Formability Assessment Based on Q-Value for Optimizing the Deep Drawing Process of Automotive Parts Made from Aluminum Alloys Sheet

Abstract

1. Introduction

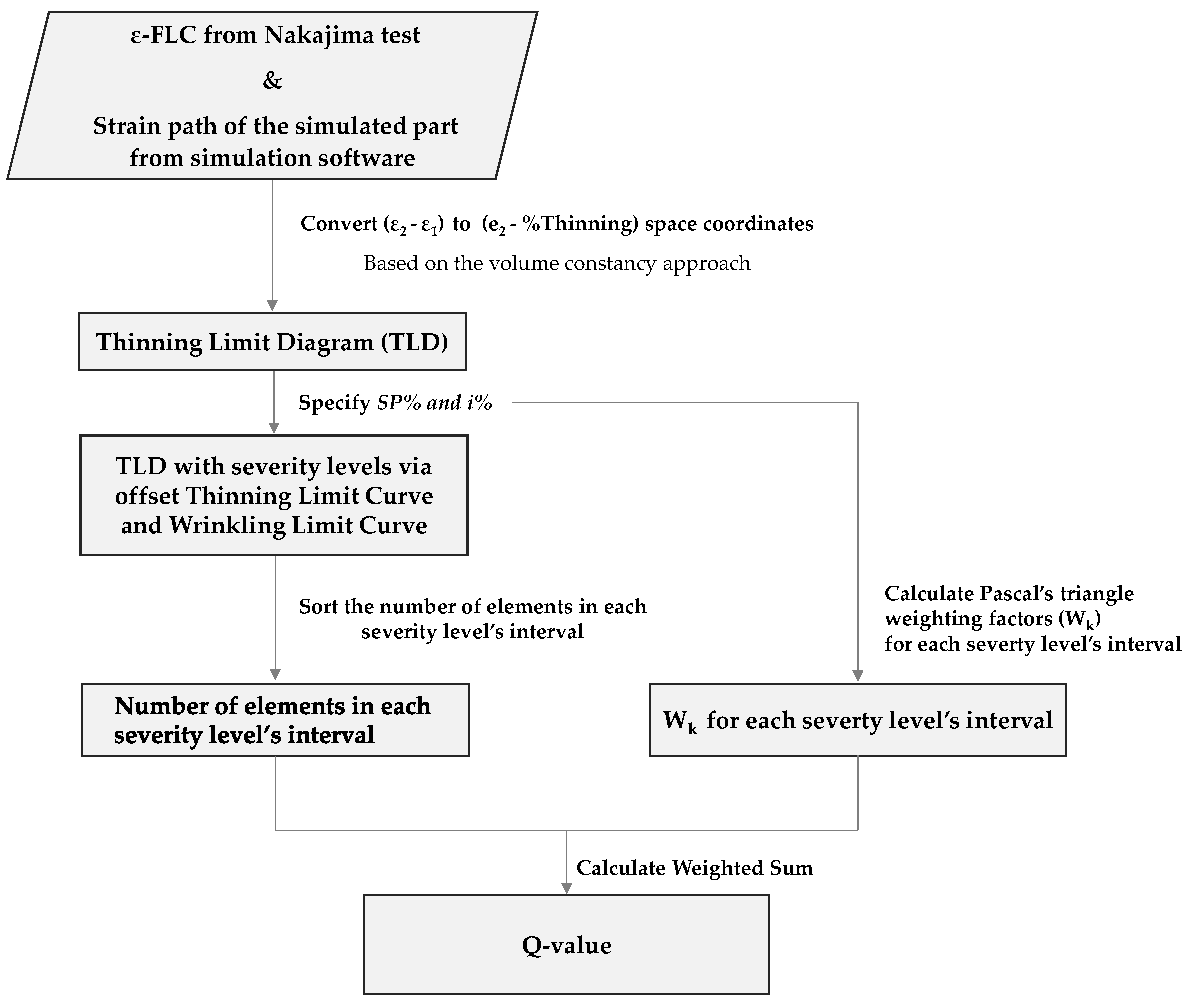

2. Quantitative Evaluation of Formability Using Thinning Limit Diagrams and Pascal’s Triangle Weighting Factors

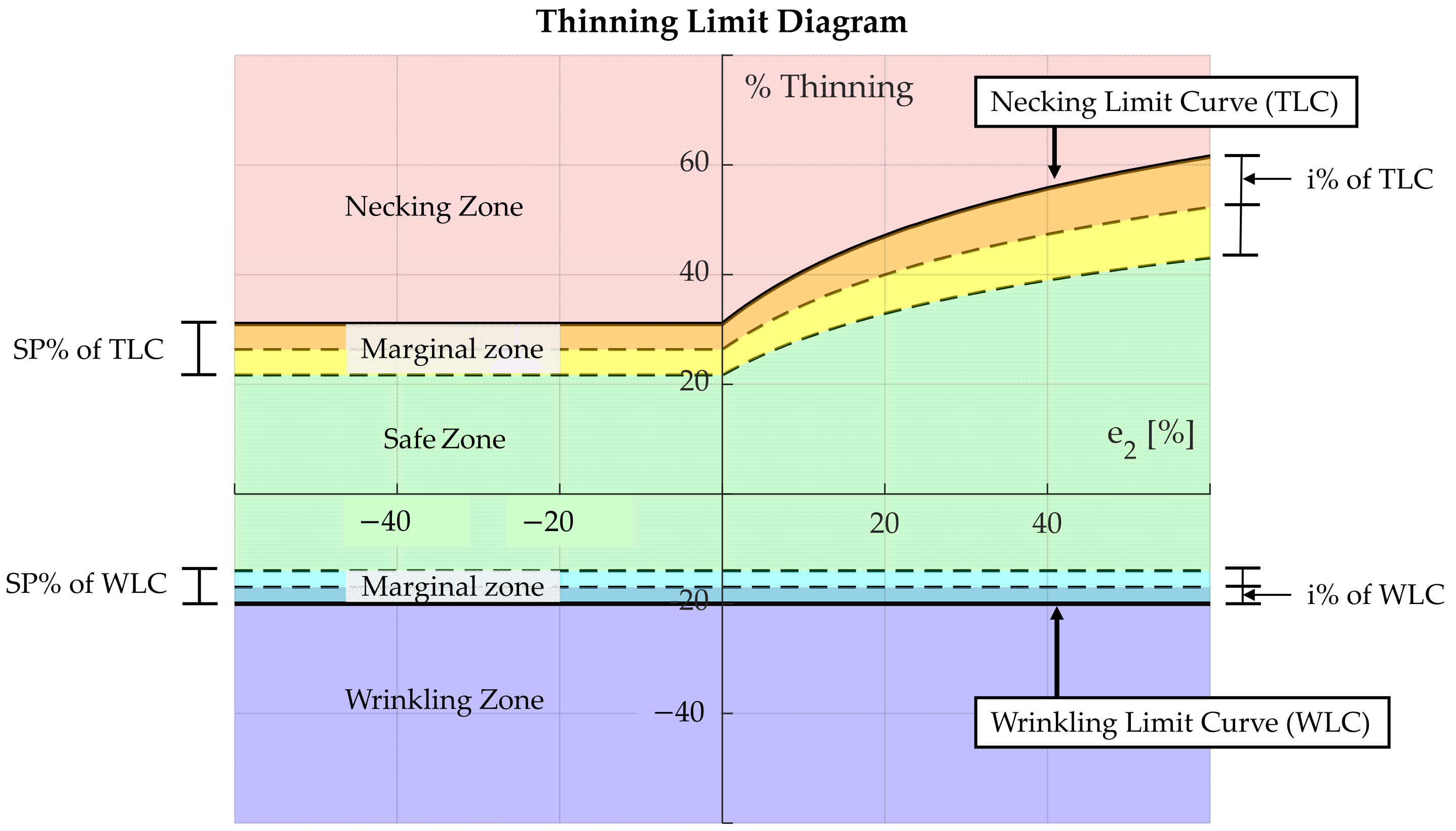

2.1. Thinning Limit Diagram

2.2. Thinning Limit Diagram with Severity Levels via Offset Limit Curves

2.3. Formability Quantifier: Q-Value and Its Calculation

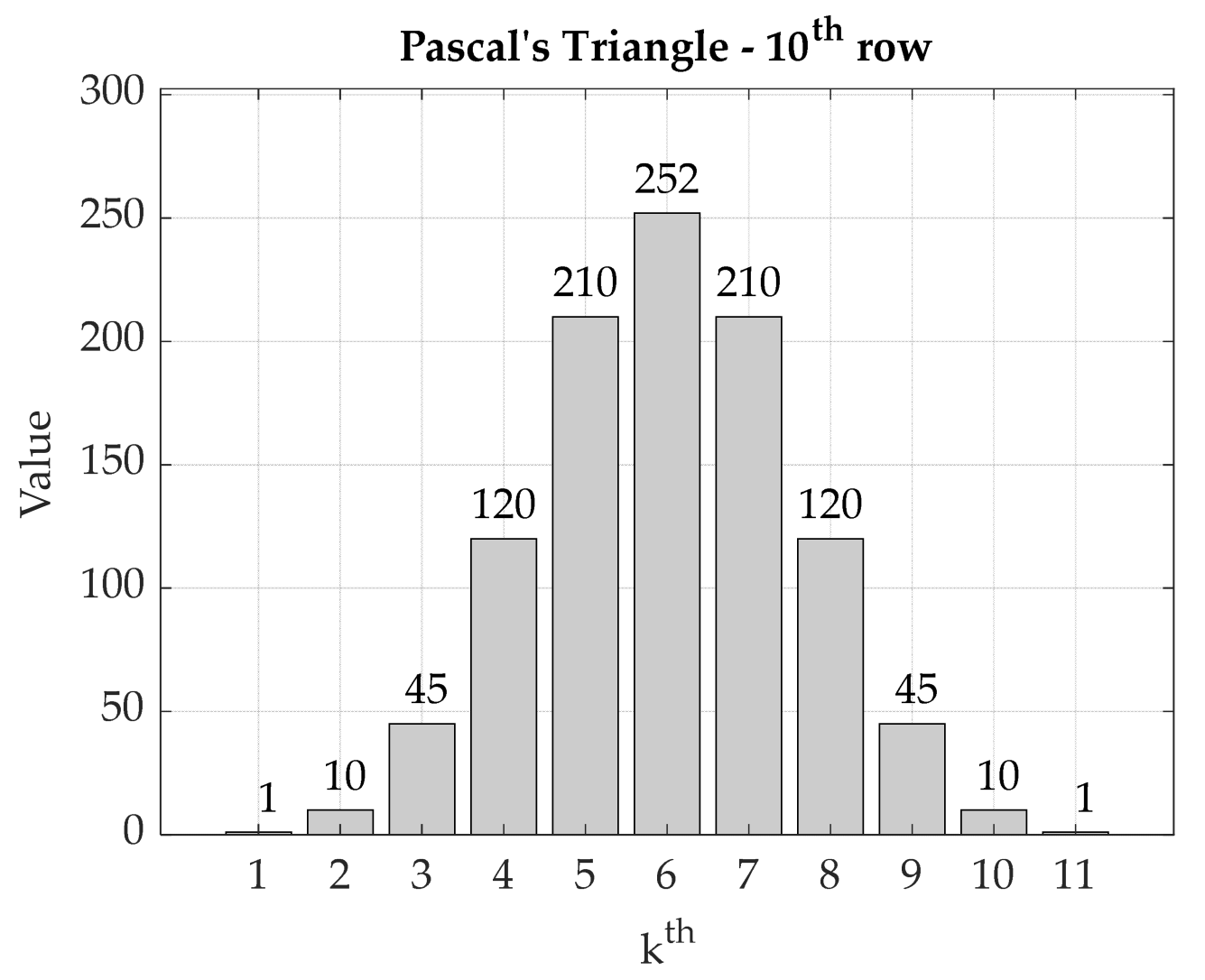

Weighting Factors: Pascal’s Triangle Number

3. Methodology

3.1. Material and Mechanical Properties

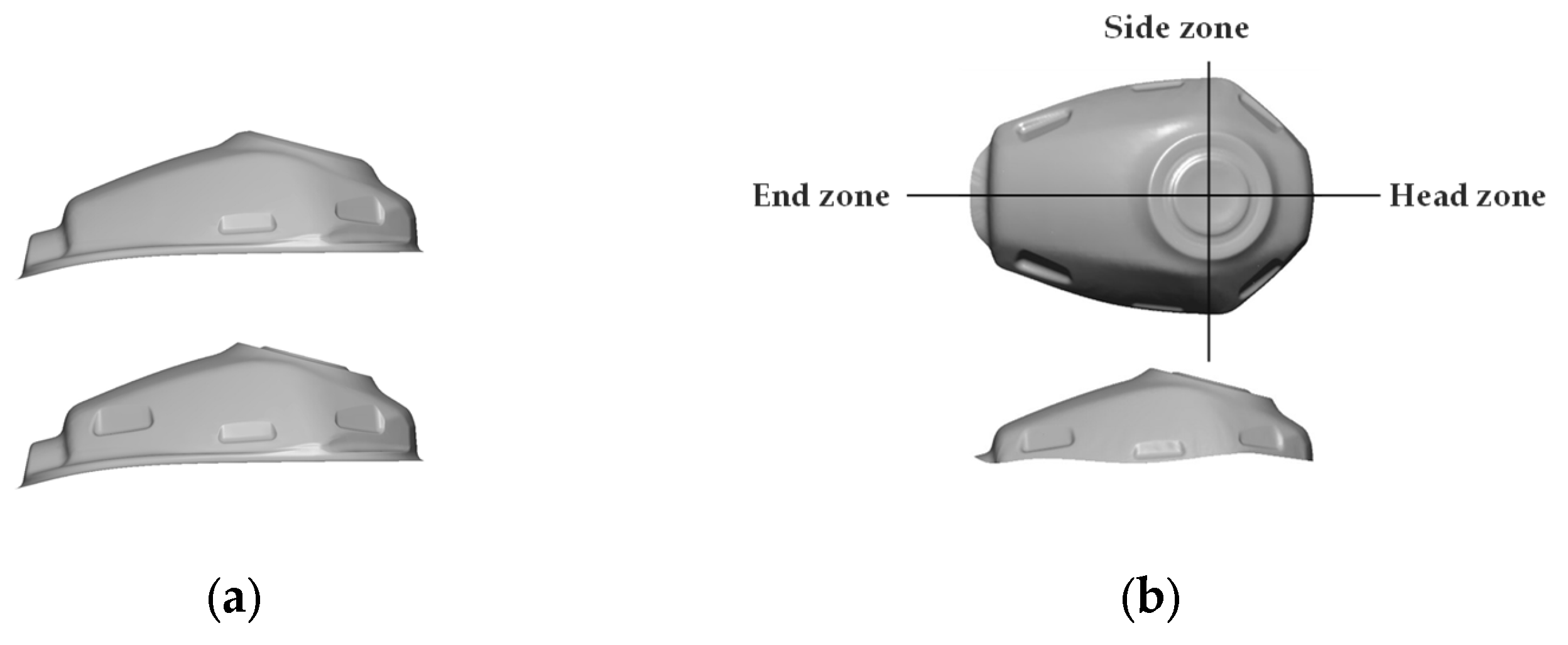

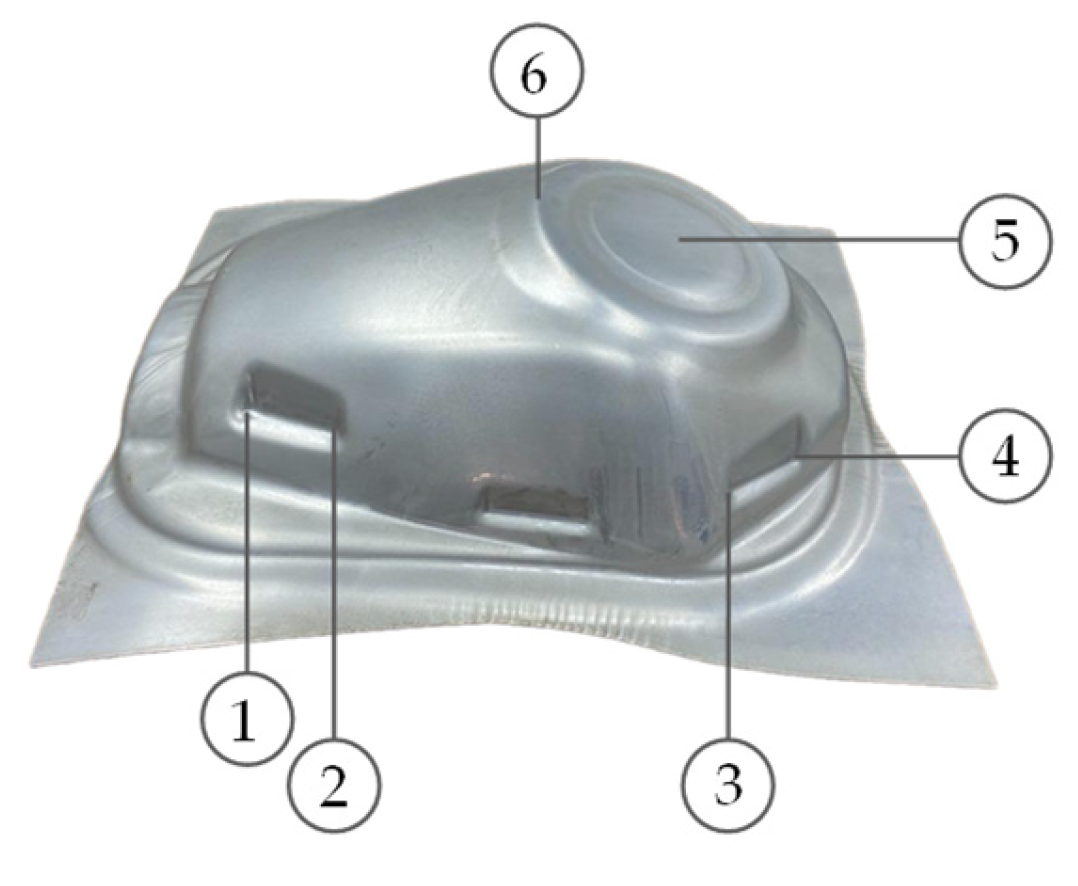

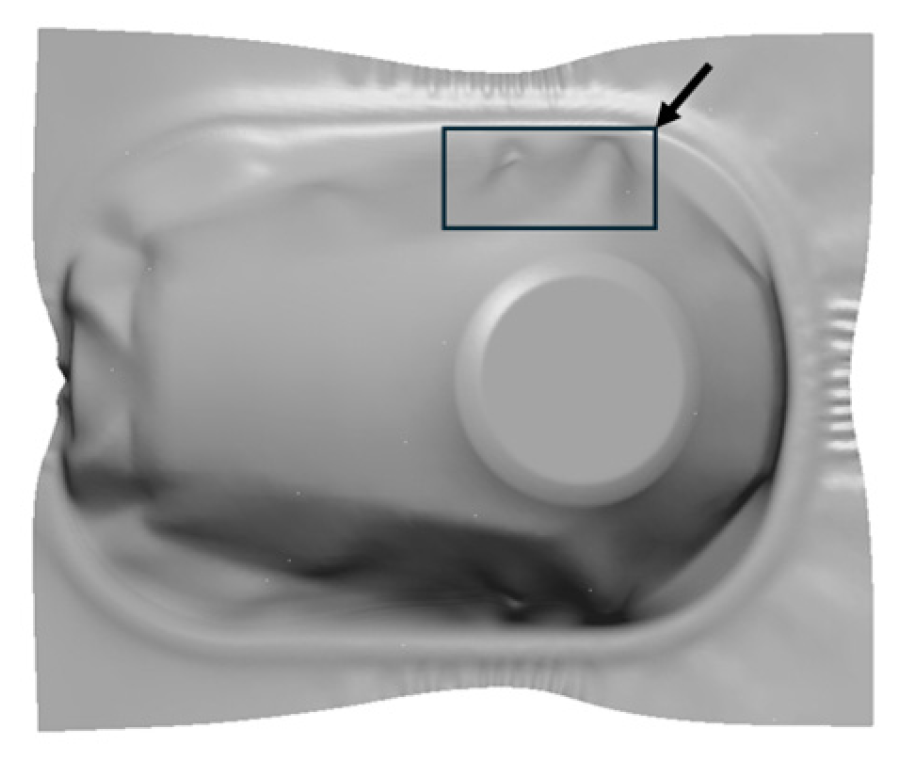

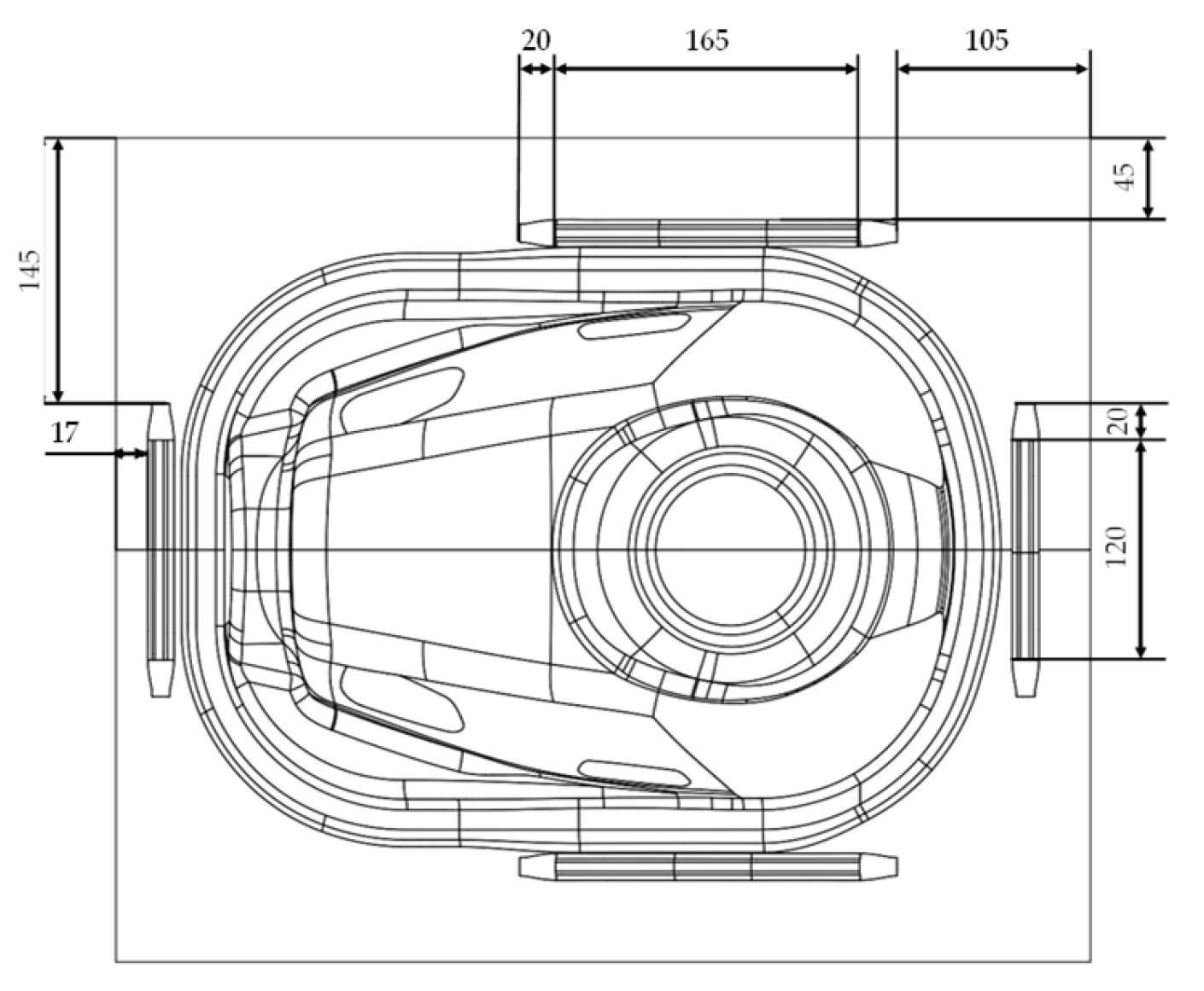

3.2. The Studied Part

3.3. Methods

- (1)

- Material Model Validation (Pre-Study): to validate and select the most accurate material model for the finite element simulation under baseline conditions.

- (2)

- An investigation of a series of process parameters is conducted within the simulation software. For each condition explored in the second stage, the resulting part’s formability is evaluated using the Q-value, and the results are analyzed.

- (3)

- The simulated condition that demonstrates the best formability is then selected for experimental validation to confirm the simulation results and the effectiveness of the formability assessment.

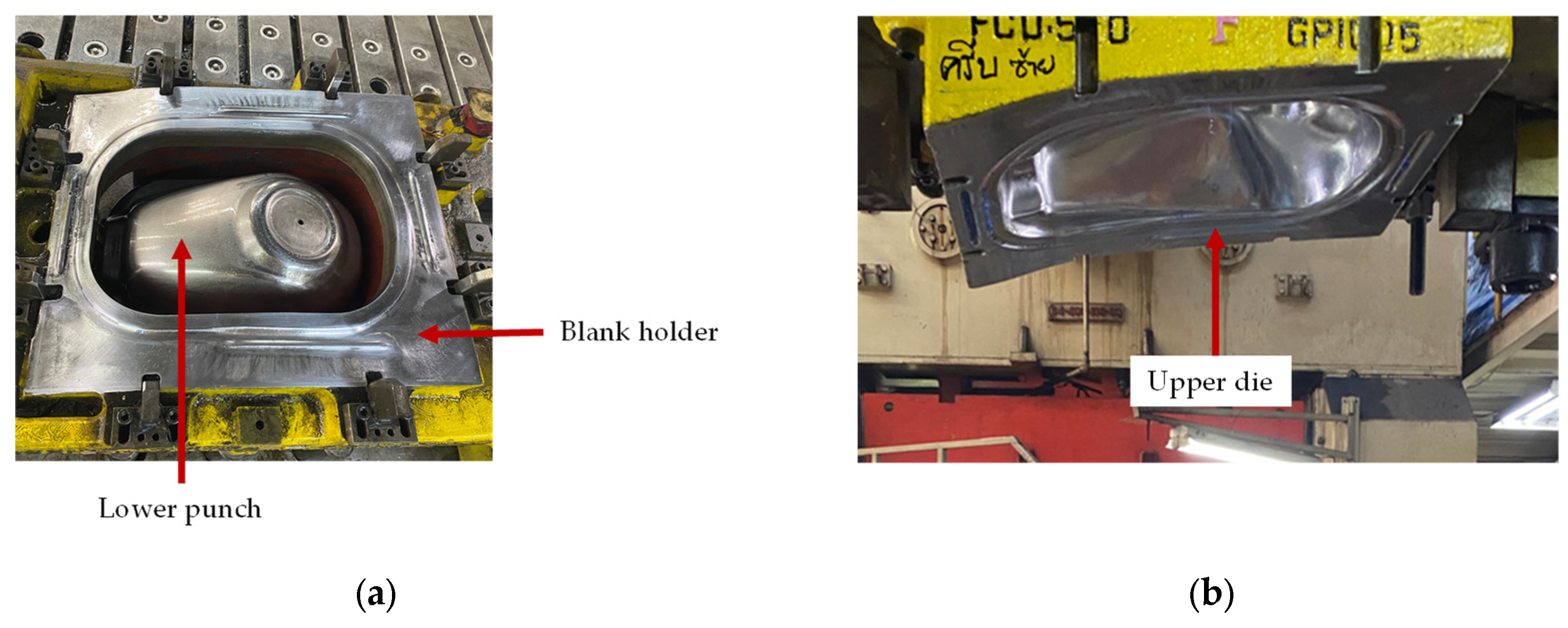

3.3.1. Simulation Setup

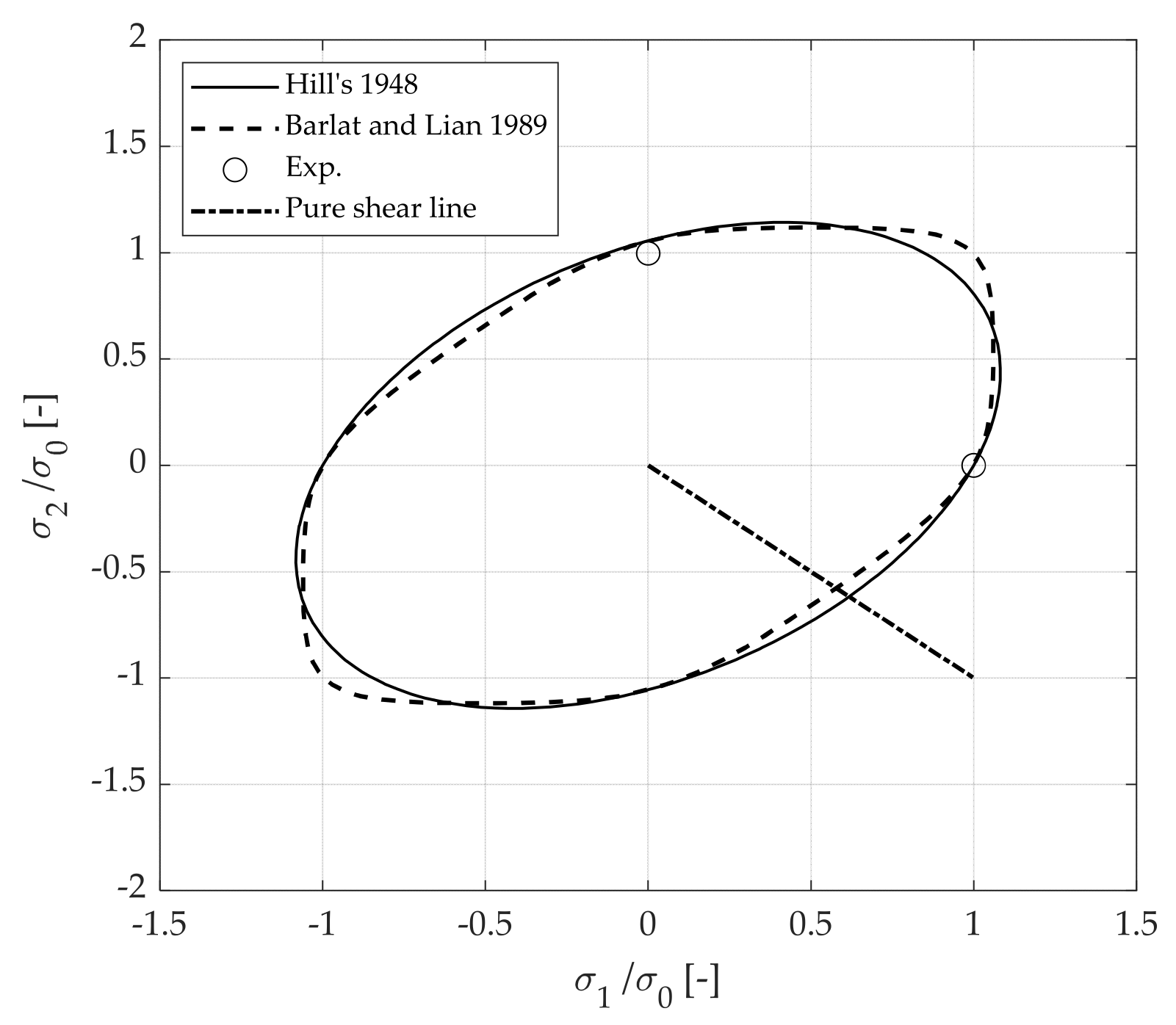

- 1.

- Hill’s 1948 yield criterion [48]

- 2.

- Barlat and Lian 1989 yield criterion [49]

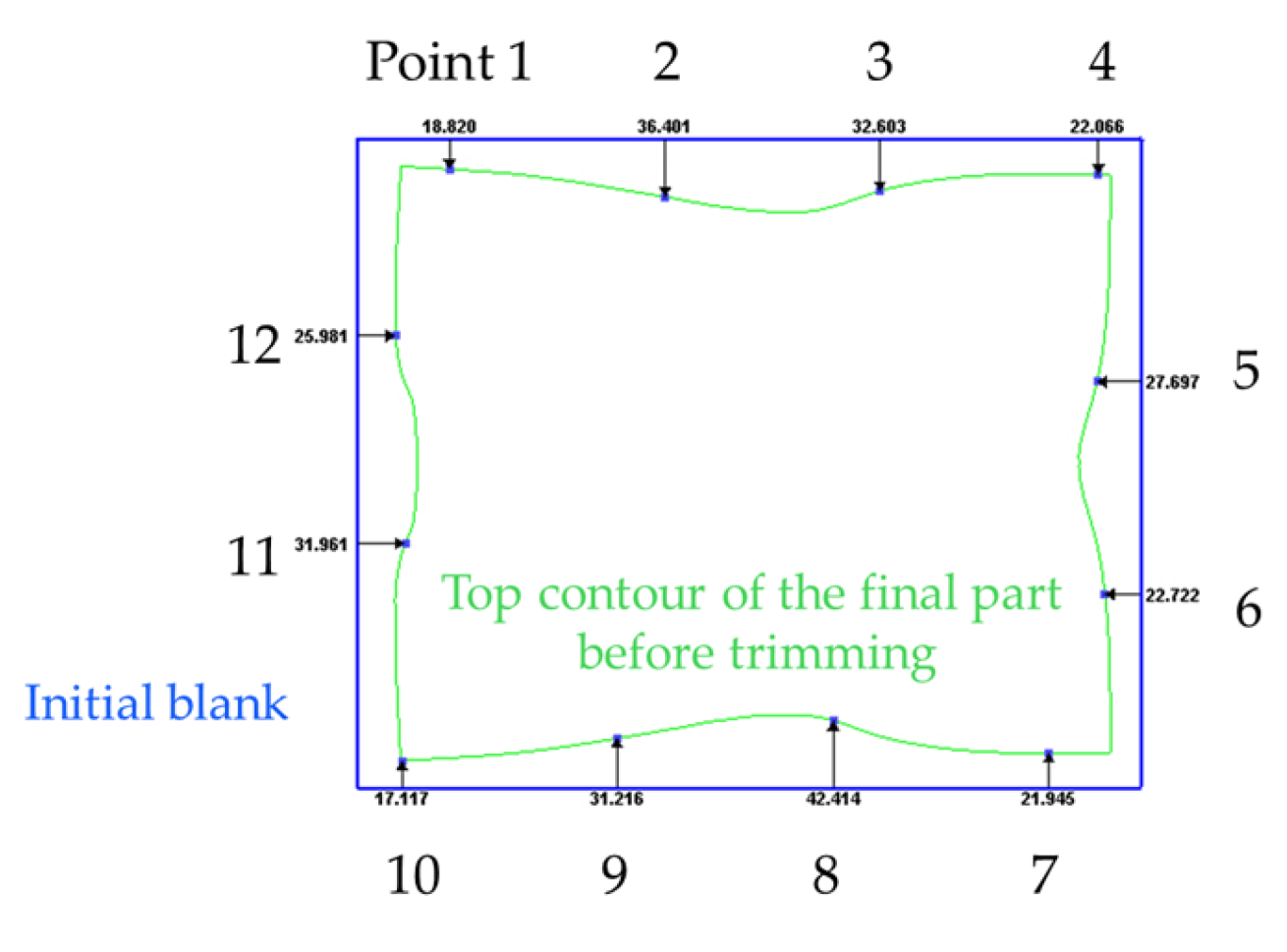

3.3.2. Baseline Condition and Model Validation

3.3.3. Varying Blank Size Conditions

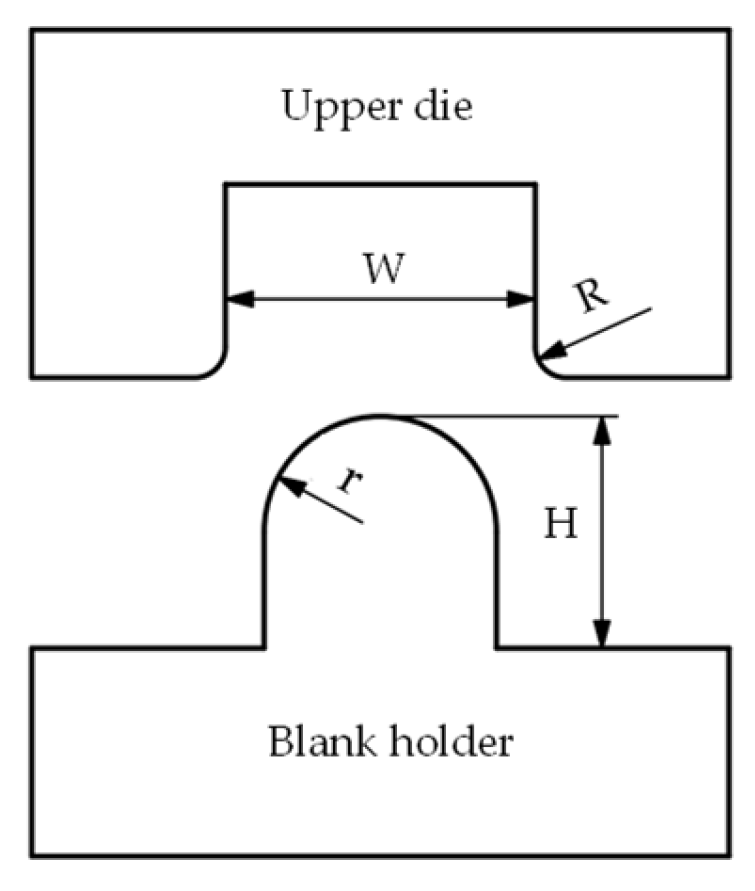

3.3.4. Drawbead Shape and Dimensions

3.3.5. Weight Factor Determination for Formability Assessment

4. Results and Discussion

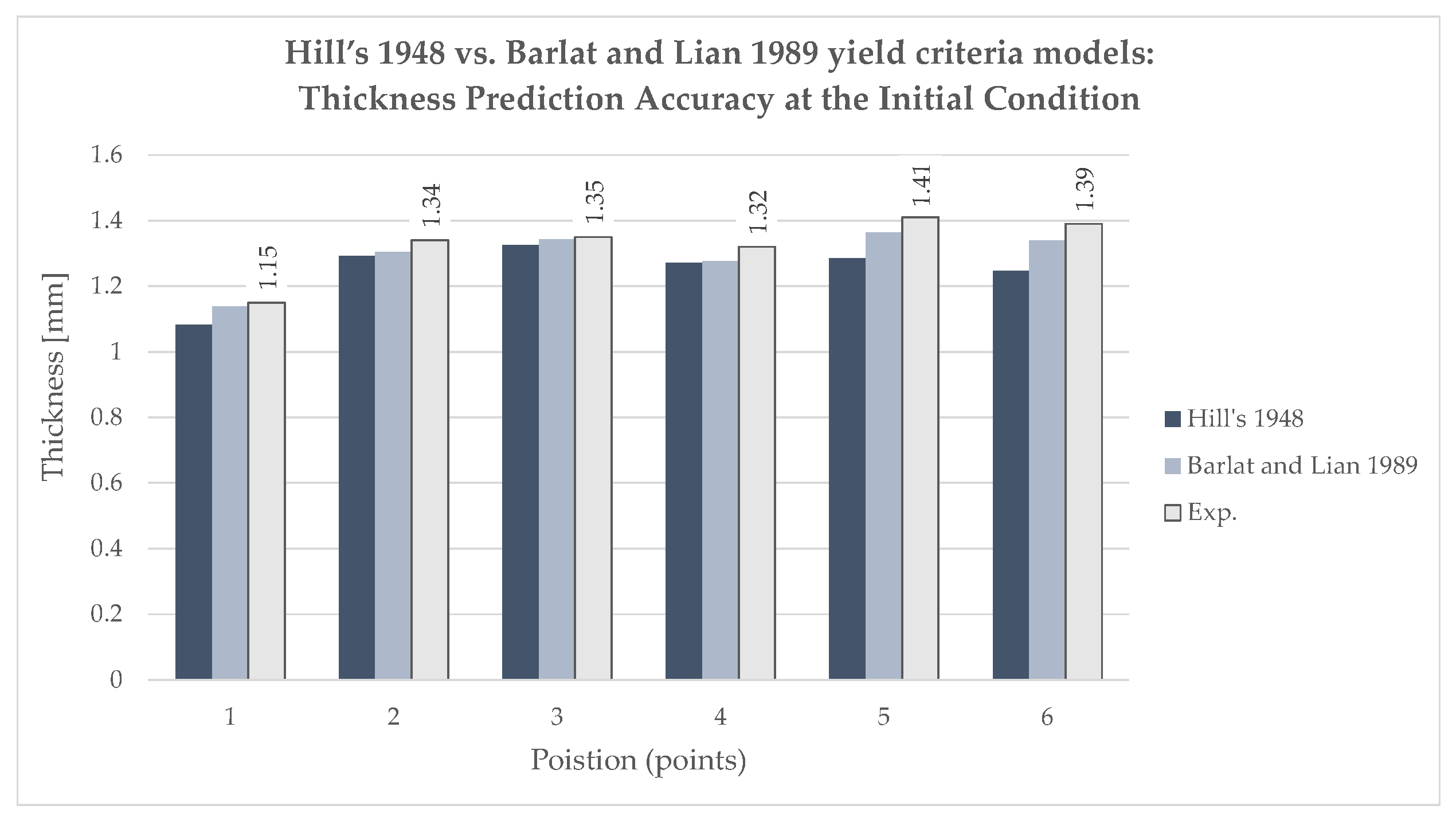

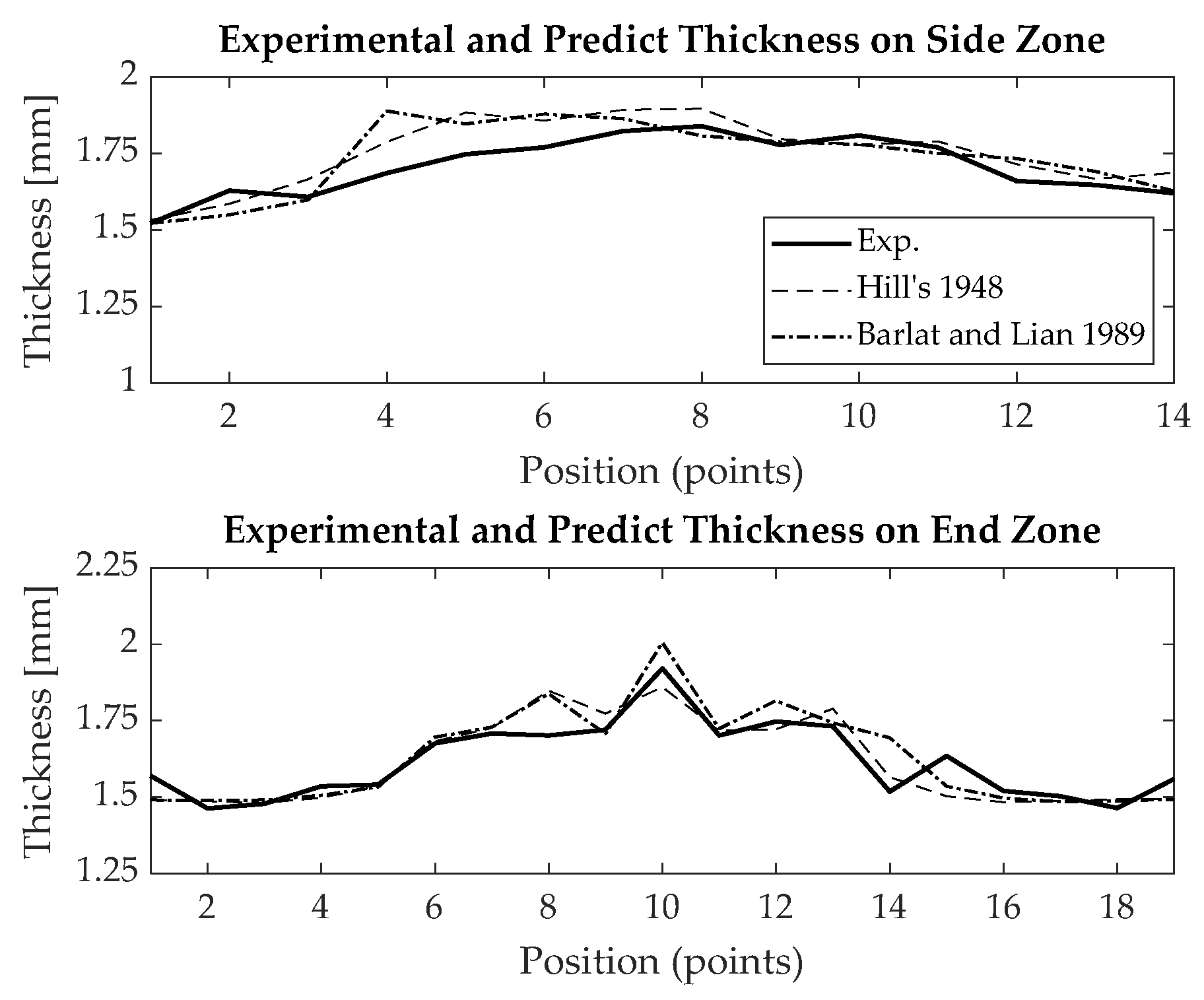

4.1. Material’s Model Validation

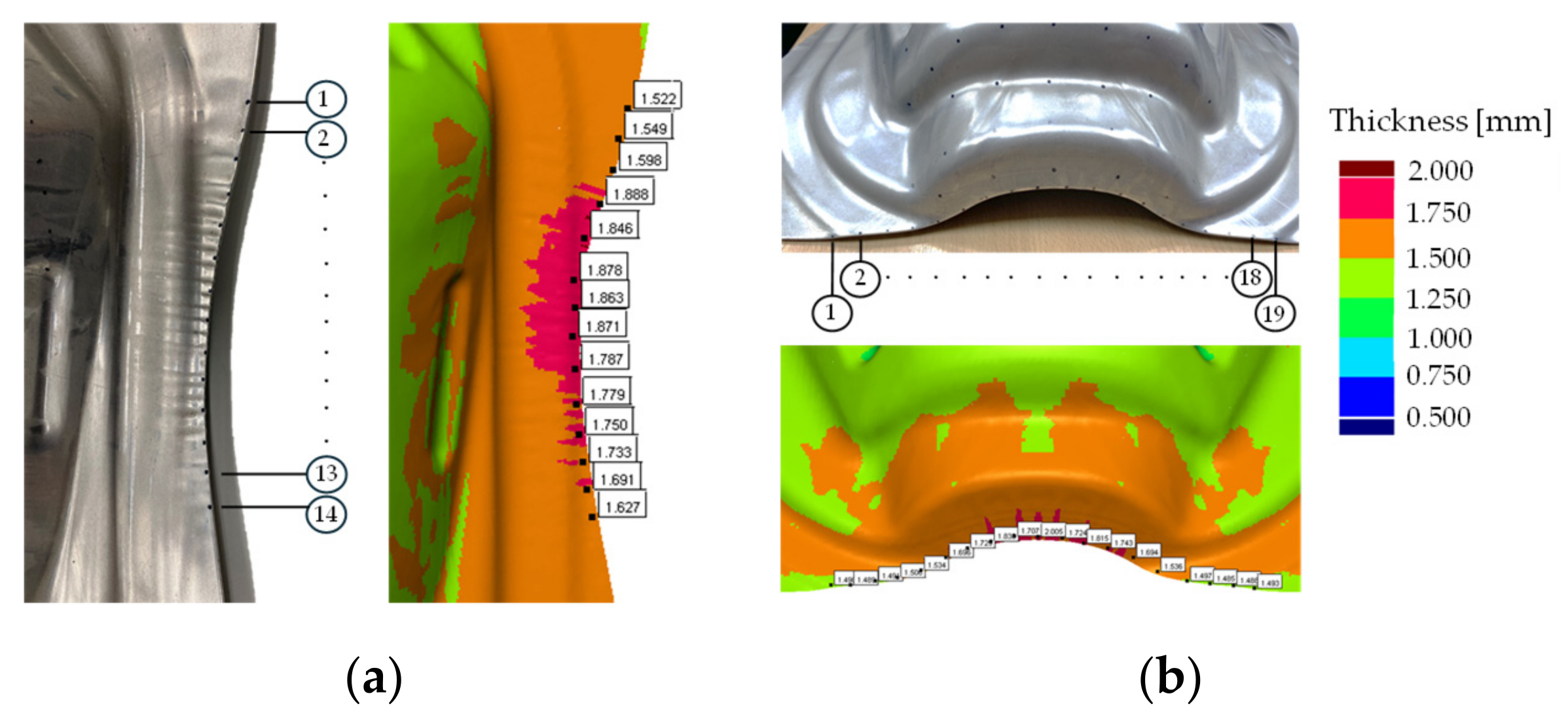

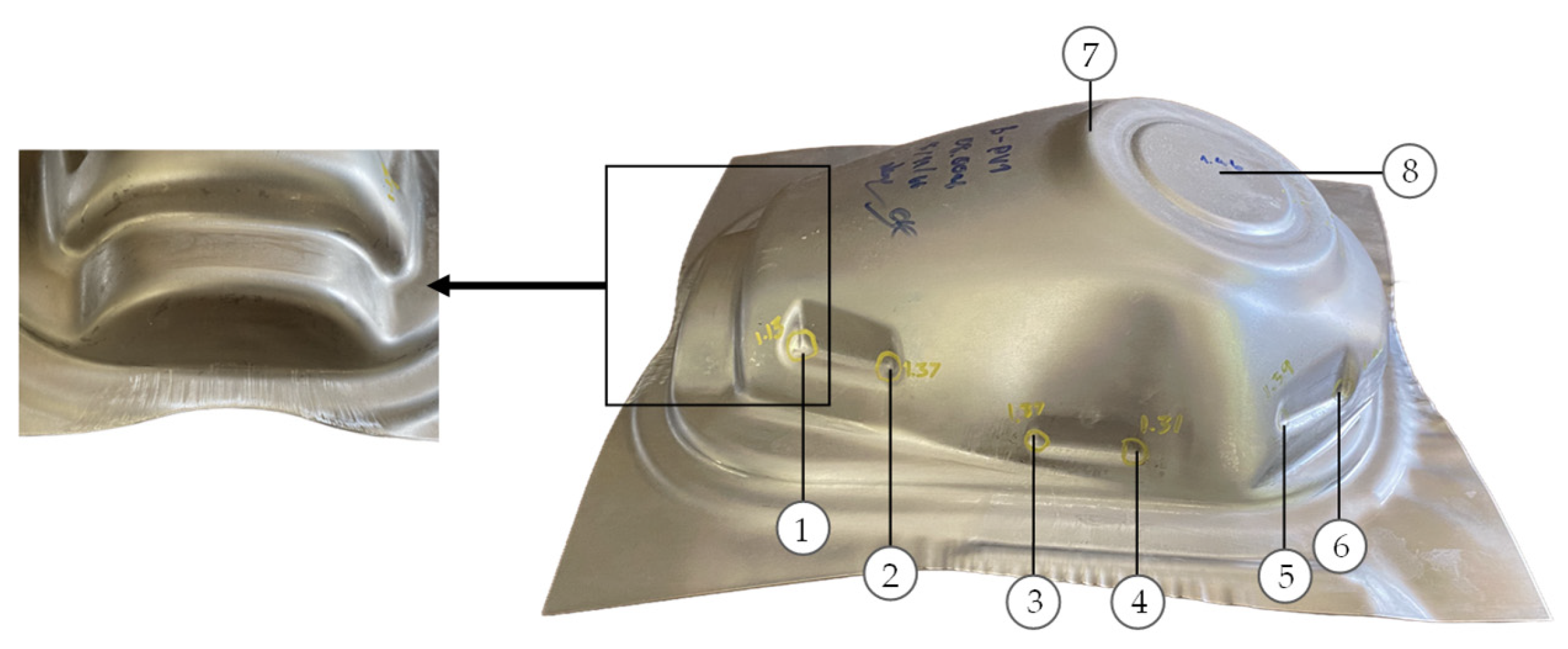

4.1.1. Comparison of Simulation and Experimental Measured Thickness at Baseline Condition

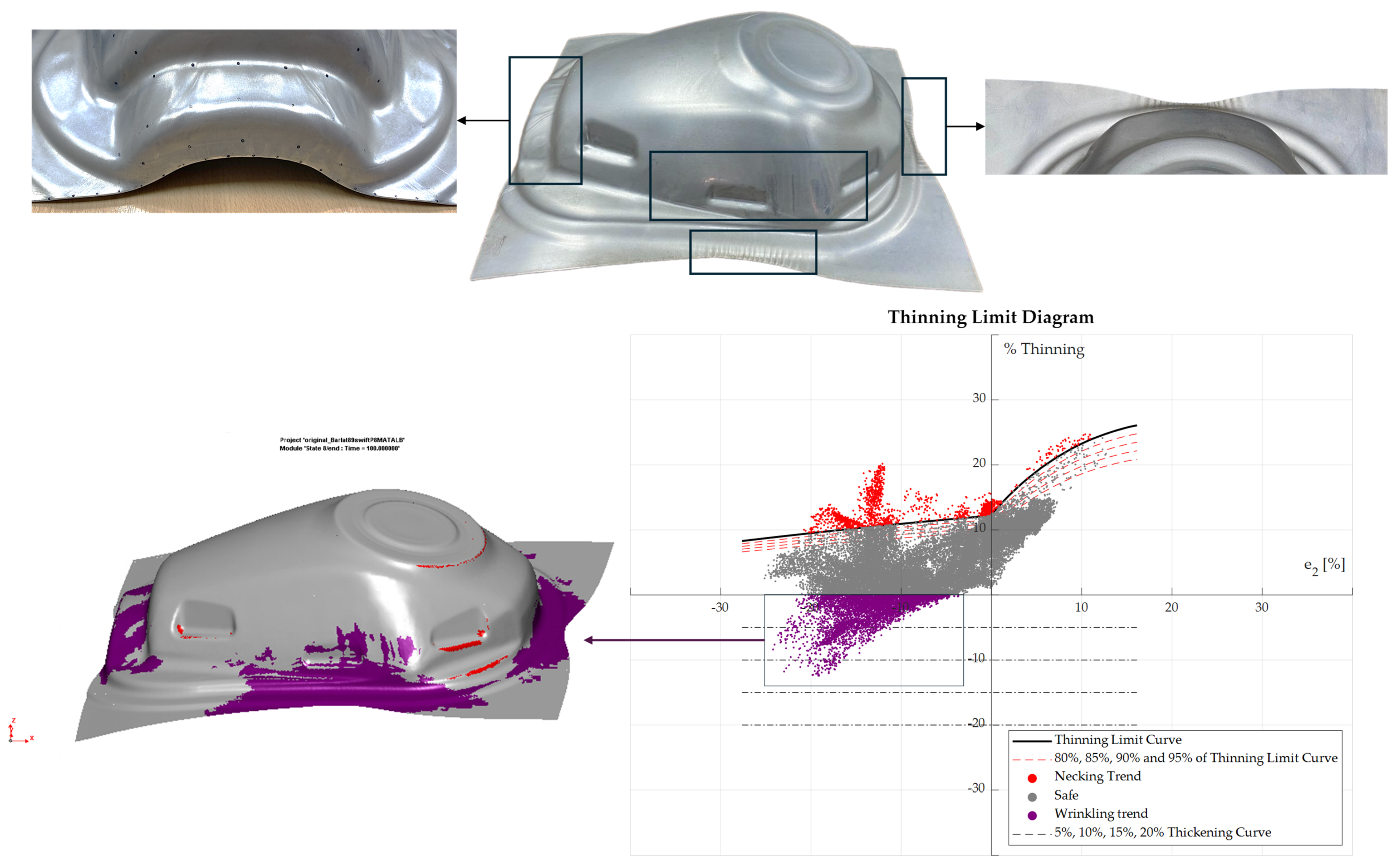

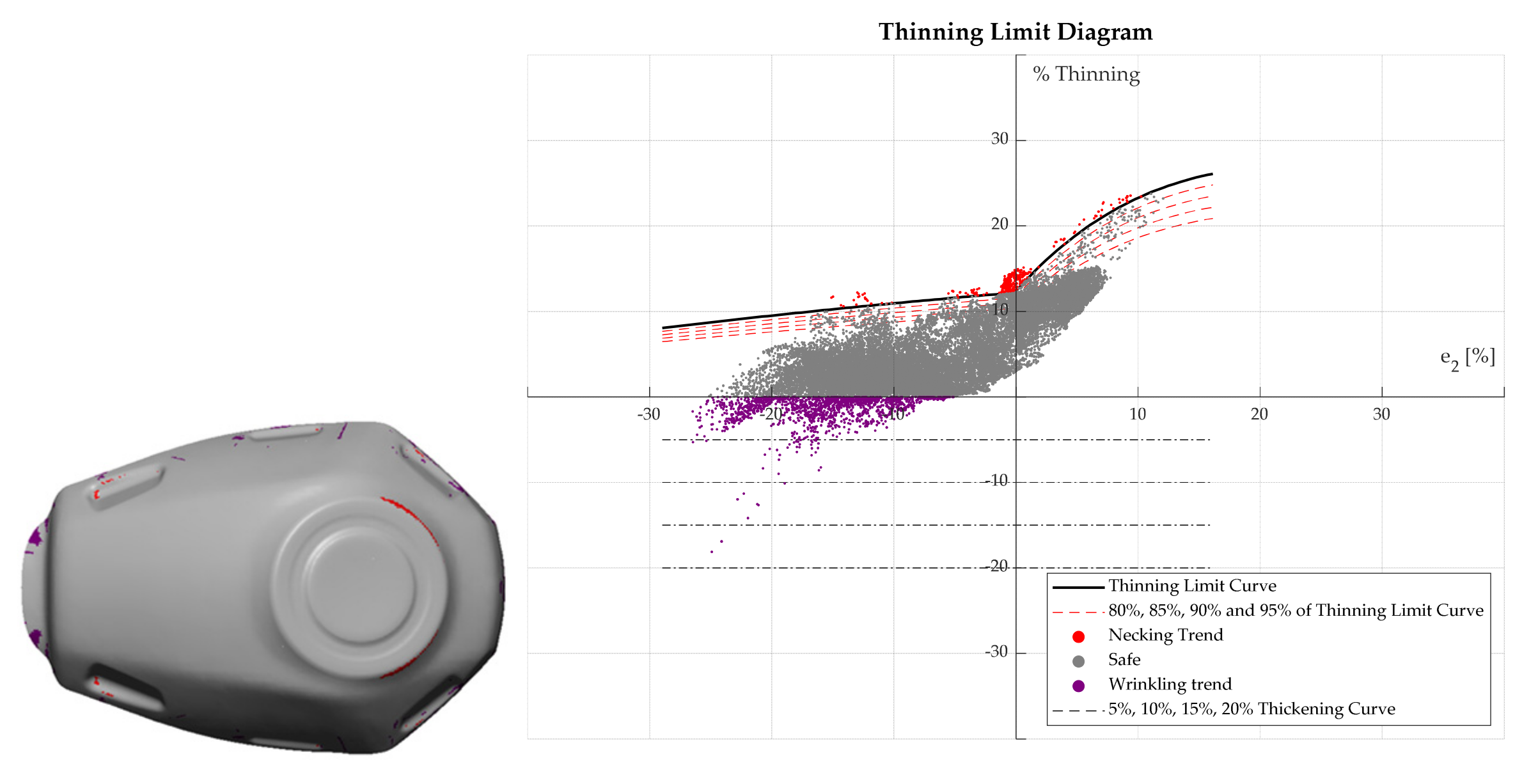

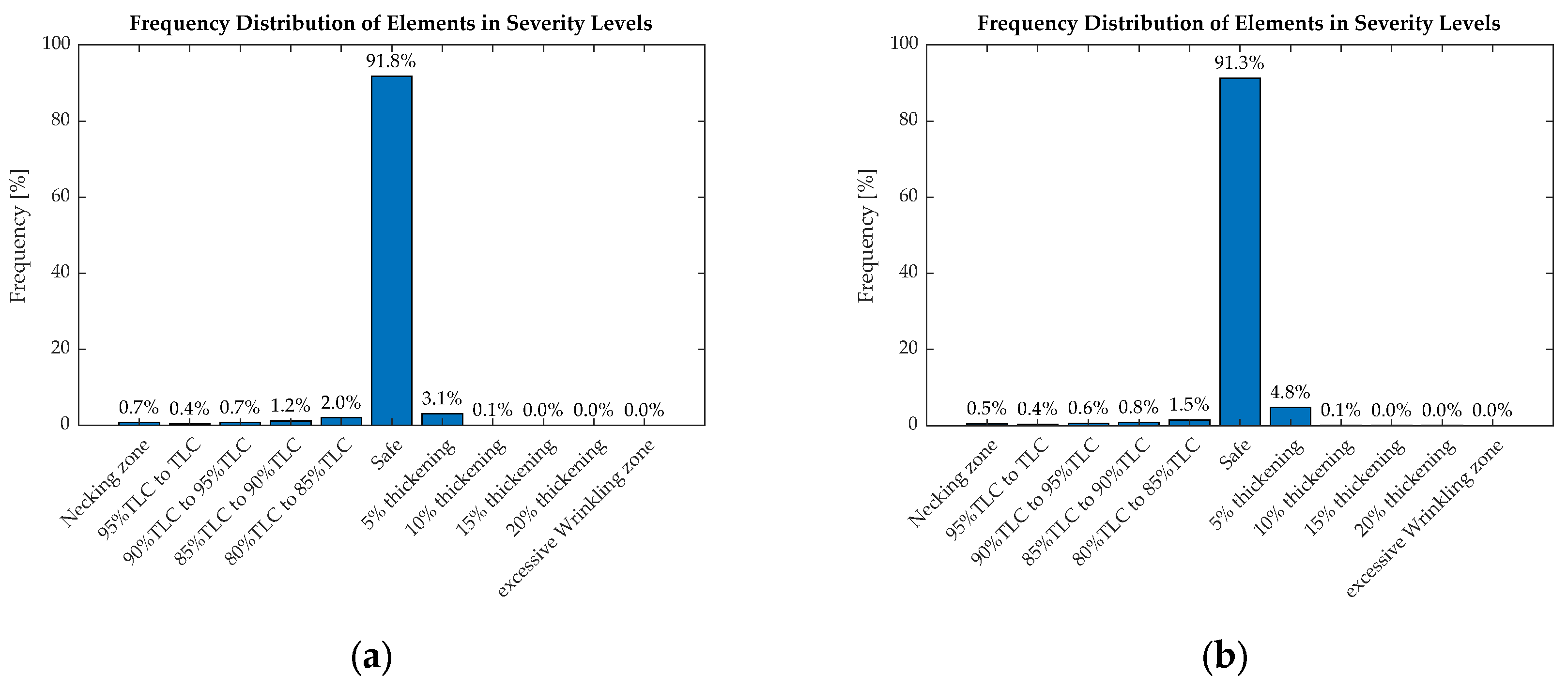

4.1.2. Accuracy of Formability Prediction Using the Thinning Limit Diagram

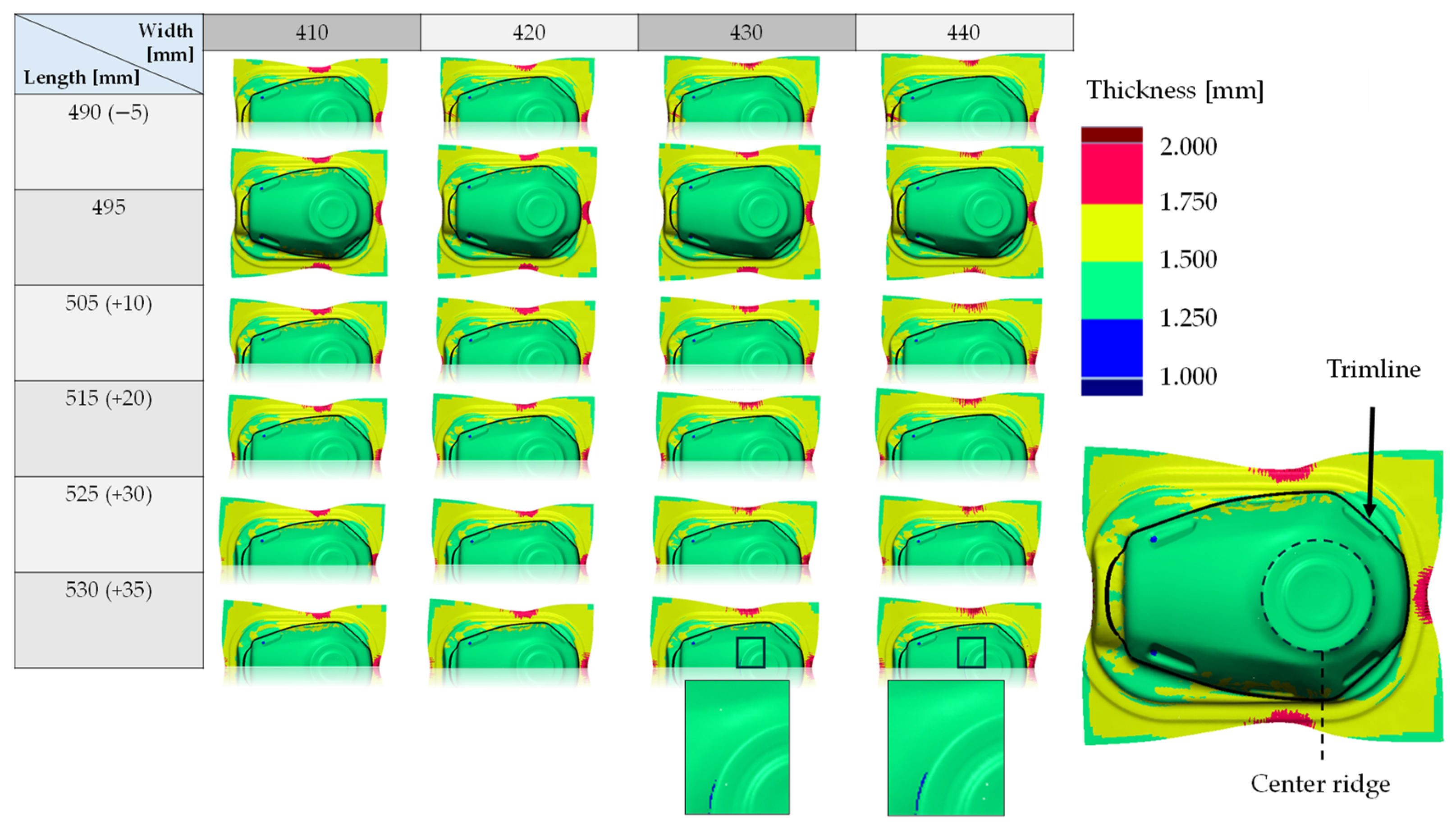

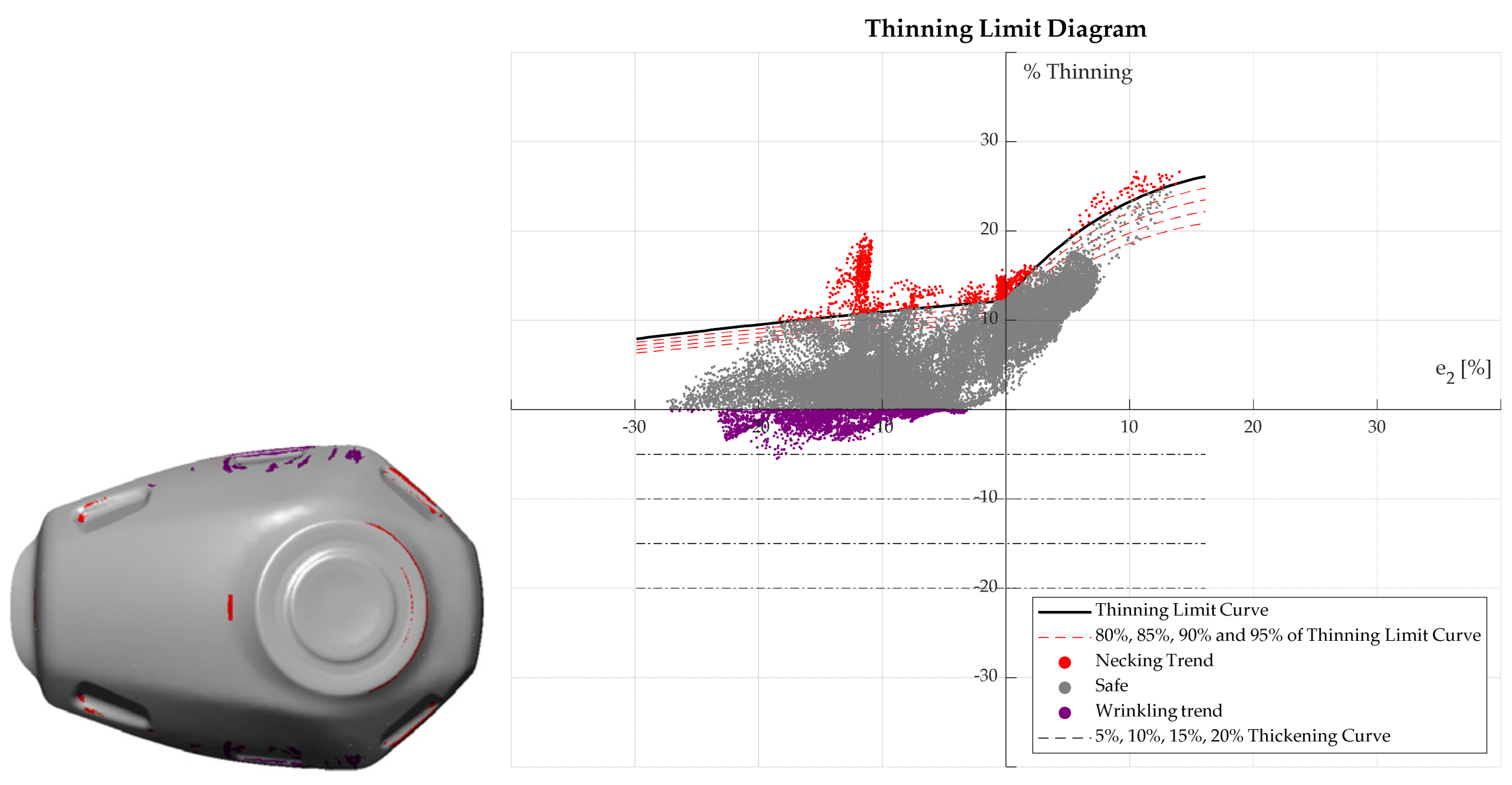

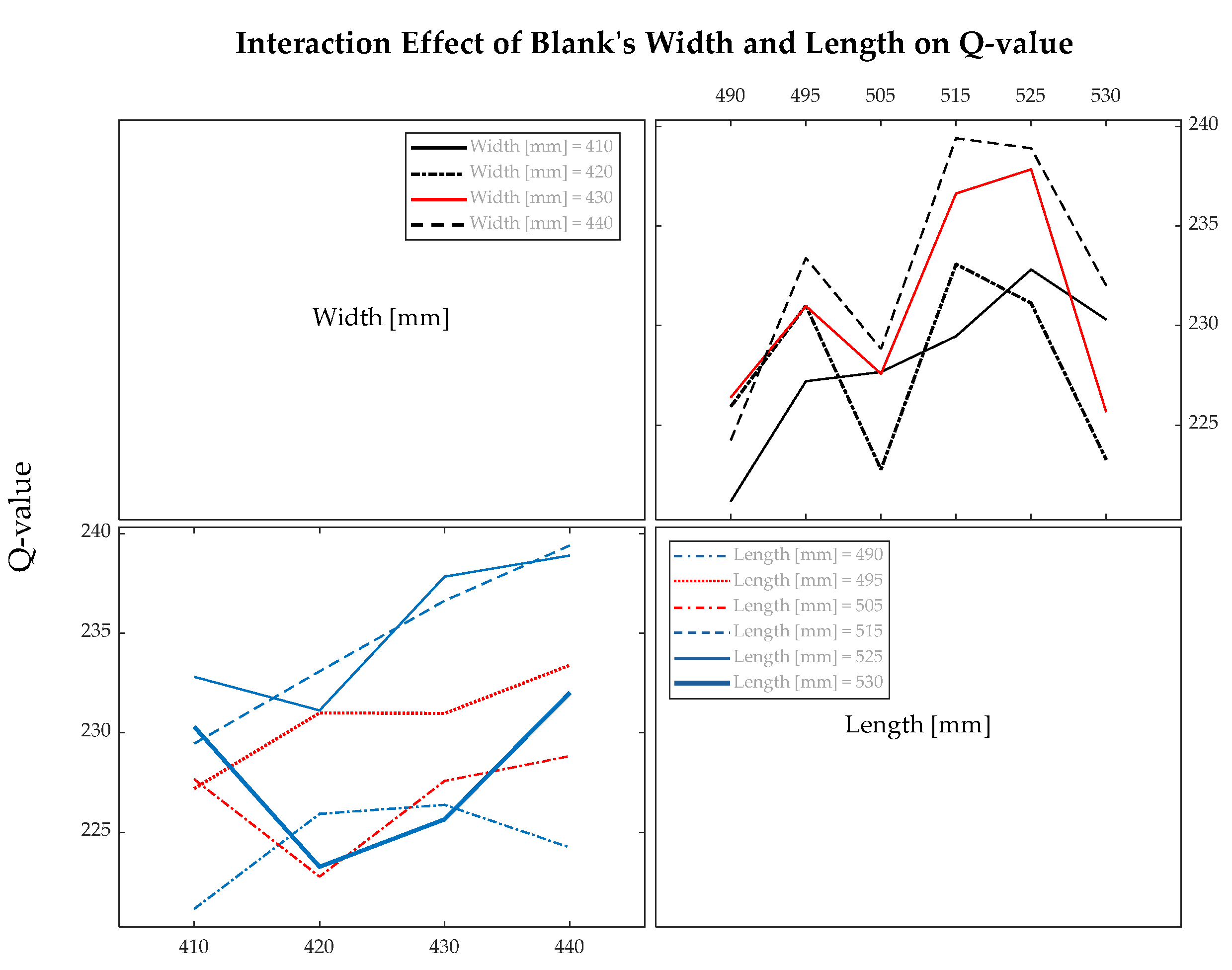

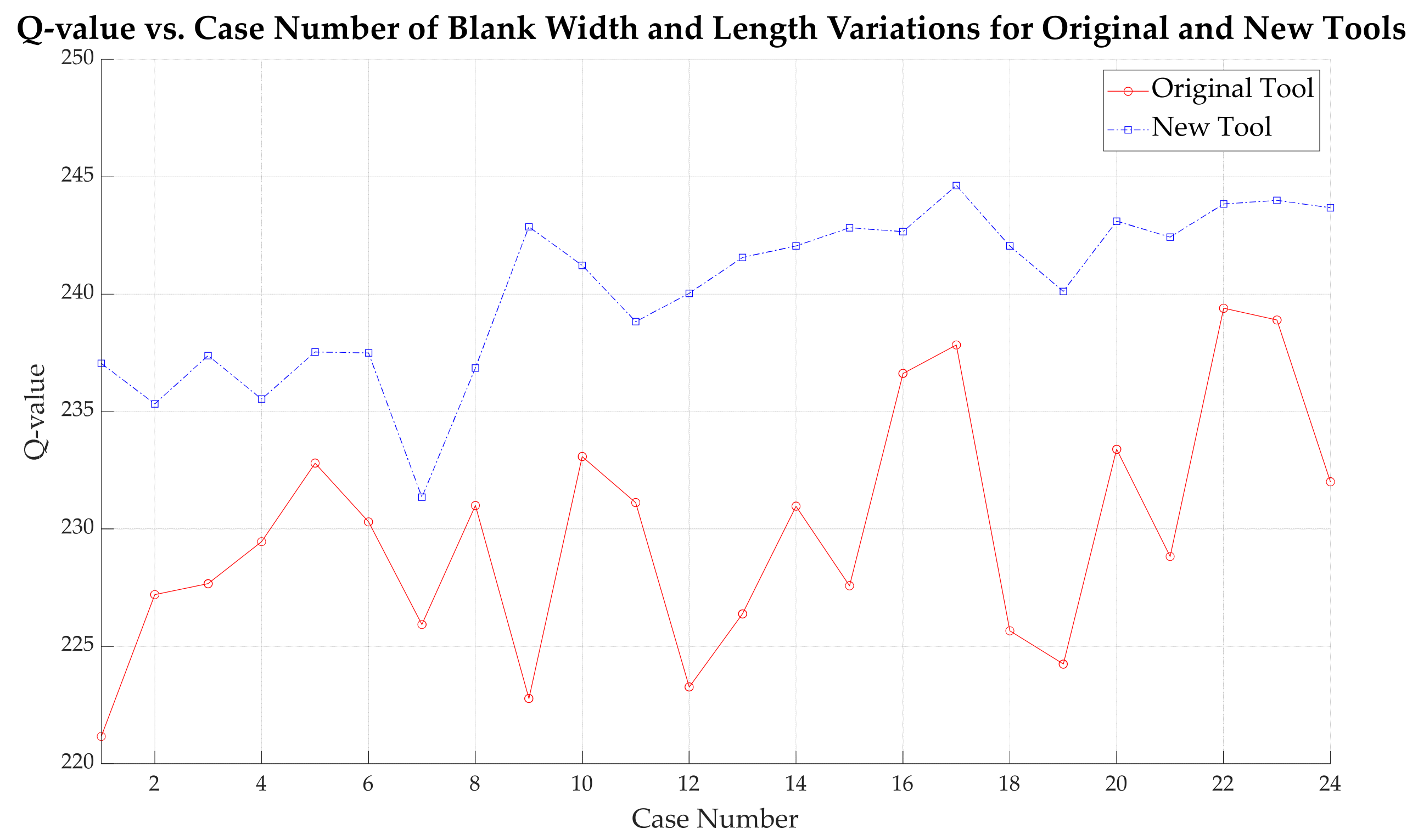

4.2. Influence of Blank’s Length and Width on Distribution of Thickness and Q-Value

4.3. Side-Wall Wrinkle Formation: Cause Analysis and Evaluation of Proposed Solutions

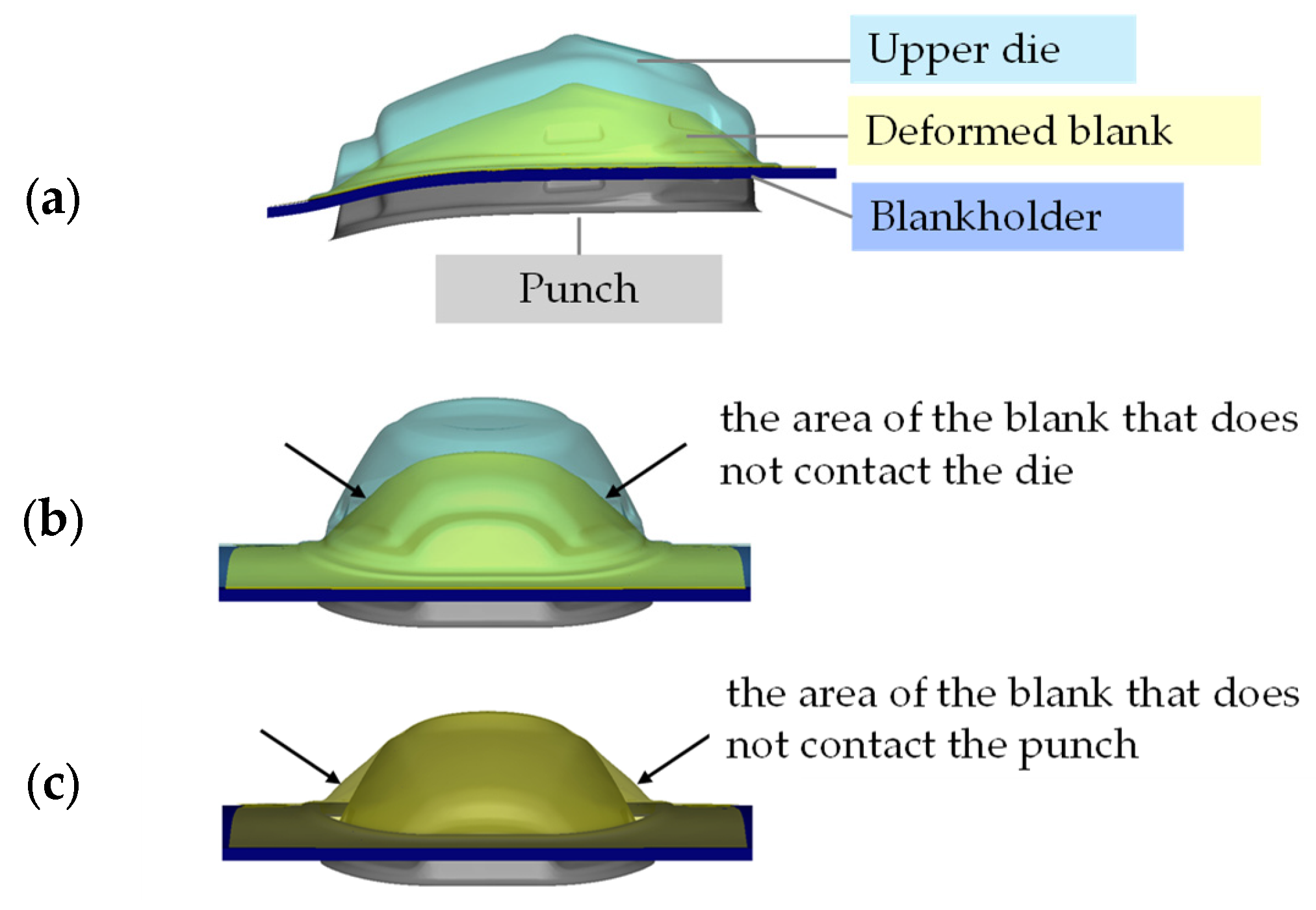

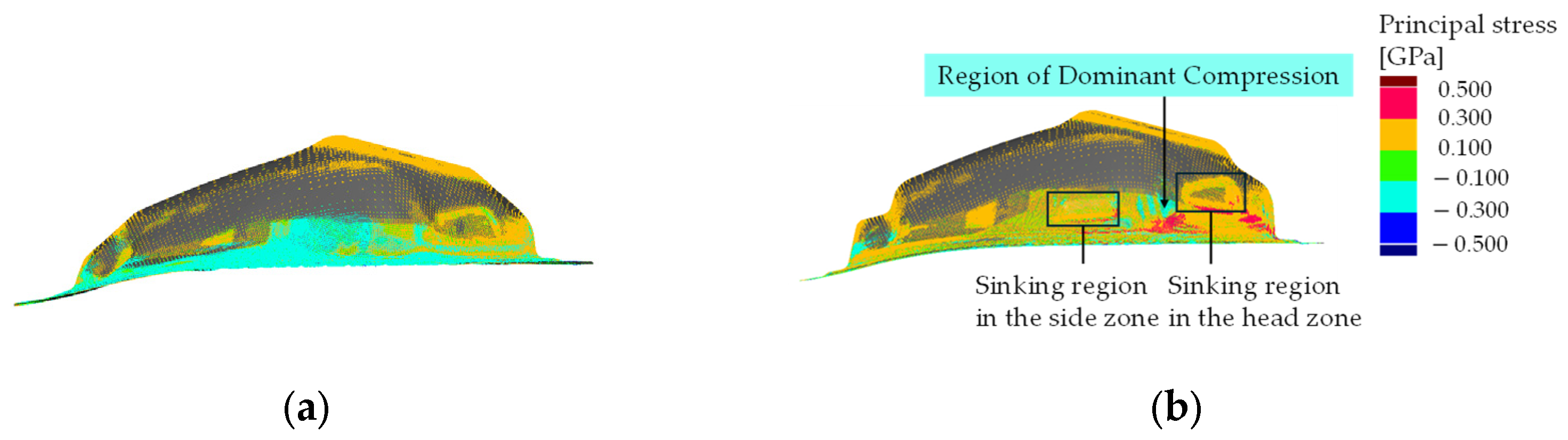

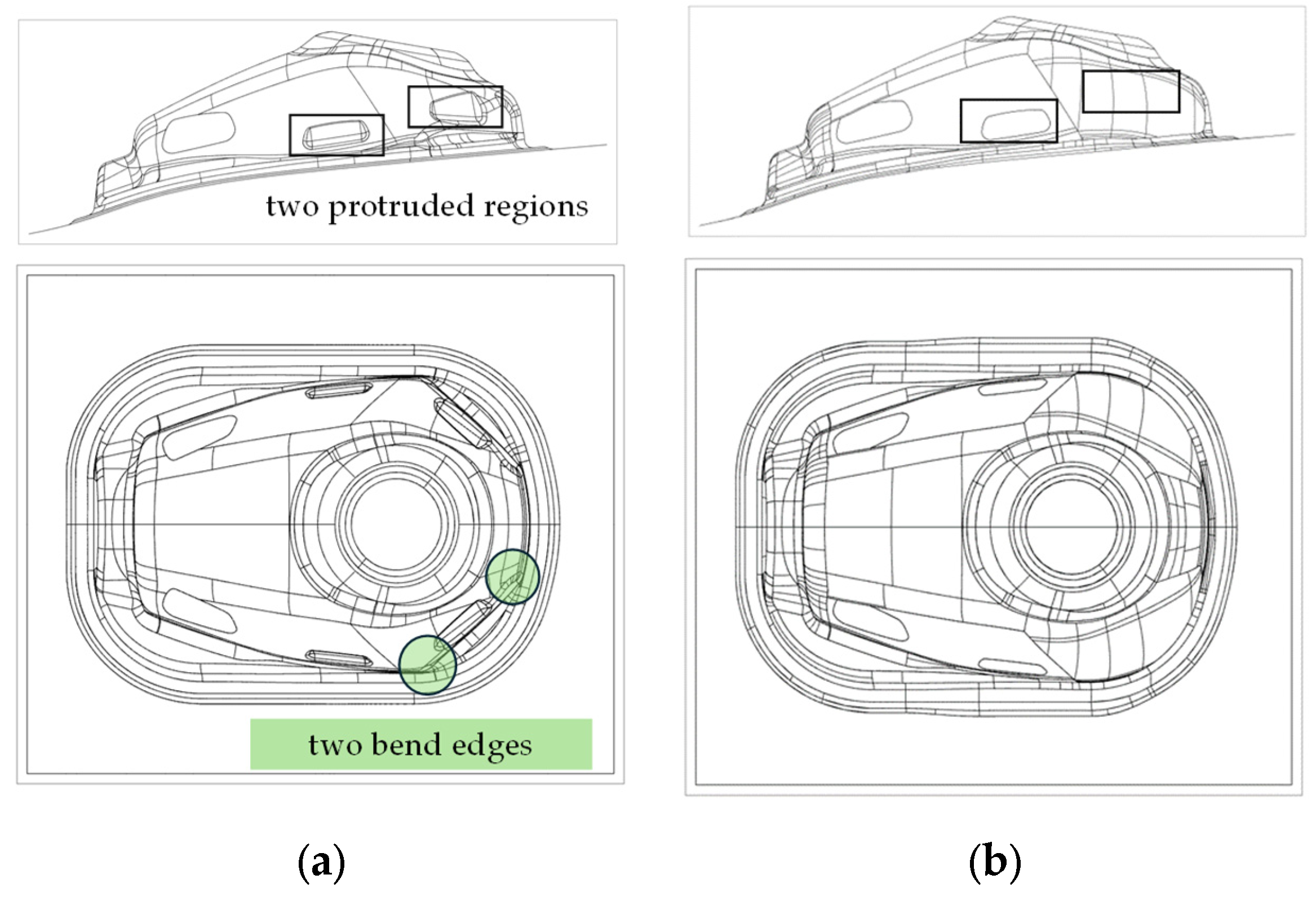

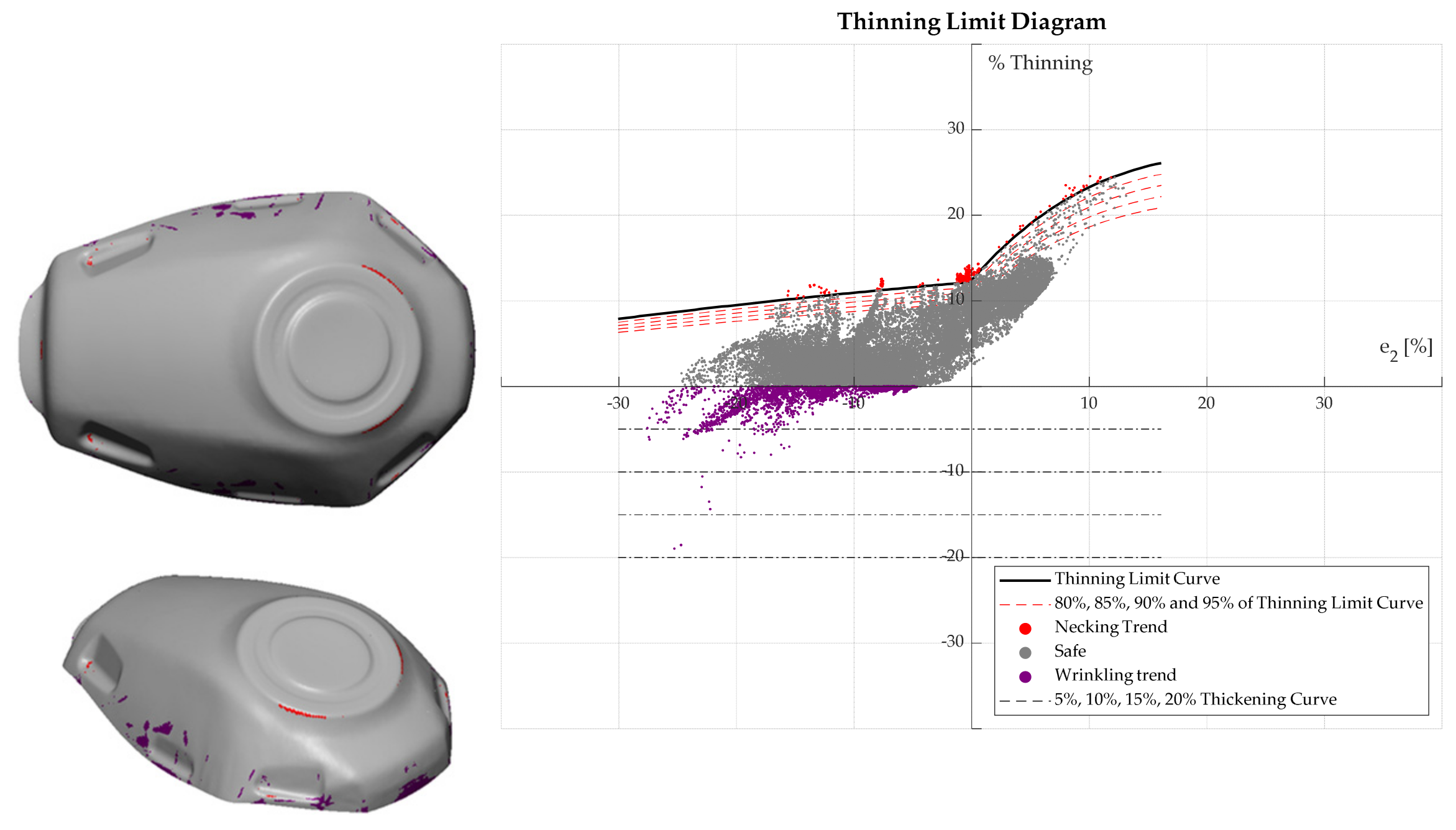

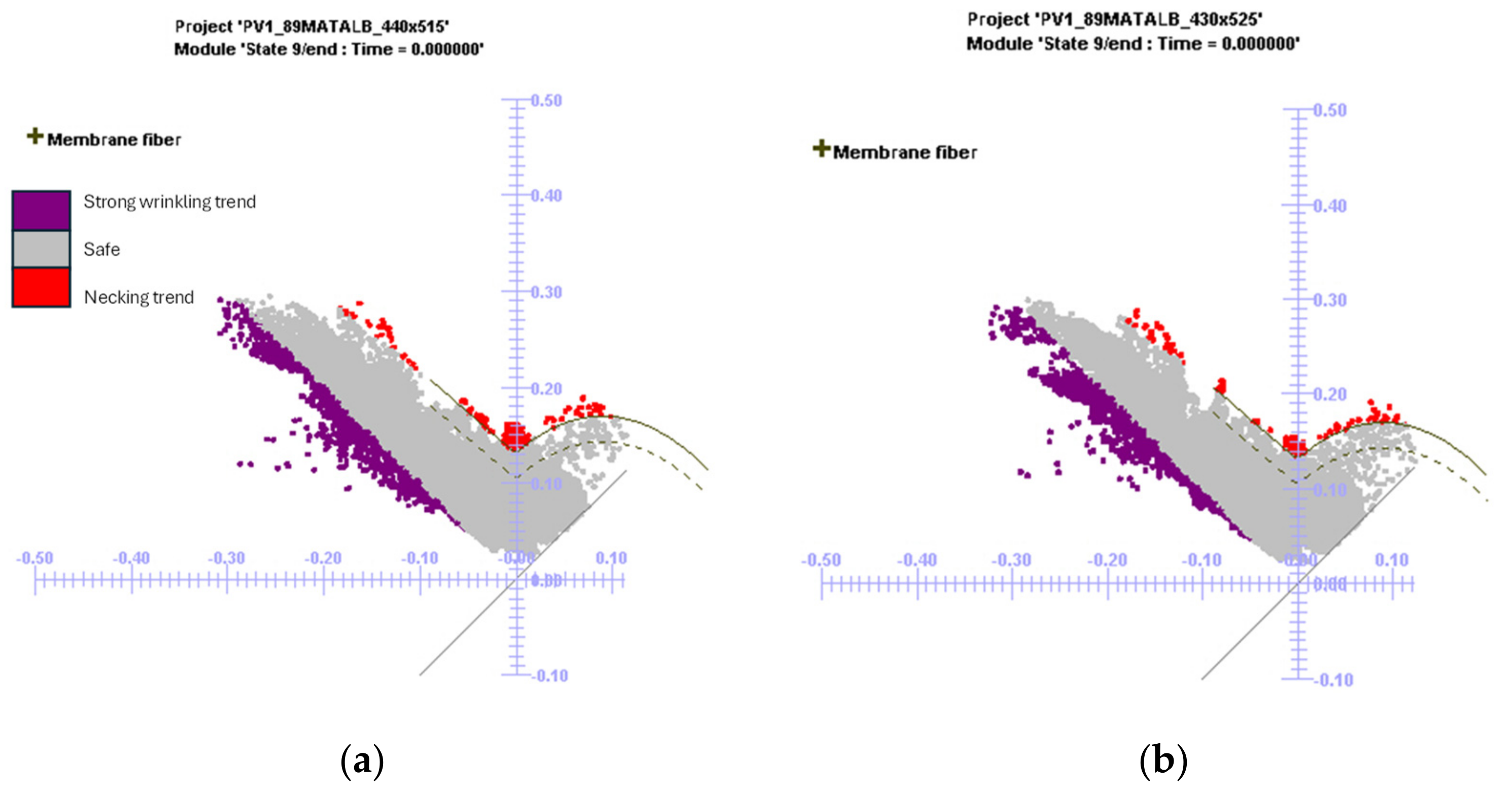

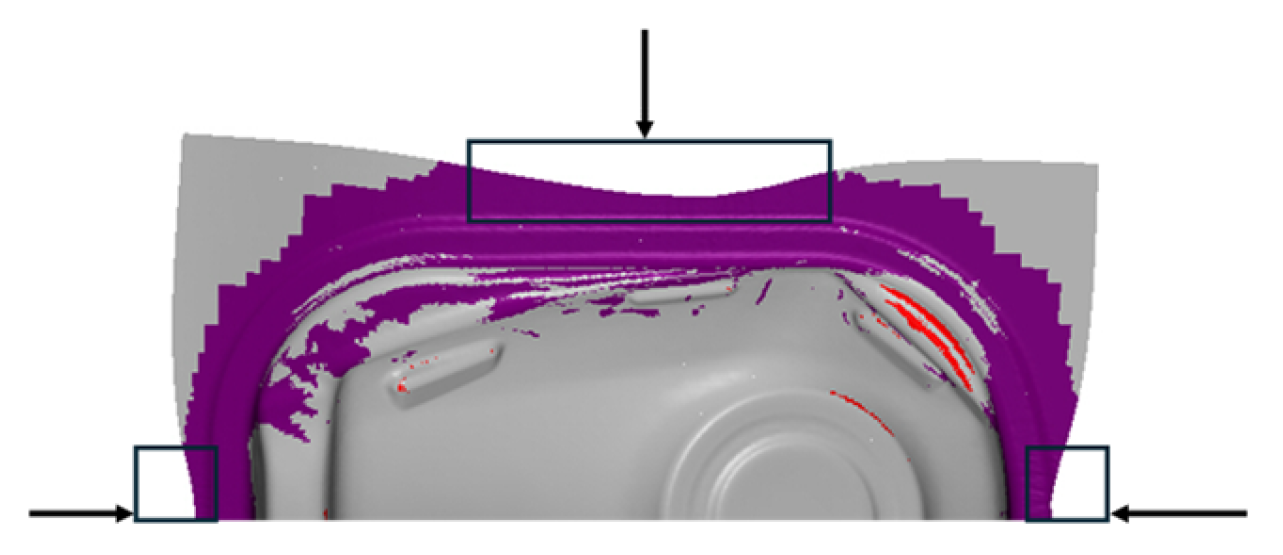

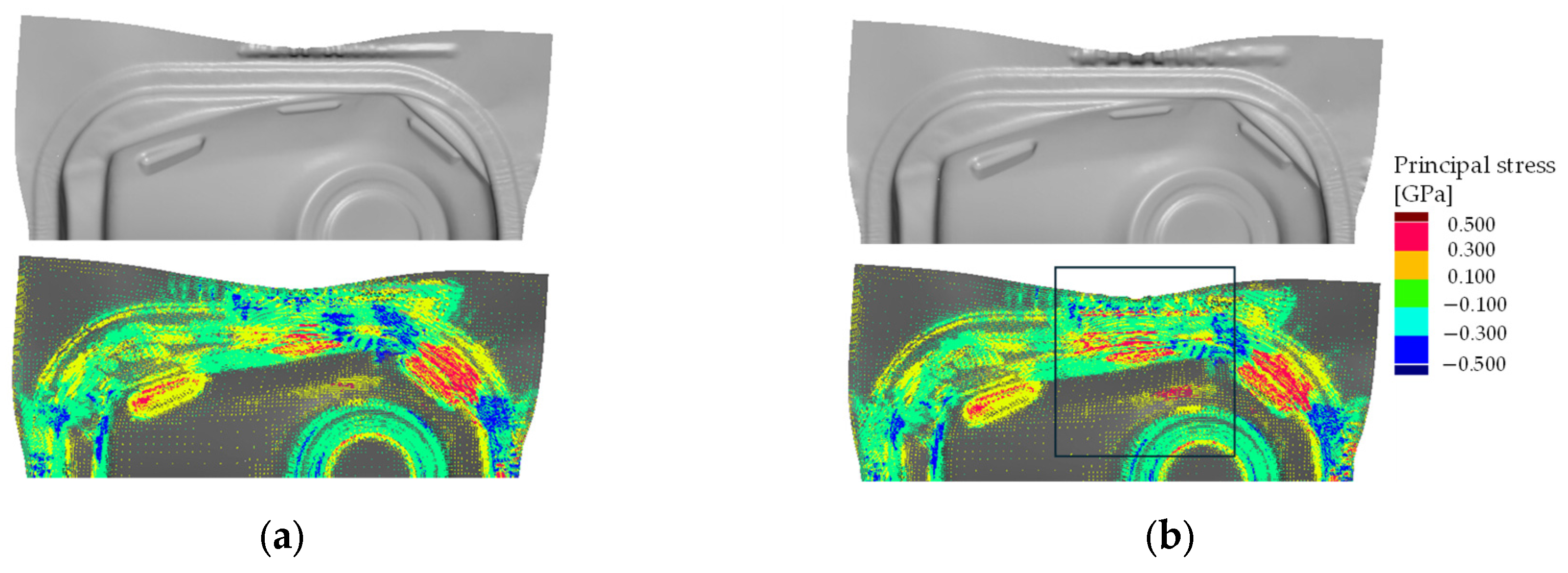

4.3.1. Cause Analysis and Proposed Solution (Tools Redesign)

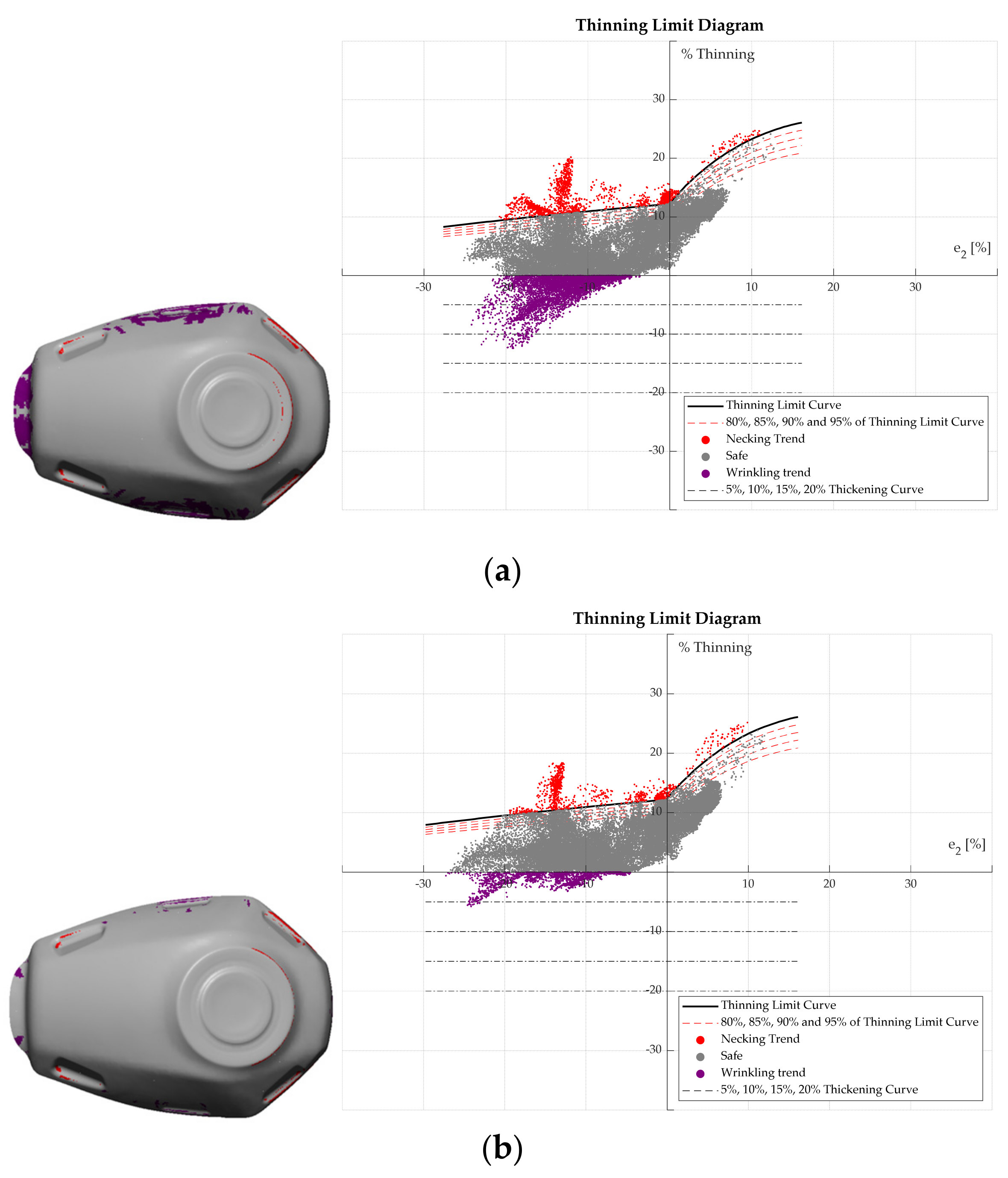

4.3.2. Effectiveness of Redesigned Tool Through Q-Values Analysis

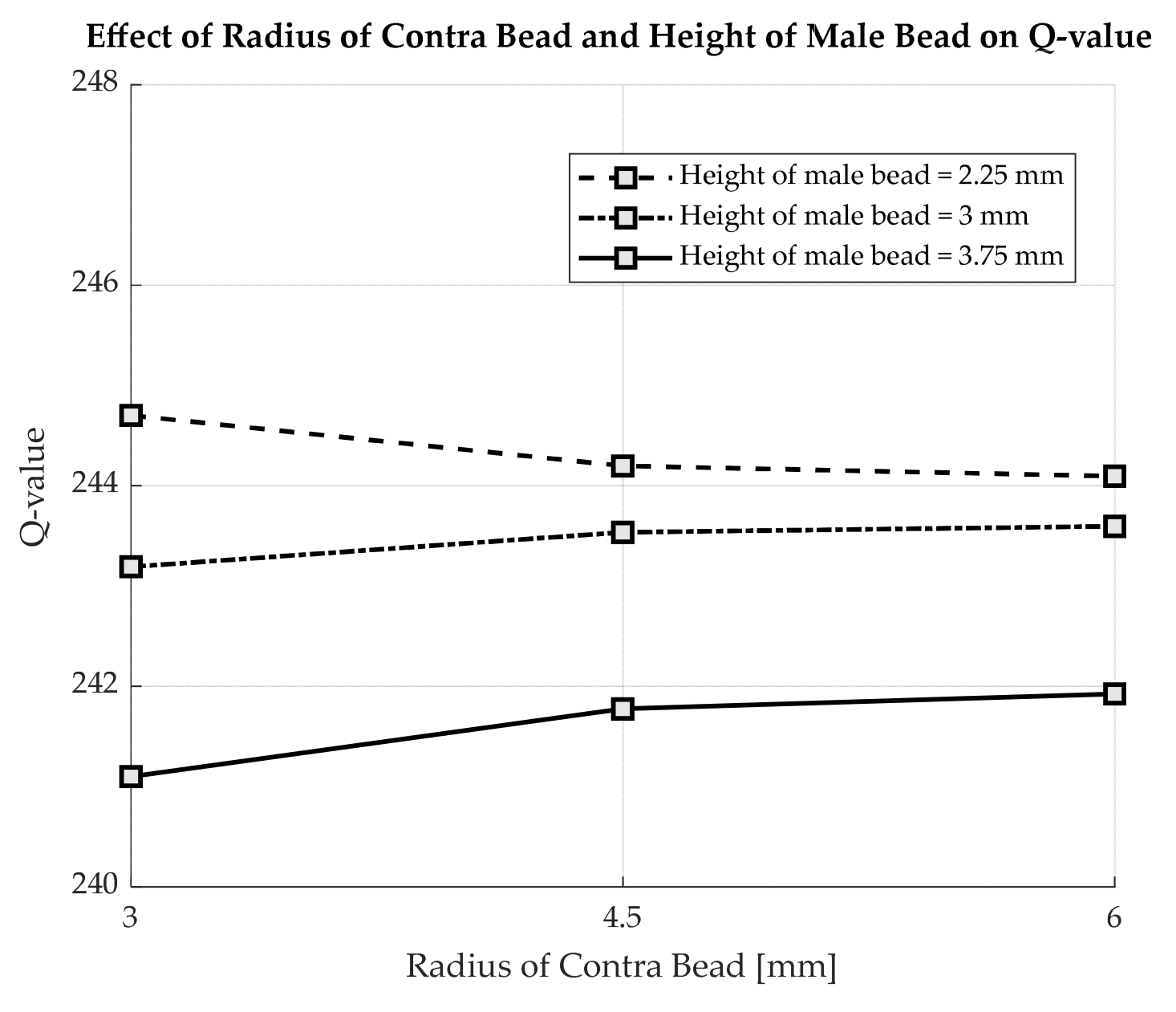

4.4. Influence of Male Bead Height and Contra-Bead Radii on the Formability of the Part

4.5. Validation of Enhanced Formability Achieved Through Q-Value Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Colgan, M.; Monaghan, J. Deep Drawing Process: Analysis and Experiment. J. Mater. Process Technol. 2003, 132, 35–41. [Google Scholar] [CrossRef]

- Jain, M.; Allin, J.; Bull, M.J. Deep Drawing Characteristics of Automotive Aluminum Alloys. Mater. Sci. Eng. A 1998, 256, 69–82. [Google Scholar] [CrossRef]

- Ghouati, O.; Gelin, J.-C.; Lenoir, H. Process Optimisation in Deep Drawing. Rev. Eur. Éléments Finis 2000, 9, 129–149. [Google Scholar] [CrossRef]

- Devendar, G.; Reddy, A.C. Study on Deep Drawing Process Parameters-A Review. Int. J. Sci. Eng. Res. 2016, 7, 149–155. [Google Scholar]

- Li, S. Sheet Metal Deep Drawing for Making Metallic Parts and Structures. In Encyclopedia of Materials: Metals and Alloys; Caballero, F.G., Ed.; Elsevier: Oxford, UK, 2022; pp. 182–196. ISBN 978-0-12-819733-2. [Google Scholar]

- Leu, D.-K. The Limiting Drawing Ratio for Plastic Instability of the Cup-Drawing Process. J. Mater. Process Technol. 1999, 86, 168–176. [Google Scholar] [CrossRef]

- Demirci, H.I.; Yaşar, M.; Demiray, K.; Karalı, M. The Theoretical and Experimental Investigation of Blank Holder Forces Plate Effect in Deep Drawing Process of AL 1050 Material. Mater. Des. 2008, 29, 526–532. [Google Scholar] [CrossRef]

- Choudhari, C.S.; Khasbage, S.S. Experimental Investigation of Forming Parameters for Square Cup Deep Drawing Process. Mater. Today Proc. 2021, 44, 4261–4267. [Google Scholar] [CrossRef]

- de Jesu´s Garci´a Zugasti, P.; Medelli´n Castillo, H.I.; de Lange, D.F. A Case Study of Drawbead Design of a Deep Drawn Rectangular Part Using FEM. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Lake Buena Vista, FL, USA, 13–19 November 2009; Volume 43772, pp. 21–26. [Google Scholar]

- Chen, F.-K.; Chiang, B. Three-Dimensional Finite Element Analysis for the Stamping of a Motorcycle Oil Tank. J. Manuf. Sci. Eng. 1998, 120, 770–773. [Google Scholar] [CrossRef]

- Khuanngern, B.; Suranuntchai, S. Analysis and Correction of Defects for Deep Drawing Process of Stainless Sink by Use of Finite Element Simulation. Key Eng. Mater. 2021, 889, 153–159. [Google Scholar] [CrossRef]

- Wang, H.; Yan, Y.; Han, F.; Wan, M. Experimental and Theoretical Investigations of the Forming Limit of 5754O Aluminum Alloy Sheet under Different Combined Loading Paths. Int. J. Mech. Sci. 2017, 133, 147–166. [Google Scholar] [CrossRef]

- Sun, L.; Cai, Z.; He, D.; Li, L. Aluminum Alloy Sheet-Forming Limit Curve Prediction Based on Original Measured Stress–Strain Data and Its Application in Stretch-Forming Process. Metals 2019, 9, 1129. [Google Scholar] [CrossRef]

- Li, X.; Chen, Y.; Lang, L.; Xiao, R. A Modified M-k Method for Accurate Prediction of Flc of Aluminum Alloy. Metals 2021, 11, 394. [Google Scholar] [CrossRef]

- Ma, B.; Yang, C.; Wu, X.; Zhan, L. Theoretical and Numerical Investigation of the Limit Strain of a 5754-O Aluminum Alloy Sheet Considering the Influence of the Hardening Law. J. Mater. Eng. Perform. 2023, 32, 10115–10127. [Google Scholar] [CrossRef]

- Butuc, M.C.; Gracio, J.J.; Barata da Rocha, A. A Theoretical Study on Forming Limit Diagrams Prediction. J. Mater. Process Technol. 2003, 142, 714–724. [Google Scholar] [CrossRef]

- Bunyan, T.; Yiemchaiyaphum, S.; Panich, S. Wrinkling Prediction of Rectangular Cup Deep Drawing Process for Aluminum Alloy Sheets by Using the Modified Yoshida Buckling Test. Proc. Key Eng. Mater. 2020, 856, 143–151. [Google Scholar] [CrossRef]

- Du, B.; Xie, J.; Li, H.; Zhao, C.; Zhang, X.; Yuan, X. Determining Factors Affecting Sheet Metal Plastic Wrinkling in Response to Nonuniform Tension Using Wrinkling Limit Diagrams. Thin-Walled Struct. 2020, 147, 106535. [Google Scholar] [CrossRef]

- Han, F.; Radonjic, R. New Approach for Wrinkle Prediction in Deep Drawing Process. Key Eng. Mater. 2015, 639, 459–466. [Google Scholar] [CrossRef]

- Zein, H.; El Sherbiny, M.; Abd-Rabou, M. Thinning and Spring Back Prediction of Sheet Metal in the Deep Drawing Process. Mater. Des. 2014, 53, 797–808. [Google Scholar] [CrossRef]

- El Sherbiny, M.; Zein, H.; Abd-Rabou, M. Thinning and Residual Stresses of Sheet Metal in the Deep Drawing Process. Mater. Des. 2014, 55, 869–879. [Google Scholar] [CrossRef]

- Palmieri, M.E.; Nono Dachille, A.; Tricarico, L. Identification of the Optimal Blank Holder Force through In-Line Measurement of Blank Draw-In in a Deep Drawing Process. J. Manuf. Mater. Process. 2023, 7, 190. [Google Scholar] [CrossRef]

- Kalujniy, O.V.; Kalujniy, V.L.; Aliiev, I.S.; Markov, O.E.; Levchenko, V.M. Investigation of Variants of Deep Drawing of Steel Hollow Parts. J. Braz. Soc. Mech. Sci. Eng. 2025, 47, 19. [Google Scholar] [CrossRef]

- Kitayama, S.; Yamada, S. Simultaneous Optimization of Blank Shape and Variable Blank Holder Force of Front Side Member Manufacturing by Deep Drawing. Int. J. Adv. Manuf. Technol. 2017, 91, 1381–1390. [Google Scholar] [CrossRef]

- Brun, M.; Ghiotti, A.; Simonetto, E.; Bruschi, S.; Filippi, S. Variable Blank Holder Pressure by Magneto-Rheological Actuators in Deep Drawing. Proc. Procedia CIRP 2023, 119, 932–937. [Google Scholar] [CrossRef]

- Dong, F.; Huang, S.; Yi, Y.; He, H.; Huang, K.; Wang, C.; Gao, S.; Jia, Y.; Yu, W. Enhanced Deep Drawing Formability and Deformation Mechanism of Aluminum Alloy at Cryogenic Temperature. J. Alloys Compd. 2023, 968, 171992. [Google Scholar] [CrossRef]

- Jang, D.H.; Kim, W.J. Warm Temperature Deformation Behavior and Processing Maps of 5182 and 7075 Aluminum Alloy Sheets with Fine Grains. Met. Mater. Int. 2018, 24, 455–463. [Google Scholar] [CrossRef]

- Budai, D.; Tisza, M.; Kovács, P.Z. Investigation of EN AW 5754 Aluminum Alloy’s Formability at Elevated Temperatures. Proc. Mater. Sci. Forum 2017, 885, 98–103. [Google Scholar] [CrossRef]

- Do, T.T.; Minh, P.S.; Le, N. Effect of Tool Geometry Parameters on the Formability of a Camera Cover in the Deep Drawing Process. Materials 2021, 14, 3993. [Google Scholar] [CrossRef]

- Li, Y.Q.; Cui, Z.S.; Ruan, X.Y.; Zhang, D.J. CAE-Based Six Sigma Robust Optimization for Deep- Drawing Process of Sheet Metal. Int. J. Adv. Manuf. Technol. 2006, 30, 631–637. [Google Scholar] [CrossRef]

- Jweeg, M.J.; Mohammed, A.I.; Jabbar, M.S. Investigation of Thickness Distribution Variation in Deep Drawing of Conical Steel Products. Eng. Technol. J. 2021, 39, 586–598. [Google Scholar] [CrossRef]

- Dilmec, M.; Halkaci, H.S.; Ozturk, F.; Livatyali, H.; Yigit, O. Effects of Sheet Thickness and Anisotropy on Forming Limit Curves of AA2024-T4. Int. J. Adv. Manuf. Technol. 2013, 67, 2689–2700. [Google Scholar] [CrossRef]

- Mostafa, M.; Abdelbarr, M.; Hassab-Allah, I.M.; Bayummi, A.; Shewakh, W.M. Optimum Process Parameters for Increasing the Drawability of Square Cup Though Conical Die. J. Adv. Eng. Trends 2023, 42, 141–153. [Google Scholar]

- Hassan, M.; Hezam, L.; El-Sebaie, M.; Purbolaksono, J. Deep Drawing Characteristics of Square Cups through Conical Dies. Proc. Procedia Eng. 2014, 81, 873–880. [Google Scholar] [CrossRef]

- Brathikan, V.M.; Sangeetha, N.; Sangeethkumar, B.; Scidarth, K. Influence of Various Blank Diameter in Deep Drawing. Mater. Today Proc. 2022, 68, 1995–1999. [Google Scholar] [CrossRef]

- Lazarescu, L.; Nicodim, I.; Banabic, D. Evaluation of Drawing Force and Thickness Distribution in the Deep-Drawing Process with Variable Blank-Holding. Key Eng. Mater. 2015, 639, 33–40. [Google Scholar] [CrossRef]

- Leelaseat, J.; Larpprasoetkun, P.; Sunanta, A.; Nakwattanaset, A.; Suranuntchai, S. Investigation on the Effect of Blank Holder Force and Initial Blank Size on the Thinning Problem of the Fuel Tank Part Made from Aluminum Alloy Sheet 5754-O under Deep Drawing Process. Key Eng. Mater. 2024, 973, 101–107. [Google Scholar] [CrossRef]

- Sun, G.; Li, G.; Gong, Z.; Cui, X.; Yang, X.; Li, Q. Multiobjective Robust Optimization Method for Drawbead Design in Sheet Metal Forming. Mater. Des. 2010, 31, 1917–1929. [Google Scholar] [CrossRef]

- Alves, J.L.; Bouvier, S.; Oliveira, M.C.; Menezes, L.F. Drawbeads: To Be or Not to Be. AIP Conf. Proc. 2005, 778, 655–660. [Google Scholar]

- Bae, G.H.; Song, J.H.; Huh, H.; Kim, S.H.; Park, S.H. Simulation-Based Prediction Model of the Draw-Bead Restraining Force and Its Application to Sheet Metal Forming Process. J. Mater. Process Technol. 2007, 187, 123–127. [Google Scholar] [CrossRef][Green Version]

- Ke, J.; Liu, Y.; Zhu, H.; Zhang, Z. Formability of Sheet Metal Flowing through Drawbead—An Experimental Investigation. J. Mater. Process Technol. 2018, 254, 283–293. [Google Scholar] [CrossRef]

- Panich, S.; Uthaisangsuk, V. Wrinkling Limit Curves with Consideration of Anisotropic Behaviour for the Deep Drawing of Aluminium Sheet Alloys. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 237, 592–615. [Google Scholar] [CrossRef]

- Senior, B.W. Flange Wrinkling in Deep-Drawing Operations. J. Mech. Phys. Solids 1956, 4, 235–246. [Google Scholar] [CrossRef]

- Hilton, P.; Pedersen, J. Looking into Pascal’s Triangle: Combinatorics, Arithmetic, and Geometry. Math. Mag. 1987, 60, 305–316. [Google Scholar] [CrossRef]

- ASTM E8/E8M-16a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Swift, H. Plastic Instability under Plane Stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- ESI Group. PAM-STAMP 2022.0—User Guide; ESI Group: Bagneux, France, 2022. [Google Scholar]

- Hill, R. A Theory of the Yielding and Plastic Flow of Anisotropic Metals. Proc. R. Soc. Lond. A Math. Phys. Sci. 1948, 193, 281–297. [Google Scholar]

- Barlat, F.; Lian, K. Plastic Behavior and Stretchability of Sheet Metals. Part I: A Yield Function for Orthotropic Sheets Under Plane Stress Conditions. Int. J. Plast. 1989, 5, 51–66. [Google Scholar]

- Xu, S.G.; Bohn, M.L.; Weinmann, K.J. Drawbeads in Sheet Metal Stamping—A Review. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 23 February 1997. [Google Scholar]

- Karnchanaseangthong, T.; Inpunyo, C.; Torsakul, S. A Study of the Effect of Drawbead Shapes in Non-Symmetry Deep Drawing Process by Using Finite Element-Simulation. Thai Ind. Eng. Netw. J. 2016, 2, 15–22. [Google Scholar]

- Phanitwong, W.; Thipprakmas, S. Analysis of Draw Bead Geometry on Wall Thinning and Concave/Convex Feature in Rectangular Deep Drawn Parts. Adv. Mat. Res. 2011, 189, 2704–2707. [Google Scholar] [CrossRef]

- Larpprasoetkun, P.; Leelaseat, J.; Nakwattanaset, A.; Suranuntchai, S. Development of Forming Limit Diagrams for Motorcycle Fuel Tank Made from AA5754-O under Deep Drawing. J. Met. Mater. Miner. 2024, 34, 2013. [Google Scholar] [CrossRef]

- Cao, J.; Boyce, M.C. Wrinkling Behavior of Rectangular Plates under Lateral Constraint. Int. J. Solids Struct. 1997, 34, 153–176. [Google Scholar] [CrossRef]

- Triantafyllidis, N. Puckering Instability Phenomena in the Hemispherical Cup Test. J. Mech. Phys. Solids 1985, 33, 117–139. [Google Scholar] [CrossRef][Green Version]

- Wang, X.; Cao, J. On the Prediction of Side-Wall Wrinkling in Sheet Metal Forming Processes. Int. J. Mech. Sci. 2000, 42, 2369–2394. [Google Scholar] [CrossRef]

- Bassoli, E.; Sola, A.; Denti, L.; Gatto, A. Experimental Approach to Measure the Restraining Force in Deep Drawing by Means of a Versatile Draw Bead Simulator. Mater. Manuf. Process. 2019, 34, 1286–1295. [Google Scholar] [CrossRef]

| Width [mm] | 490 | 495 | 505 | 515 | 525 | 530 | |

|---|---|---|---|---|---|---|---|

| Length [mm] | |||||||

| 410 | 1 | 2 | 3 | 4 | 5 | 6 | |

| 420 | 7 | 8 | 9 | 10 | 11 | 12 | |

| 430 | 13 | 14 | 15 | 16 | 17 | 18 | |

| 440 | 19 | 20 | 21 | 22 | 23 | 24 | |

| Radius of Male Bead (r) | Width of Groove (W) | Height of Male Bead (H) | Radius of Contra Bead (R) |

|---|---|---|---|

| 3 | 9 | 2.25 | 3 |

| 4.5 | |||

| 6 | |||

| 3 | 3 | ||

| 4.5 | |||

| 6 | |||

| 3.75 | 3 | ||

| 4.5 | |||

| 6 |

| Properties [Unit] | Values |

|---|---|

| Ultimate Tensile Strength [MPa] | 207.64 |

| Elastic Modulus [GPa] | 70.24 |

| [MPa] | 100.17 |

| Total Elongation [%] | 21.87 |

| 0.57 | |

| 0.80 | |

| 0.68 |

| Yield Criteria | Name of Parameters | Values |

|---|---|---|

| Hill’s 1948 [48] | H | 0.36 |

| G | 0.64 | |

| N | 1.52 | |

| F | 0.53 | |

| Barlat and Lian 1989 [49] | M | 8.00 |

| c | 0.77 | |

| a | 1.23 | |

| h | 0.95 | |

| p | 1.07 |

| Position (Points) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Draw-in value [mm] | Exp. | 21.93 | 29.14 | 23.60 | 20.17 | 31.02 | 21.79 | 25.64 | 40.63 | 27.36 | 16.87 | 33.67 | 28.33 |

| Simulation | 18.82 | 36.40 | 32.60 | 22.07 | 27.70 | 22.72 | 21.95 | 42.41 | 31.22 | 17.12 | 31.96 | 25.98 | |

| Relative error [mm] | 3.11 | 3.11 | 7.26 | 9.00 | 1.90 | 3.33 | 0.93 | 3.70 | 1.79 | 3.86 | 0.25 | 1.71 | |

| Position (Points) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

| Thickness value [mm] | Exp. | 1.15 | 1.37 | 1.37 | 1.31 | 1.39 | 1.46 | 1.34 | 1.46 |

| Simulation | 1.12 | 1.32 | 1.36 | 1.34 | 1.39 | 1.41 | 1.30 | 1.42 | |

| Absolute percentage error [%] | 2.61 | 3.65 | 0.66 | 2.21 | 0.36 | 3.22 | 3.21 | 2.74 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leelaseat, J.; Sunanta, A.; Suranuntchai, S. Formability Assessment Based on Q-Value for Optimizing the Deep Drawing Process of Automotive Parts Made from Aluminum Alloys Sheet. Metals 2025, 15, 68. https://doi.org/10.3390/met15010068

Leelaseat J, Sunanta A, Suranuntchai S. Formability Assessment Based on Q-Value for Optimizing the Deep Drawing Process of Automotive Parts Made from Aluminum Alloys Sheet. Metals. 2025; 15(1):68. https://doi.org/10.3390/met15010068

Chicago/Turabian StyleLeelaseat, Jidapa, Aekkapon Sunanta, and Surasak Suranuntchai. 2025. "Formability Assessment Based on Q-Value for Optimizing the Deep Drawing Process of Automotive Parts Made from Aluminum Alloys Sheet" Metals 15, no. 1: 68. https://doi.org/10.3390/met15010068

APA StyleLeelaseat, J., Sunanta, A., & Suranuntchai, S. (2025). Formability Assessment Based on Q-Value for Optimizing the Deep Drawing Process of Automotive Parts Made from Aluminum Alloys Sheet. Metals, 15(1), 68. https://doi.org/10.3390/met15010068