Investigating Fracture Behavior in Titanium Aluminides: Surface Roughness as an Indicator of Fracture Mechanisms in Ti-48Al-2Cr-2Nb Alloys

Abstract

1. Introduction

2. Materials and Methods

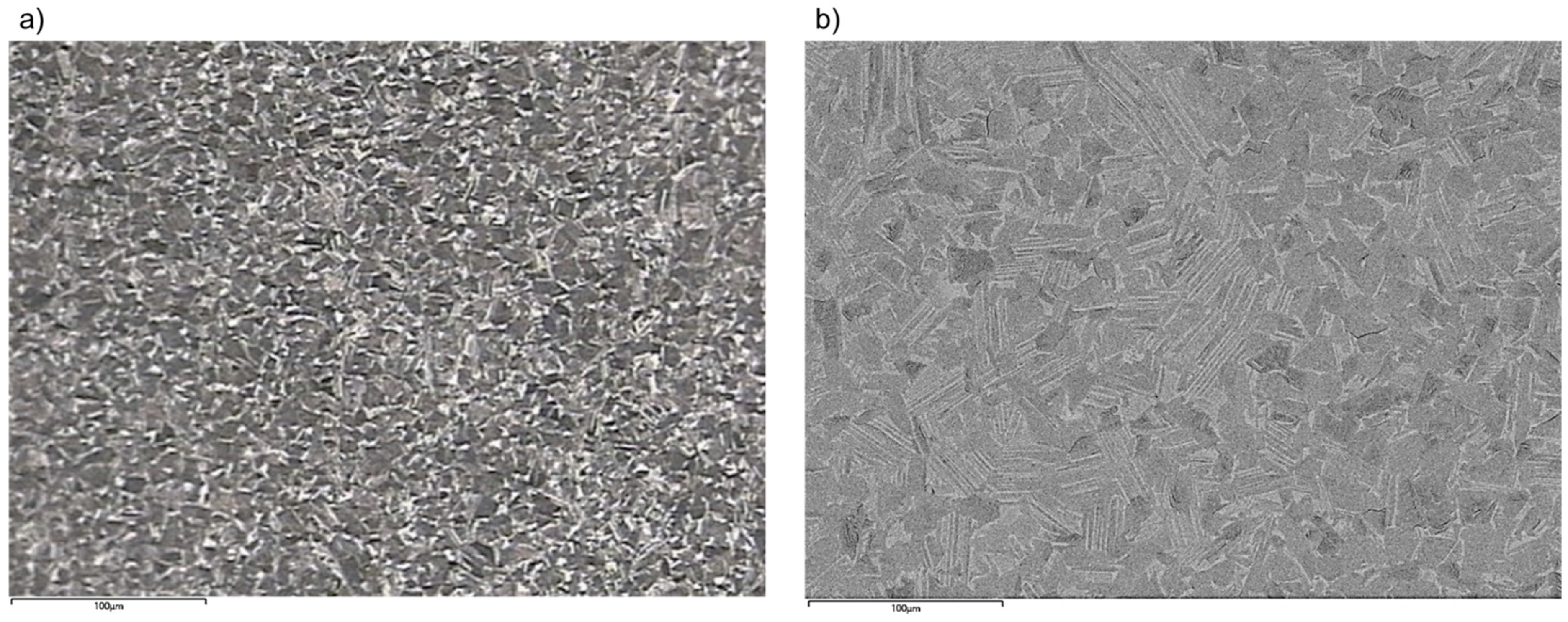

2.1. Production of Ti-48Al-2Cr-2Nb Specimens Through EBM Technology

2.2. Characterization of the Samples

3. Results

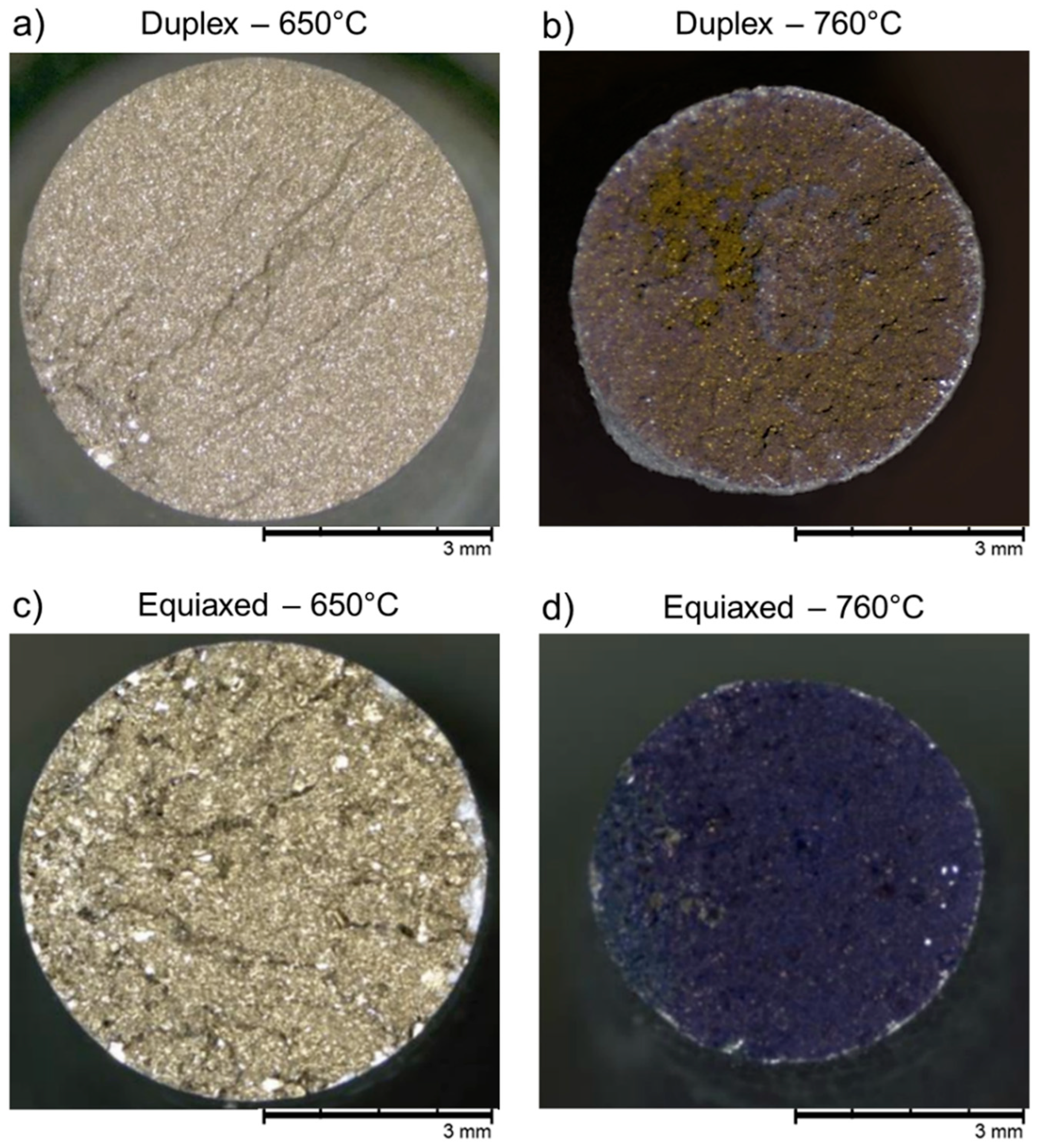

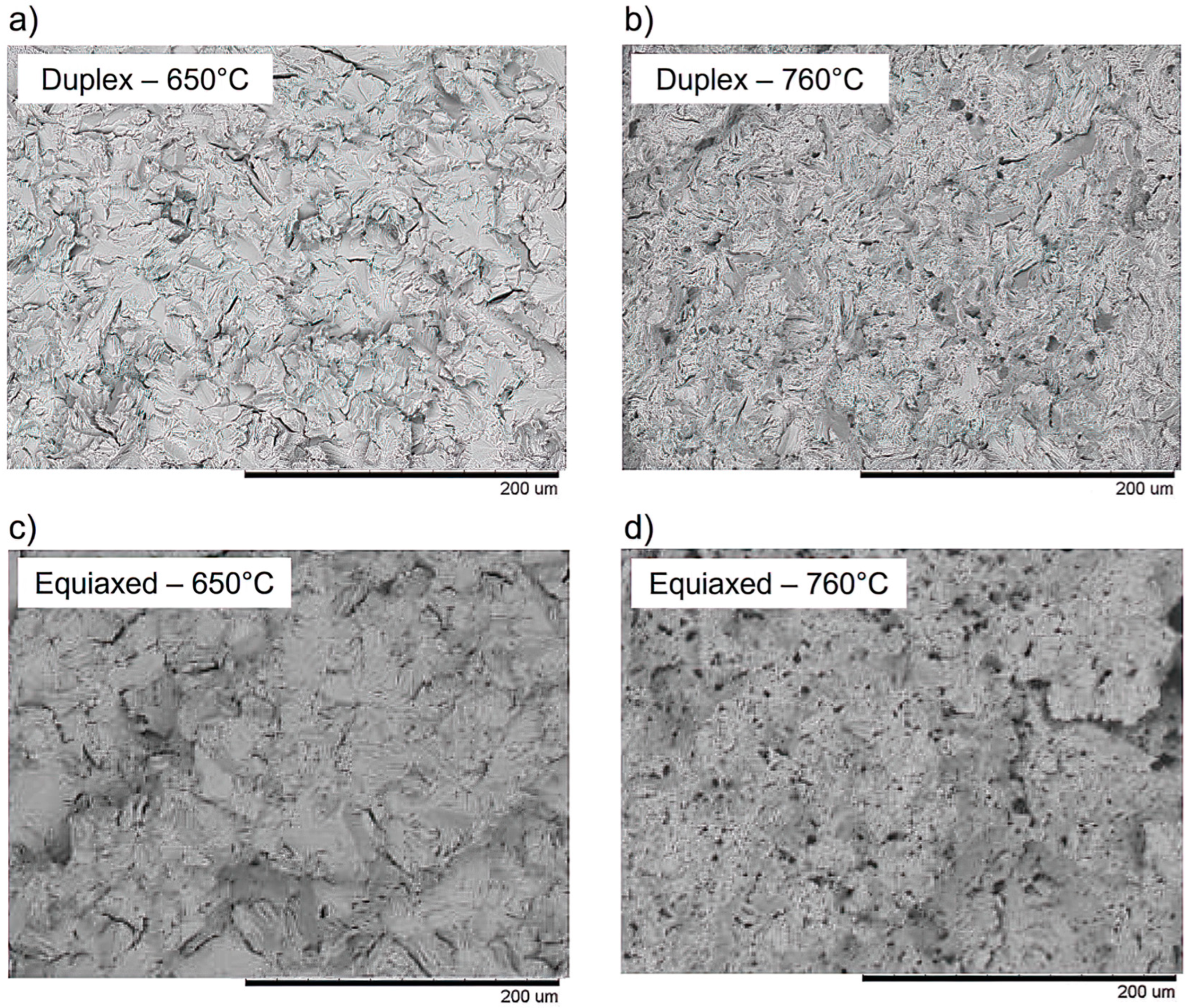

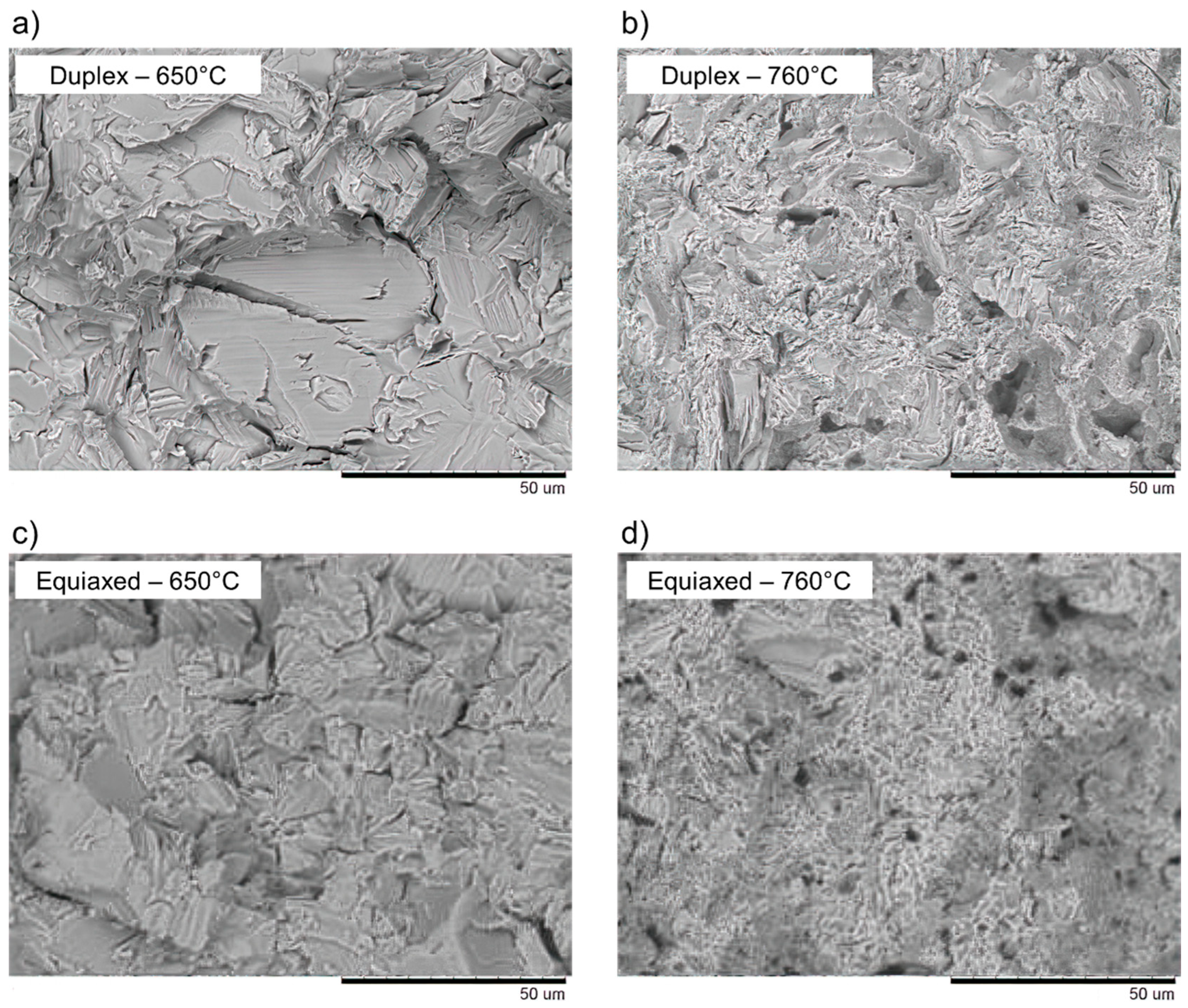

3.1. Tensile Tests

3.2. High-Cycle Fatigue Tests

4. Discussion

5. Conclusions

- Fracture behavior of Ti-48Al-2Cr-2Nb alloy was highly influenced by both the microstructure and testing temperature, with notable differences between the duplex and equiaxed microstructures under varying loading conditions.

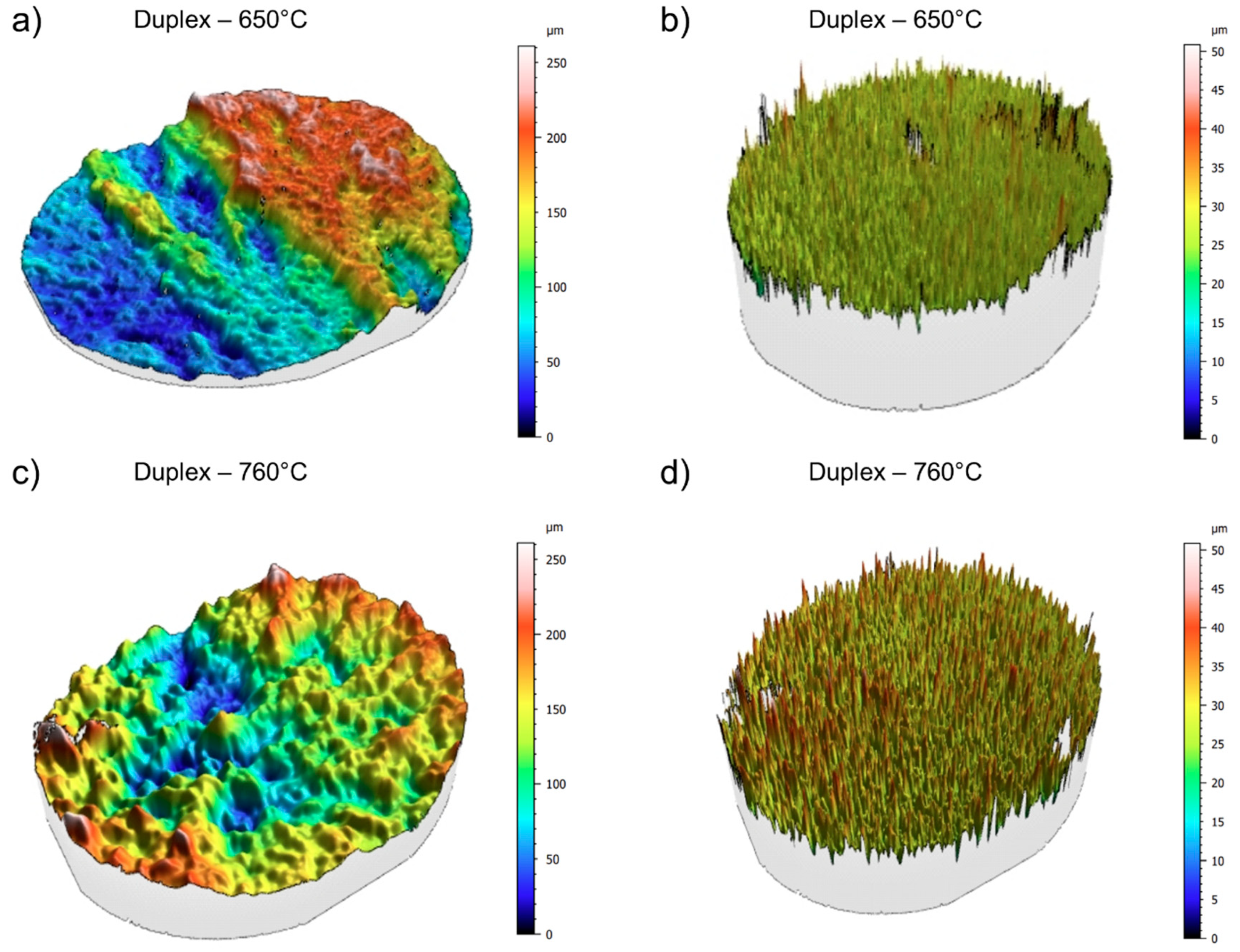

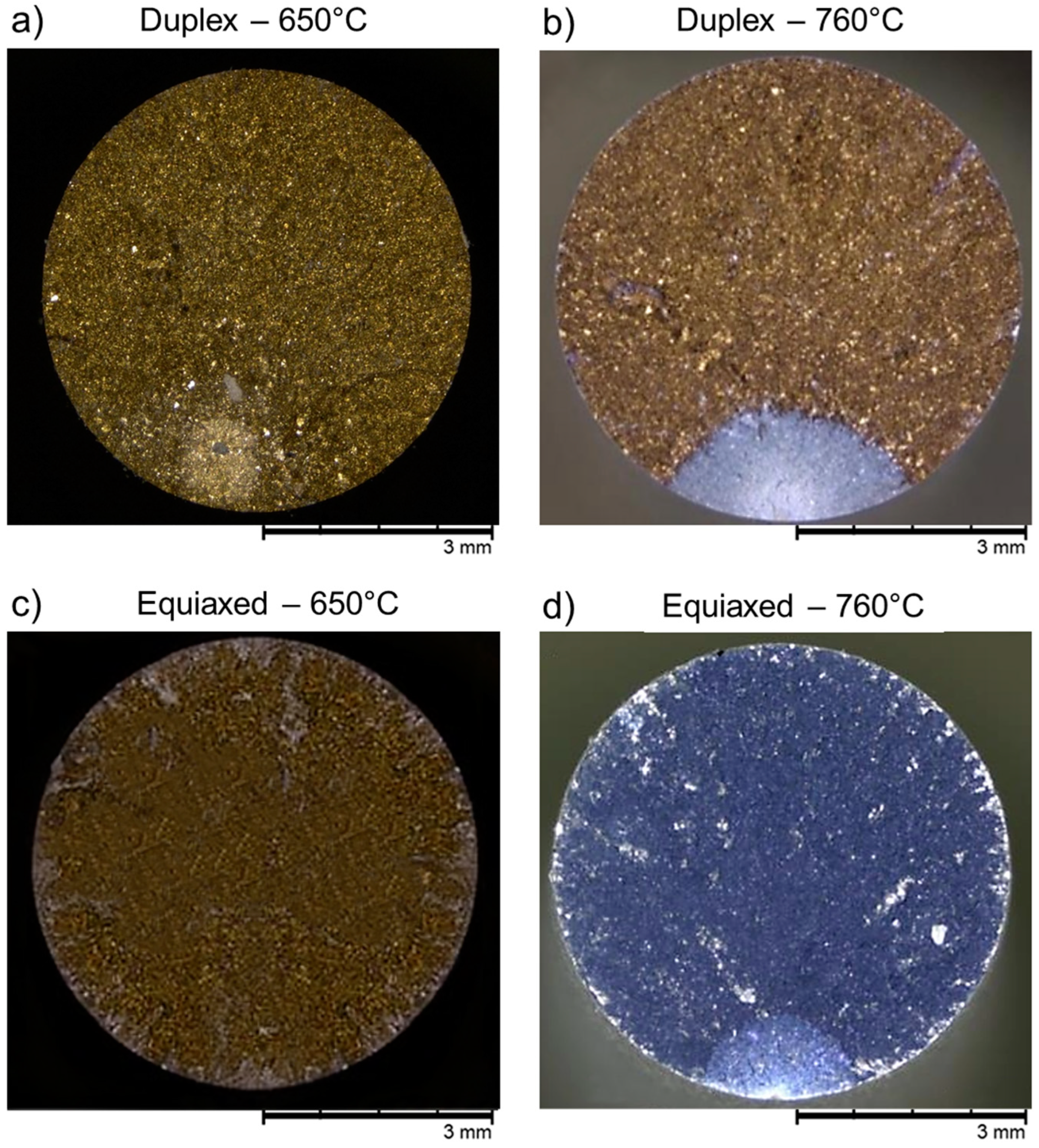

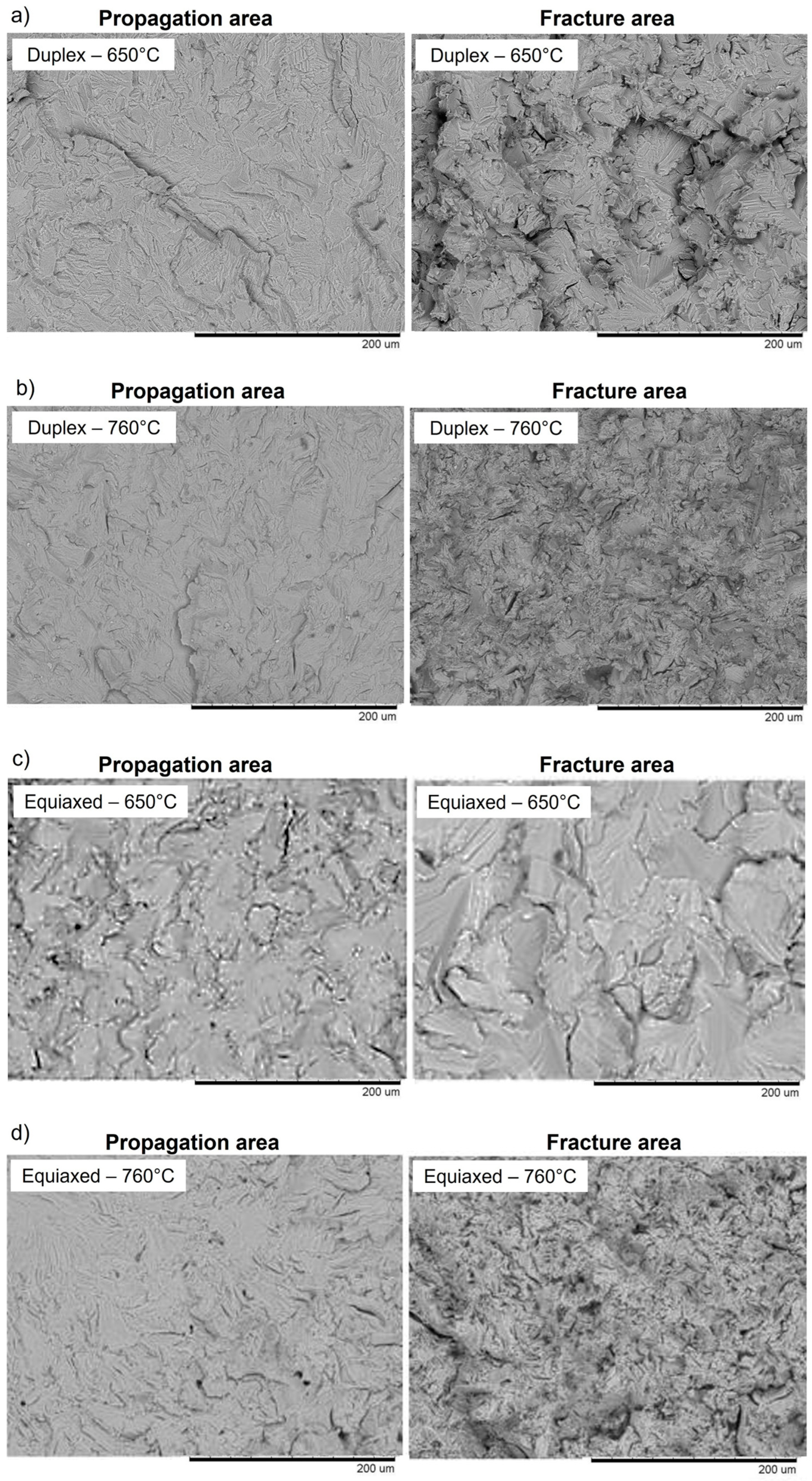

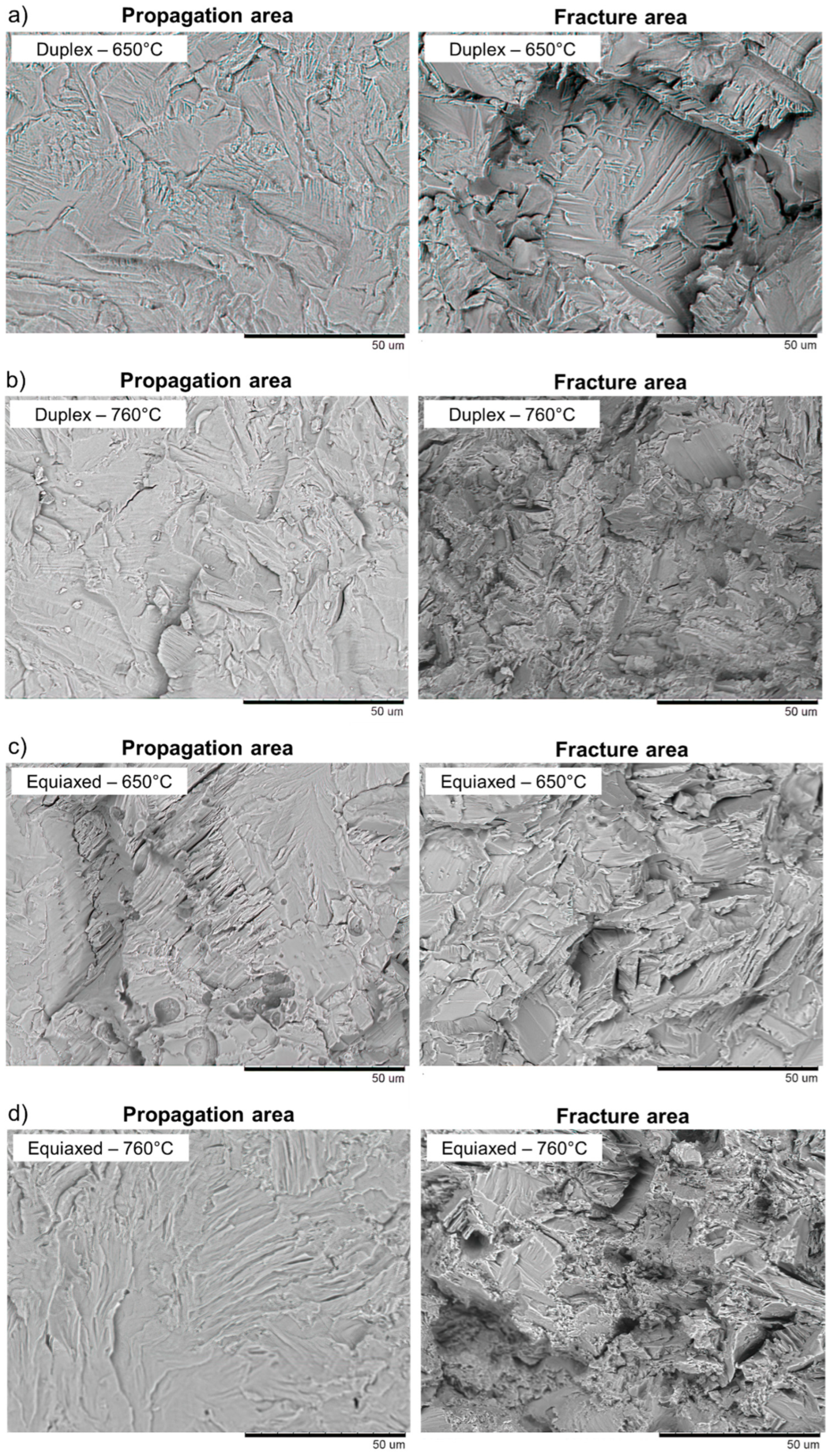

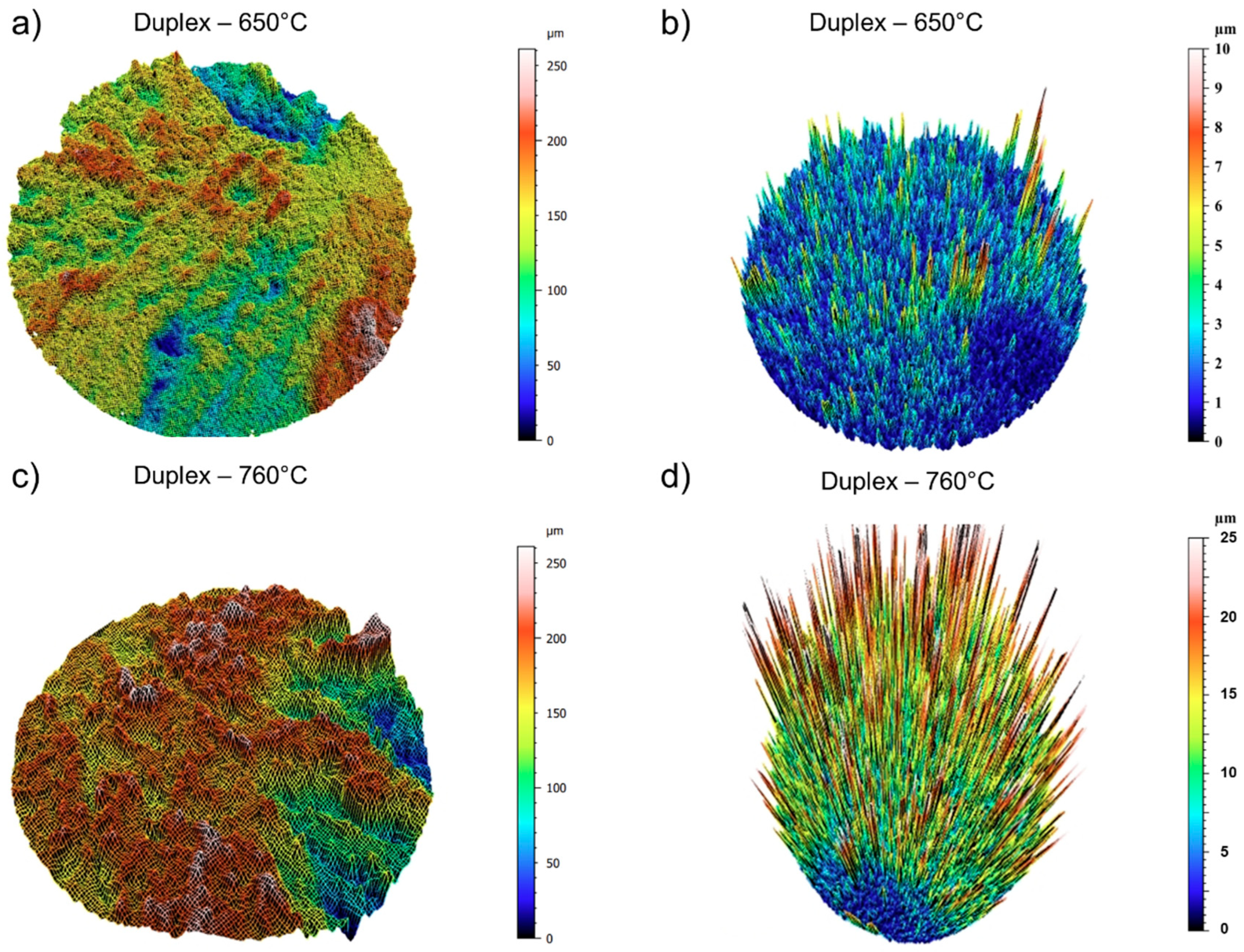

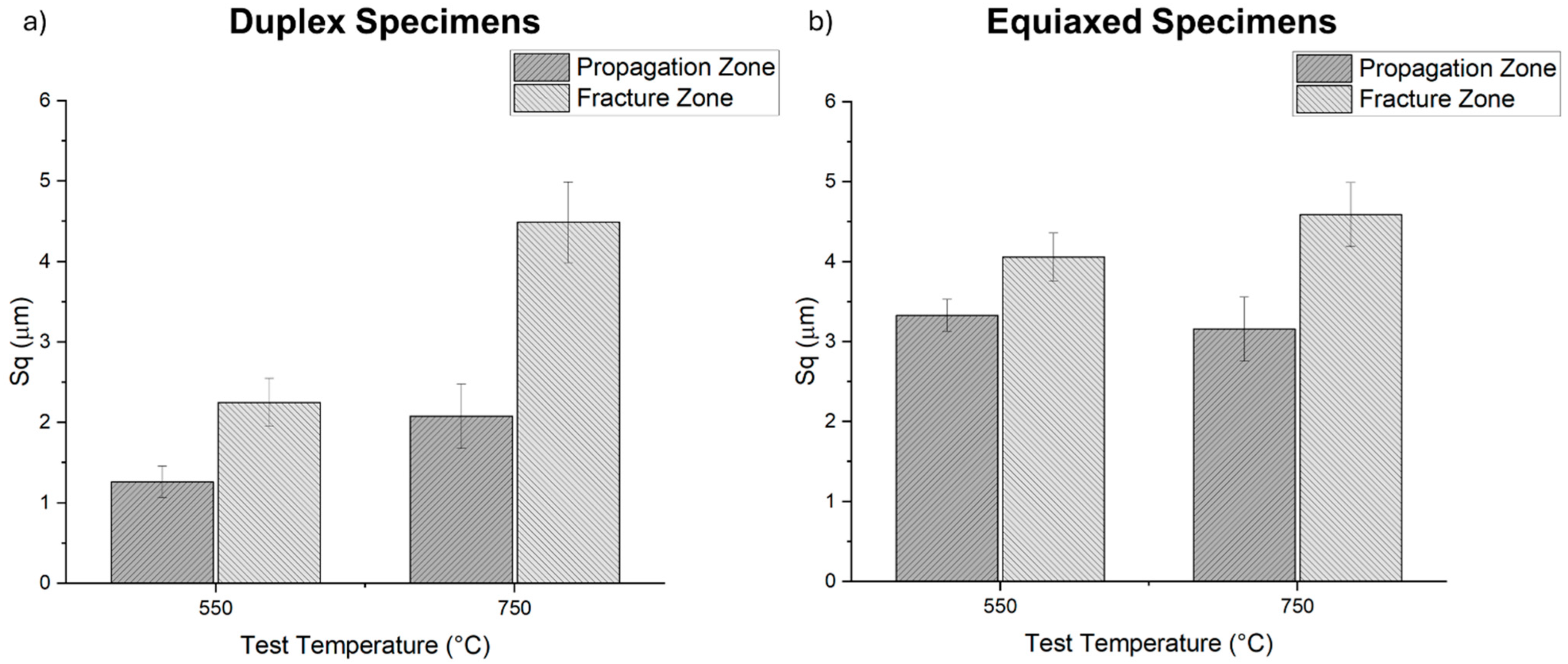

- Surface roughness was found to be a critical indicator of fracture mechanisms. The propagation zone in both tested temperatures (650 °C and 760 °C) exhibited lower Sq values, indicating brittle fracture behavior. This was consistent with the reduced surface roughness observed in this region, which suggests limited plastic deformation before fracture.

- At 650 °C, the equiaxed microstructure demonstrated a less pronounced difference in Sq values between the propagation and fracture zones compared to the duplex microstructure, indicating the influence of the hybrid lamellar-equiaxed microstructure of the duplex specimens. At 760 °C, the fracture zone showed considerably higher Sq values than the propagation zone, due to the more ductile behavior in the fracture zone. This aligns with the higher temperature promoting increased plasticity and more significant deformation before final failure.

- A reliable method for evaluating the fracture behavior of titanium aluminide components can be developed through the construction of surface height maps generated via confocal microscopy. Analysis of roughness values across these maps reveals that regions with lower roughness consistently correspond to fracture initiation and propagation zones, regardless of whether the material operates above or below the ductile-to-brittle transition temperature.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, S.; Lin, Y.-C.; Chung, R.-J. A Review of the State of Art of Fabrication Technologies of Titanium Aluminide (Ti-Al) Based on US Patents. Metals 2024, 14, 418. [Google Scholar] [CrossRef]

- Wimler, D.; Lindemann, J.; Reith, M.; Kirchner, A.; Allen, M.; Vargas, W.G.; Franke, M.; Klöden, B.; Weißgärber, T.; Güther, V.; et al. Designing Advanced Intermetallic Titanium Aluminide Alloys for Additive Manufacturing. Intermetallics 2021, 131, 107109. [Google Scholar] [CrossRef]

- Anil Kumar, V.; Gupta, R.K.; Prasad, M.J.N.V.; Narayana Murty, S.V.S. Recent Advances in Processing of Titanium Alloys and Titanium Aluminides for Space Applications: A Review. J. Mater. Res. 2021, 36, 689–716. [Google Scholar] [CrossRef]

- Sauthoff, G. Intermetallics; Wiley: Hoboken, NJ, USA, 1995; ISBN 9783527268214. [Google Scholar]

- Djanarthany, S.; Viala, J.-C.; Bouix, J. An Overview of Monolithic Titanium Aluminides Based on Ti3Al and TiAl. Mater. Chem. Phys. 2001, 72, 301–319. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Intermetallic Titanium Aluminides in Aerospace Applications—Processing, Microstructure and Properties. Mater. High Temp. 2016, 33, 560–570. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, Processing, Microstructure, Properties, and Applications of Advanced Intermetallic TiAl Alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Subramanian, P.R.; Mendiratta, M.G.; Dimiduk, D.M.; Stucke, M.A. Advanced Intermetallic Alloys—Beyond Gamma Titanium Aluminides. Mater. Sci. Eng. A 1997, 239–240, 1–13. [Google Scholar] [CrossRef]

- Gupta, R.K.; Pant, B.; Agarwala, V.; Sinha, P.P. Effect of Chromium and Niobium on the Kinetics of Synthesis of Titanium Aluminide. Met. Sci. Heat Treat. 2013, 55, 438–444. [Google Scholar] [CrossRef]

- Tlotleng, M.; Pityana, S.; Motha, S. Insights on Niobium Micro-Alloyed Laser In Situ Synthesised Gamma Titanium Aluminide Alloys. Appl. Sci. 2023, 13, 5725. [Google Scholar] [CrossRef]

- Seifi, M.; Ghamarian, I.; Samimi, P.; Ackelid, U.; Collins, P.; Lewandowski, J. Microstructure and Mechanical Properties of Ti-48Al-2Cr-2Nb Manufactured via Electron Beam Melting. In Proceedings of the 13th World Conference on Titanium; Wiley: Hoboken, NJ, USA, 2016; pp. 1317–1322. [Google Scholar]

- Liu, Z.; Wang, C.; Wang, W.; Xu, G.; Liu, X. Effects of Tantalum on the Microstructure and Properties of Ti-48Al-2Cr-2Nb Alloy Fabricated via Laser Additive Manufacturing. Mater. Charact. 2021, 179, 111317. [Google Scholar] [CrossRef]

- Mizuta, K.; Hijikata, Y.; Fujii, T.; Gokan, K.; Kakehi, K. Characterization of Ti-48Al-2Cr-2Nb Built by Selective Laser Melting. Scr. Mater. 2021, 203, 114107. [Google Scholar] [CrossRef]

- Mengis, L.; Grimme, C.; Galetz, M.C. Tribological Properties of the Uncoated and Aluminized Ti–48Al–2Cr–2Nb TiAl Alloy at High Temperatures. Wear 2021, 477, 203818. [Google Scholar] [CrossRef]

- Hernandez, J.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructures for Two-Phase Gamma Titanium Aluminide Fabricated by Electron Beam Melting. Metallogr. Microstruct. Anal. 2012, 1, 14–27. [Google Scholar] [CrossRef]

- Kuang, J.P.; Harding, R.A.; Campbell, J. Microstructures and Properties of Investment Castings of γ-Titanium Aluminide. Mater. Sci. Eng. A 2002, 329–331, 31–37. [Google Scholar] [CrossRef]

- Gupta, R.K.; Pant, B. Titanium Aluminides. In Intermetallic Matrix Composites; Elsevier: Amsterdam, The Netherlands, 2018; pp. 71–93. [Google Scholar]

- Dahar, M.S.; Seifi, S.M.; Bewlay, B.P.; Lewandowski, J.J. Effects of Test Orientation on Fracture and Fatigue Crack Growth Behavior of Third Generation As-Cast Ti–48Al–2Nb–2Cr. Intermetallics 2015, 57, 73–82. [Google Scholar] [CrossRef]

- Genc, O.; Unal, R. Development of Gamma Titanium Aluminide (γ-TiAl) Alloys: A Review. J. Alloys Compd. 2022, 929, 167262. [Google Scholar] [CrossRef]

- Liu, Z.C.; Lin, J.P.; Li, S.J.; Chen, G.L. Effects of Nb and Al on the Microstructures and Mechanical Properties of High Nb Containing TiAl Base Alloys. Intermetallics 2002, 10, 653–659. [Google Scholar] [CrossRef]

- Feng, J.; Gui, W.; Liu, Q.; Bi, W.; Ren, X.; Liang, Y.; Lin, J.; Luan, B. Ti–48Al–2Cr–2Nb Alloys Prepared by Electron Beam Selective Melting Additive Manufacturing: Microstructural and Tensile Properties. J. Mater. Res. Technol. 2023, 26, 9357–9369. [Google Scholar] [CrossRef]

- Soliman, H.A.; Elbestawi, M. Titanium Aluminides Processing by Additive Manufacturing—A Review. Int. J. Adv. Manuf. Technol. 2022, 119, 5583–5614. [Google Scholar] [CrossRef]

- Behjat, A.; Saboori, A.; Galati, M.; Iuliano, L. The Electrochemical Behaviour of Ti-48Al-2Cr-2Nb Produced by Electron Beam Powder Bed Fusion Process. Intermetallics 2024, 175, 108472. [Google Scholar] [CrossRef]

- Lin, B.; Chen, W.; Yang, Y.; Wu, F.; Li, Z. Anisotropy of Microstructure and Tensile Properties of Ti–48Al–2Cr–2Nb Fabricated by Electron Beam Melting. J. Alloys Compd. 2020, 830, 154684. [Google Scholar] [CrossRef]

- Emiralioğlu, A.; Ünal, R. Additive Manufacturing of Gamma Titanium Aluminide Alloys: A Review. J. Mater. Sci. 2022, 57, 4441–4466. [Google Scholar] [CrossRef]

- Dahar, M.S.; Tamirisakandala, S.A.; Lewandowski, J.J. Evolution of Fatigue Crack Growth and Fracture Behavior in Gamma Titanium Aluminide Ti-43.5Al-4Nb-1Mo-0.1B (TNM) Forgings. Int. J. Fatigue 2018, 111, 54–69. [Google Scholar] [CrossRef]

- Trant, C.F.; Lindley, T.C.; Martin, N.; Dixon, M.; Dye, D. Fatigue Cracking in Gamma Titanium Aluminide. Mater. Sci. Eng. A 2020, 798, 140202. [Google Scholar] [CrossRef]

- Davidson, D.L.; Campbell, J.B.; Page, R.A. The Initiation and Growth of Fatigue Cracks in a Titanium Aluminide Alloy. Metall. Trans. A 1991, 22, 377–391. [Google Scholar] [CrossRef]

- Assari, A.H.; Eghbali, B. Microstructure and Kinetics of Intermetallic Phase Formation During Solid State Diffusion Bonding in Bimetal Ti/Al. Phys. Met. Metallogr. 2019, 120, 260–268. [Google Scholar] [CrossRef]

- AlHazaa, A.; Haneklaus, N. Diffusion Bonding and Transient Liquid Phase (TLP) Bonding of Type 304 and 316 Austenitic Stainless Steel—A Review of Similar and Dissimilar Material Joints. Metals 2020, 10, 613. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ceylan, A.; Martinez, E.; Martinez, J.L.; Hernandez, D.H.; Machado, B.I.; Ramirez, D.A.; Medina, F.; Collins, S.; et al. Characterization of Titanium Aluminide Alloy Components Fabricated by Additive Manufacturing Using Electron Beam Melting. Acta Mater. 2010, 58, 1887–1894. [Google Scholar] [CrossRef]

- ASTM E21-20; Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM E606/E606M-21; Standard Test Method for Strain-Controlled Fatigue Testing. ASTM: West Conshohocken, PA, USA, 2021.

- Ellard, J.J.M.; Mathabathe, M.N.; Siyasiya, C.W.; Bolokang, A.S. Low-Cycle Fatigue Behaviour of Titanium-Aluminium-Based Intermetallic Alloys: A Short Review. Metals 2023, 13, 1491. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. (Eds.) Titanium and Titanium Alloys; Wiley: Hoboken, NJ, USA, 2003; ISBN 9783527305346. [Google Scholar]

| Sa [μm] | Sq [μm] | |

|---|---|---|

| Duplex T = 650 | 2.01 ± 0.3 | 2.65 ± 0.3 |

| Duplex T = 760 | 3.12 ± 0.2 | 3.98 ± 0.4 |

| Equiaxed T = 650 | 4.16 ± 0.2 | 5.37 ± 0.8 |

| Equiaxed T = 760 | 4.42 ± 0.3 | 7.87 ± 0.7 |

| Propagation Zone | ||

|---|---|---|

| Sa [μm] | Sq [μm] | |

| Duplex T = 650 | 0.973 ± 0.1 | 1.26 ± 0.2 |

| Duplex T = 760 | 1.63 ± 0.2 | 2.08 ± 0.4 |

| Equiaxed T = 650 | 2.33 ± 0.3 | 3.33 ± 0.2 |

| Equiaxed T = 760 | 2.43 ± 0.3 | 3.16 ± 0.4 |

| Fracture Zone | ||

| Sa [μm] | Sq [μm] | |

| Duplex T = 650 | 1.68 ± 0.2 | 2.25 ± 0.3 |

| Duplex T = 760 | 3.30 ± 0.3 | 4.49 ± 0.5 |

| Equiaxed T = 650 | 2.49 ± 0.3 | 4.06 ± 0.3 |

| Equiaxed T = 760 | 3.58 ± 0.2 | 4.59 ± 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perna, A.S.; Savio, L.; Coppola, M.; Scherillo, F. Investigating Fracture Behavior in Titanium Aluminides: Surface Roughness as an Indicator of Fracture Mechanisms in Ti-48Al-2Cr-2Nb Alloys. Metals 2025, 15, 49. https://doi.org/10.3390/met15010049

Perna AS, Savio L, Coppola M, Scherillo F. Investigating Fracture Behavior in Titanium Aluminides: Surface Roughness as an Indicator of Fracture Mechanisms in Ti-48Al-2Cr-2Nb Alloys. Metals. 2025; 15(1):49. https://doi.org/10.3390/met15010049

Chicago/Turabian StylePerna, Alessia Serena, Lorenzo Savio, Michele Coppola, and Fabio Scherillo. 2025. "Investigating Fracture Behavior in Titanium Aluminides: Surface Roughness as an Indicator of Fracture Mechanisms in Ti-48Al-2Cr-2Nb Alloys" Metals 15, no. 1: 49. https://doi.org/10.3390/met15010049

APA StylePerna, A. S., Savio, L., Coppola, M., & Scherillo, F. (2025). Investigating Fracture Behavior in Titanium Aluminides: Surface Roughness as an Indicator of Fracture Mechanisms in Ti-48Al-2Cr-2Nb Alloys. Metals, 15(1), 49. https://doi.org/10.3390/met15010049