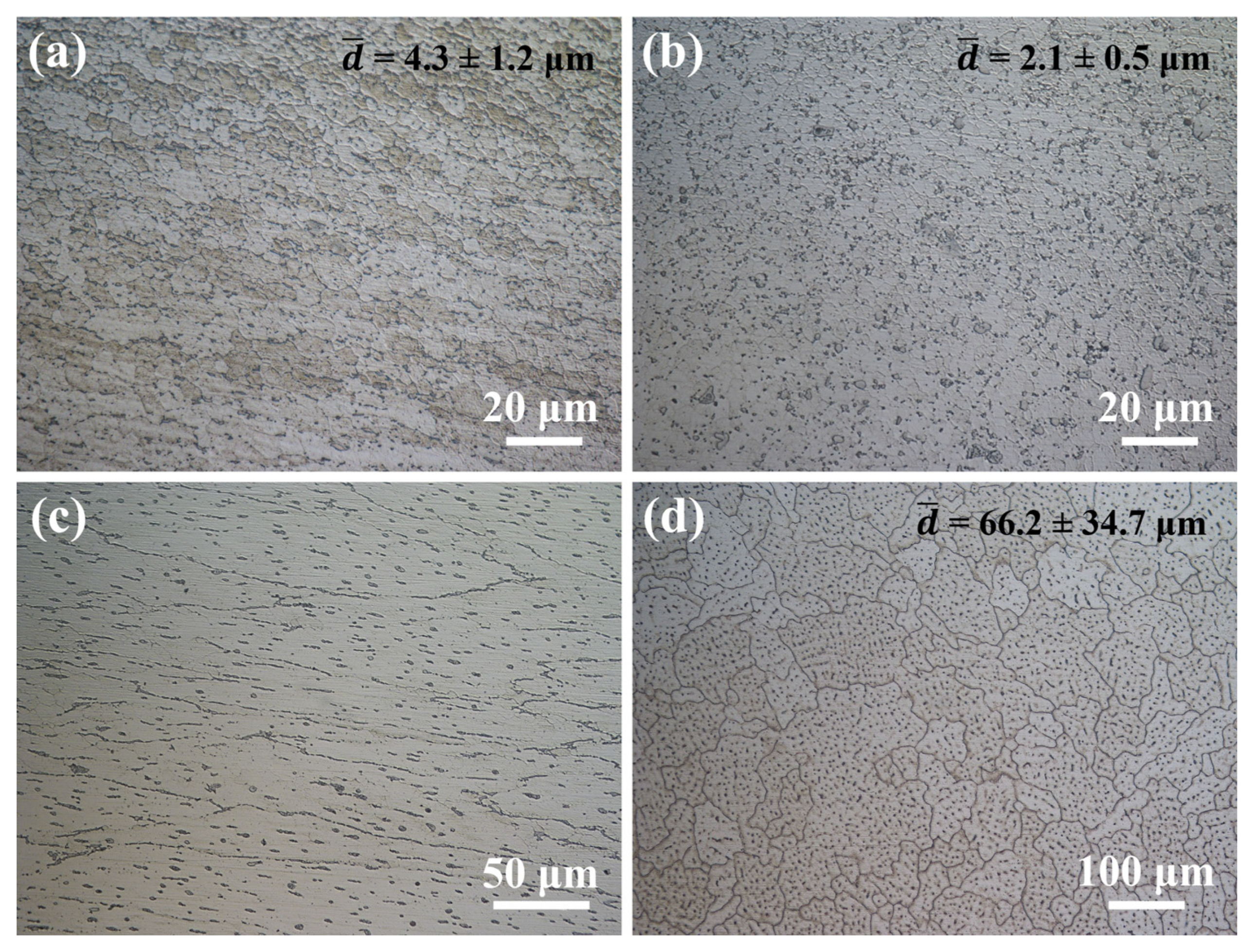

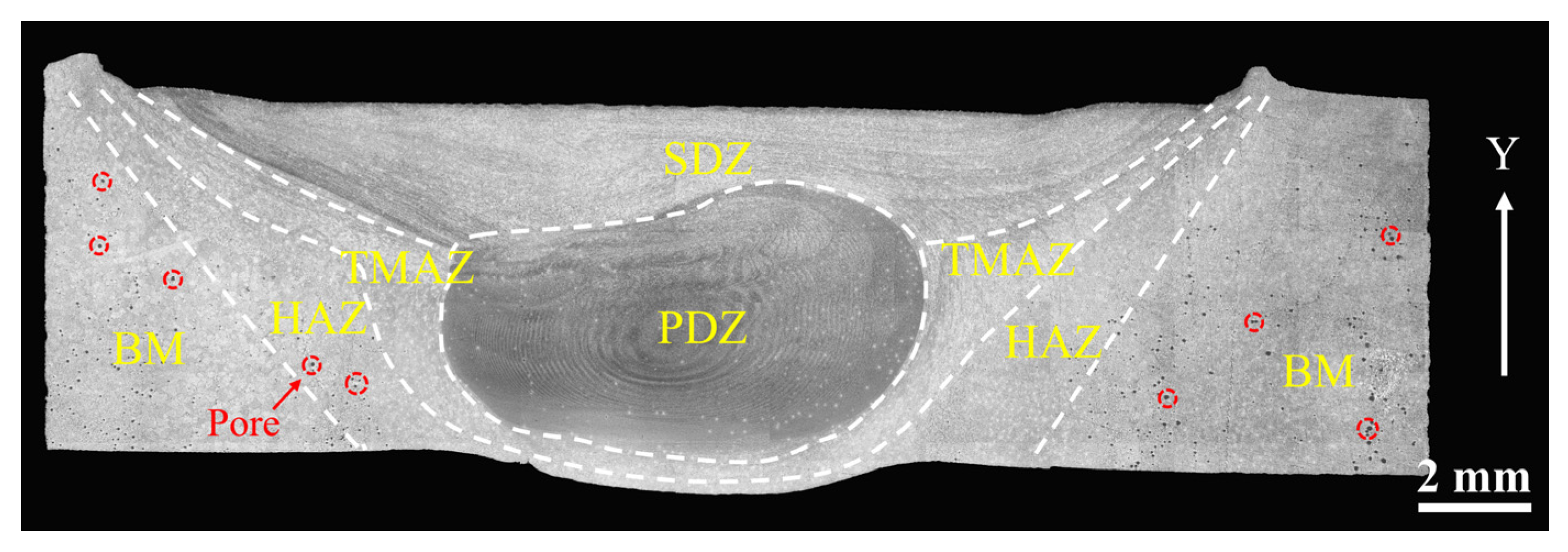

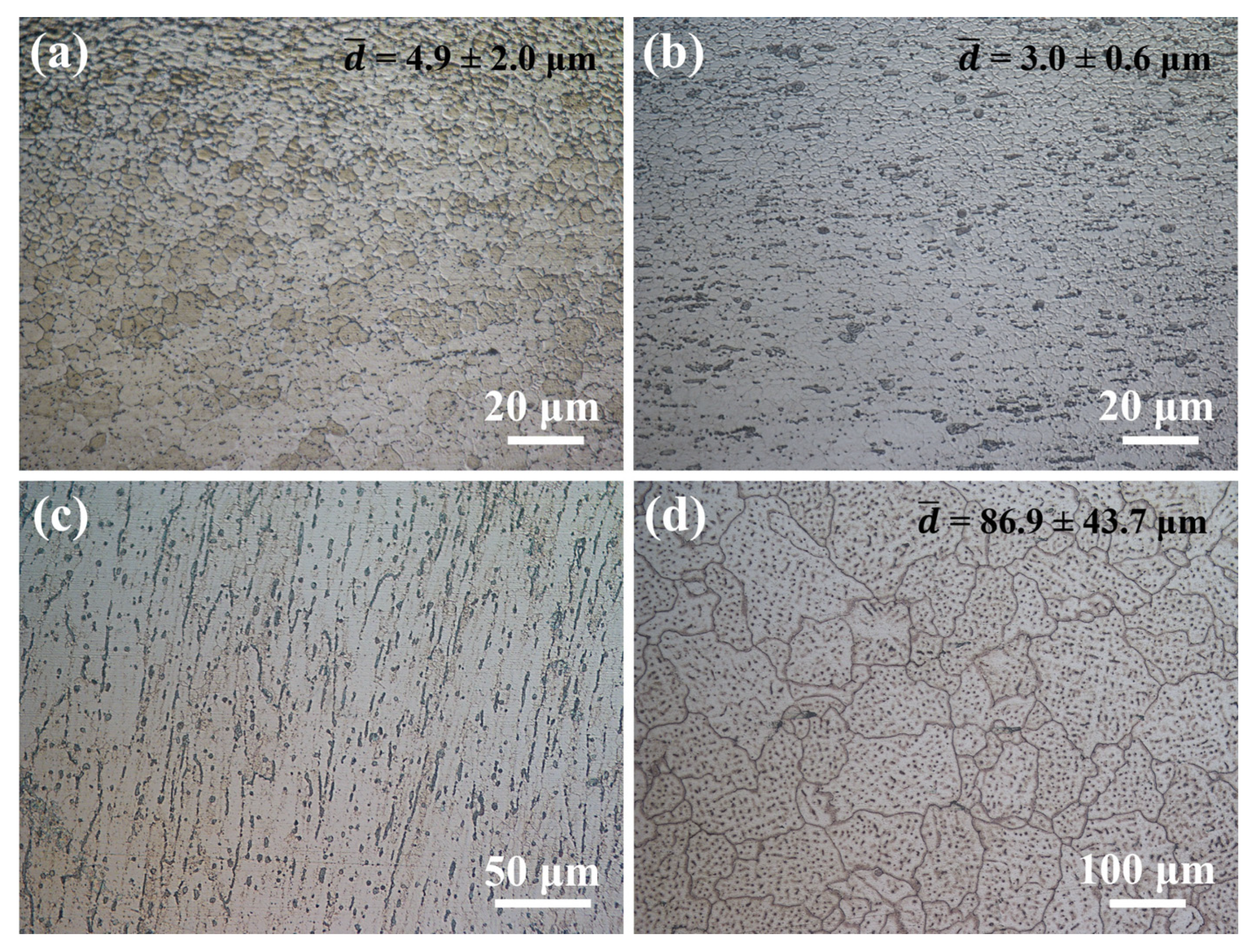

3.1. Macrostructure and Microstructure

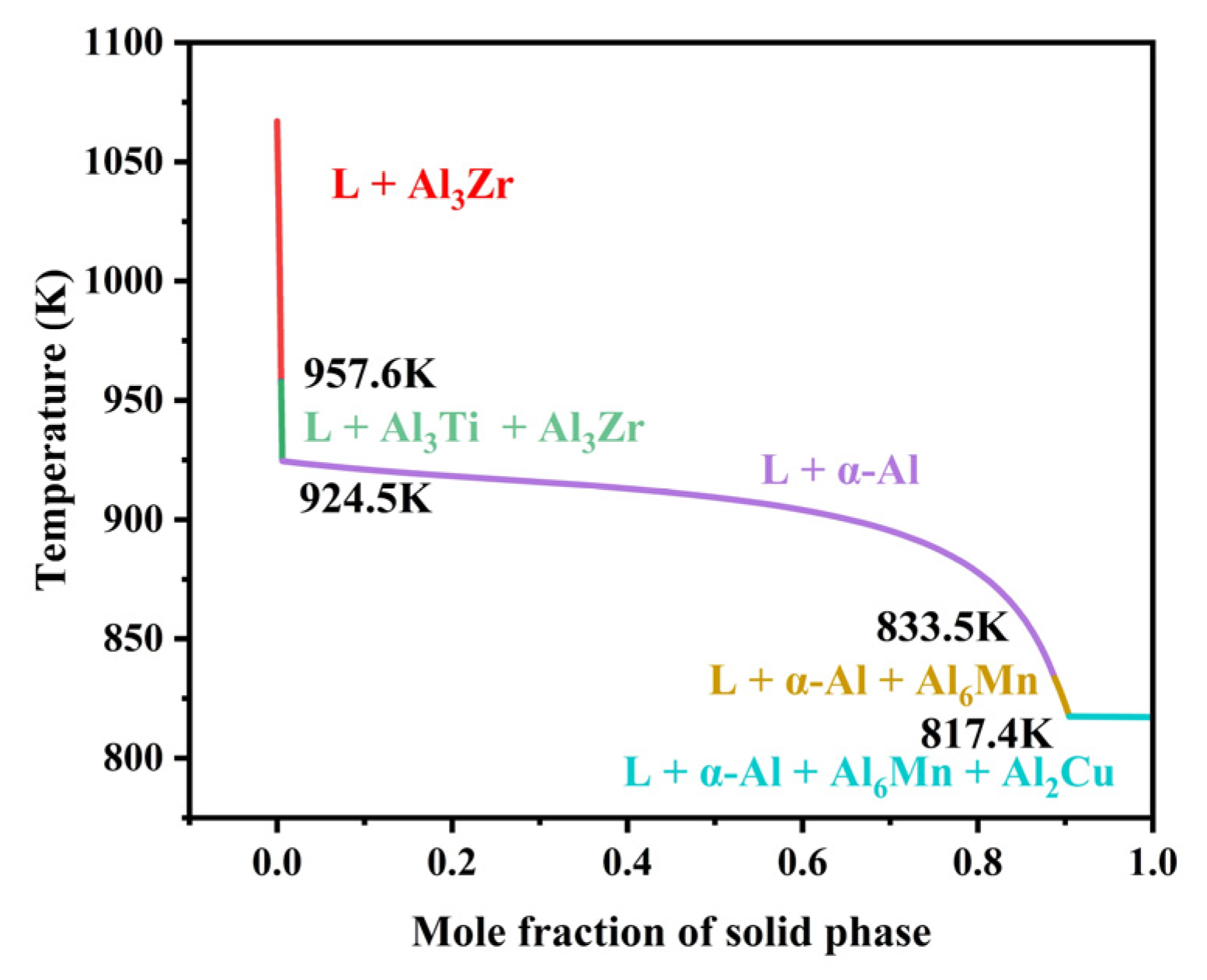

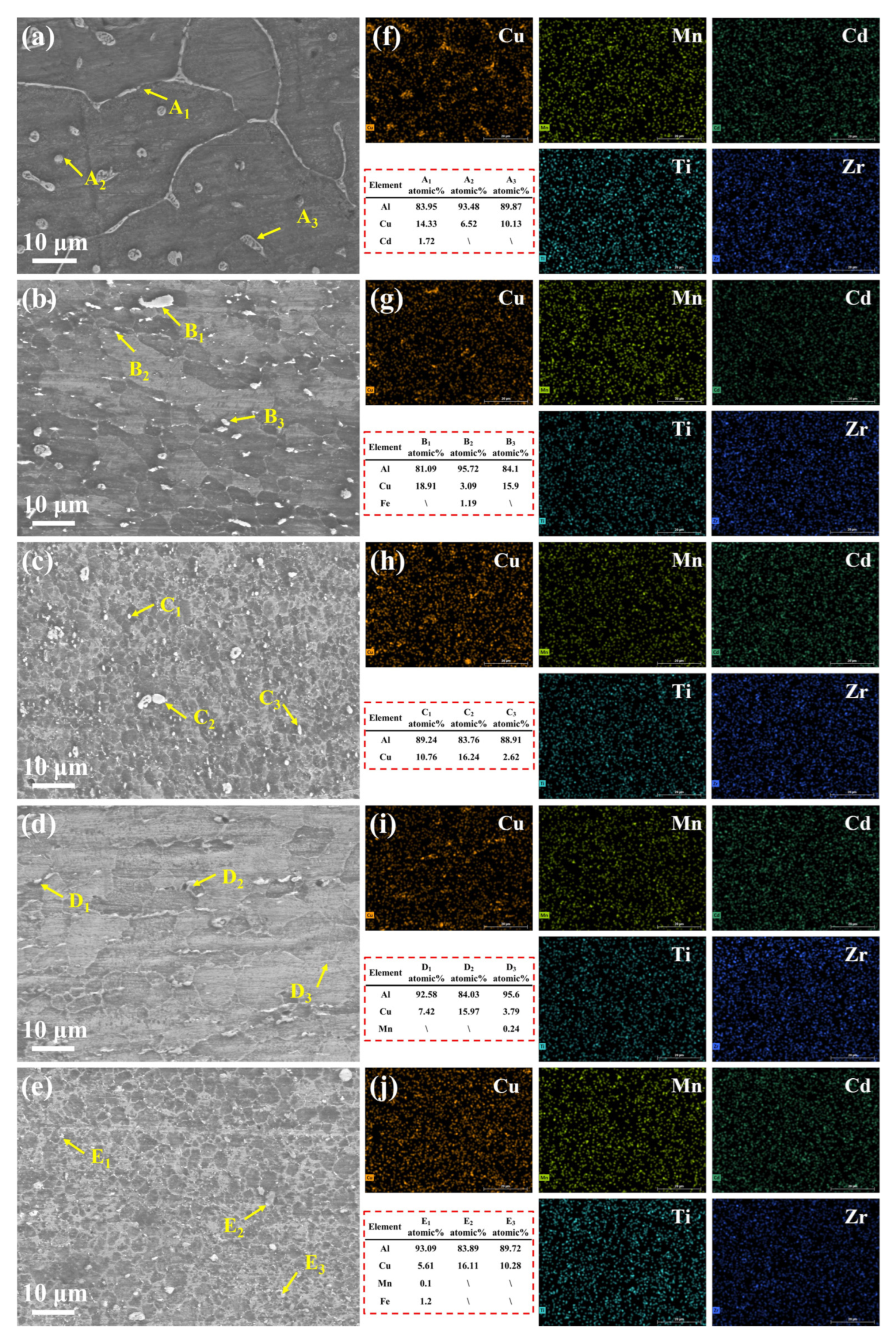

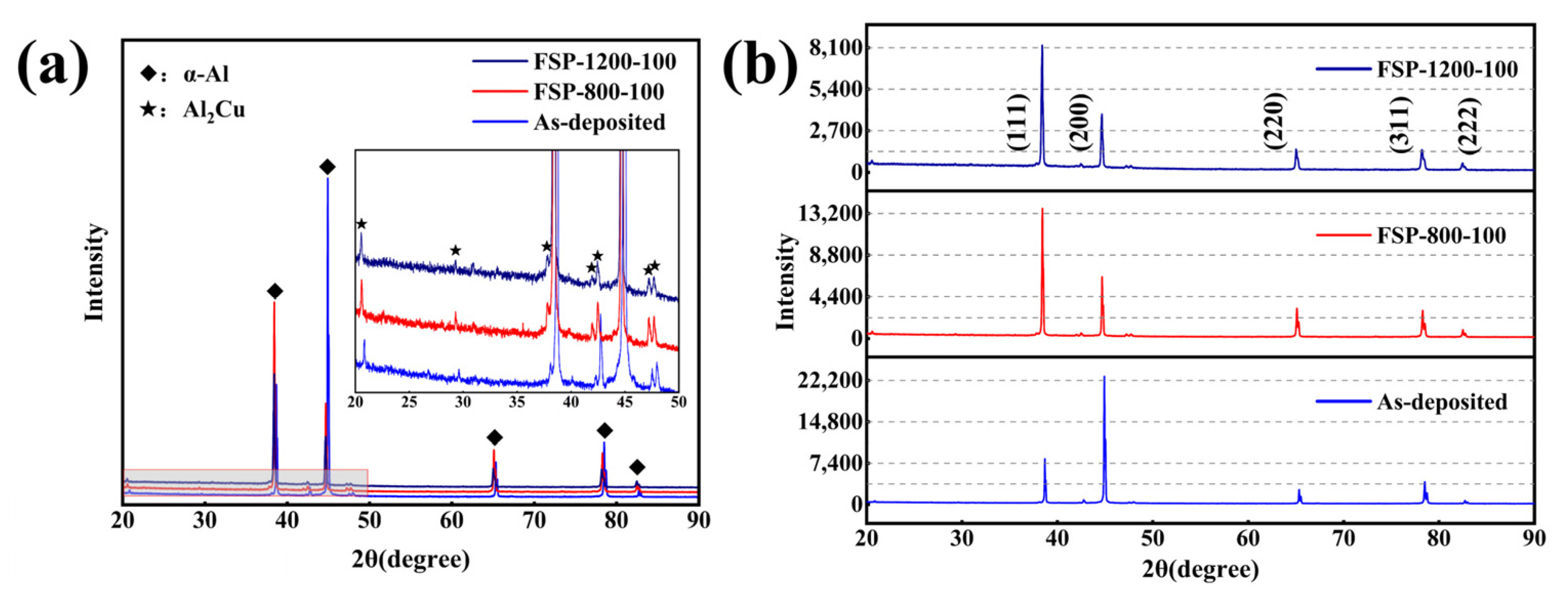

3.2. Second Phase

3.3. Mechanical Properties

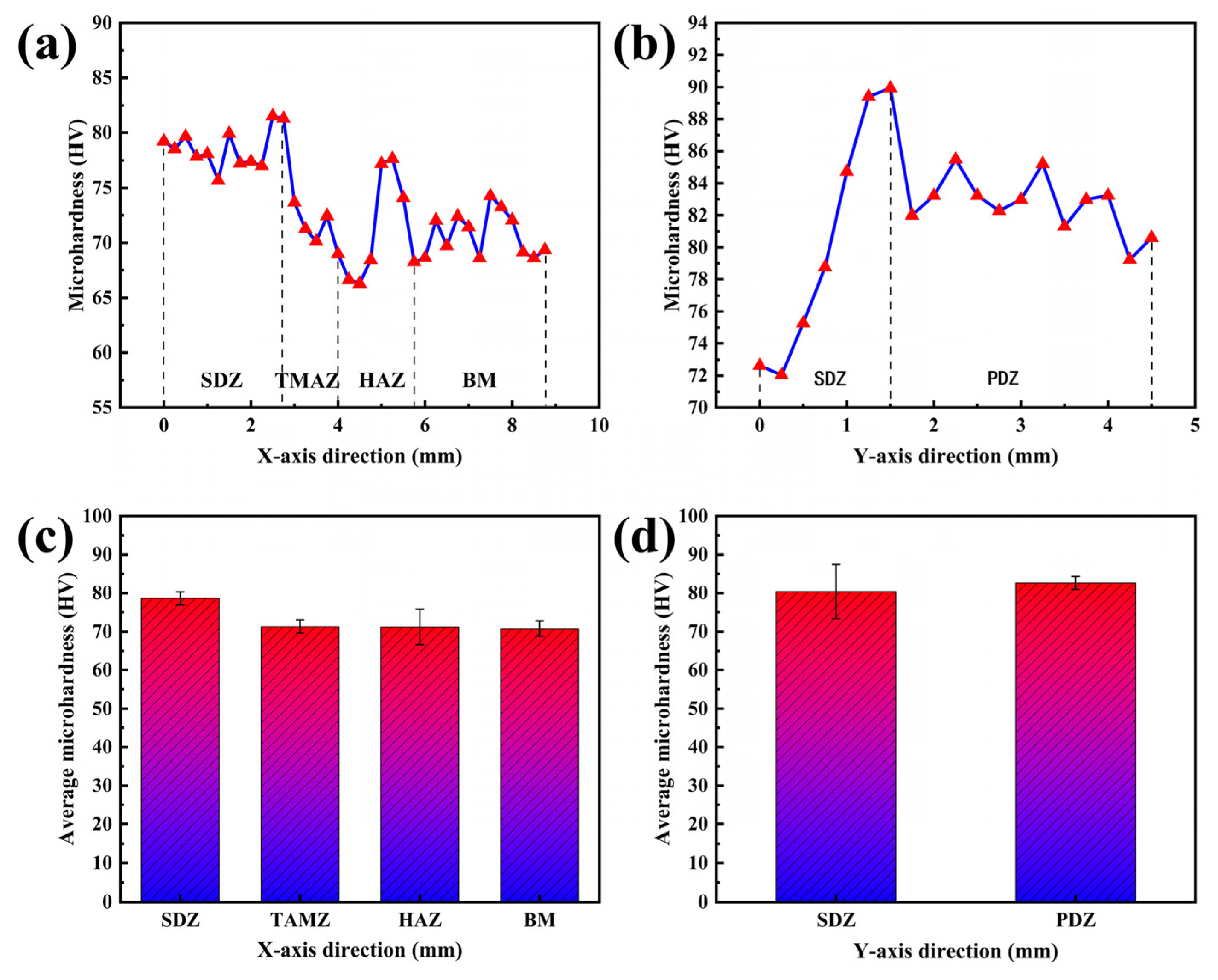

3.3.1. Microhardness

3.3.2. Tensile Properties

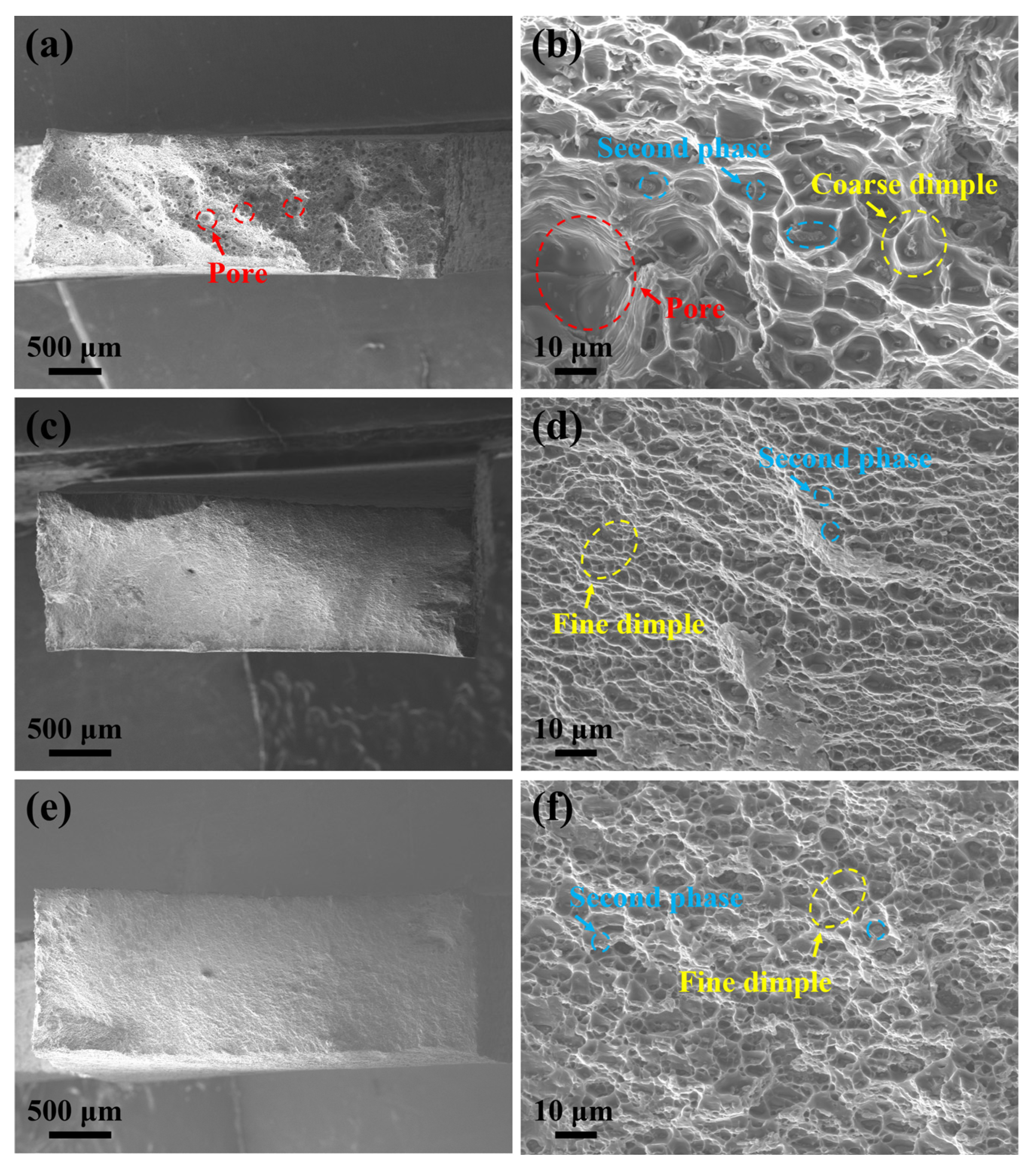

3.3.3. Fracture Analysis

4. Conclusions

- (1)

- The microstructure of the AD sample consists of coarse columnar grains and equiaxed grains, which exhibited a broad range of size distribution. This inhomogeneous microstructure reduces the mechanical properties of the component.

- (2)

- After FSP, the grain structure in the stirred zone transforms into fine recrystallized grains, and pore defects are effectively eliminated. Compared to a rotation speed of 800 min−1, a rotation speed of 1200 min−1 leads to more intense plastic deformation and a higher degree of dissolution of the second phase. However, the increased heat input associated with the higher rotation rate also leads to an increase in grain size.

- (3)

- The mechanical properties of the component were significantly enhanced after FSP post-treatment. The highest average microhardness values for the FSP-800-100 and FSP-1200 samples were recorded at 82.1 HV and 82.7 HV, respectively. The tensile strength for these samples reached 275 MPa and 280 MPa, representing an increase of over 21% compared to that of the AD samples. The elongation of FSP-800-100 and FSP-1200 samples is 22.1% and 21.0%, respectively, which is more than 50% higher than that of the AD sample. The slight difference in strength between the two processing speeds can be attributed to the conflict between the dissolution of the second phase and grain coarsening at a higher rotational rate.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [PubMed]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Tawfik, M.M.; Nemat-Alla, M.M.; Dewidar, M.M. Enhancing the properties of aluminum alloys fabricated using wire + arc additive manufacturing technique—A review. J. Mater. Res. Technol. 2021, 13, 754–768. [Google Scholar] [CrossRef]

- Wu, B.T.; Pan, Z.X.; Ding, D.H.; Cuiuri, D.; Li, H.J.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Fan, S.Y.; Guo, X.M.; Li, Z.H.; Ma, J.; Li, F.; Jiang, Q.W. A Review of High-Strength Aluminum-Copper Alloys Fabricated by Wire Arc Additive Manufacturing: Microstructure, Properties, Defects, and Post-processing. J. Mater. Eng. Perform. 2023, 32, 8517–8540. [Google Scholar] [CrossRef]

- Xue, C.P.; Zhang, Y.X.; Mao, P.C.; Liu, C.M.; Guo, Y.L.; Qian, F.; Zhang, C.; Liu, K.; Zhang, M.; Tang, S.Y.; et al. Improving mechanical properties of wire arc additively manufactured AA2196 Al–Li alloy by controlling solidification defects. Addit. Manuf. 2021, 43, 102019. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Lin, X.; Kang, N.; Wang, Z.N.; Tan, H.; Huang, W.D. Hot deformation induced microstructural evolution in local-heterogeneous wire + arc additive manufactured 2219 Al alloy. J. Alloys Compd. 2021, 865, 158949. [Google Scholar] [CrossRef]

- Fang, X.W.; Chen, G.P.; Yang, J.N.; Xie, Y.; Huang, K.; Lu, B.H. Wire and Arc Additive Manufacturing of High-Strength Al–Zn–Mg Aluminum Alloy. Front. Mater. 2021, 8, 656429. [Google Scholar] [CrossRef]

- Gierth, M.; Henckell, P.; Ali, Y.; Scholl, J.; Bergmann, J.P. Wire Arc Additive Manufacturing (WAAM) of Aluminum Alloy AlMg5Mn with Energy-Reduced Gas Metal Arc Welding (GMAW). Materials 2020, 13, 2671. [Google Scholar] [CrossRef]

- Cong, B.Q.; Cai, X.Y.; Qi, Z.W.; Qi, B.J.; Zhang, Y.T.; Zhang, R.Z.; Guo, W.; Zhou, Z.G.; Yin, Y.H.; Bu, X.Z. The effects of ultrasonic frequency pulsed arc on wire + arc additively manufactured high strength aluminum alloys. Addit. Manuf. 2022, 51, 102617. [Google Scholar] [CrossRef]

- Kuang, X.C.; Qi, B.; Zheng, H. Effect of pulse mode and frequency on microstructure and properties of 2219 aluminum alloy by ultrahigh-frequency pulse Metal-Inert Gas Welding. J. Mater. Res. Technol. 2022, 20, 3391–3407. [Google Scholar] [CrossRef]

- Zhao, X.S.; Wang, Y.X.; Song, H.; Huang, J.W.; Zhang, H.O.; Chen, X.; Huang, C.; Li, R.S. Effect of auxiliary longitudinal magnetic field on overlapping deposition of wire arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2023, 125, 1383–1401. [Google Scholar] [CrossRef]

- Hu, Y.N.; Chen, F.R.; Cao, S.L.; Fan, Y.F.; Xie, R.J. Preparation and characterization of CMT wire arc additive manufacturing Al-5%Mg alloy depositions through assisted longitudinal magnetic field. J. Manuf. Process. 2023, 101, 576–588. [Google Scholar] [CrossRef]

- Ma, C.; Li, C.; Yan, Y.; Liu, Y.; Wu, X.; Li, D.; Jin, H.; Zhang, F. Investigation of In Situ Vibration During Wire and Arc Additive Manufacturing. 3D Print Addit. Manuf. 2023, 10, 524–535. [Google Scholar] [CrossRef]

- Jin, P.; Liu, Y.B.; Li, F.X.; Li, J.Z.; Sun, Q.J. Realization of structural evolution in grain boundary, solute redistribution and improved mechanical properties by adding TiCnps in wire and arc additive manufacturing 2219 aluminium alloy. J. Mater. Res. Technol. 2021, 11, 834–848. [Google Scholar] [CrossRef]

- Li, K.; Yang, T.B.; Hou, X.R.; Ji, C.; Zhu, L.; Li, B.X.; Cao, Y.; Zhao, L.; Ma, C.Y.; Tian, Z.L. Microstructure evolution and mechanical properties of Al–Cu–Mn–Cd alloy fabricated by CMT-wire arc additive manufacturing. Mater. Sci. Eng. A 2024, 898, 146395. [Google Scholar] [CrossRef]

- Rakesh, M.; Srivastava, N.; Bhagavath, S.; Karagadde, S. Role of In Situ Formed (Al3Zr + Al3Ti) Particles on Nucleation of Primary Phase in Al-5 wt.% Cu Alloy. J. Mater. Eng. Perform. 2023, 33, 6488–6498. [Google Scholar] [CrossRef]

- Gu, J.L.; Wang, X.S.; Bai, J.; Ding, J.L.; Williams, S.; Zhai, Y.C.; Liu, K. Deformation microstructures and strengthening mechanisms for the wire+arc additively manufactured Al-Mg4.5Mn alloy with inter-layer rolling. Mater. Sci. Eng. A 2018, 712, 292–301. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Wang, J.Y.; Yang, G.; Wu, B.; Xie, H.; Wu, K.; An, D. Periodic microstructure of Al–Mg alloy fabricated by inter-layer hammering hybrid wire arc additive manufacturing: Formation mechanism, microstructural and mechanical characterization. Mater. Sci. Eng. A 2022, 860, 144314. [Google Scholar] [CrossRef]

- Wei, J.X.; He, C.S.; Qie, M.F.; Li, Y.; Zhao, Y.; Qin, G.W.; Zuo, L. Microstructure refinement and mechanical properties enhancement of wire-arc additive manufactured 2219 aluminum alloy assisted by interlayer friction stir processing. Vacuum 2022, 203, 111264. [Google Scholar] [CrossRef]

- Qie, M.F.; Wei, J.X.; He, C.S. Microstructure evolution and mechanical properties of wire-arc additive manufactured Al–Zn–Mg–Cu alloy assisted by interlayer friction stir processing. J. Mater. Res. Technol. 2023, 24, 2891–2906. [Google Scholar] [CrossRef]

- He, C.S.; Wei, J.X.; Li, Y.; Zhang, Z.Q.; Tian, N.; Qin, G.W.; Zuo, L. Improvement of microstructure and fatigue performance of wire-arc additive manufactured 4043 aluminum alloy assisted by interlayer friction stir processing. J. Mater. Sci. Technol. 2023, 133, 183–194. [Google Scholar] [CrossRef]

- Fang, X.W.; Zhang, L.J.; Chen, G.P.; Huang, K.; Xue, F.; Wang, L.; Zhao, J.Y.; Lu, B.H. Microstructure evolution of wire-arc additively manufactured 2319 aluminum alloy with interlayer hammering. Mater. Sci. Eng. A 2021, 800, 140168. [Google Scholar] [CrossRef]

- Chang, T.X.; Fang, X.W.; Liu, G.; Zhang, H.K.; Huang, K. Wire and arc additive manufacturing of dissimilar 2319 and 5B06 aluminum alloys. J. Mater. Sci. Technol. 2022, 124, 65–75. [Google Scholar] [CrossRef]

- Zhou, Y.; Chang, T.X.; Fang, X.W.; Chen, R.K.; Li, Y.F.; Huang, K. Tailoring the mechanical properties and thermal stability of additive manufactured micro-alloyed Al-Cu alloy via multi-stage heat treatment. Mater. Des. 2023, 233, 112287. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Wu, K.; Yang, G.; Wu, B.; Qin, L.Y.; Guo, X.P.; Wang, X.M. Friction stir welding of wire arc additively manufactured 205A aluminum alloy: Microstructure and mechanical properties. Mater. Sci. Eng. A 2023, 876, 145154. [Google Scholar] [CrossRef]

- Santos Macías, J.G.; Elangeswaran, C.; Zhao, L.; Van Hooreweder, B.; Adrien, J.; Maire, E.; Buffière, J.-Y.; Ludwig, W.; Jacques, P.J.; Simar, A. Ductilisation and fatigue life enhancement of selective laser melted AlSi10Mg by friction stir processing. Scr. Mater. 2019, 170, 124–128. [Google Scholar] [CrossRef]

- Deng, Q.C.; Wu, Y.J.; Su, N.; Chang, Z.Y.; Chen, J.; Peng, L.M.; Ding, W.J. Influence of friction stir processing and aging heat treatment on microstructure and mechanical properties of selective laser melted Mg-Gd-Zr alloy. Addit. Manuf. 2021, 44, 102036. [Google Scholar] [CrossRef]

- Cui, J.Y.; Guo, X.P.; Hao, S.; Guo, X.M.; Xu, R.Z. Achieving high strength-ductility properties of wire-arc additive manufactured Al-Mg-Sc aluminum alloy via friction stir processing post-treatment and high temperature aging treatment. Mater. Lett. 2023, 350, 134913. [Google Scholar] [CrossRef]

- He, P.; Bai, X.W.; Zhang, H.O. Microstructure refinement and mechanical properties enhancement of wire and arc additively manufactured 6061 aluminum alloy using friction stir processing post-treatment. Mater. Lett. 2023, 330, 133365. [Google Scholar] [CrossRef]

- Yu, L.; Wang, L.; Zhao, Y.; Wang, W.Y. Fabrication of corrosion-resistant ZL205A aluminum alloys thin-wall using WAAM: Exploring the synergistic effects of FSP and multidimensional nanomaterials. J. Alloys Compd. 2025, 1016, 178987. [Google Scholar] [CrossRef]

- Fan, S.Y.; Guo, X.P.; Tang, Y.; Guo, X.M. Microstructure and Mechanical Properties of Al-Cu-Mg Alloy Fabricated by Double-Wire CMT Arc Additive Manufacturing. Metals 2022, 12, 416. [Google Scholar] [CrossRef]

- Advanced Engineering MaterialsFan, S.Y.; Guo, X.M.; Jiang, Q.W.; Li, Z.H.; Ma, J. Microstructure Evolution and Mechanical Properties of Ti and Zr Micro-Alloyed Al-Cu Alloy Fabricated by Wire + Arc Additive Manufacturing. JOM 2023, 75, 4115–4127. [Google Scholar] [CrossRef]

- Ryan, E.M.; Sabin, T.J.; Watts, J.F.; Whiting, M.J. The influence of build parameters and wire batch on porosity of wire and arc additive manufactured aluminium alloy 2319. J. Mater. Process. Technol. 2018, 262, 577–584. [Google Scholar] [CrossRef]

- Toda, H.; Hidaka, T.; Kobayashi, M.; Uesugi, K.; Takeuchi, A.; Horikawa, K. Growth behavior of hydrogen micropores in aluminum alloys during high-temperature exposure. Acta. Mater. 2009, 57, 2277–2290. [Google Scholar] [CrossRef]

- Yu, P.F.; Wu, C.S.; Shi, L. Analysis and characterization of dynamic recrystallization and grain structure evolution in friction stir welding of aluminum plates. Acta. Mater. 2021, 207, 116692. [Google Scholar] [CrossRef]

- Khan Md, F.; Panigrahi, S.K. Achieving excellent thermal stability and very high activation energy in an ultrafine-grained magnesium silver rare earth alloy prepared by friction stir processing. Mater. Sci. Eng. A 2016, 675, 338–344. [Google Scholar] [CrossRef]

- Singh, A.; Sharma, S.K.; Batish, A. Dynamic recrystallization during solid state friction stir welding/processing/additive manufacturing: Mechanisms, microstructure evolution, characterization, modeling techniques and challenges. Crit. Rev. Solid State Mater. Sci. 2025, 50, 77–135. [Google Scholar] [CrossRef]

- Liu, X.C.; Ye, T.; Li, Y.Z.; Pei, X.J.; Sun, Z. Quasi-in-situ characterization of microstructure evolution in friction stir welding of aluminum alloy. J. Mater. Res. Technol. 2023, 25, 6380–6394. [Google Scholar] [CrossRef]

- Jata, K.V.; Semiatin, S.L. Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys. Scr. Mater. 2000, 43, 743–749. [Google Scholar] [CrossRef]

- Meng, X.C.; Huang, Y.X.; Cao, J.; Shen, J.J.; dos Santos, J.F. Recent progress on control strategies for inherent issues in friction stir welding. Prog. Mater. Sci. 2021, 115, 100706. [Google Scholar] [CrossRef]

- Šebek, F.; Kubík, P.; Hůlka, J.; Petruška, J. Strain hardening exponent role in phenomenological ductile fracture criteria. Eur. J. Mech. A-Solids 2016, 57, 149–164. [Google Scholar] [CrossRef]

- Jiang, H.F.; Zhang, Q.C.; Chen, X.D.; Chen, Z.J.; Jiang, Z.Y.; Wu, X.P.; Fan, J.H. Three types of Portevin–Le Chatelier effects: Experiment and modelling. Acta Mater. 2007, 55, 2219–2228. [Google Scholar] [CrossRef]

- Liu, X.D.; Ye, L.Y.; Tang, J.G.; Ke, B.; Dong, Y.; Chen, X.J.; Gu, Y. Superplastic deformation mechanisms of a fine-grained Al–Cu–Li alloy. Mater. Sci. Eng. A 2022, 848, 143403. [Google Scholar] [CrossRef]

- Gu, J.L.; Yang, S.L.; Gao, M.J.; Bai, J.; Zhai, Y.C.; Ding, J.L. Micropore evolution in additively manufactured aluminum alloys under heat treatment and inter-layer rolling. Mater. Des. 2020, 186, 108288. [Google Scholar] [CrossRef]

- Fang, J.X.; Zhu, Z.Y.; Zhang, X.Q.; Xie, L.L.; Huang, Z.Y. Tensile Deformation and Fracture Behavior of AA5052 Aluminum Alloy under Different Strain Rates. J. Mater. Eng. Perform. 2021, 30, 9403–9411. [Google Scholar] [CrossRef]

- Li, L.; Du, F.S. Effects of Sinusoidal Vibration of Crystallization Roller on Microstructure and Mechanical Properties of Ti/Al Laminated Composites by Twin-Roll Casting. Trans. Indian Inst. Met. 2023, 76, 2073–2083. [Google Scholar] [CrossRef]

- Mo, S.; Zhang, Y.C.; Liu, Y.H.; Liu, W.B.; Zhou, Y.S.; Zhang, J.L.; Zhang, W. Nonlinear vibration and super-harmonic resonance analysis of aluminum alloy friction stir welding. Nonlinear Dyn. 2024, 112, 11013–11041. [Google Scholar] [CrossRef]

- Choi, S.; Shim, D.; Kim, H. Reduction of Defects by Friction Stir Processing for Additively Manufactured Cast Aluminum Alloys (AlSiMg). Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 11, 1193–1205. [Google Scholar] [CrossRef]

| Alloys | Al | Cu | Mn | Mg | Si | Cd | Zr | Ti | V | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Wire | Bal. | 5.2 | 0.43 | 0.05 | 0.06 | 0.18 | 0.19 | 0.21 | 0.11 | 0.15 |

| Component | Bal. | 4.8 | 0.41 | 0.01 | 0.04 | 0.07 | 0.16 | 0.18 | 0.08 | 0.11 |

| Substrate | Bal. | 0.23 | - | 0.87 | 0.75 | - | - | 0.15 | - | 0.43 |

| Deposition Parameters | Values |

|---|---|

| I (A) | 97 |

| U (V) | 16.9 |

| Wire feeding speed (m/min) | 4.9 |

| Travel speed (mm/min) | 320 |

| Mode | Cold Metal Transfer + Pulse (CMT + P) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Fan, S.; Gong, Y.; Jiang, Q.; Li, F. Influence of Friction Stir Processing Post-Treatment on the Microstructure and Mechanical Properties of 205A Aluminum Alloy Produced by Wire Arc-Directed Energy Deposition. Metals 2025, 15, 331. https://doi.org/10.3390/met15030331

Ma J, Fan S, Gong Y, Jiang Q, Li F. Influence of Friction Stir Processing Post-Treatment on the Microstructure and Mechanical Properties of 205A Aluminum Alloy Produced by Wire Arc-Directed Energy Deposition. Metals. 2025; 15(3):331. https://doi.org/10.3390/met15030331

Chicago/Turabian StyleMa, Jing, Siyue Fan, Yuqi Gong, Qingwei Jiang, and Fei Li. 2025. "Influence of Friction Stir Processing Post-Treatment on the Microstructure and Mechanical Properties of 205A Aluminum Alloy Produced by Wire Arc-Directed Energy Deposition" Metals 15, no. 3: 331. https://doi.org/10.3390/met15030331

APA StyleMa, J., Fan, S., Gong, Y., Jiang, Q., & Li, F. (2025). Influence of Friction Stir Processing Post-Treatment on the Microstructure and Mechanical Properties of 205A Aluminum Alloy Produced by Wire Arc-Directed Energy Deposition. Metals, 15(3), 331. https://doi.org/10.3390/met15030331