Research and Development Progress of Laser–Arc Hybrid Welding: A Review

Abstract

1. Introduction

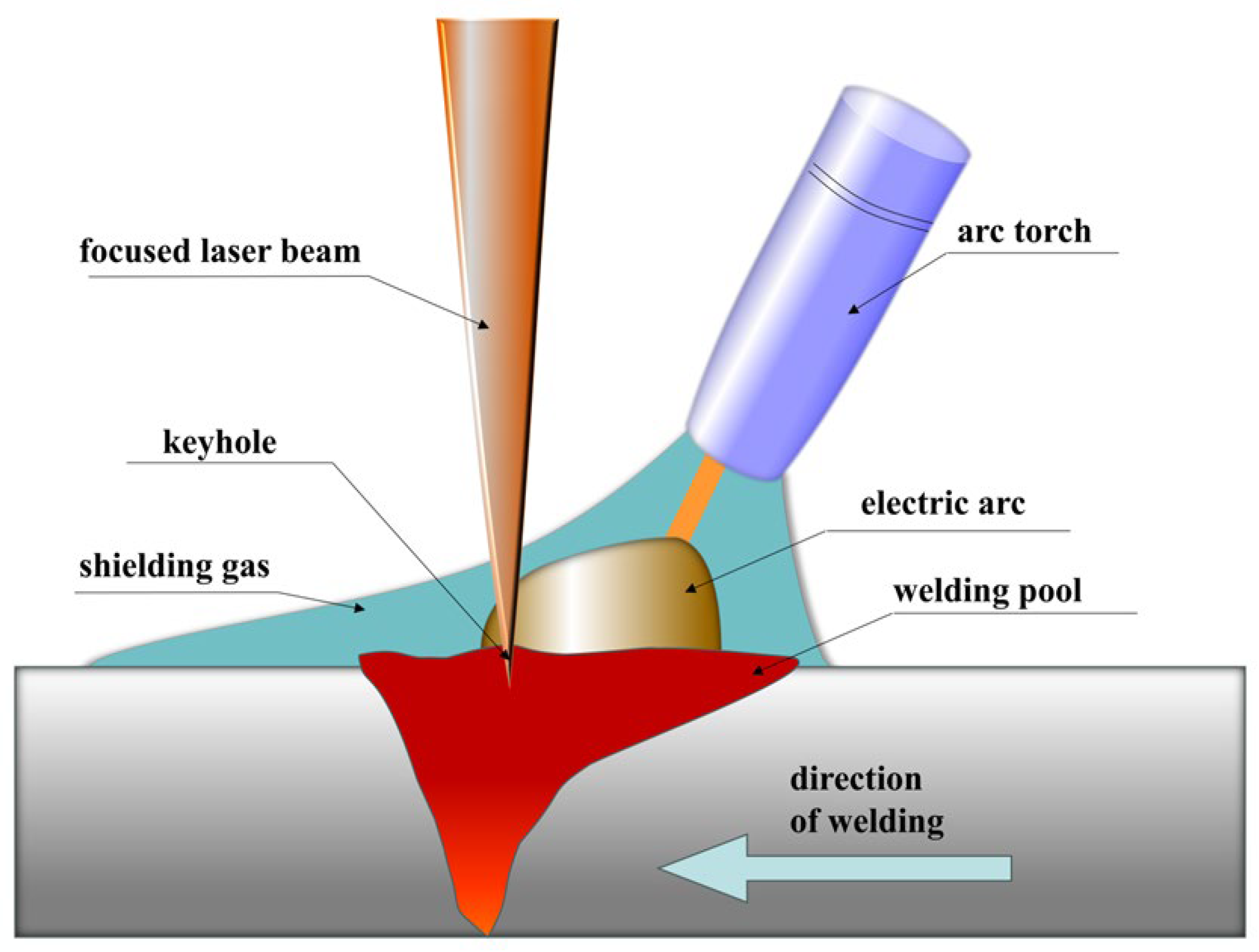

2. Laser–Arc Hybrid Welding Technology

| Hybrid Welding Process | Advantages | Key Findings | Ref. |

|---|---|---|---|

| Laser–MIG | The laser can be used for deep penetration welding and to enhance the welding speed, while MIG improves the arc stability, making it suitable for welding thicker materials. | Laser–MIG welded joints exhibit excellent tensile properties, with a yield strength of 326 MPa, an ultimate tensile strength of 634 MPa, and a joint efficiency of 101%, outperforming traditional welding methods. | [44] |

| Laser–MAG | The laser ensures deep penetration, while MAG enhances the weld strength and reduces the size of the HAZ, making it suitable for welding materials of various thicknesses. | The fusion zone (FZ) exhibits a good microstructure, which enhances mechanical properties. Additionally, the joint’s tensile strength is excellent (92.5% of the base material’s strength), and its toughness is also favorable. | [45] |

| Laser–TIG | The laser increases the welding speed and provides deep penetration welding, while TIG enhances the welding precision, making it ideal for welding thin plates and high-precision components. | Compared to traditional TIG welding, laser-induced TIG hybrid welding for aluminum alloys significantly reduces the heat input, which helps to form a finer equiaxed grain structure in the FZ relative to the base material (BM). | [46] |

| Laser–PAW | PAW ensures thermal penetration and allows the control of the heat input, while the laser increases the welding speed and precision. This combination enables the welding of thicker materials. | In coaxial hybrid welding, the combination of the plasma arc and laser reduces the side-cutting defects commonly seen in pure laser welding. Even at higher welding speeds, this improves weld formation and enhances gap-bridging capability. | [47] |

| Laser–SAW | SAW facilitates rapid deposition, with the laser providing deep penetration welding, enabling efficient welding and a smaller HAZ. | This process ensures that the tensile strengths of all the samples reach that of the base material (Rm = 762 MPa) while also preventing performance degradation because of excessive grain size. | [48] |

2.1. Hybrid Laser–TIG Process

2.2. Hybrid Laser–MIG/MAG Process

2.3. Hybrid Laser–PAW Process

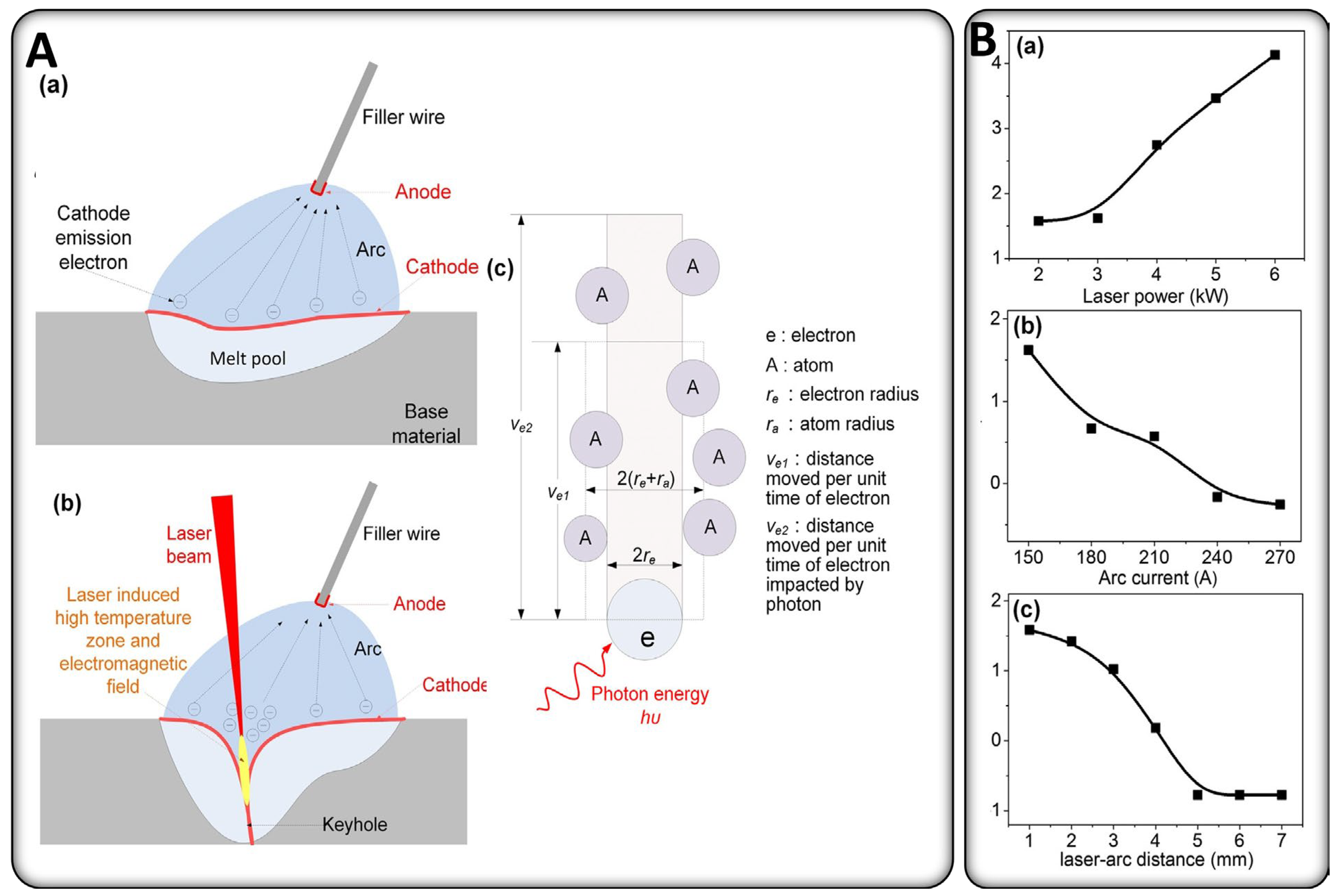

3. The Principle of the Laser–Arc Interaction

| Materials and Methods | Models | Parameter Explanation | Discussion | Ref. |

|---|---|---|---|---|

| CO2 Laser–MIG hybrid welding mild steel plates | E1 is the melting energy in LAHW E2 is the melting energy in LW E3 is the melting energy in AW | This model simplifies the complex interaction between the laser and the arc; however, the assumption of a linear relationship for the energy variation has limited applicability, as it does not account for the influences of welding parameters and material properties on the melting energy. | [88] | |

| Fiber laser–MIG hybrid welding AA6082-T6 Al alloy plates | PH is the weld penetration in LAHW PL is the weld penetration in LW PA is the weld penetration in AW | This formula assumes a linear relationship and ignores nonlinear effects and other factors, like the welding speed and material properties, limiting its applicability. | [86] | |

| Fiber laser–MIG hybrid welding AA6082-T6 Al alloy plates | AH is the cross-sectional area of the weld in LAHW AL is the cross-sectional area of the weld in LW AA is the cross-sectional area of the weld in AW | This formula assumes linearity and overlooks complex interactions between the laser and arc, limiting its broader applicability under varying welding conditions. | [86] | |

| Laser–MIG hybrid welding | IH is the statistical average current in LAHW I0 is the statistical average current in AW | This formula assumes a linear relationship and overlooks other factors, like the plasma behavior and arc stability, which may limit its accuracy and applicability. | [89] |

4. Hybrid-Welding-Process Analysis and Quality Assessment

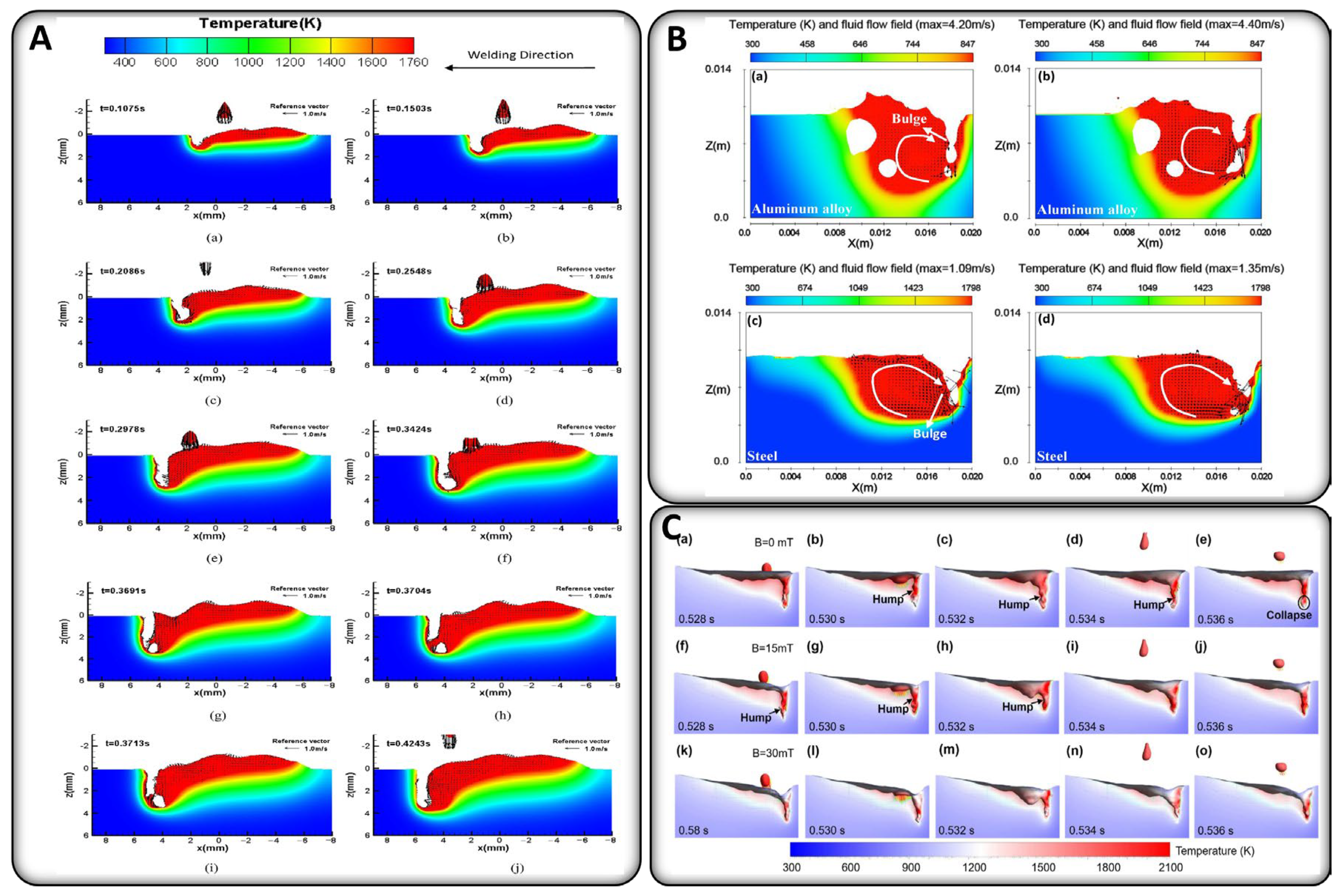

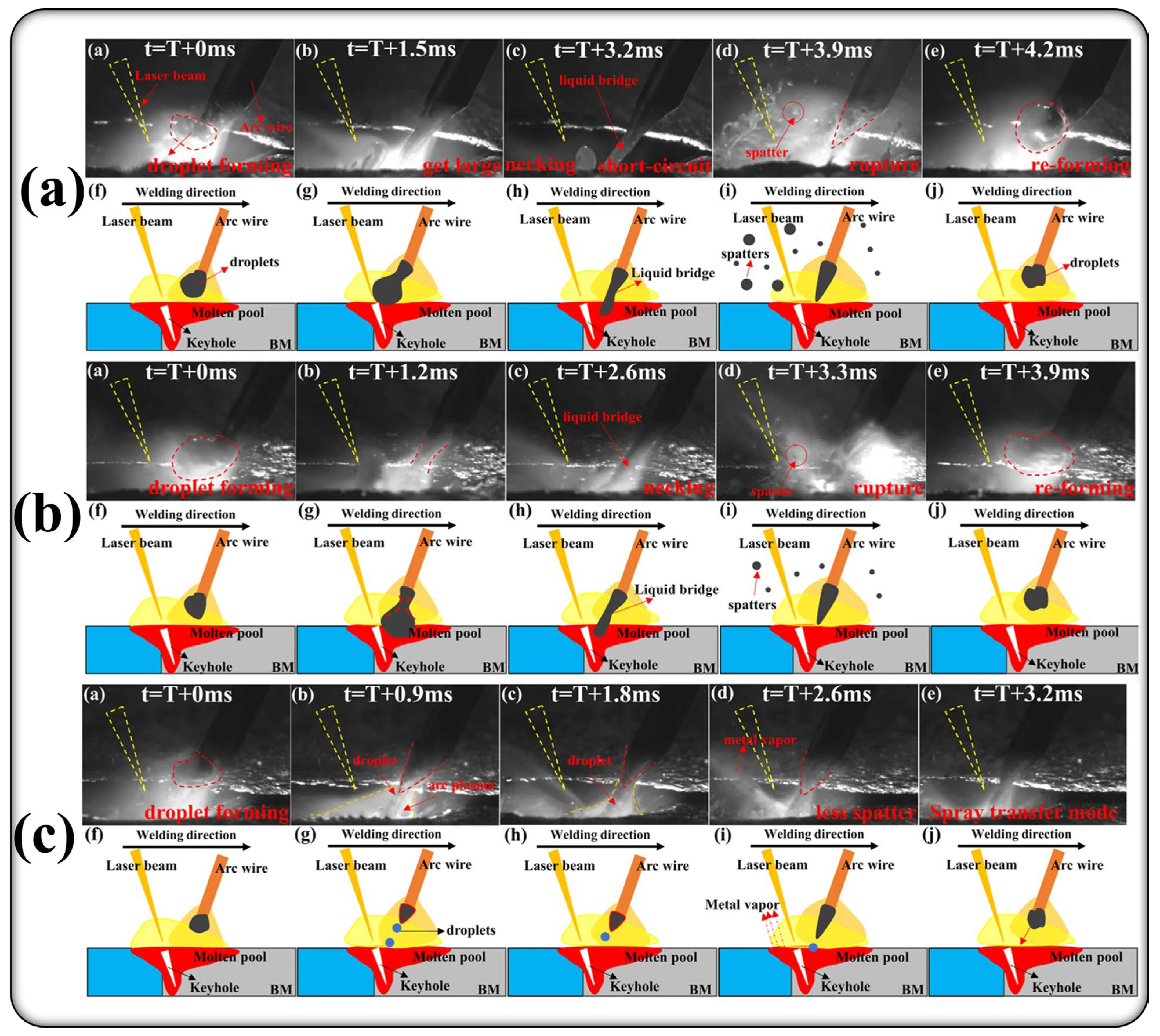

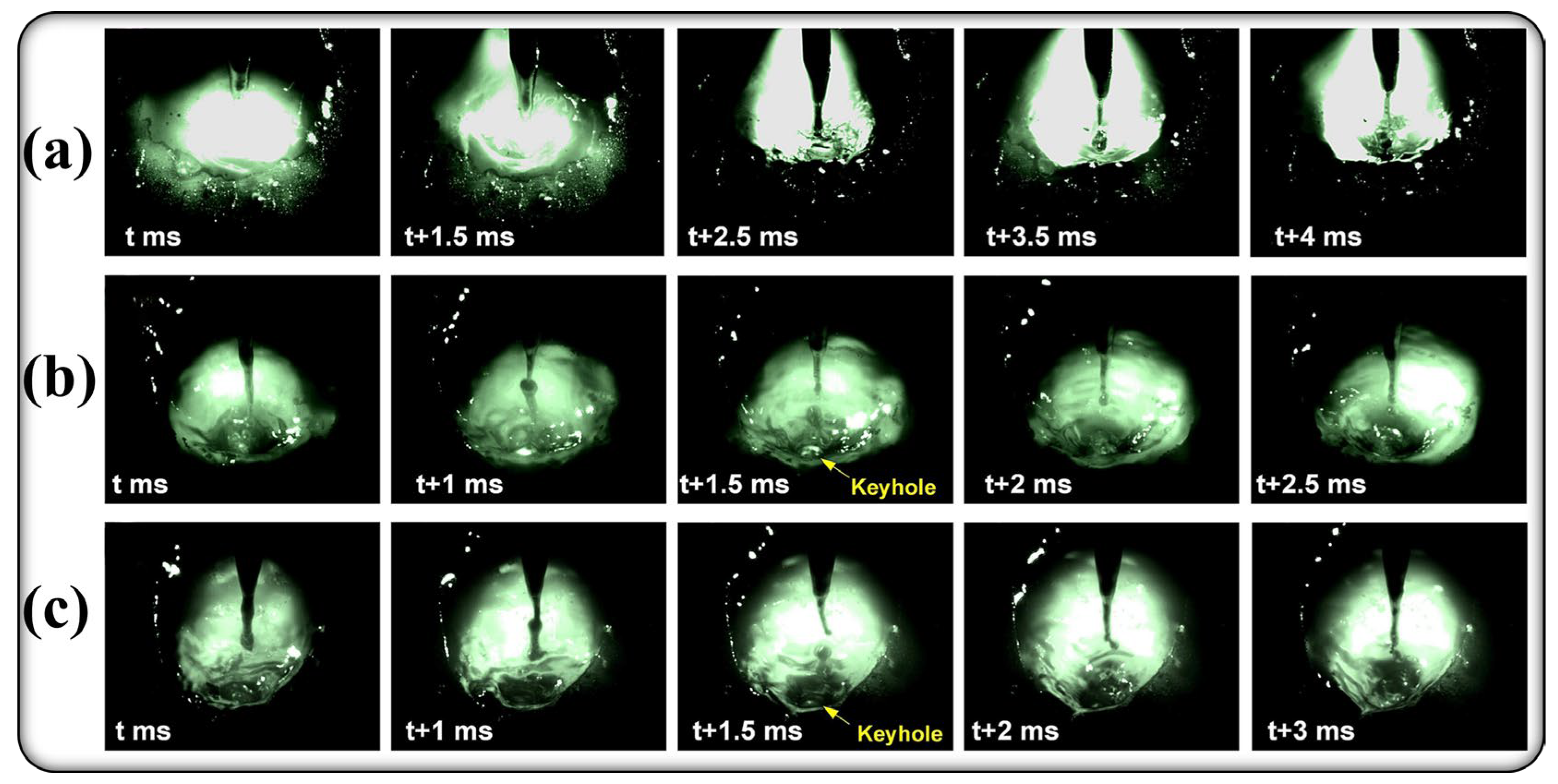

4.1. Keyhole Behavior

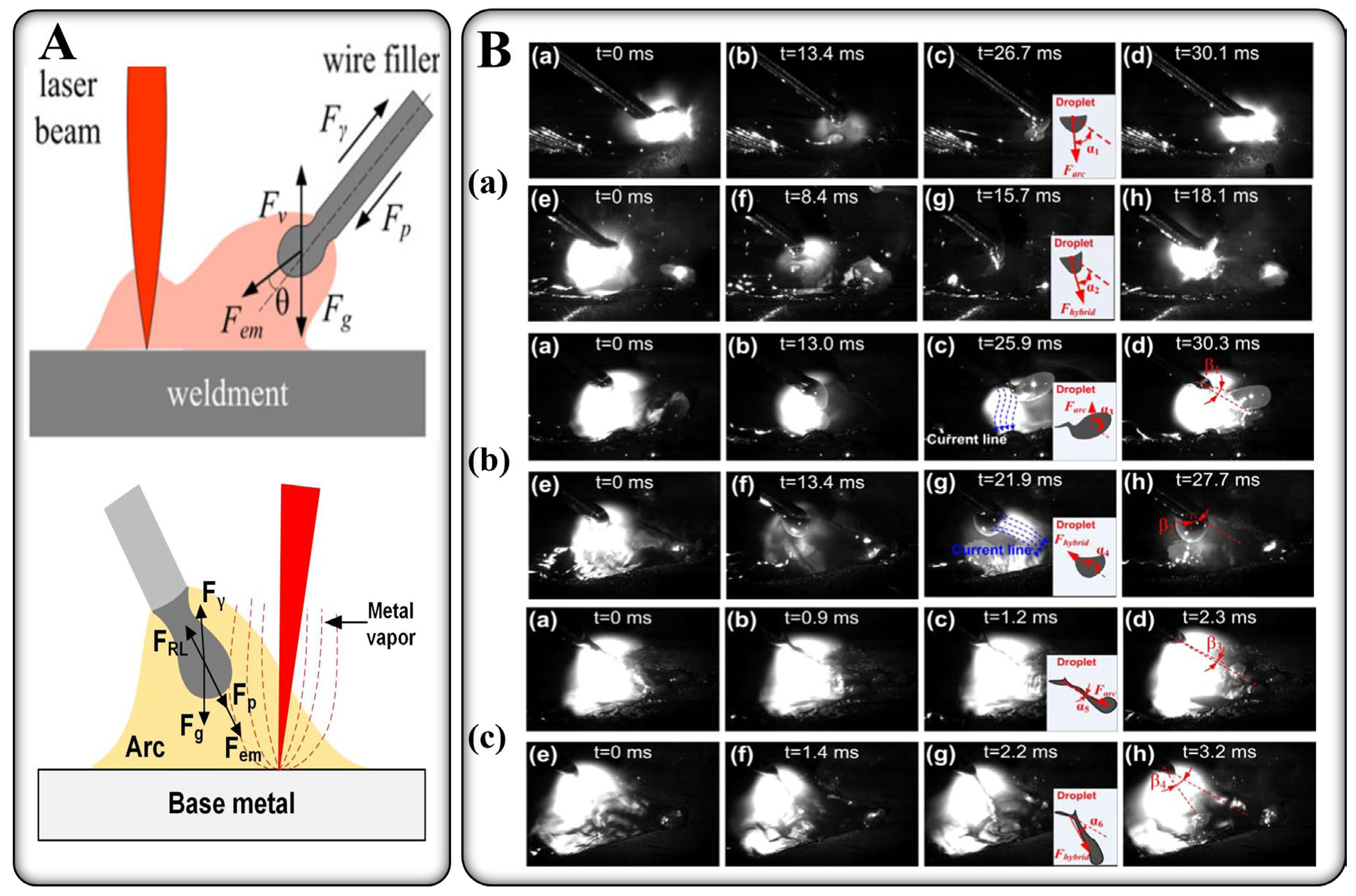

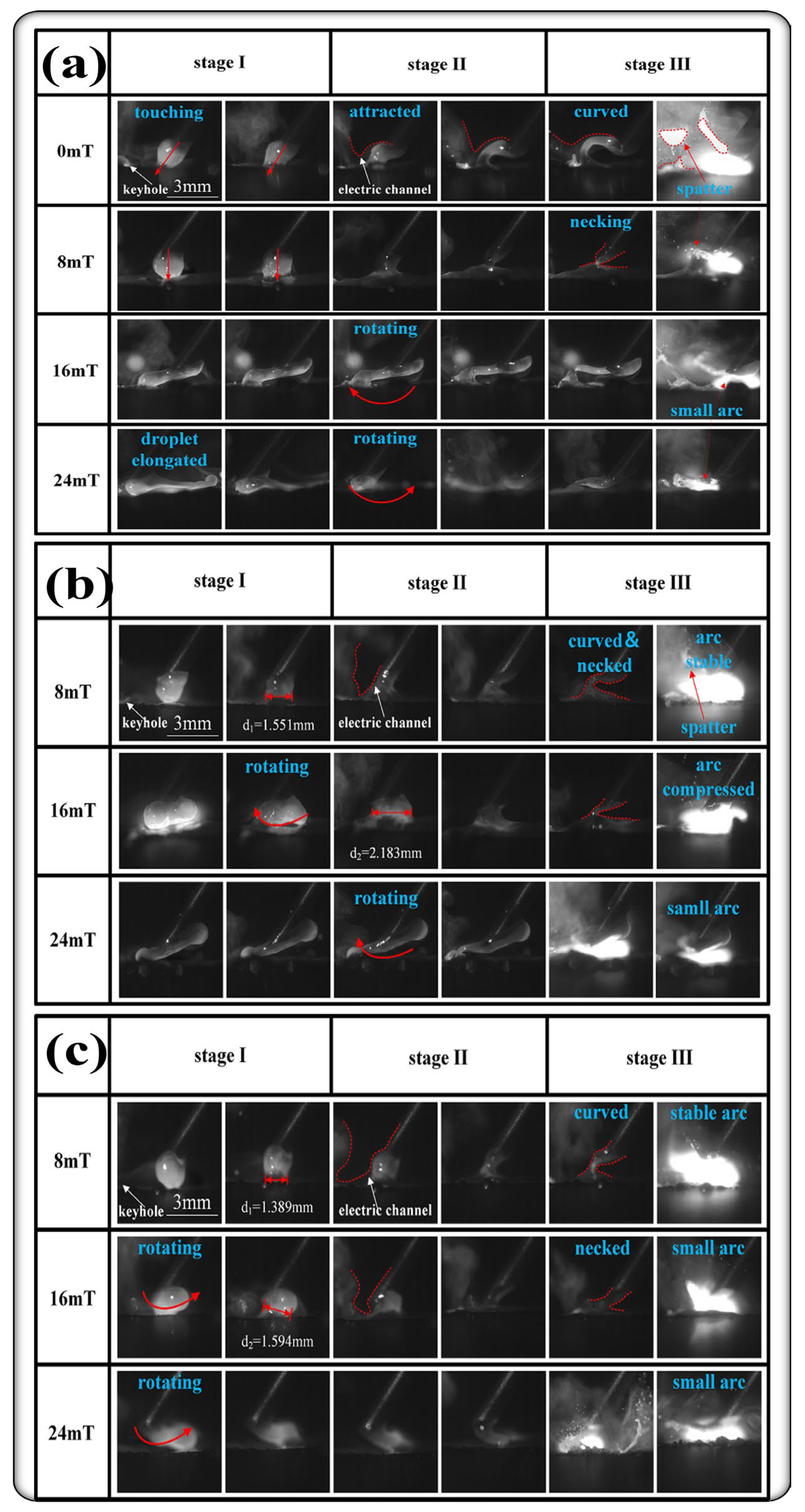

4.2. Droplet Transfer Behavior

4.3. Weld Quality and Properties

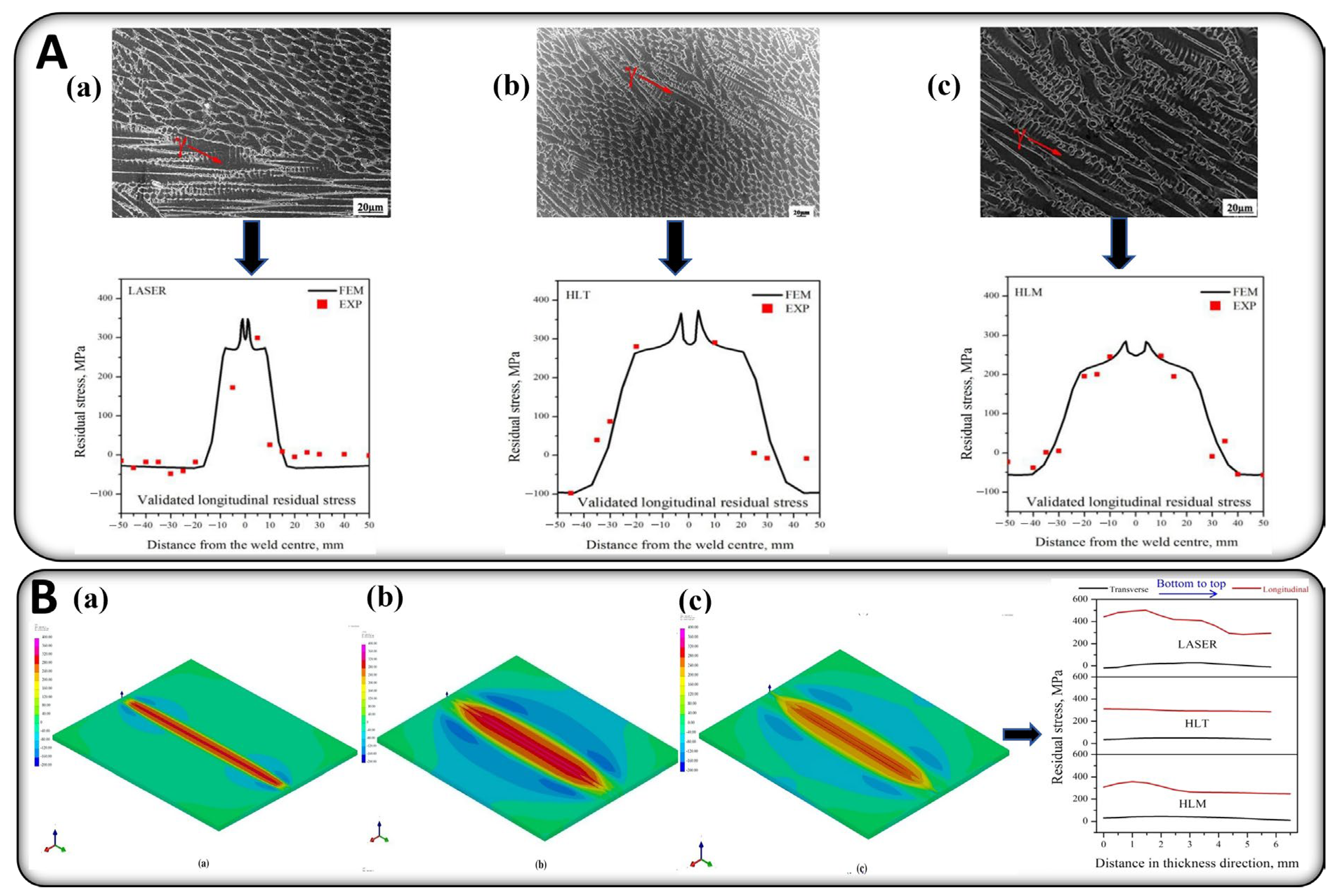

4.3.1. Analysis of the Residual Stress

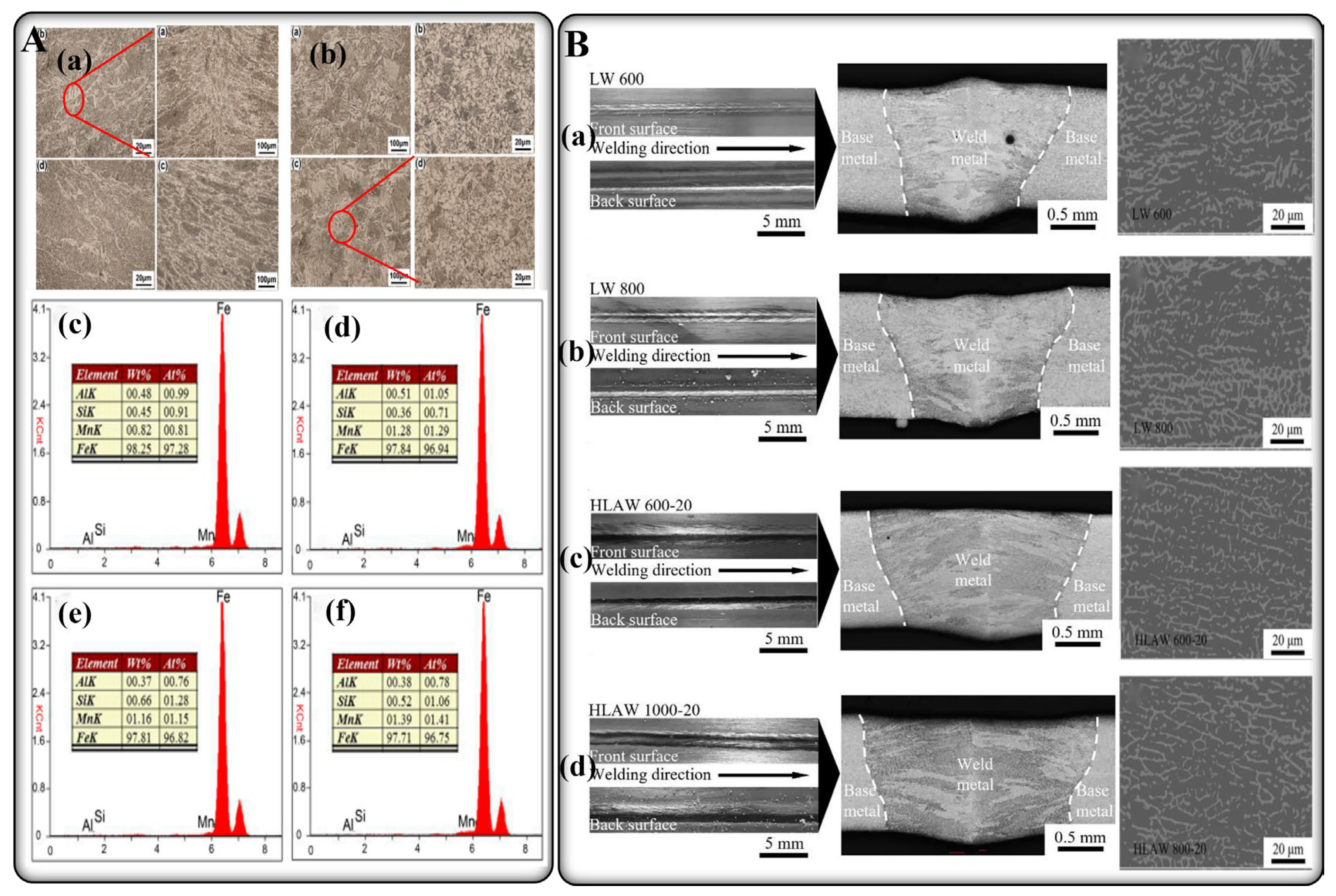

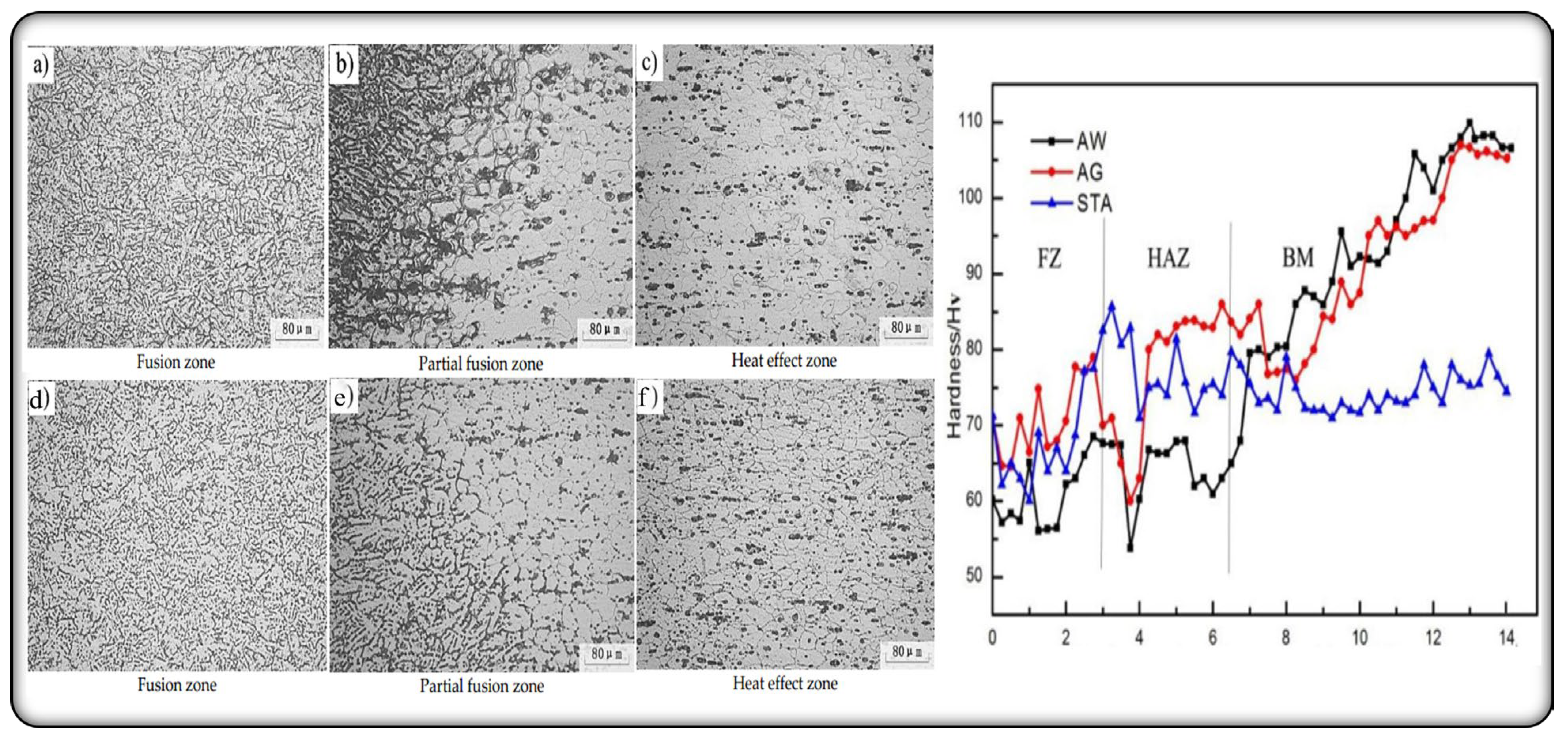

4.3.2. Analysis of Microstructures

| Material | Phase Formation Region | Main Phase Structure | Organization Formation Mechanism | Micro-Hardness (Hv) | Ref. |

|---|---|---|---|---|---|

| Chromium–molybdenum alloy steel plate | FZ | Martensite | The FZ of chromium–molybdenum alloy steel undergoes the transformation from austenite to martensite under rapid cooling conditions, resulting in a significant increase in hardness. | [141] | |

| High-strength low-carbon bainitic steel | HAZ | Martensite–Austenite | A moderate cooling rate in the HAZ causes a part of the austenite to transform to martensite, while the remaining portion forms a martensite–austenite mixed structure. | [142] | |

| High-strength low-alloy (HSLA-65) steel | FZ | Acicular ferrite | The formation of acicular ferrite is associated with a lower carbon equivalent and a lower cooling rate. Rapid cooling promotes the formation of ferrite while suppressing the generation of martensite and bainite, thereby enhancing the toughness of the joint. | [143] | |

| 40 mm thick hot-rolled annealed Q235 low-carbon steel | FZ | Acicular ferrite | The rapid cooling rate at the root FZ, along with the alloy composition (Mn and Si), promotes acicular ferrite formation, enhancing the weld strength and toughness. | [144] | |

| 316L stainless-steel plate | HAZ | Ferrite | The high Cr and Ni contents in 316L stainless steel enhance the ferrite’s stability, while slower cooling facilitates its stable precipitation in the HAZ, thereby improving the weld joint’s stability and corrosion resistance. | [145] |

4.3.3. Analysis of the Influences of the Welding Parameters

| Material | Process | Shielding Gas | Welding Speed (mm·s−1) | Laser Power (KW) | Tensile Strength (MPa) Hardness (HV) | Ref. |

|---|---|---|---|---|---|---|

| 08Cr19Mn6Ni3Cu2N stainless-steel plate | Hybrid laser–MIG welding | 95%Ar + 5%CO2 | 7.5 | 3.6 | MPa = 714 | [157] |

| High-nitrogen austenitic stainless steel | Hybrid laser–MIG/MAG arc welding | 90%Ar + 5%N2 | 11.6 | 2.2 | HV = 270~390 | [158] |

| Non-heat-treated forged aluminum alloy(5083-O) | Hybrid laser–MIG welding | 100% Ar | 30.0 | 2.5 | MPa = 74~97 | [28] |

| AISI 316L(N) SS | Hybrid laser–MIG welding | 99.999% He | 16.6 | 2.5 | HV = 155~215 | [131] |

| SA516 grade 70 steel | Hybrid laser–MIG welding | 99.999% Ar | 16.6 | 2.0 | HV = 195~465 | [77] |

| ASTM A1066/A1066M | LAHW | 80% Ar + 20% CO2 | 2.6 | 4.8 | MPa = 817 HV = 250~325 | [142] |

4.4. Welding Defects and Suppression

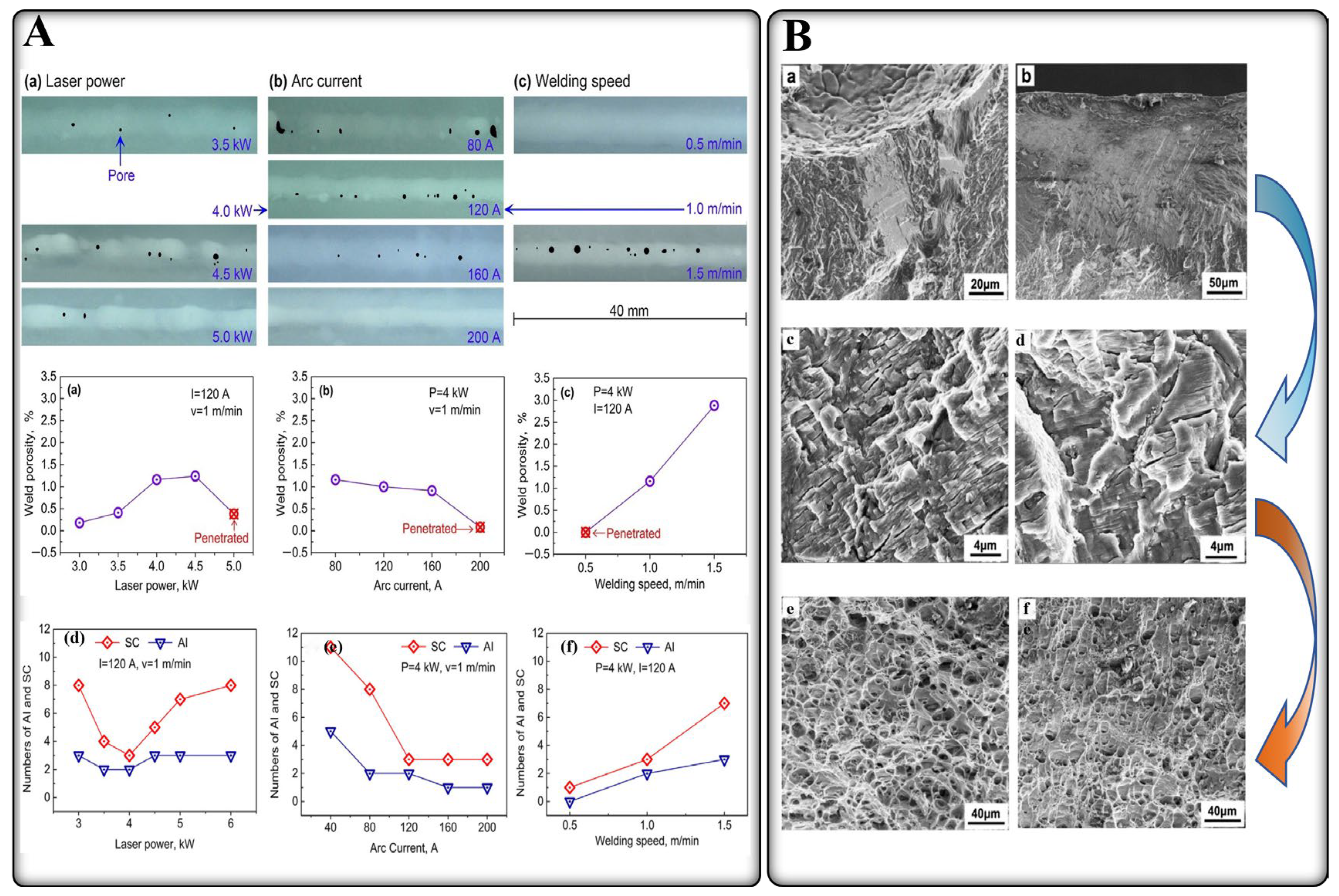

4.4.1. Porosity Defects

4.4.2. Crack Defects

4.4.3. Hump Defects

5. Industrial Applications

5.1. Applications in the Automotive Industry

5.2. Applications in the Shipbuilding Industry

5.3. Applications in the Aerospace Industry

5.4. Application of Hybrid Welding Technology in Additive Manufacturing

6. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Le Guen, E.; Fabbro, R.; Carin, M.; Coste, F.; Le Masson, P. Analysis of hybrid Nd: Yag laser-MAG arc welding processes. Opt. Laser Technol. 2011, 43, 1155–1166. [Google Scholar] [CrossRef]

- Ishide, T.; Tsubota, S.; Watanabe, M. Latest MIG, TIG, arc-YAG laser hybrid welding systems for various welding products. In Proceedings of the 1st International Symposium on High-Power Laser Macroprocessing, Osaka, Japan, 27–31 May 2002; SPIE: Bellingham, WA, USA, 2003; pp. 347–352. [Google Scholar]

- Wang, J.; Sun, Q.; Zhang, T.; Zhang, S.; Liu, Y.; Feng, J. Arc characteristics in alternating magnetic field assisted narrow gap pulsed GTAW. J. Mater. Process. Technol. 2018, 254, 254–264. [Google Scholar] [CrossRef]

- Paranthaman, V.; Srikanth, R.; Rajasekar, E. A systematic review of fatigue behaviour of laser welding titanium alloys. Mater. Today Proc. 2021, 39, 520–523. [Google Scholar] [CrossRef]

- Stavridis, J.; Papacharalampopoulos, A.; Stavropoulos, P. Quality assessment in laser welding: A critical review. Int. J. Adv. Manuf. Technol. 2018, 94, 1825–1847. [Google Scholar] [CrossRef]

- Gao, M.; Kawahito, Y.; Kajii, S. Observation and understanding in laser welding of pure titanium at subatmospheric pressure. Opt. Express 2017, 25, 13539–13548. [Google Scholar] [CrossRef]

- Silva, R.G.N.; de Paço, C.M.M.; Rodrigues, M.B.; Sousa, R.A. A comparison between LBW and hybrid laser-GMAW processes based on microstructure and weld geometry for hardenable steels. Int. J. Adv. Manuf. Technol. 2020, 110, 2801–2814. [Google Scholar] [CrossRef]

- Kurzynowski, T.; Gruber, K.; Stopyra, W.; Kuźnicka, B.; Chlebus, E. Correlation between process parameters, microstructure and properties of 316L stainless steel processed by selective laser melting. Mater. Sci. Eng. A 2018, 718, 64–73. [Google Scholar] [CrossRef]

- Wang, J.Y.; Qi, T.; Zhong, C.L.; Zhang, H.; Li, X.R.; Liu, F.D. Study on seam nitrogen behavior of high nitrogen steel hybrid welding. Optik 2021, 242, 167026. [Google Scholar] [CrossRef]

- Shu, Z.; Duan, Z.; Sun, D.; Li, Y.; Gao, D.; Li, H. Study on microstructures and mechanical properties of laser-arc hybrid welded S355J2W+N steel. Opt. Laser Technol. 2014, 59, 11–18. [Google Scholar]

- Hong, K.; Shin, Y.C. Prospects of laser welding technology in the automotive industry: A review. J. Mater. Process. Technol. 2017, 245, 46–69. [Google Scholar] [CrossRef]

- Gumenyuk, A.; Rethmeier, M. Developments in hybrid laser-arc welding technology. In Handbook of Laser Welding Technologies; Katayama, S., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 505–521. [Google Scholar] [CrossRef]

- Lippold, J.C. Welding Metallurgy and Weldability; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Zheng, J.; Meng, Y.; Ke, Y.; Zhou, Z.; Ge, C.; Xie, Y.; Guo, K.; Shao, C.; Lu, F.; Chen, H. Effect of beam oscillating amplitude on formation characteristics and mechanical properties of laser-arc hybrid welded 8-mm-thick aluminum alloy T-joints. Opt. Laser Technol. 2025, 186, 112676. [Google Scholar] [CrossRef]

- Subashini, L.; Prabhakar, K.V.; Gundakaram, R.C.; Ghosh, S.; Padmanabham, G. Single pass laser arc hybrid welding of maraging steel thick sections. Mater. Manuf. Process. 2016, 31, 2186–2198. [Google Scholar] [CrossRef]

- Wang, D.; Dong, Y.; Liu, L.; Zhu, M.; Wang, H.; Liu, C. Effect of pulsed laser and laser-arc hybrid on aluminum/steel riveting-welding hybrid bonding technology. J. Mater. Res. Technol. 2022, 17, 1043–1053. [Google Scholar] [CrossRef]

- Berdnikova, O.; Jönsson, M.; Andren, H.; Kaplan, A.F. Laser and hybrid laser-arc welding of high-strength steel N-A-XTRA-70. Mater. Sci. Forum. 2016, 870, 630–635. [Google Scholar] [CrossRef]

- Bunaziv, I.; Akselsen, O.M.; Ren, X.; Salminen, A. Hybrid welding possibilities of thick sections for Arctic applications. Phys. Procedia 2015, 78, 74–83. [Google Scholar] [CrossRef]

- Zhan, X.; Li, Y.; Ou, W.; Yu, F.; Chen, J.; Wei, Y. Comparison between hybrid laser-MIG welding and MIG welding for the invar36 alloy. Opt. Laser Technol. 2016, 85, 75–84. [Google Scholar] [CrossRef]

- Yan, S.; Nie, Y.; Zhu, Z.; Chen, H.; Gou, G.; Yu, J.; Wang, G. Characteristics of microstructure and fatigue resistance of hybrid fiber laser-MIG welded Al-Mg alloy joints. Appl. Surf. Sci. 2014, 298, 12–18. [Google Scholar] [CrossRef]

- Acherjee, B. Hybrid laser arc welding: State-of-art review. Opt. Laser Technol. 2018, 99, 60–71. [Google Scholar] [CrossRef]

- Steen, W.M.; Eboo, M. Arc augmented laser welding. J. Appl. Phys. 1979, 50, 2530–2531. [Google Scholar]

- Bunaziv, I.; Akselsen, O.M.; Ren, X.; Nyhus, B.; Eriksson, M. Laser beam and laser-arc hybrid welding of aluminum alloys. Metals 2021, 11, 1150. [Google Scholar] [CrossRef]

- Kim, Y.; Kil, S. Recent technological tendency of the laser/arc hybrid welding. J. Weld. Join. 2013, 31, 4–15. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Liu, F.; Zhang, H.; Ding, H. Effects of the relative positioning of energy sources on weld integrity for hybrid laser arc welding. Opt. Lasers Eng. 2016, 81, 87–96. [Google Scholar] [CrossRef]

- Faraji, A.H.; Moradi, M.; Goodarzi, M.; Colucci, P.; Maletta, C. An investigation on the capability of hybrid Nd: YAG laser-TIG welding technology for AA2198 Al-Li alloy. Opt. Lasers Eng. 2017, 96, 1–6. [Google Scholar] [CrossRef]

- Huang, L.; Wu, D.; Hua, X.; Liu, S.; Jiang, Z.; Li, F.; Wang, H.; Shi, S. Effect of the welding direction on the microstructural characterization in fiber laser-GMAW hybrid welding of 5083 aluminum alloy. J. Manuf. Process. 2018, 31, 514–522. [Google Scholar] [CrossRef]

- Bunaziv, I.; Akselsen, O.M.; Salminen, A.; Unt, A. The fiber laser-MIG hybrid welding of 5 mm 5083 aluminum alloy. J. Mater. Process. Technol. 2016, 233, 107–114. [Google Scholar] [CrossRef]

- Liu, L.; Hao, X.; Song, G. A new laser-arc hybrid welding technique based on energy conservation. Mater. Trans. 2006, 47, 1611–1614. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhan, X.; Zhou, X.; Liu, T.; Kang, Y. Effect of heat input on macro morphology and porosity of laser-MIG hybrid welded joint for 5A06 aluminum alloy. Int. J. Adv. Manuf. Technol. 2021, 115, 4035–4045. [Google Scholar] [CrossRef]

- Kapil, A.; Suga, T.; Tanaka, M.; Sharma, A. Towards hybrid laser-arc based directed energy deposition: Understanding bead formation through mathematical modeling for additive manufacturing. J. Manuf. Process. 2022, 76, 457–474. [Google Scholar] [CrossRef]

- Atabaki, M.M.; Nikodinovski, M.; Chenier, P.; Ma, J.; Liu, W.; Kovacevic, R. Experimental and numerical investigations of hybrid laser arc welding of aluminum alloys in the thick T-joint configuration. Opt. Lasers Eng. 2014, 59, 68–92. [Google Scholar] [CrossRef]

- Liu, F.; Yang, B.; Sun, H.; Wang, H.; Tan, C.; Wang, G.; Chen, B. Mechanism investigation for the influence of laser power on droplet transfer behaviors in laser-MIG hybrid welding. Opt. Laser Technol. 2023, 157, 108750. [Google Scholar] [CrossRef]

- Fan, H.; Zhou, P.; Li, J.; Huang, J.; Ni, Y.; Hui, Y. Microstructure and mechanical properties of arc-zone and laser zone of TC4 titanium alloy laser–TIG hybrid welded joint. Metals 2022, 12, 1854. [Google Scholar] [CrossRef]

- Li, R.; Zhang, F.; Sun, T.; Liu, B.; Chen, S.; Tian, Y. Investigation of strengthening mechanism of commercially pure titanium joints fabricated by autogenously laser beam welding and laser-MIG hybrid welding processes. Int. J. Adv. Manuf. Technol. 2019, 101, 377–389. [Google Scholar] [CrossRef]

- Möller, F.; Thomy, C. Interaction effects between laser beam and plasma arc in hybrid welding of aluminum. Phys. Procedia 2013, 41, 81–89. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, M.; Jiang, M.; Zeng, X. Effect of weld characteristic on mechanical strength of laser-arc hybrid-welded Al-Mg-Si-Mn aluminum alloy. Metall. Mater. Trans. A 2016, 47, 5438–5449. [Google Scholar] [CrossRef]

- Umroh, B.; Ginting, A.; Rahman, M.N.A. CO2 laser machining on alumina ceramic: A review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1003, 012131. [Google Scholar] [CrossRef]

- Vemanaboina, H.; Babu, M.M.; Prerana, I.C.; Gundabattini, E.; Yelamasetti, B.; Saxena, K.K.; Salem, K.H.; Khan, M.I.; Eldin, S.M.; Agrawal, M.K. Evaluation of residual stresses in CO2 laser beam welding of SS316L weldments using FEA. Mater. Res. Express 2023, 10, 016509. [Google Scholar] [CrossRef]

- Prabakaran, M.P.; Kannan, G.R.; Pandiyarajan, R. Effects of Welding Speed on Microstructure and Mechanical Properties of CO2 Laser Welded Dissimilar Butt Joints between Low Carbon Steel and Austenitic Stainless Steel. Adv. Mater. Process. Technol. 2020, 8 (Suppl. S1), 1–12. [Google Scholar] [CrossRef]

- Zhu, Z.; Lv, S.; Zhang, H.; Hui, Y.; Lei, H.; Li, Q. Highly efficient actively Q-switched Nd: YAG laser. Opt. Express 2021, 29, 32325–32332. [Google Scholar] [CrossRef]

- Li, H.N.; Xie, K.G.; Wu, B.; Zhu, W.Q. Generation of textured diamond abrasive tools by continuous-wave CO2 laser: Laser parameter effects and optimization. J. Mater. Process Technol. 2020, 275, 116279. [Google Scholar] [CrossRef]

- Sharma, A.; Yadava, V. Experimental analysis of Nd: YAG laser cutting of sheet materials—A review. Opt. Laser Technol. 2018, 98, 264–280. [Google Scholar] [CrossRef]

- Pavan, A.R.; Arivazhagan, B.; Vasudevan, M.; Prasanthi, T.N.; Sudha, C. Study on the microstructure and mechanical properties of hybrid laser + MIG welded joints of 316LN stainless steel. Opt. Laser Technol. 2023, 163, 109410. [Google Scholar] [CrossRef]

- Xie, J.; Cai, C.; Liang, Y.; Liu, Z.; Ma, Y. Microstructure and mechanical properties of heat affected zone of laser-MAG hybrid welded low carbon bainitic steel joints. Opt. Laser Technol. 2022, 148, 107729. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Liu, L. Research on Laser-TIG Hybrid Welding of 6061-T6 aluminum alloys joint and post heat treatment. Metals 2020, 10, 130. [Google Scholar] [CrossRef]

- Cai, D.; Liu, W.; Luo, Z.; Gao, S.; Chen, C.; Zhang, Y. Inhibition of undercut defect and its effect on tensile fracture mechanism of coaxial laser-plasma hybrid welding without filler. Opt. Laser Technol. 2024, 175, 110770. [Google Scholar] [CrossRef]

- Lahdo, R.; Nothdurft, S.; Hermsdorf, J.; Urbanek, P.; Puschmann, M.; Riedel, F.; Overmeyer, L.; Kaierle, S. Investigations on microstructure and mechanical properties of laser beam-submerged arc hybrid welded butt joints of duplex stainless steel S31083 (t = 16 mm) depending on the energy per unit length. Procedia CIRP 2022, 111, 409–414. [Google Scholar] [CrossRef]

- Gomes, A.S.L.; Moura, A.L.; de Araújo, C.B.; Raposo, E.P. Recent advances and applications of random lasers and random fiber lasers. Prog. Quantum Electron. 2021, 78, 100343. [Google Scholar] [CrossRef]

- Dragic, P.D.; Cavillon, M.; Ballato, J.J.A. Materials for optical fiber lasers: A review. Appl. Phys. Rev. 2018, 5, 041303. [Google Scholar] [CrossRef]

- Liu, Z.; Ma, P.; Su, R.; Tao, R.; Ma, Y.; Wang, X.; Zhou, P. High-Power Coherent Beam Polarization Combination of Fiber Lasers: Progress and Prospect [Invited]. J. Opt. Soc. Am. B 2017, 34, A7–A14. [Google Scholar] [CrossRef]

- Nemova, G. Brief review of recent developments in fiber lasers. Appl. Sci. 2024, 14, 2323. [Google Scholar] [CrossRef]

- García de Arquer, F.P.; Talapin, D.V.; Klimov, V.I.; Arakawa, Y.; Bayer, M.; Sargent, E.H. Semiconductor quantum dots: Technological progress and future challenges. Science 2021, 373, 1147–1153. [Google Scholar] [CrossRef]

- Zhang, Q.; Shang, Q.; Su, R.; Do, T.T.H.; Xiong, Q. Halide perovskite semiconductor lasers: Materials, cavity design, and low threshold. Nano Lett. 2021, 21, 1903–1914. [Google Scholar] [CrossRef] [PubMed]

- Ning, J.; Zhang, L.J.; Na, S.J.; Yin, X.Q.; Niu, J.; Zhang, J.X.; Wang, H.R. Numerical study of the effect of laser-arc distance on laser energy coupling in pulsed Nd: YAG laser/TIG hybrid welding. Int. J. Adv. Manuf. Technol. 2017, 91, 1129–1143. [Google Scholar] [CrossRef]

- Verma, R.P.; Pandey, K.N.; András, K.; Khargotra, R.; Singh, T. Difficulties and redressal in joining of aluminum alloys by GMA and GTA welding: A review. J. Mater. Res. Technol. 2023, 23, 2576–2586. [Google Scholar] [CrossRef]

- Sahoo, A.; Tripathy, S. Development in plasma arc welding process: A review. Mater. Today Proc. 2021, 41, 363–368. [Google Scholar] [CrossRef]

- Echezona, N.; Akinlabi, S.A.; Jen, T.C.; Fatoba, O.S.; Hassan, S.; Akinlabi, E.T. TIG welding of dissimilar steel: A review. In Advances in Material Science and Engineering, Lecture Notes in Mechanical Engineering; Awang, M., Emamian, S.S., Eds.; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Ardika, R.D.; Triyono, T.; Muhayat, N. A review of porosity in aluminum welding. Procedia Struct. Integr. 2021, 33, 171–180. [Google Scholar] [CrossRef]

- Wu, H.; Chang, Y.; Mei, Q.; Liu, D. Research advances in high-energy TIG arc welding. Int. J. Adv. Manuf. Technol. 2019, 33, 391–410. [Google Scholar] [CrossRef]

- Olivares, E.A.G.; Silva, R.H.G.; Dutra, J.C. Study of keyhole TIG welding by comparative analysis of two high-productivity torches for joining medium-thickness carbon steel plates. Weld. Int. 2017, 31, 337–347. [Google Scholar] [CrossRef]

- Vemanaboina, H.; Gundabattini, E.; Akella, S.; Rao, A.U.; Buddu, R.K.; Ferro, P.; Berto, F. Mechanical and metallurgical properties of CO2 laser beam INCONEL 625 welded joints. Appl. Sci. 2021, 11, 7002. [Google Scholar] [CrossRef]

- Anbarasu, P.; Yokeswaran, R.; Godwin Antony, A.; Sivachandran, S. Investigation of filler material influence on hardness of TIG welded joints. Mater. Today Proc. 2020, 21, 964–967. [Google Scholar] [CrossRef]

- Casalino, G.; Dassisti, M.; Perulli, P. FEM model for TIG hybrid laser butt welding of 6 mm thick austenitic to martensitic stainless steels. Procedia CIRP 2020, 88, 116–121. [Google Scholar] [CrossRef]

- Yan, J.; Gao, M.; Zeng, X. Study on microstructure and mechanical properties of 304 stainless steel joints by TIG, laser, and laser-TIG hybrid welding. Opt. Lasers Eng. 2010, 48, 512–517. [Google Scholar] [CrossRef]

- Silva, R.G.N.; Pereira, M.; Rodrigues, M.B.; Pereira, A.D.; Schwedersky, M.B. Electric evaluation of hybrid laser-TIG welding: Interaction between arc and laser plume. J. Laser Appl. 2020, 32, 022012. [Google Scholar] [CrossRef]

- Avilov, V.; Decker, I.; Pursch, H.; Wendelstorf, J. Study of a laser-enhanced welding arc using advanced split anode technique. Weld. J. 1994, 11, 112–123. [Google Scholar]

- Dutra, J.C.; Gonçalves e Silva, R.H.; Riffel, K.C.; Marques, C. High-performance GMAW process for deep penetration applications. Weld. World 2020, 64, 999–1009. [Google Scholar] [CrossRef]

- Ribeiro, R.A.; Assunção, P.D.C.; Dos Santos, E.B.F.; Braga, E.M.; Gerlich, A.P. An overview on the cold wire pulsed gas metal arc welding. Weld. World 2020, 64, 123–140. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, Y.; Zhang, Z.; Fang, C.; Xu, K.; He, P.; Zhang, Z. Research on the Sidewall Penetration Mechanisms of Cable-Type Welding Wire Narrow Gap GMAW Process. Int. J. Adv. Manuf. Technol. 2022, 120, 2443–2455. [Google Scholar] [CrossRef]

- Bidi, L.; Le Masson, P.; Cicala, E.; Primault, C. Experimental design method to the weld bead geometry optimization for hybrid laser-MAG welding in a narrow chamfer configuration. Opt. Lasers Technol. 2017, 89, 114–125. [Google Scholar] [CrossRef]

- Pan, Q.; Mizutani, M.; Kawahito, Y.; Katayama, S. Effect of shielding gas on laser-MAG arc hybrid welding results of thick high-tensile-strength steel plates. Weld. World 2016, 60, 653–664. [Google Scholar] [CrossRef]

- Cai, C.; Yu, J.; Chen, Z.; Li, Z.; Chen, H.; Tang, P.; Xiong, F. Welding Process Stability in Narrow-Gap Oscillating Laser-MIG Hybrid Welding of Titanium Alloys with Various Oscillating Patterns. J. Manuf. Process. 2025, 133, 151–162. [Google Scholar] [CrossRef]

- Subashini, L.; Prabhakar, K.V.P.; Ghosh, S.; Padmanabham, G. Comparison of laser-MIG hybrid and autogenous laser welding of M250 maraging steel thick sections—Understanding the role of filler wire addition. Int. J. Adv. Manuf. Technol. 2020, 107, 1581–1594. [Google Scholar] [CrossRef]

- Jiang, Z.; Hua, X.; Huang, L.; Wu, D.; Li, F.; Zhang, Y. Double-sided hybrid laser-MIG welding plus MIG welding of 30-mm-thick aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 97, 903–913. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, P.; Yan, H.; Liu, Z.; Yu, Z.; Wu, D.; Shi, H.; Tian, Y. Research on weld formation mechanism of laser-MIG arc hybrid welding with butt gap. Opt. Lasers Technol. 2021, 133, 106530. [Google Scholar] [CrossRef]

- Oyyaravelu, R.; Kuppan, P.; Arivazhagan, N. Comparative study on metallurgical and mechanical properties of laser and laser-arc-hybrid welding of HSLA steel. Mater. Today Proc. 2018, 5, 12693–12705. [Google Scholar] [CrossRef]

- Tashiro, S. Interaction Mechanism of Arc, Keyhole, and Weld Pool in Keyhole Plasma Arc Welding: A Review. Materials 2024, 17, 1348. [Google Scholar] [CrossRef]

- Ribeiro, R.A.; Dos Santos, E.B.F.; Assunção, P.D.C.; Braga, E.M.; Gerlich, A.P. Cold wire gas metal arc welding: Droplet transfer and geometry. Weld. J. 2019, 98, 135s–149s. [Google Scholar] [CrossRef]

- Jiang, F.; Li, C.; Chen, S.J. Experimental investigation on heat transfer of different phases in variable polarity plasma arc welding. Weld. World 2019, 63, 1153–1162. [Google Scholar] [CrossRef]

- Khanna, P.; Singh, S.J.; Kumar, D.; Suman, S. Investigation of Bead Geometry Parameters During MIG Welding of Stainless Steel 202 Plates. In Recent Developments in Mechanics and Design; INCOME 2023; Lecture Notes in Mechanical Engineering; Singh, D.K., Hegde, S., Mishra, A., Eds.; Springer: Singapore, 2024. [Google Scholar] [CrossRef]

- Wu, D.; Tashiro, S.; Hua, X.; Tanaka, M. Analysis of the energy propagation in the keyhole plasma arc welding using a novel fully coupled plasma arc-keyhole-weld pool model. Int. J. Heat Mass Transf. 2019, 141, 604–614. [Google Scholar] [CrossRef]

- Korzhyk, V.; Bushma, O.; Khaskin, V.; Dong, C.; Sydorets, V. Analysis of the current state of the processes of hybrid laser-plasma welding. In Proceedings of the Second International Conference on Mechanics, Materials and Structural Engineering (ICMMSE 2017), Beijing, China, 14–16 April 2017; Atlantis Press: Dordrecht, The Netherlands, 2017; pp. 80–90. [Google Scholar] [CrossRef]

- Meng, Y.; Gao, M.; Zeng, X.Y. Effects of arc types on the laser-arc synergic effects of hybrid welding. Opt. Express 2018, 26, 14775–14785. [Google Scholar] [CrossRef]

- Zou, J.L.; Wu, S.K.; Xiao, R.S.; Li, F. Effects of a paraxial TIG arc on high-power fiber laser welding. Mater. Des. 2015, 86, 321–327. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, M.; Zeng, X.Y. Influences of synergy effect between laser and arc on laser-arc hybrid welding of aluminum alloys. Opt. Laser Technol. 2019, 120, 105766. [Google Scholar] [CrossRef]

- Liu, W.; Ma, J.; Yang, G.; Kovacevic, R. Hybrid laser-arc welding of advanced high-strength steel. J. Mater. Process. Technol. 2014, 214, 2823–2833. [Google Scholar] [CrossRef]

- Gao, M.; Zeng, X.Y.; Hu, Q.W. Effects of welding parameters on melting energy of CO2 laser–GMA hybrid welding. Sci. Technol. Weld. Join. 2006, 11, 517–522. [Google Scholar] [CrossRef]

- Meng, Y.; Gao, M.; Zeng, X.Y. Quantitative analysis of synergic effects during laser-arc hybrid welding of AZ31 magnesium alloy. Opt. Laser Eng. 2018, 111, 183–192. [Google Scholar] [CrossRef]

- Gao, M.; Zeng, X.; Hu, Q. Effects of gas shielding parameters on weld penetration of CO2 laser-TIG hybrid welding. J. Mater. Process. Technol. 2007, 184, 177–183. [Google Scholar] [CrossRef]

- Gao, Z.M.; Jiang, P.; Wang, C.; Shao, X.; Pang, S.; Zhou, Q.; Li, X.; Wang, Y. Study on droplet transfer and weld quality in laser-MIG hybrid welding of 316L stainless steel. Int. J. Adv. Manuf. Technol. 2017, 88, 483–493. [Google Scholar] [CrossRef]

- Zhang, S.W.; Wang, Y.; Zhu, M.; Feng, Y.; Nie, P.; Li, Z. Effects of heat source arrangements on Laser-MAG hybrid welding characteristics and defect formation mechanism of 10CrNi3MoV steel. J. Manuf. Process. 2020, 58, 563–573. [Google Scholar] [CrossRef]

- Moradi, M.; Ghoreishi, M.; Frostevarg, J.; Kaplan, A.F. An investigation on stability of laser hybrid arc welding. Opt. Laser Eng. 2013, 51, 481–487. [Google Scholar] [CrossRef]

- Kouraytem, N.; Li, X.; Cunningham, R.; Zhao, C.; Parab, N.; Sun, T.; Rollett, A.D.; Spear, A.D.; Tan, W. Effect of laser-matter interaction on molten pool flow and keyhole dynamics. Phys. Rev. Appl. 2019, 11, 064054. [Google Scholar] [CrossRef]

- Shrestha, S.; Chou, K.Y. A numerical study on the keyhole formation during laser powder bed fusion process. J. Manuf. Sci. Eng. 2019, 141, 101002. [Google Scholar] [CrossRef]

- Ning, J.; Zhang, L.J.; Zhang, L.L.; Long, J.; Yin, X.Q.; Zhang, J.X.; Na, S.J. Effects of power modulation on behaviors of molten pool and keyhole during laser–arc hybrid welding of pure copper. Mater. Des. 2020, 194, 108829. [Google Scholar] [CrossRef]

- Wu, C.S.; Zhang, H.T.; Chen, J. Numerical simulation of keyhole behaviors and fluid dynamics in laser–gas metal arc hybrid welding of ferrite stainless steel plates. J. Manuf. Process. 2017, 25, 235–245. [Google Scholar] [CrossRef]

- Courtois, M.; Carin, M.; Le Masson, P.; Gaied, S.; Balabane, M. A complete model of keyhole and melt pool dynamics to analyze instabilities and collapse during laser welding. J. Laser Appl. 2014, 26, 042001. [Google Scholar] [CrossRef]

- Tan, C.W.; Dong, Y.; Sun, H.F.; Liu, F.; Han, X.; Dong, Q.; Chen, B.; Song, X. Numerical study on weld pool behaviors and keyhole dynamics in magnetic-field-assisted laser-arc hybrid welding of aluminum alloy. J. Mater. Res. Technol. 2023, 26, 6446–6461. [Google Scholar] [CrossRef]

- Xu, X.K.; Song, G.; Zhao, S.; Liu, L.M. Effect of distance between the heat sources on energy transfer behavior in keyhole during laser-GTA welding titanium alloy. J. Manuf. Process. 2020, 55, 317–325. [Google Scholar] [CrossRef]

- Xu, G.X.; Li, P.F.; Cao, Q.N.; Hu, Q.; Gu, X.; Du, B. Modelling of fluid flow phenomenon in laser + GMAW hybrid welding of aluminum alloy considering three phase coupling and arc plasma shear stress. Opt. Laser Technol. 2018, 100, 244–255. [Google Scholar] [CrossRef]

- Miyagi, M.; Wang, J. Keyhole dynamics and morphology visualized by in-situ X-ray imaging in laser melting of austenitic stainless steel. J. Mater. Process. Technol. 2020, 282, 116673. [Google Scholar] [CrossRef]

- Kaplan, A.F.H. Local flashing events at the keyhole front in laser welding. Opt. Laser Eng. 2015, 68, 35–41. [Google Scholar] [CrossRef]

- Zhang, L.J.; Zhang, J.X.; Gumenyuk, A.; Rethmeier, M.; Na, S.J. Numerical simulation of full penetration laser welding of thick steel plate with high power high brightness laser. J. Mater. Process. Technol. 2014, 214, 1710–1720. [Google Scholar] [CrossRef]

- Rong, Y.M.; Xu, J.J.; Cao, H.Y.; Zheng, H.; Huang, Y.; Zhang, G. Influence of steady magnetic field on dynamic behavior mechanism in full penetration laser beam welding. J. Manuf. Process. 2017, 26, 399–406. [Google Scholar] [CrossRef]

- Li, M.; Xu, J.; Huang, Y.; Rong, Y. Improving keyhole stability by external magnetic field in full penetration laser welding. JOM 2018, 70, 1261–1266. [Google Scholar] [CrossRef]

- Zhan, X.H.; Liu, X.; Li, Y.; Zhao, Y.; Wang, J. Molten pool behavior and solidification characterization in steady magnetic field assisted laser-MIG hybrid welding of aluminum alloy. J. Manuf. Process. 2022, 84, 622–638. [Google Scholar] [CrossRef]

- Liu, F.Y.; Xu, B.X.; Song, K.; Tan, C.; Zhao, H.; Wang, G.; Chen, B.; Song, X. Improvement of penetration ability of heat source for 316 stainless steel welds produced by alternating magnetic field assisted laser-MIG hybrid welding. J. Mater. Process. Technol. 2022, 299, 117329. [Google Scholar] [CrossRef]

- Huang, L.J.; Hua, X.; Wu, D.; Li, F. Numerical study of keyhole instability and porosity formation mechanism in laser welding of aluminum alloy and steel. J. Mater. Process. Technol. 2018, 252, 421–431. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Y.; Zhang, Y. Droplet transfer model for laser-enhanced GMAW. Int. J. Adv. Manuf. Technol. 2013, 64, 207–217. [Google Scholar] [CrossRef]

- Liu, Q.Y.; Wu, D.; Wang, Q.; Zhang, P.; Yan, H.; Sun, T.; Zeng, J.; Yan, M.; Liu, Z.; Li, R. Research status of stability in dynamic process of laser-arc hybrid welding based on droplet transfer behavior: A review. Coatings 2023, 13, 205. [Google Scholar] [CrossRef]

- Liu, S.Y.; Liu, F.D.; Xu, C.Y.; Zhang, H. Experimental investigation on arc characteristic and droplet transfer in CO2 laser–metal arc gas (MAG) hybrid welding. Int. J. Heat Mass Transf. 2013, 62, 604–611. [Google Scholar] [CrossRef]

- Li, R.; Yue, J.; Sun, R.; Mi, G.; Wang, C.; Shao, X. A study of droplet transfer behavior in ultra-narrow gap laser arc hybrid welding. Int. J. Adv. Manuf. Technol. 2016, 87, 2997–3008. [Google Scholar] [CrossRef]

- Zhang, W.; Hua, X.; Liao, W.; Li, F.; Wang, M. Behavior of the plasma characteristic and droplet transfer in CO2 laser–GMAW-P hybrid welding. Int. J. Adv. Manuf. Technol. 2014, 72, 935–942. [Google Scholar] [CrossRef]

- Cai, C.; Feng, J.C.; Li, L.Q.; Chen, Y. Influence of laser on the droplet behavior in short-circuiting, globular, and spray modes of hybrid fiber laser-MIG welding. Opt. Laser Technol. 2016, 83, 108–118. [Google Scholar] [CrossRef]

- Liu, S.Y.; Zhang, F.; Dong, S.; Zhang, H.; Liu, F. Characteristics analysis of droplet transfer in laser-MAG hybrid welding process. Int. J. Heat Mass Transf. 2018, 121, 805–811. [Google Scholar] [CrossRef]

- Gao, X.D.; Wang, Y.; Chen, Z.Q.; Ma, B.; Zhang, Y. Analysis of welding process stability and weld quality by droplet transfer and explosion in MAG-laser hybrid welding process. J. Manuf. Process. 2018, 32, 522–529. [Google Scholar] [CrossRef]

- Chen, Y.B.; Feng, J.C.; Li, L.Q.; Li, Y.; Chang, S. Effects of welding positions on droplet transfer in CO2 laser–MAG hybrid welding. Int. J. Adv. Manuf. Technol. 2013, 68, 1351–1359. [Google Scholar] [CrossRef]

- Jing, H.; Ye, X.; Hou, X.; Qian, X.; Zhang, P.; Yu, Z.; Wu, D.; Fu, K. Influence of Laser Power and Butt Gap on Droplet Transfer and Weld Formation in Laser-Arc Hybrid Welding. J. Phys. Conf. Ser. 2021, 2002, 012009. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, Z.; Ni, Z.; Xu, J.M.; Dong, S.W.; Xu, G.X.; Chen, S.J. Effect of distance between heat sources on droplet transfer behavior and weld formation of AH36 during laser and CWW GMAW arc hybrid welding. J. Iron Steel Res. Int. 2024, 31, 3069–3079. [Google Scholar] [CrossRef]

- Cai, B.; Fu, J.; Zhao, Y.; Chen, F.; Qin, Y.; Song, S. Effect of alternating magnetic field on arc plasma characteristics and droplet transfer during narrow gap laser-MIG hybrid welding. Metals 2021, 11, 1712. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, D.; Wang, Q.; Zhang, P.; Yan, H.; Sun, T.; Yan, M.; Zeng, J.; Liu, Z.; Feng, J.; et al. Influencing mechanism of high speed on the droplet transfer and process stability during high-power laser-arc hybrid welding. Int. J. Adv. Manuf. Technol. 2023, 128, 4427–4442. [Google Scholar] [CrossRef]

- Zhu, Z.W.; Ma, X.Q.; Wang, C.M.; Mi, G. Modification of droplet morphology and arc oscillation by magnetic field in laser-MIG hybrid welding. Opt. Laser Eng. 2020, 131, 106138. [Google Scholar] [CrossRef]

- Gui, X.; Gao, X.; Zhang, Y.; Wu, J. Investigation of welding parameters effects on temperature field and structure field during laser-arc hybrid welding. Mod. Phys. Lett. B 2022, 36, 2150467. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, H.; Wang, L.; Gao, M.; Zeng, X. Microcracking and mechanical properties in laser-arc hybrid welding of wrought Al-6Cu aluminum alloy. Metall. Mater. Trans. A 2018, 49, 4441–4445. [Google Scholar] [CrossRef]

- Lv, X.Z.; Liu, L.M. Microstructure and mechanical performance of AZ31/6061 lap joints welded by laser-TIG hybrid welding with Zn-Al alloy filler metal. J. Magnes. Alloy 2023, 12, 3325–3338. [Google Scholar] [CrossRef]

- Zhang, W.; Hua, X.; Liao, W.; Li, F.; Wang, M. Study of metal transfer in CO2 laser + GMAW-P hybrid welding using argon–helium mixtures. Opt. Laser Technol. 2014, 56, 158–166. [Google Scholar] [CrossRef]

- Turichin, G.; Kuznetsov, M.; Klimova-Korsmik, O.; Sklyar, M.; Zhitenev, A.; Kurakin, A.; Pozdnyakov, A. Laser-Arc hybrid welding perspective ultra-high strength steels: Influence of the chemical composition of weld metal on microstructure and mechanical properties. Procedia CIRP 2018, 74, 752–756. [Google Scholar] [CrossRef]

- Gao, Y.K.; Hao, K.D.; Xu, L.Y.; Han, Y.; Zhao, L.; Ren, W.; Jing, H. Microstructure homogeneity and mechanical properties of laser-arc hybrid welded AZ31B magnesium alloy. J. Magnes. Alloys 2022, 12, 1986–1995. [Google Scholar] [CrossRef]

- Sun, G.F.; Wang, Z.D.; Lu, Y.; Zhou, R.; Ni, Z.H.; Gu, X.; Wang, Z.G. Numerical and experimental investigation of thermal field and residual stress in laser-MIG hybrid welded NV E690 steel plates. J. Manuf. Process. 2018, 34, 106–120. [Google Scholar] [CrossRef]

- Ragavendran, M.; Vasudevan, M. Effect of Laser and Hybrid Laser Welding Processes on the Residual Stresses and Distortion in AISI Type 316L(N) Stainless Steel Weld Joints. Metall. Mater. Trans. B 2021, 52, 2582–2603. [Google Scholar] [CrossRef]

- Hong, X.L.; Huang, B.S.; Li, T.L.; Chen, P.; Zheng, J.N.; Zhu, Y.Y. Effects of welding speed and welding current on the residual stress and deformation of SAF 2507/316L dissimilar plasma arc welding. J. Mater. Eng. Perform. 2024, 33, 13745–13763. [Google Scholar] [CrossRef]

- Chen, L.; Mi, G.Y.; Zhang, X.; Wang, C.M. Numerical and experimental investigation on microstructure and residual stress of multi-pass hybrid laser-arc welded 316L steel. Mater. Des. 2019, 168, 107653. [Google Scholar] [CrossRef]

- Yang, J.; Dong, H.; Wu, G.; Xiong, F. Experimental and numerical simulation study on microstructure, residual stress, and mechanical properties of Fe–Mn–C–Cr cryogenic high-manganese steel arc-welded joint. J. Mater. Res. Technol. 2025, 35, 1335–1347. [Google Scholar] [CrossRef]

- Hammad, A.; Churiaque, C.; Sánchez-Amaya, J.M.; Abdel-Nasser, Y. Experimental and numerical investigation of hybrid laser arc welding process and the influence of welding sequence on the manufacture of stiffened flat panels. J. Manuf. Process. 2021, 61, 527–538. [Google Scholar] [CrossRef]

- Katayama, S. Handbook of Laser Welding Technologies; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Han, R.H.; Li, Y.Y.; Lu, S.P. Macro-micro modeling and simulation for the morphological evolution of the solidification structures in the entire weld. Int. J. Heat Mass Transf. 2017, 106, 1345–1355. [Google Scholar] [CrossRef]

- Djeloud, H.; Moussaoui, M.; Kouider, R.; Al-Kassir, A.; Carrasco-Amador, J.P. Study of the heat exchange and relaxation conditions of residual stresses due to welding of austenitic stainless steel. Energies 2023, 16, 3176. [Google Scholar] [CrossRef]

- Schempp, P.; Rethmeier, M. Understanding grain refinement in aluminum welding. Weld. World 2015, 59, 767–784. [Google Scholar] [CrossRef]

- Wang, L.; Gao, M.; Hao, Z. A pathway to mitigate macrosegregation of laser-arc hybrid Al-Si welds through beam oscillation. Int. J. Heat Mass Transf. 2020, 151, 119467. [Google Scholar] [CrossRef]

- Du, Z.L.; Sun, X.C.; Ng, F.L.; Chew, Y.X.; Tan, C.L.; Bi, G.J. Thermo-metallurgical simulation and performance evaluation of hybrid laser arc welding of chromium-molybdenum steel. Mater. Des. 2021, 210, 110029. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, Z.; Liu, Y.; Zhao, X.; Chen, J.; Chen, H. Effect of the cooling rate of thermal simulation on the microstructure and mechanical properties of low-carbon bainite steel by laser-arc hybrid welding. Coatings 2022, 12, 1045. [Google Scholar] [CrossRef]

- Munro, C.; Nolting, A.E.; Cao, X.J.; Wanjara, P. Hybrid laser-arc welding of HSLA-65 steel plate: Microstructural and mechanical property evaluation of butt welds. Mater. Sci. Forum 2012, 706–709, 2992–2997. [Google Scholar] [CrossRef]

- Zhang, C.; Li, G.; Gao, M.; Zeng, X. Microstructure and mechanical properties of narrow gap laser-arc hybrid welded 40 mm thick mild steel. Materials 2017, 10, 106. [Google Scholar] [CrossRef]

- Xie, L.; Shi, W.; Wu, T.; Gong, M.; Cai, D.; Han, S.; He, K. Effect of hybrid laser arc welding on the microstructure and mechanical and fracture properties of 316L sheet welded joints. Metals 2022, 12, 2181. [Google Scholar] [CrossRef]

- Shen, L.; Chen, Y.; Zhu, H.; Lei, Y.; Qiu, C. Ti6Al4V alloy remelting by modulation laser: Deep penetration, high compactness, and metallurgical bonding with matrix. Micromachines 2022, 13, 1107. [Google Scholar] [CrossRef]

- Chen, G.; Hirohata, M.; Hyoma, K.; Matsumoto, N.; Inose, K. Deformation and residual stress of T-shaped joints fabricated by laser-arc hybrid welding for steel bridge members. Weld. World 2024, 68, 459–473. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, M.; Zeng, X. Effect of microstructural characteristics on high cycle fatigue properties of laser-arc hybrid welded AA6082 aluminum alloy. J. Mater. Process Technol. 2016, 231, 479–487. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, H.; Qiu, P.; Zhu, Z. Residual stress and fatigue strength of hybrid laser-MIG-welded A7N01P-T4. Metall. Mater. Trans. B 2017, 48, 591–601. [Google Scholar] [CrossRef]

- Yang, Z.; Huan, J.; Xu, K.; He, P. Effect of Polarities and Shielding Gases in CWW GMAW. Mater. Manuf. Process. 2024, 39, 227–236. [Google Scholar] [CrossRef]

- Sathiya, P.; Mishra, M.K.; Soundararajan, R.; Shanmugarajan, B. Shielding gas effect on weld characteristics in arc-augmented laser welding process of super austenitic stainless steel. Opt. Laser Technol. 2013, 45, 46–55. [Google Scholar] [CrossRef]

- Rao, Z.H.; Liao, S.M.; Tsai, H.L. Effects of shielding gas compositions on arc plasma and metal transfer in gas metal arc welding. J. Appl. Phys. 2010, 107, 043305. [Google Scholar] [CrossRef]

- Zhu, Y.; Cai, Y.; Wang, M. Effects of He content in shielding gases on high-efficient hybrid laser arc welding with C-276 filler metal. J. Mater. Process Technol. 2022, 299, 117367. [Google Scholar] [CrossRef]

- Tani, G.; Campana, G.; Fortunato, A.; Ascari, A. The influence of shielding gas in hybrid laser-MIG welding. Appl. Surf. Sci. 2007, 253, 19–25. [Google Scholar] [CrossRef]

- Ahn, J.; He, E.; Chen, L.; Dear, J.; Davies, C. The effect of Ar and He shielding gas on fibre laser weld shape and microstructure in AA 2024-T3. J. Manuf. Process. 2023, 29, 62–73. [Google Scholar] [CrossRef]

- Wallerstein, D.; Vaamonde, E.; Prada, A.; Torres, E.A.; Urtiga Filho, S.L.; Santos, T.F. Influence of welding gases and filler metals on hybrid laser-GMAW and Laser-FCAW welds. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2021, 235, 2754–2767. [Google Scholar] [CrossRef]

- Fang, N.; Huang, R.; Wang, X.; Tian, J.; Li, S.; Wu, P.; Xu, K.; He, P.; Wen, G.; Jiang, L. Effect of shielding gas on the microstructure and properties of laser-MAG hybrid welded joint for nickel-saving stainless steel. Adv. Mater. Sci. Eng. 2022, 2022, 9330521. [Google Scholar] [CrossRef]

- Bai, D.; Liu, F.; Zhang, H. Effect of Welding Shielding Gas Composition on the Properties of Laser-Arc Hybrid Welding Joint of High Nitrogen Stainless Steel. J. Phys. Conf. Ser. 2021, 1838, 012020. [Google Scholar] [CrossRef]

- Yang, X.; Chen, H.; Zhu, Z.; Cai, C.; Zhang, C. Effect of shielding gas flow on welding process of laser-arc hybrid welding and MIG welding. J. Manuf. Process. 2019, 38, 530–542. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, Z.; Xu, K.; He, P.; Shi, M.; Chen, S.; Fang, C. Effect of energy parameters on droplet transfer behavior and weld formation in laser-arc hybrid welding with cable-type welding wire. J. Mater. Res. Technol. 2023, 26, 4191–4205. [Google Scholar] [CrossRef]

- Gao, Z.; Shao, X.; Jiang, P.; Cao, L.; Zhou, Q.; Yue, C.; Liu, Y.; Wang, C. Parameters optimization of hybrid fiber laser-arc butt welding on 316L stainless steel using Kriging model and GA. Opt. Laser Technol. 2016, 83, 153–162. [Google Scholar] [CrossRef]

- Wang, L.; Gao, M.; Zeng, X. Experiment and prediction of weld morphology for laser oscillating welding of AA6061 aluminum alloy. Sci. Technol. Weld. Join. 2019, 24, 334–341. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Z.; Wang, X.; Feng, Y.; Wang, M.; Shan, J. Narrow groove laser-arc hybrid welding of thick-sectioned HSLA steel using laser beam oscillation. Weld. J. 2022, 101, 181–196. [Google Scholar] [CrossRef]

- Shi, L.; Jiang, L.; Gao, M. Numerical research on melt pool dynamics of oscillating laser-arc hybrid welding. Int. J. Heat Mass Transf. 2022, 185, 122421. [Google Scholar] [CrossRef]

- Zhan, X.; Zhao, Y.; Liu, Z.; Gao, Q.; Bu, H. Microstructure and porosity characteristics of 5A06 aluminum alloy joints using laser-MIG hybrid welding. J. Manuf. Process. 2018, 35, 437–445. [Google Scholar] [CrossRef]

- Wang, Z.; Gong, M.; Zhou, L.; Gao, M. A review of numerical simulation of laser–arc hybrid welding. Materials 2023, 16, 3561. [Google Scholar] [CrossRef]

- Jiang, Y.; Meng, Y.; Chen, H.; Wu, X.; Deng, A. Effects of oscillating frequency on keyhole stability and porosity inhibition in high-power laser-arc hybrid welding of 10-mm-thick 6082 aluminum alloy. J. Mater. Res. Technol. 2024, 30, 385–396. [Google Scholar] [CrossRef]

- Yazdian, N.; Mohammadpour, M.; Kong, F.; Kovacevic, R. Hybrid laser/arc girth welding of 304L stainless steel tubes, part 1–Pore mitigation, thermal analysis and mechanical properties. Int. J. Press. Vess. Piping. 2018, 163, 75–93. [Google Scholar] [CrossRef]

- Cai, C.; He, S.; Chen, H.; Zhang, W. The influences of Ar-He shielding gas mixture on welding characteristics of fiber laser-MIG hybrid welding of aluminum alloy. Opt. Laser Technol. 2019, 113, 37–45. [Google Scholar] [CrossRef]

- Panwisawas, C.; Perumal, B.; Ward, R.M.; Turner, N.; Turner, R.P.; Brooks, J.W.; Basoalto, H.C. Keyhole formation and thermal fluid flow-induced porosity during laser fusion welding in titanium alloys: Experimental and modelling. Acta Mater. 2017, 126, 251–263. [Google Scholar] [CrossRef]

- Vorontsov, A.; Zykova, A.; Chumaevskii, K.; Osipovich, K.; Rubtsov, V.; Astafurova, E.; Kolubaev, E. Advanced high-strength AA5083 welds by high-speed hybrid laser-arc welding. Mater. Lett. 2021, 291, 129594. [Google Scholar] [CrossRef]

- Miao, H.; Yu, G.; He, X.; Li, S.; Chen, X. Comparative study of hybrid laser-MIG leading configuration on porosity in aluminum alloy bead-on-plate welding. Int. J. Adv. Manuf. Technol. 2017, 91, 2681–2688. [Google Scholar] [CrossRef]

- Yan, S.; Zhu, Z.; Ma, C.; Qin, Q.H.; Chen, H.; Fu, Y.N. Porosity formation and its effect on the properties of hybrid laser welded Al alloy joints. Int. J. Adv. Manuf. Technol. 2019, 104, 2645–2656. [Google Scholar] [CrossRef]

- Leo, P.; Renna, G.; Casalino, G.; Olabi, A.G. Effect of power distribution on the weld quality during hybrid laser welding of an Al–Mg alloy. Opt. Laser Technol. 2015, 73, 118–126. [Google Scholar] [CrossRef]

- Ola, O.T.; Doern, F.E. Keyhole-induced porosity in laser-arc hybrid welded aluminum. Int. J. Adv. Manuf. Technol. 2015, 80, 3–10. [Google Scholar] [CrossRef]

- Hagenlocher, C.; Stritt, P.; Weber, R.; Graf, T. Strain signatures associated to the formation of hot cracks during laser beam welding of aluminum alloys. Opt. Laser Eng. 2018, 100, 131–140. [Google Scholar] [CrossRef]

- Ivanov, M.; Cherniavsky, A.; Tingaev, A.; Bezgans, Y.; Derbenev, D.; Shaburova, N.; Suleymanova, I.; Alrukhaymi, A.; Sonar, T. Experimental and Numerical Investigation on Cold Cracking Susceptibility of Naval Grade High Strength Steel Welds for Lightweight Shipbuilding Structures. Int. J. Lightweight Mater. Manuf. 2024, 7, 597–613. [Google Scholar] [CrossRef]

- Oana, S.-A.; Karancsi, O.; Mitelea, I.; Uţu, I.-D.; Craciunescu, C.M. The role of filler material selection in the laser welding process of deformable 6xxx series aluminum alloys. Mater. Today Proc. 2023, 78 Pt 2, 287–294. [Google Scholar] [CrossRef]

- Wang, L.; Li, X.; Gao, M.; Zeng, X. Stabilization mechanism and weld morphological features of fiber laser-arc hybrid welding of pure copper. J. Manuf. Process. 2017, 27, 207–213. [Google Scholar] [CrossRef]

- Tang, G.; Zhao, X.; Li, R.; Liang, Y.; Jiang, Y.; Chen, H. The effect of arc position on laser-arc hybrid welding of 12-mm-thick high strength bainitic steel. Opt. Laser Technol. 2020, 121, 105780. [Google Scholar] [CrossRef]

- Xue, B.; Chang, B.; Wang, S.; Hou, R.; Wen, P.; Du, D. Humping formation and suppression in high-speed laser welding. Materials 2022, 15, 2420. [Google Scholar] [CrossRef]

- Bunaziv, I.; Dørum, C.; Nielsen, S.E.; Suikkanen, P.; Ren, X.; Nyhus, B.; Eriksson, M.; Akselsen, O.M. Laser-arc hybrid welding of 12- and 15-mm thick structural steel. Int. J. Adv. Manuf. Technol. 2020, 107, 2649–2669. [Google Scholar] [CrossRef]

- Beyer, E.; Brenner, B.; Poprawe, R. Hybrid laser welding techniques for enhanced welding efficiency. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Detroit, MI, USA, 14–17 October 1996; AIP Publishing: Melville, NY, USA, 1996. [Google Scholar] [CrossRef]

- Graf, T.; Staufer, H. Laser-hybrid welding drives VW improvements. Weld J. 2003, 82, 42–48. [Google Scholar]

- Kah, P. Usability of Laser–Arc Hybrid Welding Processes in Industrial Applications; Lappeenranta University of Technology: Lappeenranta, Finland, 2011; Available online: https://urn.fi/URN:ISBN:978-952-265-100-6 (accessed on 13 September 2024)ISBN 978-952-265-100-6.

- Casalino, G.; Campanelli, S.L.; Ludovico, A.D. Laser-arc hybrid welding of wrought to selective laser molten stainless steel. Int. J. Adv. Manuf. Technol. 2013, 68, 209–216. [Google Scholar] [CrossRef]

- Lillemäe, I.; Vääräniemi, J.; Österberg, T. Fatigue strength of thin laser-hybrid welded full-scale deck structure. Int. J. Fatigue 2017, 95, 282–292. [Google Scholar] [CrossRef]

- Petring, D.; Fuhrmann, C. Recent progress and innovative solutions for laser-arc hybrid welding. In Proceedings of the Pacific International Conference on Applications of Lasers and Optics, Laser Institute of America, Melbourne, Australia, 19–21 April 2004; Volume 2004. No. 1. [Google Scholar] [CrossRef]

- Petring, D. Developments in hybridisation and combined laser beam welding technologies. In Handbook of Laser Welding Technologies; Woodhead Publishing: Cambridge, UK, 2013; pp. 478–504. [Google Scholar] [CrossRef]

- Kah, P.; Salminen, A.; Martikainen, J. The effect of the relative location of laser beam with arc in different hybrid welding processes. In Proceedings of the International Congress on Applications of Lasers and Electro-Optics (ICALEO), Orlando, FL, USA, 2–5 November 2009. [Google Scholar] [CrossRef]

- Welding, L.A. First application of hybrid laser-arc welding to commercial ships. Mitsubishi Heavy Ind. Tech. Rev. 2010, 47, 59. [Google Scholar]

- Uemura, T.; Gotoh, K.; Uchino, I. Expansion of laser–arc hybrid welding to horizontal and vertical-up welding. Weld. World 2022, 66, 495–506. [Google Scholar] [CrossRef]

- Kristensen, J.K. Trends and developments within welding and allied processes. In Proceedings of the IIW International Conference in Connection with Annual Assembly, Copenhagen, Denmark, 24–25 June 2002. [Google Scholar]

- Ola, F.E. Fusion weldability studies in aerospace AA7075-T651 using high-power continuous wave laser beam techniques. Mater. Des. 2015, 77, 50–58. [Google Scholar] [CrossRef]

- Vaidya, W.V.; Angamuthu, K.; Koçak, M.; Grube, R.; Hackius, J. Strength and fatigue resistance of laser-MIG hybrid butt welds of an airframe aluminium alloy AA6013. Weld. World 2006, 50, 88–97. [Google Scholar] [CrossRef]

- Gong, M.; Meng, Y.; Zhang, S.; Zhang, Y.; Zeng, X.; Gao, M. Laser-arc hybrid additive manufacturing of stainless steel with beam oscillation. Addit. Manuf. 2020, 33, 101180. [Google Scholar] [CrossRef]

- Gong, M.; Zhang, S.; Lu, Y.; Wang, D.; Gao, M. Effects of laser power on texture evolution and mechanical properties of laser-arc hybrid additive manufacturing. Addit. Manuf. 2021, 46, 102201. [Google Scholar] [CrossRef]

- Liu, H.; Xu, L.; Hao, K.; Han, Y.; Zhao, L.; Ren, W. Optimizing microstructure and minimizing defects in laser-arc hybrid additive manufacturing of Al-Cu alloy: The role of laser mode. Mater. Sci. Eng. A 2025, 922, 147647. [Google Scholar] [CrossRef]

- Liu, M.; Ma, G.; Liu, D.; Yu, J.; Niu, F.; Wu, D. Microstructure and mechanical properties of aluminum alloy prepared by laser-arc hybrid additive manufacturing. J. Laser Appl. 2020, 32, 022052. [Google Scholar] [CrossRef]

- Li, X.; Xu, X.; Hu, X.; Shi, H.; Li, X.; Liu, W.; Gan, W.; Xu, C.; Wang, X. Microstructure and mechanical properties of Cu-Cr-Zr alloy prepared by electron beam additive manufacturing and laser-MIG hybrid welding. J. Manuf. Process. 2024, 117, 24–39. [Google Scholar] [CrossRef]

- Ma, S.; Chen, X.; Jiang, M.; Li, B.; Wang, Z.; Lei, Z.; Chen, Y. Surface morphology, microstructure and mechanical properties of Al–Mg–Sc alloy thin wall produced by laser-arc hybrid additive manufacturing. Thin-Walled Struct. 2023, 186, 110674. [Google Scholar] [CrossRef]

- Wang, C.; Suder, W.; Ding, J.; Williams, S. Wire based plasma arc and laser hybrid additive manufacture of Ti-6Al-4V. J. Mater. Process. Technol. 2021, 293, 117080. [Google Scholar] [CrossRef]

| Method | Applicable Materials | Process Overview | Advantages | Disadvantages | Best Application Scenarios |

|---|---|---|---|---|---|

| LAHW | Stainless steels, aluminum, titanium, and high-strength steels | Combines laser and arc welding for deep penetration and high precision. | High speed Deep penetration Smaller HAZs | Complex control High equipment cost | Suitable for welding medium-thick and thick plates, providing excellent weld formation with minimal defects and a wide range of industrial applications. |

| LW | Thin metals, high-strength steels, aluminum, and non-ferrous alloys | Uses a focused laser beam for high precision with minimal heat distortion. | High precision Low distortion Fast | Limited to thin materials High initial cost | Ideal for welding thinner plates because of its high precision and low heat input, commonly used in industries such as electronics and aerospace. |

| PAW | Stainless steels, titanium, nickel alloys, and non-ferrous metals | Uses a focused plasma arc for high energy density and deep penetration. | High precision Deep penetration Clean welds | Complex process High operational costs | Well suited for welding difficult materials (such as titanium and nickel alloys) that require deep penetration, particularly in aerospace and high-end manufacturing sectors. |

| TIG | Stainless steels, aluminum, copper alloys, etc. | Non-consumable tungsten electrodes with optional filler materials. | Clean, precise welds Good for thin metals | Slow speed High skill required Porosity risk | Optimal for welding lightweight materials, thanks to its high precision, and frequently applied in aerospace, automotive, medical, and other industries. |

| MIG/MAG | Carbon steels, stainless steels, aluminum, etc. | Uses an electric arc and consumable electrode with shielding gas. | Versatile High deposition rate Easy automation | Larger HAZs Less precise More spatter | Ideal for thick plate welding and large-scale production, with high deposition rates, and commonly used in shipbuilding and heavy industries. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Song, X.; Yang, Z.; Duan, R.; Xu, J.; Wang, W.; Chen, L.; Shi, M.; Chen, S. Research and Development Progress of Laser–Arc Hybrid Welding: A Review. Metals 2025, 15, 326. https://doi.org/10.3390/met15030326

He Y, Song X, Yang Z, Duan R, Xu J, Wang W, Chen L, Shi M, Chen S. Research and Development Progress of Laser–Arc Hybrid Welding: A Review. Metals. 2025; 15(3):326. https://doi.org/10.3390/met15030326

Chicago/Turabian StyleHe, Yang, Xinyu Song, Zhidong Yang, Ruihai Duan, Jiangmin Xu, Wenqin Wang, Liangyu Chen, Mingxiao Shi, and Shujin Chen. 2025. "Research and Development Progress of Laser–Arc Hybrid Welding: A Review" Metals 15, no. 3: 326. https://doi.org/10.3390/met15030326

APA StyleHe, Y., Song, X., Yang, Z., Duan, R., Xu, J., Wang, W., Chen, L., Shi, M., & Chen, S. (2025). Research and Development Progress of Laser–Arc Hybrid Welding: A Review. Metals, 15(3), 326. https://doi.org/10.3390/met15030326