Research on the Microstructure and Properties of QT400-18 Laser Cladding Remanufacturing

Abstract

1. Introduction

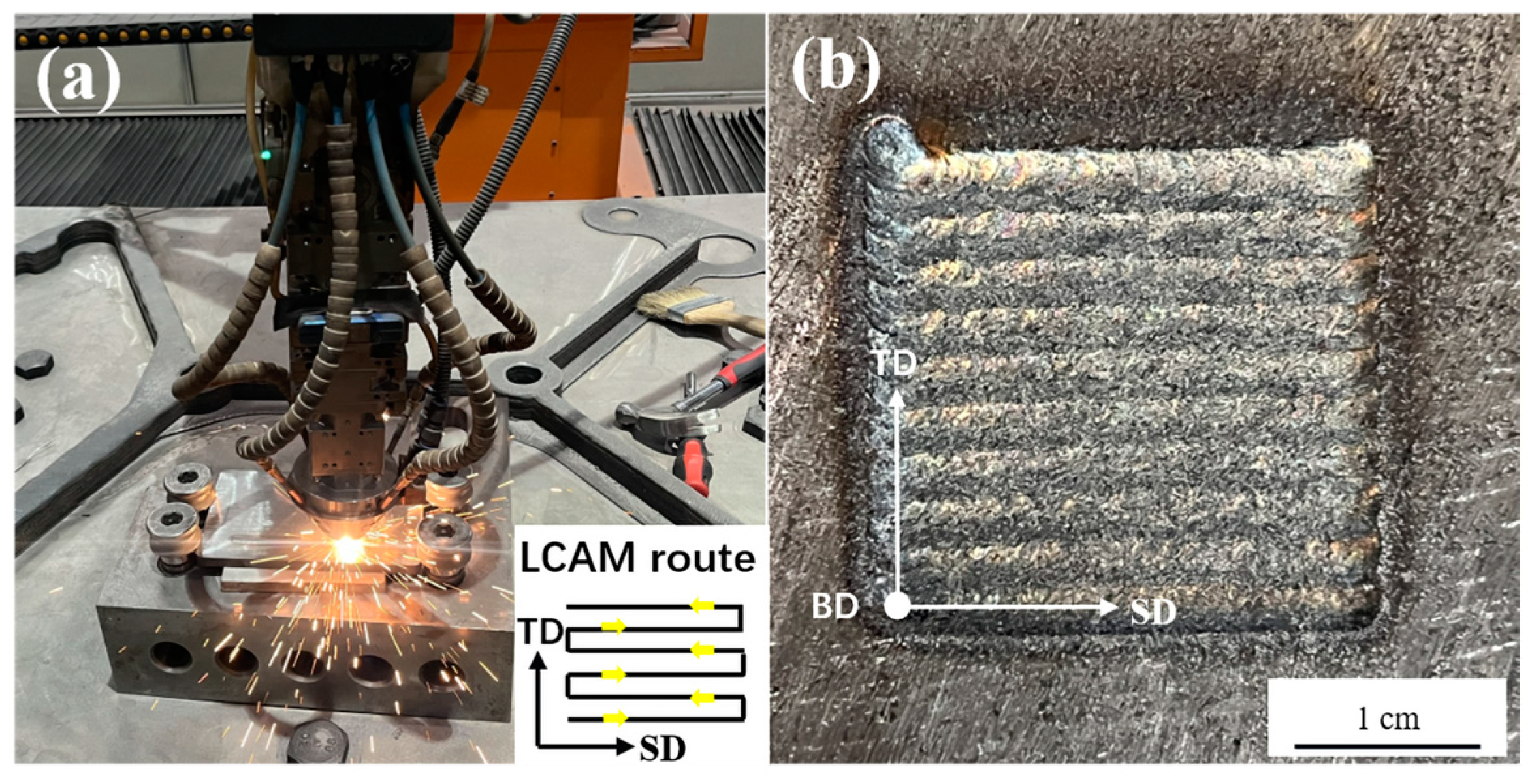

2. Materials and Methods

3. Results and Discussion

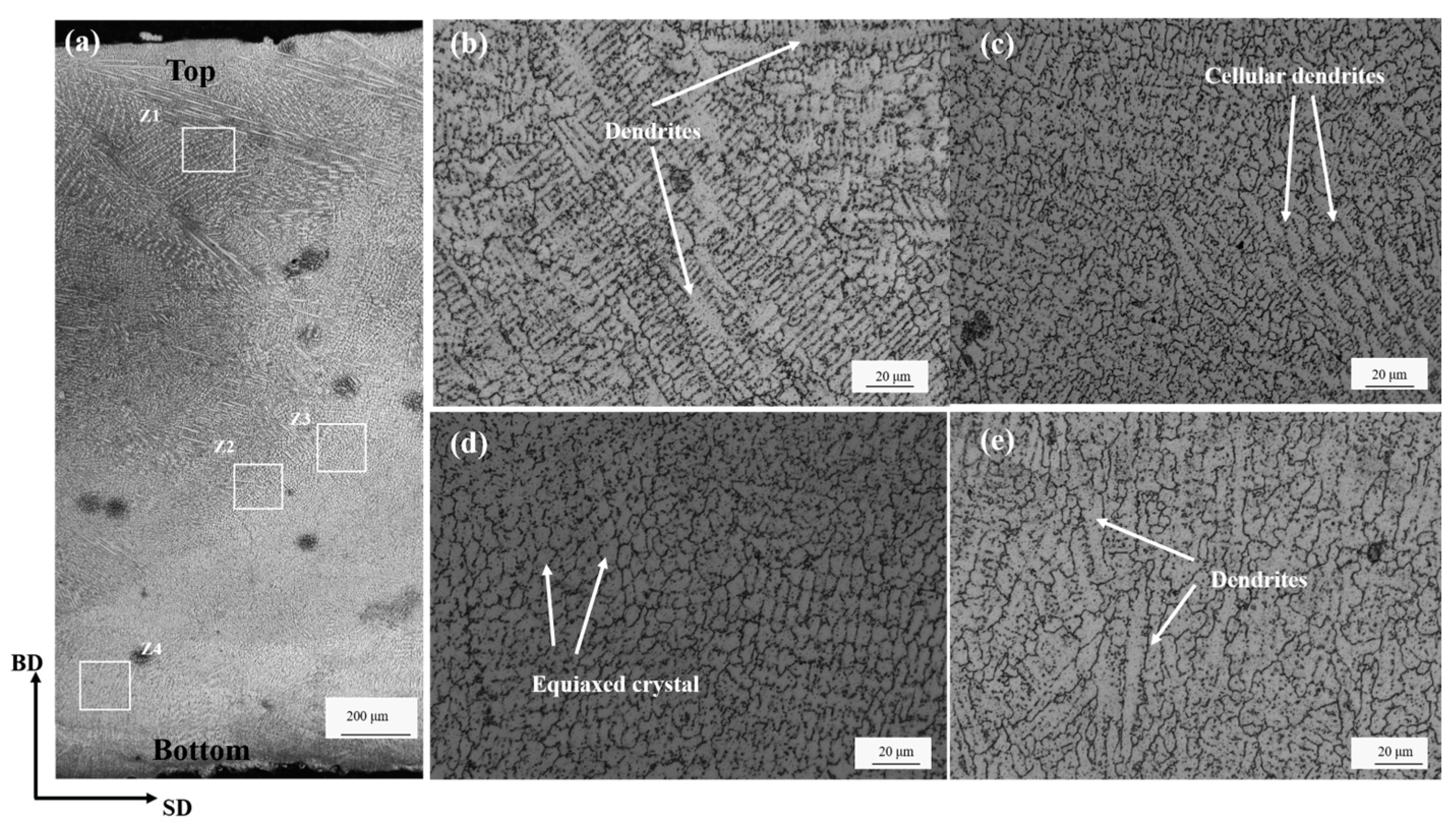

3.1. Microstructure of the Cladding Layer

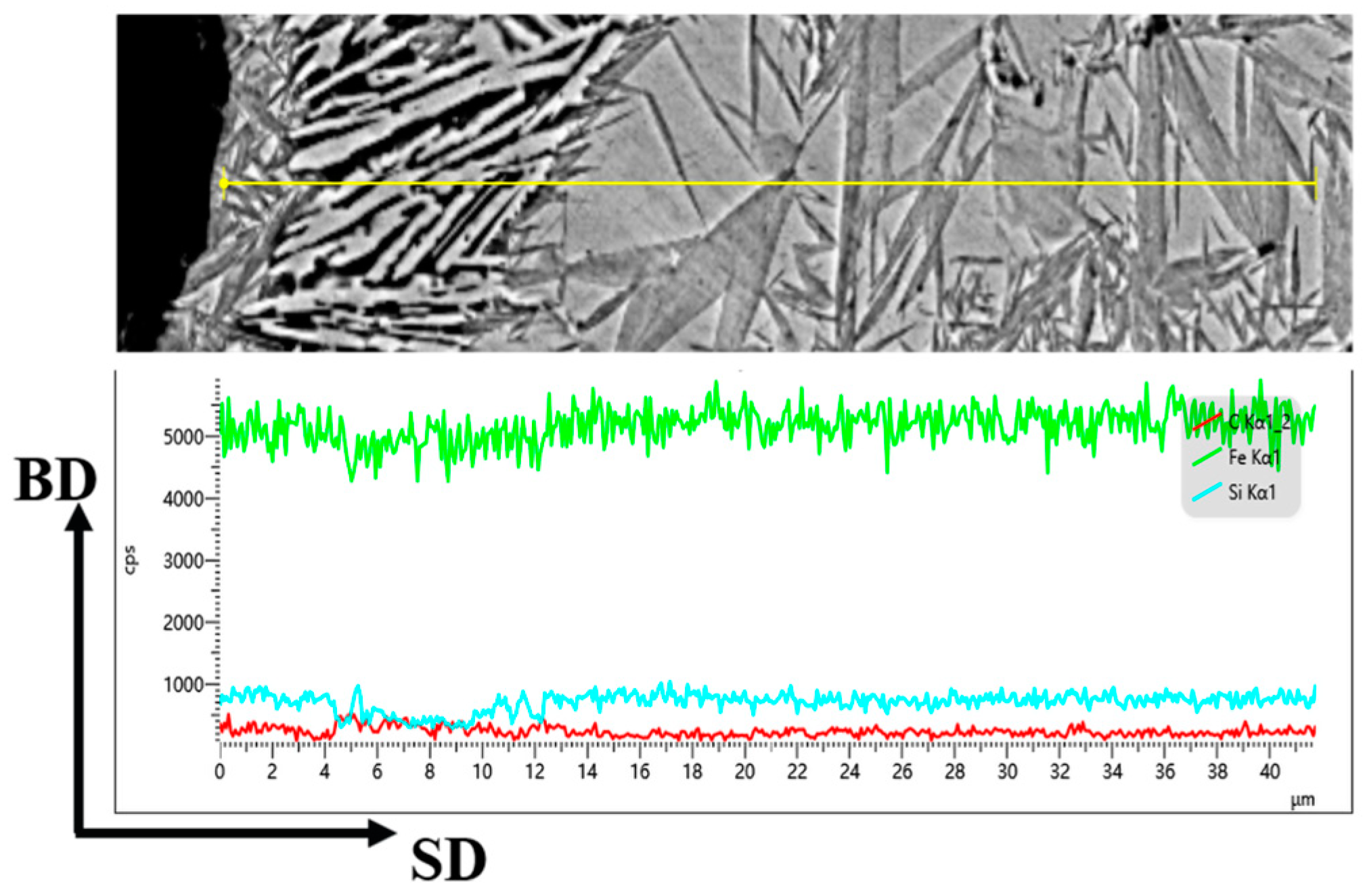

3.2. Microstructure of the Partially Melted Zone and Heat-Affected Zone

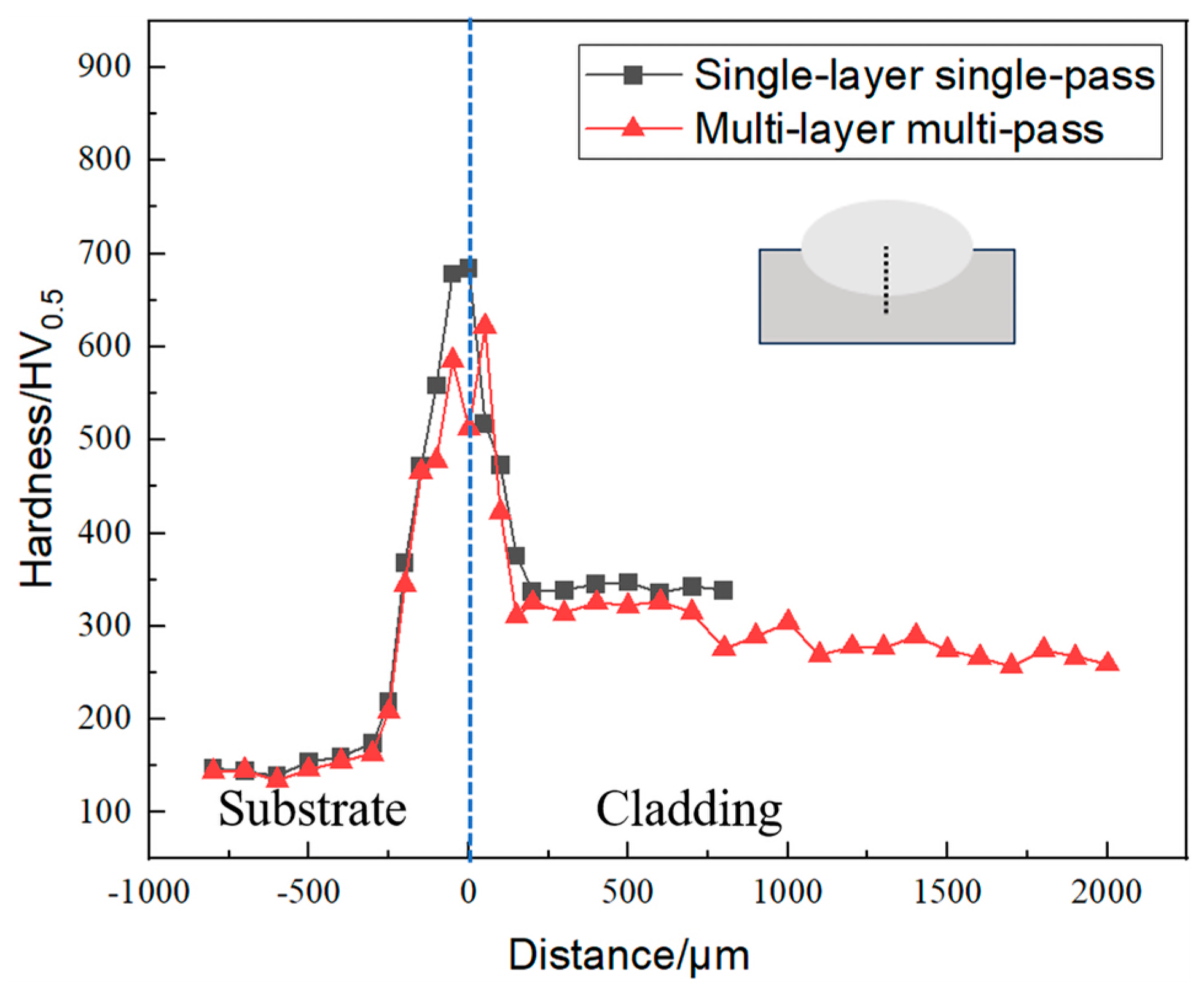

3.3. Hardness Analysis

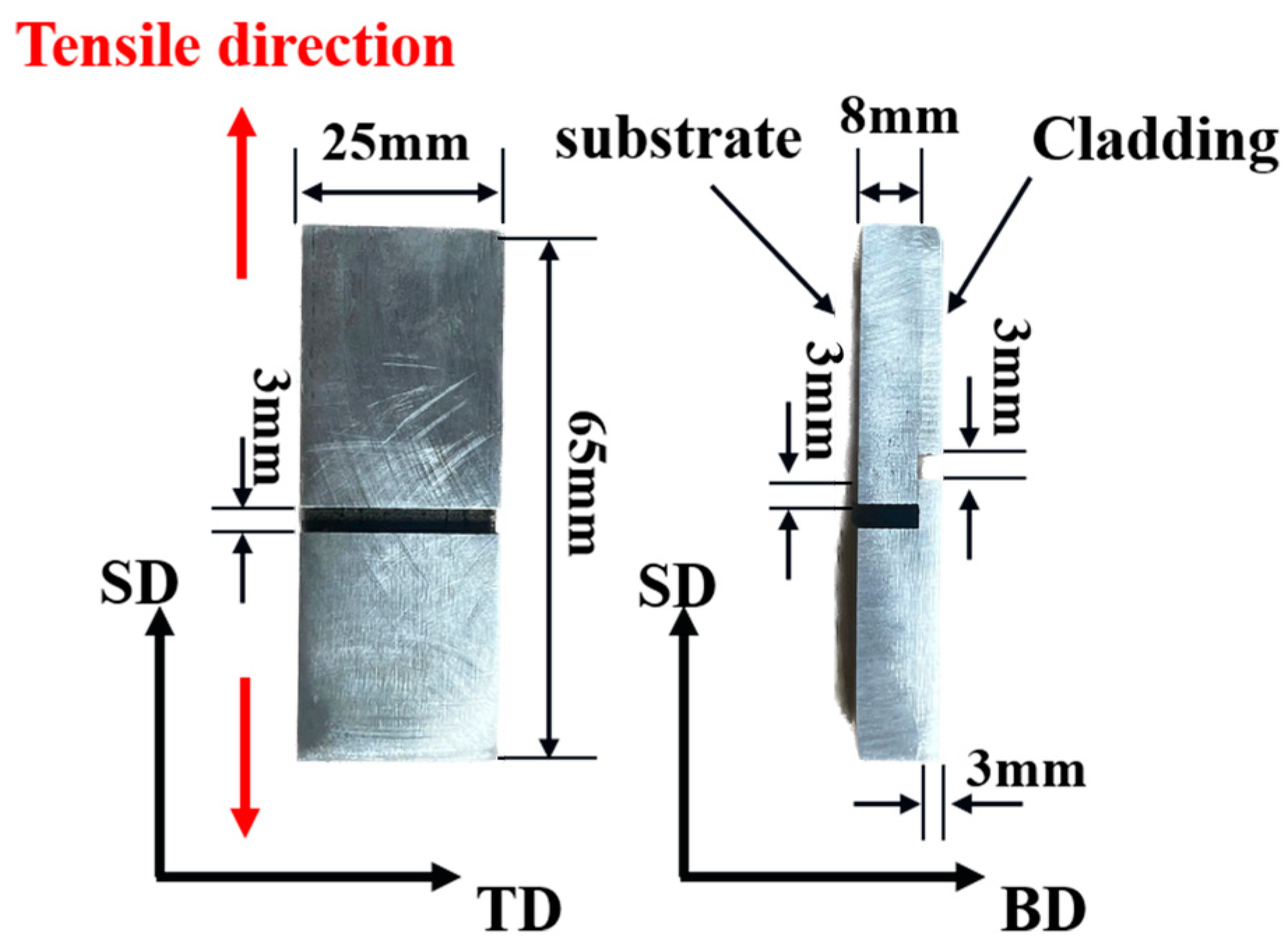

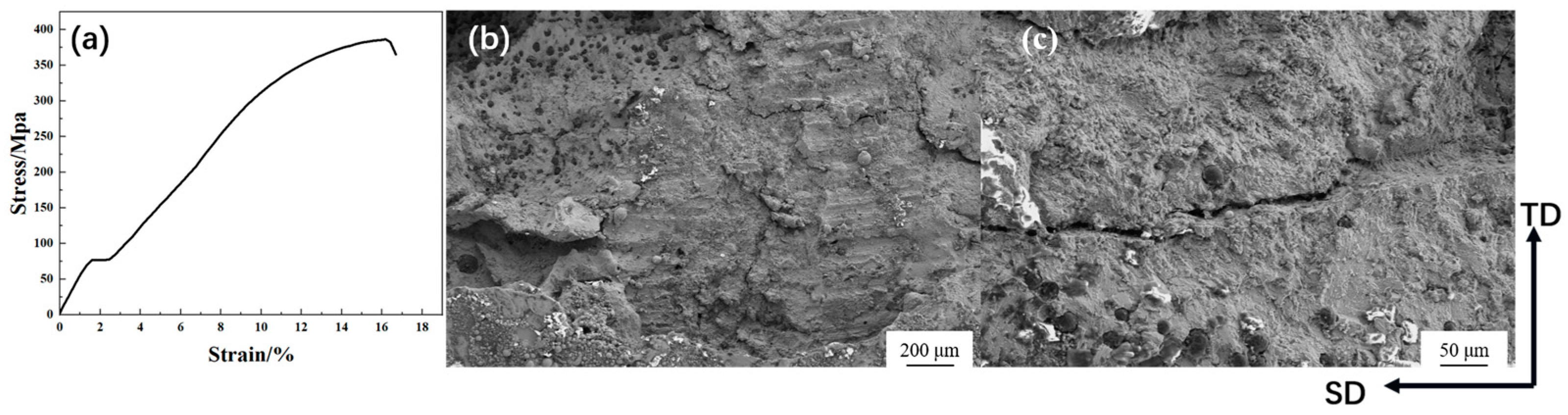

3.4. Interface Strength Analysis

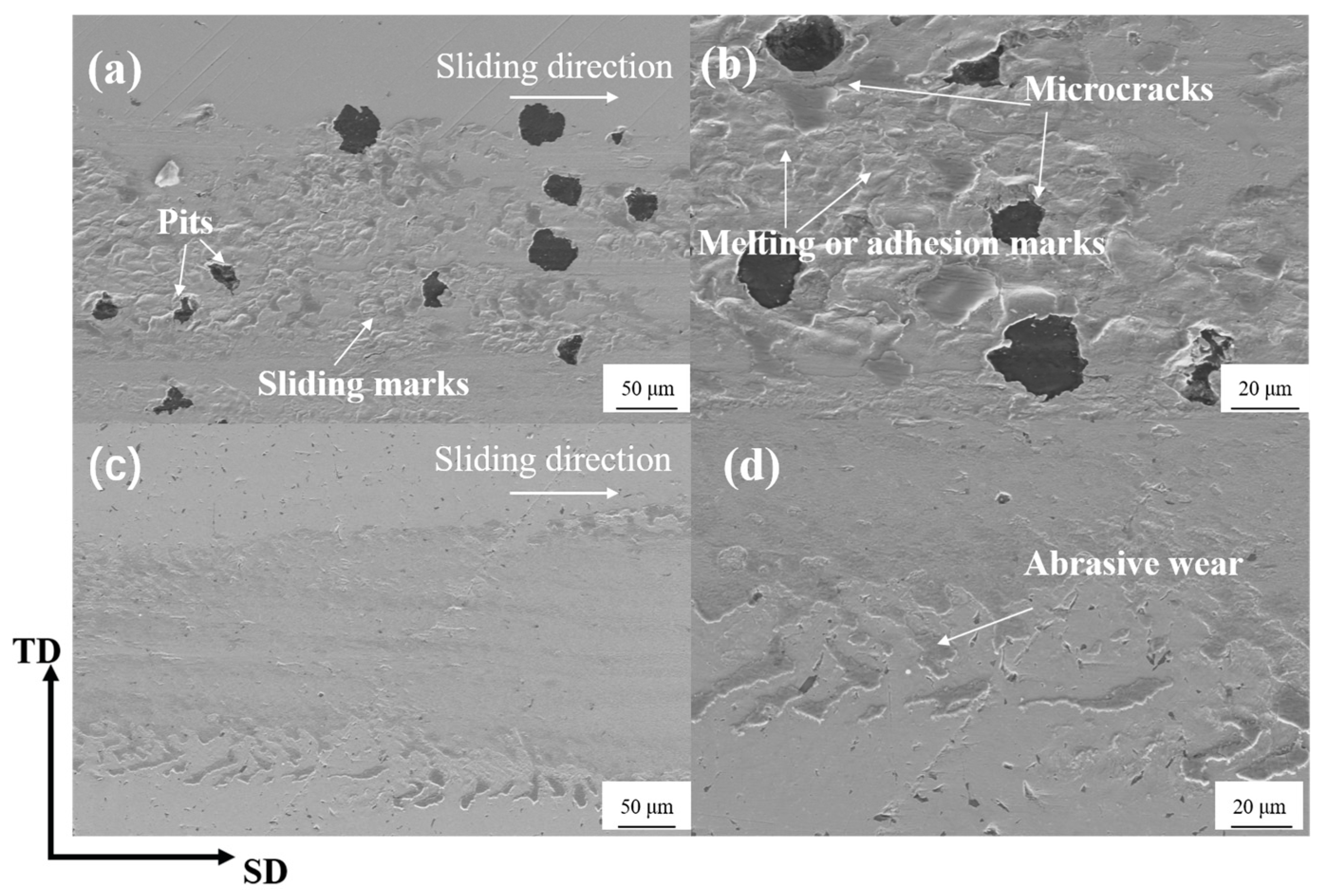

3.5. Friction and Wear Performance Analysis

4. Conclusions

- (1)

- In both the single-layer single-pass and multi-layer multi-pass laser cladding processes, the grain growth morphology transitioned from the interface to the top of the clad layer. In the single-layer single-pass cladding process, the microstructure sequentially formed dendrites, cellular dendrites, and equiaxed crystal. In the multi-layer multi-pass cladding process, the sequence evolved as dendrites, cellular dendrites, equiaxed crystal, and dendrites. The XRD results indicate that the multi-layer multi-pass cladding layer primarily consisted of a γ (Ni, Fe) solid solution, accompanied by a small amount of carbides. The distribution of these carbides significantly enhanced the strength and wear resistance of the clad layer.

- (2)

- In the single-layer single-pass cladding process, a “double-shell structure” formed around the graphite spheres in the partially melted zone, with martensite in the inner layer near the graphite sphere and ledeburite in the outer layer. During the multi-layer multi-pass cladding process, the “double-shell structure” around the graphite spheres in the partially melted zone consisted of ferrite in the inner layer near the graphite sphere and ledeburite in the outer layer.

- (3)

- The mechanical property tests indicate that the average microhardness of the clad layer was significantly higher than that of the substrate. Specifically, the average microhardness of the single-layer single-pass clad layer was 350 HV0.5, approximately 2.1 times that of the substrate, while the multi-layer multi-pass clad layer had an average microhardness of 285 HV0.5, about 1.7 times that of the substrate. The interfacial bonding strength between the multi-layer multi-pass clad layer and the substrate reached 386 MPa, approximately 96.5% of the substrate’s strength, demonstrating an excellent metallurgical bonding performance. The average coefficient of friction (COF) of the multi-layer multi-pass clad layer (0.42) was lower than that of the substrate (0.45). The wear volume of the substrate and the multi-layer multi-pass cladding layer was 3.588 × 10⁵ μm3 and 1.682 × 10⁴ μm3, respectively. Additionally, the wear mechanism of the substrate involved a combination of adhesive wear, abrasive wear, and fatigue wear, whereas the multi-layer multi-pass clad layer primarily exhibited mild abrasive wear.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Labrecque, C.; Gagne, M. Ductile iron: Fifty years of continuous development. Can. Metall. Q. 1998, 37, 343–378. [Google Scholar] [CrossRef]

- Chapetti, M.D. High-cycle fatigue of austempered ductile iron (ADI). Int. J. Fatigue 2007, 29, 860–868. [Google Scholar] [CrossRef]

- Meneghetti, G.; Campagnolo, A.; Berto, D.; Pullin, E.; Masaggia, S. Fatigue strength of austempered ductile iron-to-steel dissimilar arc-welded joints. Weld. World 2021, 65, 667–689. [Google Scholar] [CrossRef]

- Cardoso, P.H.S.; Israel, C.L.; Strohaecker, T.R. Abrasive wear in Austempered Ductile Irons: A comparison with white cast irons. Wear 2014, 313, 29–33. [Google Scholar] [CrossRef]

- Sadeghi, A.; Moloodi, A.; Golestanipour, M.; Shahri, M.M. An investigation of abrasive wear and corrosion behavior of surface repair of gray cast iron by SMAW. J. Mater. Res. Technol. 2017, 6, 90–95. [Google Scholar] [CrossRef]

- Jeshvaghani, R.A.; Harati, E.; Shamanian, M. Effects of surface alloying on microstructure and wear behavior of ductile iron surface-modified with a nickel-based alloy using shielded metal arc welding. Mater. Des. 2011, 32, 1531–1536. [Google Scholar] [CrossRef]

- Mahmoudiniya, M.; Thorr, A.S.; Petrov, R.H.; Hermans, M.J.; Kestens, L.A. Wire arc additive manufacturing of NiFe alloy/ductile cast iron bimetallic structure; Phase transformations, microstructure and crystallographic texture. Mater. Charact. 2025, 220, 114650. [Google Scholar] [CrossRef]

- Lin, C.M.; Chandra, A.S.; Morales-Rivas, L.; Huang, S.Y.; Wu, H.C.; Wu, Y.E.; Tsai, H.L. Repair welding of ductile cast iron by laser cladding process: Microstructure and mechanical properties. Int. J. Cast Met. Res. 2014, 27, 378–383. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, R.; Zhao, C.; Wei, R.; Li, H.; Deng, R.; Bai, Q.; Liu, Y. Multi-layer laser cladding analysis and high-temperature oxidative wear behavior of cast iron with a low expansion coefficient. Surf. Coat. Technol. 2023, 474, 130079. [Google Scholar] [CrossRef]

- Wang, R.; Ouyang, C.; Li, Q.; Bai, Q.; Zhao, C.; Liu, Y. Study of the microstructure and corrosion properties of a Ni-based alloy coating deposited onto the surface of ductile cast iron using high-speed laser cladding. Materials 2022, 15, 1643. [Google Scholar] [CrossRef]

- Manoj, A.; Saurabh, A.; Narala SK, R.; Saravanan, P.; Natu, H.P.; Verma, P.C. Surface modification of grey cast iron by laser cladding for automotive brake disc application. Wear 2023, 532, 205099. [Google Scholar] [CrossRef]

- Liu, H.; Hao, J.; Han, Z.; Yu, G.; He, X.; Yang, H. Microstructural evolution and bonding characteristic in multi-layer laser cladding of NiCoCr alloy on compacted graphite cast iron. J. Mater. Process. Technol. 2016, 232, 153–164. [Google Scholar] [CrossRef]

- Li, Y.; Dong, S.; Yan, S.; Liu, X.; He, P.; Xu, B. Surface remanufacturing of ductile cast iron by laser cladding Ni-Cu alloy coatings. Surf. Coat. Technol. 2018, 347, 20–28. [Google Scholar] [CrossRef]

- Arias-González, F.; Del Val, J.; Comesaña, R.; Penide, J.; Lusquiños, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Pou, J. Fiber laser cladding of nickel-based alloy on cast iron. Appl. Surf. Sci. 2016, 374, 197–205. [Google Scholar] [CrossRef]

- Mazzarisi, M.; Angelastro, A.; Latte, M.; Colucci, T.; Palano, F.; Campanelli, S.L. Thermal monitoring of laser metal deposition strategies using infrared thermography. J. Manuf. Process. 2023, 85, 594–611. [Google Scholar] [CrossRef]

- Rezayat, M.; Aboutorabi Sani, A.; Talafi Noghani, M.; Saghafi Yazdi, M.; Taheri, M.; Moghanian, A.; Mohammadi, M.A.; Moradi, M.; Garcia, A.M.M.; Besharatloo, H. Effect of lateral laser-cladding process on the corrosion performance of Inconel 625. Metals 2023, 13, 367. [Google Scholar] [CrossRef]

- Latte, M.; Mazzarisi, M.; Guerra, M.G.; Campanelli, S.L.; Galantucci, L.M. Key performance indexes for the evaluation of geometrical characteristics and subsurface defects through laser line monitoring of laser metal deposition process. Opt. Laser Technol. 2025, 182, 112085. [Google Scholar] [CrossRef]

- Ouyang, M.; Zhu, H.; Qiu, C.; Shen, L. Laser repairing nodular cast iron with improved interface and performance using Fe-14Ni-19Cr austenitic powder. Mater. Lett. 2022, 325, 132826. [Google Scholar] [CrossRef]

- Yang, P.; Song, Y.; Wang, J.; Hu, F.; Xie, L. Semiconductor laser cladding of an Fe-based alloy on nodular cast iron. Weld. World 2021, 65, 785–792. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, A.; Wang, Y.; Xiong, D.; Tang, H. Diode laser cladding of Fe-based alloy on ductile cast iron and related interfacial behavior. Surf. Coat. Technol. 2016, 286, 64–71. [Google Scholar] [CrossRef]

- Zafar, F.; Emadinia, O.; Conceição, J.; Vieira, M.; Reis, A. A review on direct laser deposition of Inconel 625 and Inconel 625-based composites—Challenges and prospects. Metals 2023, 13, 787. [Google Scholar] [CrossRef]

- Huang, J.; Liu, S.; Yu, S.; An, L.; Yu, X.; Fan, D.; Yang, F. Cladding Inconel 625 on cast iron via bypass coupling micro-plasma arc welding. J. Manuf. Process. 2020, 56, 106–115. [Google Scholar] [CrossRef]

- Wu, X.; Wu, Y.; Li, B.; Zhang, W.; Li, L.; Wang, Z. Investigation on the high-temperature oxidation behavior and mechanism of laser-cladded Inconel625 coating at various temperatures. Surf. Coat. Technol. 2024, 478, 130438. [Google Scholar] [CrossRef]

- GB/T 6396-2008; Test Methods for Mechanical and Technological Properties of Clad Steel Plates. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ): Beijing, China, 2008.

- Jack, D.H.; Jack, K.H. Invited review: Carbides and nitrides in steel. Mater. Sci. Eng. 1973, 11, 1–27. [Google Scholar] [CrossRef]

- Zhao, H.; Li, J.; Zheng, Z.; Wang, A.; Zeng, D.; Miao, Y. The microstructures and tribological properties of composite coatings formed via PTA surface alloying of copper on nodular cast iron. Surf. Coat. Technol. 2016, 286, 303–312. [Google Scholar] [CrossRef]

- Soriano, C.; Leunda, J.; Lambarri, J.; Navas, V.G.; Sanz, C. Effect of laser surface hardening on the microstructure, hardness and residual stresses of austempered ductile iron grades. Appl. Surf. Sci. 2011, 257, 7101–7106. [Google Scholar] [CrossRef]

| C | Mn | Si | S | P | Mg | Re | Fe |

|---|---|---|---|---|---|---|---|

| 3.5–4.0 | <0.35 | 2.5–3.0 | <0.03 | <0.07 | 0.03–0.06 | 0.02–0.05 | Res. |

| Ni | Cr | Mo | Nb | Al | Ti | C | Fe |

|---|---|---|---|---|---|---|---|

| 35.54 | 10.75 | 4.5 | 1.8 | 0.1 | 0.1 | 0.015 | Res. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Dong, P.; Zhang, H.; Niu, X.; Liang, C.; Li, K. Research on the Microstructure and Properties of QT400-18 Laser Cladding Remanufacturing. Metals 2025, 15, 312. https://doi.org/10.3390/met15030312

Yan J, Dong P, Zhang H, Niu X, Liang C, Li K. Research on the Microstructure and Properties of QT400-18 Laser Cladding Remanufacturing. Metals. 2025; 15(3):312. https://doi.org/10.3390/met15030312

Chicago/Turabian StyleYan, Jiakai, Peng Dong, Hongxia Zhang, Xujing Niu, Chen Liang, and Kewei Li. 2025. "Research on the Microstructure and Properties of QT400-18 Laser Cladding Remanufacturing" Metals 15, no. 3: 312. https://doi.org/10.3390/met15030312

APA StyleYan, J., Dong, P., Zhang, H., Niu, X., Liang, C., & Li, K. (2025). Research on the Microstructure and Properties of QT400-18 Laser Cladding Remanufacturing. Metals, 15(3), 312. https://doi.org/10.3390/met15030312