1. Introduction

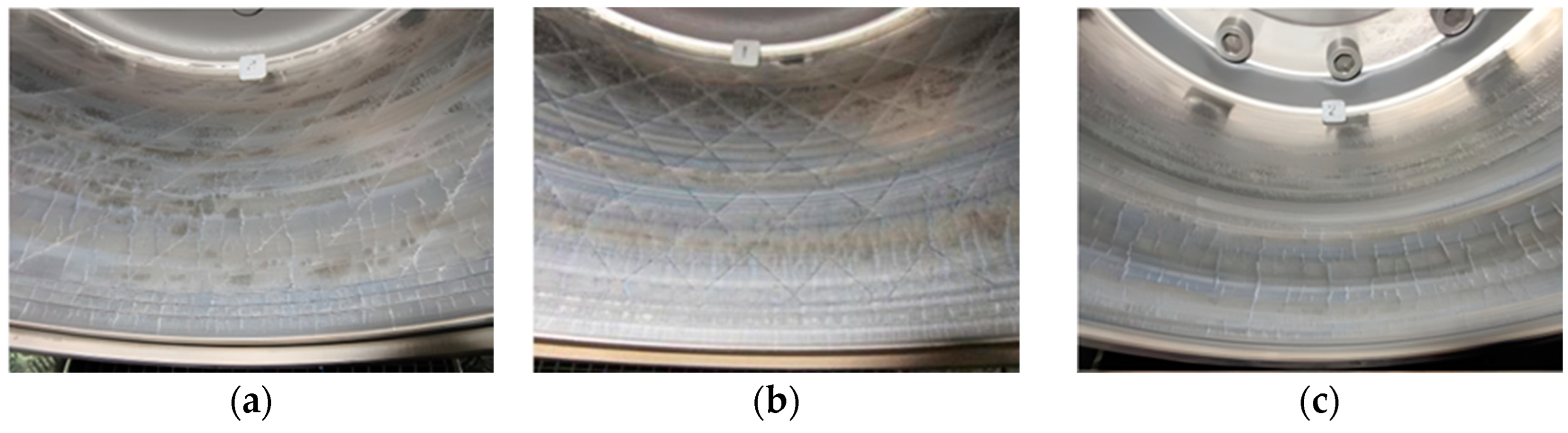

Brake systems are critical for ensuring vehicle safety. With the increasing demand in modern transportation for larger, heavier, and faster vehicles, brake systems face greater challenges, including higher friction, extended operating times, and more severe working environments. These factors significantly reduce the service life of brakes and increase transportation costs due to frequent maintenance and replacement. The interaction between the brake drum and brake pad causes wear, leading to material loss and transfer, which results in an increased gap between the braking components. Furthermore, the heat generated by friction induces thermal fatigue in the brake drum, potentially leading to crack formation. Consequently, brake drums and pads must exhibit excellent wear resistance, high thermal fatigue resistance, and a stable friction coefficient, particularly under high-temperature conditions, to ensure consistent braking performance. Additionally, it is crucial to optimize the compatibility between the brake drum and brake pad to achieve balanced performance.

In nature, organisms exhibit exceptional wear resistance, closely tied to their surface structures and material composition. Biomimetics, an interdisciplinary field, harnesses these biological mechanisms to address human technological challenges. By studying the non-smooth surfaces of certain animals and plants, researchers have discovered wear-resistant surfaces composed of alternating hard and soft tissues with uneven topographies. Yuan Y et al. fabricated various bionic coupling units on the surface of a 7075 aluminum alloy, demonstrating a significant improvement in wear resistance [

1]. Sysaykeo D et al. proposed a bionic design combined with wear simulation method, simulated bionic bearings suitable for misalignment configuration, and compared them with traditional bearings. The simulation showed that the bionic bearing has a longer service life [

2]. Shankar S et al. investigated the contact stress and wear of zirconia (ZrO2) and alumina (Al

2O

3) hip implants under dangerous and normal gait activities and achieved good results [

3]. In order to improve the sliding wear resistance of grey cast iron under wet slip conditions, specimens with different bionic units were fabricated and improved according to the bionic theory. Two kinds of bionic units were laser-machined on the surface of the specimens, and the wear resistance of the specimens was investigated by the indentation method. The wear surface morphology and stress distribution of the specimens were observed. The results showed that the coupled bionic units greatly improve the wear resistance of cast iron compared with other samples [

4]. Pang X et al. successfully improved multiple properties by using lasers to mimic the “non-smooth structural units” of the dung beetle’s cuticle, creating alternating soft and hard striped surface structures on gray cast iron [

5]. Their research revealed that factors such as the shape, material, and arrangement of the laser-processed hard-phase bionic units determine the wear resistance of the non-smooth cast iron surfaces [

6,

7,

8]. By adjusting these parameters, the wear resistance can be tailored to specific requirements, offering the potential to develop brake drums with both superior wear resistance and effective wear coordination with friction components. The successful application of bionic theory heavily relies on the chosen processing method. Li H et al. introduced a novel laser bionic texture processing technique that improved the fatigue and wear resistance of 40Cr alloy steel by varying the distribution distances and angles of the bionic textures [

9]. D H Yu et al. confirmed that laser processing of non-smooth surfaces on metal materials significantly enhances wear resistance and thermal fatigue resistance, achieving a synergy between laser technology and bionic principles [

10]. Zhao G et al., inspired by the wear-resistant surfaces of shells, processed units with varying hardness using laser melting, and wear tests, and confirmed the positive impact of these bionic units on wear resistance [

11].

From the perspective of failure modes, the failure of brake drums is primarily influenced by two factors: wear and thermal fatigue. Wear failure occurs due to friction between the brake drum and the brake pads, resulting in surface material stripping. Over time, this wear reduces the thickness and strength of the brake drum, which is a common form of failure. Under heavy load and complex road conditions, the high braking force and frequent braking generate significant heat, making brake drums prone to thermal fatigue failure. During braking, a large amount of heat is generated [

12], and compared to disc brakes, brake drums have poorer heat dissipation, making them more susceptible to thermal fatigue. Research on the thermal fatigue resistance of gray cast iron mainly focuses on the graphite content, matrix structure, and chemical composition of the material. Gwoździk M et al. analyzed chemical components using energy dispersive X-ray spectroscopy (EDS) combined with scanning electron microscopy (SEM) to measure surface morphology (roughness) using Gaussian filter VHX microscopic imaging systems. They determined relevant parameters such as the arithmetic mean height, maximum height, and peak height [

13]. Blessley S et al. used atomic force microscopy (AFM) and scanning electron microscopy (SEM) to study the effect of voltage and concentration of polyetherimide (PEI) on the surface morphology and corrosion characteristics of AZ91D by electrospinning coating [

14]. Tong X et al. found that the higher the graphite content in gray cast iron, the poorer the thermal fatigue performance of the brake drum after laser bionic treatment [

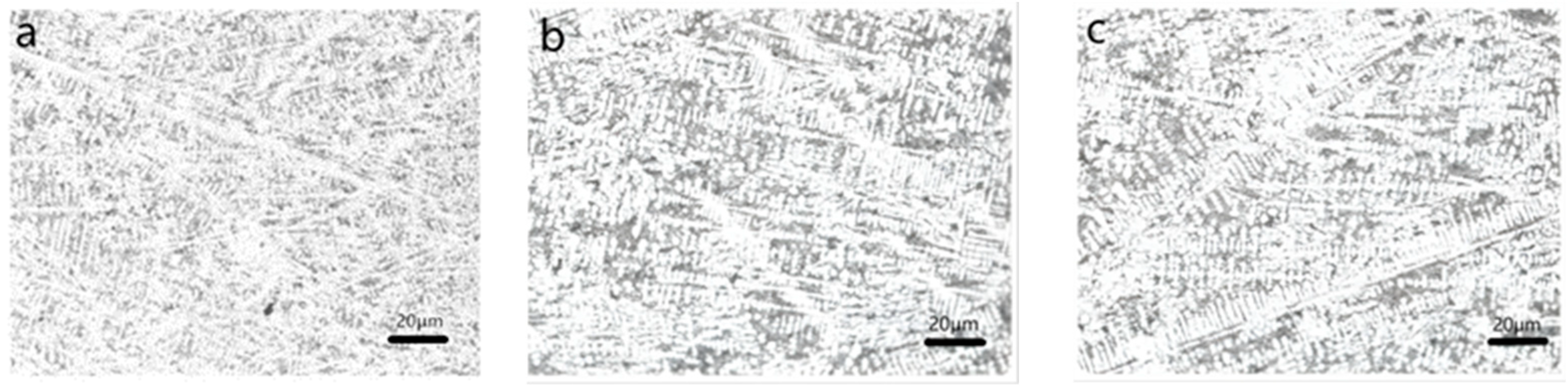

15]. Regarding the matrix structure, pearlitic gray cast iron tends to have better thermal fatigue resistance than ferritic gray cast iron [

16]. Among alloying elements, chromium (Cr) and molybdenum (Mo) have a significant impact on thermal fatigue resistance. Cr increases the phase transition temperature of cast iron, enhancing the stability of the microstructure, which greatly reduces the stresses and strains generated during phase transitions. Mo, on the other hand, primarily increases the tensile strength and yield strength of the material, with minimal impact on thermal conductivity, making it one of the most effective elements for improving the thermal fatigue performance of cast iron [

17,

18].

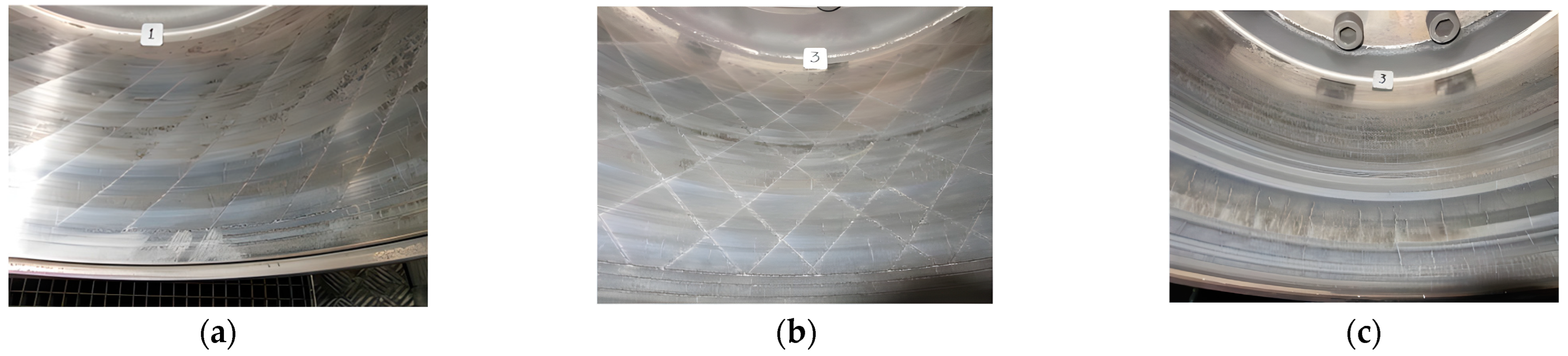

In terms of bionic brake drum friction and wear, Pang Z B et al. investigated the quantitative relationship between bionic-coupled unit properties and gray cast iron abrasion resistance and established the regression equation between unit properties and gray cast iron abrasion resistance. This made it possible to select the characteristic parameters of the unit according to the demand of abrasion resistance and created the conditions for the improvement of the bionic model. They also studied the effect of the shape of bionic-coupled units on the wear resistance of gray cast iron under dry linear reciprocating sliding conditions [

19], and the study showed that the grid-like units have better resistance to dry friction and wear. Chen Z K et al. studied the effect of different shapes of units and distribution on the fatigue wear resistance of gray cast iron surface [

20]. The results showed that the surface pressure is fixed when the pressure of different shapes of units to withstand different amounts of pressure, the parent body to withstand different pressures, to improve the fatigue wear resistance of the parent body is also different, the grid-like units have better fatigue wear resistance. Yang W S et al. investigated the effect of the bionic-coupled unit morphology on rolling contact fatigue wear resistance of train track steel [

21]. Due to the higher positive pressure on the train track, the unit can withstand higher pressure, which is conducive to the improvement of the fatigue resistance of the train track. Others [

22] investigated the friction and wear properties of quenched low-carbon alloy steel with twice laser-carburized units. For low-carbon alloy steels, the hardness of laser-treated units is also low due to the low-carbon content of the parent body itself, and the increase in the carbon content in the units by two laser carburization resulted in a substantial increase in hardness compared to the direct fusion coagulated units. Thus, their wear resistance was also improved. Chen ZK et al. carried out modifications by laser surface remelting, including parallel, perpendicular, and gradient to the wear direction of the units, and found that different orientations of the bionic units could improve the fatigue wear resistance [

23]. Su W et al. investigated the effect of laser bionic units arrangement on the dry sliding wear resistance of bionic surfaces, and found that the best wear resistance was obtained when the arrangement angle of the units was at an angle of 450 to the friction direction [

24,

25,

26].

In the area of brake drum thermal fatigue, A. S A. et al. determined the quantitative relationship between abrasive wear and crack generation in brake drums during braking of wheeled vehicles through theoretical analyses [

27]. Travaglia C A P et al. proposed a methodology for predicting the durability of the friction material of a drum brake based on a specific wear mass and the energy dissipated during the braking cycle [

28]. Wang J et al. developed a numerical prediction model for estimating thermal fatigue crack initiation and extension in low alloy steels [

29]. Yu D et al. investigated the development and growth of cracks in the inner wall of brake drums and proposed a non-unit bionic coupling model based on the results of the study [

30]. The thermal fatigue crack extension process mainly goes through crack initiation and microcrack formation, but only a few microcracks continue to expand rapidly or preferentially expand into the main crack. Repeated thermal and mechanical cycles lead to plastic deformation and cracking of the brake disc [

31]. When the braking temperature is too high, it will lead to the extension of surface cracks to the outer edge of the brake drum friction surface [

32]. Liu Y et al. conducted thermal fatigue cycling experiments on laser-mimetic-treated specimens and discussed the relationship between the fractal dimensions of thermal fatigue cracks and the thermal fatigue cycles. The results showed that fractal size can better characterize the fatigue crack growth behavior on the bionic coupled surface of creep graphite cast iron [

33,

34]. Yin X et al. developed a fatigue life finite element model for disc brakes and found that the maximum stress on the disc brake surface is the same as the minimum fatigue life region, which accurately analyzed the fatigue life in this region and predicted the location of fatigue cracks [

35]. Miao SS et al. found that the unique microstructure of biomimetic units with alternating hard and soft phases can weaken the impact force of solid particles, and that the hard phase resists plastic deformation, and the soft phase absorbs the impact energy and prevents crack expansion [

36]. Zhao Y et al. compared the friction wear resistance and thermal fatigue resistance of biomimetic-coupled materials and gray cast iron for brake drums. and the soft phase absorbed the impact energy and hinders crack extension. The results showed that the frictional wear resistance and thermal fatigue resistance of the biomimetic-coupled specimens were better than those of the untreated specimens [

37]. W Macek et al. studied the relationship between fatigue characteristics and fracture surface morphology features. A fatigue life prediction model was proposed which is very useful for failure analysis [

38,

39].

The above studies analyzed the performance of bionic brake drums from multiple perspectives such as laser treatment theory, failure modes, friction and wear, and thermal fatigue performance, but have not fully considered the impact of laser treatment on the surface morphology of bionic brake drums and the interaction with brake pads made of different materials, focusing excessively on enhancing the wear resistance of bionic brake drums.

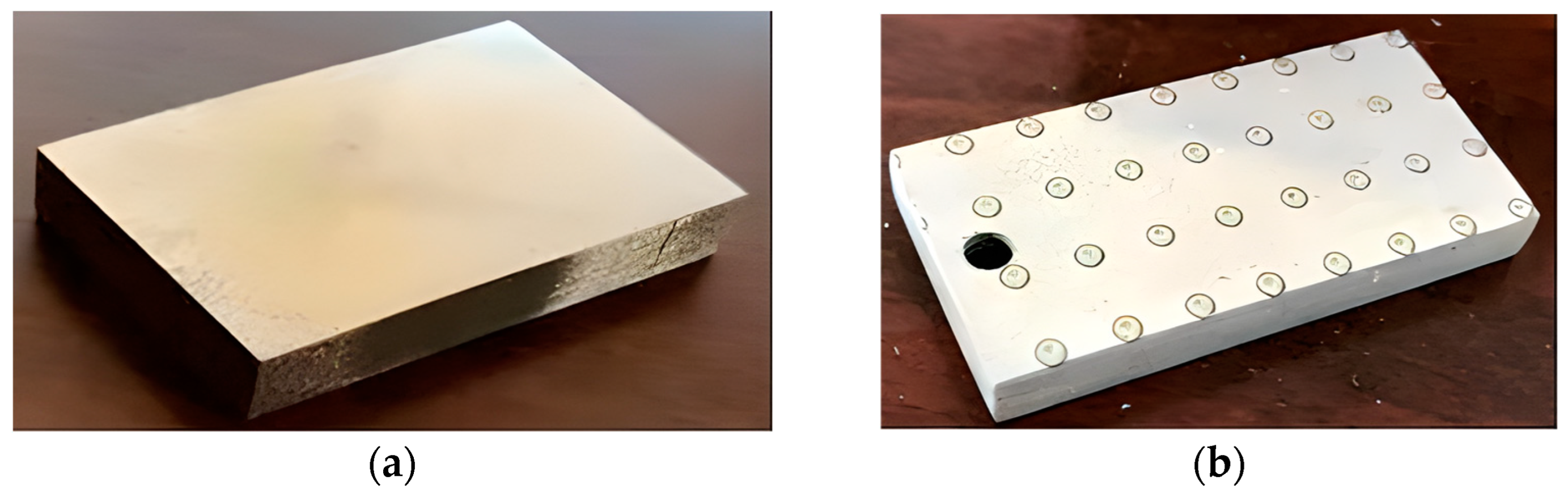

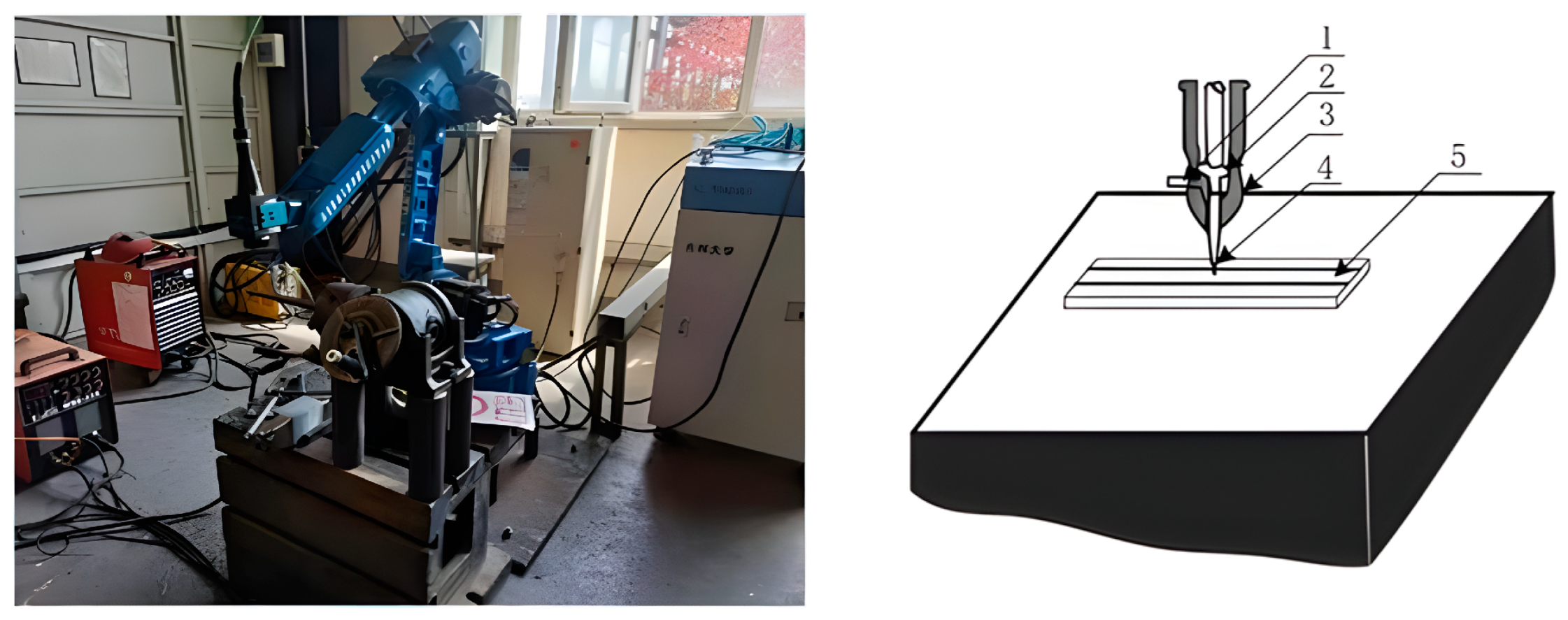

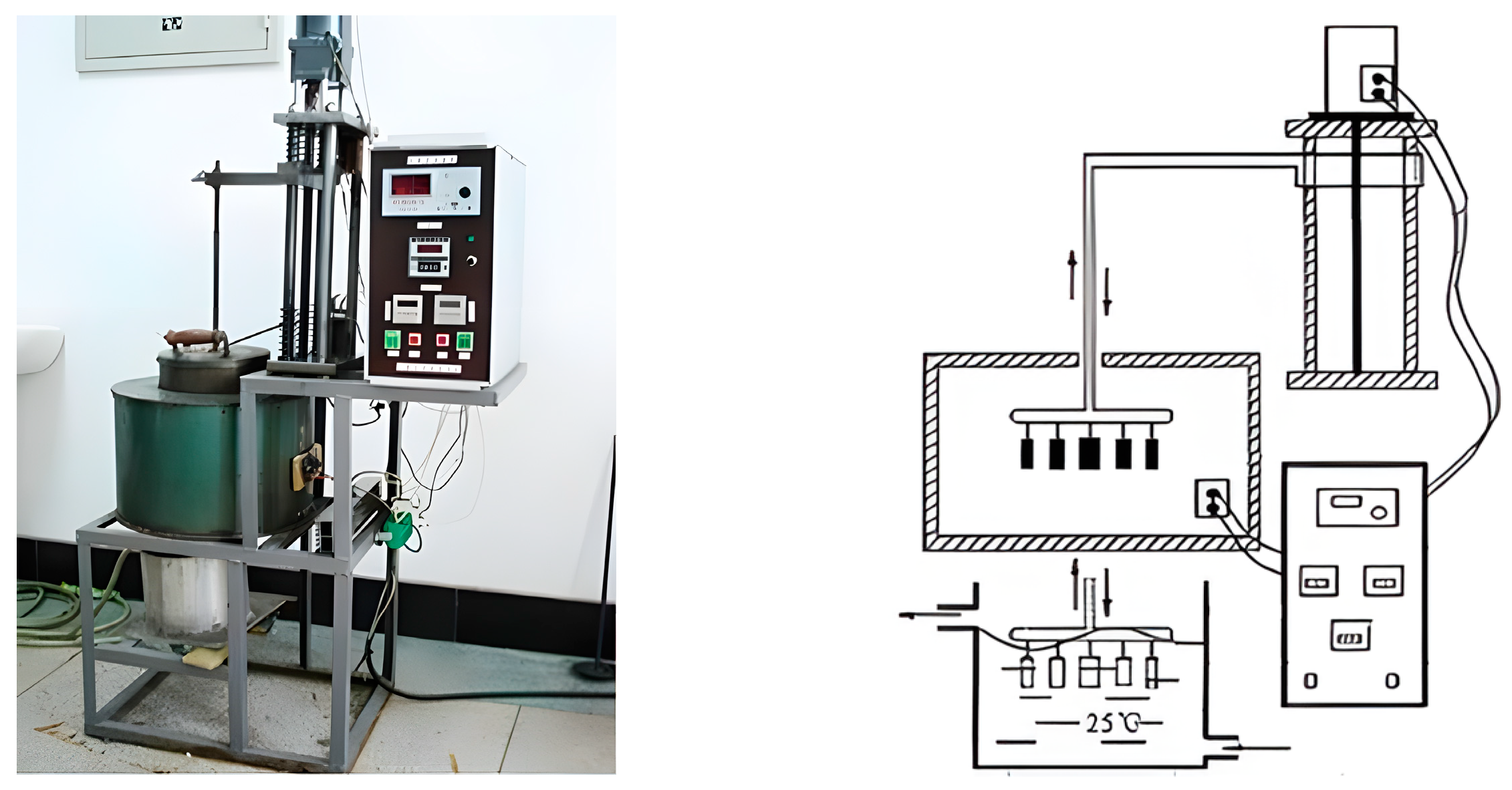

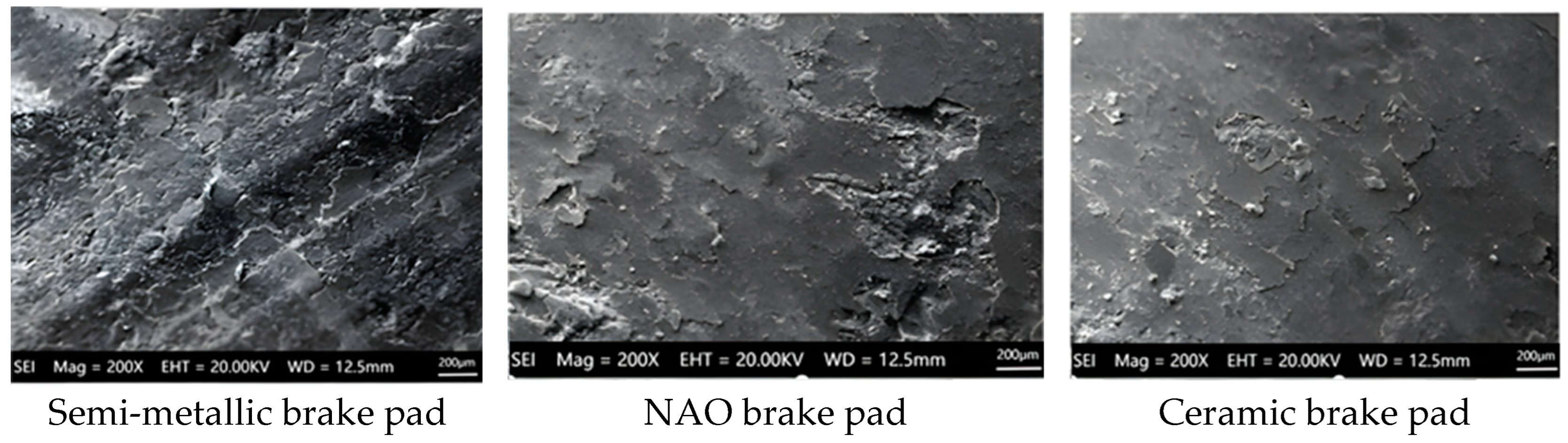

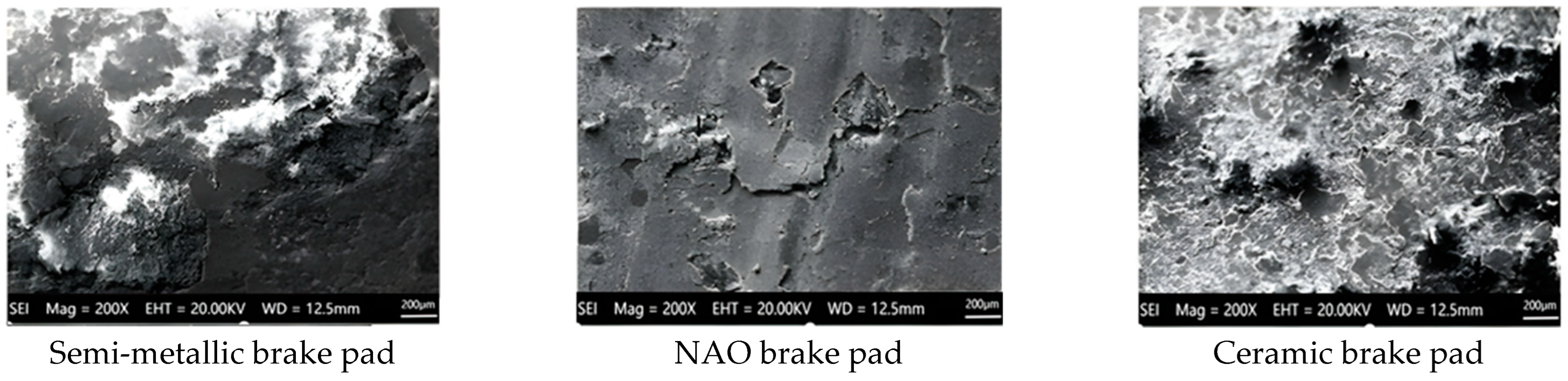

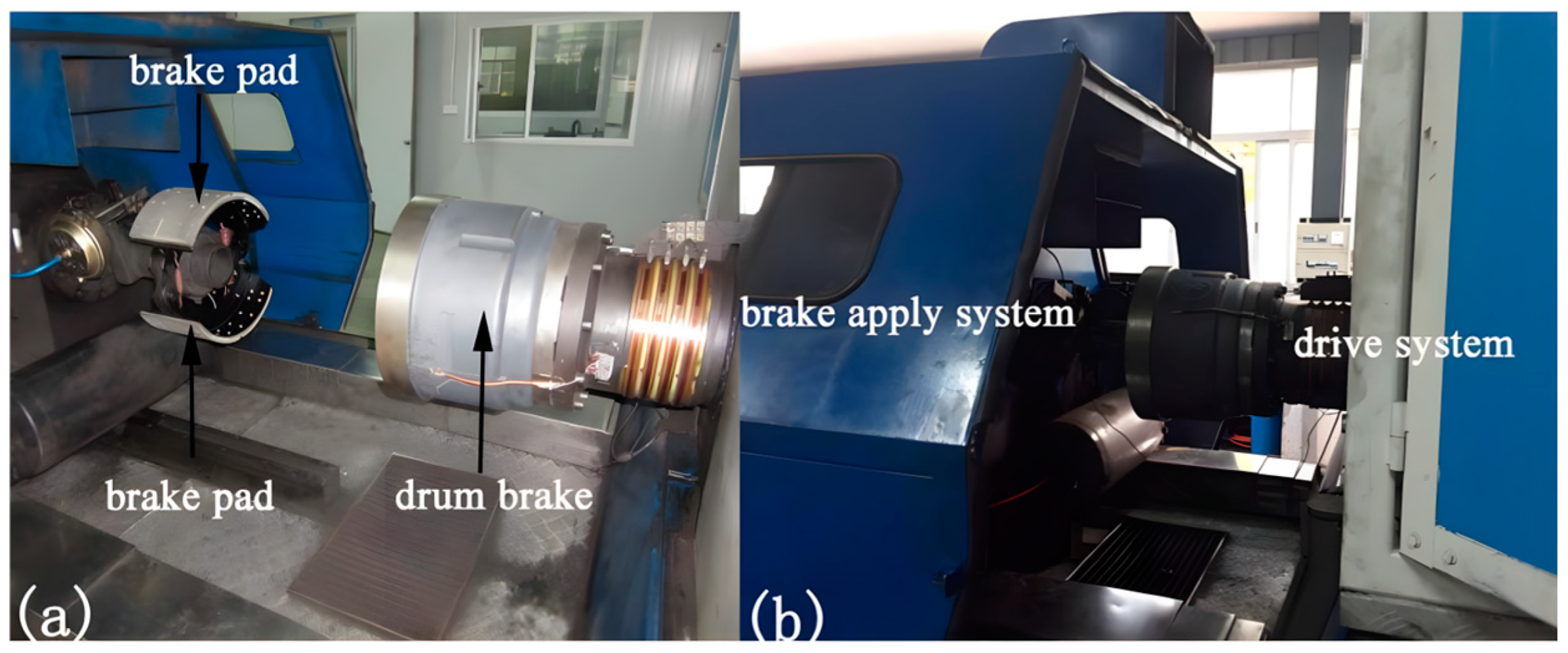

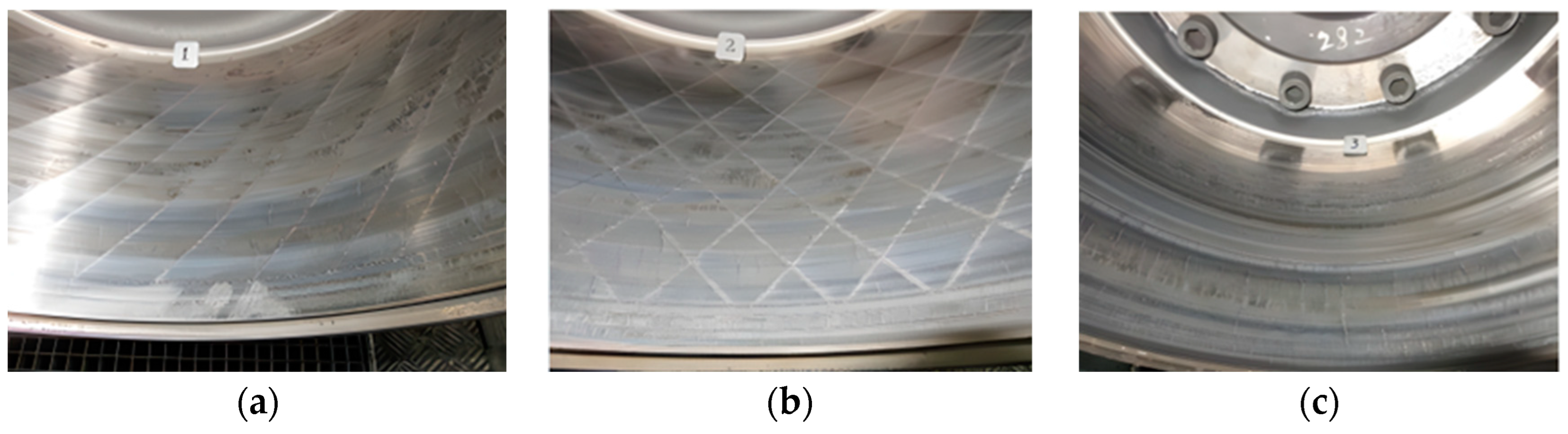

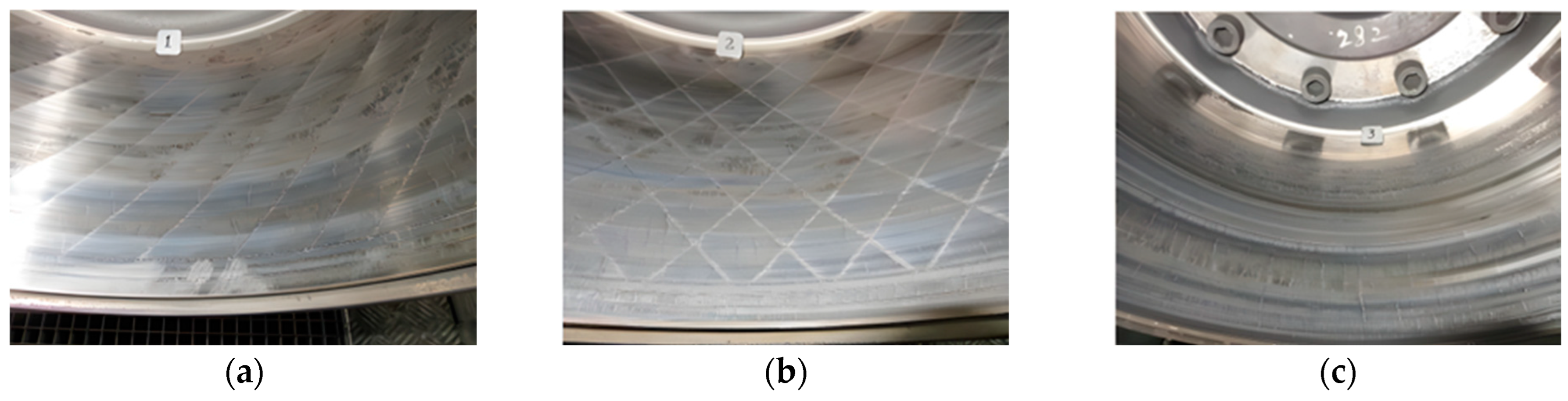

This study aims to investigate the impact of bionic brake drum surface morphology on wear and thermal fatigue performance, analyze the friction and wear relationship between brake drums and pads, and evaluate their performance at various temperatures. The innovation of this study is that firstly, a design laser processing method of bionic brake drum is proposed, and then the mutual influence between different processed pattern bionic brake drums and different material brake pads is analyzed through sample production and wear experiments. The performance of bionic brake drums is compared with that of traditional brake drums by conducting bench tests, which further verifies the superiority of bionic brake drums in terms of performance and, therefore, provides new ideas for the optimized matching of bionic brake drums and brake pads from the perspective of improving the service life of the braking system.