Study on Stress Corrosion Cracking Mechanism of Steel Wires with Different Strength Levels

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

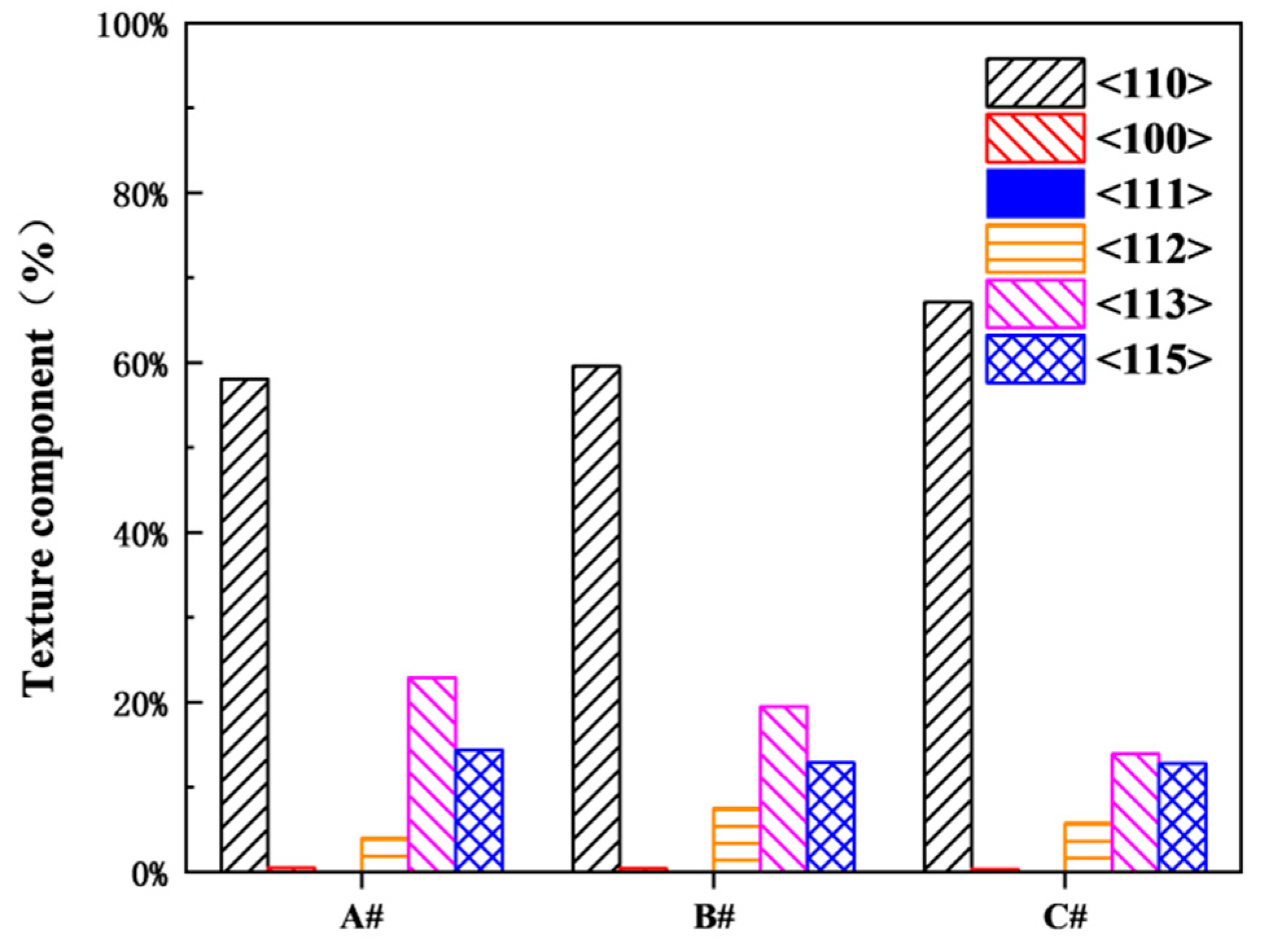

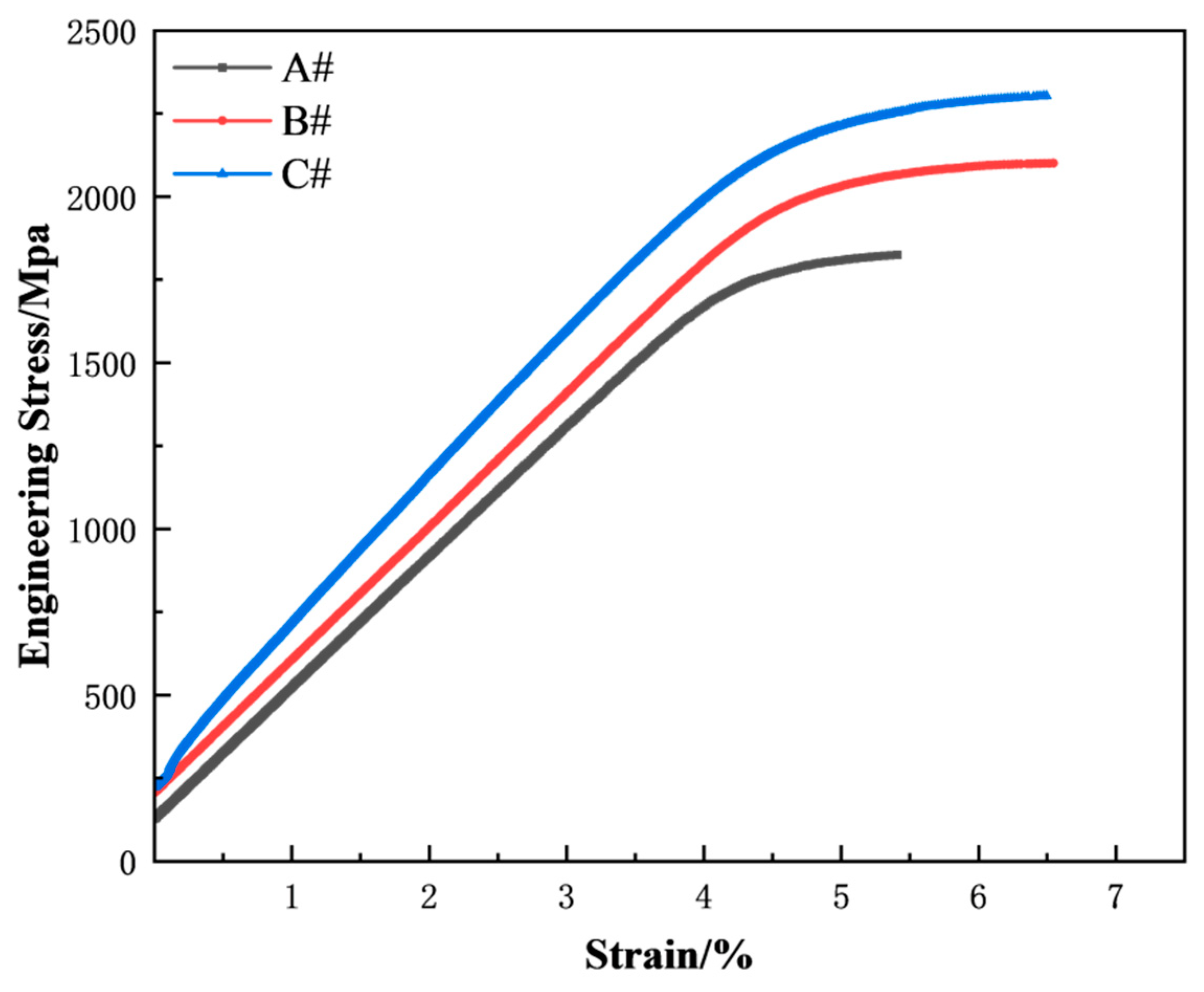

3.1. Microstructure and Mechanical Properties

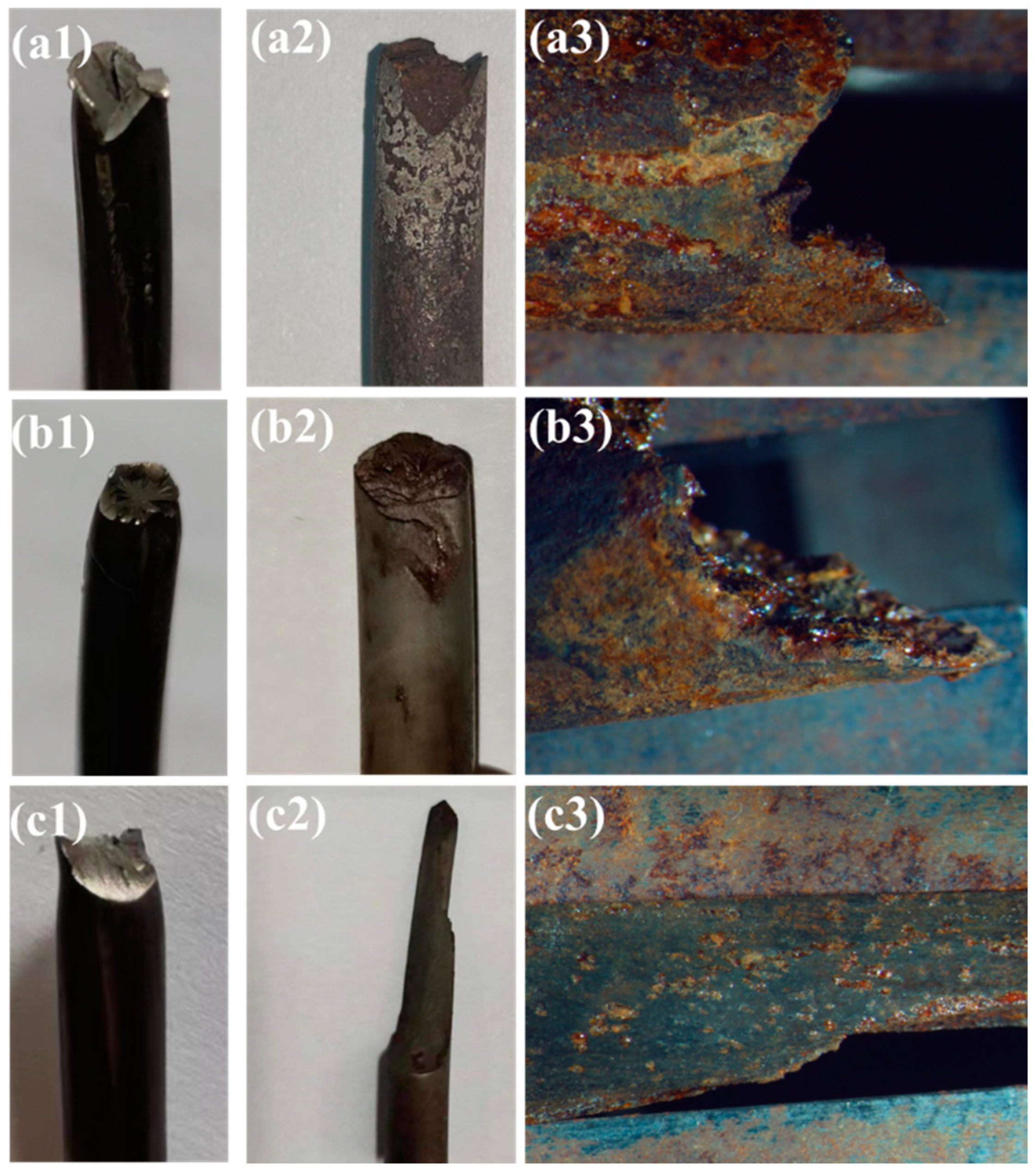

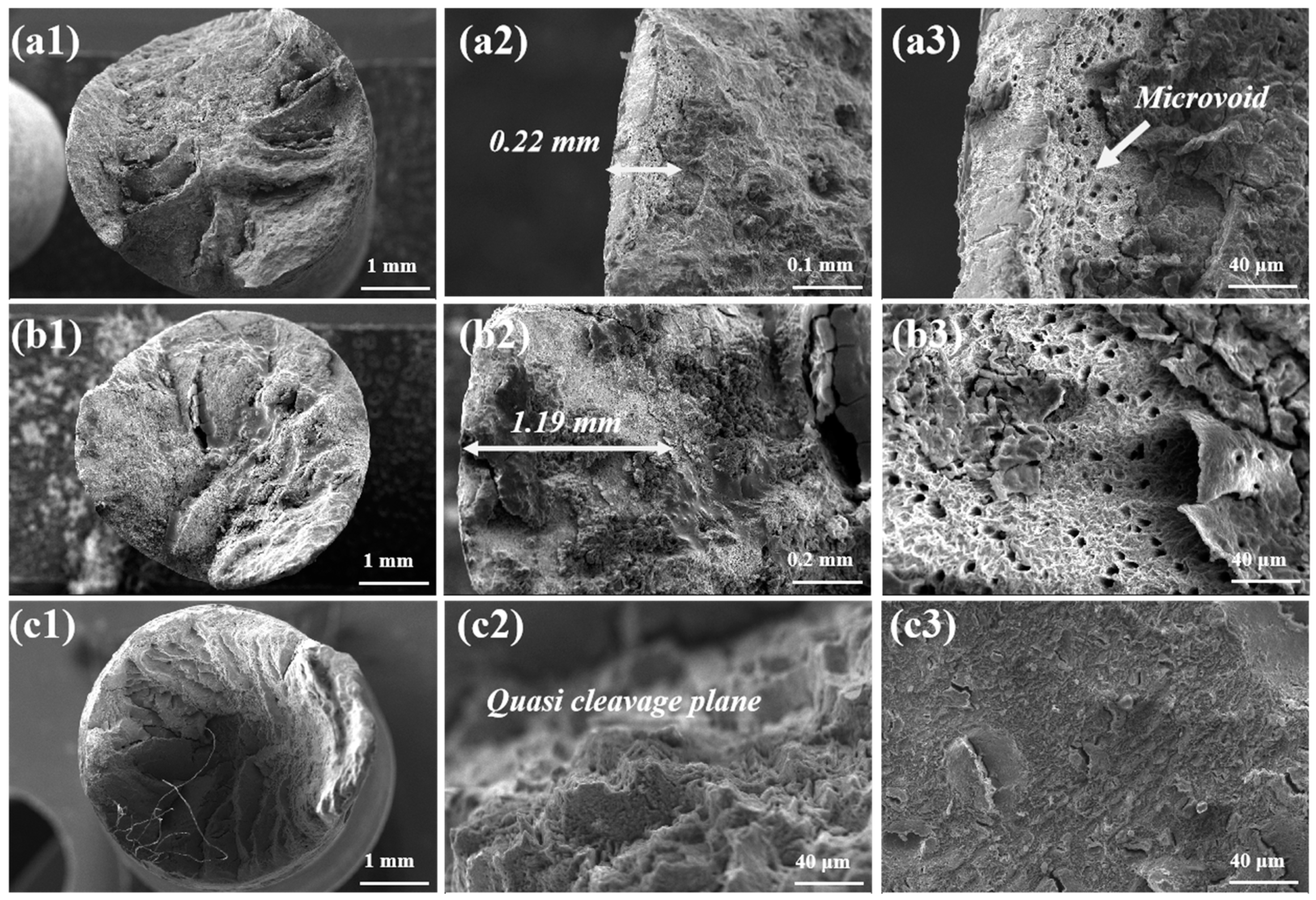

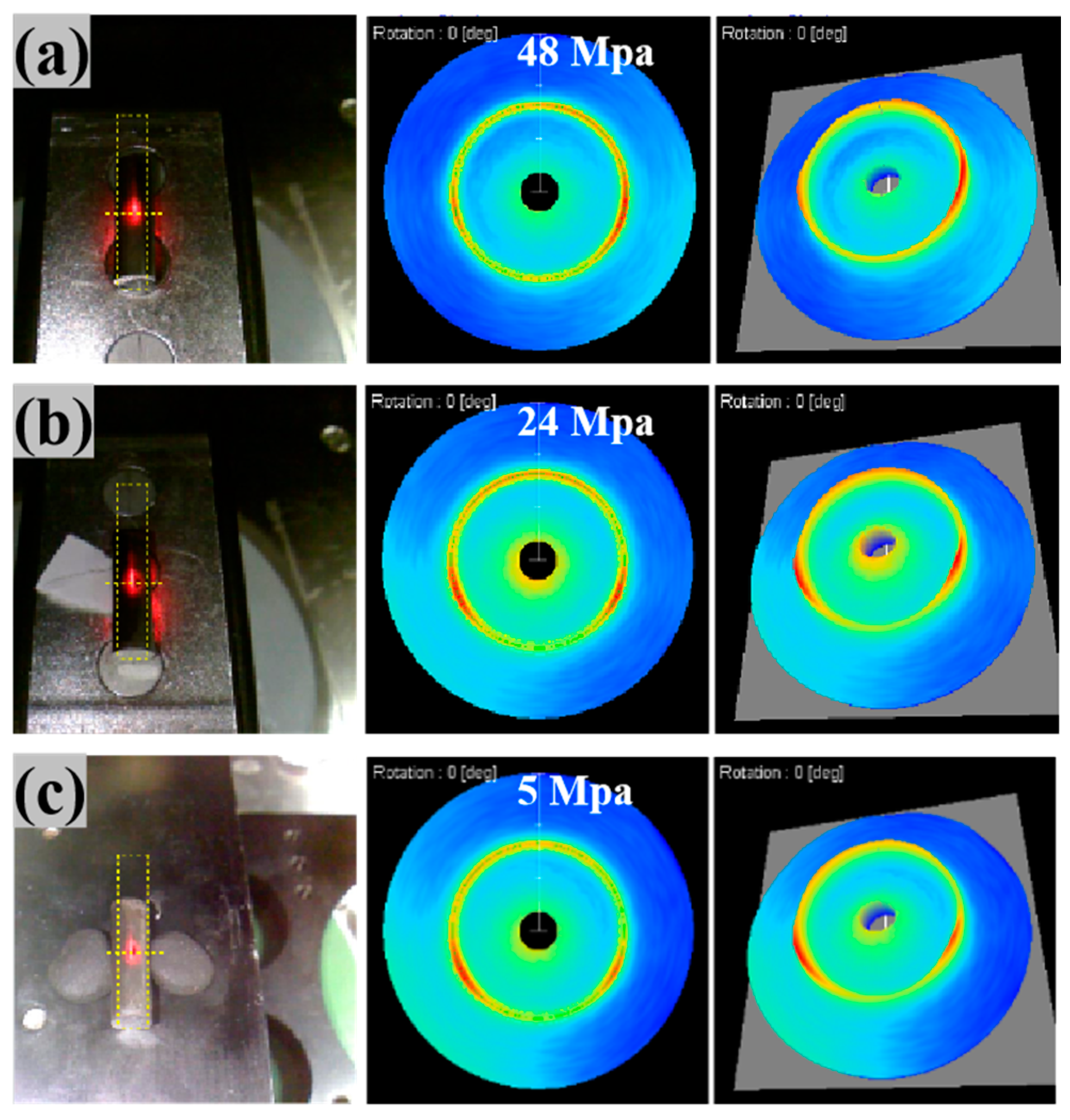

3.2. Stress Corrosion Cracking Mechanism

4. Conclusions

- (1)

- Steel C has the highest tensile strength at 2303 MPa, followed by Steel B at 2100 MPa, and Steel A with the lowest tensile strength at 1830 MPa. The strength difference is primarily attributed to the boundary strengthening effect.

- (2)

- The stress corrosion sensitivity follows the order: Steel B < Steel A < Steel C. The stress corrosion cracking mechanisms for the lower strength Steels A and B are anodic dissolution, while Steel C, with higher strength, exhibits hydrogen embrittlement.

- (3)

- Although Steel C has the smallest pearlite interlamellar spacing and exhibits good corrosion resistance, its stress corrosion failure time is the shortest due to hydrogen embrittlement.

- (4)

- Compared to Steel A, Steel B not only has smaller pearlite interlamellar spacing, enhancing its corrosion resistance, but its higher strength also improves local stress stability, resulting in the best resistance to stress corrosion cracking with a failure time of 3.81 h.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, H.; Yang, Y.; Wang, X.; Tang, H. Effects of the Position and Chloride-Induced Corrosion of Strand on Bonding Behavior between the Steel Strand and Concrete. Structures 2023, 58, 105500. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Failure Analysis of Cold Drawn Prestressing Steel Wires Subjected to Stress Corrosion Cracking. Eng. Fail. Anal. 2005, 12, 654–661. [Google Scholar] [CrossRef]

- Lee, J.; Lee, Y.-J.; Shim, C.-S. Probabilistic Prediction of Mechanical Characteristics of Corroded Strands. Eng. Struct. 2020, 203, 109882. [Google Scholar] [CrossRef]

- Stovpchenko, G.; Medovar, L.; Stepanenko, D.; Jiang, Z.; Dong, Y.; Liu, Y. Energy and Environmental Savings by and for Steel Lightweight. ISIJ Int. 2024, 64, 165–173. [Google Scholar] [CrossRef]

- Chen, M.; Lu, X.; Zhou, Z.; Du, Y.; Xu, X.; Li, X. Mechanical Properties of 2100 MPa Parallel Wire Strands under and after Elevated Temperature. J. Constr. Steel Res. 2024, 212, 108323. [Google Scholar] [CrossRef]

- Liu, L.; Wang, L.; Yu, S.; Li, M. Mechanical Properties of Steel Strands Cooled by Different Methods After High-Temperature Treatment. Int. J. Steel Struct. 2022, 22, 333–342. [Google Scholar] [CrossRef]

- Xie, J.; Zhao, X.; Yan, J.-B. Mechanical Properties of High Strength Steel Strand at Low Temperatures: Tests and Analysis. Constr. Build. Mater. 2018, 189, 1076–1092. [Google Scholar] [CrossRef]

- Peng, J.; Xiao, J.; Yang, Y.; Dong, Y.; Zhang, J. Long-Term Experimental Study and Prediction of the Mechanical Performance on Corroded Prestressing Steel Strands Subjected to Marine Salt Spray Environment. Constr. Build. Mater. 2024, 425, 136069. [Google Scholar] [CrossRef]

- Peng, W.; Fan, W. Experimental Study on Corrosion Development Model and Fatigue Performance of Strand Steel for Coastal Structures. J. Mar. Sci. Eng. 2023, 11, 665. [Google Scholar] [CrossRef]

- Meng, E.; Yao, G.; Yu, Y.; Jiang, D. Analysis on Physical and Mechanical Performance and Damage Mechanism of Steel Strand under Coupling Effects of Load and Environment. Mater. Corros. 2018, 69, 1539–1547. [Google Scholar] [CrossRef]

- Chen, Y.; Qin, W.; Wang, Q.; Tan, H. Influence of Corrosion Pit on the Tensile Mechanical Properties of a Multi-Layered Wire Rope Strand. Constr. Build. Mater. 2021, 302, 124387. [Google Scholar] [CrossRef]

- Zhao, N.; He, Y.; Lin, L.; Liu, R.; Zhao, Q.; Zheng, W. Strength-Toughness Balance and Hydrogen Embrittlement Susceptibility of a Precipitation-Strengthened Steel Adopted Tempering Process. Metals 2022, 12, 1534. [Google Scholar] [CrossRef]

- Chen, T.-C.; Chen, S.-T.; Tsay, L.-W.; Shiue, R.-K. Correlation between Fatigue Crack Growth Behavior and Fracture Surface Roughness on Cold-Rolled Austenitic Stainless Steels in Gaseous Hydrogen. Metals 2018, 8, 221. [Google Scholar] [CrossRef]

- Wang, W.; Fu, H.; Zhang, H.; Yan, Y.; Li, J. Effect of Grain Orientation on Hydrogen Embrittlement Behavior of Interstitial-Free Steel. Metals 2022, 12, 981. [Google Scholar] [CrossRef]

- Yuan, J.; Li, P.; Zhang, H.; Yin, S.; Xu, M. Electrochemical Characteristics and Corrosion Mechanisms of High-Strength Corrosion-Resistant Steel Reinforcement under Simulated Service Conditions. Metals 2024, 14, 876. [Google Scholar] [CrossRef]

- Fideles, F.F.D.M.; Florez, M.A.C.; Rodrigues, M.V.G.; Cardoso, J.L.; Aranas, C.; Rodrigues, S.F.; Lima, M.N.D.S.; Pascoal, C.V.P.; De Moura, T.A.; Reis, G.S.; et al. Influence of the Morphology of Eutectoid Steels on Corrosion Resistance in NaCl Aqueous Medium with and without CO2. Metals 2023, 13, 1782. [Google Scholar] [CrossRef]

- Vignal, V.; Rault, V.; Krawiec, H.; Lukaszczyk, A.; Dufour, F. Microstructure and Corrosion Behaviour of Deformed Pearlitic and Brass-Coated Pearlitic Steels in Sodium Chloride Solution. Electrochim. Acta 2016, 203, 416–425. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Stress Corrosion Cracking Paths in Cold Drawn Pearlitic Steels. Procedia Struct. Integr. 2022, 39, 475–478. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Composite Microstructure of Cold-Drawn Pearlitic Steel and Its Role in Stress Corrosion Behavior. J. Mater. Eng. Perform. 2000, 9, 272–279. [Google Scholar] [CrossRef]

- Torkkeli, J.; Saukkonen, T.; Hänninen, H. Effect of Pearlite on Stress Corrosion Cracking of Carbon Steel in Fuel-Grade Ethanol. Corros. Rev. 2018, 36, 281–293. [Google Scholar] [CrossRef]

- Wang, L.; Li, T.; Dai, L.; Chen, W.; Huang, K. Corrosion Morphology and Mechanical Behavior of Corroded Prestressing Strands. J. Adv. Concr. Technol. 2020, 18, 545–557. [Google Scholar] [CrossRef]

- GB/T 21839-2019; Test Methods for Steel for Prestressed Concrete. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Standardization Administration of China, Standards Press of China: Beijing, China, 2019.

- Nam, W.J.; Song, H.R.; Bae, C.M. Effect of Microstructural Features on Ductility of Drawn Pearlitic Carbon Steels. ISIJ Int. 2005, 45, 1205–1210. [Google Scholar] [CrossRef]

- Zhang, X.; Hansen, N.; Godfrey, A.; Huang, X. Dislocation-Based Plasticity and Strengthening Mechanisms in Sub-20 Nm Lamellar Structures in Pearlitic Steel Wire. Acta Mater. 2016, 114, 176–183. [Google Scholar] [CrossRef]

- Zhang, X.; Godfrey, A.; Huang, X.; Hansen, N.; Liu, Q. Microstructure and Strengthening Mechanisms in Cold-Drawn Pearlitic Steel Wire. Acta Mater. 2011, 59, 3422–3430. [Google Scholar] [CrossRef]

- Galvele, J.R.; Torresi, R.M.; Carranza, R.M. Passivity Breakdown, Its Relation to Pitting and Stress-Corrosion-Cracking Processes. Corros. Sci. 1990, 31, 563–571. [Google Scholar] [CrossRef]

- Wang, Y.; Li, K.Y.; Scenini, F.; Jiao, J.; Qu, S.J.; Luo, Q.; Shen, J. The Effect of Residual Stress on the Electrochemical Corrosion Behavior of Fe-Based Amorphous Coatings in Chloride-Containing Solutions. Surf. Coat. Technol. 2016, 302, 27–38. [Google Scholar] [CrossRef]

- Katiyar, P.K.; Misra, S.; Mondal, K. Effect of Different Cooling Rates on the Corrosion Behavior of High-Carbon Pearlitic Steel. J. Mater. Eng. Perform. 2018, 27, 1753–1762. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Qu, J.; Cui, C. Electrochemical Dissolution of MCrAlY Coatings and Oxide Layers on Ni-Based Superalloys in 3.5% NaCl and Aqua-Regia Solutions. Int. J. Electrochem. Sci. 2024, 19, 100451. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, L.; Huang, W.; Min, X.; Luo, G.; Wang, H.; Zhou, L.; Xie, Z.; Fang, F. Stress Corrosion Cracking Mechanisms in Bridge Cable Steels: Anodic Dissolution or Hydrogen Embrittlement. Int. J. Hydrog. Energy 2025, 97, 46–56. [Google Scholar] [CrossRef]

- Kawamori, M.; Yuse, F. In-Situ Measurement of Hydrogen Entry and Hydrogen Embrittlement of Steel by Atmospheric Corrosion. Corros. Sci. 2023, 219, 111212. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | |

|---|---|---|---|---|---|

| A | 0.84 | 0.74 | 0.25 | 0.0012 | 0.006 |

| B | 0.83 | 0.74 | 0.46 | 0.009 | 0.008 |

| C | 0.99 | 0.75 | 0.25 | 0.011 | 0.001 |

| Steel Type | 0.2% Yield Stress, σ0.2 (MPa) | Ultimate Tensile Stress, σmax (MPa) | Elongation, εm (%) |

|---|---|---|---|

| A# | 1720 | 1830 | 5.2 |

| B# | 1779 | 2100 | 6.3 |

| C# | 2241 | 2303 | 6.2 |

| Steel Type | A# | B# | C# |

|---|---|---|---|

| Failure time (h) | 2.25 | 3.52 | 1.51 |

| 2.29 | 3.73 | 1.55 | |

| 2.43 | 3.73 | 1.56 | |

| 2.55 | 3.88 | 1.61 | |

| 2.62 | 3.90 | 1.66 | |

| 2.63 | 3.92 | 1.68 | |

| 2.63 | 4.00 | 1.88 | |

| Average time (h) | 2.49 | 3.81 | 1.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, G.; Ma, X.; Ma, K. Study on Stress Corrosion Cracking Mechanism of Steel Wires with Different Strength Levels. Metals 2025, 15, 139. https://doi.org/10.3390/met15020139

Zhao G, Ma X, Ma K. Study on Stress Corrosion Cracking Mechanism of Steel Wires with Different Strength Levels. Metals. 2025; 15(2):139. https://doi.org/10.3390/met15020139

Chicago/Turabian StyleZhao, Guangze, Xu Ma, and Ke Ma. 2025. "Study on Stress Corrosion Cracking Mechanism of Steel Wires with Different Strength Levels" Metals 15, no. 2: 139. https://doi.org/10.3390/met15020139

APA StyleZhao, G., Ma, X., & Ma, K. (2025). Study on Stress Corrosion Cracking Mechanism of Steel Wires with Different Strength Levels. Metals, 15(2), 139. https://doi.org/10.3390/met15020139