Abstract

Laser powder bed fusion (L-PBF), as one of the additive manufacturing (AM) or 3D printing techniques, has been widely used for the net-shape fabrication of high-entropy alloys (HEAs). However, microstructural defects are often present in the FeCoNiCrMn high-entropy alloy fabricated via L-PBF, which necessitate subsequent heat treatment for optimization. In this study, FeCoNiCrMn HEA samples were fabricated using L-PBF and subsequently annealed at different temperatures. The influence of heat treatment on the microstructure and mechanical properties was investigated. The results revealed that the cellular substructure remained stable at 650 °C, while at 1100 °C dislocation recovery and compositional homogenization occurred, leading to the dissolution of the cellular substructure. After annealing at 1200 °C, the elongation of the alloy increased by 82%, while the yield strength and ultimate tensile strength decreased by 37% and 10%, respectively, compared to the as-built state. The cellular substructure not only contributed to strength through dislocation strengthening but also acted as nucleation sites for subsequent twinning, resulting in improved work hardening capability. Annealing-induced grain growth and substructure elimination improved the capacity of coordinated plastic deformation, while weakening the contribution of grain rotation and twinning mechanisms.

1. Introduction

High-entropy alloys (HEAs) represent a novel category of multi-principal alloys, composed of five equiatomic or near-equiatomic elements [1]. Since the discovery of HEAs by Cantor et al. [2] and Yeh et al. [3] in 2004, these alloys have attracted widespread attention from researchers globally. The multi-principal characteristics of high-entropy alloys lead to an increase in configurational entropy and lattice distortion [4]. These factors result in mechanical properties that differ significantly from conventional alloys, offering superior strength [5], hardness [6], ductility [7], and low-temperature mechanical properties [8,9], which make them highly suitable for structural applications. Furthermore, high-entropy alloys offer flexibility in composition design and property modulation.

The equiatomic face-centered cubic (FCC) structured FeCoNiCrMn HEA is one of the earliest discovered HEAs [2], and it has been the subject of extensive research due to its excellent low-temperature toughness [10], thermal stability [11], fatigue resistance [12], and radiation resistance [13]. HEAs are primarily prepared through casting [14]. The emergence of additive manufacturing (AM), known as 3D printing, has opened new opportunities for the development of HEAs. AM enables the layer-by-layer printing of complex shapes, achieving near-net shaping, and the high cooling rate suppresses grain growth, making it suitable for the fabrication of complex metal components and composition design [15]. Laser powder bed fusion (L-PBF) is suitable for high-precision printing, with a cooling rate of 105 to 107 K/s [16], and is widely used for printing FeCoNiCrMn HEAs [17,18]. FeCoNiCrMn HEAs typically achieve a strength-ductility trade-off through solid solution strengthening [19], dislocation strengthening [20], phase transformation-induced plasticity [21,22,23], and twinning-induced plasticity [24]. FeCoCrNiMn HEAs, due to their relatively low stacking fault energy, can undergo stacking faults, Lomer–Cottrell locks, and nanoscale twinning during deformation, exhibiting excellent work hardening capability [25,26]. AM of HEAs, with its high cooling rates, results in a high dislocation density cellular substructure, significantly enhancing the alloy yield strength (σy) [27,28]. The AM FeCoCrNiMn alloy exhibits a significant compositional segregation, which provides additional hardening capability [29]. AM technology for fabricating HEAs not only facilitates shaping but also tailors the microstructure and mechanical properties.

Due to issues such as porosity [30], microcracks [31], and microstructural inhomogeneity [32] introduced during AM, post-processing is required to improve the mechanical properties of alloys [33]. Heat treatment and hot isostatic pressing (HIP) are the main methods of post-processing for AM. Li et al. [34] increased the ultimate tensile strength (σUTS) of FeCoCrNiMn from 601 MPa to 649 MPa through HIP to improve the alloy density. However, the HIP process is complex, expensive, and limited by dimensional shrinkage, which restricts its wide applications. In contrast, heat treatment is a cost-effective and widely used process, and has become the preferred post-processing method for AM. Park et al. [35] controlled the volume fraction of carbides in C0.1CoCrFeMnNi HEAs through annealing, thereby enhancing the alloy strength and uniform elongation. Chen et al. [36] reported that aging treatment increased the σUTS of (CoCrFeNi)94Al3Ti3 HEAs to 1503 MPa. Bai et al. [37] employed annealing as a post-processing method after additive manufacturing, resulting in a heterogeneous structure with an ultimate tensile strength of 725 MPa and a ductility of 22%. Therefore, the heat treatment process has a significant impact on the microstructure-mechanical property relationship of high-entropy alloys. In addition, heat treatment affects the dislocation cellular substructure induced by AM [38]. Voisin et al. [39] reported that the cellular substructure disappears in the temperature range of 600–1000 °C due to element diffusion in austenitic stainless steel fabricated by laser powder bed fusion. Gao et al. [40] utilized high-density dislocation cellular substructures and pre-deformation, followed by annealing, to achieve a fully recrystallized microstructure. Recent studies on L-PBF FeCoNiCrMn HEAs emphasize the critical role of cellular substructures in enhancing strength, yet their thermal stability remains underexplored.

The relationship between heat treatment processes, microstructures, and mechanical properties, especially the evolution of the cellular substructure, is crucial for optimizing heat treatment processes and developing high-performance L-PBF HEAs. Based on the outstanding mechanical properties of FeCoNiCrMn, coupled with its single-phase FCC crystal structure, which is conducive to substructure research, FeCoNiCrMn was selected as the subject of this study. This study focuses on this important issue by applying different heat treatment processes to obtain various microstructures. Scanning electron microscopy (SEM), electron backscatter diffraction (EBSD), and transmission electron microscopy (TEM) are used to investigate the microstructural evolution of the cellular substructure after heat treatment. In conjunction with mechanical properties, the relationship between the cellular substructure, mechanical performance, and deformation mechanisms is discussed. The results of this study contribute to a better understanding of the relationship between heat treatment processes, microstructure, and mechanical properties in HEAs.

2. Materials and Methods

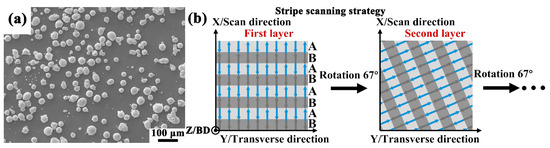

The L-PBF samples were fabricated using Farsoon Hi-Tech additive manufacturing equipment. The pre-alloyed FeCoNiCrMn powder, produced by gas-atomization method, was used for L-PBF. The powder had excellent sphericity, with the D10, D50, and D90 parameters of particle size distributions being 15.7 μm, 35.7 μm, and 57.6 μm, respectively, as shown in Figure 1a. The samples were printed on a carbon steel substrate, which was preheated to 150 °C to reduce their thermal stresses. The 3D printing parameters were set as follows: a laser power of 300 W, a scanning speed of 900 mm/s, a hatch spacing of 100 μm, and a layer thickness of 30 μm. A stripe scanning strategy was employed, with an interlayer rotation of 67°, as shown in Figure 1b.

Figure 1.

(a) Morphology of FeCoNiCrMn powders. (b) Schematic illustration of the stripe scanning strategy.

The tensile and heat-treated samples were obtained by EDM-wire cutting from the printed pieces, which had dimensions of 127 × 25 × 30 mm. The dimensions of the tensile samples were 30.5 × 15 × 2 mm, with a gauge length of 10 mm. Annealing was applied to the as-built samples at temperatures of 650 °C, 800 °C, 1100 °C, and 1200 °C, followed by water cooling. The annealing process was conducted under vacuum sealing. It should be noted that the scan direction (SD), transverse direction (TD), and building direction (BD) are defined as the X, Y, and Z directions, respectively. The scan direction of the first layer is designated as the scan direction (SD) considering the subsequent rotations (Figure 1b). The transverse direction (TD) is defined as the direction perpendicular to both the scan direction and the building direction. Uniaxial tensile testing of the dog-bone shaped specimens was conducted on an Instron 5985 universal testing machine (Instron, Norwood, MA, USA), with the loading direction (LD) parallel to the SD. The tests were performed at room temperature at a strain rate of 5 × 10−4 s−1.

Phases and microstructures were investigated using X-ray diffraction (XRD), optical microscopy (OM), SEM, EBSD, and TEM. XRD measurements were performed with Cu Kα radiation (wavelength 1.54 Å) at a voltage of 35 kV and a current of 60 mA, using a Bruker D8 Discover Plus (Bruker AXS, Karlsruhe, Germany) equipment. XRD data were analyzed using JADE 6.5 software. SEM and EBSD analyses were conducted on a ZEISS GEMINI 300 field emission SEM (Carl Zeiss AG, Jena, Germany) equipped with an Oxford Symmetry EBSD detector (Oxford Instruments, Oxford, UK). Secondary electron (SE), backscattered electron (BSE), and EBSD tests were performed at accelerating voltages of 10 kV, 15 kV, and 20 kV, respectively. The XRD, SEM, and EBSD samples were initially polished using OPS-silica suspension (Struers, Ballerup, Denmark), followed by vibratory polishing with a Presi vibrotech 300 (Presi, Grenoble, France). SEM samples were etched with aqua regia for 15 s. To identify the substructure growth direction, etching was performed prior to the EBSD test to reveal the substructure orientation. EBSD data were processed using AztecCrystal 2.1 software. TEM samples were prepared using ion milling with a Gatan PIPS II 695 system (Gatan, Inc., Pleasanton, CA, USA). Initial thinning was performed at 6 kV, followed by gradual reduction of the voltage to achieve well-defined thin regions. Dislocation morphology was observed in TEM using a JEM F200 system (JEOL, Tokyo, Japan) at an accelerating voltage of 200 kV.

3. Results and Discussion

3.1. Microstructure

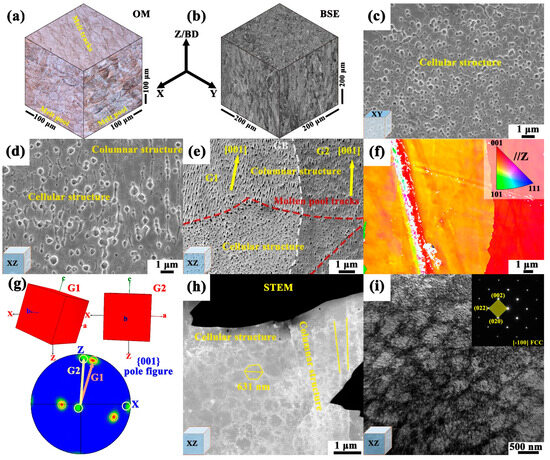

As shown in Figure 2a, the as-built sample exhibits characteristic features of additive manufacturing, with melt tracks in the XY plane being parallel within the same layer, while the XZ plane displays a fish-scale-like melt pool morphology. The as-built sample exhibits a columnar grains with a growth direction parallel to Z. The distribution of grain sizes is heterogeneous and the height of the columnar grains can extend up to hundreds of micrometers, as illustrated in Figure 2b. Due to the high cooling and solidification rates associated with L-PBF, numerous dendritic substructures are present within the grain, which can be categorized into cellular and columnar substructures [41]. Figure 2c presents a typical SEM image of the XY plane proximal to the melt tracks after etching. In the XY plane, the microstructure of the L-PBF FeCoNiCrMn high-entropy alloy is predominantly characterized by equiaxed cellular substructure, with the minor presence of optimally grown columnar substructure observed near the melt tracks. The dimensions of these substructures are smaller than 1 μm. The columnar substructure in the L-PBF metal exhibits preferential growth in the direction of maximum supercooling, being specifically perpendicular to the melt tracks. As illustrated in Figure 2d, a combination of cellular and columnar substructures is observed in the XZ plane, with the morphology of cellular substructure consistent with that of the XY surface. Cellular and columnar substructures can be observed in the same sample as shown in the STEM image (Figure 2h). To further elucidate the growth characteristics of the columnar substructure, EBSD analyses were conducted on the XZ plane, as depicted in Figure 2f,g. Figure 2e reveals two groups of columnar substructure with divergent growth directions, corresponding to G1 and G2 grains. These two groups of columnar substructures are not precisely perpendicular to the melt pool bottom but exhibit a certain angle. According to the pole figure and their columnar substructure growth direction, their growth orientations are [001]. In cubic metals, the <001> direction is the preferred growth direction [38].

Figure 2.

(a) OM image of the as-built sample. (b) BSE image of the as-built sample. (c,d) The substructure morphology of the XY plane and XZ plane. (e) The substructure morphology of the XZ plane. (f) Inverse pole figure (IPF) orientation map in (e). (g) Pole figure analysis of G1 and G2 marked in (e), with G1 and G2 highlighted in yellow and orange, respectively. (h,i) STEM and TEM images of the XZ plane with the inset in (i) showing the selected area electron diffraction (SAED) patterns.

Consequently, the columnar substructure growth process does not exclusively adhere to the direction of maximum supercooling, which is perpendicular to the melt pool bottom. Rather, the growth direction results from competition between the maximum degree of supercooling and the optimal <001> growth direction, favoring the <001> direction that is closest to being perpendicular to the melt pool bottom. Furthermore, the cellular substructure is typically observed at the upper region of the melt pool, while the columnar substructure is predominantly found at the lower region. The microstructure is dependent on the ratio of temperature gradient (G) to solidification rate (R) [42]. In the proximity of the bottom of the melt pool in the XZ plane and the melt tracks in the XY plane, the G is higher, whereas the R is lower, thus favoring the formation of a columnar substructure. Cellular and columnar substructures can be formed simultaneously within individual grains without a significant orientation difference between the two morphologies, as shown in Figure 2e–g. The substructure features a high density of dislocations, with entangled dislocation walls forming the cell boundaries, while the intracellular region contains only a minimal amount of dislocations, as shown in Figure 2i. Additionally, the substructure walls exhibit notable compositional segregation, with Mn segregating at the cell boundaries (Figure 3f).

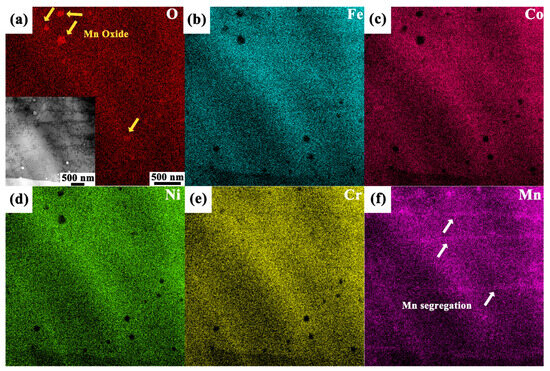

Figure 3.

(a–f) STEM-EDS elemental maps of O, Fe, Co, Ni, Cr, and Mn.

3.2. Post-Heat Treatment

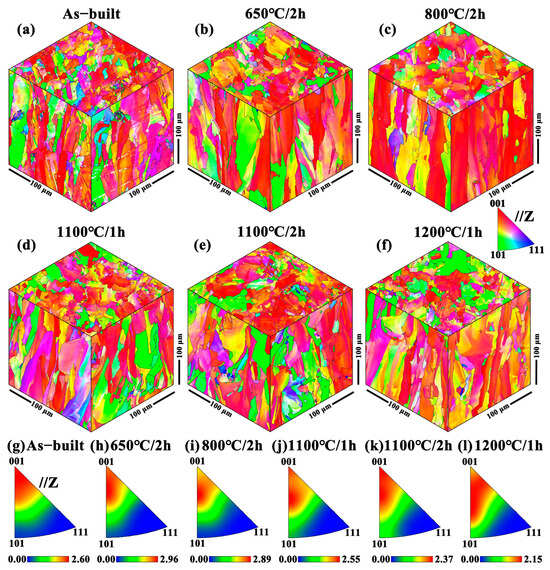

Figure 4a–f presents IPF orientation maps of the FeCoNiCrMn high-entropy alloy before and after heat treatment. The grain morphology exhibited no significant change before and after heat treatment, with all grains maintaining their columnar substructure, albeit with varying grain sizes. The texture exhibited a <001>//Z orientation both prior to and after heat treatment and the thermal processing does not significantly change the crystal orientation, as shown in Figure 4g–l. As the annealing temperature increases, the <001>//Z texture shows a slight decrease.

Figure 4.

A lot of EBSD scans/analyses. (a–f) IPF orientation maps of the FeCoNiCrMn high-entropy alloy before and after heat treatment: (a) as-built and heat-treated at (b) 650 °C/2 h, (c) 800 °C/2 h, (d) 1100 °C/1 h, (e) 1100 °C/2 h, and (f) 1200 °C/1 h. (g–l) IPFs of the FeCoNiCrMn alloy before and after heat treatment: (g) as-built, and heat-treated at (h) 650 °C/2 h, (i) 800 °C/2 h, (j) 1100 °C/1 h, (k) 1100 °C/2 h, and (l) 1200 °C/1 h.

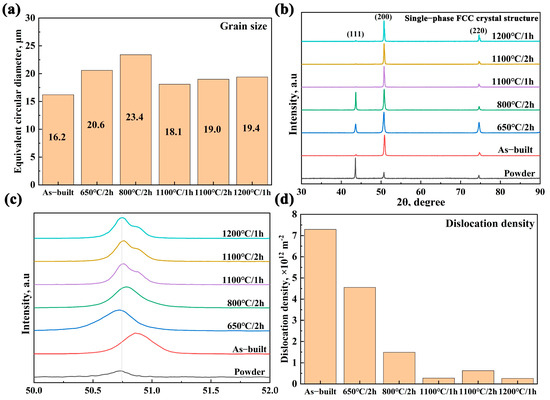

The average grain size obtained from two regions in the gauge sections of the heat-treated tensile samples, as depicted in Figure 5a, exhibits an increase following heat treatment; however, a reduction in grain size was observed at 1100 °C for 1 h, attributed to partial recrystallization. Heat treatment was then conducted at a higher temperature of 1200 °C for 1 h and at a longer duration of 1100 °C for 2 h. However, no significant increase in the recrystallized fraction was observed. The recrystallization process during heat treatment is attributed to the insufficient residual stress from 3D printing to achieve complete recrystallization. Consequently, recrystallization occurs only in a limited area and necessitates a greater driving force [40]. Therefore, after annealing at temperatures of 1100 °C and above, the grain size showed only a slight increase compared to the as-built state. In addition, the pre-alloyed powders, as-built and heat-treated samples, exhibited a single-phase FCC crystal structure, with no other noticeable diffraction peaks, as illustrated in Figure 5b. The inset SAED pattern in Figure 2i also confirms that the alloy has an FCC crystal structure. As shown in Figure 5c, after annealing, the (200) diffraction peak shifts to the left, indicating an increase in lattice constant and a decrease in lattice stress.

Figure 5.

(a) Grain size distribution of the as-built and annealed samples, derived from EBSD data on the XY plane; (b) XRD patterns for the as-built and annealed samples; (c) magnified view of the XRD (200) diffraction peak; (d) dislocation density of the as-built and annealed samples, calculated from the (200) diffraction peak.

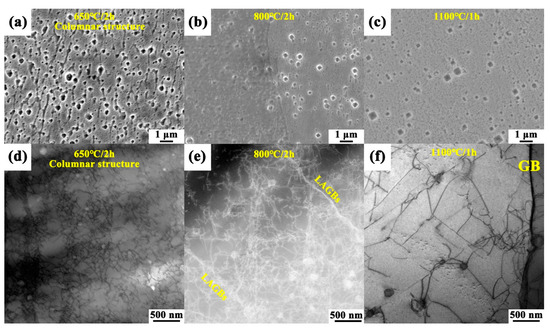

As shown in Figure 6a–c, the morphology of the cellular substructure remained largely stable after heat treatment at 650 °C. However, the cellular substructure gradually diminished after heat treatment at 800 °C and completely disappeared at 1100 °C. Figure 6d–f show the TEM images of samples annealed at different temperatures. After annealing at 650 °C for 2 h, a large number of dislocations were retained, and the columnar substructure remained intact. In the sample annealed at 800 °C for 2 h, although the dislocation density remained relatively high, the substructure features were no longer visible, with many dislocations being absorbed by the low angle grain boundary (LAGB, 2~15°). At 1100 °C, only a few free dislocations remained, some of which were pinned by second-phase particles, while most dislocations were absorbed by grain boundaries. At high temperatures, the disappearance of high-density dislocation cellular substructures is mainly due to dislocation recovery. This includes edge dislocation climb and dislocation annihilation upon interaction with dislocations of opposite signs, leading to a reduction in dislocation density [43]. Additionally, compositional homogenization at elevated temperatures eliminates segregation within the cellular substructure, weakening its ability to trap dislocations. Ultimately, the dislocations are absorbed by high-angle grain boundaries, further decreasing the dislocation density. As shown in Figure 3, the second phase, typically consisting of Mn oxide, is commonly observed in L-PBF-fabricated FeCoNiCrMn high-entropy alloy, as reported in previous studies [44,45]. The high-density dislocation cellular substructure can provide a strong resistance to dislocation slip, resulting in improved σy. Dislocation density (ρ) can be estimated using XRD as follows [46,47]:

where β is the full width at half maximum (FWHM), which can be calculated using the following equation [46,47]:

where βobs is the FWHM of the as-built and heat-treated samples and βinst is the instrumental FWHM, measured using FeCoNiCrMn powders. The dislocation density of the as-built and annealed samples was calculated based on the XRD (200) diffraction peak, as shown in Figure 5d and summarized in Table 1. After annealing at 1100 °C, the significant decrease in dislocation density and the increase in lattice constant indicate a reduction in residual stress and the disappearance of the cellular substructure.

Figure 6.

(a–c) SEM images of the FeCoNiCrMn high-entropy alloy samples annealed at 650 °C for 2 h, 800 °C for 2 h, and 1100 °C for 1 h; (d–f) STEM images of the samples annealed at 650 °C for 2 h, 800 °C for 2 h, and 1100 °C for 1 h, where all the SEM and STEM images were taken from the XZ plane.

Table 1.

Calculations for estimating the dislocation density in the as-built and annealed samples of FeCoNiCrMn high-entropy alloy, annealed at 650 °C for 1 h, 800 °C for 2 h, 1100 °C for 1 h, 1100 °C for 2 h, and 1200 °C for 1 h.

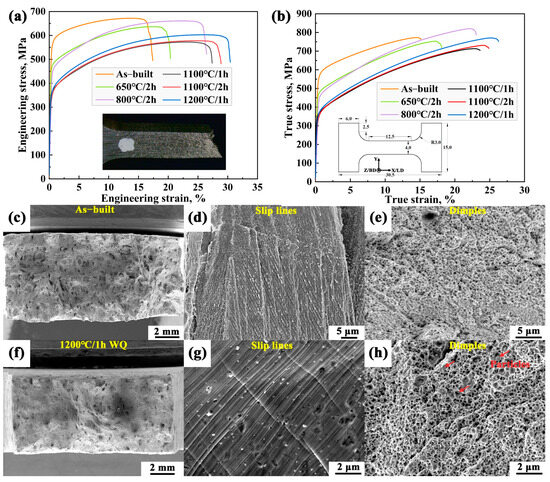

3.3. Deformation Mechanism

Figure 7a shows the tensile stress-strain curves of the as-built and annealed FeCoNiCrMn HEA samples, with the tensile properties summarized Table 2. The as-built sample exhibits a higher σy due to the high-density dislocation cellular substructure (Figure 2i). At an annealing temperature of 650 °C, the retention of cellular substructure characteristics leads to mechanical properties that are similar to those of the as-built sample. After homogenization at temperatures of 1100 °C and higher, the σy of the alloy decreases, accompanied by a significant increase in elongation. As the annealing temperature increases further, elongation continues to rise, and σUTS also improves. Upon annealing at temperatures 1200 °C, the elongation increased by 82%, while its σy and σUTS decreased by 37% and 10%, respectively, in comparison to the as-built state. The 1200 °C for 1 h heat treatment condition gave the best overall mechanical properties, with a tensile strength of 603 MPa and an elongation of 30.2%. The tensile strength and elongation at 1200 °C surpass the values reported for other post-annealed additive-manufactured FeCoNiCrMn alloys (455 MPa, 28%), highlighting the potential of heat treatment in additive manufacturing for microstructural tailoring [48]. The fracture morphologies of the as-built and annealed samples are shown in Figure 7c–h. A large number of voids were observed (Figure 7c,f), with the fracture mode characterized by void coalescence. In contrast, the sample annealed at 1200 °C for 1 h exhibits fewer voids compared to the as-built sample. High-temperature heat treatment can eliminate tensile residual stresses in as-built samples, which contributes to improved tensile strength and ductility [49]. Additionally, grain coarsening and partial recrystallization reduce internal defects within the alloy. Therefore, heat treatment improves the density of the alloy while simultaneously reducing the risk of void coalescence fracture during deformation, as evidenced by fewer voids observed in the fracture surface (Figure 7f) [50]. It should be pointed out that the effects of grain coarsening and tensile residual stress relaxation on strength are opposite. Both as-built and annealed samples had relatively flat areas in some places (within voids), these flat areas displayed a fine and dense line pattern due to the activation of multiple slip systems, indicating superior plastic deformation ability. The presence of multiple slip lines on the fracture surface indicates that multiple slip mechanisms occur to alleviate stress concentration in the void regions. In addition, the sample annealed at 1200 °C for 1 h exhibits a denser line pattern, suggesting improved ductility (Figure 7d,g). The majority of the tensile fracture surfaces exhibited dimples (Figure 7e,h), with the size of the dimples being smaller than 1 μm. The annealed sample exhibited fewer voids (Figure 7f) and more distinctive dimples (Figure 7h); this corresponded well to the improved toughness and ductility (Figure 7a,b).

Figure 7.

(a,b) Engineering stress-strain and true stress-strain curves for the as-built and annealed states. (c–e) Typical fracture morphologies of the as-built sample, (f–h) typical fracture morphologies of the sample annealed at 1200 °C for 1 h.

Table 2.

Room-temperature tensile properties of the as-built and annealed FeCoNiCrMn HEA samples annealed at 650 °C for 1 h, 800 °C for 2 h, 1100 °C for 1 h, 1100 °C for 2 h, and 1200 °C for 1 h.

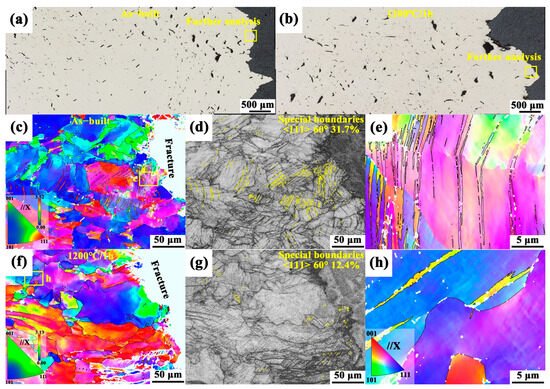

Figure 8a,b presents the OM images after tensile tests of the as-built and 1200 °C/1h heat-treated samples, taken from the XY plane of the samples. In the as-built sample, the cracking is predominantly concentrated near the fracture surface, particularly the large-sized cracks. In contrast, in the 1200 °C/1 h heat-treated sample, the cracking exhibits a more uniform distribution, with some large-sized cracks also observed in regions distant from the fracture location. Following heat treatment at 1200 °C, FeCoNiCrMn exhibits improved homogeneity in plastic deformation capacity compared to as-built samples. Figure 8c,f presents the IPF maps before and after heat treatment. The grain rotation in the as-built samples is more pronounced, resulting in the formation of a <111>//X texture that is aligned with the tensile direction after deformation. The <111> orientation is considered a hard orientation, which plays a significant role in enhancing texture strengthening [51]. In contrast, the samples subjected to heat treatment at 1200 °C for 1 h exhibit a larger grain size with less evident grain rotation behavior. Grain rotation is a common phenomenon in the deformation of polycrystalline materials. The substructure introduced by LPBF facilitates the overall rotation of the grains through the subgrain rotation mechanism, resulting in more pronounced grain rotation [52]. In FCC materials, the crystals rotate in the direction of the {111} close-packed plane, which is parallel to the tensile axis [53]. Due to the relatively low stacking fault energy of FeCoNiCrMn high-entropy alloy, twinning is one of the important deformation mechanisms [54]. Notably, the sample that underwent heat treatment at 1200 °C for 1 h exhibited a lower twin density, as shown in Figure 8g,h. The as-built sample showed a high density of twins, which were transmitted through LAGBs, leading to bending. In contrast, the sample that was heat-treated at 1200 °C for 1 h exhibited a lower twin density and appeared straighter. As shown in Figure 8d, twins originate at the high angle grain boundary (HAGB, >15°) and grow into the grains, extending through the entire grain. The presence of high-density dislocations and compositional segregation within the cellular substructure, along with their interaction, can increase flow stress. This, in turn, may cause the flow stress to exceed the critical stress for twinning, resulting in a higher density of twins [55,56]. The role of the substructure can be summarized as follows: first, it provides high-density dislocations and boundaries; second, it facilitates grain rotation and twin formation; and third, compositional segregation enhances the dislocation trapping capability of the substructure walls. Therefore, the as-built sample exhibits a higher work hardening capacity, with a σUTS greater than that of the sample annealed at 1200 °C for 1 h by 54 MPa. However, the dense dislocation cellular substructure also leads to increased deformation incompatibility, resulting in a 13.5% reduction in elongation. Localized stress concentration causes secondary cracks to form primarily near the fracture surface rather than being evenly distributed. Meanwhile, grain rotation is intensified due to increased deformation incompatibility and flow stress, making it a significant deformation characteristic in the as-built sample.

Figure 8.

(a,b) Deformed microstructure characterized by OM for the as-built and 1200 °C/1 h annealed samples. (c–e) IPF + grain boundary (GB) map, band contrast (BC) + special GB map, and the high-magnification image within the yellow box in (c) of the as-built sample. (f–h) IPF + GB map, BC + special GB map, and the high-magnification image within the yellow box in (f) of the 1200 °C/1 h heat-treated sample. Special grain boundaries are highlighted in yellow in (d,g).

Based on multiple deformation mechanisms, the overall σy can be calculated as follows [57]:

where σ0, σG, and σD are the strengths of the lattice friction, grain boundary, and dislocation, respectively. The σ0 value has been experimentally measured to be 194 MPa [58]. The σG can be calculated using the Hall–Petch relationship as follows:

where k is the grain boundary strengthening coefficient and d is the average grain size, measured using EBSD. The σD can be calculated using the Taylor hardening law:

where M is the Taylor factor, G is the shear modulus, α is a material constant, b is the Burgers vector, and ρ is the dislocation density. M, G, k, α, and b values for the FeCoCrNiMn high-entropy alloy are 3.06, 81 GPa, 494 MPa·μm1/2, 0.2, and 0.254 nm, respectively [58]. Based on the previously calculated grain size and dislocation density, the σG and σD values are obtained to be 122.6 MPa and 34.0 MPa for the as-built sample and 112.2 MPa and 6.4 MPa for the 1200 °C/1 h annealed sample, respectively. Therefore, the primary hardening mechanism in the as-built sample is dislocation strengthening through the cellular substructure. However, the calculated σy of the as-built sample, 350.6 MPa, does not match the experimental value. In the calculation via equation 3, the contribution of the twin is ignored. Furthermore, the high-density dislocation cellular substructure not only strengthens through dislocation hardening but also involves the cell walls, which can be considered as LAGBs. This along with the twin boundaries would contribute to grain boundary strengthening. Additionally, compositional segregation is another factor contributing to the strength, leading to an overestimation of the contribution of the cellular substructure to the mechanical properties. However, in the as-built sample, a significantly higher volume fraction of nanotwins and pronounced texture strengthening induced by grain rotation during deformation contribute to additional hardening. Therefore, the as-built sample possesses a more complex multi-scale microstructure, providing sustained work hardening during subsequent deformation. In contrast, the deformation mechanism in the high-temperature annealed state is primarily dominated by dislocation slip, which enhances its uniform deformation capability. As a result, the 1200 °C for 1 h heat treatment condition offers better overall performance, while the as-built condition shows a superior yield strength.

4. Conclusions

FeCoNiCrMn samples were fabricated with laser powder bed fusion (L-PBF) and annealed at different temperatures. The microstructures of the as-built and annealed samples were extensively characterized and the deformation mechanisms were discussed. The following conclusions could be drawn:

- (1)

- The L-PBF FeCoNiCrMn alloy exhibited two substructures, i.e., the high-density dislocation cellular the columnar substructures. The columnar substructure demonstrated <001> epitaxial growth, resulting from the competition between the direction of maximum undercooling and the preferred growth direction.

- (2)

- The cellular substructure remained stable at temperatures up to 650 °C but began to dissipate at 800 °C. The high-density dislocation cellular substructure played a decisive role in the mechanical properties of the alloy through dislocation strengthening and grain boundary-like strengthening.

- (3)

- The cellular substructure also served as a site for twin formation during subsequent deformation, facilitating twin formation and inducing grain rotation, which contributed to work hardening. In contrast, the high-temperature annealing state exhibited an increased capacity for uniform plastic deformation due to homogenization, leading to improved ductility.

Author Contributions

Conceptualization, S.Q. and J.J.; methodology, A.F., G.C., J.S. (Jingli Sun), J.S. (Jun Shen) and D.C.; software, J.L., H.W. and G.Z.; validation, S.Q., J.S. (Jingli Sun), G.C. and J.S. (Jun Shen); formal analysis, J.L., J.S. (Jingli Sun) and G.Z.; investigation, S.Q., G.C. and J.L.; resources, D.C., J.S. (Jun Shen) and H.W.; data curation, A.F.; writing—original draft preparation, J.L. and G.Z.; writing—review and editing, D.C., J.J., S.Q., A.F. and H.W.; visualization, J.L.; supervision, D.C., J.J. and S.Q.; project administration, A.F.; funding acquisition, S.Q. and D.C. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the National Natural Science Foundation of China (NSFC) (Grant 52271012). D.C. would like to thank the Natural Sciences and Engineering Research Council of Canada (NSERC) for the financial support. J.J. acknowledges financial support from the Department of Science and Technology of Fuzhou City (2024-Y-017, 2024-SG-003, and 2024-SG-004), the National Natural Science Foundation of China (Grant 52371165 and 12275237), the Key Laboratory of Silicon-based Materials, Ministry of Education, P. R. China, the Space Application System of the China Manned Space Program (KJZ-YY-NCL09), and the China-ESA international cooperation.

Data Availability Statement

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

Acknowledgments

The authors also acknowledge the Advanced Materials Research Institute and the Yangtze Delta Analytical Characterization Platform.

Conflicts of Interest

Guoxing Zhu is employed by the company Xiamen Hagongda 3D Technology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| L-PBF | Laser powder bed fusion |

| AM | Additive manufacturing |

| HEAs | High-entropy alloys |

| FCC | Face-centered cubic |

| HIP | Hot isostatic pressing |

| OM | Optical microscopy |

| SEM | Scanning electron microscopy |

| EBSD | Electron backscatter diffraction |

| TEM | Transmission electron microscopy |

| XRD | X-ray diffraction |

| SE | Secondary electron |

| BSE | Backscattered electron |

| BD | Building direction |

| SD | Scan direction |

| TD | Transverse direction |

| LD | Loading direction |

| G | Temperature gradient |

| R | Solidification rate |

| IPF | Inverse pole figure |

| PF | Pole figure |

| BC | Band contrast |

| LAGBs | Low-angle grain boundaries |

| HAGBs | High-angle grain boundaries |

| GB | Grain boundary |

References

- Cantor, B. Multicomponent high-entropy Cantor alloys. Prog. Mater. Sci. 2021, 120, 100754. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Lee, C.; Song, G.; Gao, M.C.; Feng, R.; Chen, P.; Brechtl, J.; Chen, Y.; An, K.; Guo, W.; Poplawsky, J.D.; et al. Lattice distortion in a strong and ductile refractory high-entropy alloy. Acta Mater. 2018, 160, 158–172. [Google Scholar] [CrossRef]

- Xiang, S.; Luan, H.; Wu, J.; Yao, K.-F.; Li, J.; Liu, X.; Tian, Y.; Mao, W.; Bai, H.; Le, G.; et al. Microstructures and mechanical properties of CrMnFeCoNi high entropy alloys fabricated using laser metal deposition technique. J. Alloys Compd. 2019, 773, 387–392. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, W.; Zhang, E.; Wang, W.; Wei, R.; Chen, J.; Yuan, S.; Wang, T.; Zhang, T.; Guan, S.; et al. Microstructure of and mechanical properties of an as-cast fine-grain dual-phase Fe-based high entropy alloy formed via solid-state phase transformation. Mater. Sci. Eng. A 2022, 838, 142779. [Google Scholar] [CrossRef]

- Gludovatz, B.; George, E.P.; Ritchie, R.O. Processing, Microstructure and Mechanical Properties of the CrMnFeCoNi High-Entropy Alloy. JOM 2015, 67, 2262–2270. [Google Scholar] [CrossRef]

- Chou, T.H.; Huang, J.C.; Yang, C.H.; Lin, S.K.; Nieh, T.G. Consideration of kinetics on intermetallics formation in solid-solution high entropy alloys. Acta Mater. 2020, 195, 71–80. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Lu, C.; Niu, L.; Chen, N.; Jin, K.; Yang, T.; Xiu, P.; Zhang, Y.; Gao, F.; Bei, H.; Shi, S.; et al. Enhancing radiation tolerance by controlling defect mobility and migration pathways in multicomponent single-phase alloys. Nat. Commun. 2016, 7, 13564. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Wang, Q.; Zhang, H.; Dai, L.; Mukai, T.; Wu, Y.; Liu, X.; Wang, H.; Nieh, T.G.; Lu, Z. Dynamic deformation behavior of a face-centered cubic FeCoNiCrMn high-entropy alloy. Sci. Bull. 2018, 63, 362–368. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, K.; Meng, Z.; Zhang, K.; Hodgson, P.; Birbilis, N.; Weyland, M.; Fraser, H.L.; Lim, S.C.V.; Peng, H.; et al. Ultrastrong nanotwinned titanium alloys through additive manufacturing. Nat. Mater. 2022, 21, 1258–1262. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive manufacturing of metals: Microstructure evolution and multistage control. J. Mater. Sci. Technol. 2022, 100, 224–236. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Z.G.; Chen, H.; Wang, A.G.; Liu, J.Q.; Liu, H.W.; Zheng, R.K.; Nai, S.M.L.; Primig, S.; Babu, S.S.; et al. Effect of cyclic rapid thermal loadings on the microstructural evolution of a CrMnFeCoNi high-entropy alloy manufactured by selective laser melting. Acta Mater. 2020, 196, 609–625. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, H.; Li, W.; Mao, A.; Wang, L.; Song, G.; He, Y. Microstructure and nanoindentation creep behavior of CoCrFeMnNi high-entropy alloy fabricated by selective laser melting. Addit. Manuf. 2019, 28, 766–771. [Google Scholar] [CrossRef]

- Li, Z. Interstitial equiatomic CoCrFeMnNi high-entropy alloys: Carbon content, microstructure, and compositional homogeneity effects on deformation behavior. Acta Mater. 2019, 164, 400–412. [Google Scholar] [CrossRef]

- Yu, P.; Fan, N.; Zhang, Y.; Wang, Z.; Li, W.; Lupoi, R.; Yin, S. Microstructure evolution and composition redistribution of FeCoNiCrMn high entropy alloy under extreme plastic deformation. Mater. Res. Lett. 2022, 10, 124–132. [Google Scholar] [CrossRef]

- Zhang, W.; Shen, J.; Oliveira, J.P.; Kooi, B.J.; Pei, Y. Crystallographic orientation-dependent deformation characteristics of additive manufactured interstitial-strengthened high entropy alloys. Scr. Mater. 2023, 222, 115049. [Google Scholar] [CrossRef]

- Wang, N.; Cao, Q.; Wang, X.; Ding, S.; Zhang, D.; Jiang, J.-Z. Unusual deformation-induced martensitic transformation in Fe-Co-Ni-Cr-Mn high entropy alloy thin films. J. Alloys Compd. 2022, 920, 165959. [Google Scholar] [CrossRef]

- Bajaj, D.; Feng, A.H.; Qu, S.J.; Li, D.Y.; Chen, D.L. Orientation-dependent lattice rotation and phase transformation in an additively manufactured high-entropy alloy. J. Mater. Sci. Technol. 2025, 227, 11–25. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Huang, S.; Li, W.; Lu, S.; Tian, F.; Shen, J.; Holmström, E.; Vitos, L. Temperature dependent stacking fault energy of FeCrCoNiMn high entropy alloy. Scr. Mater. 2015, 108, 44–47. [Google Scholar] [CrossRef]

- An, Z.; Mao, S.; Liu, Y.; Yang, L.; Vayyala, A.; Wei, X.; Liu, C.; Shi, C.; Jin, H.; Liu, C.; et al. Inherent and multiple strain hardening imparting synergistic ultrahigh strength and ductility in a low stacking faulted heterogeneous high-entropy alloy. Acta Mater. 2023, 243, 118516. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Nguyen, Q.B.; Ng, F.L.; An, X.H.; Liao, X.Z.; Liaw, P.K.; Nai, S.M.L.; Wei, J. Hierarchical microstructure and strengthening mechanisms of a CoCrFeNiMn high entropy alloy additively manufactured by selective laser melting. Scr. Mater. 2018, 154, 20–24. [Google Scholar] [CrossRef]

- Pham, M.-S.; Dovgyy, B.; Hooper, P.A.; Gourlay, C.M.; Piglione, A. The role of side-branching in microstructure development in laser powder-bed fusion. Nat. Commun. 2020, 11, 749. [Google Scholar] [CrossRef] [PubMed]

- Melia, M.A.; Carroll, J.D.; Whetten, S.R.; Esmaeely, S.N.; Locke, J.; White, E.; Anderson, I.; Chandross, M.; Michael, J.R.; Argibay, N.; et al. Mechanical and Corrosion Properties of Additively Manufactured CoCrFeMnNi High Entropy Alloy. Addit. Manuf. 2019, 29, 100833. [Google Scholar] [CrossRef]

- Joseph, J.; Hodgson, P.; Jarvis, T.; Wu, X.; Stanford, N.; Fabijanic, D.M. Effect of hot isostatic pressing on the microstructure and mechanical properties of additive manufactured AlxCoCrFeNi high entropy alloys. Mater. Sci. Eng. A 2018, 733, 59–70. [Google Scholar] [CrossRef]

- Zhang, C.; Feng, K.; Kokawa, H.; Han, B.; Li, Z. Cracking mechanism and mechanical properties of selective laser melted CoCrFeMnNi high entropy alloy using different scanning strategies. Mater. Sci. Eng. A 2020, 789, 139672. [Google Scholar] [CrossRef]

- Liu, L.; Ding, Q.; Zhong, Y.; Zou, J.; Wu, J.; Chiu, Y.-L.; Li, J.; Zhang, Z.; Yu, Q.; Shen, Z. Dislocation network in additive manufactured steel breaks strength–ductility trade-off. Mater. Today 2018, 21, 354–361. [Google Scholar] [CrossRef]

- Liu, F.C.; Feng, A.H.; Pei, X.; Hovanski, Y.; Mishra, R.S.; Ma, Z.Y. Friction stir based welding, processing, extrusion and additive manufacturing. Prog. Mater. Sci. 2024, 146, 101330. [Google Scholar] [CrossRef]

- Li, R.; Niu, P.; Yuan, T.; Cao, P.; Chen, C.; Zhou, K. Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical property. J. Alloys Compd. 2018, 746, 125–134. [Google Scholar] [CrossRef]

- Park, J.M.; Kim, E.S.; Kwon, H.; Sathiyamoorthi, P.; Kim, K.T.; Yu, J.-H.; Kim, H.S. Effect of heat treatment on microstructural heterogeneity and mechanical properties of 1%C-CoCrFeMnNi alloy fabricated by selective laser melting. Addit. Manuf. 2021, 47, 102283. [Google Scholar] [CrossRef]

- Chen, X.; Kong, J.; Feng, S.; Dong, K.; Liang, Y.; Wang, Q.; Yang, Y.; Liu, X. A precipitation-strengthened high-entropy alloy prepared by selective laser melting in-situ alloying and post-heat treatment. J. Alloys Compd. 2023, 936, 168145. [Google Scholar] [CrossRef]

- Bai, Y.; Jiang, H.; Yan, K.; Li, M.; Wei, Y.; Zhang, K.; Wei, B. Phase transition and heterogeneous strengthening mechanism in CoCrFeNiMn high-entropy alloy fabricated by laser-engineered net shaping via annealing at intermediate-temperature. J. Mater. Sci. Technol. 2021, 92, 129–137. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Wei, S.; Ni, X.; Zhang, L.; Li, R.; Wang, L.; Man, C.; Li, X. About metastable cellular structure in additively manufactured austenitic stainless steels. Addit. Manuf. 2021, 38, 101804. [Google Scholar] [CrossRef]

- Voisin, T.; Forien, J.-B.; Perron, A.; Aubry, S.; Bertin, N.; Samanta, A.; Baker, A.; Wang, Y.M. New insights on cellular structures strengthening mechanisms and thermal stability of an austenitic stainless steel fabricated by laser powder-bed-fusion. Acta Mater. 2021, 203, 116476. [Google Scholar] [CrossRef]

- Gao, S.; Hu, Z.; Duchamp, M.; Krishnan, P.S.S.R.; Tekumalla, S.; Song, X.; Seita, M. Recrystallization-based grain boundary engineering of 316L stainless steel produced via selective laser melting. Acta Mater. 2020, 200, 366–377. [Google Scholar] [CrossRef]

- Li, W.; Huang, Y.; Xie, Z.; Chen, H.; Li, W.; Liu, B.; Wang, B. Mechanical property and cellular structure of an additive manufactured FeCoNiCrMo0.2 high-entropy alloy at high-velocity deformation. J. Mater. Sci. Technol. 2023, 139, 156–166. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Otto, F.; Pharr, G.M.; George, E.P. Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys. Intermetallics 2014, 46, 131–140. [Google Scholar] [CrossRef]

- Tong, Z.; Ren, X.; Jiao, J.; Zhou, W.; Ren, Y.; Ye, Y.; Larson, E.A.; Gu, J. Laser additive manufacturing of FeCrCoMnNi high-entropy alloy: Effect of heat treatment on microstructure, residual stress and mechanical property. J. Alloys Compd. 2019, 785, 1144–1159. [Google Scholar] [CrossRef]

- Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef]

- Bajaj, D.; Chen, Z.; Qu, S.J.; Feng, A.H.; Li, D.Y.; Chen, D.L. Distinct origins of deformation twinning in an additively-manufactured high-entropy alloy. Addit. Manuf. 2023, 74, 103716. [Google Scholar] [CrossRef]

- Chierchia, R.; Böttcher, T.; Heinke, H.; Einfeldt, S.; Figge, S.; Hommel, D. Microstructure of heteroepitaxial GaN revealed by X-ray diffraction. J. Appl. Phys. 2003, 93, 8918–8925. [Google Scholar] [CrossRef]

- Wu, D.; Xu, Y.; Li, W.; Fan, N.; Yang, Y.; Yin, S. Significant improvement of mechanical properties of cold-spray-additive manufactured FeCoNiCrMn high-entropy alloy via post-annealing. Mater. Charact. 2023, 206, 113350. [Google Scholar] [CrossRef]

- Tong, Z.; Wan, W.; Liu, H.; Zhou, W.; Ye, Y.; Ren, X. Combination of annealing and laser shock peening for tailoring microstructure and mechanical properties of laser directed energy deposited CrMnFeCoNi high-entropy alloy. Addit. Manuf. 2023, 61, 103345. [Google Scholar] [CrossRef]

- Sangid, M.D.; Book, T.A.; Naragani, D.; Rotella, J.; Ravi, P.; Finch, A.; Kenesei, P.; Park, J.-S.; Sharma, H.; Almer, J.; et al. Role of heat treatment and build orientation in the microstructure sensitive deformation characteristics of IN718 produced via SLM additive manufacturing. Addit. Manuf. 2018, 22, 479–496. [Google Scholar] [CrossRef]

- Zheng, M.; Li, C.; Zhang, X.; Ye, Z.; Yang, X.; Gu, J. The influence of columnar to equiaxed transition on deformation behavior of FeCoCrNiMn high entropy alloy fabricated by laser-based directed energy deposition. Addit. Manuf. 2021, 37, 101660. [Google Scholar] [CrossRef]

- Wang, B.; Wang, X.; Li, Z.; Ma, R.; Zhao, S.; Xie, F.; Zhang, X. Shear localization and microstructure in coarse grained beta titanium alloy. Mater. Sci. Eng. A 2016, 652, 287–295. [Google Scholar] [CrossRef]

- Zheng, M.; Li, C.; Zhang, L.; Zhang, X.; Ye, Z.; Yang, X.; Gu, J. In-situ investigation of deformation behavior in additively manufactured FeCoCrNiMn high entropy alloy. Mater. Sci. Eng. A 2022, 840, 142933. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Y.; Wang, Y.; Li, Z.; Wang, D.; Kosiba, K. Temperature-dependent dynamic compressive properties and failure mechanisms of the additively manufactured CoCrFeMnNi high entropy alloy. Mater. Des. 2022, 224, 111324. [Google Scholar] [CrossRef]

- Liu, Y.; Ren, J.; Guan, S.; Li, C.; Zhang, Y.; Muskeri, S.; Liu, Z.; Yu, D.; Chen, Y.; An, K.; et al. Microstructure and mechanical behavior of additively manufactured CoCrFeMnNi high-entropy alloys: Laser directed energy deposition versus powder bed fusion. Acta Mater. 2023, 250, 118884. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Y.; Zhang, Y.; Zhang, L.-C.; Wang, L. Deformation mechanisms of additively manufactured TiNbTaZrMo refractory high-entropy alloy: The role of cellular structure. Int. J. Plast. 2024, 173, 103884. [Google Scholar] [CrossRef]

- Li, H.G.; Huang, Y.J.; Zhao, W.J.; Chen, T.; Sun, J.F.; Wei, D.Q.; Du, Q.; Zou, Y.C.; Lu, Y.Z.; Zhu, P.; et al. Overcoming the strength-ductility trade-off in an additively manufactured CoCrFeMnNi high entropy alloy via deep cryogenic treatment. Addit. Manuf. 2022, 50, 102546. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).