Effect of Hot Rolling on the Microstructure and Properties of Dispersion-Strengthened W-La Alloy

Abstract

1. Introduction

2. Tests and Methods

2.1. Material Preparation

2.1.1. Billet Preparation

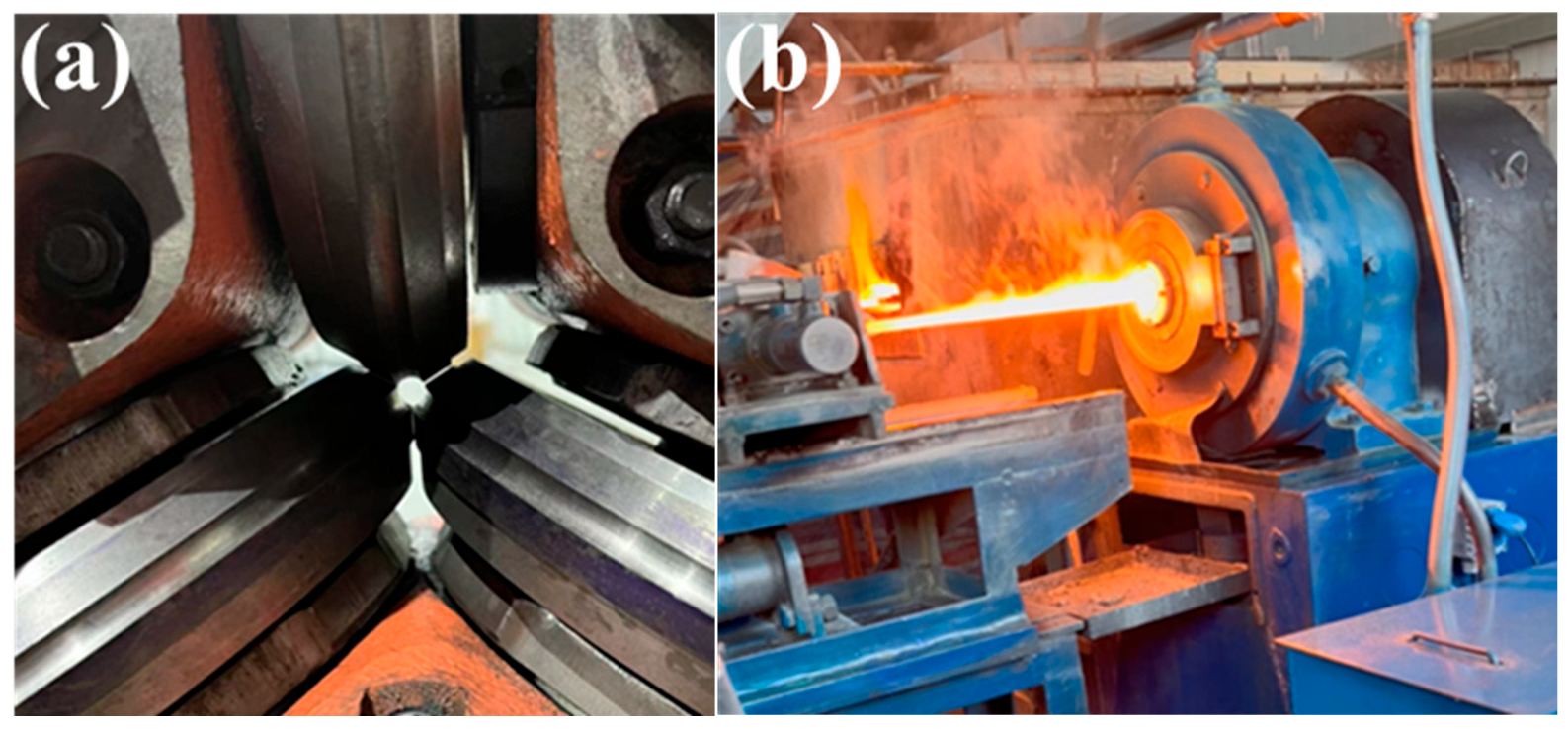

2.1.2. Rolling Processing

2.1.3. Rotary Forging and Annealing Treatment

2.2. Test Scheme

2.2.1. Rolling Test

2.2.2. Rotary Forging Test

2.2.3. Annealing Test

2.3. Test Method

3. Results and Discussion

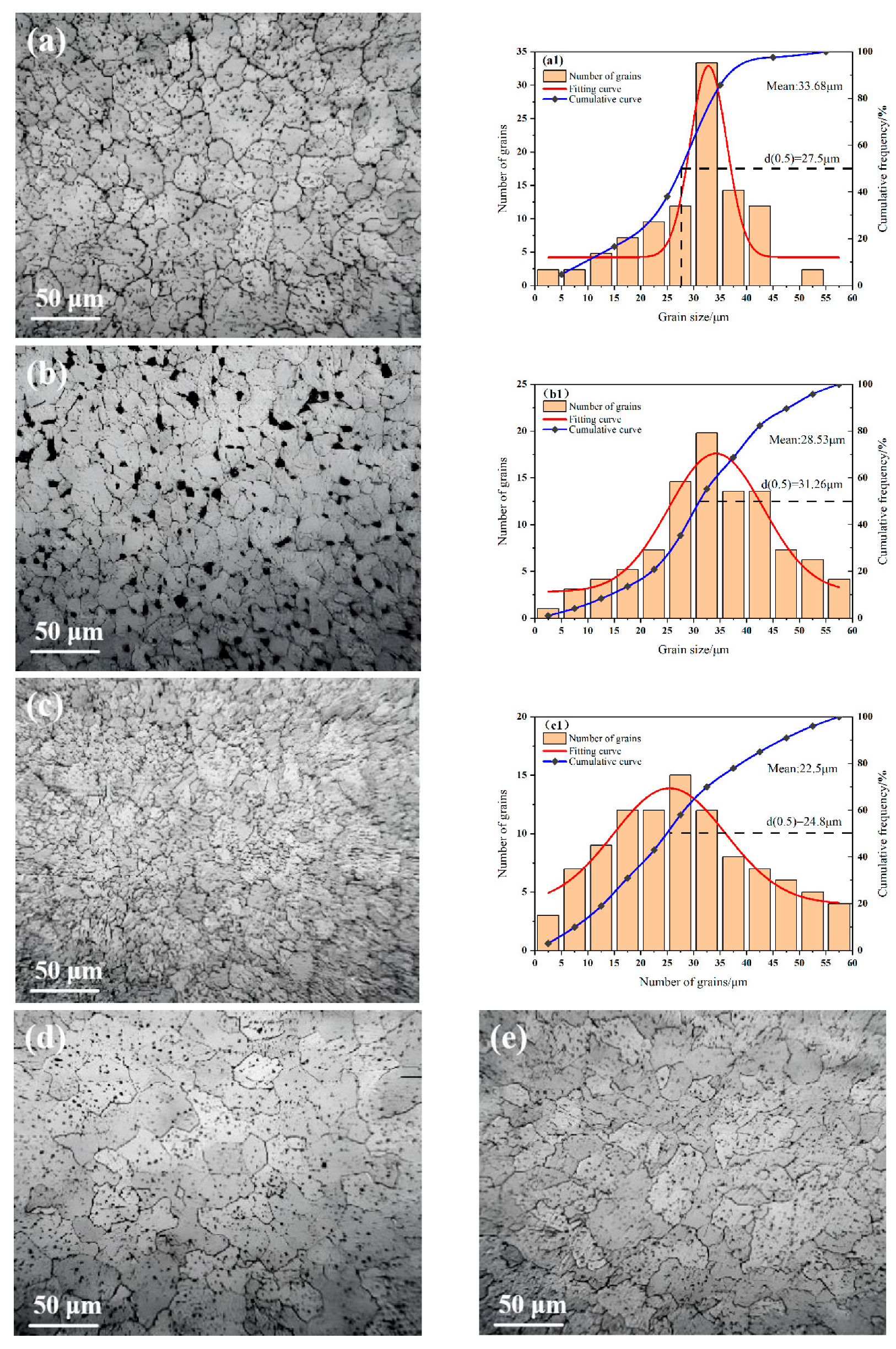

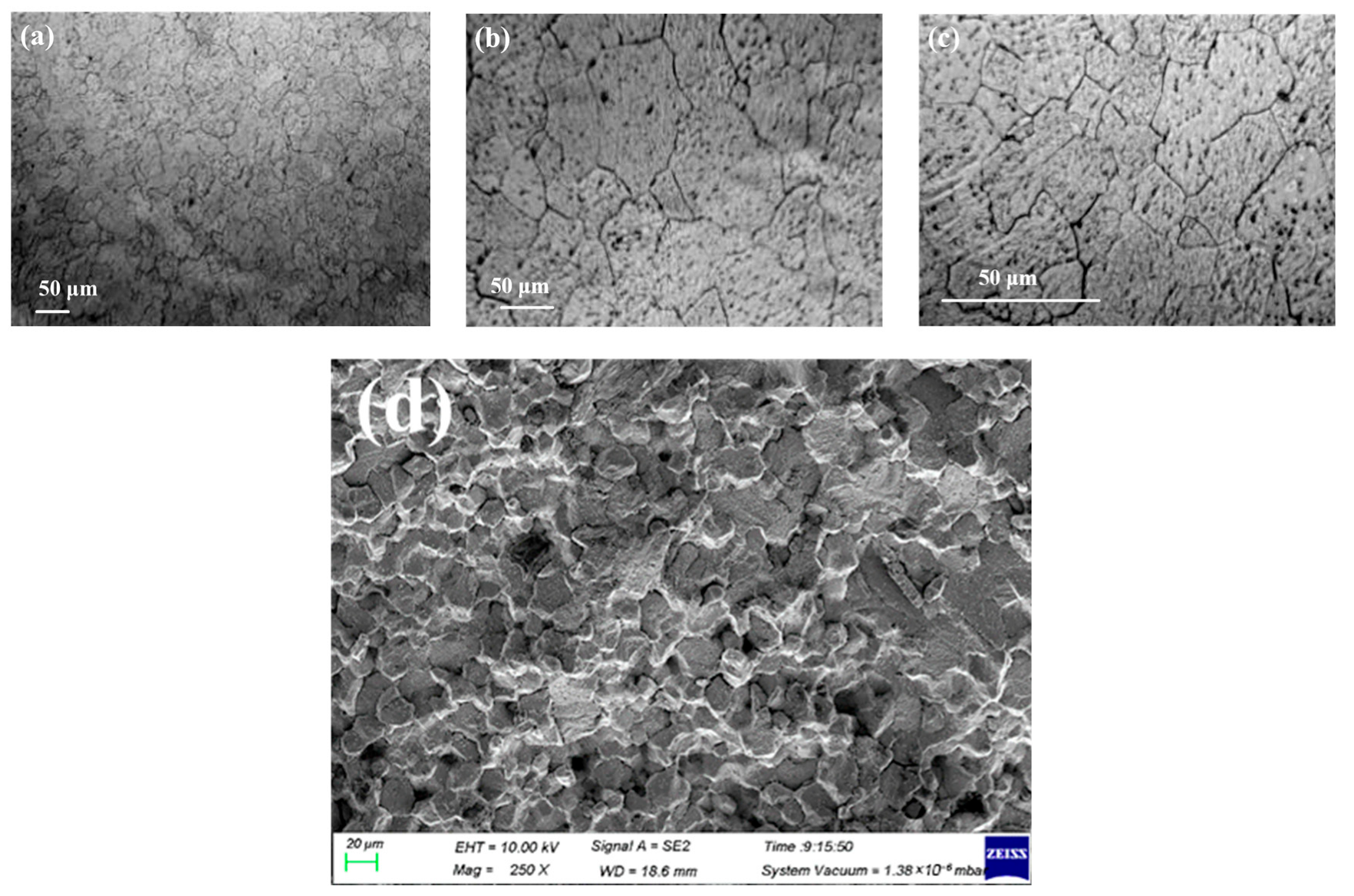

3.1. Effect of Rotary Forging on Microstructure and Morphology of W-La Alloy Cross-Section

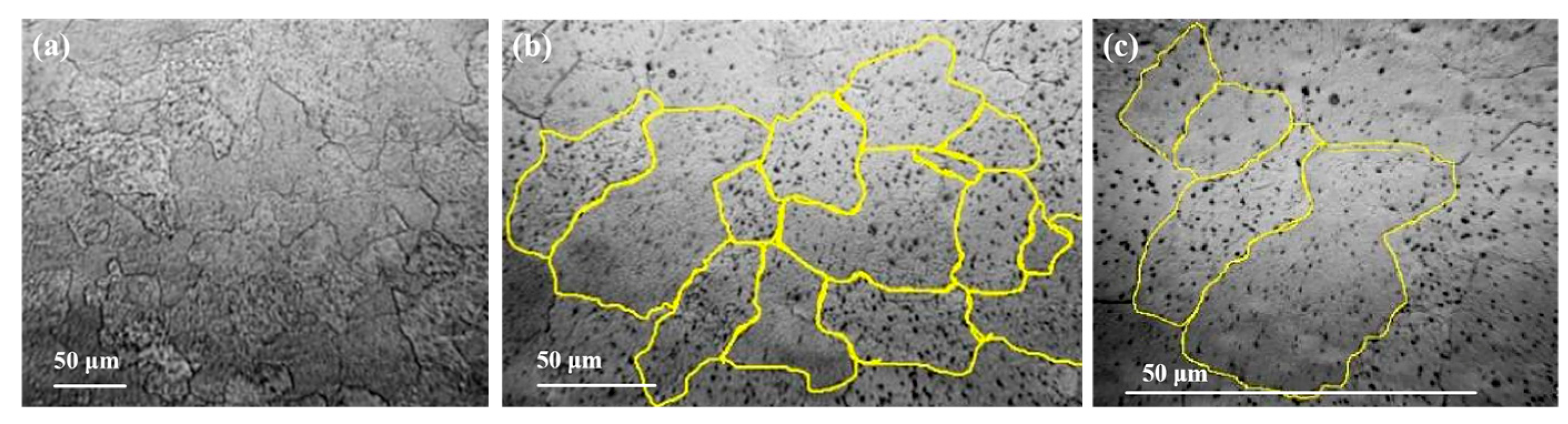

3.2. Effect of Rolling on Microstructure and Morphology of W-La Alloy Cross-Section

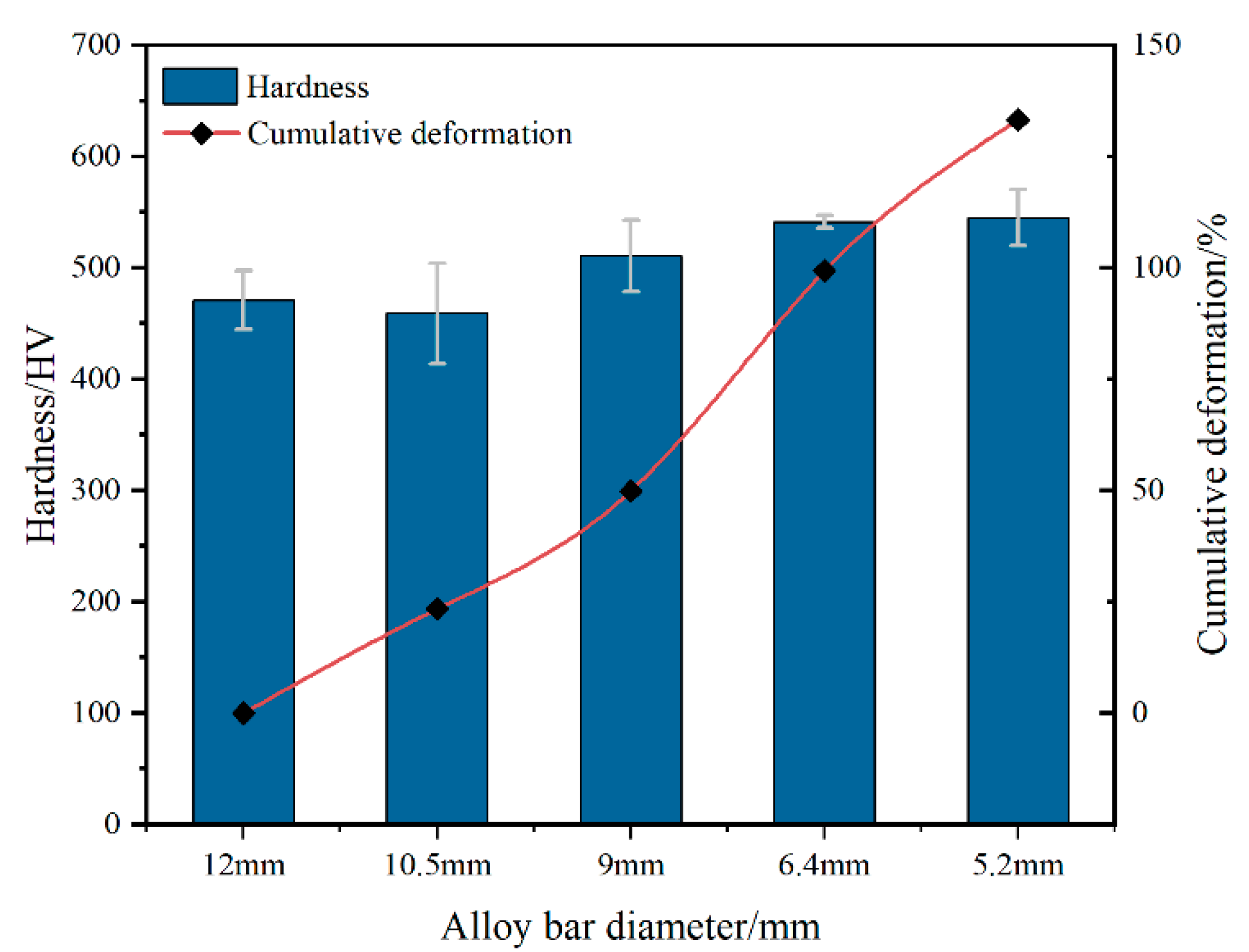

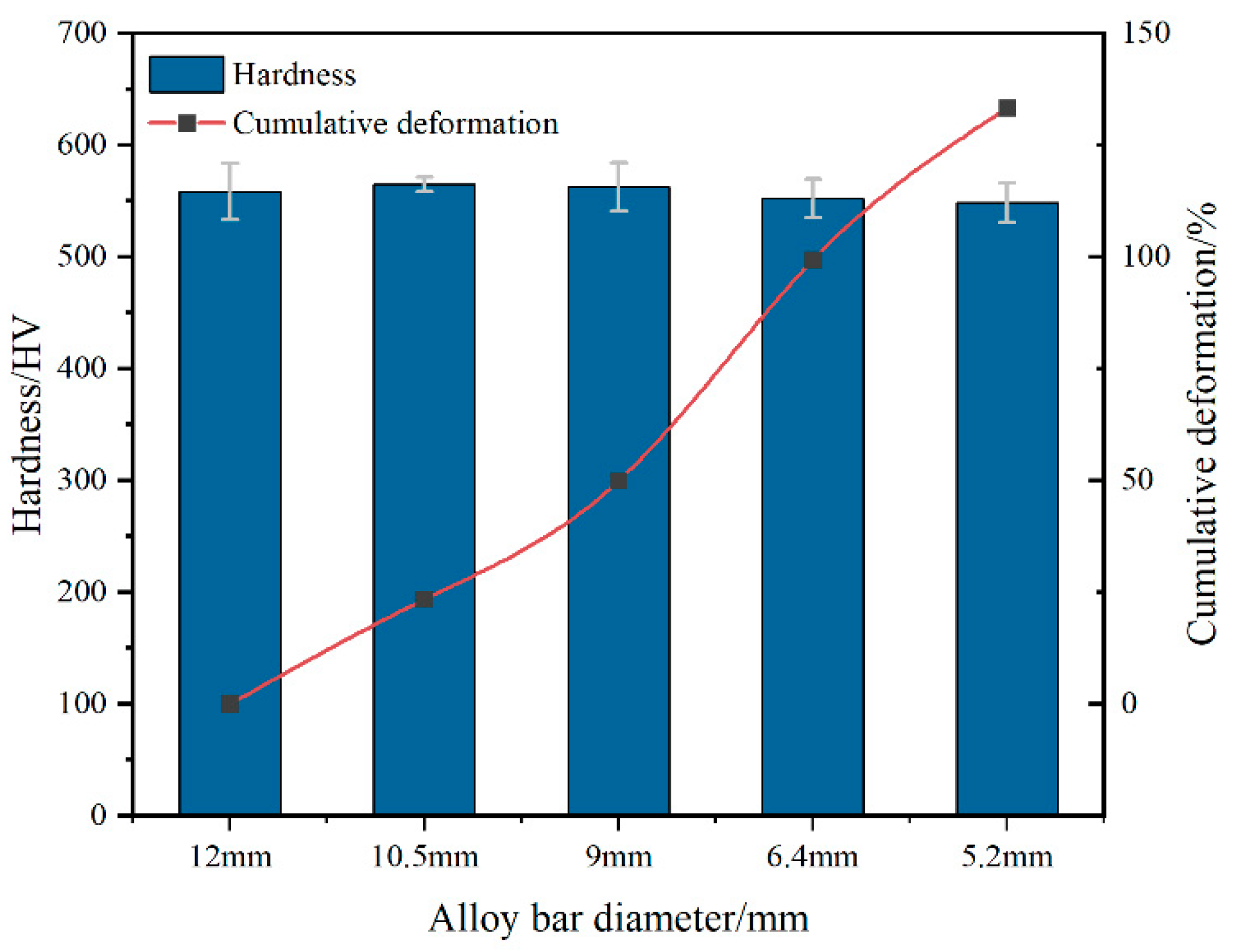

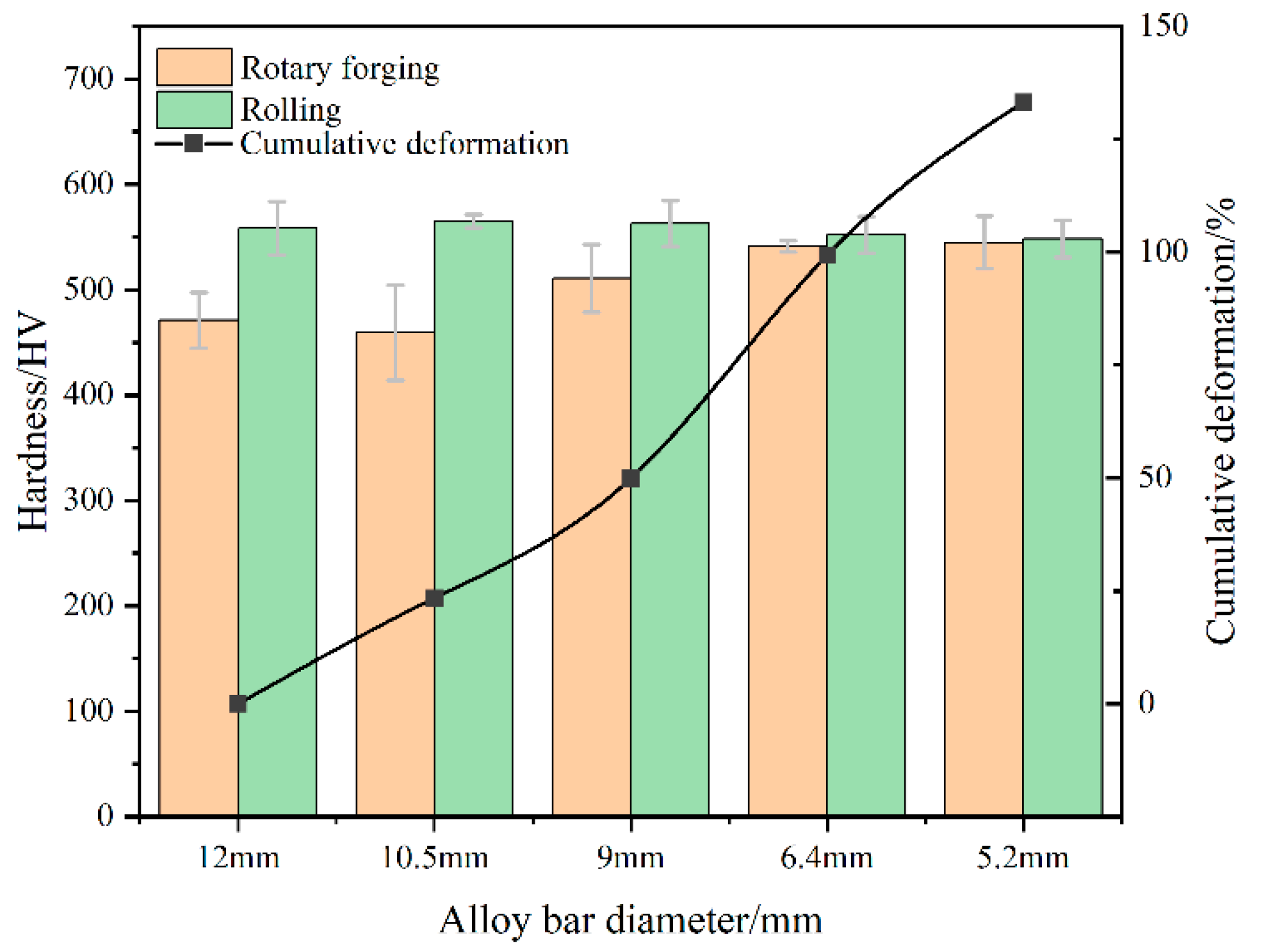

3.3. Hardness Distribution of W-La Alloy Under Rotary Forging and Rolling Processing

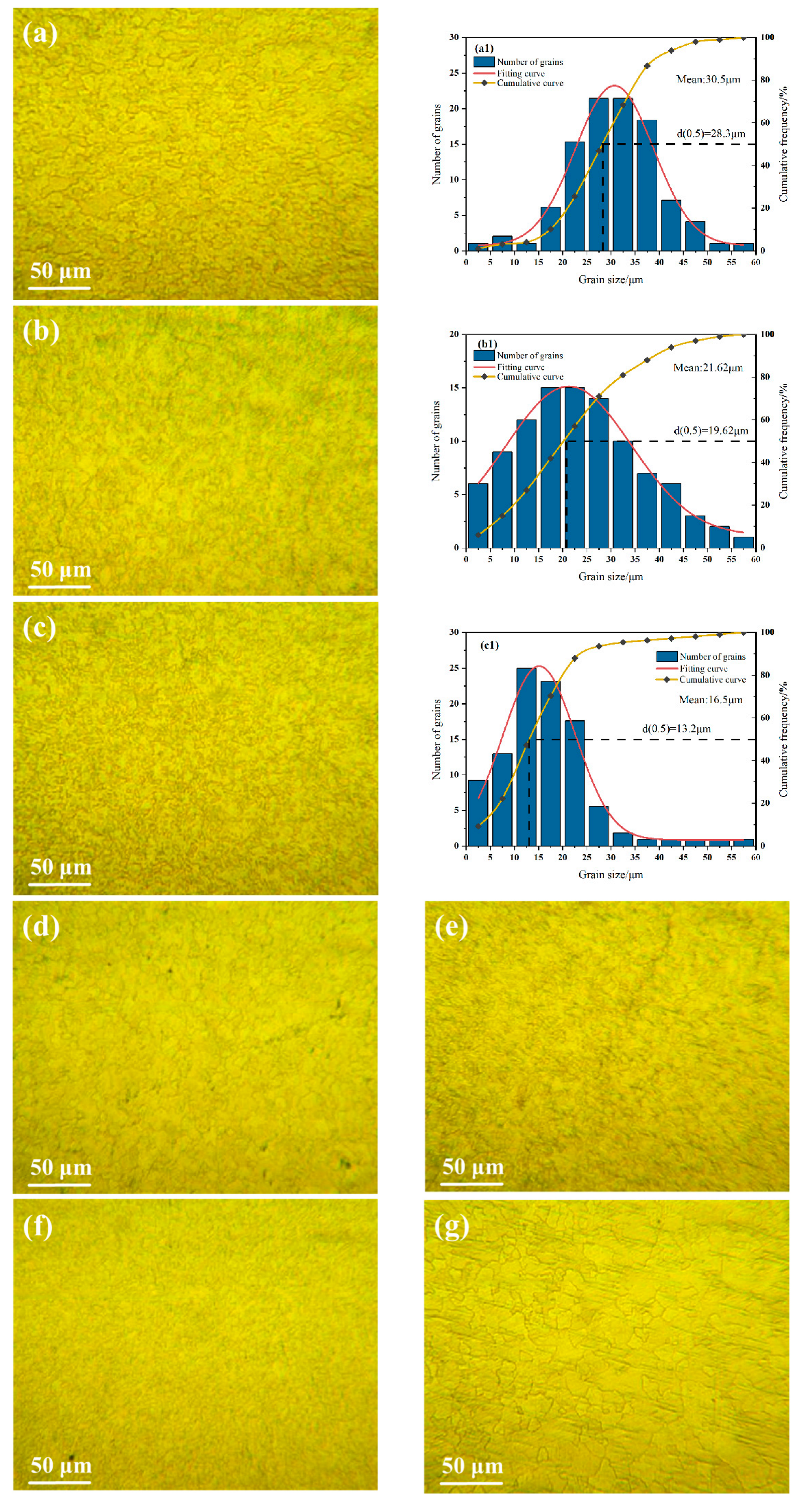

3.4. Evolution of Grain Size of W-La Alloy at Different Annealing Temperatures

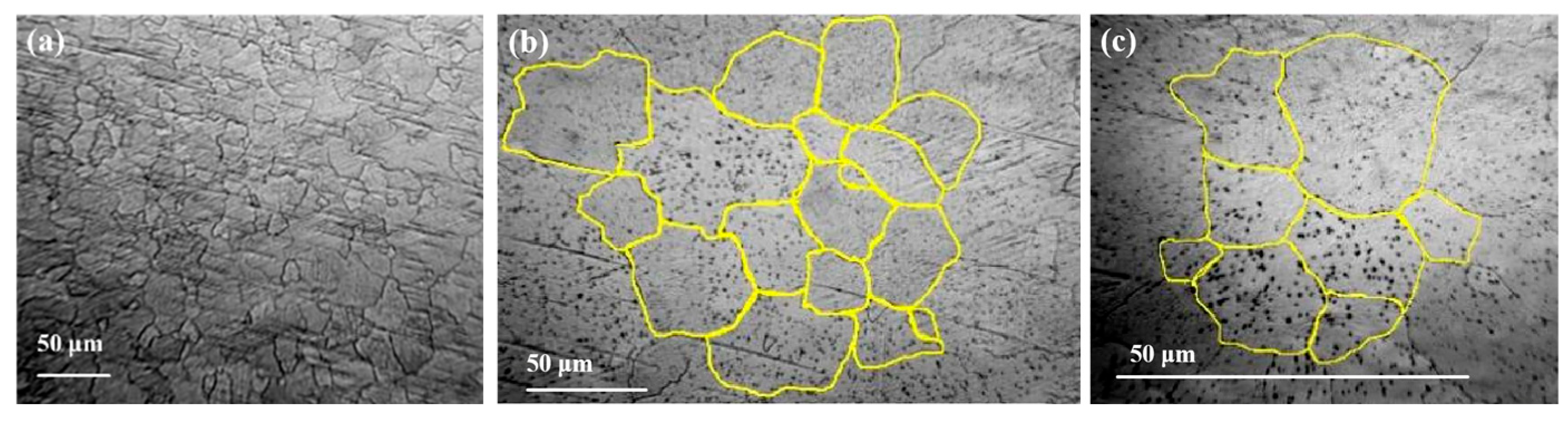

3.5. Effect of Different Annealing Temperatures on Hardness of W-La Alloy

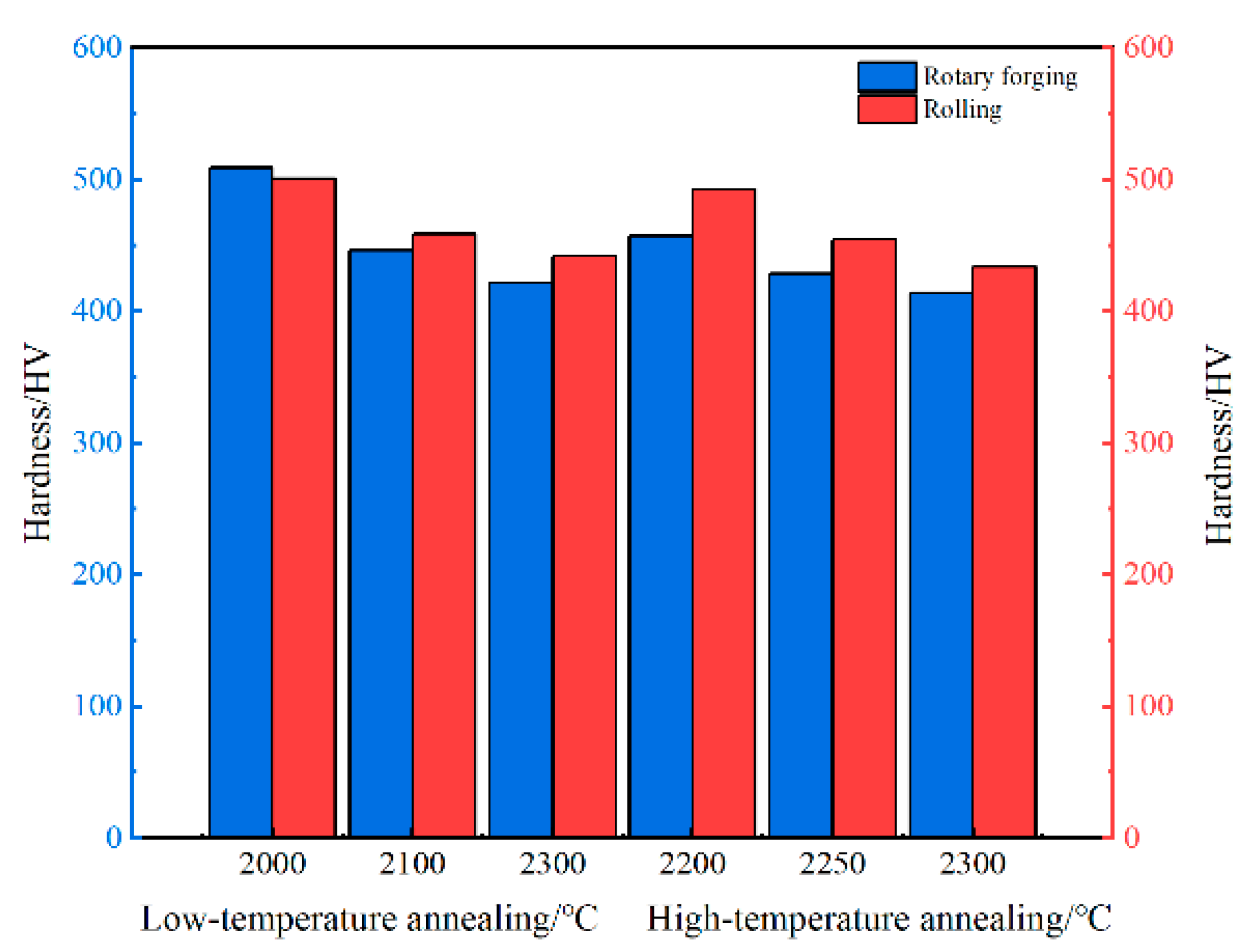

3.6. Density Distribution of W-La Alloy Under Rotary Forging and Rolling Processing

4. Conclusions

- (1)

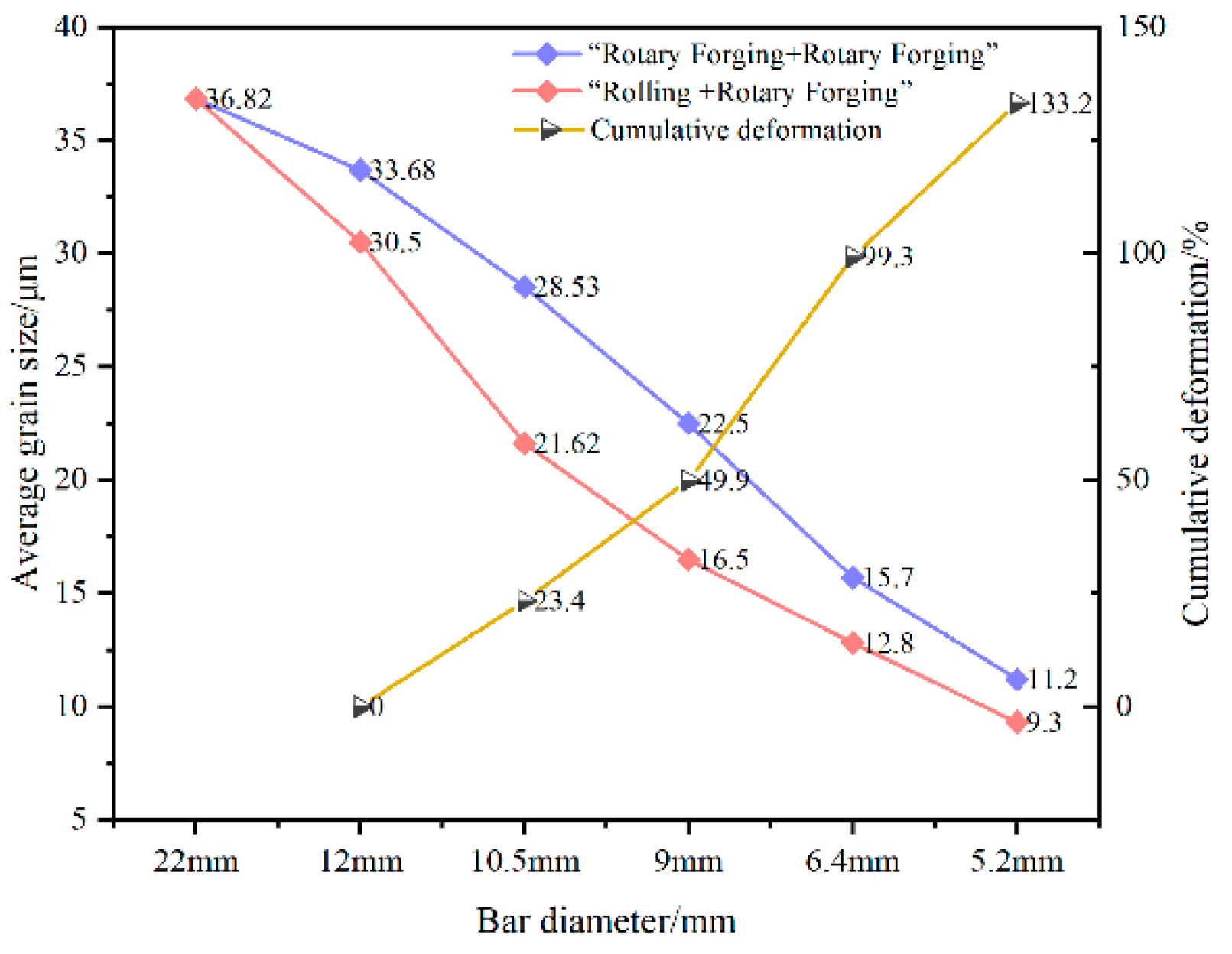

- Research has demonstrated that combining hot rolling with rotary forging effectively refines the grain structure of tungsten alloys. During the processing stage from ø22 mm to ø10.5 mm, hot rolling reduced the average grain size from 36.82 μm to 21.62 μm (a refinement of 41.3%), whereas rotary forging only refined it from 36.82 μm to 28.53 μm (a refinement of 22.5%). At the ø5.2 mm diameter stage, hot rolling further refined the grain size to 9.3 μm, whereas rotary forging achieved 11.2 μm. According to the Hall–Page formula, hot rolling increased yield strength by 97.9 MPa, while rotary forging increased it by 80.5 MPa, indicating hot rolling’s superior strengthening effect.

- (2)

- The hardness of hot-rolled material was significantly higher than that of rotary forging. At the ø5.2 mm diameter stage, hot rolling yielded a hardness of 548.4 HV, whereas rotary forging produced 544.9 HV. Hot rolling substantially enhanced the material’s comprehensive properties through uniform deformation and dynamic recrystallization mechanisms.

- (3)

- The annealing response of the rolled process markedly outperformed that of rotary forging. Following annealing at 2300 °C, the rolled ø9.0 mm bar exhibited a grain count of 2196 per/mm2, surpassing the rotary forged sample’s 1900 per/mm2. After annealing, the grain size distribution became more uniform, with significantly enhanced microstructural compactness. For ø5.2 mm bars annealed at 2300 °C, the rolled grain size reached 2350 per/mm2, meeting the ideal range (2000–2500 per/mm2) for subsequent wire drawing. In contrast, the rotary forging process yielded only 2246 per/mm2, demonstrating superior microstructural controllability of the rolling process after annealing.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, F.; Luo, G.; Li, Q.; Wang, W. Study on the application of tungsten in nuclear fusion reactors. China Tungsten Ind. 2017, 32, 41–48+55. [Google Scholar]

- Ouyang, W. Advantages and applications of tungsten-based high-density alloy technology. Sci. Technol. Outlook 2016, 26, 69. [Google Scholar]

- Xie, K. Application of refractory metal tungsten and molybdenum pipes and research progress of their preparation technology. Cem. Carbide 2018, 35, 219–225. [Google Scholar]

- Miao, Z.; Wu, Z.; Wang, D. Preparation and mechanical properties of rare earth reinforced tungsten alloy for photovoltaic cutting. China Molybdenum Ind. 2023, 47, 57–60. [Google Scholar]

- Puyang, S.A.; Lyu, Y.M.; Nian, F.; Xu, Y.P.; Yang, Z.S.; Zhou, H.S.; Luo, G.-N. Deuterium retention and surface morphology modification in oxidized tungsten exposed to D plasma. Int. J. Hydrogen Energy 2021, 46, 31346–31352. [Google Scholar] [CrossRef]

- Boda, A.; Shenoy, K.T.; Mohan, S. Diffusion, permeation and solubility of hydrogen, deuterium and tritium in crystalline tungsten: First principles DFT simulations. Int. J. Hydrogen Energy 2020, 45, 29095–29109. [Google Scholar] [CrossRef]

- Ueda, Y.; Coenen, J.W.; De Temmerman, G.; Doerner, R.P.; Linke, J.; Philipps, V.; Tsitrone, E. Research status and issues of tungsten plasma facing materials for ITER and beyond. Fusion Eng. Des. 2014, 89, 901–906. [Google Scholar] [CrossRef]

- Stork, D.; Agostini, P.; Boutard, J.L.; Buckthorpe, D.; Diegele, E.; Dudarev, S.L.; Zinkle, S.J. Developing structural, high-heat flux and plasma facing materials for a near-term DEMO fusion power plant: The EU assessment. J. Nucl. Mater. 2014, 455, 277–291. [Google Scholar] [CrossRef]

- Gludovatz, B.; Wurster, S.; Weingärtner, T.; Hoffmann, A.; Pippan, R. Influence of impurities on the fracture behaviour of tungsten. Philos. Mag. 2011, 91, 3006–3020. [Google Scholar] [CrossRef]

- Gumbsch, P. Brittle fracture and the brittle-to-ductile transition of tungsten. J. Nucl. Mater. 2003, 323, 304–312. [Google Scholar] [CrossRef]

- Gludovatz, B.; Wurster, S.; Hoffmann, A.; Pippan, R. Fracture toughness of polycrystalline tungsten alloys. Int. J. Refract. Met. Hard Mater. 2010, 28, 674–678. [Google Scholar] [CrossRef]

- Cheng, G.M.; Xu, W.Z.; Jian, W.W.; Yuan, H.; Tsai, M.H.; Zhu, Y.T.; Zhang, Y.F.; Millett, P.C. Dislocations with edge components in nanocrystalline bcc Mo. J. Mater. Res. 2013, 28, 1820–1826. [Google Scholar] [CrossRef]

- Li, H.; Stefan, W.; Christian, M. Dislocation-core symmetry and slip planes in tungsten alloys: Ab initio calculations and microcantilever bending experiments. Acta Mater. 2012, 60, 748–758. [Google Scholar] [CrossRef]

- Xie, Z.; Liu, R.; Fang, Q.; Zhang, T.; Jiang, Y.; Wang, X.; Liu, C. Microstructure and Mechanical Properties of Nano-Size Zirconium Carbide Dispersion Strengthened Tungsten Alloys Fabricated by Spark Plasma Sintering Method. Plasma Sci. Technol. 2015, 17, 1066–1071. [Google Scholar] [CrossRef]

- Liu, R.; Xie, Z.M.; Hao, T.; Zhou, Y.; Wang, X.P.; Fang, Q.F.; Liu, C.S. Fabricating high performance tungsten alloys through zirconium micro-alloying and nano-sized yttria dispersion strengthening. J. Nucl. Mater. 2014, 451, 35–39. [Google Scholar] [CrossRef]

- Zhang, Y.; Ganeev, A.V.; Wang, J.T.; Jin, Q.L.; Igor, V.A. Observations on the ductile-to-brittle transition in ultrafine-grained tungsten of commercial purity. Mater. Sci. Eng. 2009, 503, 37–40. [Google Scholar] [CrossRef]

- Reiser, J.; Hoffmann, J.; Jäntsch, U.; Klimenkov, M.; Bonk, S.; Bonnekoh, C.; Rieth, M.; Hoffmann, A.; Mrotzek, T. Ductilisation of tungsten (W): On the shift of the brittle-to-ductile transition (BDT) to lower temperatures through cold rolling. Int. J. Refract. Met. Hard Mater. 2016, 54, 351–369. [Google Scholar] [CrossRef]

- Petaccia, M.G.; Gervasoni, J.L. Nano-yttria in oxide dispersion strengthened tungsten under alpha particle irradiation. Nucl. Mater. Energy 2019, 20, 100681. [Google Scholar] [CrossRef]

- Lukas, K.; Dirk, H. A thermodynamically consistent model for elastoplasticity, recovery, recrystallization and grain coarsening. Int. J. Solids Struct. 2018, 152–153, 185–195. [Google Scholar] [CrossRef]

- Wang, Y.J.; Yan, Q.Z. Grain boundary strengthened W-ZrB alloy via freeze-drying technique and spark plasma sintering. Fusion Eng. Des. 2019, 149, 111333. [Google Scholar] [CrossRef]

- Wang, C.J.; Zhang, L.Q.; Wei, S.Z.; Kun, M.P.; Xiao, C.W.; Qing, K.L. Preparation, microstructure, and constitutive equation of W-0.25 wt% Al2O3 alloy. Mater. Sci. Eng. A 2019, 744, 79–85. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Zhou, Z.J.; Zhong, M.; Jun, T.; Lian, Y.Y.; Liu, X. Thermal shock behaviour of fine grained W–Y2O3 materials fabricated via two different manufacturing technologies. J. Nucl. Mater. 2016, 470, 236–243. [Google Scholar] [CrossRef]

- Ren, C.; Fang, Z.Z.; Xu, L.; Jonathan, P.; James, J.; Paramore, D.; Butler, B.G. An investigation of the microstructure and ductility of annealed cold-rolled tungsten. Acta Mater. 2019, 162, 202–213. [Google Scholar] [CrossRef]

- Bonk, S.; Hoffmann, J.; Hoffmann, A.; Reiser, J. Cold rolled tungsten (W) plates and foils: Evolution of the microstructure. Int. J. Refract. Met. Hard Mater. 2016, 60, 92–98. [Google Scholar] [CrossRef]

- Zhao, B.L.; Xia, Y.P.; Zhang, L.F.; Ke, J.G.; Cheng, X.; Xie, Z.M.; Liu, R.; Miao, S.; Hao, T.; Wu, X.B.; et al. Effects of rolling reduction on microstructural evolution and mechanical properties of W-0.5wt%ZrC alloys. Mater. Sci. Eng. 2022, 830, 142310. [Google Scholar] [CrossRef]

- Liu, R.; Xie, Z.M.; Zhang, T.; Fang, Q.F.; Wang, X.P.; Hao, T.; Liu, C.S.; Dai, Y. Mechanical properties and microstructures of W-1%YO microalloyed with Zr. Mater. Sci. Eng. 2016, 660, 19–23. [Google Scholar] [CrossRef]

- Shen, T.L.; Dai, Y. Microstructure and tensile properties of tungsten at elevated temperatures. J. Nucl. Mater. 2016, 468, 348–354. [Google Scholar] [CrossRef]

- Xue, K.; Guo, Y.S.; Shi, J.F. The brittle-to-ductile transition of pure tungsten processed by closed dual equal channel angular pressing process. Mater. Sci. Eng. 2022, 832, 142513. [Google Scholar] [CrossRef]

- Hao, T.; Fan, Z.Q.; Zhang, T. Strength and ductility improvement of ultrafine-grained tungsten produced by equal-channel angular pressing. J. Nucl. Mater. 2014, 455, 595–599. [Google Scholar] [CrossRef]

- Ren, C.; Fang, Z.Z.; Koopman, M. Methods for improving ductility of tungsten—A review. Int. J. Refract. Met. Hard Mater. 2018, 503, 28–31. [Google Scholar] [CrossRef]

- Wei, Q.; Jiao, T.; Ramesh, K.T. Mechanical behaviour and dynamic failure of high-strength ultrafine grained tungsten under uniaxial compression. Acta Mater. 2006, 54, 77–87. [Google Scholar]

- Fan, J.; Du, J.; Cao, J.; Sun, Y.; Zhang, J. Study on the Influence of Deformation and Temperature on the Properties of High-Strength Tungsten Alloy Wire. Micromachines 2025, 16, 922. [Google Scholar] [CrossRef]

- Wen, F.; Zheng, W.; Qiang, S. Effect of thermomechanical processing via rotary swaging on grain boundary character distribution and intergranular corrosion in 304 austenitic stainless steel. J. Mater. Res. Technol. 2022, 19, 2470–2482. [Google Scholar] [CrossRef]

- Kunčická, L.; Macháčková, A.; Lavery, N.P.; Kocich, R.; Cullen, J.C.T.; Hlaváč, L.M. Effect of thermomechanical processing via rotary swaging on properties and residual stress within tungsten heavy alloy. Int. J. Refract. Met. Hard Mater. 2020, 87, 105120. [Google Scholar] [CrossRef]

- Zan, X.; Gu, M.; Wang, K. Recrystallization kinetics of 50% hot-rolled 2% Y2O3 dispersed tungsten. Fusion Eng. Des. 2019, 144, 1–5. [Google Scholar] [CrossRef]

- Zhang, T.; Du, W.Y.; Zhan, C.Y. The high thermal stability induced by a synergistic effect of ZrC nanoparticles and Re solution in W matrix in hot rolled tungsten alloy. Nucl. Eng. Technol. 2022, 54, 2801–2808. [Google Scholar] [CrossRef]

- Yin, X. Production Principle, Technology and Properties of Tungsten Wire; Metallurgical Industry Press: Beijing, China, 1998. [Google Scholar]

- Luo, L.; Zhao, Z.; Yao, G. Research progress on the effect of rolling on the properties of particle reinforced tungsten alloys for fusion devices. Trans. Nonferrous Met. Soc. China 2022, 32, 76–86. [Google Scholar]

- Zhang, X.; Yan, Q.; Lang, S. Preparation of pure tungsten via various rolling methods and their influence on macro-texture and mechanical properties. Mater. Des. 2017, 126, 1–11. [Google Scholar] [CrossRef]

- Kiran, U.R.; Kumar, J.; Kumar, V.; Sankaranarayana, M.; Nageswara Rao, G.V.S.; Nandy, T.K. Effect of cyclic heat treatment and swaging on mechanical properties of the tungsten heavy alloys. Mater. Sci. Eng. A 2016, 656, 256–265. [Google Scholar] [CrossRef]

- He, X.; Deng, Y.; Guo, X. In-situ EBSD tensile revealing the evolution mechanism of high angle grain boundaries in Al–Zn–Mg alloy profile with heterogeneous structures. Mater. Sci. Eng. A 2024, 901, 146539. [Google Scholar] [CrossRef]

| Process Stage | Pressure (MPa) | Holding Time (s) |

|---|---|---|

| Pre-pressing | 50 | 30 |

| Intermediate pressing | 100 | 30 |

| High pressing | 150 | 10 |

| Final pressing | 180 | 60 |

| Process | Processing Stage | Bar Diameter (mm) | Temperature (°C) | Compression Ratio (%) |

|---|---|---|---|---|

| “Rolling + Rotary forging” | Rolling four | 12.0 | 1650 | 70.2 |

| Rolling eight | 10.5 | 1620 | 23.4 | |

| Rolling ten | 9.0 | 1590 | 26.5 | |

| Rotary forging one | 6.4 | 1560 | 49.4 | |

| Rotary forging two | 5.2 | 1520 | 33.9 |

| Process | Processing Stage | Bar Diameter (mm) | Temperature (°C) | Compression Ratio (%) |

|---|---|---|---|---|

| “Rotating forging + Rotating forging” | Initial billet | 14.0 | 1500 | ~ |

| Rotary forging one | 12.0 | 1500 | 26.5 | |

| Rotary forging two | 10.5 | 1450 | 23.4 | |

| Rotary forging three | 9.0 | 1400 | 26.5 | |

| Rotary forging four | 6.4 | 1350 | 49.4 | |

| Rotary forging five | 5.2 | 1300 | 33.9 |

| Bar Diameter | Processing Method | Annealing Temperature (°C) |

|---|---|---|

| ø9.0 mm | Rotary forging | 2000 |

| 2100 | ||

| 2300 | ||

| Rolling | 2000 | |

| 2100 | ||

| 2300 | ||

| ø5.2 mm | “Rotating forging + Rotating forging” | 2200 |

| 2300 | ||

| 2400 | ||

| “Rolling + Rotary forging” | 2200 | |

| 2300 | ||

| 2400 |

| Processing Method | Bar Diameter (mm) | Compression Ratio (%) | Hardness (HV) |

|---|---|---|---|

| “Rotating forging + Rotating forging” | 12 | ~ | 471.0 |

| 10.5 | 23.4 | 459.1 | |

| 9.0 | 26.5 | 510.8 | |

| Annealing 9.0 | ~ | 446.1 | |

| 6.4 | 49.4 | 541.3 | |

| 5.2 | 33.9 | 544.9 | |

| Annealing 5.2 | ~ | 433.5 |

| Processing Method | Processing Stage | Bar Diameter (mm) | Compression Ratio (%) | Hardness (HV) |

|---|---|---|---|---|

| “Rolling + Rotary forging” | Rolling four | 12 | ~ | 558.3 |

| Rolling eight | 10.5 | 23.4 | 565.0 | |

| Rolling ten | 9.0 | 26.5 | 562.7 | |

| Rolling ten annealing | 9.0 | ~ | 467.2 | |

| Rotary forging one | 6.4 | 49.4 | 552.2 | |

| Rotary forging two | 5.2 | 33.9 | 548.4 | |

| Rotary forging two annealing | 5.2 | ~ | 460.4 |

| Bar Diameter | Processing Method | Annealing Temperature (°C) | Grain Size (Pieces/mm2) |

|---|---|---|---|

| ø9.0 mm | Rotary forging | 2000 | 1611 |

| 2100 | 1750 | ||

| 2300 | 1900 | ||

| Rolling | 2000 | 1800 | |

| 2100 | 1950 | ||

| 2300 | 2196 | ||

| ø5.2 mm | “Rotating forging + Rotating forging” | 2200 | 1984 |

| 2300 | 2100 | ||

| 2400 | 2246 | ||

| “Rolling + Rotary forging” | 2200 | 2050 | |

| 2300 | 2180 | ||

| 2400 | 2350 |

| Bar Diameter | Processing Method | Annealing Temperature (°C) | Hardness (HV) |

|---|---|---|---|

| ø9.0 mm | Rotary forging | 2000 | 509.2 |

| 2100 | 446.1 | ||

| 2300 | 422.1 | ||

| Rolling | 2000 | 500.8 | |

| 2100 | 458.9 | ||

| 2300 | 442.0 | ||

| ø5.2 mm | “Rotating forging + Rotating forging” | 2200 | 457.5 |

| 2300 | 428.6 | ||

| 2400 | 414.5 | ||

| “Rolling + Rotary forging” | 2200 | 492.7 | |

| 2300 | 454.6 | ||

| 2400 | 433.9 |

| Bar Diameter (mm) | Processing Method | Compression Ratio (%) | Density (g/cm3) | Relative Density (%) |

|---|---|---|---|---|

| 12.0 | Rotating forging | ~ | 18.67 | 96.5 |

| Rolling | 18.82 | 97.3 | ||

| 10.5 | Rotating forging | 23.4 | 18.70 | 96.6 |

| Rolling | 18.90 | 97.7 | ||

| 9.0 | Rotating forging | 26.5 | 18.77 | 96.9 |

| Rolling | 19.00 | 98.2 | ||

| 6.4 | Rotating forging + Rotating forging | 49.4 | 18.87 | 97.5 |

| Rolling + Rotating forging | 19.15 | 99.0 | ||

| 5.2 | Rotating forging + Rotating forging | 33.9 | 18.89 | 97.6 |

| Rolling + Rotating forging | 19.20 | 99.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, J.; Zhu, T.; Cao, J.; Sun, Y.; Zhang, J. Effect of Hot Rolling on the Microstructure and Properties of Dispersion-Strengthened W-La Alloy. Metals 2025, 15, 1157. https://doi.org/10.3390/met15101157

Fan J, Zhu T, Cao J, Sun Y, Zhang J. Effect of Hot Rolling on the Microstructure and Properties of Dispersion-Strengthened W-La Alloy. Metals. 2025; 15(10):1157. https://doi.org/10.3390/met15101157

Chicago/Turabian StyleFan, Junling, Tianlin Zhu, Jun Cao, Yongzhen Sun, and Junchao Zhang. 2025. "Effect of Hot Rolling on the Microstructure and Properties of Dispersion-Strengthened W-La Alloy" Metals 15, no. 10: 1157. https://doi.org/10.3390/met15101157

APA StyleFan, J., Zhu, T., Cao, J., Sun, Y., & Zhang, J. (2025). Effect of Hot Rolling on the Microstructure and Properties of Dispersion-Strengthened W-La Alloy. Metals, 15(10), 1157. https://doi.org/10.3390/met15101157