Effects of the Primary Carbide Distribution on the Evolution of the Grain Boundary Character Distribution in a Nickel-Based Alloy

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

4. Conclusions

- (1)

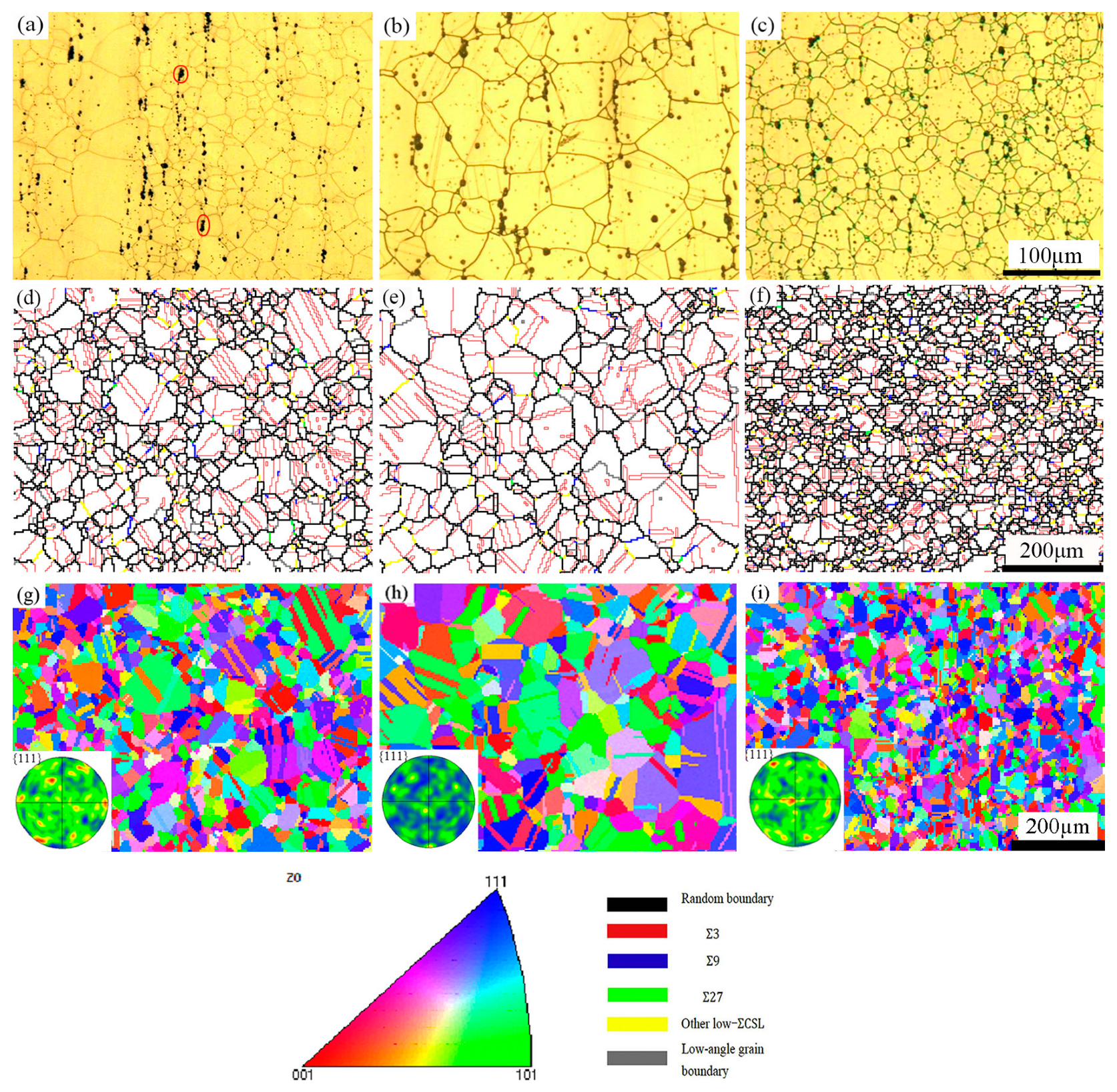

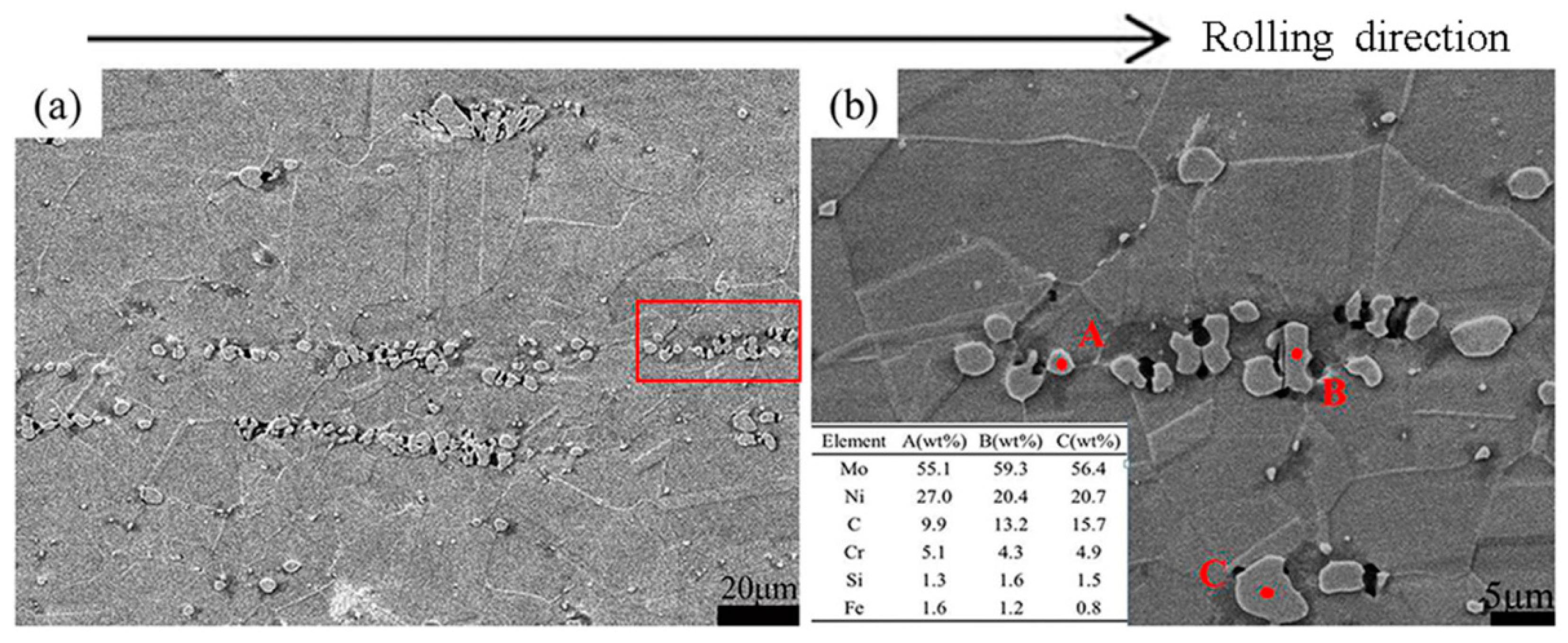

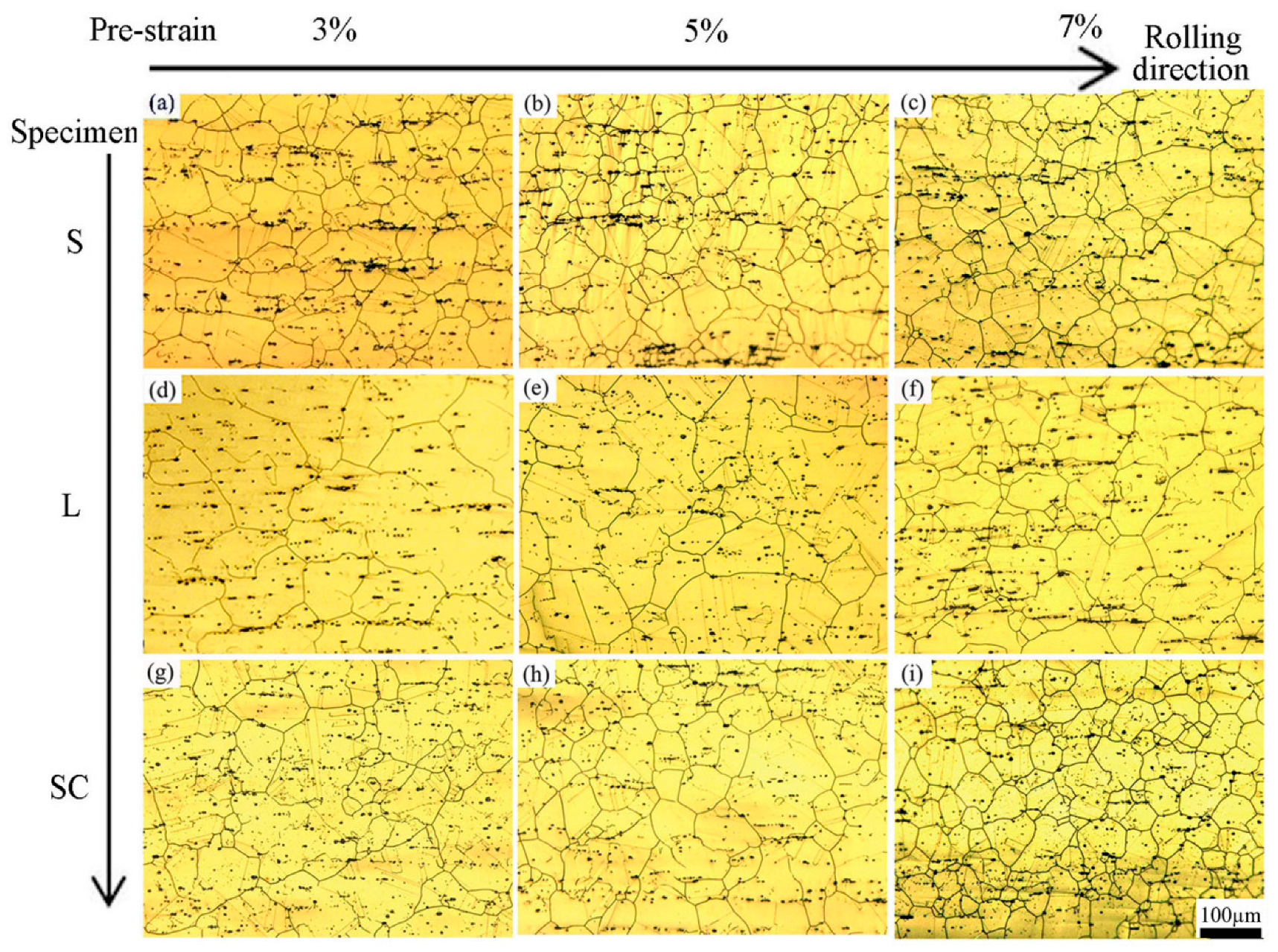

- The distribution of primary carbides is intentionally altered by changing the cold-rolling direction in a nickel-based alloy (GH3535, Ni-16Mo-7Cr-4Fe), and its effects on the grain boundary character distribution were investigated in this work.

- (2)

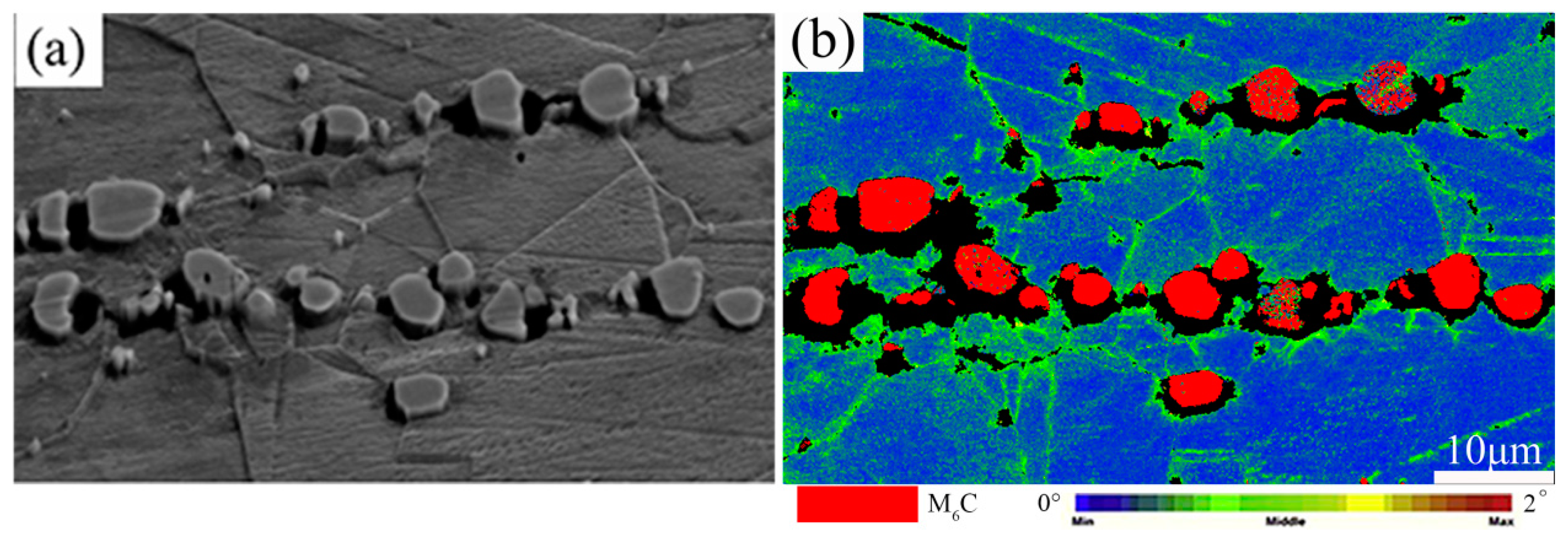

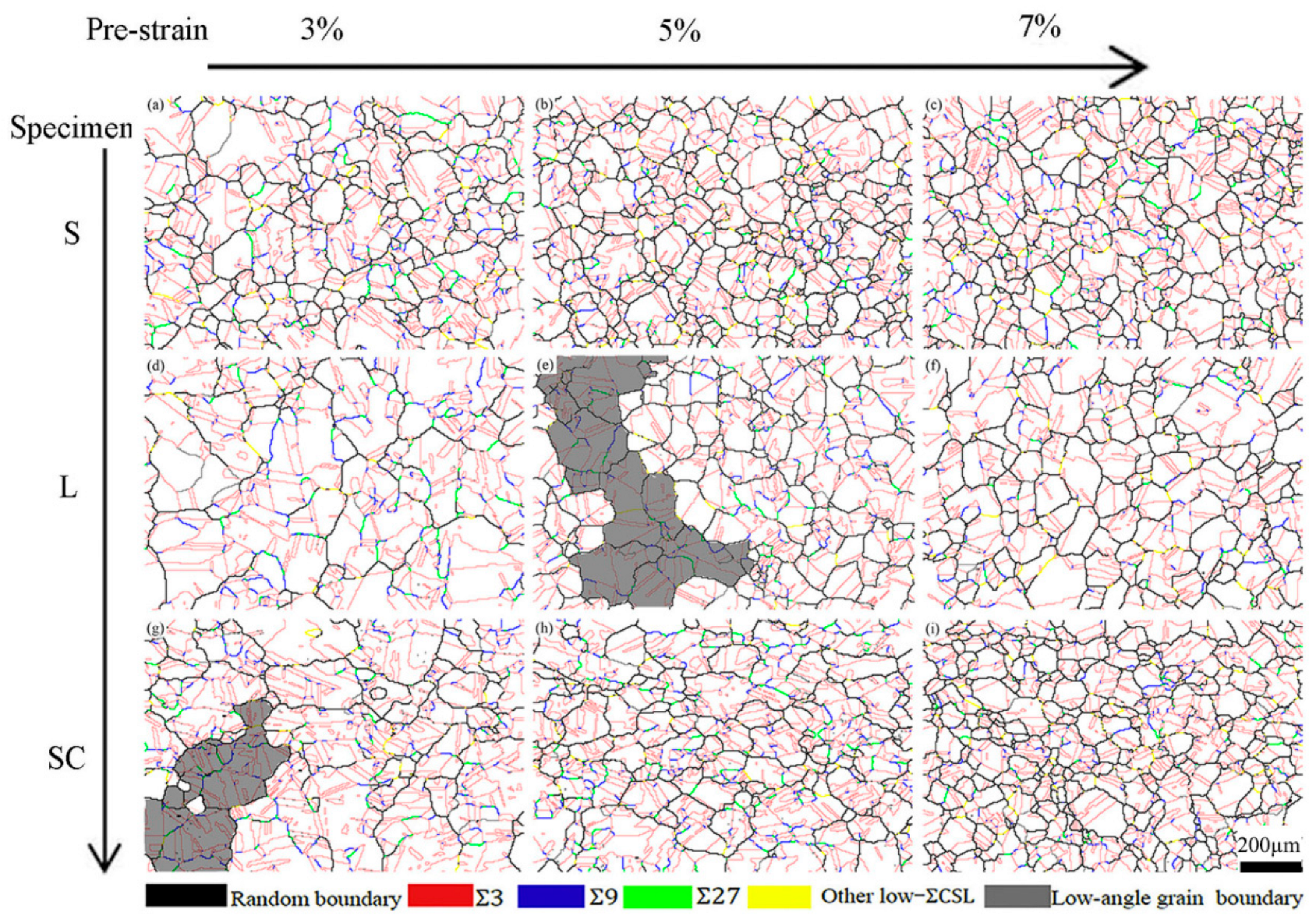

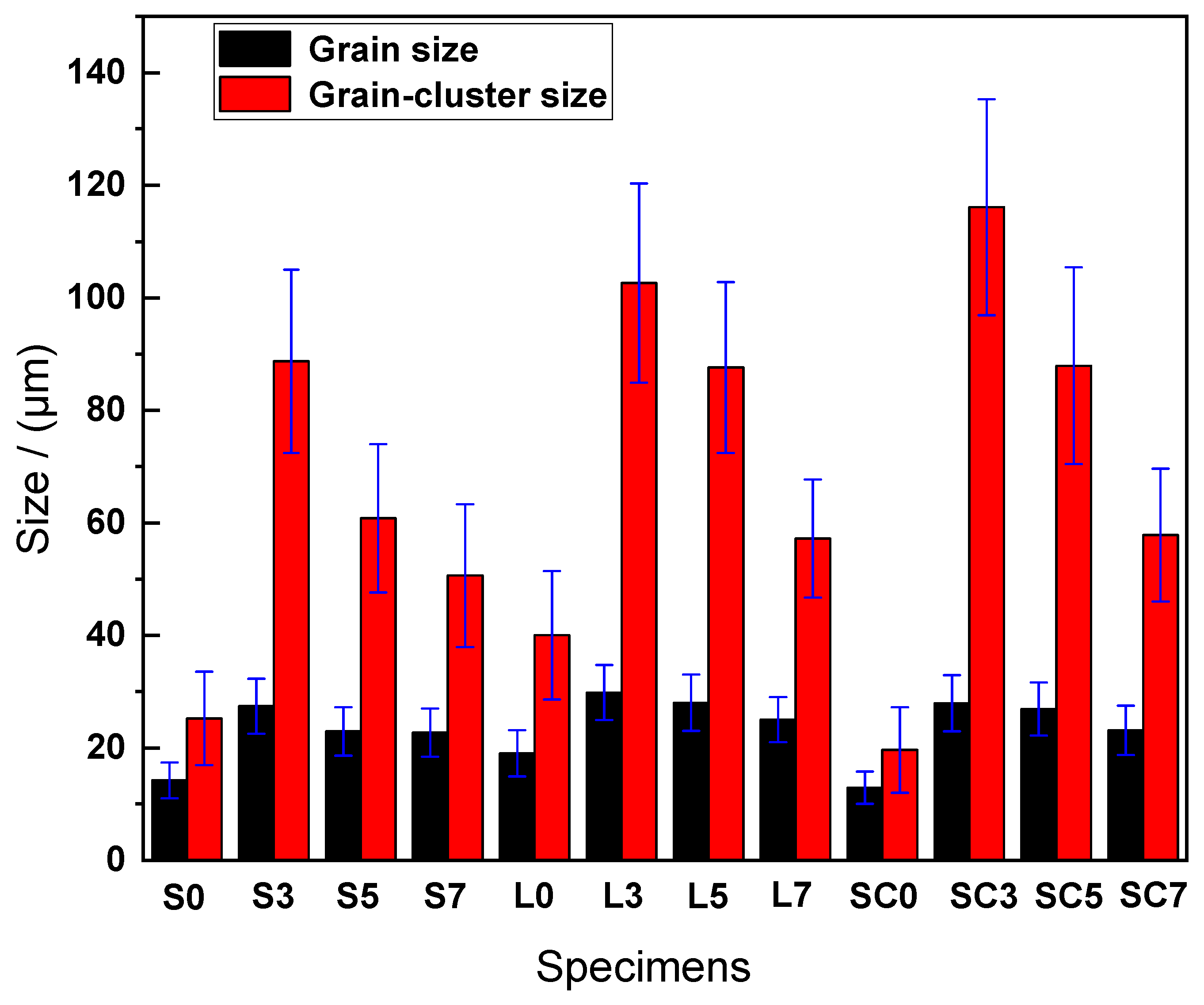

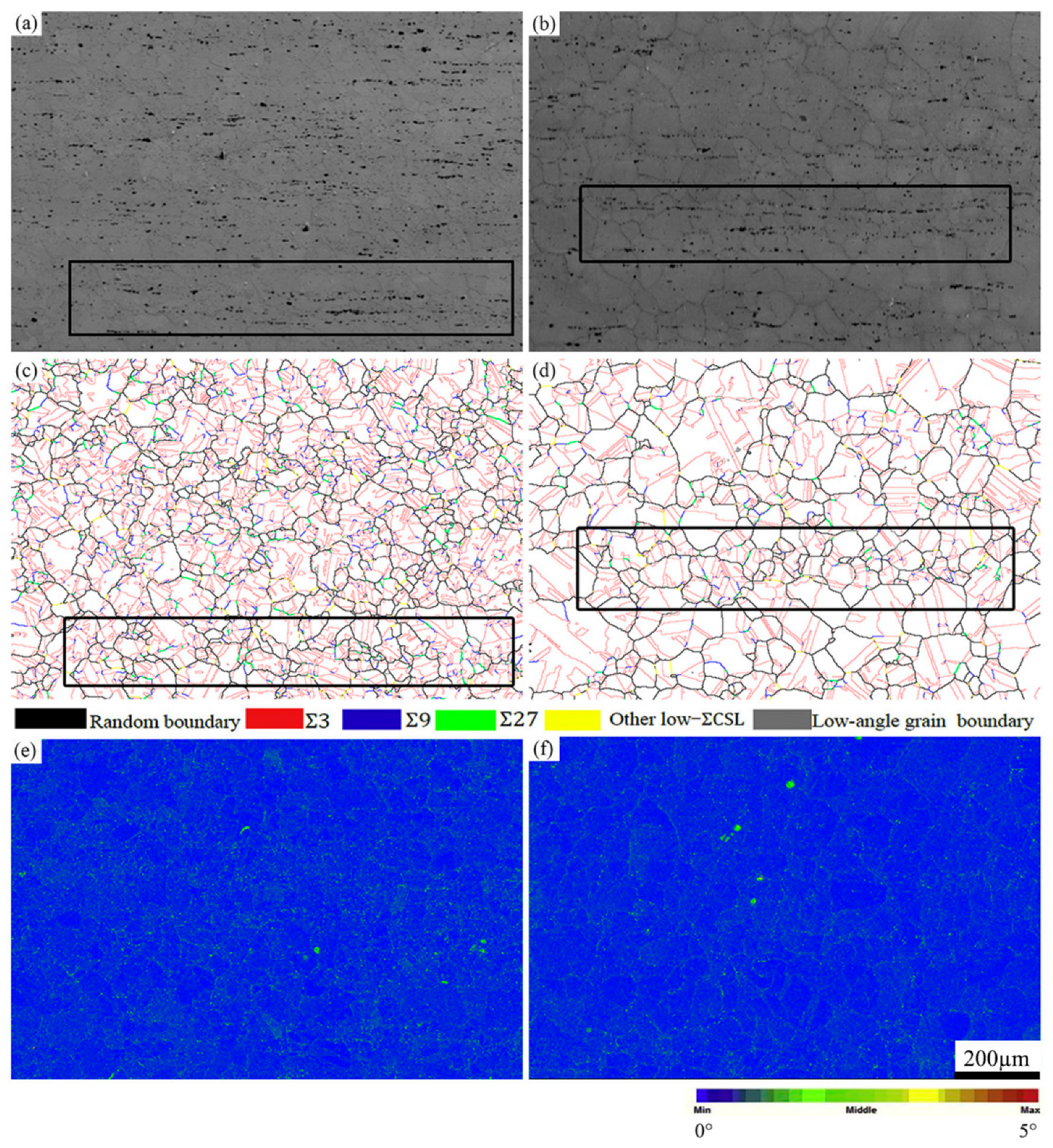

- In the sample with many string-like primary carbides along the rolling direction, the intensively distributed primary carbide strings not only induced the occurrence of particle-stimulated nucleation of recrystallization, which increased the random boundary density, but also prevented or delayed the migration of GBs due to the pinning effect.

- (3)

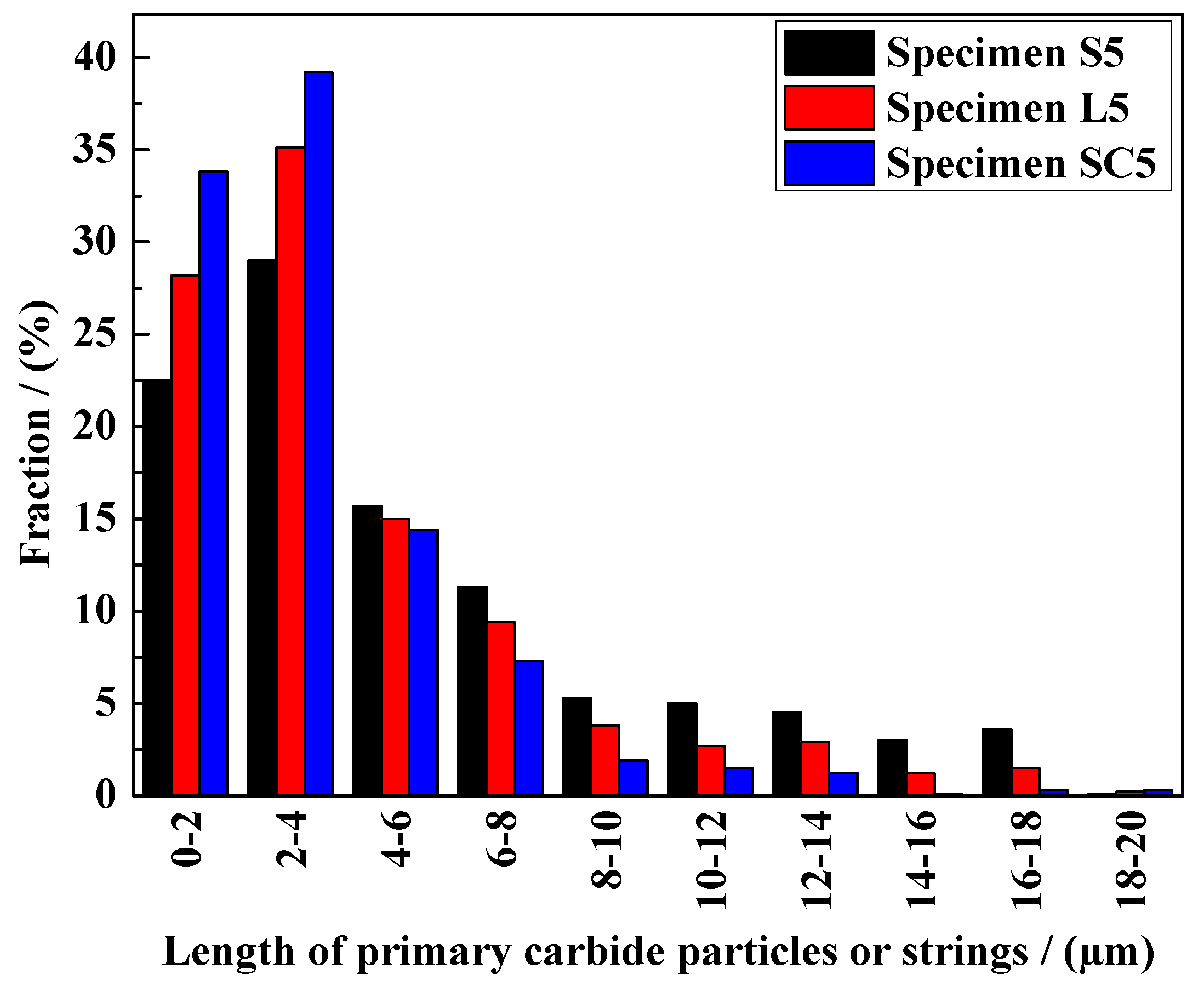

- By applying cross-rolling and subsequent annealing, the strings of primary carbides were substantially fragmented, resulting in more dispersive primary carbides. In this case, a higher proportion of Σ3n grain boundaries associated with extensive multiple twinning events can be achieved via routine GBE-type thermal-mechanical processing.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, Z.; Gao, L.; Qi, W.; Zhang, C.; Wang, X.; Song, J.; He, X.; Zhang, C.; Tang, H.; Rohan, H.; et al. Molten FLiNaK salt infiltration into degassed nuclear graphite under inert gas pressure. Carbon 2015, 84, 511–518. [Google Scholar] [CrossRef]

- Ren, W.; Muralidharan, G.; Wilson, D.F.; Holcomb, D.E. Considerations of alloy N for fluoride salt-cooled high-temperature reactor applications. In Proceedings of the ASME 2011 Pressure Vessels and Piping Conference, Baltimore, MD, USA, 17–21 July 2011; pp. 725–736. [Google Scholar]

- Rosenthal, M.; Haubenreich, P.; Briggs, R. The development status of molten-salt breeder reactors. ORNL-4812 1972, 1–30. [Google Scholar] [CrossRef]

- Yamada, G.; Kokawa, H.; Yasuda, Y.; Tokita, S.; Yokoyama, T.; Sato, Y.S.; Fujii, H.T.; Tsurekawa, S. Effect of post-GBE strain-sensitisation on corrosion resistance of grain boundary engineered 304 austenitic stainless steel. Philos. Mag. 2013, 93, 1443–1453. [Google Scholar] [CrossRef]

- Telang, A.; Gill, A.S.; Tammana, D.; Wen, X.S.; Kumar, M.; Teysseyre, S.; Mannava, S.R.; Qian, D.; Vasudevan, V.K. Surface grain boundary engineering of Alloy 600 for improved resistance to stress corrosion cracking. Mater. Sci. Eng. A 2015, 648, 280–288. [Google Scholar] [CrossRef]

- Das, A. Grain boundary engineering: Fatigue fracture. Philos. Mag. 2017, 97, 867–916. [Google Scholar] [CrossRef]

- Safari, H.; Rezaeian, A.; Karimzadeh, F. Novel role of thermomechanical grain boundary engineering in the microstructure evolution of austenitic stainless steel. J. Mater. Res. Technol. 2024, 30, 146–163. [Google Scholar] [CrossRef]

- Wang, X.; Xue, H.; Zhao, Y.; Zhao, M.; Zhang, T.; Wang, F. Effect of grain boundary engineering on corrosion behavior of 316 L stainless steel bipolar plate in proton exchange membrane fuel cells environment. Mater. Today Commun. 2024, 38, 107773. [Google Scholar] [CrossRef]

- Tokita, S.; Kokawa, H.; Sato, Y.S.; Fujii, H.T. In situ EBSD observation of grain boundary character distribution evolution during thermomechanical process used for grain boundary engineering of 304 austenitic stainless steel. Mater. Charact. 2017, 131, 31–38. [Google Scholar] [CrossRef]

- Cao, W.; Xia, S.; Bai, Q.; Zhang, W.Z.; Zhou, B.X.; Li, Z.J.; Jiang, L. Effects of initial microstructure on the grain boundary network during grain boundary engineering in Hastelloy N alloy. J. Alloys Compd. 2017, 704, 724–733. [Google Scholar] [CrossRef]

- Liu, T.G.; Xia, S.; Li, H.; Zhou, B.X.; Bai, Q.; Su, C.; Cai, Z.G. Effect of initial grain sizes on the grain boundary network during grain boundary engineering in Alloy 690. J. Mater. Res. 2013, 28, 1165–1176. [Google Scholar] [CrossRef]

- Liu, T.G.; Xia, S.; Li, H.; Zhou, B.X.; Bai, Q. Effect of the pre-existing carbides on the grain boundary network during grain boundary engineering in a nickel based alloy. Mater. Charact. 2014, 91, 89–100. [Google Scholar] [CrossRef]

- Bian, B.; Taheriniya, S.; Muralikrishna, G.M.; Sen, S.; Gammer, C.; Steinbach, I.; Divinski, S.V.; Wilde, G. Coupling of alloy chemistry, diffusion and structure by grain boundary engineering in Ni–Cr–Fe. Acta Mater. 2024, 264, 119602. [Google Scholar] [CrossRef]

- Lind, J.; Li, S.F.; Kumar, M. Twin related domains in 3D microstructures of conventionally processed and grain boundary engineered materials. Acta Mater. 2016, 114, 43–53. [Google Scholar] [CrossRef]

- Kobayashi, S.; Kobayashi, R.; Watanabe, T. Control of grain boundary connectivity based on fractal analysis for improvement of intergranular corrosion resistance in SUS316L austenitic stainless steel. Acta Mater. 2016, 102, 397–405. [Google Scholar] [CrossRef]

- Randle, V. Twinning-related grain boundary engineering. Acta Mater. 2004, 52, 4067–4081. [Google Scholar] [CrossRef]

- Bai, Q.; Zhao, Q.; Xia, S.; Wang, B.S.; Zhou, B.X.; Su, C. Evolution of grain boundary character distributions in alloy 825 tubes during high temperature annealing: Is grain boundary engineering achieved through recrystallization or grain growth? Mater. Charact. 2017, 123, 178–188. [Google Scholar] [CrossRef]

- David, B.B.; Jonathan, L.; Rupalee, P.M.; Timothy, J.R.; Mukul, K. The formation and characterization of large twin related domains. Acta Mater. 2017, 129, 500–509. [Google Scholar] [CrossRef]

- Pereloma, E.V.; Mannan, P.; Gilberto, C.; Saleh, A.A. Particle stimulated nucleation during dynamic and metadynamic recrystallisation of Ni-30%Fe-Nb-C alloy. Mater. Charact. 2017, 125, 94–98. [Google Scholar] [CrossRef]

- Katnagallu, S.S.; Mandal, S.; Cheekur Nagaraja, A.; de Boer, B.; Sarma, V.S. Role of carbide precipitates and process parameters on achieving grain boundary engineered microstructure in a Ni-based superalloy. Metall. Mater. Trans. A 2015, 46, 4740–4754. [Google Scholar] [CrossRef]

- Feng, W.; Yang, S.; Yan, Y.B. Dependence of grain boundary character distribution on the initial grain size of 304 austenitic stainless steel. Philos. Mag. 2017, 97, 1057–1070. [Google Scholar] [CrossRef]

- Kaithwas, C.K.; Bhuyan, P.; Pradhan, S.K.; Mandal, S. Microstructure evolution during low-strain thermo-mechanical processing and its repercussion on intergranular corrosion in alloy 600H. Mater. Charact. 2018, 145, 582–593. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Sarma, V.S. One-step and iterative thermo-mechanical treatments to enhance Σ3n boundaries in a Ti-modified austenitic stainless steel. J. Mater. Sci. 2011, 46, 275–284. [Google Scholar] [CrossRef]

- Owen, G.; Randle, V. On the role of iterative processing in grain boundary engineering. Scr. Mater. 2006, 55, 959–962. [Google Scholar] [CrossRef]

- Barr, C.M.; Leff, A.C.; Demott, R.W.; Doherty, R.D.; Taheri, M.L. Unraveling the origin of twin related domains and grain boundary evolution during grain boundary engineering. Acta Mater. 2018, 144, 281–291. [Google Scholar] [CrossRef]

- Li, H.; Xia, S.; Zhou, B.X.; Chen, W.J.; Hu, C.L. The dependence of carbide morphology on grain boundary character in the highly twinned Alloy 690. J. Nucl. Mater. 2010, 399, 108–113. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.R.; Zhang, K.; Liu, W.Q.; Xia, S.; Zhou, B.X. Effects of the triple junction types on the grain boundary carbide precipitation in a nickel-based superalloy, a statistical analysis. Philos. Mag. 2019, 99, 318–327. [Google Scholar] [CrossRef]

- Li, H. Twinning structure of M23C6 carbide precipitated at twin related grain boundaries in alloy 600. Philos. Mag. 2016, 96, 551–559. [Google Scholar] [CrossRef]

- Palumbo, G.; Aust, K.T.; Lehockey, E.M.; Erb, U.; Lin, P. On a more restrictive geometric criterion for “special” CSL grain boundaries. Scr. Mater. 1998, 38, 1685–1690. [Google Scholar] [CrossRef]

- Xu, Z.; Jiang, L.; Dong, J.; Li, Z.; Zhou, X. The effect of silicon on precipitation and decomposition behaviors of M6C carbide in a Ni–Mo–Cr superalloy. J. Alloys Compd. 2015, 620, 197–203. [Google Scholar] [CrossRef]

- Schäfer, C.; Song, J.; Gottstein, G. Modeling of texture evolution in the deformation zone of second-phase particles. Acta Mater. 2009, 57, 1026–1034. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Bhuyan, P.; Kaithwas, C.; Mandal, S. Strain-annealing based grain boundary engineering to evaluate its sole implication on intergranular corrosion in extra-low carbon type 304L austenitic stainless steel. Metall. Mater. Trans. A 2018, 49, 2817–2831. [Google Scholar] [CrossRef]

- Oliferuk, W.; Maj, M. Effect of pre-strain direction on energy storage process during tensile deformation of polycrystal. Mater. Sci. Eng. A 2004, 387, 218–221. [Google Scholar] [CrossRef]

- Field, D.P.; Bradford, L.T.; Nowell, M.M.; Lillo, T.M. The role of annealing twins during recrystallization of Cu. Acta Mater. 2007, 55, 4233–4421. [Google Scholar] [CrossRef]

- Jin, Y.; Lin, B.; Bernacki, M.; Rohrer, G.S.; Rollett, A.D.; Bozzolo, N. Annealing twin development during recrystallization and grain growth in pure nickel. Mater. Sci. Eng. A 2014, 597, 295–303. [Google Scholar] [CrossRef]

- Xu, W.; Ferry, M.; Cairney, J.M.; Humphreys, F.J. Three-dimensional investigation of particle-stimulated nucleation in a nickel alloy. Acta Mater. 2007, 55, 5157–5167. [Google Scholar] [CrossRef]

- Huang, Y.; Humphreys, F.J. The effect of solutes on grain boundary mobility during recrystallization and grain growth in some single-phase aluminum alloys. Mater. Chem. Phys. 2012, 132, 166–174. [Google Scholar] [CrossRef]

| Ni | Mo | Cr | Fe | Mn | Si | C |

|---|---|---|---|---|---|---|

| Bal. | 16.60 | 7.09 | 3.83 | 0.52 | 0.46 | 0.04 |

| Cold Rolling (%) | Pre-Processing Annealing | Sample ID | Strain (%) | GBE-Processing Annealing | Sample ID |

|---|---|---|---|---|---|

| - | - | - | 3 | - | S3 |

| 50 | 1100 × 30 min | S0 | 5 | - | S5 |

| - | - | - | 7 | - | S7 |

| - | - | - | 3 | - | L3 |

| 50 | 1177 × 30 min | L0 | 5 | 1177 × 20 min | L5 |

| - | - | - | 7 | - | L7 |

| - | - | - | 3 | - | SC3 |

| 50 | 1100 × 30 min | SC0 | 5 | - | SC5 |

| (cross-rolling) | - | - | 7 | - | SC7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, S.; Ma, Y.; Bai, Q. Effects of the Primary Carbide Distribution on the Evolution of the Grain Boundary Character Distribution in a Nickel-Based Alloy. Metals 2024, 14, 960. https://doi.org/10.3390/met14090960

Xia S, Ma Y, Bai Q. Effects of the Primary Carbide Distribution on the Evolution of the Grain Boundary Character Distribution in a Nickel-Based Alloy. Metals. 2024; 14(9):960. https://doi.org/10.3390/met14090960

Chicago/Turabian StyleXia, Shuang, Yuanye Ma, and Qin Bai. 2024. "Effects of the Primary Carbide Distribution on the Evolution of the Grain Boundary Character Distribution in a Nickel-Based Alloy" Metals 14, no. 9: 960. https://doi.org/10.3390/met14090960

APA StyleXia, S., Ma, Y., & Bai, Q. (2024). Effects of the Primary Carbide Distribution on the Evolution of the Grain Boundary Character Distribution in a Nickel-Based Alloy. Metals, 14(9), 960. https://doi.org/10.3390/met14090960