A Review of Wear-Resistant Coatings for Steel Substrates: Applications and Challenges

Abstract

1. Introduction

2. Types of Wear-Resistant Coating Materials

2.1. Metal-Based Wear-Resistant Coating

2.1.1. Cobalt-Based Wear-Resistant Coatings

2.1.2. Nickel-Based Wear-Resistant Coatings

2.1.3. Iron-Based Wear-Resistant Coatings

2.2. Ceramic-Based Wear-Resistant Coatings

2.2.1. Oxide Ceramics

2.2.2. Carbide Ceramics

2.3. Polymer-Based Wear-Resistant Coatings

2.3.1. Thermosetting Resin Coatings

2.3.2. Self-Lubricating Coatings

2.4. Composite Wear-Resistant Coatings

2.5. Nano-Coatings

3. Preparation Technologies for Wear-Resistant Coating Materials

3.1. Thermal Spraying Technology

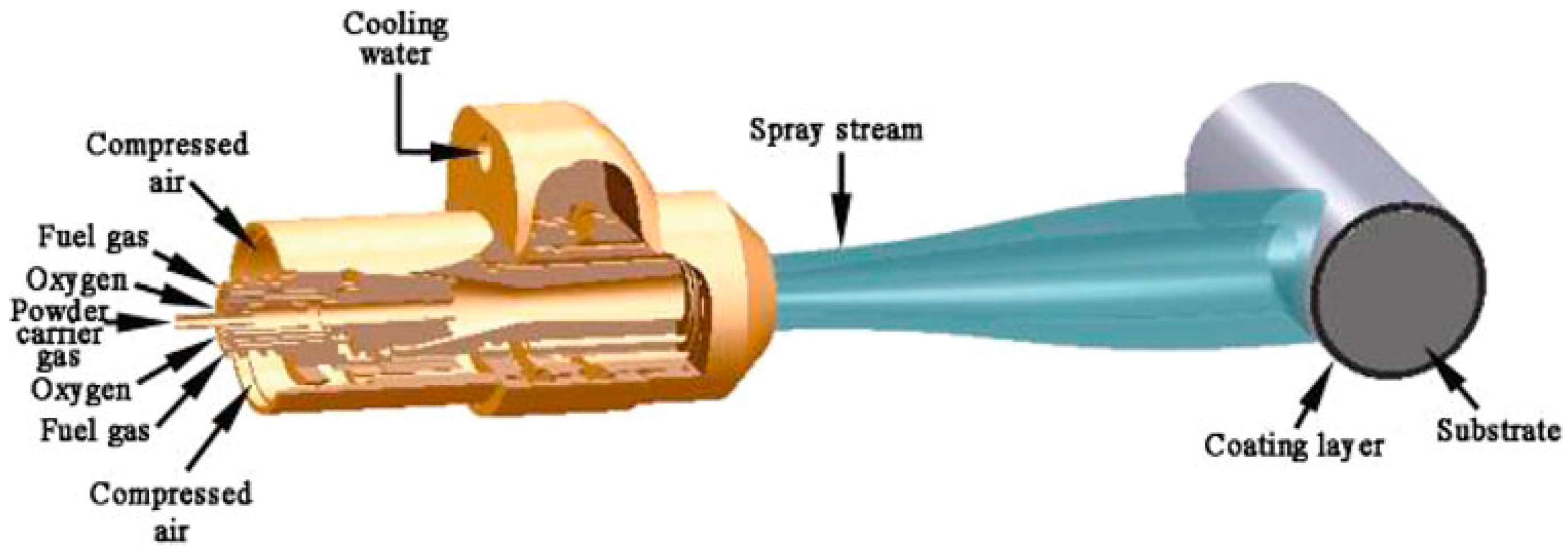

3.1.1. High-Velocity Oxygen Fuel Spraying

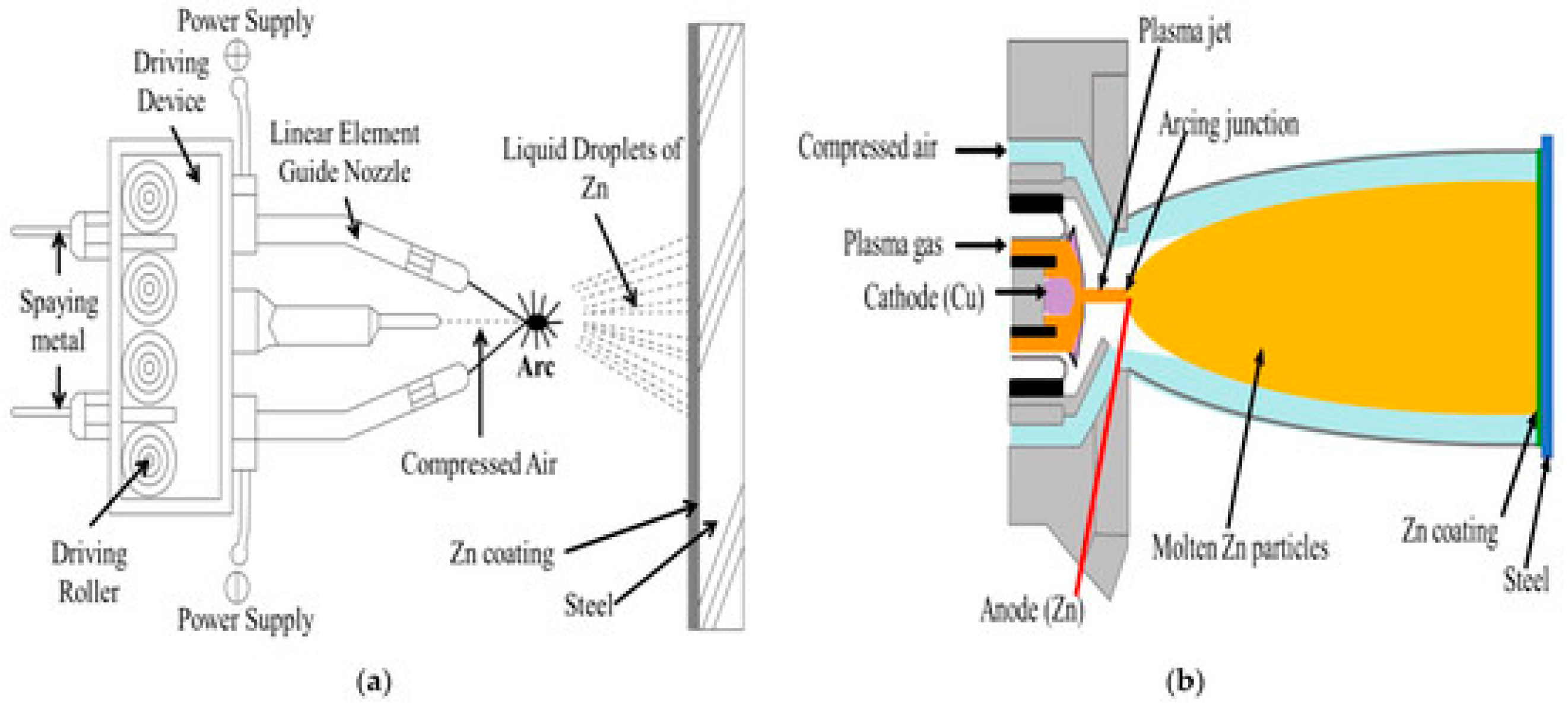

3.1.2. Arc Spraying

3.1.3. Plasma Spraying

3.2. Vapor-Deposition Technology

3.2.1. Physical Vapor Deposition

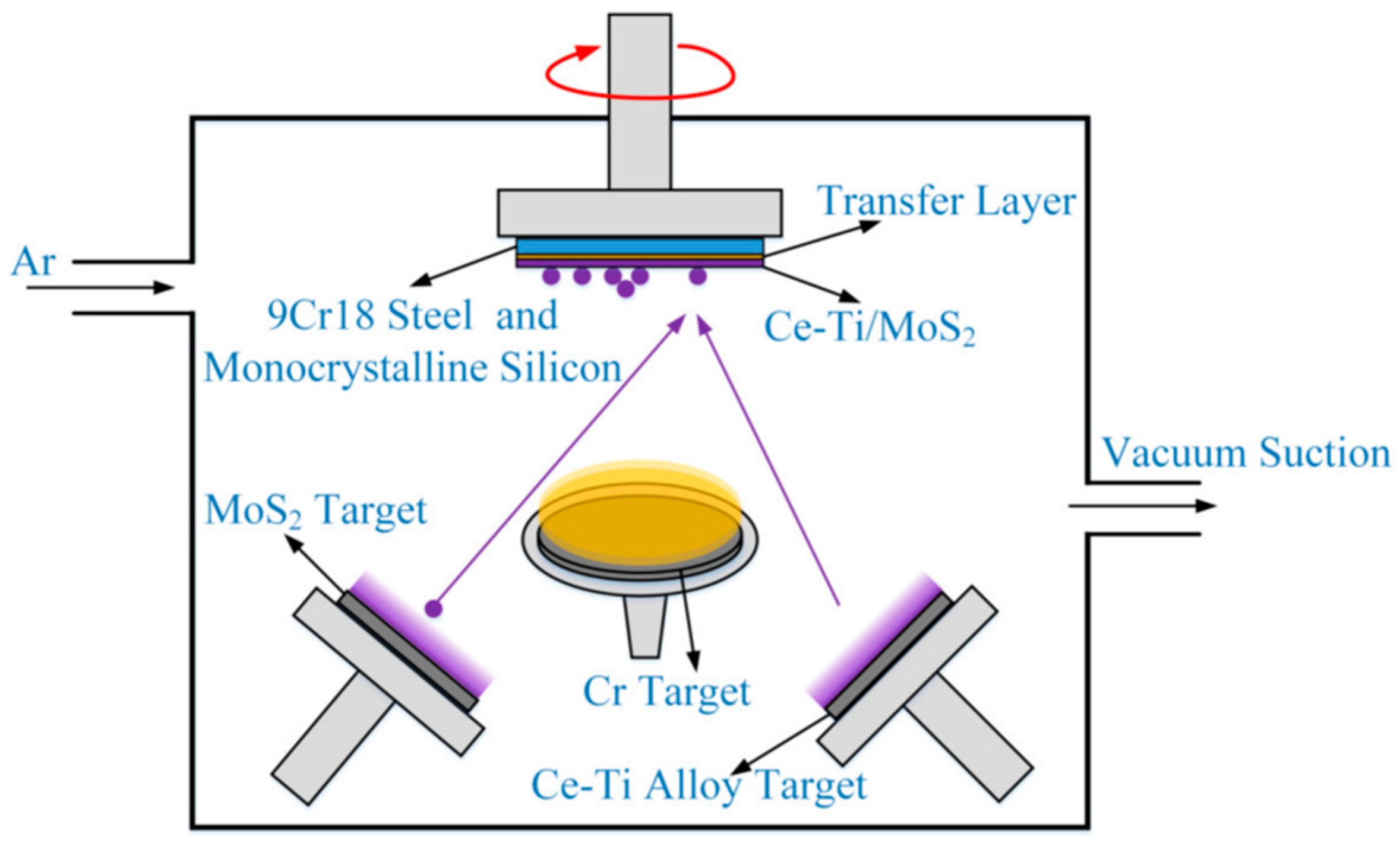

Magnetron Sputtering

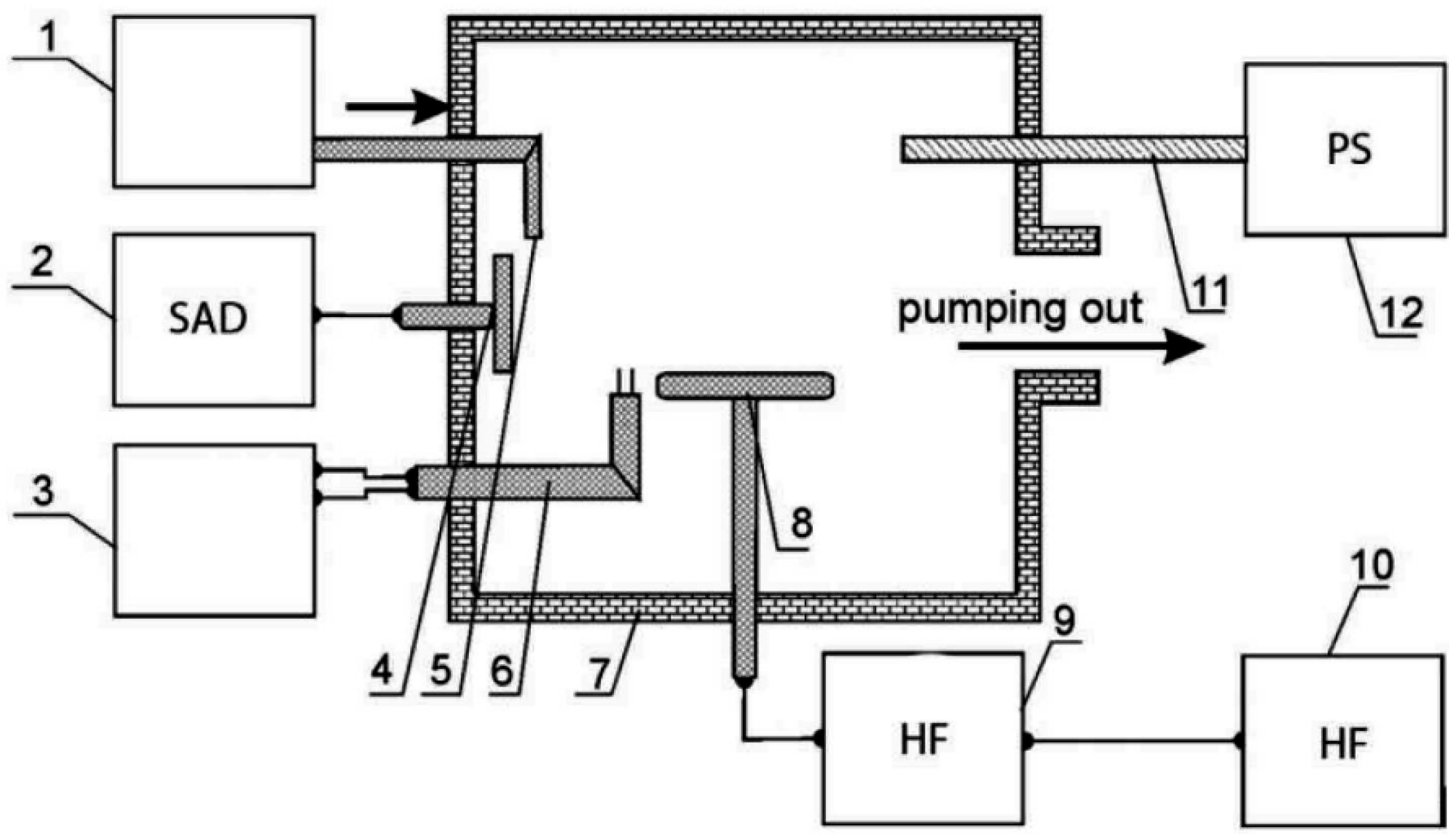

Ion-Plating Technology

Vacuum Evaporation Deposition Technology

3.2.2. Chemical Vapor Deposition

3.3. Surface-Modification Technology

3.3.1. Laser Cladding

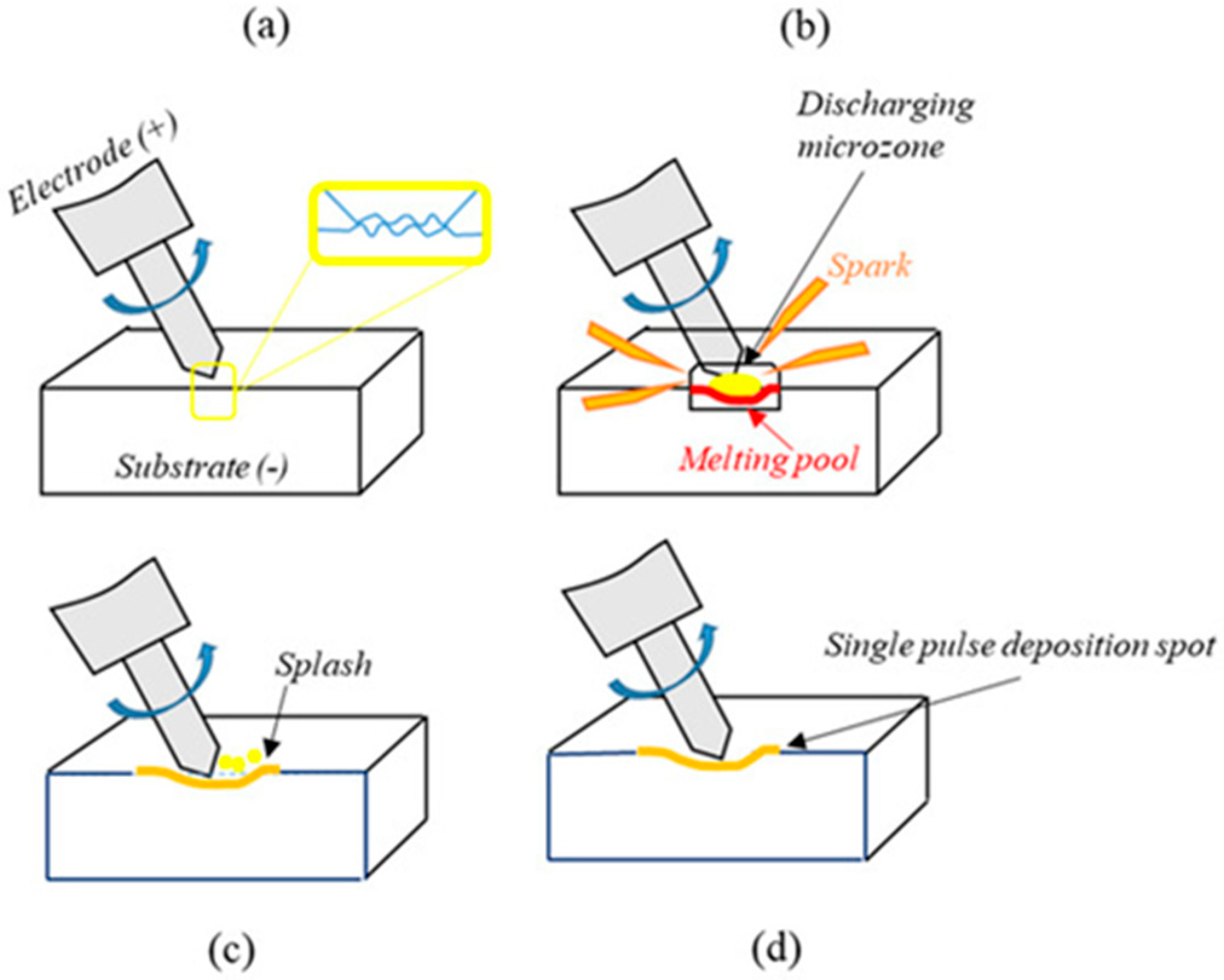

3.3.2. Electrospark Deposition

3.4. Other Preparation Technologies

3.4.1. Plasma Surfacing Welding

3.4.2. Submerged Arc Surfacing Welding (SASW)

3.4.3. Electroplating

3.4.4. Electroless Plating

3.4.5. Sol–Gel Method

4. Evaluation of Wear-Resistant Coating Performance

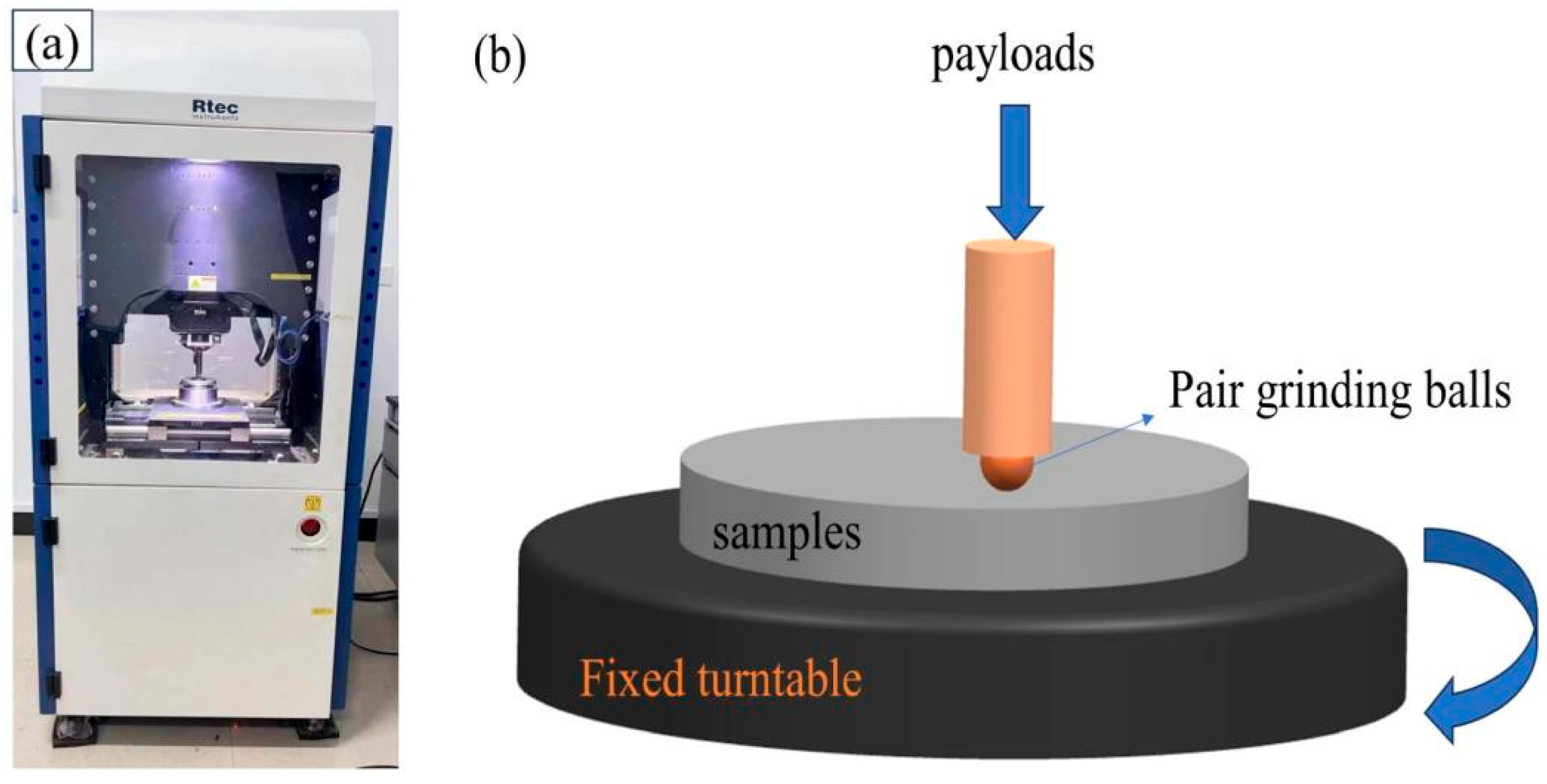

4.1. Wear Resistance

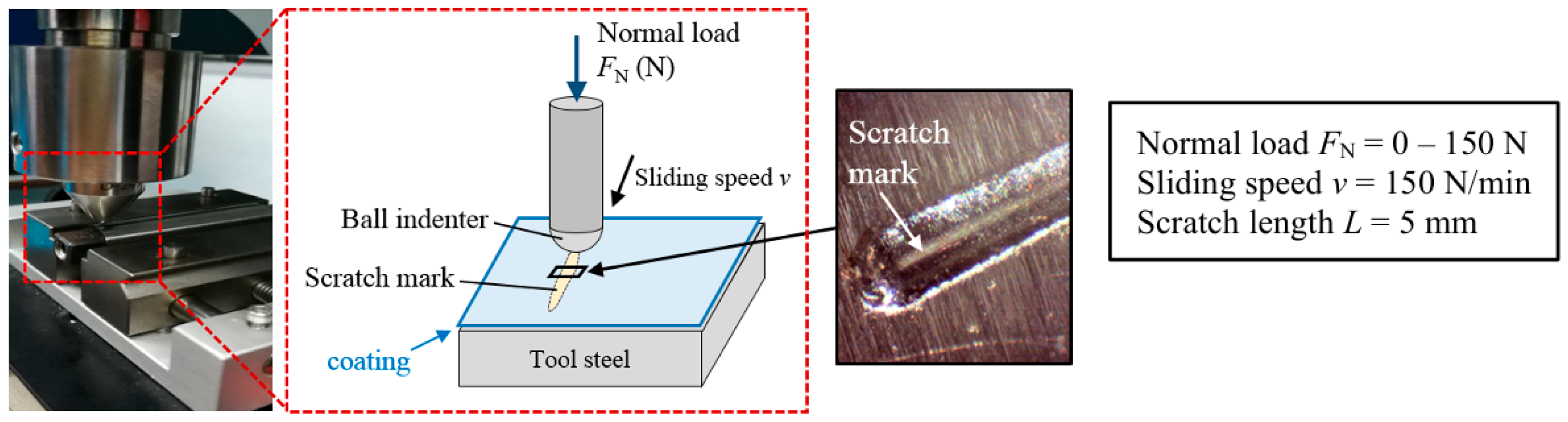

4.2. Bonding Strength

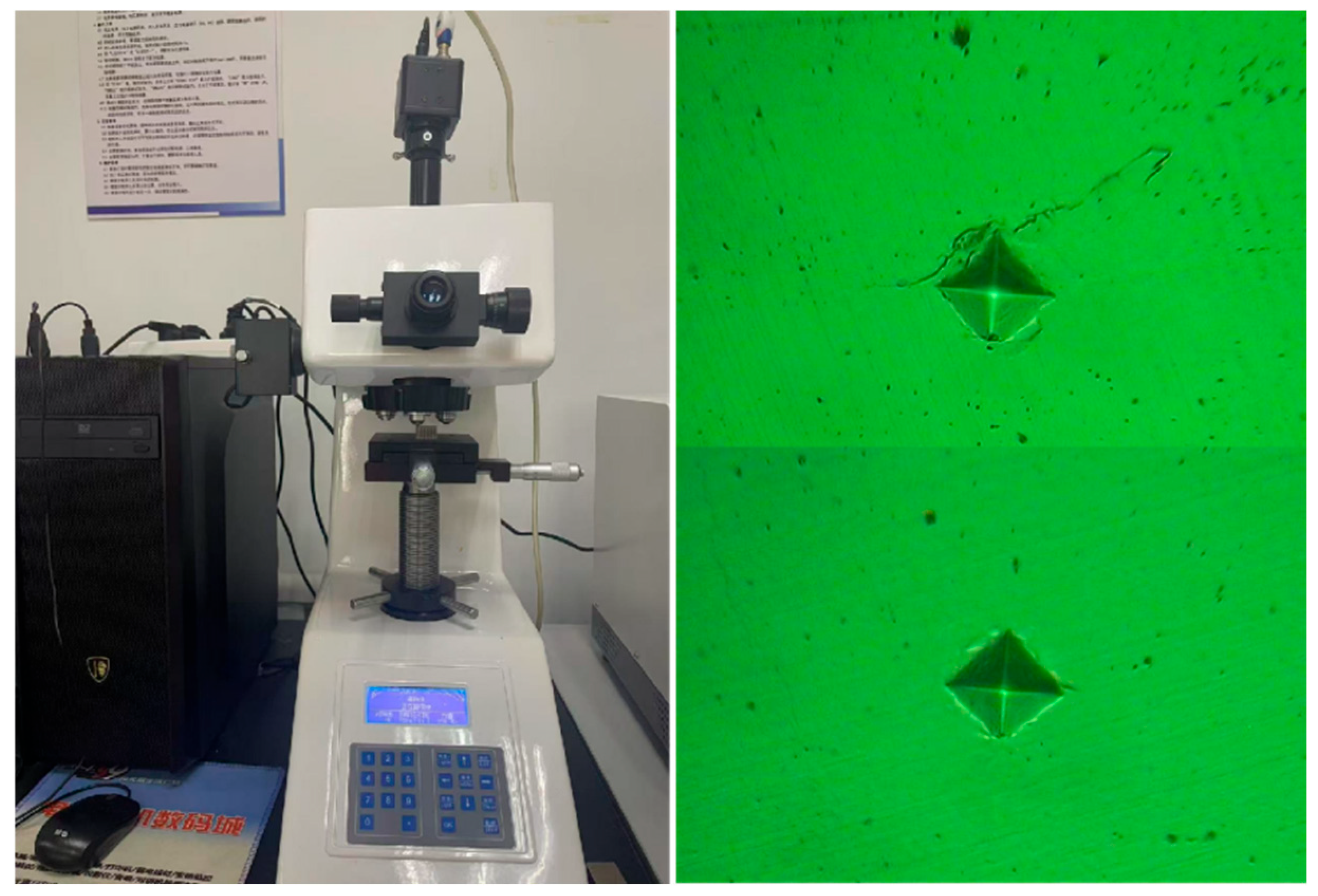

4.3. Hardness

4.4. Corrosion Resistance

4.5. High-Temperature Resistance

4.6. Other Key Properties

4.6.1. Coefficient of Friction

4.6.2. Toughness

4.6.3. Impact Resistance

4.6.4. Insulation Property

4.6.5. Adhesion

4.6.6. Cohesion

5. Conclusions and Prospects

5.1. Conclusions

5.2. Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, J.; Xue, L. Laser Cladding of CPM Tool Steels on Hardened H13 Hot-Work Steel for Low-Cost High-Performance Automotive Tooling. JOM 2012, 64, 688–693. [Google Scholar] [CrossRef]

- Gullino, A.; Matteis, P.; D’Aiuto, F. Review of Aluminum-To-Steel Welding Technologies for Car-Body Applications. Metals 2019, 9, 315. [Google Scholar] [CrossRef]

- Jia, N.; Zhang, H.F.; Liu, X.F.; Cai, M.J. Research on Fire Resistance of Stainless Steel Car Body Floor Structure in Urban Rail Vehicles. In Proceedings of the ASME 2020 International Mechanical Engineering Congress and Exposition (IMECE2020), Virtual, 1 January 2020; Volume 6. [Google Scholar]

- Dolores, E.; Guillermo, G.; Christopher, J.U. Metal Shipwrecks in Patagonia, Argentina: Contributions to Their Research and Management. Int. J. Naut. Archaeol. 2020, 49, 303–317. [Google Scholar] [CrossRef]

- Smith, B.H.; Szyniszewski, S.; Hajjar, J.F.; Schafer, B.W.; Arwade, S.R. Steel Foam for Structures: A Review of Applications, Manufacturing and Material Properties. J. Constr. Steel Res. 2011, 71, 1–10. [Google Scholar] [CrossRef]

- Deng, E.F.; Zong, L.; Ding, Y.; Zhang, Z.; Zhang, J.F.; Shi, F.W.; Cai, L.M.; Gao, S.C. Seismic Performance of Mid-to-high Rise Modular Steel Construction—A Critical Review. Thin-Walled Struct. 2020, 155, 106924. [Google Scholar] [CrossRef]

- Gao, B.; Yang, C.; Zou, Y.X.; Wang, F.S.; Zhou, X.J.; Barbieri, D.M.; Wu, S.P. Compaction Procedures and Associated Environmental Impacts Analysis for Application of Steel Slag in Road Base Layer. Sustainability 2021, 13, 4396. [Google Scholar] [CrossRef]

- Yokoyama, K.; Oka, T.; Noto, K. Development of a Small-Size Superconducting Bulk Magnet System Using a 13 K Refrigerator. IEEE Trans. Appl. Supercond. 2010, 20, 973–976. [Google Scholar] [CrossRef]

- de Araujo Cardoso, R.F.; da Cunha, M.A.; Mendonça Brandão, L.P. Optimization of the Magnetic Losses of Electrical Steels Through Addition of Al and Si Using a Hot Dipping Process. J. Mater. Res. Technol. 2013, 2, 276–281. [Google Scholar] [CrossRef]

- Lee, H.; Sohn, S.S.; Lee, S.; Kwak, J.; Lee, B. Thermodynamic analysis of the effect of C, Mn and Al on microstructural evolution of lightweight steels. Scr. Mater. 2013, 68, 339–342. [Google Scholar] [CrossRef]

- Sun, M.; Yang, X.; Du, C.; Liu, Z.; Li, Y.; Wu, Y.; San, H.; Su, X.; Li, X. Distinct Beneficial Effect of Sn on the Corrosion Resistance of Cr-Mo Low Alloy Steel. J. Mater. Sci. Technol. 2021, 81, 175–189. [Google Scholar] [CrossRef]

- Zhao, M.; Huang, L.; Li, C.; Li, J.; Li, P. Evaluation of the Deformation Behaviors and Hot Workability of a High-Strength Low-Alloy Steel. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2021, 810, 141031. [Google Scholar] [CrossRef]

- Bai, W.; Chen, W.; Yang, C.; Hong, Y.; Wang, R. Fine Classification Method of Stainless Steel Based on LIBS Technology. Laser Optoelectron. Prog. 2022, 59, 2330001. [Google Scholar]

- Nagode, A.; Kosec, L.; Ule, B.; Kosec, G. Review of creep resistant alloys for power plant applications. Metalurgija 2011, 50, 45–48. [Google Scholar]

- Remigiusz, M.; Marek, K.; Anita, M.; Edyta, O.; Witold, P.; Andrzej, S.; Marian, S.; Waldemar, T.; Jan, W.; Andrzej, W. The Effect of a Gear Oil on Abrasion, Scuffing, and Pitting of the DLC-Coated 18Crnimo7-6 Steel. Coatings 2019, 9, 2. [Google Scholar]

- Waldemar, T.; Remigiusz, M.; Edyta, O.; Andrzej, S.; Marek, K.; Andrzej, N.W.; Jakub, N. Abrasive Wear, Scuffing and Rolling Contact Fatigue of DLC-Coated 18Crnimo7-6 Steel Lubricated by a Pure and Contaminated Gear Oil. Materials 2021, 14, 7086. [Google Scholar]

- Su, X.; Xu, G.; Zhu, M.; Zhang, Q.; Cai, F.; Liu, M. Investigation on the Interaction Between Corrosion and Wear of U68CuCr Rail Steel with Different Corrosion Periods. Wear 2023, 516, 204598. [Google Scholar] [CrossRef]

- Sun, J.; Xi, L.; Du, S.; Pan, E. Tool Maintenance Optimization for Multi-Station Machining Systems with Economic Consideration of Quality Loss and Obsolescence. Robot. Comput.-Integr. Manuf. 2009, 26, 145–155. [Google Scholar]

- Chaus, A.S.; Sitkevich, M.; Pokorny, P. Wear Resistance and Cutting Performance of High-Speed Steel Ball Nose End Mills Related to the Initial State of Tool Surface. Wear 2021, 472–473, 203711. [Google Scholar] [CrossRef]

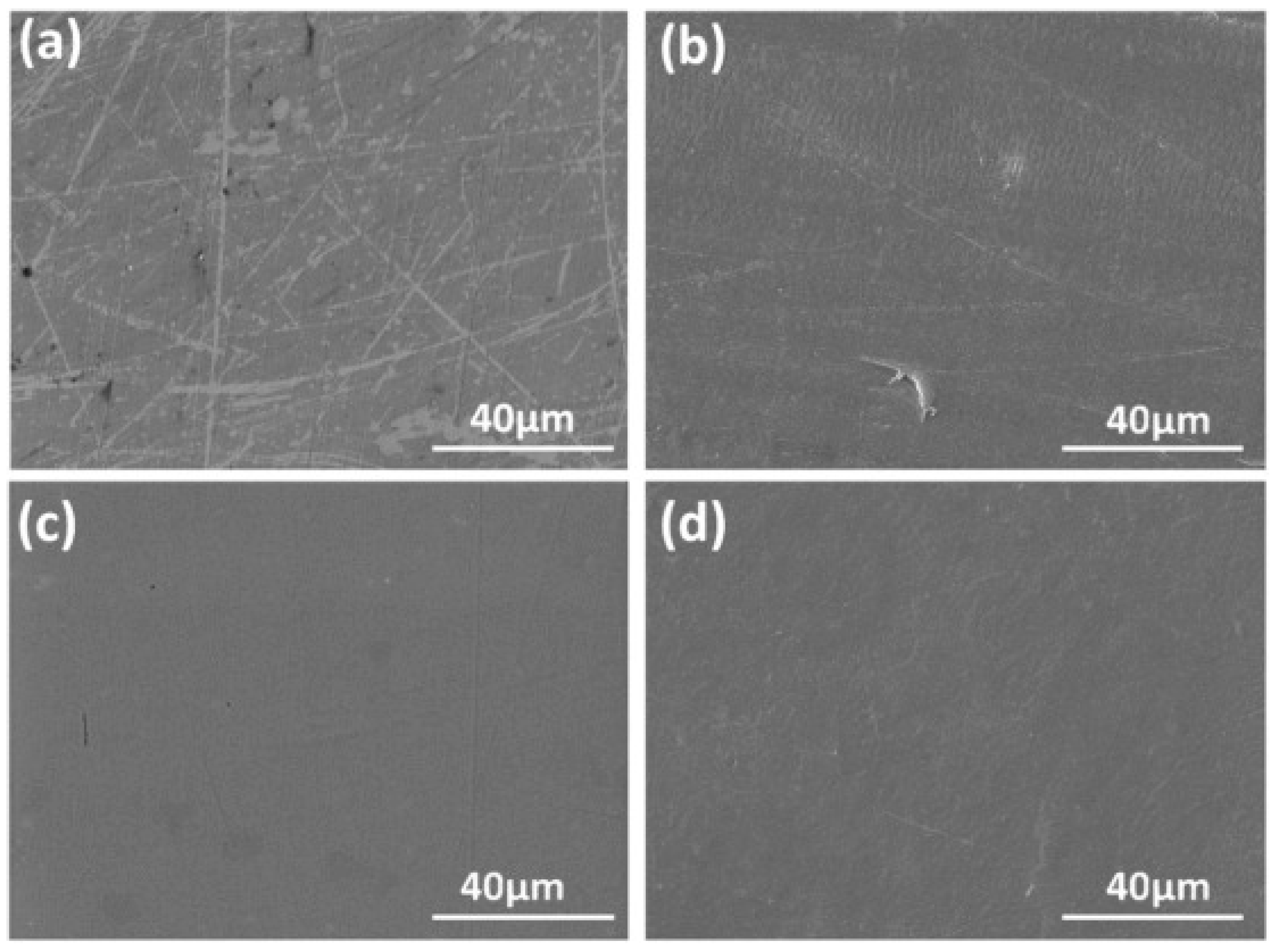

- Wang, C.; Chen, L.; Hu, S.; Xi, Y.; Zhang, H.; Tian, K.; Fei, S.; Deng, H.; Shen, G. Effects of Surface Integrity on Wear Resistance of 42crmo Steel Subjected to Ultrasonic Shot Peening. J. Manuf. Process. 2025, 149, 679–696. [Google Scholar] [CrossRef]

- Grigoriev, S.N. Technologies of Coatings and Surface Hardening: Industrial Applications. Coatings 2023, 13, 511. [Google Scholar] [CrossRef]

- Julia, J.M.; Rodriguez-Tembleque, L. Wear and Subsurface Stress Evolution in a Half-Space under Cyclic Flat-Punch Indentation. Lubricants 2023, 11, 265. [Google Scholar] [CrossRef]

- Dwivedi, D.K. Surface Damage: Causes and Mechanisms. In Surface Engineering; Springer: New Delhi, India, 2018; pp. 17–43. [Google Scholar]

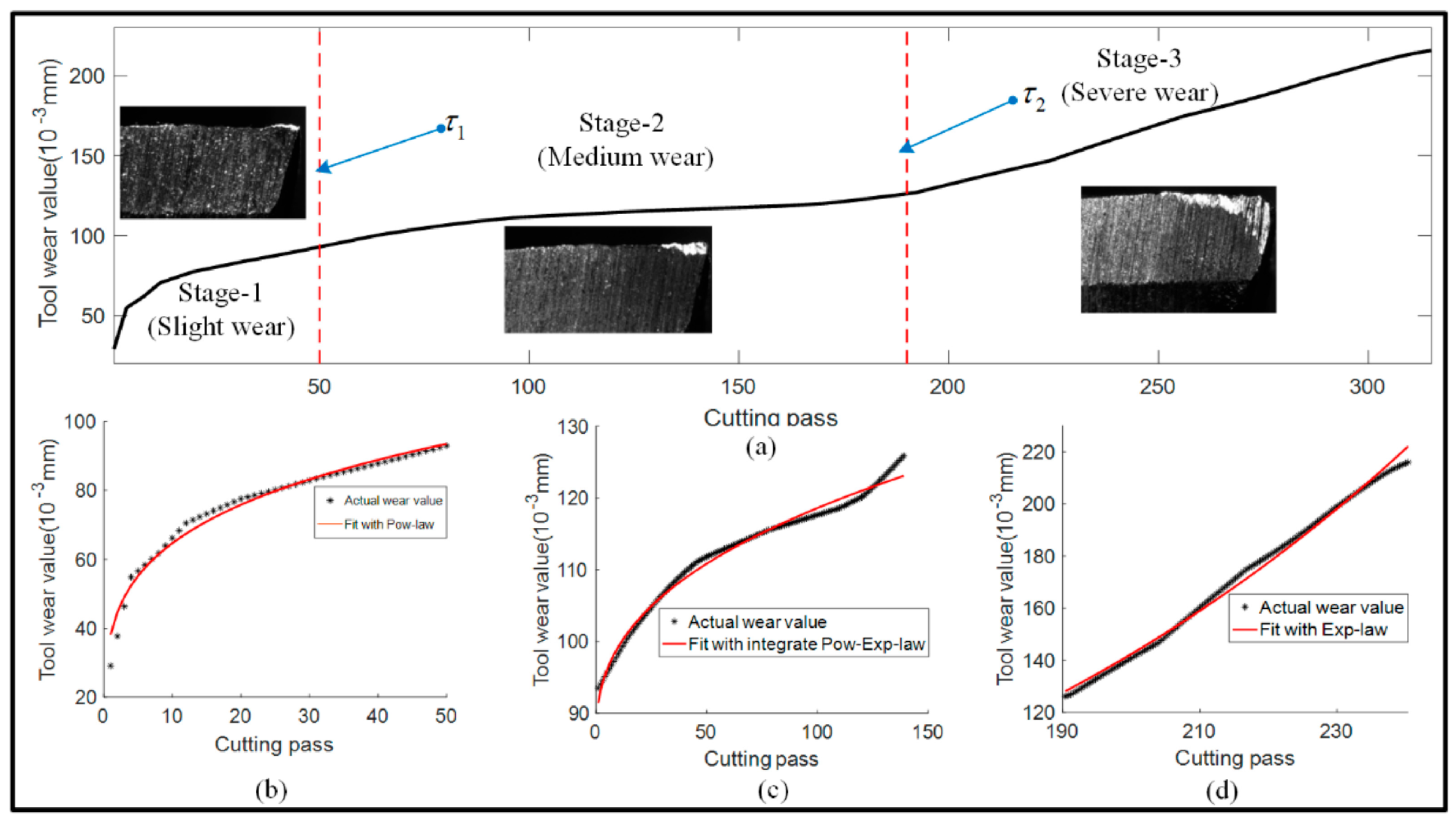

- Liu, W.C.; Yang, W.A.; You, Y.P. Three-Stage Wiener-Process-Based Model for Remaining Useful Life Prediction of a Cutting Tool in High-Speed Milling. Sensors 2022, 22, 4763. [Google Scholar] [CrossRef]

- Williams, J.A. Wear and wear particles—Some fundamentals. Tribol. Int. 2005, 38, 863–870. [Google Scholar] [CrossRef]

- Barai, V.; Dhanalkotwar, V.; Ramteke, S.M.; Jaju, S.B.; Untawale, S.; Sharma, A.; Chelladurai, H.; Amarnath, M. Intelligent Fault Diagnosis of Scuffed Piston Rings Using Vibration Signature Analysis. J. Vib. Eng. Technol. 2023, 12, 1019–1035. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, Y.; Zhang, W.; Liao, W. Fracture Analysis of Stainless Steel Universal Joints in Power Grid Equipment: A Comparative Study of Cast and Forged Structures. Eng. Fail. Anal. 2023, 153, 107585. [Google Scholar] [CrossRef]

- Chen, W.; Feng, Y.; Wan, Y.; Zhang, L.; Yang, D.; Gao, X.; Yu, Q.; Wang, D. Investigation on Anti-Wear and Corrosion-Resistance Behavior of Steel-Steel Friction Pair Enhanced by Ionic Liquid Additives under Conductive Conditions. Tribol. Int. 2023, 177, 108002. [Google Scholar] [CrossRef]

- Biswajit, S.; Subrat, B.; Rameswar, B.; Soumya, S.M.; Ajit, B. Wear: A Serious Problem in Industry. In Tribology in Materials and Manufacturing-Wear, Friction and Lubrication; Amazon: Seattle, WA, USA, 2021. [Google Scholar]

- Pashechko, M.; Dziedzic, K.; Jozwik, J. Analysis of Wear Resistance of Borided Steel C45. Materials 2020, 13, 5529. [Google Scholar] [CrossRef]

- Andrijana, M.; Vlatko, M.; Pejo, K.; Nikolina, B. Effect of Carbon Content and Boronizing Parameters on Growth Kinetics of Boride Layers Obtained on Carbon Steels. Materials 2022, 15, 1858. [Google Scholar] [CrossRef]

- Kayali, Y.; Kanca, E.; Gunen, A. Effect of Boronizing on Microstructure, High-Temperature Wear and Corrosion Behavior of Additive Manufactured Inconel 718. Mater. Charact. 2022, 191, 112155. [Google Scholar] [CrossRef]

- Michal, T.; Grzegorz, L.; Michal, K.; Ryszard, D.; Tadeusz, W. The Effect of Chemical Composition on the Microstructure and Properties of Multicomponent Nickel-Based Boride Layers Produced on C45 Steel by the Hybrid Method. Coatings 2024, 14, 197. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; Zhang, Y.; Lian, G.; Cao, Q.; Que, L. A Comparative Study on Microstructure and Tribological Characteristics of Mo2FeB2/Wc Self-Lubricating Composite Coatings with Addition of WS2, MoS2, and H-Bn. Mater. Des. 2023, 225, 111581. [Google Scholar] [CrossRef]

- Cui, G.J.; Liu, H.Q.; Li, S.; Gao, G.J.; Kou, Z.M. Design and High-Temperature Tribological Properties of CoCrW with Rare Earth Fluoride Composites. J. Mater. Res. Technol. 2020, 9, 2402–2411. [Google Scholar] [CrossRef]

- Yuan, J.; Yao, Y.; Zhuang, M.; Du, Y.; Wang, L.; Yu, Z. Effects of Cu and WS2 Addition on Microstructural Evolution and Tribological Properties of Self-Lubricating Anti-Wear Coatings Prepared by Laser Cladding. Tribol. Int. 2021, 157, 106872. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.; Zhou, J.; Wei, H.; Zeng, R.; Li, W. Effect of Cu Addition on the Microstructure and Tribological Performance of Ni60 Directional Structure Coating. Int. J. Miner. Metall. Mater. 2023, 30, 715–723. [Google Scholar] [CrossRef]

- Liu, X.; Bi, J.; Meng, Z.; Li, R.; Li, Y.; Zhang, T. Tribological Behaviors of High-Hardness Co-based Amorphous Coatings Fabricated by Laser Cladding. Tribol. Int. 2021, 162, 107142. [Google Scholar] [CrossRef]

- Riddihough, M. Stellite as a wear-resistant material. Tribology 1970, 3, 211–215. [Google Scholar] [CrossRef]

- Farnia, A.; Malek Ghaini, F.; Ocelík, V.; De Hosson, J.T.M. Microstructural Characterization of Co-Based Coating Deposited by Low Power Pulse Laser Cladding. J. Mater. Sci. 2012, 48, 2714–2723. [Google Scholar] [CrossRef]

- Li, X.; Zhang, C.H.; Zhang, S.; Wu, C.L.; Liu, Y.; Zhang, J.B.; Shahzad, M.B. Manufacturing of Ti3SiC2 Lubricated Co-based Alloy Coatings Using Laser Cladding Technology. Opt. Laser Technol. 2019, 114, 209–215. [Google Scholar] [CrossRef]

- Ocken, H. The galling wear resistance of new iron-base hardfacing alloys: A comparison with established cobalt- and nickel-base alloys. Surf. Coat. Technol. 1995, 76–77, 456–461. [Google Scholar] [CrossRef]

- Burdett, W.B. Development of cobalt free wear resistant alloys for nuclear applications. Surf Eng. 1992, 8, 131–135. [Google Scholar] [CrossRef]

- Fu, W.; Chen, Q.Y.; Yang, C.; Yi, D.L.; Yao, H.L.; Wang, H.T.; Ji, G.C.; Wang, F. Microstructure and Properties of High Velocity Oxygen Fuel Sprayed (Wc-Co)-ni Coatings. Ceram. Int. 2020, 46, 14940–14948. [Google Scholar] [CrossRef]

- Eyaprakash, N.; Yang, C.H.; Sivasankaran, S. Laser Cladding Process of Cobalt and Nickel Based Hard-Micron-layers on 316L-Stainless-steel-substrate. Mater. Manuf. Process. 2019, 35, 142–151. [Google Scholar] [CrossRef]

- Wu, T.; Shi, W.; Xie, L.; Gong, M.; Huang, J.; Xie, Y.; He, K. Study on the Effect of Ni60 Transition Coating on Microstructure and Mechanical Properties of Fe/WC Composite Coating by Laser Cladding. Opt. Laser Technol. 2023, 163, 109387. [Google Scholar] [CrossRef]

- Li, C.; Sun, R.; Li, Y.; Zhao, Z.; Qi, X.; Pei, M.; Li, F.; Li, J. Wear Mechanism of a Laser Cladded Fe-based Self-Lubricating Composite Coating for Protecting Counter-Abrasive Parts. Surf. Coat. Technol. 2023, 459, 129402. [Google Scholar] [CrossRef]

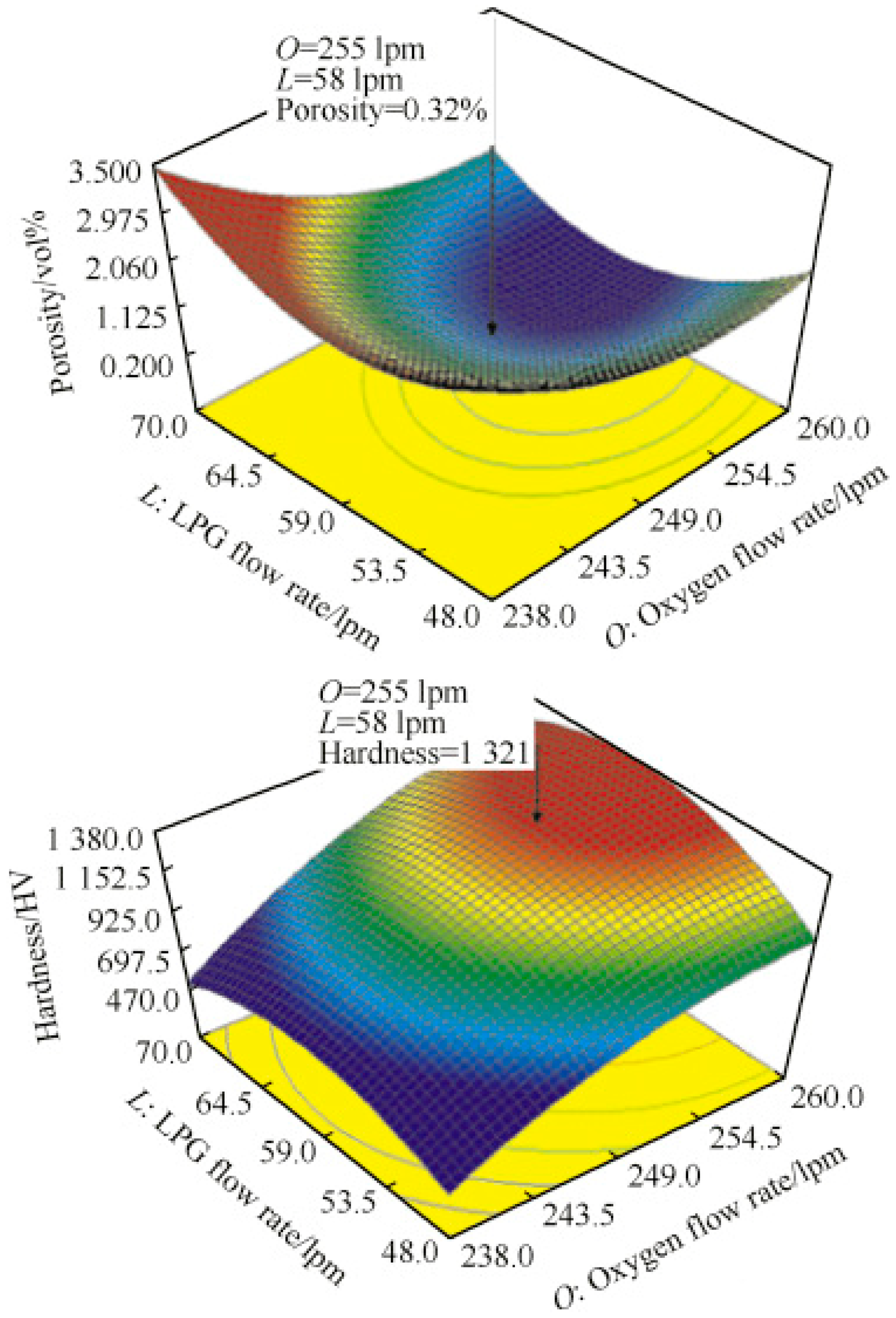

- Vignesh, S.; Shanmugam, K.; Balasubramanian, V.; Sridhar, K. Identifying the Optimal Hvof Spray Parameters to Attain Minimum Porosity and Maximum Hardness in Iron Based Amorphous Metallic Coatings. Def. Technol. 2017, 13, 101–110. [Google Scholar] [CrossRef]

- Martins Freitas, B.J.; De Oliveira, V.A.; Gargarella, P. Microstructural Characterization and Wear Resistance of Boride-Reinforced Steel Coatings Produced by Selective Laser Melting (SLM). Surf. Coat. Technol. 2021, 426, 127779. [Google Scholar] [CrossRef]

- Abu-Warda, N.; López, A.J.; López, M.D.; Utrilla, M.V. High Temperature Corrosion and Wear Behavior of HVOF-sprayed Coating of Al2O3-NiAl on AISI 304 Stainless Steel. Surf. Coat. Technol. 2018, 359, 35–46. [Google Scholar] [CrossRef]

- Li, Y.; Liu, J.; Deng, J.; He, J.; Qin, Y.; Xing, Y.; Yin, F. Fabrication of Graphene Oxide Reinforced Plasma Sprayed Al2O3 Coatings. Ceram. Int. 2023, 49, 1667–1677. [Google Scholar] [CrossRef]

- Jiang, W.; Lu, H.; Liu, X.; Wang, H.; Li, D.; Liu, C.; Wang, M.; Song, X. Outstanding High-Temperature Oxidation-and Wear-Resistance of WC Based Cermets. J. Mater. Sci. Technol. 2023, 155, 33–46. [Google Scholar] [CrossRef]

- Anuj, B.; Deepak, K.G.; Prabhjot, S.; Anil, K.S.; Munish, K.G.; Niraj, B.; Jayant, K.; Gautam, S. Erosive Wear Behaviour of HVOF-sprayed Ni-20Cr2O3 Coating on Pipeline Materials. Int. J. Refract. Met. Hard Mater. 2020, 92, 105332. [Google Scholar]

- Ding, Z.; Fang, Z.; Wang, G.; Wu, C.; Yang, S. Microstructure and Properties of Mo-Si-B-Y2O3 Composite Coating on Nickel-Based Alloy by Laser Cladding. Opt. Laser Technol. 2023, 164, 109473. [Google Scholar] [CrossRef]

- Kong, X.; Sun, W.; Wang, Q.; Chen, M.; Zhang, T.; Wang, F. Improving High-Temperature Wear Resistance of NiCr Matrix Self-Lubricating Composites by Controlling Oxidation and Surface Texturing. J. Mater. Sci. Technol. 2022, 131, 253–263. [Google Scholar] [CrossRef]

- Shen, X.; He, X.; Gao, L.; Su, G.; Xu, C.; Xu, N. Study on Crack Behavior of Laser Cladding Ceramic-Metal Composite Coating with High Content of WC. Ceram. Int. 2022, 48, 17460–17470. [Google Scholar] [CrossRef]

- You, A.; Wang, N.; Chen, Y.; Jiang, C.; Zhang, Y.; Zhao, Q.; Shi, Y.; Li, Y.; Zhang, F.; Zhao, Y. Effect of Linear Energy Density on Microstructure and Wear Resistance of WC-Co-Cr Composite Coating by Laser Cladding. Surf. Coat. Technol. 2023, 454, 129185. [Google Scholar] [CrossRef]

- Marta, O.; Jon, I.A.; Aitzol, L.; Eneko, U. Study of the Flexural Behaviour and Bonding Strength of WC-Co Metal Matrix Composite Coatings Produced by Laser Directed Energy Deposition. Surf. Coat. Technol. 2023, 463, 129538. [Google Scholar]

- Ortiz-Membrado, L.; Garcia-Gonzalez, S.; Orrit-Prat, J. Improved Adhesion of Cathodic Arc Pvd Alcrsin Coating on Ion-Implanted Wc-Co Substrates. Int. J. Refract. Met. Hard Mater. 2023, 113, 106187. [Google Scholar] [CrossRef]

- Wu, Q.L.; Zheng, H.T.; Zhang, Z.H.; Hu, P.; Fan, C.H.; Zhong, N.; Liu, Y. High-temperature Wear and Cyclic Oxidation Behavior of (Ti, W)C Reinforced Stainless Steel Coating Deposited by PTA on a Plain Carbon Steel. Surf. Coat. Technol. 2021, 425, 127736. [Google Scholar] [CrossRef]

- Zhang, M.; Li, M.; Chi, J.; Wang, S.; Ren, L.; Fang, M.; Zhou, C. Microstructure Evolution, Recrystallization and Tribological Behavior of TiC/WC Composite Ceramics Coating. Vacuum 2019, 166, 64–71. [Google Scholar] [CrossRef]

- Bahadur, S.; Gong, D. The Action of Fillers in the Modification of the Tribological Behavior of Polymers. Wear 1992, 158, 41–59. [Google Scholar] [CrossRef]

- Tanaka, K. Transfer of Semicrystalline Polymers Sliding Against a Smooth Steel Surface. Wear 1982, 75, 183–199. [Google Scholar] [CrossRef]

- Ziegler, G.; Kleebe, H.J.; Motz, G.; Weibelzahl, W. Synthesis, Microstructure and Properties of Sicn Ceramics Prepared from Tailored Polymers. Mater. Chem. Phys. 1999, 61, 55–63. [Google Scholar] [CrossRef]

- Kaishi, W.; Martin, G.; Günter, M.; Rajendra, K.B. High performance environmental barrier coatings, Part II: Active filler loaded SiOC system for superalloys. J. Eur. Ceram. Soc. 2011, 31, 3011–3020. [Google Scholar] [CrossRef]

- Schuetz, A.; Guenthner, M.; Motz, G.; Greissl, O.; Glatzel, U. Characterisation of Novel Precursor-Derived Ceramic Coatings with Glass Filler Particles on Steel Substrates. Surf. Coat. Technol. 2012, 207, 319–327. [Google Scholar] [CrossRef]

- Biswas, S.K.; Vijayan, K. Friction and wear of PTFE-a review. Wear 1992, 158, 193–211. [Google Scholar] [CrossRef]

- Kameda, T.; Ohkuma, K.; Oka, S. Polytetrafluoroethylene (PTFE): A resin material for possible use in dental prostheses and devices. Dent. Mater. J. 2019, 38, 136–142. [Google Scholar] [CrossRef]

- Dhanumalayan, E.; Joshi, G.M. Performance properties and applications of polytetrafluoroethylene (PTFE)—A review. Adv. Compos. Hybrid Mater. 2018, 1, 247–268. [Google Scholar] [CrossRef]

- Sawyer, W.G.; Freudenberg, K.D.; Bhimaraj, P.; Schadler, L.S. A Study on the Friction and Wear Behavior of Ptfe Filled with Alumina Nanoparticles. Wear 2003, 254, 573–580. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Ni, Z. The friction and wear of γ-irradiated polytetrafluoroethylene. Wear 1984, 100, 221–242. [Google Scholar] [CrossRef]

- Blanchet, T.A. Sliding wear mechanism of polytetrafluoroethylene (PTFE) and PTFE composites. Wear 1992, 153, 229–243. [Google Scholar] [CrossRef]

- Bahadur, S.; Tabor, D. The wear of filled polytetrafluoroethylene. Wear 1984, 98, 1–13. [Google Scholar] [CrossRef]

- Li, F.; Yan, F.Y.; Yu, L.G.; Liu, W.M. The Tribological Behaviors of Copper-Coated Graphite Filled Ptfe Composites. Wear 2000, 237, 33–38. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, Y.F.; Xu, B.; Lu, Y.J.; Zhou, C.L.; Wu, X.Y.; Li, J.J. Fabrication and Tribological Properties of a Self-Lubricating Wear-Resistant Coating Based on Structural Coupling. Ceram. Int. 2018, 45, 3910–3920. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, H.; Sun, C.; Dai, J. Microstructure and Wear Properties of Multi Ceramics Reinforced Metal-Matrix Composite Coatings on Ti–6Al–4V Alloy Fabricated by Laser Surface Alloying. Surf. Eng. 2019, 35, 683–691. [Google Scholar] [CrossRef]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Gao, J.; Chen, Z.; Du, K.; Zhang, Y.; Bi, Y.; Su, J.; Zhang, S. A Coordination-Driven Interface System for Improving the Performance of High-Filled Bamboo Fiber/poly (butylene Succinate-Co-butylene Adipate) (PBSA) Biocomposites. J. Clean. Prod. 2023, 418, 138198. [Google Scholar] [CrossRef]

- Zai, W.; Wong, M.H.; Man, H.C. Improving the Wear and Corrosion Resistance of CoCrMo-UHMWPE Articulating Surfaces in the Presence of an Electrolyte. Appl. Surf. Sci. 2018, 464, 404–411. [Google Scholar] [CrossRef]

- Ling, L.; Xiao, M.; Han, M.; Ren, S.; Wang, S.; Meng, Y.Z. Porous Composite Membrane of PVDF/Sulfonic Silica with High Ion Selectivity for Vanadium Redox Flow Battery. J. Membr. Sci. 2019, 585, 230–237. [Google Scholar] [CrossRef]

- Peng, G.; Qiao, Q.; Huang, K.; Wu, J.; Wang, Y.; Fu, X.; Zhang, Z.; Fang, T.; Zhang, B.; Huang, Y.; et al. Ni-Fe-MoO42− LDHs/epoxy Resin Varnish: A Composite Coating on Carbon Steel for Long-Time and Active Corrosion Protection. Prog. Org. Coat. 2020, 140, 105514. [Google Scholar] [CrossRef]

- Sun, Y.; Yuan, J.; Wang, M.; Wang, H.; Chen, Z.; Liu, X.; Li, S.; Zhao, W.; Yang, J. Enhanced Tribological Performance of NiAl-based Composite Coatings: Design of the Composition in Coatings by Addition of Mo and Nanodiamond. Tribol. Int. 2025, 203, 110405. [Google Scholar] [CrossRef]

- Beltrami, M.; Mavric, A.; Dal Zilio, S.; Fanetti, M.; Kapun, G.; Lazzarino, M. A Comparative Study of Nanolaminate CrN/Mo2N and CrN/W2N As Hard and Corrosion Resistant Coatings. Surf. Coat. Technol. 2023, 455, 129209. [Google Scholar] [CrossRef]

- Elder, B.; Neupane, R.; Tokita, E.; Ghosh, U.; Hales, S.; Kong, Y.L. Nanomaterial Patterning in 3D Printing. Adv. Mater. 2020, 32, e1907142. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.F.; Hou, Z.W.; Lin, L.; Li, F.; Zhao, Y.; Li, X.Z. 3D Nanoprinting of Semiconductor Quantum Dots by Photoexcitation-Induced Chemical Bonding. Science 2022, 377, 1112–1116. [Google Scholar] [CrossRef] [PubMed]

- Kiryukhantsev-Korneev, P.V.; Sheveyko, A.N.; Vorotilo, S.A.; Levashov, E.A. Wear-resistant Ti–Al–Ni–C–N Coatings Produced by Magnetron Sputtering of SHS-targets in the DC and HIPIMS Modes. Ceram. Int. 2020, 46, 1775–1783. [Google Scholar] [CrossRef]

- Movassagh-Alanagh, F.; Mahdavi, M. Improving Wear and Corrosion Resistance of AISI 304 Stainless Steel by a Multilayered Nanocomposite Ti/TiN/TiSiN Coating. Surf. Interfaces 2020, 18, 100428. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.; Men, Y.; Li, X.; Liang, Y.; Ren, L. Fabrication of Nano-Tic Functional Gradient Wear-Resistant Composite Coating on 40cr Gear Steel Using Laser Cladding under Starved Lubrication Conditions. Opt. Laser Technol. 2020, 126, 106136. [Google Scholar] [CrossRef]

- Ozkan, D.; Erarslan, Y.; Kincal, C.; Gurlu, O.; Yagci, M.B. Wear and Corrosion Resistance Enhancement of Chromium Surfaces Through Graphene Oxide Coating. Surf. Coat. Technol. 2020, 391, 125595. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Zhang, Y.; Tan, Y.W.; Stormer, H.L.; Kim, P. Experimental Observation of the Quantum Hall Effect and Berry’S Phase in Graphene. Nature 2005, 438, 201–204. [Google Scholar] [CrossRef]

- Ma, Y.; Qi, P.; Ma, J.; Wei, L.; Zhao, L.; Cheng, J.; Su, Y.; Gu, Y.; Lian, Y.; Peng, Y.; et al. Wax-Transferred Hydrophobic CVD Graphene Enables Water-Resistant and Dendrite-Free Lithium Anode Toward Long Cycle Li-Air Battery. Adv. Sci. 2021, 8, 2100488. [Google Scholar] [CrossRef]

- Wang, L.; Bai, X.; Wen, B.; Du, Z.; Lin, Y. Honeycomb-like Co/C Composites Derived from Hierarchically Nanoporous ZIF-67 As a Lightweight and Highly Efficient Microwave Absorber. Compos. Part B Eng. 2019, 166, 464–471. [Google Scholar] [CrossRef]

- Chang, H.; Luo, Z.Y.; Shi, X.R.; Cao, X.X.; Liang, S.Q. Stable and Reversible Zinc Metal Anode with Fluorinated Graphite Nanosheets Surface Coating. Trans. Nonferrous Met. Soc. China 2024, 34, 3358–3371. [Google Scholar] [CrossRef]

- Herman, H.; Sampath, S.; McCune, R. Thermal spray: Current status and future trends. MRS Bull. 2000, 25, 17–25. [Google Scholar] [CrossRef]

- Czupryński, A.; Adamiec, J.; Adamiak, M.; Żuk, M.; Kříž, A.; Mele, C.; Kciuk, M. High-Temperature Corrosion of Flame-Sprayed Power Boiler Components with Nickel Alloy Powders. Mater. Charact. 2023, 16, 1658. [Google Scholar] [CrossRef]

- Nyambura, S.M. A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coatings. Nanomaterials 2021, 11, 2527. [Google Scholar]

- Kwon, H.; Kim, J.; Lee, C. Surface Metallization and Ceramic Deposition on Thermoplastic-Polymer and Thermosetting-Polymer Composite Via Atmospheric Plasma Spraying. Met. Mater. Int. 2020, 27, 3293–3306. [Google Scholar] [CrossRef]

- Ye, Y.; Guo, Z.; Zhou, Z.; Zhang, B.; Wang, Q.; Shen, B. Improved Corrosion and Corrosion-Wear Properties of Fe-based High-Entropy Amorphous Coatings by Modulating Heat Input of HVAF. Corros. Sci. 2024, 232, 112049. [Google Scholar] [CrossRef]

- Galedari, S.A.; Mahdavi, A.; Azarmi, F. A Comprehensive Review of Corrosion Resistance of Thermally-Sprayed and Thermally-Diffused Protective Coatings on Steel Structures. J. Therm. Spray Technol. 2019, 28, 645–677. [Google Scholar] [CrossRef]

- Talib, R.J.; Saad, S.; Toff, M.R.M. Thermal Spray Coating Technology—A Review. Int. J. Multidiscip. Res. 2023, 5, 1–8. [Google Scholar] [CrossRef]

- Picas, J.A.; Forn, A.; Rilla, R. HVOF thermal sprayed coatings on aluminium alloys and aluminium matrix composites. Surf. Coat. Technol. 2005, 200, 1178–1181. [Google Scholar] [CrossRef]

- Garcia-Rodriguez, S.; Torres, B.; Lopez, A.J.; Otero, E.; Rams, J. Characterization and Mechanical Properties of Stainless Steel Coatings Deposited by HVOF on ZE41 Magnesium Alloy. Surf. Coat. Technol. 2019, 359, 73–84. [Google Scholar] [CrossRef]

- Ramesh, M.R.; Prakash, S.; Nath, S.K.; Sapra, P.K.; Venkataraman, B. Solid particle erosion of HVOF sprayed WC-Co/NiCrFeSiB coatings. Wear 2010, 269, 197–205. [Google Scholar] [CrossRef]

- Yao, H.L.; Yang, C.; Yi, D.L.; Zhang, M.X.; Wang, H.T.; Chen, Q.Y.; Bai, X.B.; Ji, G.C. Microstructure and Mechanical Property of High Velocity Oxy-Fuel Sprayed WC-Cr3C2-Ni Coatings. Surf. Coat. Technol. 2020, 397, 126010. [Google Scholar] [CrossRef]

- Wu, Y.; Lin, P.; Chu, C.; Wang, Z.; Cao, M.; Hu, J. Cavitation Erosion Characteristics of a Fe–Cr–Si–B–Mn Coating Fabricated by High Velocity Oxy-Fuel (HVOF) Thermal Spray. Mater. Lett. 2007, 61, 1867–1872. [Google Scholar]

- Gateman, S.M.; Alidokht, S.A.; Mena-Morcillo, E.; Schulz, R.; Chromik, R.R.; Kietzig, A.-M.; Parkin, I.P.; Mauzeroll, J. Wear Resistant Solid Lubricating Coatings Via Compression Molding and Thermal Spraying Technologies. Surf. Coat. Technol. 2021, 426, 127790. [Google Scholar] [CrossRef]

- Lima, C.R.C.; Belem, M.J.X.; Fals, H.D.C.; Della Rovere, C.A. Wear and Corrosion Performance of Stellite 6(R) Coatings Applied by HVOF Spraying and GTAW Hotwire Cladding. J. Mater. Process. Technol. 2020, 284, 116734. [Google Scholar] [CrossRef]

- Buytoz, S.; Ulutan, M.; Islak, S.; Kurt, B.; Çelik, O.N. Microstructural and Wear Characteristics of High Velocity Oxygen Fuel (HVOF) Sprayed NiCrBSi-SiC Composite Coating on SAE 1030 Steel. Arab. J. Sci. Eng. 2013, 38, 1481–1491. [Google Scholar] [CrossRef]

- Jitendra, K.S.; Soumen, M.; Raihana, J.A.; Han-Seung, L.; Hyun-Min, Y. Role of Coating Processes on the Corrosion Kinetics and Mechanism of Zinc in Artificial Seawater. Materials 2021, 14, 7464. [Google Scholar] [CrossRef]

- Luo, L.; Liu, S.; Yu, J.; Zhao, Q.; Sun, N.; Li, J. High-temperature erosion behavior of high-velocity arc-spraying FeMnCr/Cr3C2 coatings. Xiyou Jinshu Cailiao Yu Gongcheng/Rare Met. Mater. Eng. 2010, 39, 234–237. [Google Scholar]

- Qiao, L.; Duan, J.; Gao, W.; Hong, S. Corrosion Behavior of Arc-Sprayed Pore-Sealed Zn and Al Coatings in Seawater Containing Sulfate-Reducing Bacteria (SRB). J. Therm. Spray Technol. 2021, 30, 1557–1565. [Google Scholar] [CrossRef]

- Fang, L.; Huang, J.; Liu, Y.; Zhang, B.; Li, H. Cored-wire Arc Spray Fabrication of Novel Aluminium-Copper Coatings for Anti-Corrosion/fouling Hybrid Performances. Surf. Coat. Technol. 2019, 357, 794–801. [Google Scholar] [CrossRef]

- Ndumia, J.N.; Kang, M.; Gbenontin, B.V.; Lin, J.; Liu, J.; Nyambura, S.M. Evaluation of Thermal Shock Failure Mechanism of Arc-Sprayed Fe-based Coatings Deposited on Different Substrates. Surf. Coat. Technol. 2023, 474, 130081. [Google Scholar] [CrossRef]

- Jarligo, M.O.; Mack, D.E.; Mauer, G.; Vaßen, R.; Stöver, D. Atmospheric Plasma Spraying of High Melting Temperature Complex Perovskites for TBC Application. J. Therm. Spray Technol. 2010, 19, 303–310. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhou, K.S.; Deng, C.M.; Liu, M.; Deng, Z.Q.; Deng, C.G.; Song, J.B. Deposition and CMAS Corrosion Mechanism of 7YSZ Thermal Barrier Coatings Prepared by Plasma Spray-Physical Vapor Deposition. J. Inorg. Mater. 2015, 30, 287–293. [Google Scholar] [CrossRef]

- Deng, Z.Q.; Liu, M.; Mao, J.; Zhang, X.F.; Chen, W.L.; Chen, Z.K. Deposition Mechanism Based on Plasma Spray-Physical Vapor Deposition. J. Inorg. Mater. 2017, 32, 1285. [Google Scholar] [CrossRef]

- An, L.T.; Gao, Y.; Zhang, T. Effect of Powder Injection Location on Ceramic Coatings Properties When Using Plasma Spray. J. Therm. Spray Technol. 2007, 16, 967–973. [Google Scholar] [CrossRef]

- Srinivasan, V.; Friis, M.; Vaidya, A.; Streibl, T.; Sampath, S. Particle Injection in Direct Current Air Plasma Spray: Salient Observations and Optimization Strategies. Plasma Chem. Plasma Process. 2007, 27, 609–623. [Google Scholar] [CrossRef]

- Kashkarov, E.B.; Sidelev, D.; Rombaeva, M.; Syrtanov, M.S.; Bleykher, G.A. Chromium Coatings Deposited by Cooled and Hot Target Magnetron Sputtering for Accident Tolerant Nuclear Fuel Claddings. Surf. Coat. Technol. 2020, 389, 125618. [Google Scholar] [CrossRef]

- Tian, C.L.; Cai, H.C.; Xue, Y.J. Effect of Working Pressure on Tribological Properties of Ce-Ti/MoS2 Coatings Using Magnetron Sputter. Coatings 2022, 12, 1576. [Google Scholar] [CrossRef]

- Zhang, X.F.; Li, M.; Zhang, A.; Guo, S.Q.; Mao, J.; Deng, C.M. Al-modification for PS-PVD 7YSZ TBCs to Improve Particle Erosion and Thermal Cycle Performances. J. Adv. Ceram. 2022, 11, 1093–1103. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Shpak, A.P.; Beresnev, V.M.; Il'Yashenko, M.; Komarov, F.; Shypylenko, A.; Kaverin, M.; Zukovski, P.; Kunitskyi, Y.; Kolesnikov, D.; et al. Structure and Properties of Nano- and Microcomposite Coating Based on Ti-Si-N/WC-Co-Cr. Acta Phys. Pol. A Gen. Phys. Phys. Condens. Matter Opt. Quantum Electron. At. Mol. Phys. Appl. Phys. 2011, 120, 100–104. [Google Scholar] [CrossRef]

- Taran, A.; Garkusha, I.; Taran, V.; Muratov, R.; Starikov, V.; Baturin, A. Structure and Properties of Nanostructured ZrN Coatings Obtained by Vacuum-Arc Evaporation Using RF Discharge. Nanotechnol. Percept. 2018, 14, 167–177. [Google Scholar] [CrossRef]

- Wang, L.J.; Wang, M.C.; Chen, H. Corrosion Mechanism Investigation of TiAlN/CrN Superlattice Coating by Multi-Arc Ion Plating in 3.5 Wt% NaCl Solution. Surf. Coat. Technol. 2020, 391, 125660. [Google Scholar] [CrossRef]

- Qiu, X.; Liu, X.; Jiang, S.; Jiang, G.; Zhang, Q. Growth Mechanism for Zinc Coatings Deposited by Vacuum Thermal Evaporation. J. Iron Steel Res. Int. 2021, 28, 1047–1053. [Google Scholar] [CrossRef]

- Tillmann, W.; Hagen, L.; Stangier, D.; Krabiell, M.; Schroeder, P.; Tiller, J. Influence of Etching-Pretreatment on Nano-Grained WC-Co Surfaces and Properties of PVD/HVOF Duplex Coatings. Surf. Coat. Technol. 2019, 374, 32–43. [Google Scholar] [CrossRef]

- Nelson, F.L.D.; Alexander, L.M.; Christoph, P.J.; Alexander, F.; Dirk, B.; Wolfgang, T. Arc-enhanced Glow Discharge Ion Etching of WC-Co Cemented Carbide for Improved PVD Thin Film Adhesion and Asymmetric Cutting Edge Preparation of Micro Milling Tools. Surf. Coat. Technol. 2024, 491, 131166. [Google Scholar]

- Sabzi, M.; Mousavi Anijdan, S.H.; Shamsodin, M.; Farzam, M.; Hojjati-Najafabadi, A.; Feng, P.; Park, N.; Lee, U. A Review on Sustainable Manufacturing of Ceramic-Based Thin Films by Chemical Vapor Deposition (CVD): Reactions Kinetics and the Deposition Mechanisms. Coatings 2023, 13, 188. [Google Scholar] [CrossRef]

- Kellermann, K.; Ehrhardt, S.; Fandrey, J.; Rosiwal, S.M.; Singer, R.F. Influence of Surface Roughness on the Tribological Properties of Hf-Cvd Diamond Coated Heat-Treatable Steel. Wear 2010, 269, 811–815. [Google Scholar] [CrossRef]

- Xiao, L.; Shan, Y.; Fan, X.; Chen, C.; Lu, S.; Hu, X. Preparation of Diamond Films with Cracked Textures on Stainless Steel Using W/W-N Film as an Interlayer. Coatings 2024, 14, 1494. [Google Scholar]

- Muresan, M.G.; Charvatova Campbell, A.; Ondracka, P.; Bursikova, V.; Perina, V.; Polcar, T. Protective Double-Layer Coatings Prepared by Plasma Enhanced Chemical Vapor Deposition on Tool Steel. Surf. Coat. Technol. 2015, 272, 229–238. [Google Scholar] [CrossRef]

- Tomlinson, K.; Fletcher, D.I.; Lewis, R. Evaluation of Laser Cladding as an In-Situ Repair Method on Rail Steel. Tribol. Int. 2023, 180, 108210. [Google Scholar] [CrossRef]

- Panziera, R.C.; Pereira, M.; Castro Rde, M.; Curi, E.I.M.; Neto, F.G. Effect of Tungsten Carbide Reinforcement Phase on the Abrasive Wear Performance of Metal Matrix Composites Deposited by Laser Cladding. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 596. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, P.; Lan, Q.; Meng, G.; Ren, Y.; Yang, Z. Recent research and development status of laser cladding: A review. Opt. Laser Technol. 2021, 138, 106915. [Google Scholar] [CrossRef]

- Brandau, B.; Hemschik, R.; Sousa, J.P.; Brueckner, F.; Kaplan, A. Enhancing Laser Cladding Stability: Defects and Schlieren-Based Analytics During L-DED. Addit. Manuf. 2025, 103, 104758. [Google Scholar] [CrossRef]

- Xing, H.; Kong, D.J.; Song, R.G. Microstructures and Properties of Laser Cladding Al-TiC-CeO2 Composite Coatings. Materials 2019, 48, 3634–3642. [Google Scholar]

- Wang, K.; Du, D.; Liu, G.; Chang, B.; Hong, Y. Microstructure and Properties of WC Reinforced Ni-based Composite Coatings with Y2O3 Addition on Titanium Alloy by Laser Cladding. Sci. Technol. Weld. Join. 2019, 24, 517–524. [Google Scholar] [CrossRef]

- Chen, S.; Wang, H.; Huang, X.; Qin, S.; Hu, X. Study on the Microstructure and Performance of the Multi-Field Composite-Assisted Laser Cladding of Nickel-Based Tungsten Carbide Coatings. Metals 2024, 14, 1188. [Google Scholar] [CrossRef]

- Yuan, W.; Li, R.; Chen, Z.; Gu, J.; Tian, Y. A Comparative Study on Microstructure and Properties of Traditional Laser Cladding and High-Speed Laser Cladding of Ni45 Alloy Coatings. Surf. Coat. Technol. 2021, 405, 126582. [Google Scholar] [CrossRef]

- Zhang, Y.; Lou, L.Y.; Xu, Q.L.; Li, Y.; Li, C.J.; Li, C.X. Microstructure and Wear Resistance of Ni-Based WC Coating by Ultra-High Speed Laser Cladding. Acta Metall. Sin. 2020, 56, 1530–1540. [Google Scholar]

- Barile, C.; Casavola, C.; Pappalettera, G.; Renna, G. Advancements in Electrospark Deposition (ESD) Technique: A Short Review. Coatings 2022, 12, 1536. [Google Scholar] [CrossRef]

- Kemal, K. Investigation and Characterization of Electrospark Deposited Chromium Carbide-Based Coating on the Steel. Surf. Coat. Technol. 2015, 272, 1–7. [Google Scholar]

- Kudryashov, A.E.; Zamulaeva, E.I.; Levashov, E.A.; Manakova, O.S.; Petrzhik, M.I. Application of Electrospark Deposition Process and Modified SHS Electrode Materials to Improve the Endurance of Hot Mill Rolls. Part 1. Features of Coating Formation on SPHN-60 White Cast Iron Substrates. Surf. Eng. Appl. Electrochem. 2019, 55, 390–401. [Google Scholar] [CrossRef]

- Wei, S.S.; You, B.; Sun, S.L.; Li, Y.Y.; Lin, R.C.; Lin, Y.L. Study on Salt Spray Corrosion and Friction Wear Performance of CrN Coated Cemented Carbide Sealing Ring. Mater. Res. Express 2024, 11, 106511. [Google Scholar] [CrossRef]

- Sulaiman, M.H.; Sheng, A.O.C.; Farahana, R.N.; Bienk, K. Corrosion resistance of PVD hard coatings for tribological engineering applications. IOP Conf. Ser. Mater. Sci. Eng. 2019, 670, 012054. [Google Scholar] [CrossRef]

| Element | Function | Advantage |

|---|---|---|

| Chromium | Improves the corrosion and oxidation resistances of the coating, forms solid solutions or compounds with the matrix, and enhances high-temperature stability. | Can form a dense oxide film (Cr2O3) in high-temperature or corrosive environments to protect the matrix from further erosion. |

| Zirconium | Forming high-hardness ceramic phases with carbon, nitrogen, oxygen and other elements (such as ZrC, ZrN, ZO2) is easy, which can refine the matrix grains (by inhibiting grain growth), reduce the stress concentration caused by coarse organization, and reduce the risk of delamination. | Excellent chemical stability, its oxide (ZrO2) has good high-temperature and corrosion resistances and can form a dense oxide film on the surface of the material, which hinders the oxidation wear or corrosion medium from corroding the matrix at high temperatures. |

| Molybdenum, Tungsten | Improves the hardness and wear resistance of the matrix through solid solution strengthening, forms hard phases (e.g., MoC, WC), and enhances the resistance to abrasive wear. | Has good compatibility with Co and Ni matrices, can significantly improve the wear resistance of the coating under high loads, and simultaneously enhances high-temperature strength. |

| Titanium, Vanadium | Easily combines with carbon and nitrogen to form high-hardness carbides (e.g., TiC, VC) or nitrides (e.g., TiN) and improves wear resistance through dispersion strengthening. | The formed hard phases have extremely high hardness (e.g., TiC has a Vickers hardness of approximately 2800 HV), which can effectively resist abrasive cutting without significantly reducing the toughness of the coating. |

| Aluminum | Improves the oxidation resistance of the coating and enhances high-temperature strength and thermal-fatigue resistance. | Low cost, forms Al2O3 protective film in high-temperature environments, and is suitable for high-temperature wear-resistant scenarios that also require oxidation resistance. |

| Carbon | Combines with matrix metals (e.g., Fe, Co) or added metals (e.g., Ti, W) to form carbides (e.g., Fe3C, WC), significantly improving the hardness and wear resistance of the coating. | Carbides are evenly distributed, which can significantly improve wear resistance while maintaining a certain level of toughness, and are suitable for the conventional strengthening of metal-based wear-resistant coatings. |

| Nitrogen | Combines with metals such as Ti and Cr to form nitrides (e.g., TiN, CrN), which have high hardness and good chemical stability and refine the coating grains. | Nitride coatings have a low friction coefficient (e.g., the friction coefficient of TiN is approximately 0.4) and have both wear-resistant and friction-reducing effects; they are often used in precision components. |

| Boron | Forms borides (e.g., FeB, NiB) with the matrix, improves the hardness and red hardness (the ability to maintain hardness at high temperatures) of the coating, and enhances the fluidity of the coating (facilitating the coating process). | Borides have high hardness (e.g., the Vickers hardness of FeB is approximately 1800 HV) and can reduce coating brittleness, suitable for scenarios requiring both hardness and toughness. |

| Silicon | Forms silicides or combines with oxygen to generate SiO2 film, improves the corrosion resistance and high-temperature stability of the coating, and refines the grains simultaneously. | Enhances the corrosion resistance of the coating in acid-base environments and has low cost; suitable for wear-resistant coatings that require corrosion resistance (e.g., chemical equipment). |

| Type of System | Flame or Plasma Exit Temperature (°C) | Heat Transfer or Substrate (°C) | Particle Impact Velocity (m/s) | Oxide Content (%) | Porosity (%) | Adhesion (Bond Strength) |

|---|---|---|---|---|---|---|

| Flame Spraying | 2500–3000 | 500–700 | 30–180 | 4–6 | 10 | Low |

| HVOF | 2500–3100 | 500–700 | 500–800 | 0.2 | 1.0–10 | Very High |

| Wire Arc | 4000–6000 | 500–800 | 240 | 0.5–3 | 10–20 | High |

| Plasma Spraying | 5500–8300 | 700–1000 | 200–600 | 0.1–1 | 1.0–10 | Very High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Feng, C.; Lin, T.; Zhu, R.; Zhang, J.; Yang, H.; Yi, S.; He, J.; Tu, M.; Wei, G. A Review of Wear-Resistant Coatings for Steel Substrates: Applications and Challenges. Metals 2025, 15, 1231. https://doi.org/10.3390/met15111231

Wang Y, Feng C, Lin T, Zhu R, Zhang J, Yang H, Yi S, He J, Tu M, Wei G. A Review of Wear-Resistant Coatings for Steel Substrates: Applications and Challenges. Metals. 2025; 15(11):1231. https://doi.org/10.3390/met15111231

Chicago/Turabian StyleWang, Yanhong, Chao Feng, Tao Lin, Rong Zhu, Jie Zhang, Huapeng Yang, Shanghai Yi, Junlin He, Mingwei Tu, and Guangsheng Wei. 2025. "A Review of Wear-Resistant Coatings for Steel Substrates: Applications and Challenges" Metals 15, no. 11: 1231. https://doi.org/10.3390/met15111231

APA StyleWang, Y., Feng, C., Lin, T., Zhu, R., Zhang, J., Yang, H., Yi, S., He, J., Tu, M., & Wei, G. (2025). A Review of Wear-Resistant Coatings for Steel Substrates: Applications and Challenges. Metals, 15(11), 1231. https://doi.org/10.3390/met15111231