Effect of Processing Parameters on the Microstructure and Corrosion Properties of AlCrFeCoNi High-Entropy Alloy Coatings Fabricated by Laser Cladding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Preparation of Coatings

2.2. Microstructure Characterization

2.3. Microhardness Tests

2.4. Electrochemical Measurements

3. Results

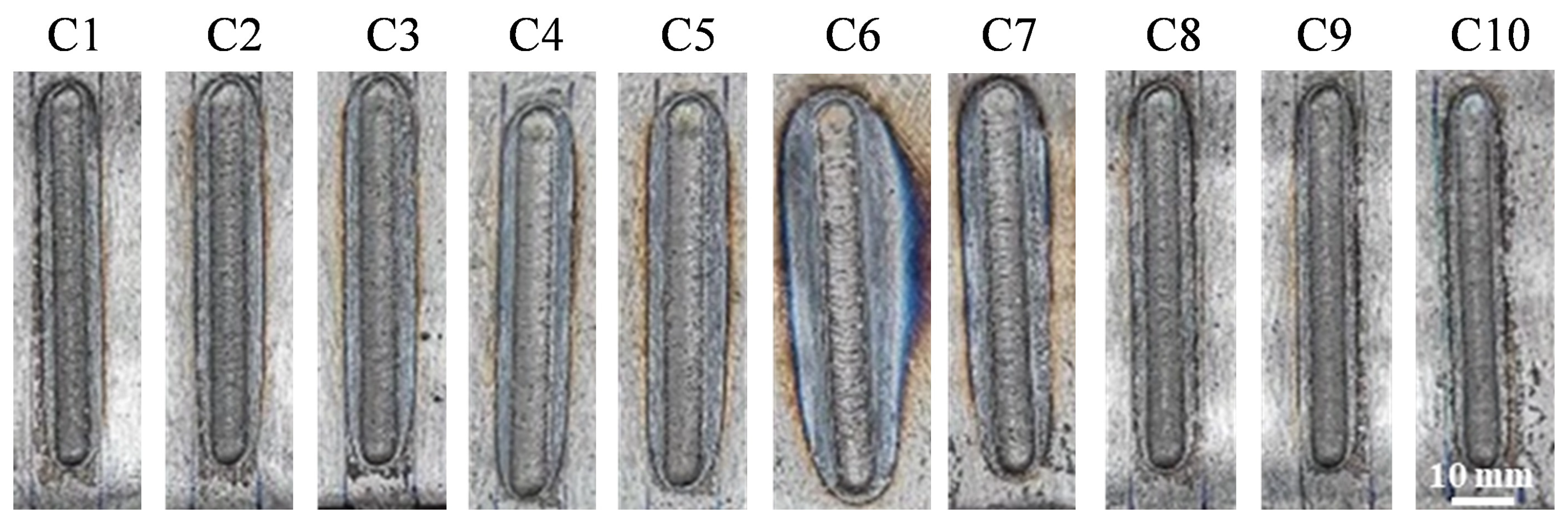

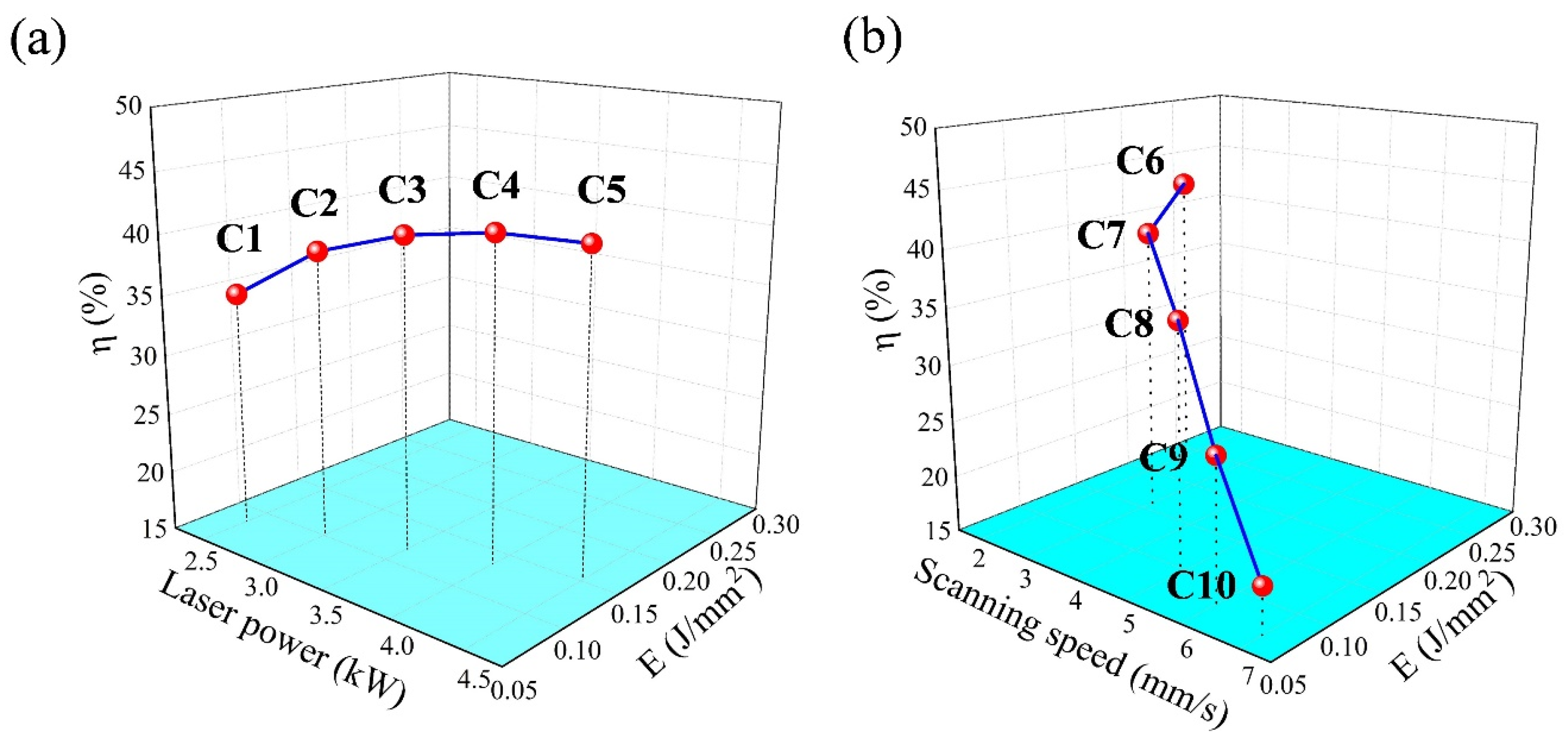

3.1. Coatings’ Morphology

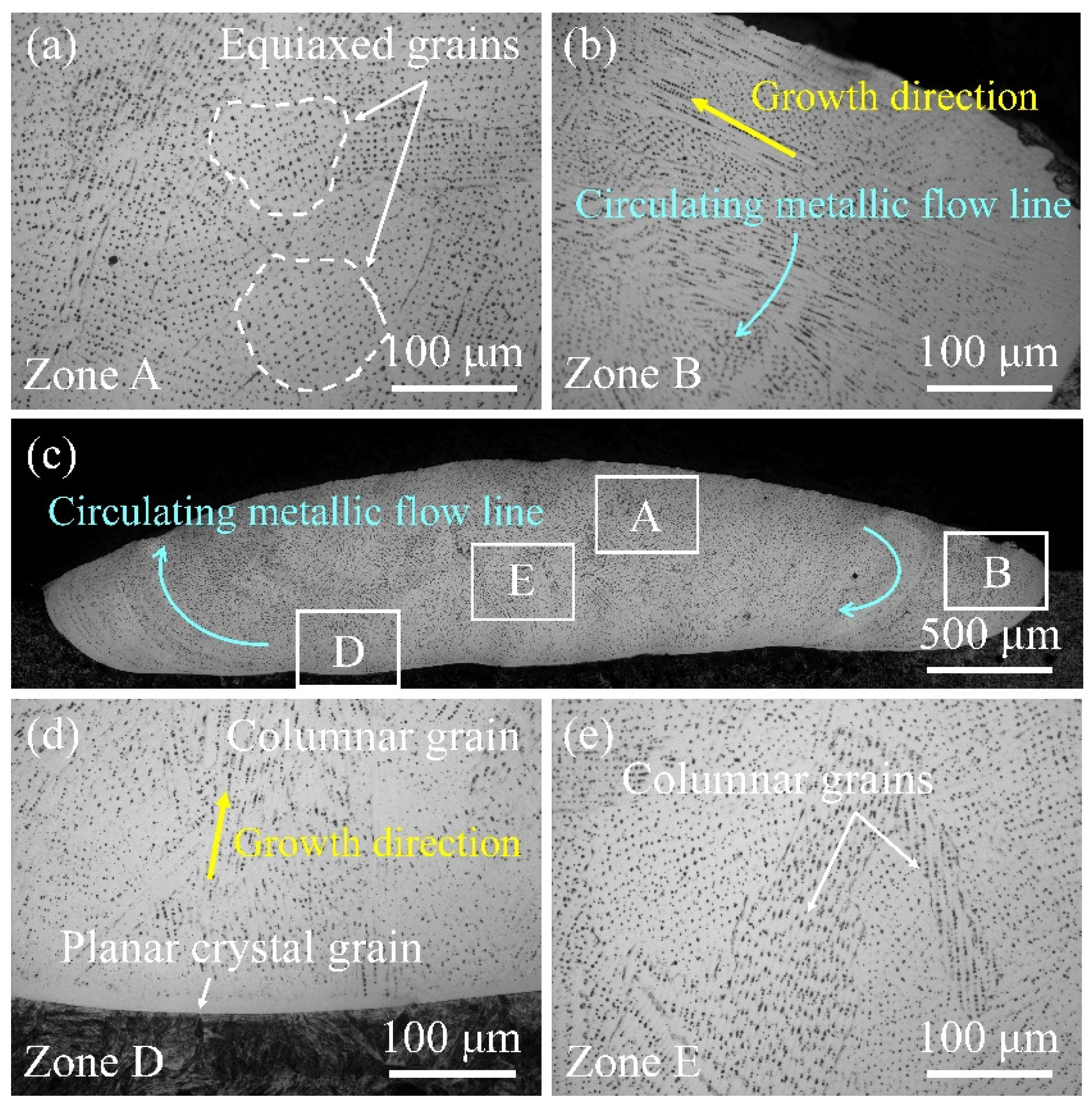

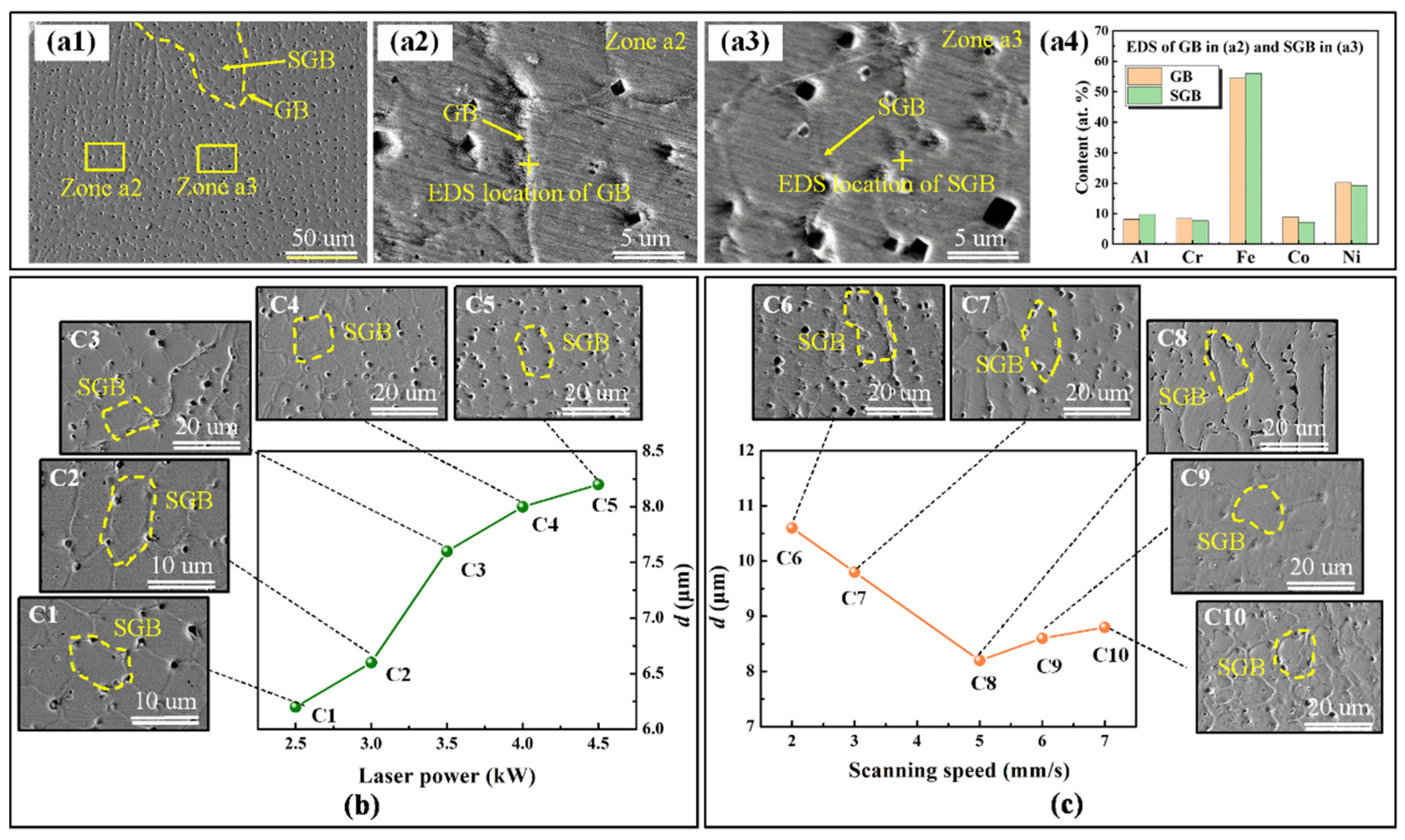

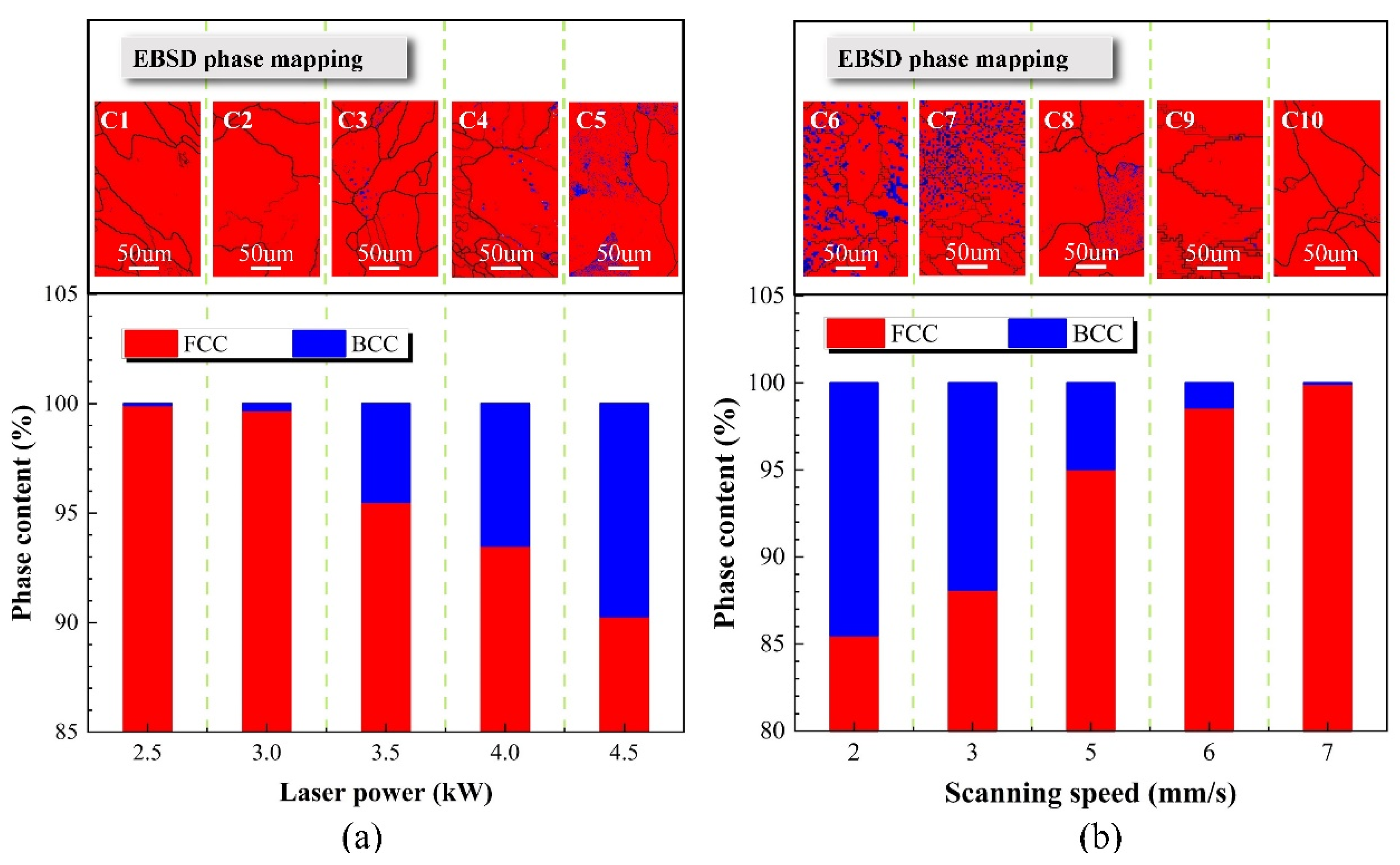

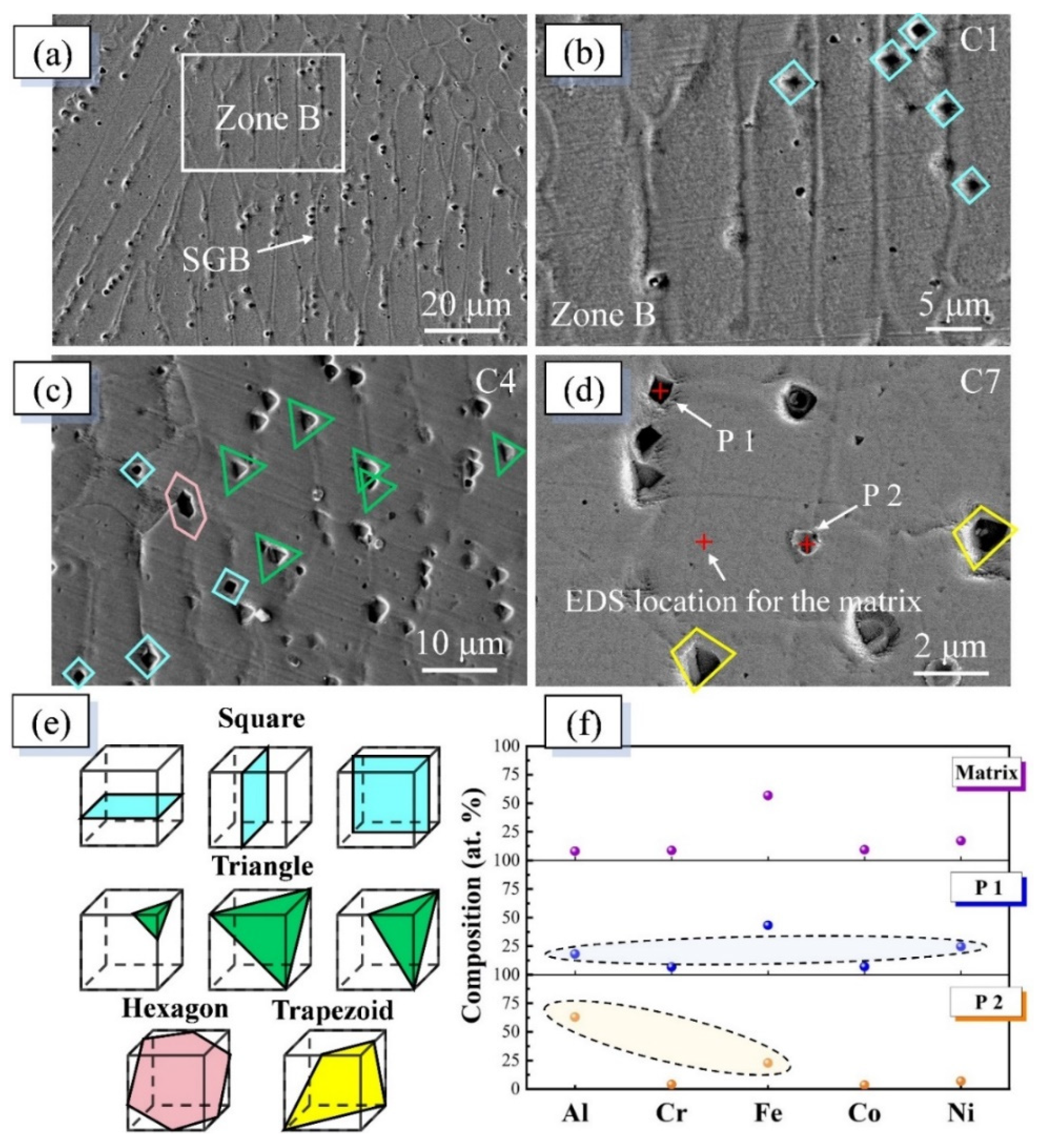

3.2. Microstructure Analysis

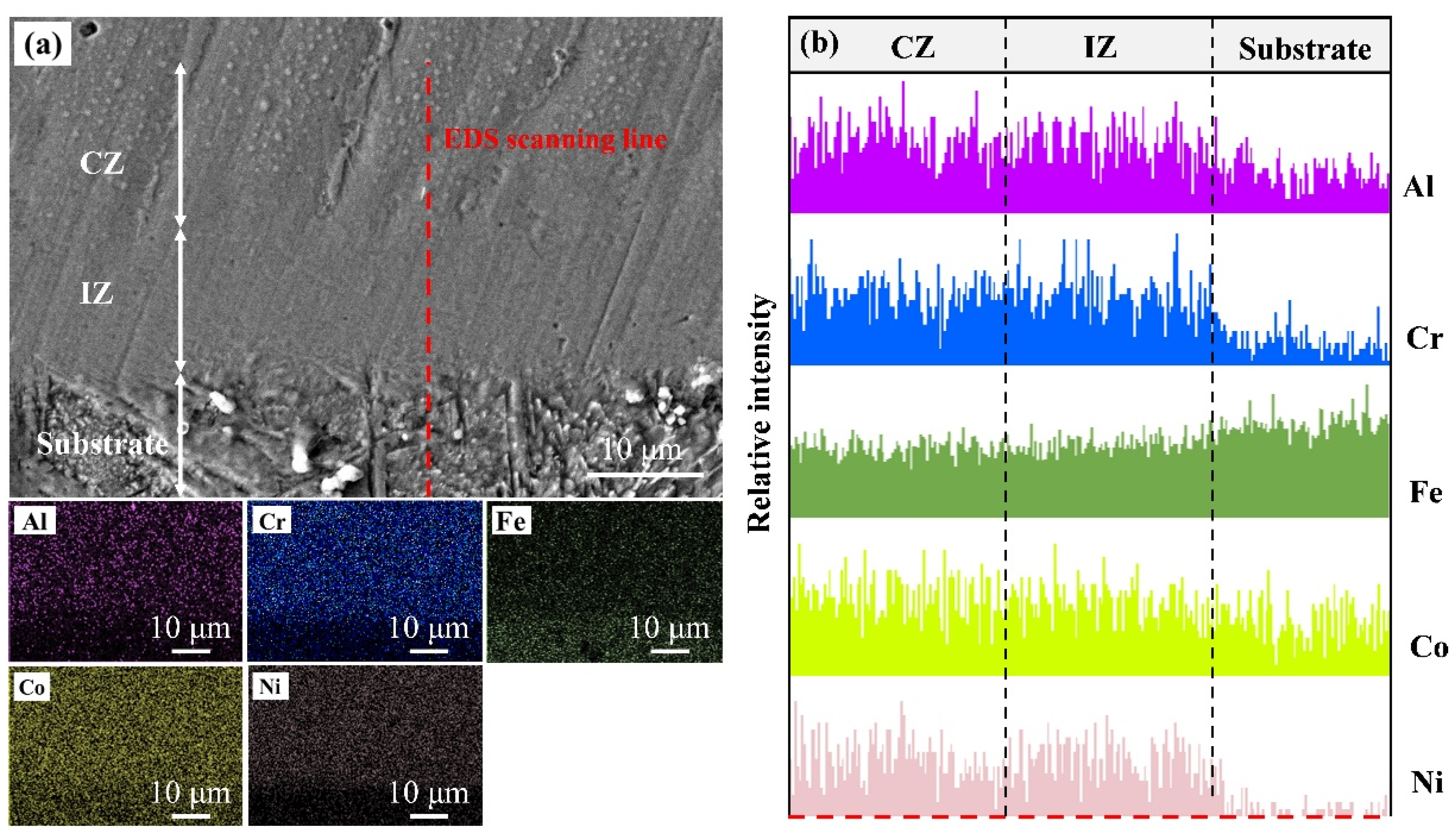

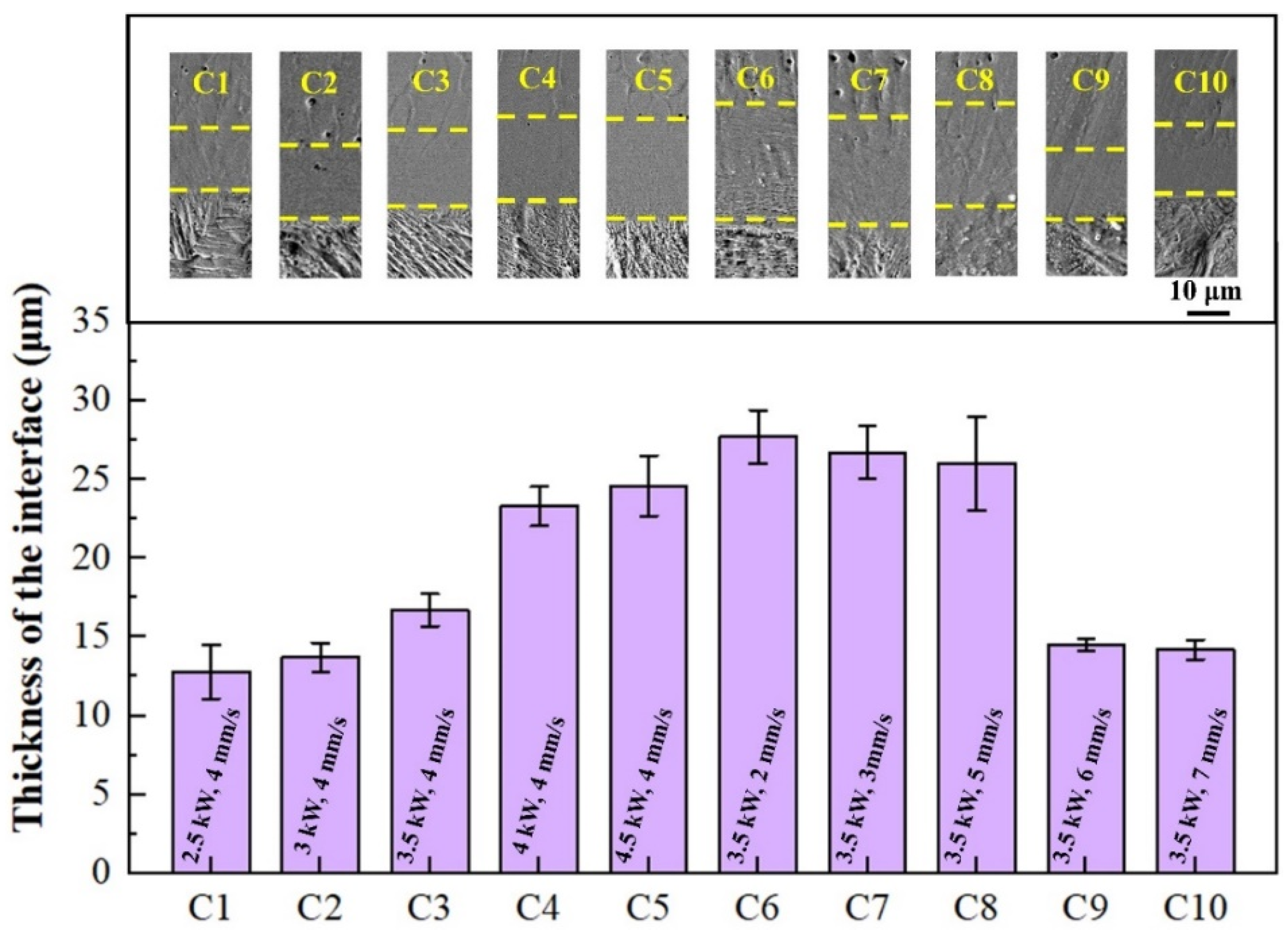

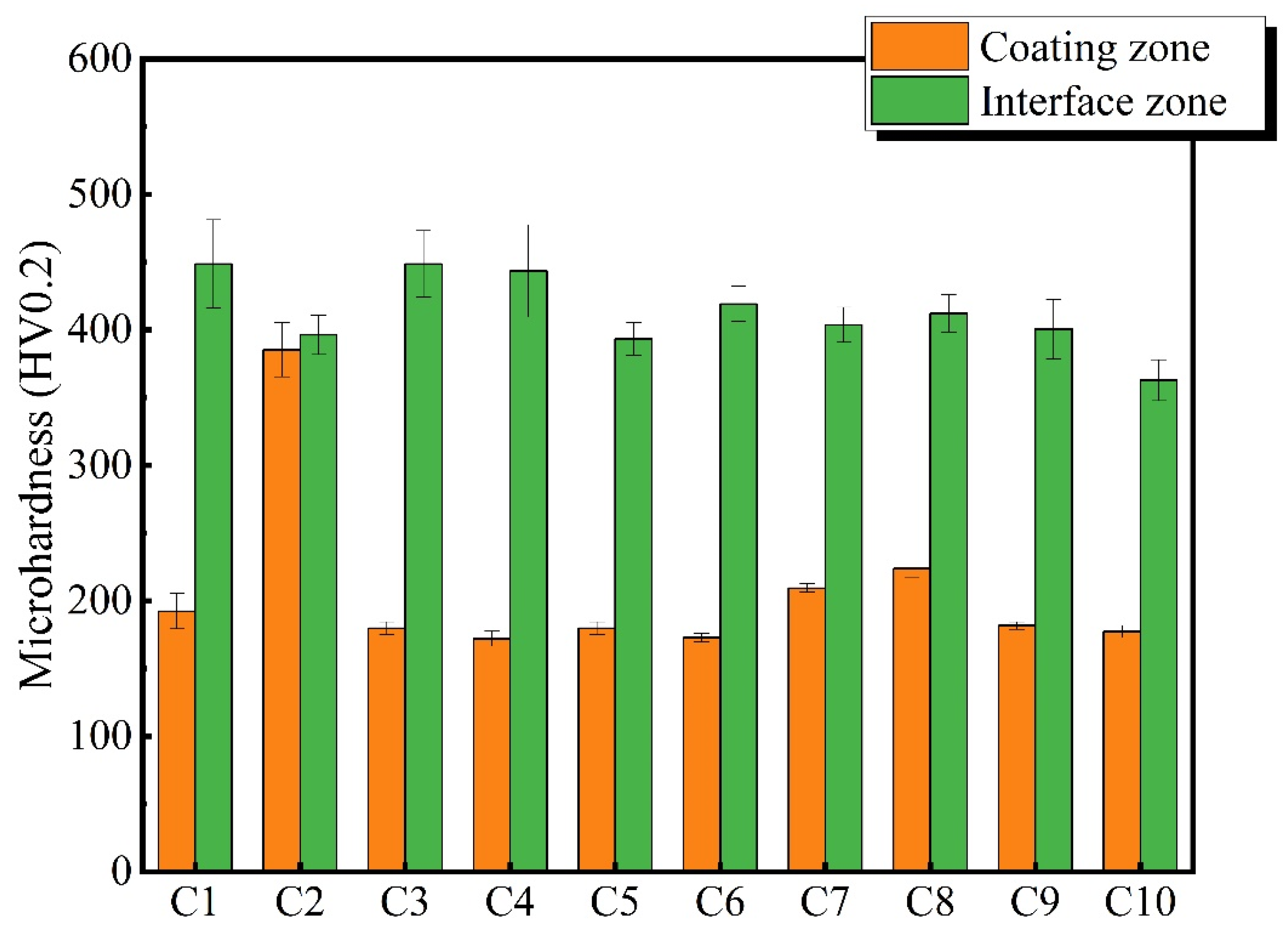

3.3. Interface Characteristics and Microhardness

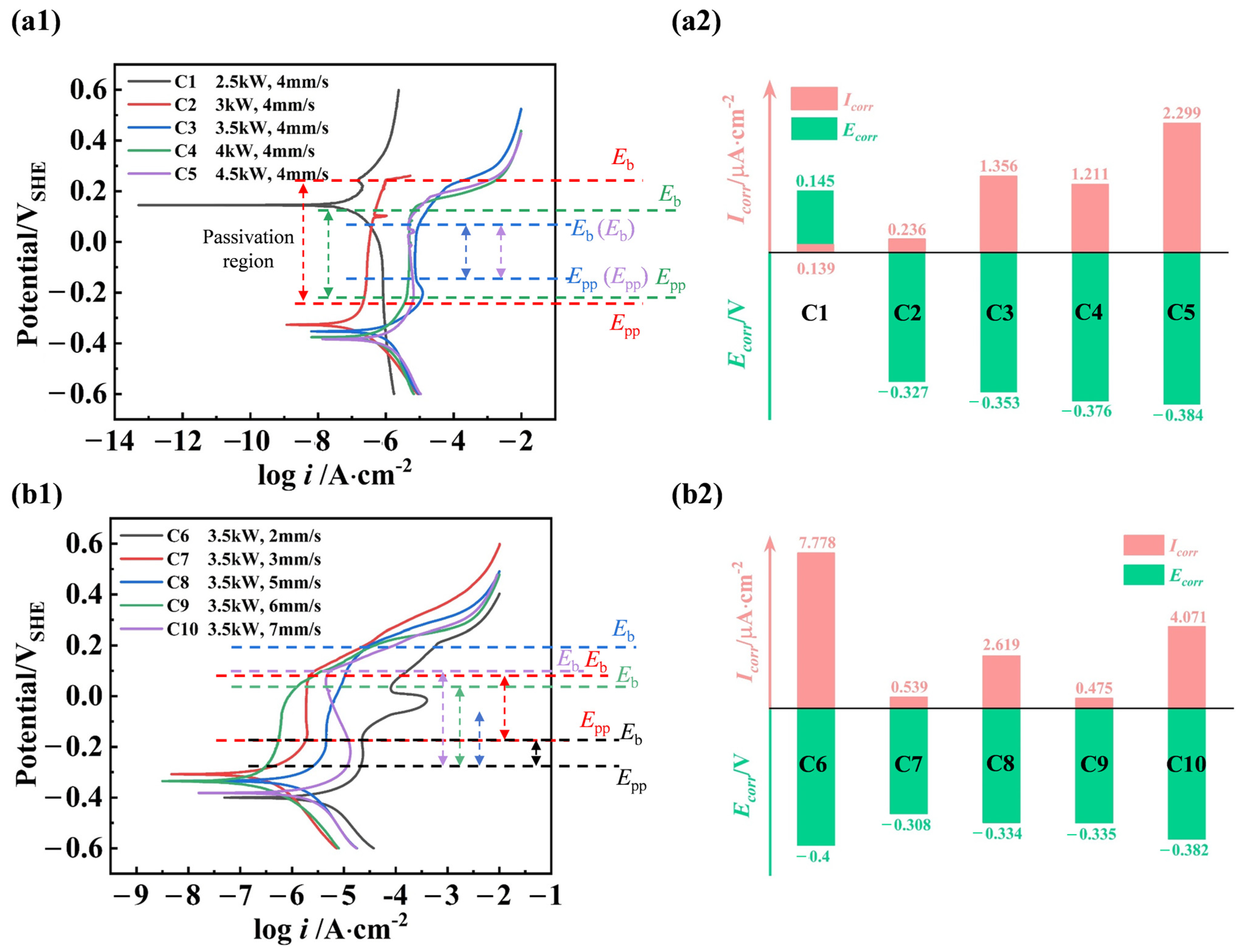

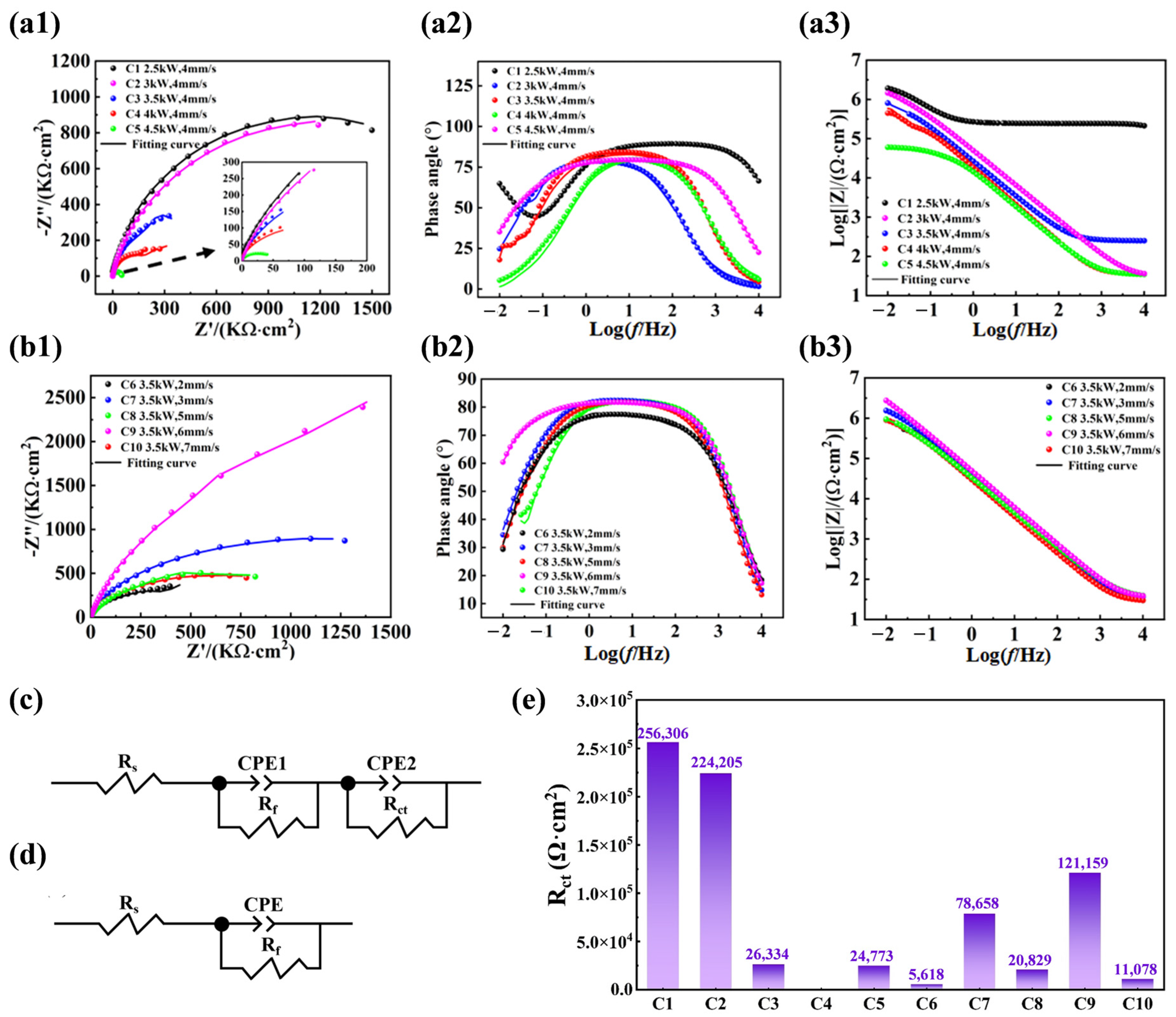

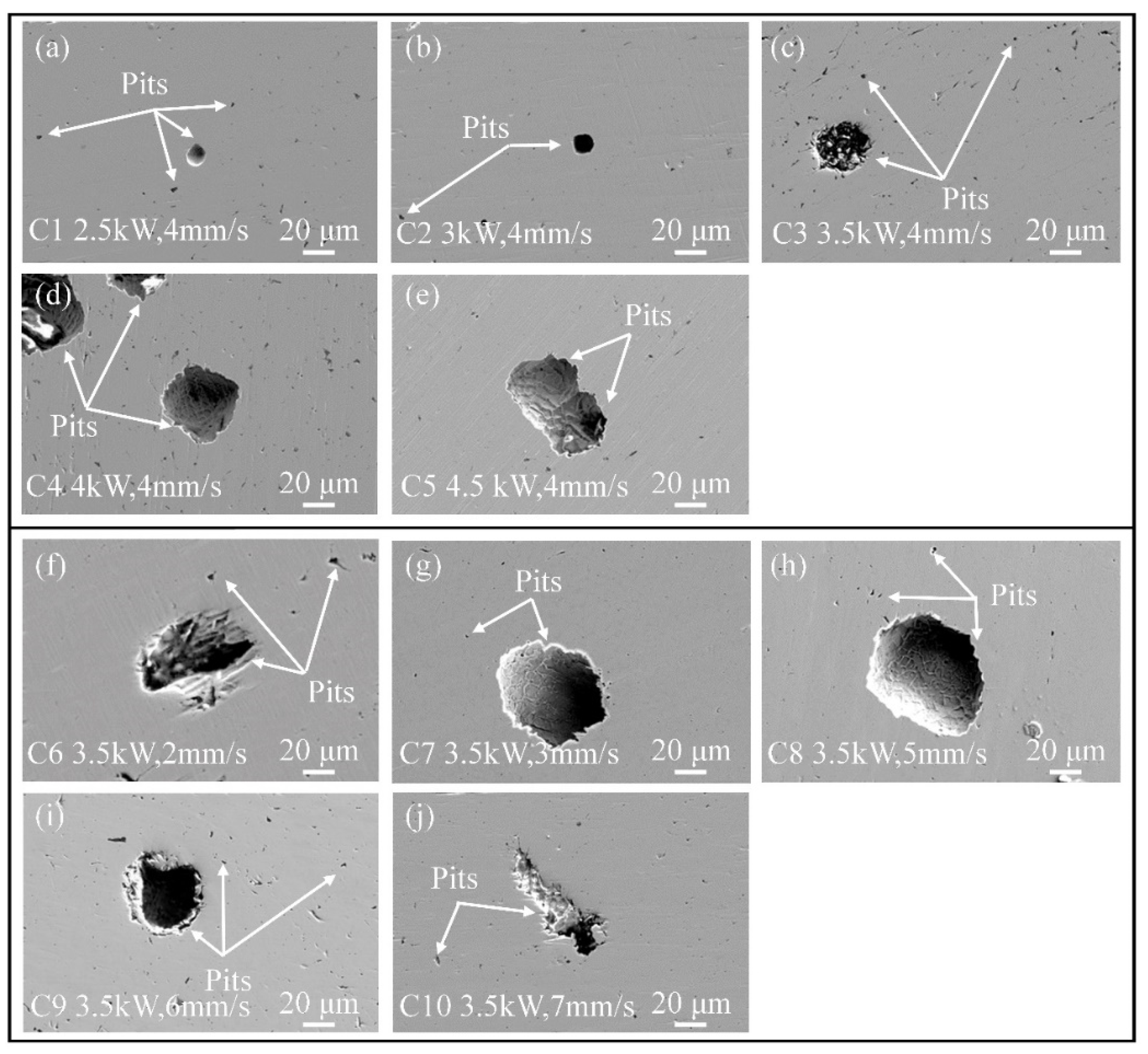

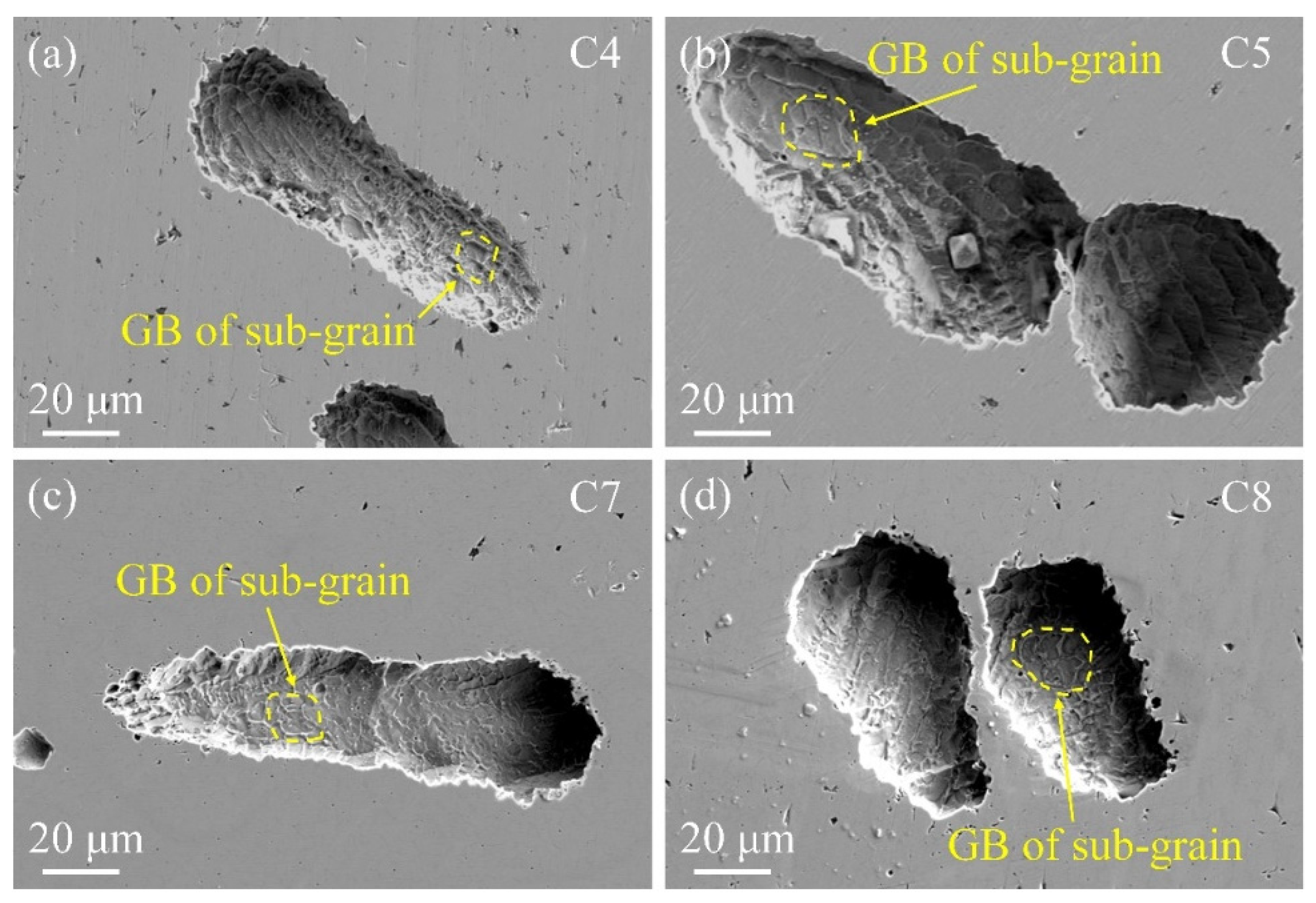

3.4. Electrochemical Corrosion Behavior

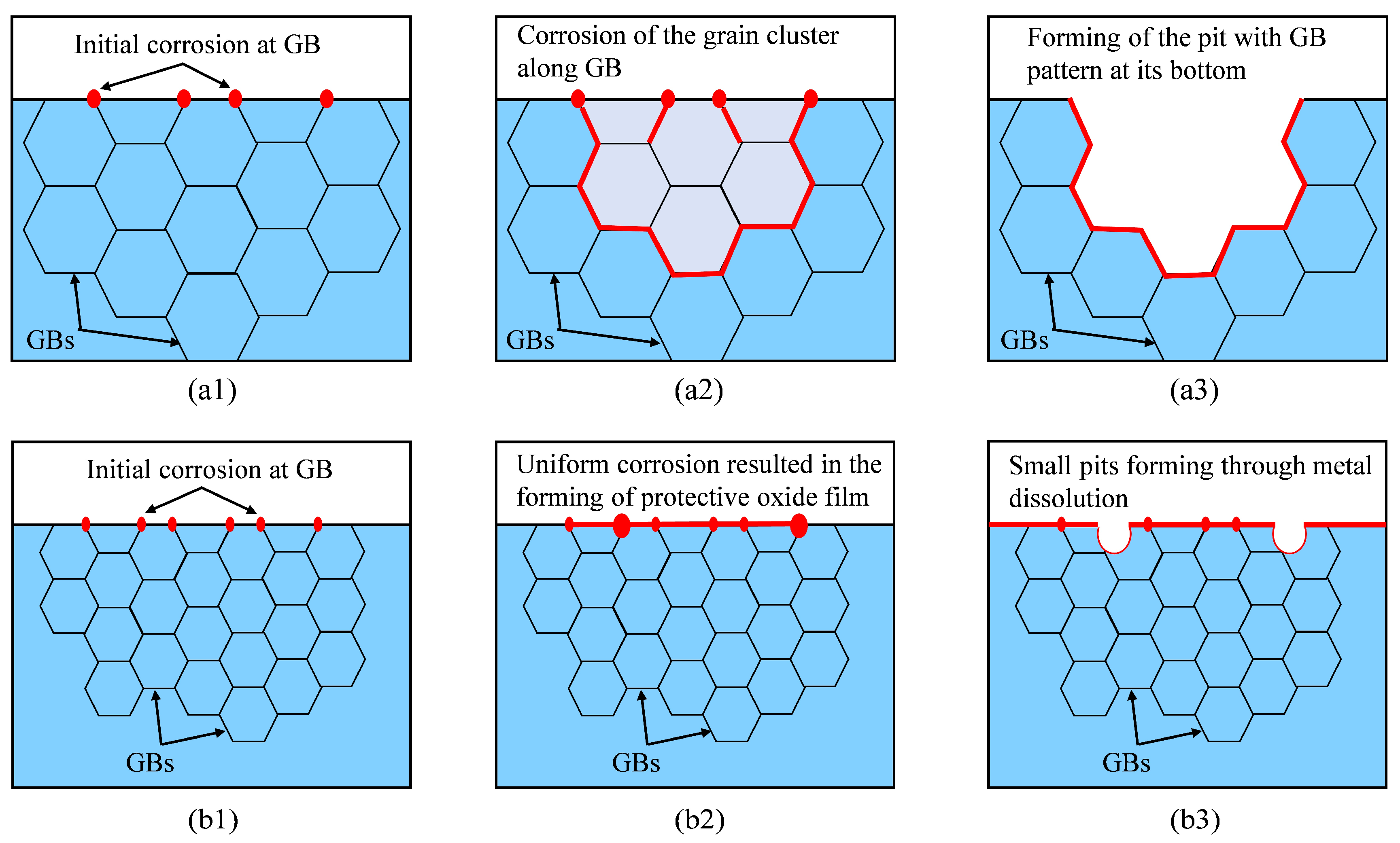

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Er, D.; Azar, G.T.P.; Kazmanlı, K.; Ürgen, M. The corrosion protection ability of TiAlN coatings produced with CA-PVD under superimposed pulse bias. Surf. Coat. Technol. 2018, 346, 1–8. [Google Scholar] [CrossRef]

- Liu, Z.; Dong, Y.; Chu, Z.; Yang, Y.; Li, Y.; Yan, D. Corrosion behavior of plasma sprayed ceramic and metallic coatings on carbon steel in simulated sea water. Mater. Des. 2013, 52, 630–637. [Google Scholar] [CrossRef]

- Chen, W.; Gao, W. Sol-enhanced electroplating of nano structured Ni-TiO composite coatings the effects of sol concentration on the mechanical and corrosion properties. Electrochim. Acta 2010, 55, 6865–6871. [Google Scholar] [CrossRef]

- Ye, X.; Ma, M.; Liu, W.; Li, L.; Zhong, M.; Liu, Y.; Wu, Q. Synthesis and characterization of high-entropy alloy AlxFeCoNiCuCr by laser cladding. Adv. Mater. Sci. Eng. 2011, 5, 485942. [Google Scholar]

- Çam, G.; Koçak, M. Progress in joining of advanced materials. Int. Mater. Rev. 1998, 43, 1–44. [Google Scholar] [CrossRef]

- Desale, G.R.; Paul, C.P.; Gandhi, B.K.; Jain, S.C. Erosion wear behavior of laser clad surfaces of low carbon austenitic steel. Wear 2009, 266, 975–987. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, S.; Gao, W.; Zhou, C.; Liu, F.; Lin, X. Microstructure and properties of laser cladding FeCrBSi composite powder coatings with higher Cr content. J. Mater. Process. Technol. 2014, 214, 899–905. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire Arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Wen, P.; Cai, Z.; Feng, Z.; Wang, G. Microstructure and mechanical properties of hot wire laser clad layers for repairing precipitation hardening martensitic stainless steel. Opt. Laser. Technol. 2015, 75, 207–213. [Google Scholar] [CrossRef]

- Huang, G.K.; Qu, L.D.; Lu, Y.Z.; Wang, Y.Z.; Li, H.G.; Qin, Z.X.; Lu, X. Corrosion resistance improvement of 45 steel by Fe-based amorphous coating. Vacuum 2018, 153, 39–42. [Google Scholar] [CrossRef]

- Qiu, X.W.; Zhang, Y.P.; He, L.; Liu, C.G. Microstructure and corrosion resistance of AlCrFeCuCo high entropy alloy. J. Alloys Compd. 2013, 549, 195–199. [Google Scholar] [CrossRef]

- Qiu, X.W.; Zhang, Y.P.; Liu, C.G. Effect of Ti content on structure and properties of Al2CrFeNiCoCuTix high-entropy alloy coatings. J. Alloys Compd. 2014, 585, 282–286. [Google Scholar] [CrossRef]

- Huang, P.K.; Yeh, J.W.; Shun, T.T.; Chen, S.K. Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating. Adv. Eng. Mater. 2004, 6, 74–78. [Google Scholar] [CrossRef]

- Mishra, R.S.; Haridas, R.S.; Agrawal, P. High Entropy Alloys tunability of deformation mechanisms through integration of compositional and microstructural domains. Mater. Sci. Eng. A 2021, 812, 141085. [Google Scholar] [CrossRef]

- Tao, Y.; Ma, Q.; Lu, Y.; Huang, D.; Zhang, H. Improvement of thermal shock resistance and hot mechanical properties by FCC/BCC/B2 multiphase strengthened microstructure in laser cladded high-entropy alloy coatings. Surf. Coat. Technol. 2023, 472, 129919. [Google Scholar] [CrossRef]

- Juan, Y.F.; Li, J.; Jiang, Y.Q.; Jia, W.L.; Lu, Z.J. Modified criterions for phase prediction in the multi-component laser-clad coatings and investigations into microstructural evolution/wear resistance of FeCrCoNiAlMox laser-clad coatings. Appl. Surf. Sci. 2019, 465, 700–714. [Google Scholar] [CrossRef]

- Ma, S.G.; Zhang, Y. Effect of Nb addition on the microstructure and properties of AlCoCrFeNi high-entropy alloy. Mater. Sci. Eng. A 2012, 532, 480–486. [Google Scholar] [CrossRef]

- Wang, W.R.; Wang, W.L.; Wang, S.C.; Tsai, Y.C.; Lai, C.H.; Yeh, J.W. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 2012, 26, 44–51. [Google Scholar] [CrossRef]

- Kao, Y.F.; Chen, T.J.; Chen, S.K.; Yeh, J.W. Microstructure and mechanical Property of as-cast, homogenized, and deformed AlxCoCrFeNi (0≤x≤2) high-entropy alloys. J. Alloys Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Li, D.L.; Zhou, F.; Yu, S.H. Microstructure and corrosion resistance of FeCrNiMnMoxB0.5 high-entropy alloy coating prepared by laser cladding. High Power Laser Part Beams 2015, 28, 190–195. [Google Scholar]

- Wu, H.; Zhang, S.; Zhang, H.F.; Wang, R.; Wu, C.L.; Zhang, C.H.; Chen, J. Design, microstructure, wear and corrosion behaviors of laser clad FeNiCoCrMo0.3Nbx hypoeutectic high entropy alloys coatings. Mater. Character. 2024, 216, 114277. [Google Scholar] [CrossRef]

- Qiu, X.W.; Wu, M.J.; Liu, C.G.; Zhang, Y.P.; Huang, C.X. Corrosion performance of Al2CrFeCoxCuNiTi high-entropy alloy coatings in acid liquids. J. Alloys Compd. 2017, 708, 353–357. [Google Scholar] [CrossRef]

- Song, B.X.; Yu, T.B.; Jiang, X.Y.; Xi, W.C.; Lin, X.L. Development mechanism and solidification morphology of molten pool generated by laser cladding. Int. J. Therm. Sci. 2021, 159, 106579. [Google Scholar] [CrossRef]

- Yin, H.; Felicelli, S.D. Dendrite growth simulation during solidification in the LENS process. Acta Mater. 2010, 58, 1455–1465. [Google Scholar] [CrossRef]

- Liu, T.T.; Qu, X.G.; Zheng, Y.; Wang, Y.J.; Yu, C.; Lu, H. Revealing multiphysics effects on microstructure characteristics in powder-fed laser cladding based on a comprehensive model. J. Mater. Res. Technol. 2024, 29, 3673–3685. [Google Scholar] [CrossRef]

- Liang, Y.; Liao, Z.Y.; Zhang, L.L.; Cai, M.W.; Wei, X.S.; Shen, J. A review on coatings deposited by extreme high-speed laser cladding: Processes, materials, and properties. Opt. Laser Technol. 2023, 164, 109472. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Zhao, P.L. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Dimiduk, D.M.; Woodward, C.; Miracle, D.B. Oxidation behavior of a refractory NbCrMo0.5Ta0.5TiZr alloy. J. Mater. Sci. 2012, 47, 6522–6534. [Google Scholar] [CrossRef]

- Shockner, R.; Edry, I.; Pinkas, M.; Meshi, L. Systematic study of the effect of Cr on the micro-structure, phase content and hardness of the AlCrxFeCoNi alloys. J. Alloys Compd. 2023, 940, 168897. [Google Scholar] [CrossRef]

- Wang, Y.P.; Li, B.S.; Ren, M.X.; Yang, C.; Fu, H.Z. Microstructure and compressive properties of AlCrFeCoNi high entropy alloy. Mater. Sci. Eng. A 2008, 491, 154–158. [Google Scholar] [CrossRef]

- Zhou, Z.; Yan, X.; Dai, Y. Effect of precipitation on the mechanical and damping properties of (FeCrCoNi)95Ti5 high-entropy alloy. Intermetallics 2025, 178, 108645. [Google Scholar] [CrossRef]

- Vignesh, M.; Sujit, M.; Radhika, N.; Sathishkumar, M.; Muthu, S.M.; Dash, K.; Mishra, S.R. Influence of Cu and Co addition on metallurgical and wear characteristics of AlCrFeNi high entropy alloy. Sci. Rep. 2024, 14, 27398. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Wang, H.; Liu, Q. Microstructure evolution and strengthening mechanism of laser-cladding MoFexCrTiWAlN by refractory high-entropy alloy coatings. J. Alloys Compd. 2020, 834, 155147. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Rehman, E.U.; Ullah, S.; Tariq, A. A review on laser cladding of high-entropy alloys, their recent trends and potential applications. J. Manuf. Process. 2021, 68, 225–273. [Google Scholar] [CrossRef]

- Bellezze, T.; Giuliani, G.; Roventi, G. Study of stainless steels corrosion in a strong acid mixture. Part 1: Cyclic potentiodynamic polarization curves examined by means of an analytical method. Corros. Sci. 2018, 130, 113–125. [Google Scholar] [CrossRef]

| Coatings | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 |

|---|---|---|---|---|---|---|---|---|---|---|

| LP | 2.5 | 3 | 3.5 | 4 | 4.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 |

| SS | 4 | 4 | 4 | 4 | 4 | 2 | 3 | 5 | 6 | 7 |

| Coatings | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Epp/V | / | −0.256 | −0.149 | −0.216 | −0.216 | −0.271 | −0.159 | −0.213 | −0.228 | / |

| Eb/V | / | 0.243 | 0.052 | 0.101 | 0.077 | −0.156 | 0.074 | −0.066 | −0.035 | / |

| ip/μA·cm−2 | / | 0.286 | 8.25 | 4.95 | 5.62 | 22.5 | 2.03 | 4.61 | 1.09 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Bai, M.; Xu, W.; Chu, T. Effect of Processing Parameters on the Microstructure and Corrosion Properties of AlCrFeCoNi High-Entropy Alloy Coatings Fabricated by Laser Cladding. Metals 2025, 15, 231. https://doi.org/10.3390/met15030231

Liu J, Bai M, Xu W, Chu T. Effect of Processing Parameters on the Microstructure and Corrosion Properties of AlCrFeCoNi High-Entropy Alloy Coatings Fabricated by Laser Cladding. Metals. 2025; 15(3):231. https://doi.org/10.3390/met15030231

Chicago/Turabian StyleLiu, Jingfu, Minghan Bai, Wenjing Xu, and Tongjiao Chu. 2025. "Effect of Processing Parameters on the Microstructure and Corrosion Properties of AlCrFeCoNi High-Entropy Alloy Coatings Fabricated by Laser Cladding" Metals 15, no. 3: 231. https://doi.org/10.3390/met15030231

APA StyleLiu, J., Bai, M., Xu, W., & Chu, T. (2025). Effect of Processing Parameters on the Microstructure and Corrosion Properties of AlCrFeCoNi High-Entropy Alloy Coatings Fabricated by Laser Cladding. Metals, 15(3), 231. https://doi.org/10.3390/met15030231