Biocompatibility, Corrosion Resistance, and Wear Resistance of TiNbZr-Based Composites Reinforced with Borides

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

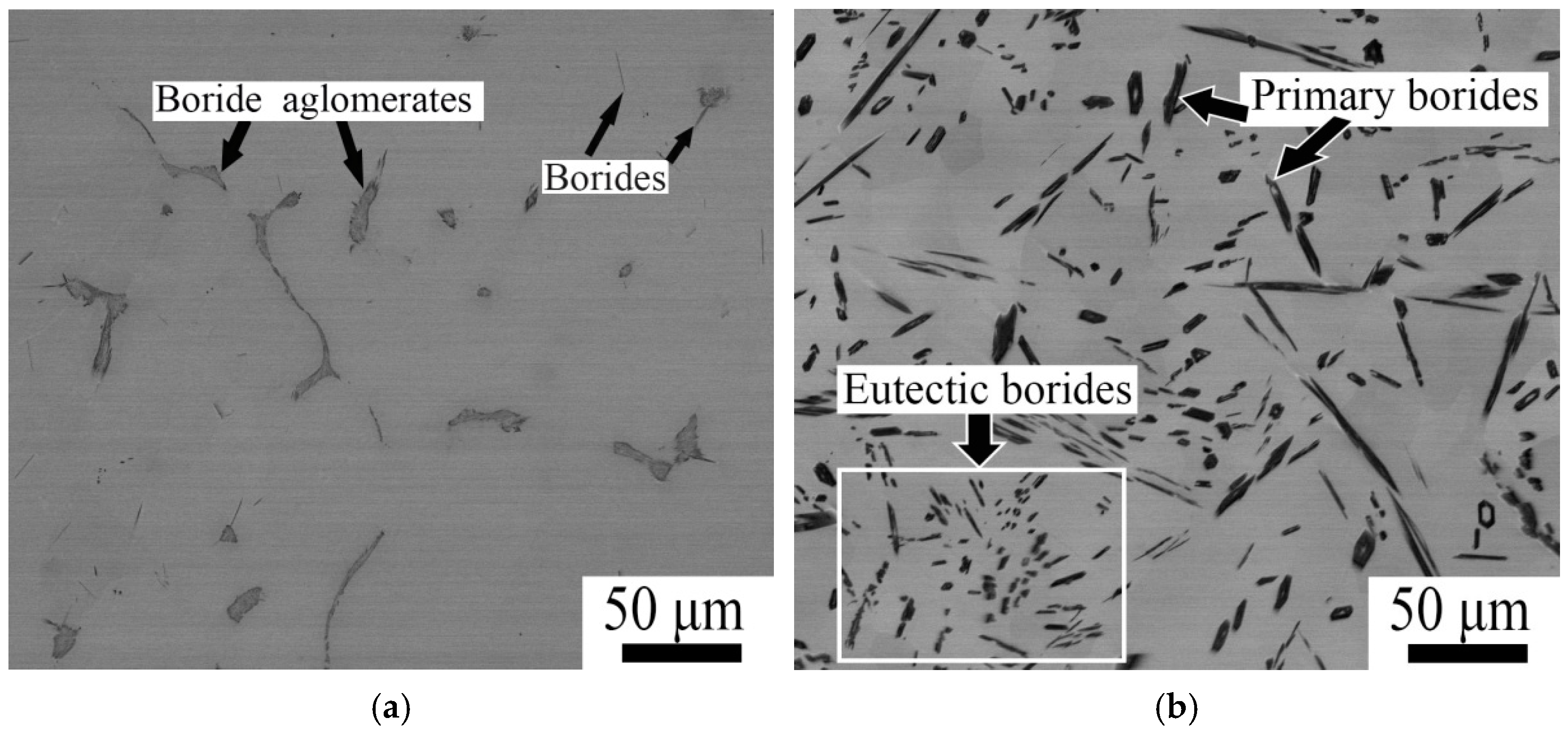

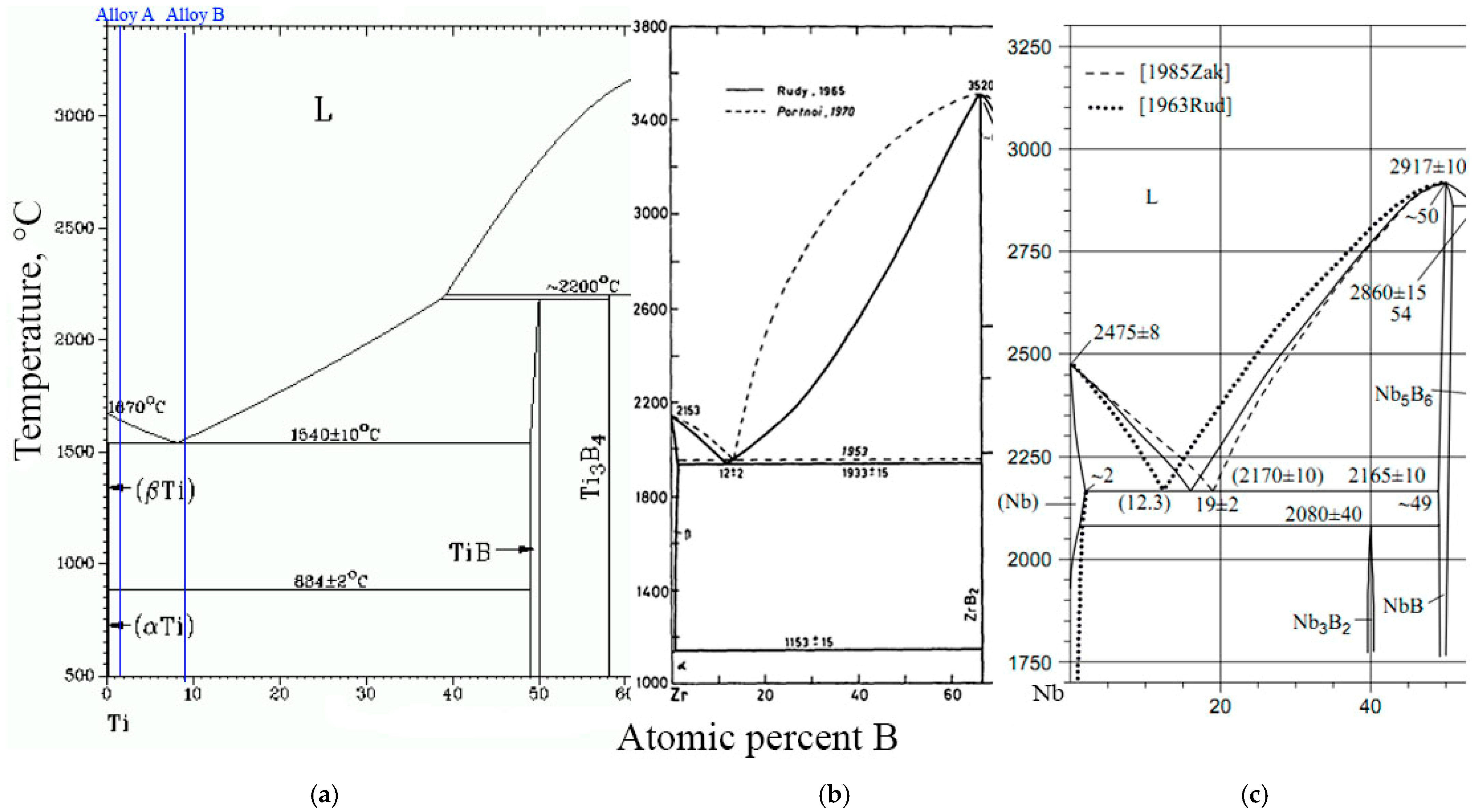

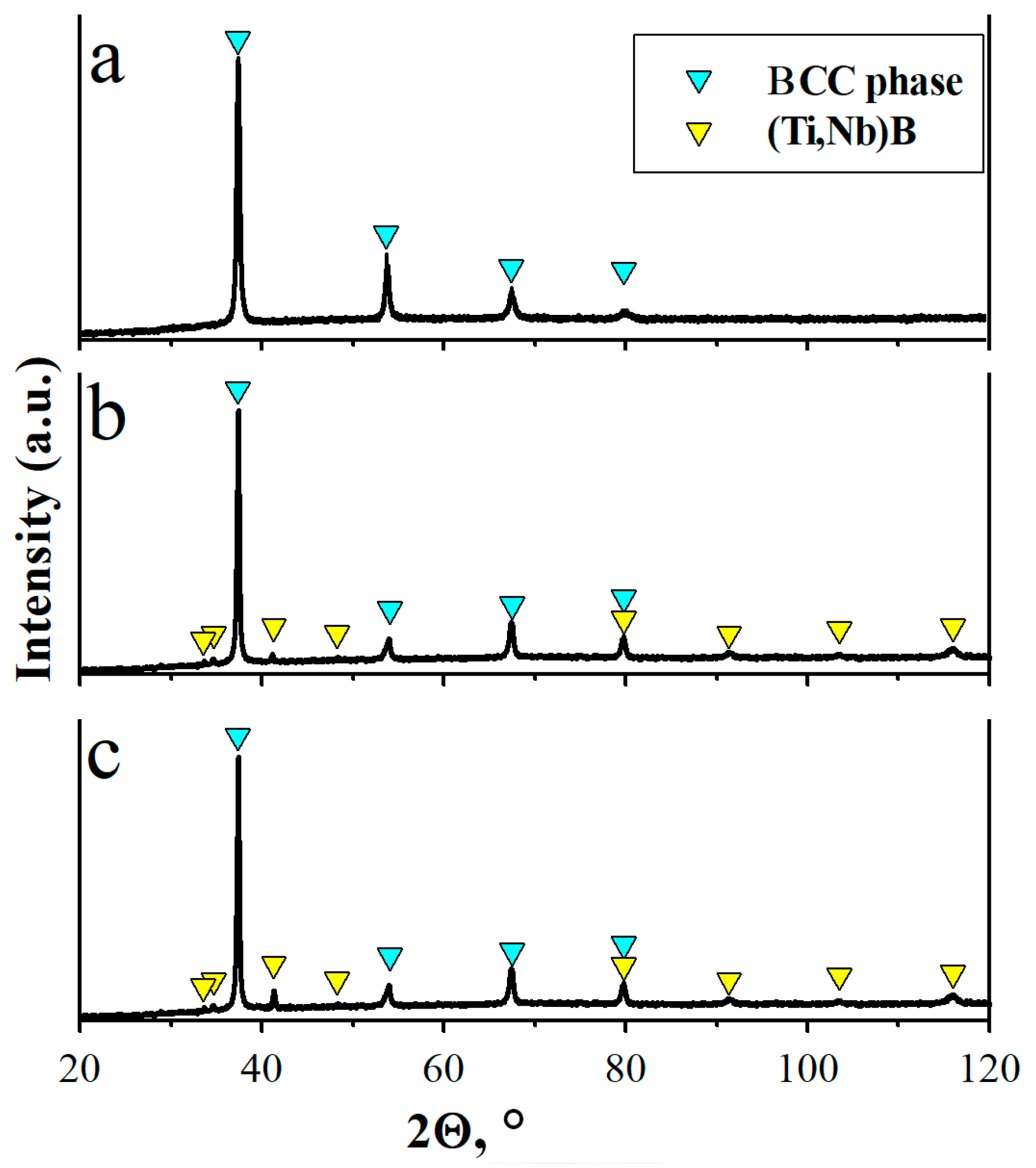

3.1. Initial Microstructure

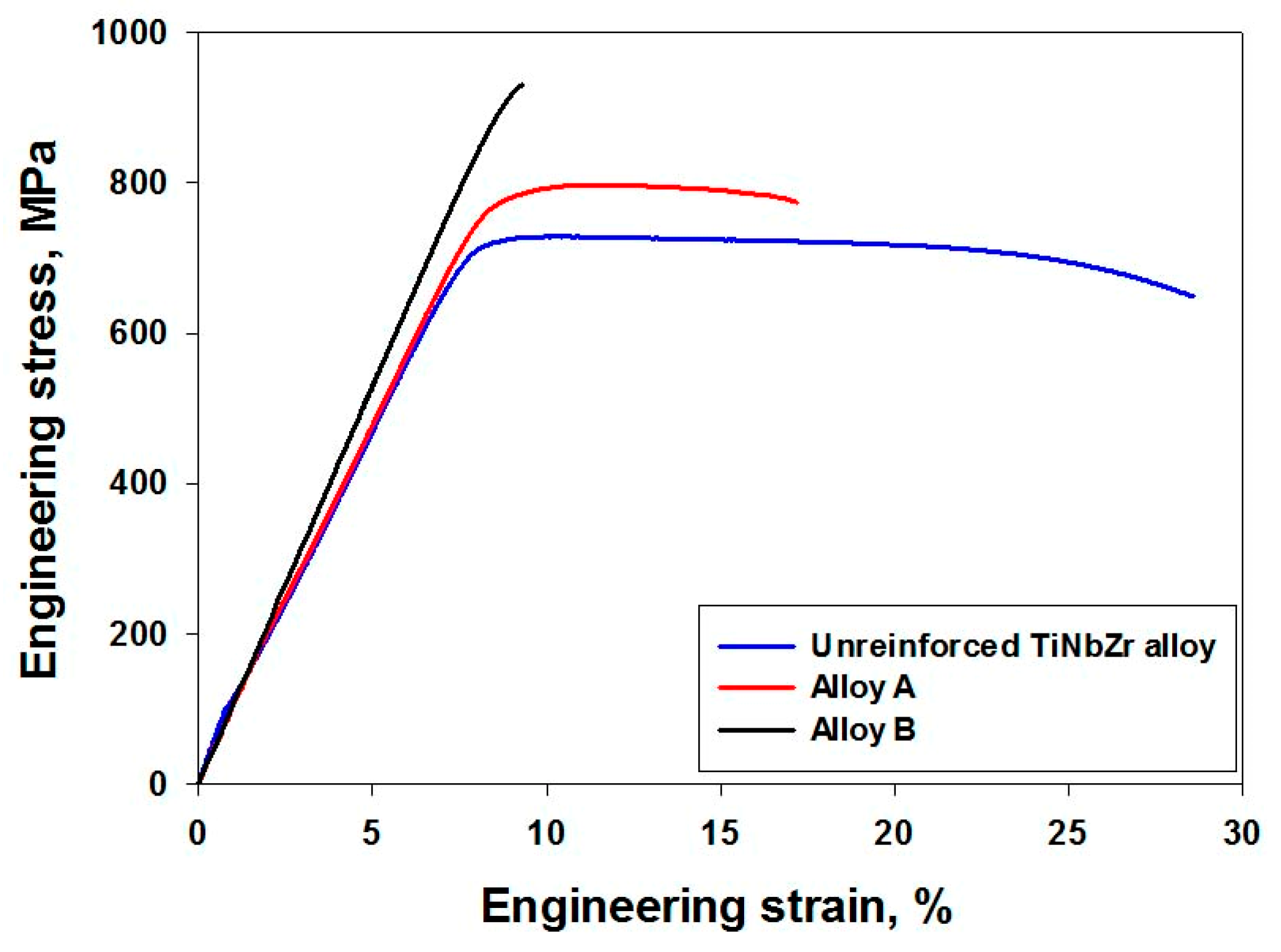

3.2. Mechanical Properties

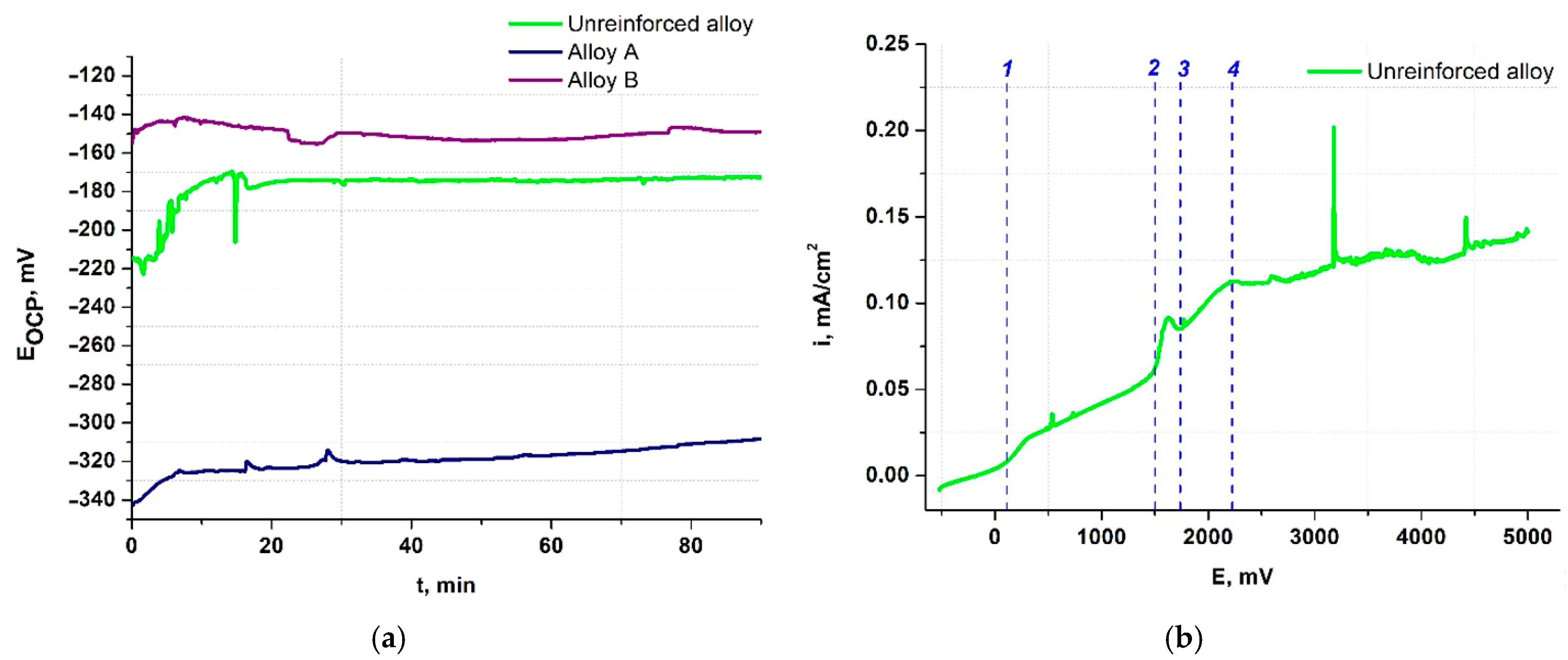

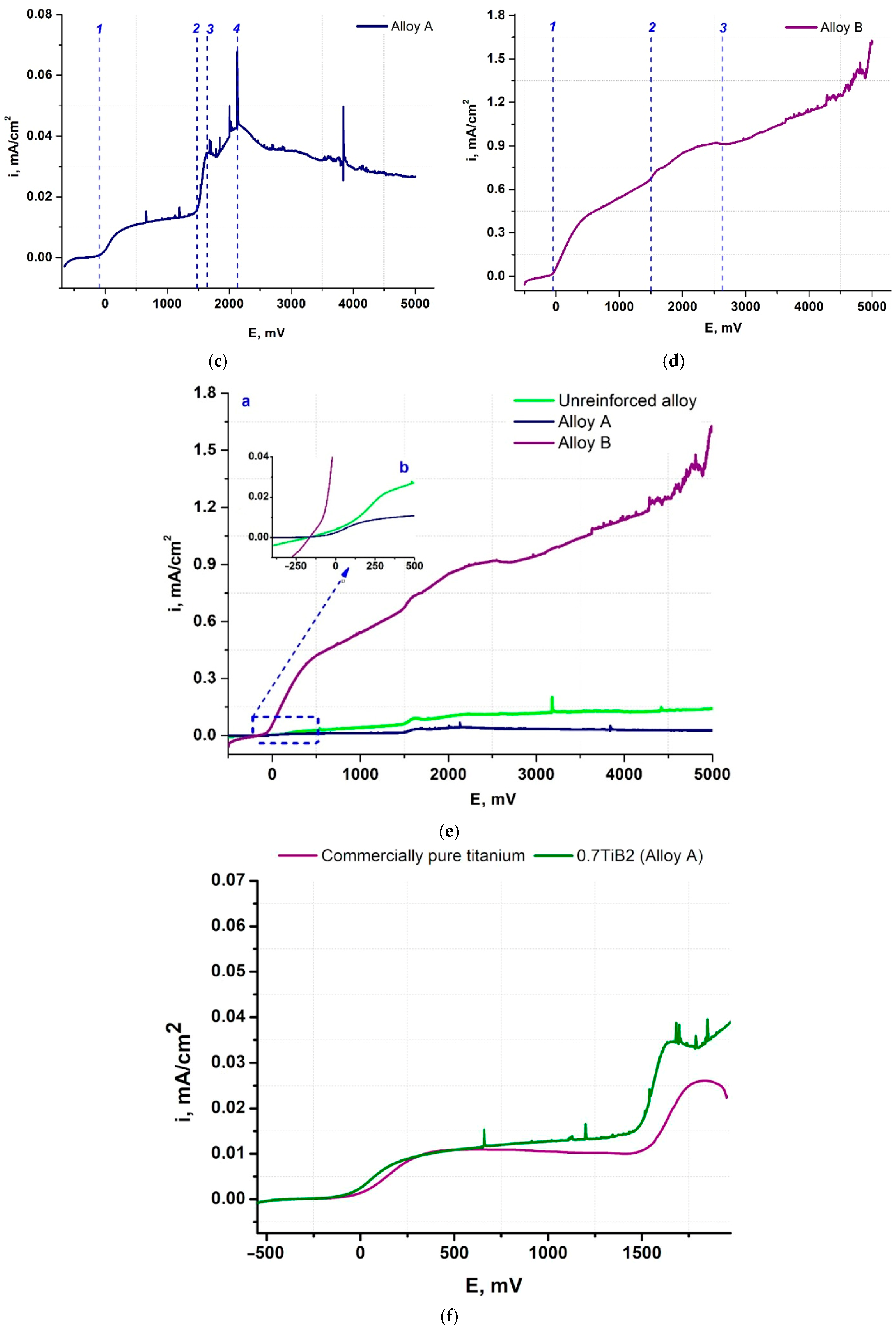

3.3. Corrosion Properties

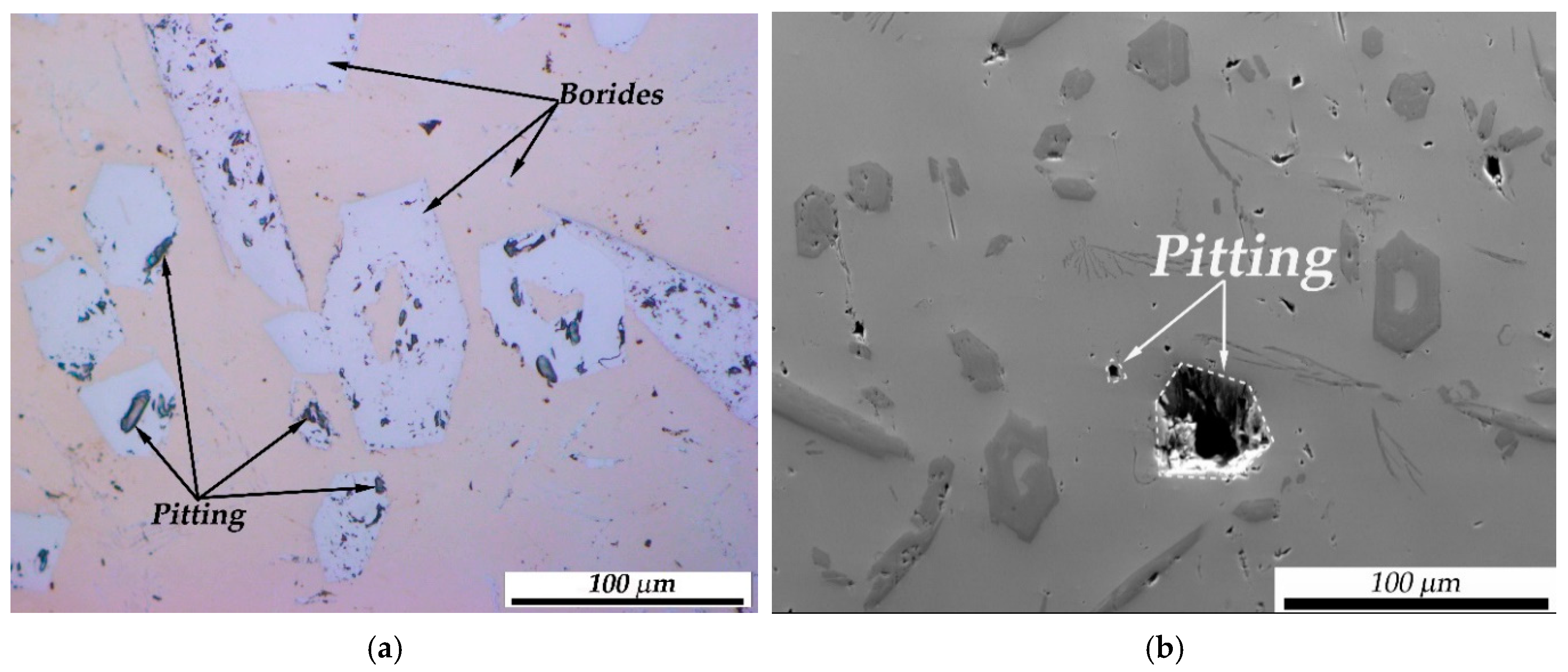

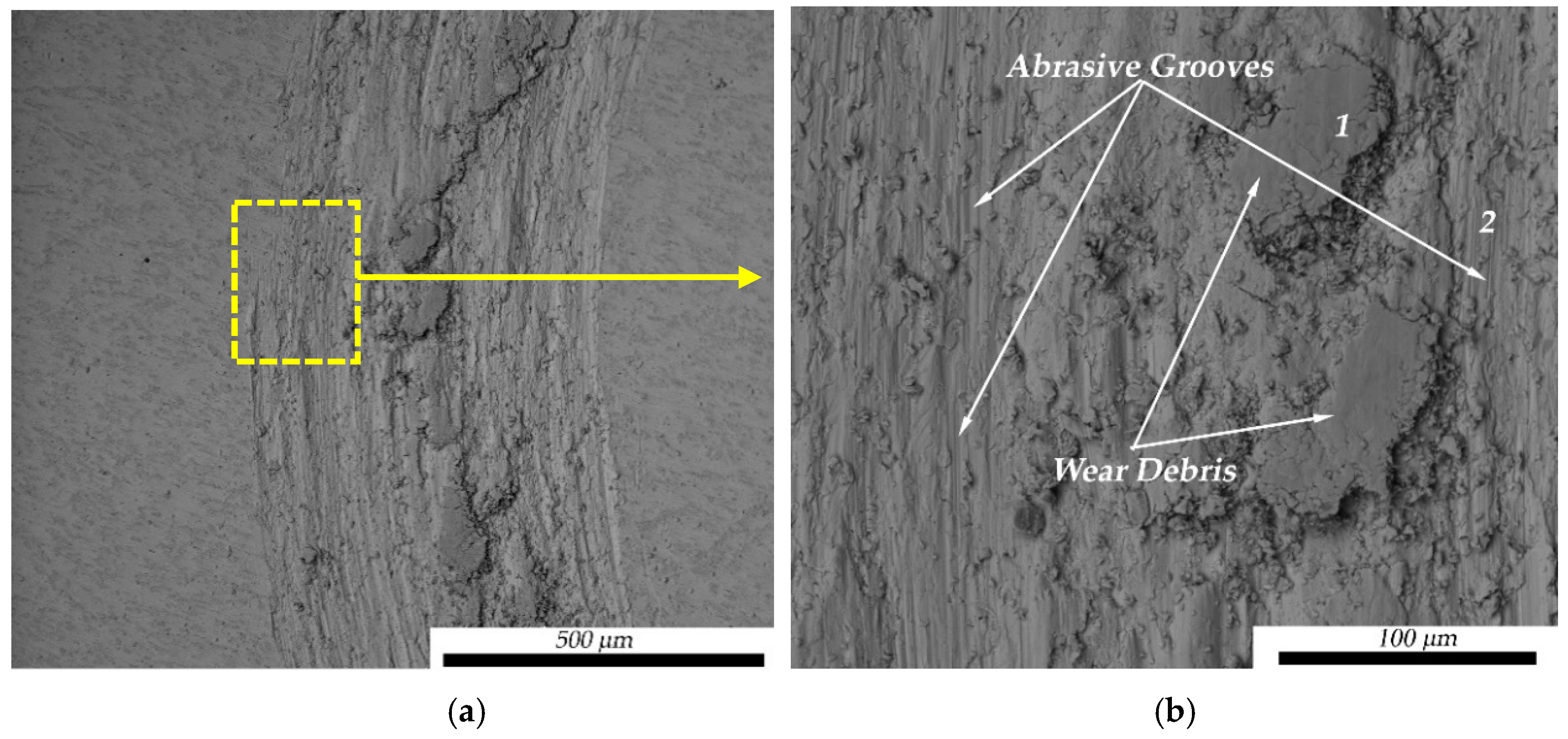

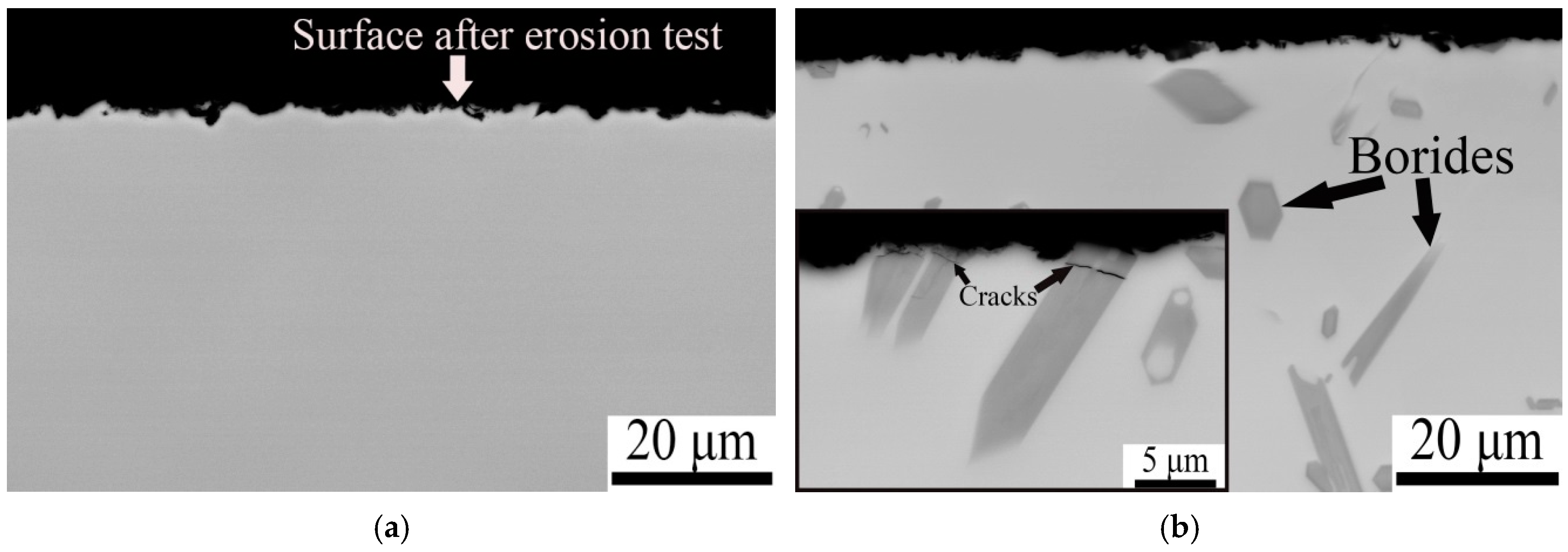

3.4. Tribological Properties

3.5. Biocompatibility

4. Conclusions

- The microstructure of the composites consisted of the TiNbZr β matrix and (Ti,Nb)B fibers. The (Ti,Nb)B fibers had a needle-like shape with the average diameter of ~0.4 and ~2.0 µm for Alloys A and B, respectively. The volume fractions of the borides in the structures of the two states of the composites were found to be ~2.5 and ~12.4% for Alloys A and B, respectively;

- The addition of 12.4% of (Ti,Nb)B was shown to deteriorate the corrosion resistance of Alloy B compared to that of the unreinforced TiNbZr alloy and Alloy A. Alloy A and the unreinforced alloy showed similar corrosion resistance values;

- Tribological tests showed that the introduction of boride particles to the TiNbZr alloy reduced the friction coefficient from 1.15 for the unreinforced alloy to 1.13 for Alloy A (2.5% of (Ti,Nb)B), and reduced it twofold, from 1.15 to 0.58, for Alloy B, with 12.4% of (Ti,Nb)B;

- The full biocompatibility of the TiNbZr–(Ti,Nb)B composites was established during in vivo experiments. No significant differences were found between the Ti-6Al-4V alloy, the unreinforced TiNbZr alloy and TiNbZr–(Ti,Nb)B composites containing 2.5% and 12.4% borides.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, L.C.; Chen, L.Y. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Okazaki, Y. A new Ti-15Zr-4Nb-4Ta alloy for medical applications. Curr. Opin. Solid State Mater. Sci. 2001, 5, 45–53. [Google Scholar] [CrossRef]

- Flaten, T.P. Aluminium as a risk factor in Alzheimer’s disease, with emphasis on drinking water. Brain Res. Bull. 2001, 55, 187–196. [Google Scholar] [CrossRef]

- Lima, P.D.; Vasconcellos, M.C.; Montenegro, R.C.; Bahia, M.O.; Costa, E.T.; Antunes, L.M. Genotoxic effects of aluminum, iron and manganese in human cells and experimental systems: A review of the literature. Hum. Exp. Toxicol. 2011, 30, 1435–1444. [Google Scholar] [CrossRef] [PubMed]

- Ozan, S.; Lin, J.; Li, Y.; Ipek, R.; Wen, C. Development of Ti–Nb–Zr alloys with high elastic admissible strain for temporary orthopedic devices. Acta Biomater. 2015, 20, 176–187. [Google Scholar] [CrossRef] [PubMed]

- Laheurte, P.; Prima, F.; Eberhardt, A.; Gloriant, T.; Wary, M.; Patoor, E. Mechanical properties of low modulus β titanium alloys designed from the electronic approach. J. Mech. Behav. Biomed. Mater. 2010, 3, 565–573. [Google Scholar] [CrossRef] [PubMed]

- Senkov, O.N.; Rao, S.; Chaput, K.J.; Woodward, C. Compositional effect on microstructure and properties of NbTiZr-based complex concentrated alloys. Acta Mater. 2018, 151, 201–215. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Black, J. Biological Performance of Materials, Fundamentals of Biocompatibility; CRC Taylor & Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- Huiskes, R.; Weinans, H.; Vanrietbergen, B. The relationship between stress shielding and bone-resorption around total hip stems and the effects of flexible materials. Clin. Orthop. Relat. Res. 1992, 274, 124–134. [Google Scholar] [CrossRef]

- Meng, Q.; Guo, S.; Liu, Q.; Hu, L.; Zhao, X. A β-type TiNbZr alloy with low modulus and high strength for biomedical applications. Prog. Nat. Sci. Mater. Int. 2014, 24, 157–162. [Google Scholar] [CrossRef]

- Rho, J.Y.; Tsui, T.Y.; Pharr, G.M. Elastic properties of human cortical and trabecular lamellar bone measured by nanoindentation. Biomaterials 1997, 18, 1325–1330. [Google Scholar] [CrossRef] [PubMed]

- Hanawa, T.; Hiromoto, S.; Asami, K.; Okuno, O.; Asaoka, K. Surface oxide films on titanium alloys regenerated in Hanks’ solution. Mater. Trans. 2002, 43, 3000–3004. [Google Scholar] [CrossRef]

- Mishchenko, O.; Ovchynnykov, O.; Kapustian, O.; Pogorielov, M. New Zr-Ti-Nb Alloy for Medical Application: Development, Chemical and Mechanical Properties, and Biocompatibility. Materials 2020, 13, 1306. [Google Scholar] [CrossRef]

- Aguilar Maya, A.E.; Grana, D.R.; Hazarabedian, A.; Kokubu, G.A.; Luppo, M.I.; Vigna, G. Zr–Ti–Nb porous alloys for biomedical application. Mater. Sci. Eng. C 2012, 32, 321–329. [Google Scholar] [CrossRef]

- Hayat, M.D.; Singh, H.; He, Z.; Cao, P. Titanium metal matrix composites: An overview. Compos. Part A Appl. Sci. Manuf. 2019, 121, 418–438. [Google Scholar] [CrossRef]

- Huang, L.; An, Q.; Geng, L.; Wang, S.; Jiang, S.; Cui, X.; Zhang, R.; Sun, F.; Jiao, Y.; Chen, X.; et al. Multiscale Architecture and Superior High-Temperature Performance of Discontinuously Reinforced Titanium Matrix Composites. Adv. Mater. 2021, 33, 2000688. [Google Scholar] [CrossRef] [PubMed]

- Shetty, R.; Hegde, A.; Shetty SV, U.K.; Nayak, R.; Naik, N.; Nayak, M. Processing and Mechanical Characterisation of Titanium Metal Matrix Composites: A Literature Review. J. Compos. Sci. 2022, 6, 388. [Google Scholar] [CrossRef]

- Ozerov, M.; Klimova, M.; Sokolovsky, V.; Stepanov, N.; Popov, A.; Boldin, M.; Zherebtsov, S. Evolution of microstructure and mechanical properties of Ti/TiB metal-matrix composite during isothermal multiaxial forging. J. Alloys Compd. 2019, 770, 840–848. [Google Scholar] [CrossRef]

- Ravi Chandran, K.S.; Panda, K.B.; Sahay, S.S. TiBw-reinforced Ti composites: Processing, properties, application, prospects, and research needs. JOM 2004, 56, 42–48. [Google Scholar] [CrossRef]

- Morsi, K. Review: Titanium–titanium boride composites. J. Mater. Sci. 2019, 54, 6753–6771. [Google Scholar] [CrossRef]

- Samuel, S.; Nag, S.; Scharf, T.W.; Banerjee, R. Wear resistance of laser-deposited boride reinforced Ti-Nb-Zr-Ta alloy composites for orthopedic implants. Mater. Sci. Eng. C 2008, 28, 414–420. [Google Scholar] [CrossRef]

- Nag, S.; Samuel, S.; Puthucode, A.; Banerjee, R. Characterization of novel borides in Ti-Nb-Zr-Ta + 2B metal-matrix composites. Mater. Charact. 2009, 60, 106–113. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.B.; Dhara, S.; Chakraborty, M. Influence of in situ TiB reinforcements and role of heat treatment on mechanical properties and biocompatibility of β Ti-alloys. J. Mech. Behav. Biomed. Mater. 2012, 10, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Ozerov, M.; Sokolovsky, V.; Nadezhdin, S.; Zubareva, E.; Zherebtsova, N.; Stepanov, N.; Huang, L.; Zherebtsov, S. Microstructure and mechanical properties of medium-entropy TiNbZr alloy-based composites, reinforced with boride particles. J. Alloys Compd. 2023, 938, 168512. [Google Scholar] [CrossRef]

- Ozerov, M.; Sokolovsky, V.; Stepanov, N.; Zherebtsov, S. Microstructure and tensile properties of TiNbZr alloy-based metal-matrix composites, reinforced with borides. AIP Conf. Proc. 2023, 2899, 020109. [Google Scholar]

- Ozerov, M.; Sokolovsky, V.; Yurchenko, N.; Astakhov, I.; Povolyaeva, E.; Plekhov, O.; Tagirov, D.; Stepanov, N.; Zherebtsov, S. Effect of Cold Rolling on Microstructure and Mechanical Properties of a Cast TiNbZr-Based Composite Reinforced with Borides. Metals 2024, 14, 104. [Google Scholar] [CrossRef]

- Makau, F.M.; Morsi, K.; Gude, N.; Alvarez, R.; Sussman, M.; May-Newman, K. Viability of Titanium-Titanium Boride Composite as a Biomaterial. ISRN Biomater. 2013, 1, 970535. [Google Scholar] [CrossRef]

- Kabu, M.; Akosman, M.S. Biological Effects of Boron. Rev. Environ. Contam. Toxicol. 2013, 225, 57–75. [Google Scholar] [PubMed]

- Nielsen, F.H. Update on human health effects of boron. J. Trace Elem. Med. Biol. 2014, 28, 383–387. [Google Scholar] [CrossRef] [PubMed]

- Otte, J.A.; Zou, J.; Patel, R.; Lu, M.; Dargusch, M.S. TiB Nanowhisker Reinforced Titanium Matrix Composite with Improved Hardness for Biomedical Applications. Nanomaterials 2020, 10, 2480. [Google Scholar] [CrossRef]

- Aljafery, A.M.A.; Fatalla, A.A.; Haider, J. Cytotoxicity, Corrosion Resistance, and Wettability of Titanium and Ti-TiB2 Composite Fabricated by Powder Metallurgy for Dental Implants. Metals 2024, 14, 538. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, J.; Dai, N.; Qin, P.; Attar, H.; Zhang, L.-C. Corrosion Behaviour of Selective Laser Melted Ti-TiB Biocomposite in Simulated Body Fluid. Electrochim. Acta 2017, 232, 89–97. [Google Scholar] [CrossRef]

- Ozerov, M.; Gazizova, M.; Zherebtsova, N.; Stepanov, N.; Zherebtsov, S. Corrosion properties of a Ti-15Mo/TiB composite produced by spark plasma sintering. AIP Conf. Proc. 2019, 2167, 020260. [Google Scholar]

- Bahl, S.; Raj, S.; Vanamali, S.; Suwas, S.; Chatterjee, K. Effect of boron addition and processing of Ti–6Al–4V on corrosion behaviour and biocompatibility. Mater. Technol. 2014, 29, 64–68. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Okulov, I.V.; Wendrock, H.; Bönisch, M.; Volegov, A.S.; Calin, M.; Eckert, J.; Dargusch, M.S. Nanoindentation and wear properties of Ti and Ti-TiB composite materials produced by selective laser melting. Mater. Sci. Eng. A 2017, 688, 20–26. [Google Scholar] [CrossRef]

- Ozerov, M.; Stepanov, N.; Zherebtsov, S. Wear resistance of Ti/TiB composites produced by spark plasma sintering. AIP Conf. Proc. 2017, 1909, 020164. [Google Scholar]

- Yazdi, R.; Kashani-Bozorg, S.F. Microstructure and wear of in-situ Ti/(TiN + TiB) hybrid composite layers produced using liquid phase process. Mater. Chem. Phys. 2015, 152, 147–157. [Google Scholar] [CrossRef]

- Sivakumar, B.; Singh, R.; Pathak, L.C. Corrosion behavior of titanium boride composite coating fabricated on commercially pure titanium in Ringer’s solution for bioimplant applications. Mater. Sci. Eng. C 2015, 48, 243–255. [Google Scholar] [CrossRef] [PubMed]

- Sivakumar, B.; Pathak, L.C.; Singh, R. Response of boride coating on the Ti-6Al-4V alloy to corrosion and fretting corrosion behavior in Ringer’s solution for bio-implant application. Appl. Surf. Sci. 2018, 433, 1158–1174. [Google Scholar]

- Majumdar, P.; Singh, S.B.; Chakraborty, M. Wear properties of Ti–13Zr–13Nb (wt.%) near β titanium alloy containing 0.5 wt.% boron in dry condition, Hank’s solution and bovine serum. Mater. Sci. Eng. C 2010, 30, 1065–1075. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.B.; Dhara, S.; Chakraborty, M. Influence of boron addition to Ti–13Zr–13Nb alloy on MG63 osteoblast cell viability and protein adsorption. Mater. Sci. Eng. C 2015, 46, 62–68. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.B.; Chatterjee, U.K.; Chakraborty, M. Corrosion behaviour of heat treated boron free and boron containing Ti–13Zr–13Nb (wt%) alloy in simulated body fluid. J. Mater. Sci. Mater. Med. 2011, 22, 797–807. [Google Scholar] [CrossRef]

- ASTMG99-959; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2000.

- DIN50324; Tribology; Testing of Friction and Wear Model Test for Sliding Friction of Solids (Ball-on-Disc System). DIN: Berlin, Germany, 1992.

- ISO 10993-6-2021; Medical Devices. Biological Evaluation of Medical Devices. Part 6. Tests for Local Effects after Implantation. ISO: Moscow, Russia, 2021.

- An, Q.; Huang, L.; Qian, Q.; Jiang, Y.; Wang, S.; Zhang, R.; Geng, L.; Wang, L. Insights into in-situ TiB/dual-phase Ti alloy interface and its high load-bearing capacity. J. Mater. Sci. Technol. 2022, 119, 156–166. [Google Scholar] [CrossRef]

- Murray, J.L.; Liao, P.K.; Spear, K.E. The B−Ti (Boron-Titanium) system. Bull. Alloy Phase Diagr. 1986, 7, 550–555. [Google Scholar] [CrossRef]

- Rogl, P.; Potter, P.E. A critical review and thermodynamic calculation of the binary system: Zirconium-boron. Calphad 1988, 12, 191–204. [Google Scholar] [CrossRef]

- Rogl, P.; Korniyenko, K.; Velikanova, T. Boron—Carbon—Niobium. Calphad 2009, 1, 1–25. [Google Scholar] [CrossRef]

- Ozerov, M.; Klimova, M.; Kolesnikov, A.; Stepanov, N.; Zherebtsov, S. Deformation behavior and microstructure evolution of a Ti/TiB metal-matrix composite during high-temperature compression tests. Mater. Des. 2016, 112, 17–26. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Ozerov, M.; Povolyaeva, E.; Sokolovsky, V.; Stepanov, N.; Moskovskikh, D.; Salishchev, G. Effect of hot rolling on the microstructure and mechanical properties of a Ti-15Mo/TiB metal-matrix composite. Metals 2020, 10, 40. [Google Scholar] [CrossRef]

- Gazizova, M.Y.; Ivanov, M.B.; Vershinina, T.N. Investigation of Corrosion Behavior of Bioactive Coverings on Commercially Pure Titanium and its Alloys. J. Nano-Electron. Phys. 2015, 7, 04081. [Google Scholar]

- Kaczmarek, M.; Jurczyk, M.U.; Miklaszewski, A.; Paszel-Jaworska, A.; Romaniuk, A.; Lipińska, N.; Żurawski, J.; Urbaniak, P.; Jurczyk, K. In vitro biocompatibility of titanium after plasma surface alloying with boron. Mater. Sci. Eng. C 2016, 69, 1240–1247. [Google Scholar] [CrossRef] [PubMed]

- Hu, M.; Wang, L.; Li, G.; Huang, Q.; Liu, Y.; He, J.; Wu, H.; Song, M. Investigations on microstructure and properties of Ti-Nb-Zr medium-entropy alloys for metallic biomaterials. Intermetallics 2022, 145, 107568. [Google Scholar] [CrossRef]

| Alloy | Element | At.% |

|---|---|---|

| Alloy A | Ti | 33.47 |

| Nb | 32.56 | |

| Zr | 32.44 | |

| B | 1.53 | |

| Alloy B | Ti | 32.71 |

| Nb | 29.03 | |

| Zr | 29.15 | |

| B | 9.11 |

| State | Young’s Modulus, GPa | Yield Strength, MPa | Ductility, % | Microhardness, HV |

|---|---|---|---|---|

| Unreinforced TiNbZr alloy | 74.4 ± 0.05 | 650 ± 22 | 21 ± 2 | 190 ± 6 |

| Alloy A | 75.4 ± 0.05 | 750 ± 25 | 10 ± 1 | 238 ± 7 |

| Alloy B | 113 ± 0.05 | 900 ± 29 | 0.5 ± 0.1 | 319 ± 8 |

| State | EOCP, mV | Ecor, mV | icor × 10−2 mA/cm2 |

|---|---|---|---|

| Unreinforced alloy | −172 | 1475 | 5.8 |

| Alloy A | −308 | 1488 | 1.6 |

| Alloy B | −149 | −72 | 1.2 |

| CP titanium | 290 | 1581 | 1.2 |

| State | Wear Factor of Samples, ×10−4 mm3/Hm | Wear Factor of Ball, ×10−5 mm3/Hm | Coefficient of Friction, µ |

|---|---|---|---|

| Unreinforced alloy | 4.14 | 3.14 | 1.15 |

| Alloy A | 4.39 | 1.87 | 1.13 |

| Alloy B | 5.69 | 1.91 | 0.58 |

| State | Erosion Rate, mm3/g |

|---|---|

| Unreinforced alloy | 6.06 × 10−3 |

| Alloy A | 5.71 × 10−3 |

| Alloy B | 5.58 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozerov, M.; Sokolovsky, V.; Gazizova, M.; Povolyaeva, E.; Tagirov, D.; Yapryntsev, M.; Yunusov, F.; Nadezhdin, S. Biocompatibility, Corrosion Resistance, and Wear Resistance of TiNbZr-Based Composites Reinforced with Borides. Metals 2025, 15, 240. https://doi.org/10.3390/met15030240

Ozerov M, Sokolovsky V, Gazizova M, Povolyaeva E, Tagirov D, Yapryntsev M, Yunusov F, Nadezhdin S. Biocompatibility, Corrosion Resistance, and Wear Resistance of TiNbZr-Based Composites Reinforced with Borides. Metals. 2025; 15(3):240. https://doi.org/10.3390/met15030240

Chicago/Turabian StyleOzerov, Maxim, Vitaly Sokolovsky, Marina Gazizova, Elizaveta Povolyaeva, Damir Tagirov, Maxim Yapryntsev, Firuz Yunusov, and Sergey Nadezhdin. 2025. "Biocompatibility, Corrosion Resistance, and Wear Resistance of TiNbZr-Based Composites Reinforced with Borides" Metals 15, no. 3: 240. https://doi.org/10.3390/met15030240

APA StyleOzerov, M., Sokolovsky, V., Gazizova, M., Povolyaeva, E., Tagirov, D., Yapryntsev, M., Yunusov, F., & Nadezhdin, S. (2025). Biocompatibility, Corrosion Resistance, and Wear Resistance of TiNbZr-Based Composites Reinforced with Borides. Metals, 15(3), 240. https://doi.org/10.3390/met15030240