Active and Passive Filling Stir Repairing of AISI 304 Alloy

Abstract

1. Introduction

Metal Component Repair with FSSW Techniques

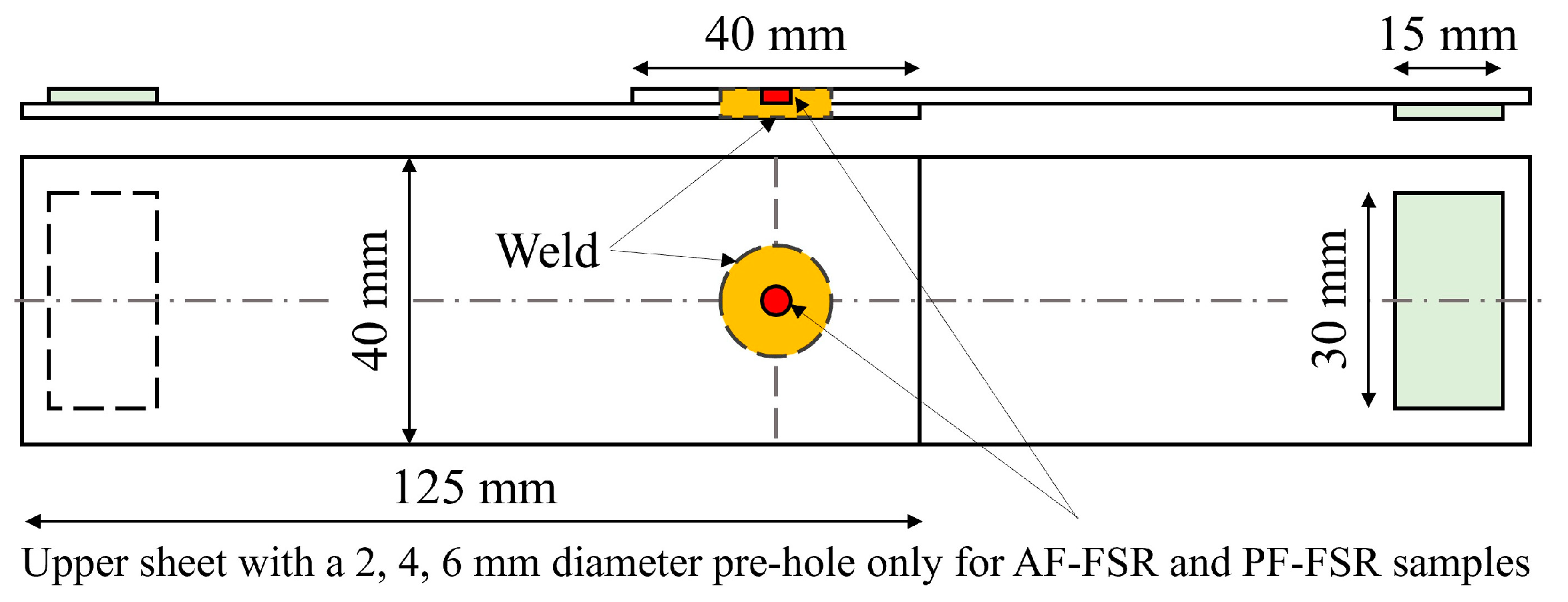

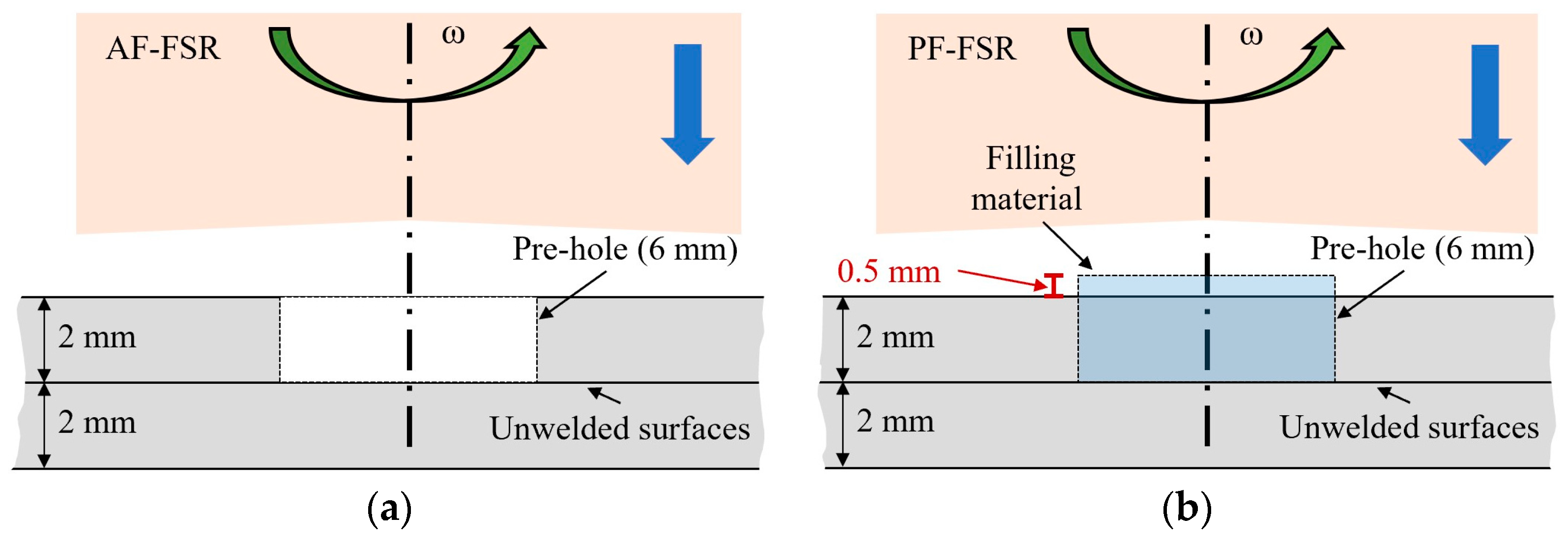

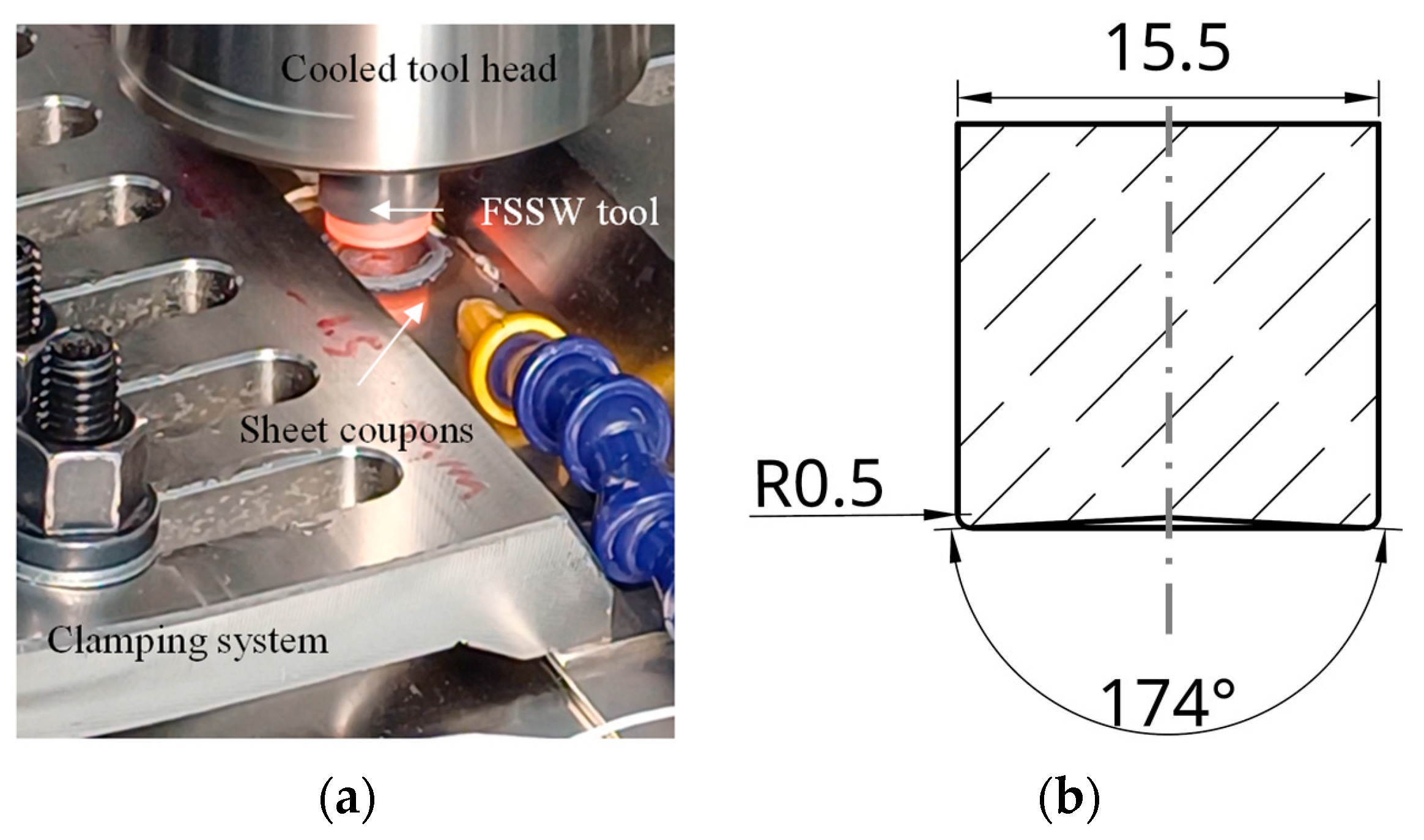

2. Materials and Methods

3. Test Results and Their Analysis

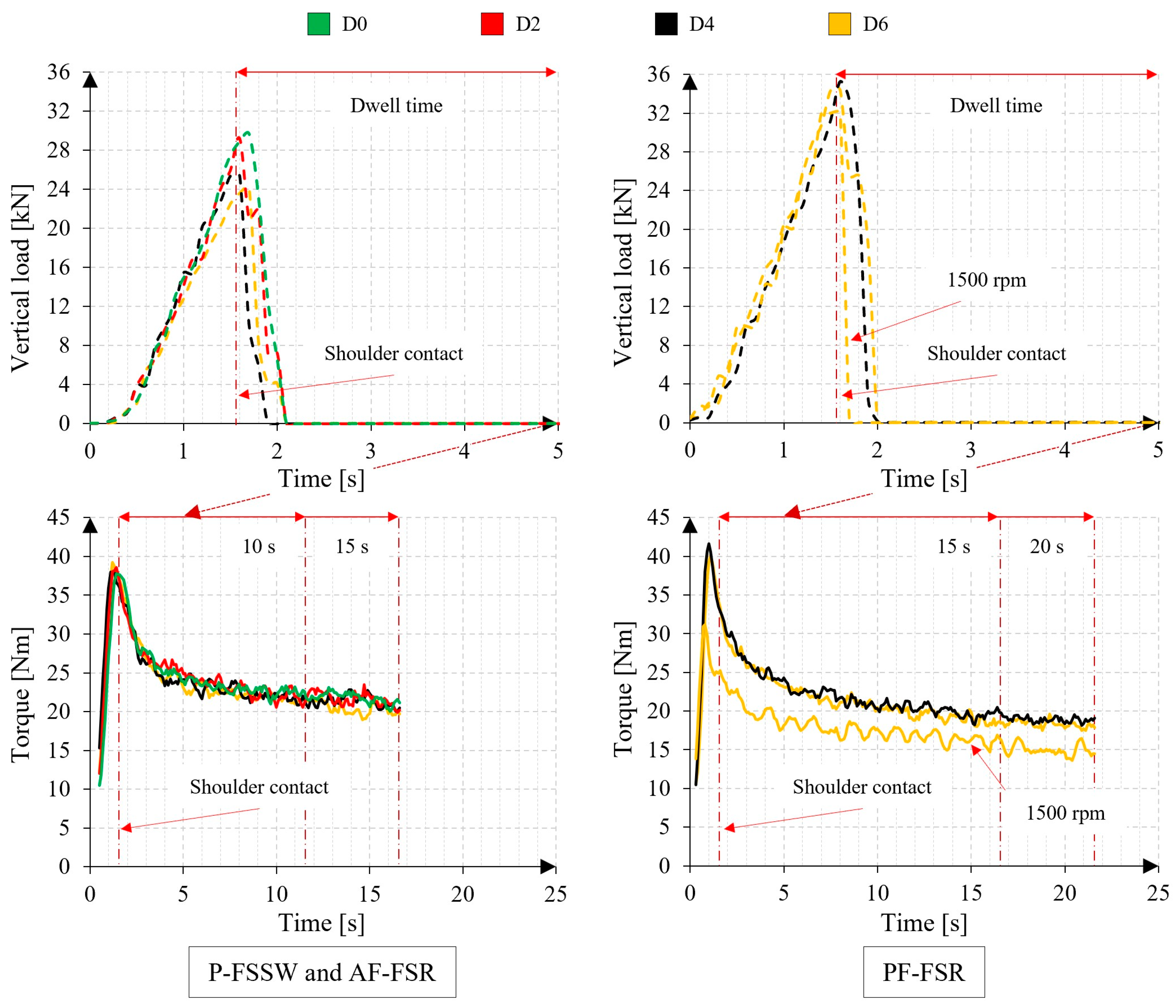

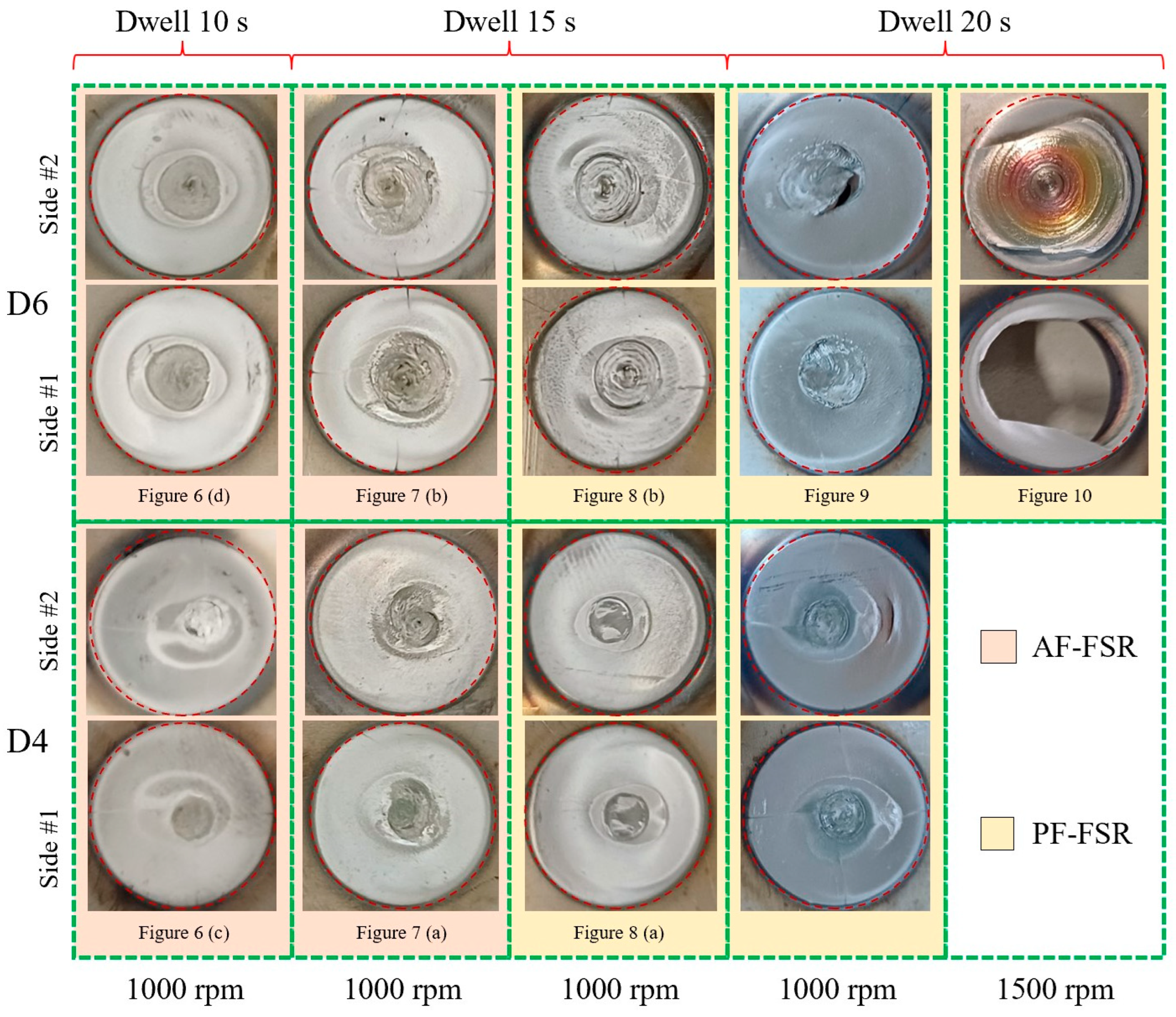

3.1. AF-FSR, PF-FSR, and P-FSSW Process Parameters

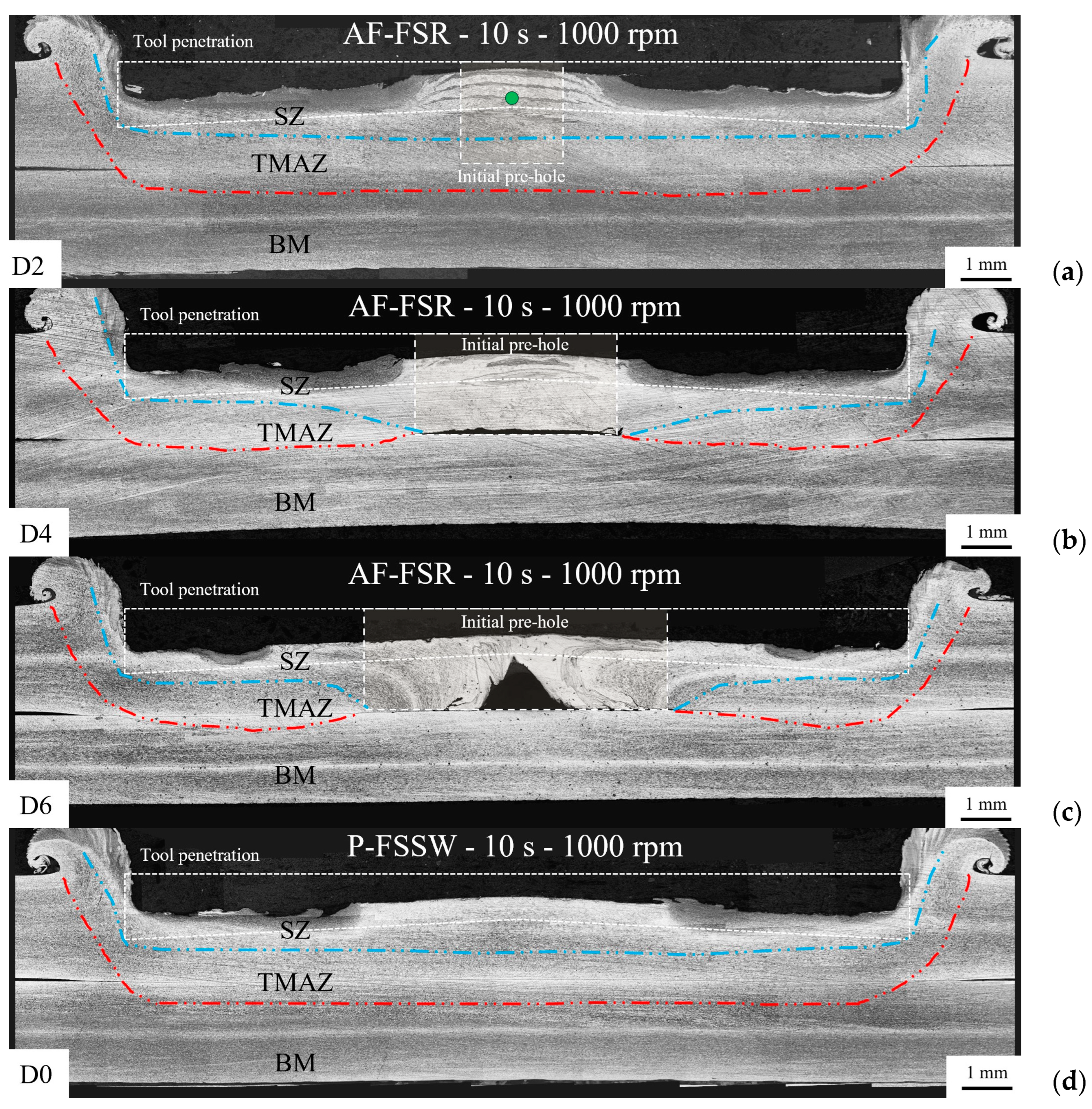

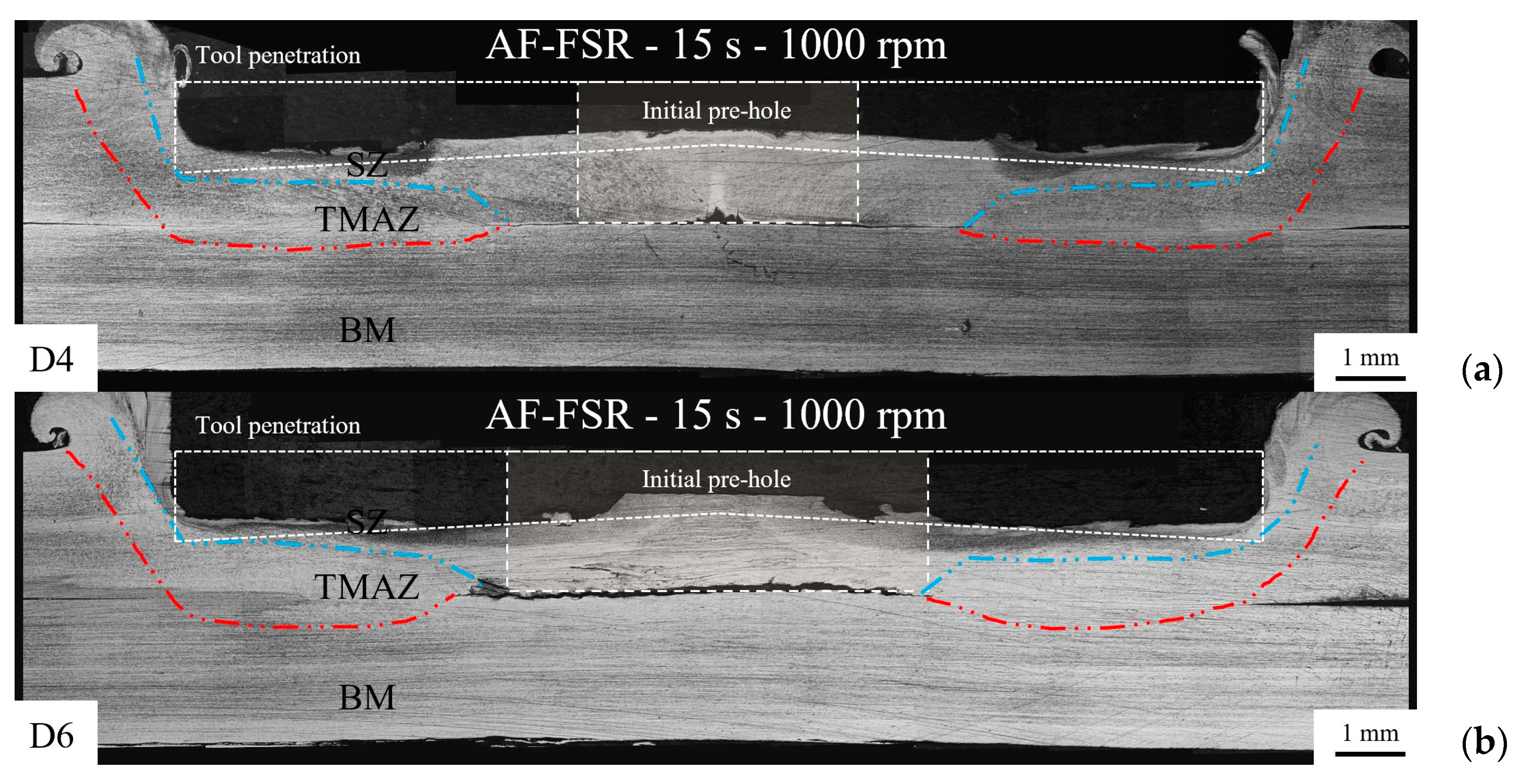

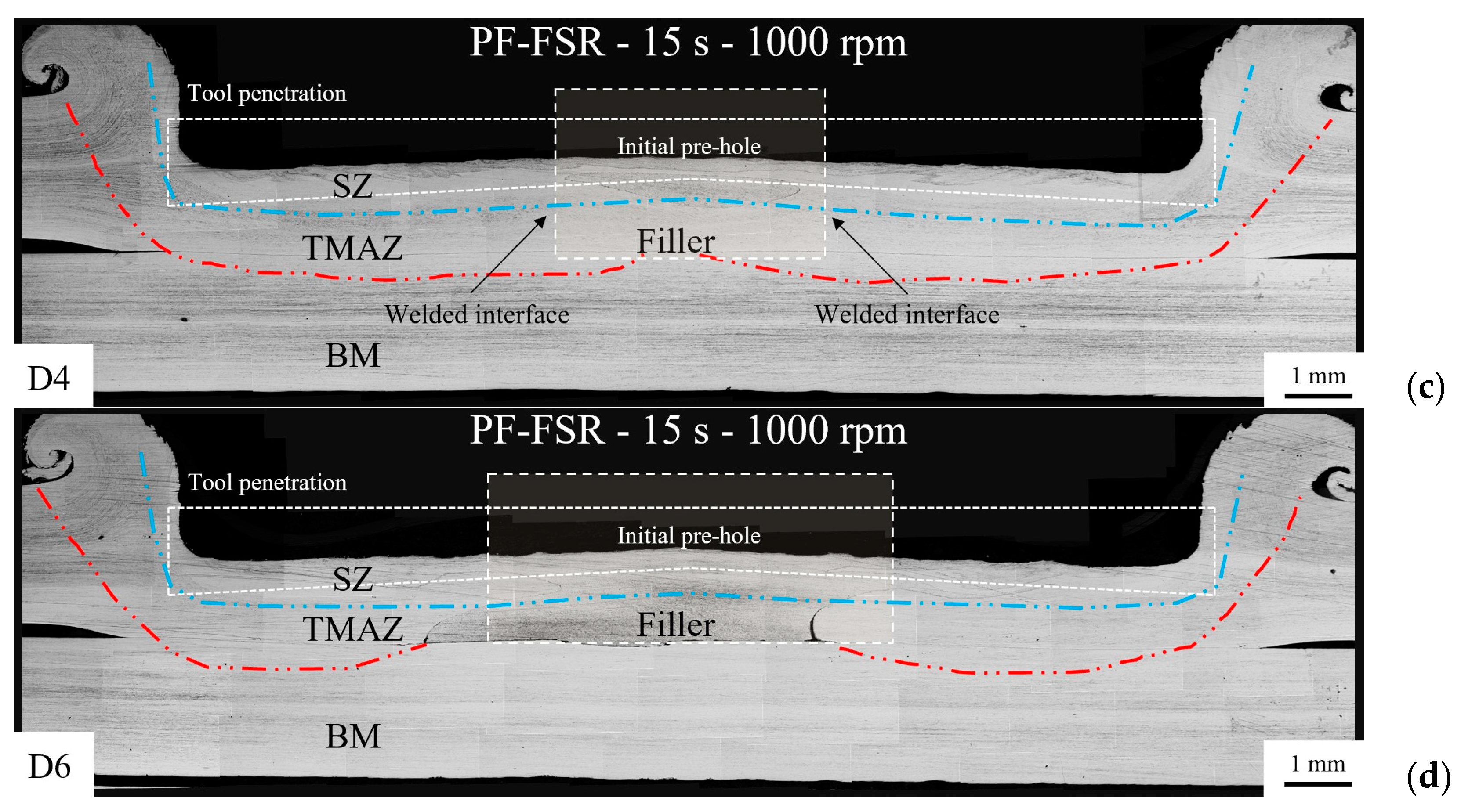

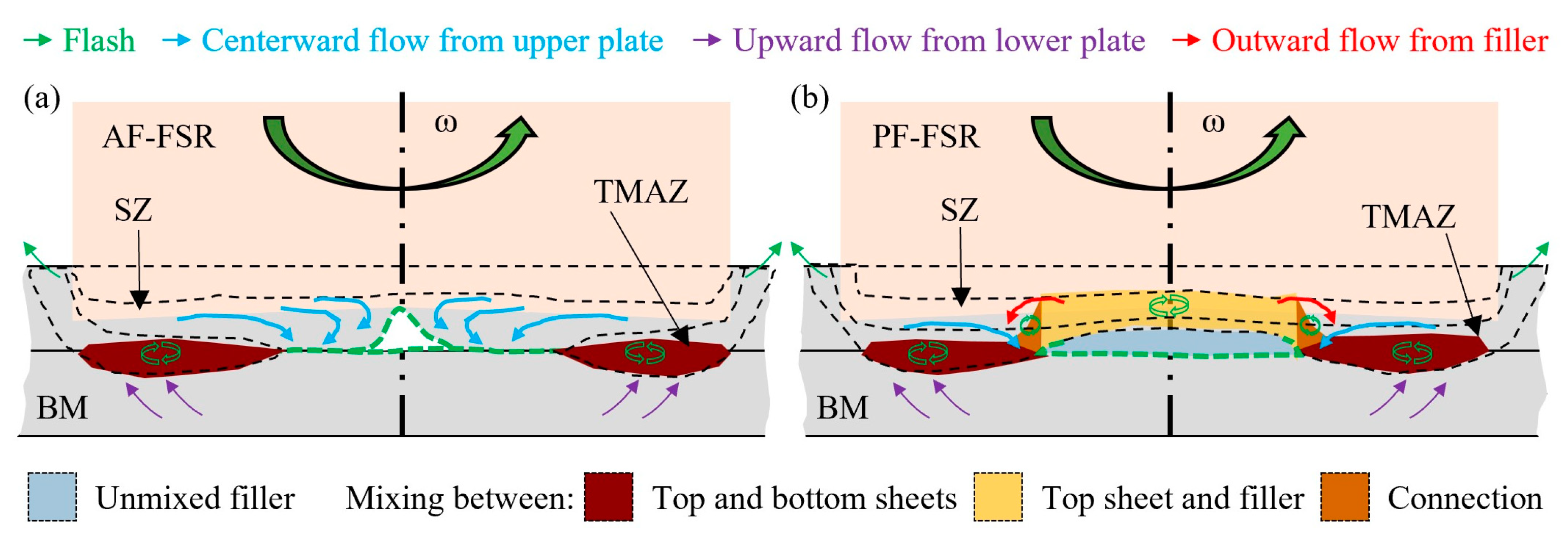

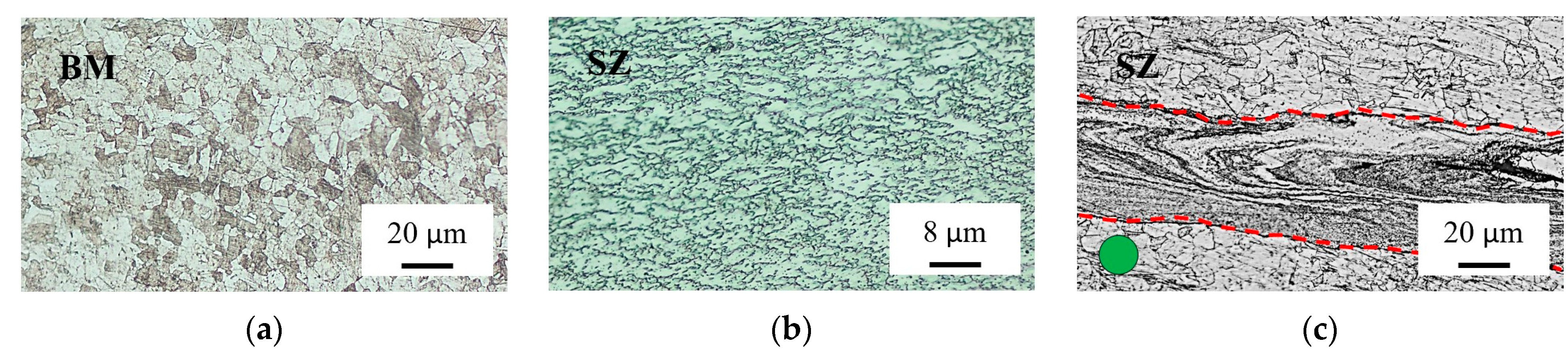

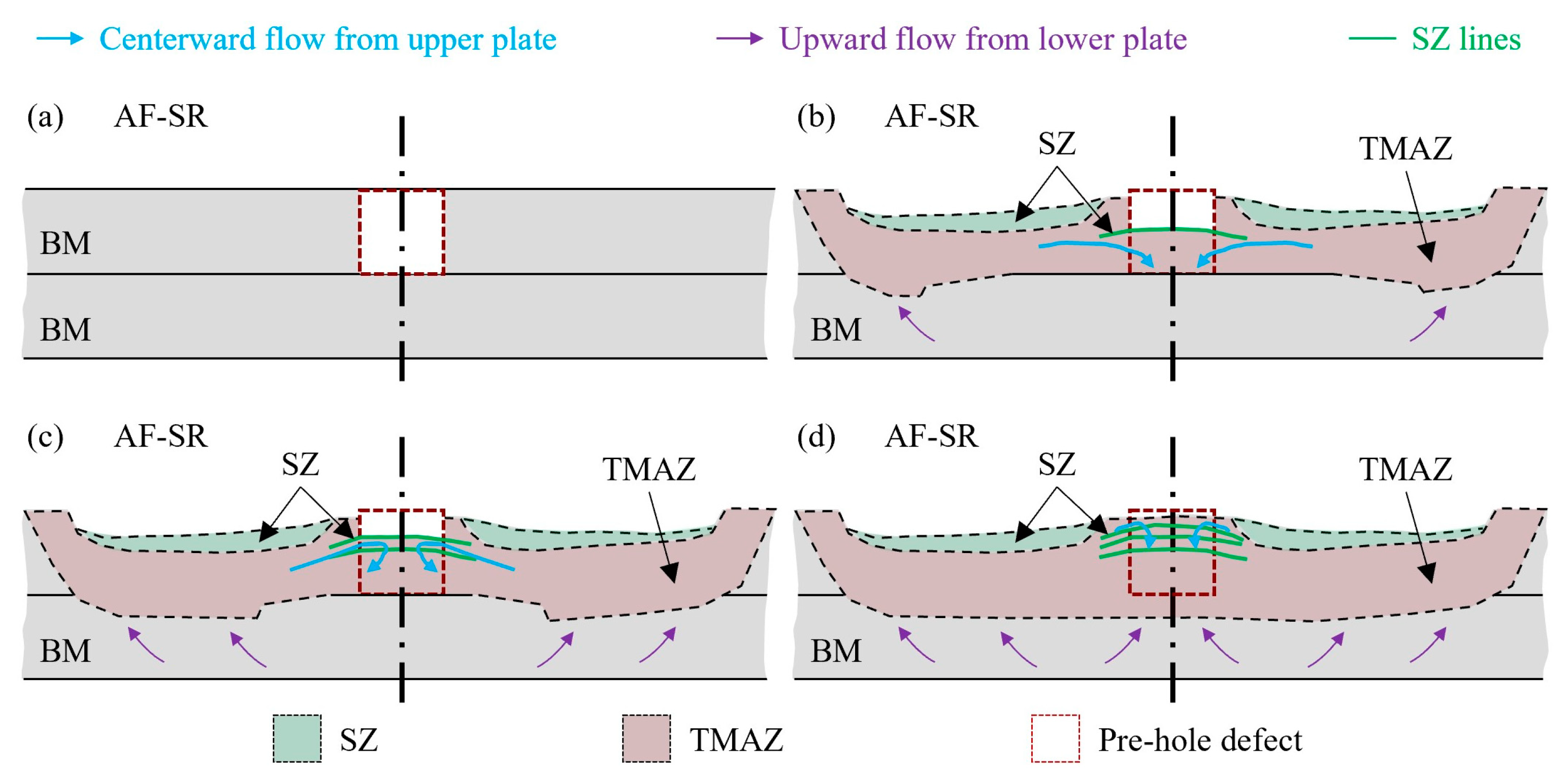

3.2. Microstructure Examination

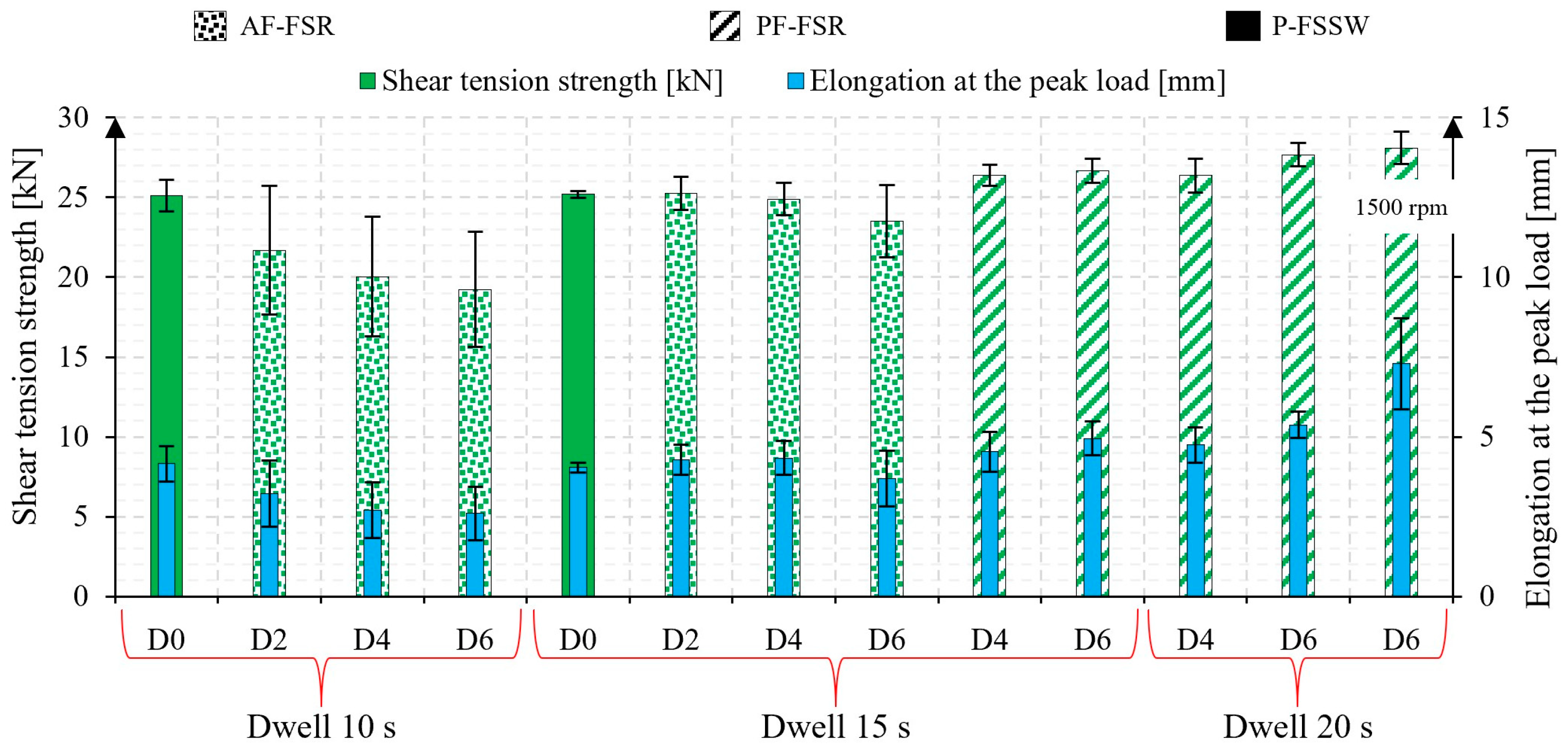

3.3. Sheet Stack Shear Tension Strength

4. Conclusions

- -

- PF-FSR demonstrated superior mechanical strength and consistency, particularly for 6 mm holes. Metal fillers in PF-FSR facilitated better defect filling and minimized voids, resulting in higher shear tension strength, exceeding 25 kN for larger holes, with lower data variability.

- -

- PF-FSR promoted efficient material mixing and filling of pre-holes, reducing unrepaired regions. Metal fillers enhanced mixing, ensuring a more homogeneous repair. AF-FSR struggled with larger holes, often leaving significant voids and reduced strength, especially in 6 mm holes, even with extended dwell times.

- -

- Parameters like rotational speed and dwell time significantly impacted repair quality. For PF-FSR, higher rotational speeds and dwell times generally improved pre-hole filling. However, excessive values caused deformation and flash formation. Rotational speeds up to 1500 rpm and dwell times up to 20 s ensured complete filling of larger holes but led to notable thinning and deformation. Thus, optimizing these parameters is crucial to balance effective repair and material integrity.

- -

- FSR of aluminum and magnesium alloys is well-documented, showing strong feasibility thanks to low vertical load and torque requirements, low tool wear rate, and good defect filling. FSR of austenitic stainless steels still presents significant challenges due to their low thermal conductivity and high strain hardening during plastic deformation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jawahir, I.; Bradley, R. Technological Elements of Circular Economy and the Principles of 6R-Based Closed-loop Material Flow in Sustainable Manufacturing. Procedia CIRP 2016, 40, 103–108. [Google Scholar] [CrossRef]

- Duflou, J.; Seliger, G.; Kara, S.; Umeda, Y.; Ometto, A.; Willems, B. Efficiency and feasibility of product disassembly: A case-based study. CIRP Ann. 2008, 57, 583–600. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Deng, L.; Niu, P.; Ke, L.; Liu, J.; Kang, J. Repairing of exit-hole in friction-stir-spot welded joints for 2024-T4 aluminum alloy by resistance welding. Int. J. Miner. Metall. Mater. 2023, 30, 660–669. [Google Scholar] [CrossRef]

- Lunetto, V.; De Maddis, M.; Russo Spena, P. Similar and dissimilar lap friction stir welding of titanium alloys: On the elimination of the hook defect. Int. J. Adv. Manuf. Technol. 2023, 126, 3417–3435. [Google Scholar] [CrossRef]

- Orlando, M.; De Maddis, M.; Razza, V.; Lunetto, V. Non-destructive detection and analysis of weld defects in dissimilar pulsed GMAW and FSW joints of aluminium castings and plates through 3D X-ray computed tomography. Int. J. Adv. Manuf. Technol. 2024, 132, 2957–2970. [Google Scholar] [CrossRef]

- Sajed, M. Parametric study of two-stage refilled friction stir spot welding. J. Manuf. Process. 2016, 24, 307–317. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, D.; Nakata, K.; Tsumura, T.; Fujii, H.; Ikeuchi, K.; Michishita, Y.; Fujiya, Y.; Morimoto, M. New technique of self-refilling friction stir welding to repair keyhole. Sci. Technol. Weld. Join. 2012, 17, 649–655. [Google Scholar] [CrossRef]

- Qi, S.; Wen, Q.; Ji, S.; Meng, X.; Wu, B.; Qi, W. New technique of radial-additive friction stir repairing for exceeded tolerance holes. Int. J. Adv. Manuf. Technol. 2019, 105, 4761–4771. [Google Scholar] [CrossRef]

- Huang, R.; Ji, S.; Meng, X.; Li, Z. Drilling-filling friction stir repairing of AZ31B magnesium alloy. J. Mater. Process. Technol. 2018, 255, 765–772. [Google Scholar] [CrossRef]

- Niu, S.; Wu, B.; Ma, L.; Lv, Z.; Yan, D. Passive filling friction stir repairing AZ31-B magnesium alloy by external stationary shoulder. Int. J. Adv. Manuf. Technol. 2018, 97, 2461–2468. [Google Scholar] [CrossRef]

- Sajed, M.; Seyedkashi, S.H. Multilayer friction stir plug welding: A novel solid-state method to repair cracks and voids in thick aluminum plates. CIRP J. Manuf. Sci. Technol. 2020, 31, 467–477. [Google Scholar] [CrossRef]

- Ji, S.; Meng, X.; Huang, R.; Ma, L.; Gao, S. Microstructures and mechanical properties of 7N01-T4 aluminum alloy joints by active-passive filling friction stir repairing. Mater. Sci. Eng. A 2016, 664, 94–102. [Google Scholar] [CrossRef]

- Rao, H.; Jordon, J.; Boorgu, S.; Kang, H.; Yuan, W.; Su, X. Influence of the key-hole on fatigue life in friction stir linear welded aluminum to magnesium. Int. J. Fatigue 2017, 105, 16–26. [Google Scholar] [CrossRef]

- Wang, T.; Liu, T.; Roosendaal, T.; Upadhyay, P. Reinforcing the exit hole from friction stir welding and processing. Materialia 2022, 26, 101611. [Google Scholar] [CrossRef]

- Wen, Q.; Guo, R.; Song, Q.; Dong, Z.; Liu, G.; Huang, R.; Yang, K. Active-passive filling friction stir repairing of casting defects in ZL210 aluminum alloys. Int. J. Adv. Manuf. Technol. 2020, 106, 5307–5315. [Google Scholar] [CrossRef]

- Lv, Z.; Han, S.; Hu, W.; Dong, Z.; Huang, R.; Yang, K. Solid-State Repair of Casting Defects in ZL210 Aluminum Alloy. J. Mater. Eng. Perform. 2020, 29, 5886–5893. [Google Scholar] [CrossRef]

- Ji, S.; Huang, R.; Zhang, L.; Meng, X.; Lv, Z. Microstructure and Mechanical Properties of Friction Stir Repaired Al–Cu Casting Alloy. Trans. Indian Inst. Met. 2018, 71, 2057–2065. [Google Scholar] [CrossRef]

- Lattanzi, L.; Fabrizi, A.; Fortini, A.; Merlin, M.; Timelli, G. Effects of microstructure and casting defects on the fatigue behavior of the high-pressure die-cast AlSi9Cu3(Fe) alloy. Procedia Struct. Integr. 2017, 7, 505–512. [Google Scholar] [CrossRef]

- Ghavimi, A.; Aboutalebi, M.; Seyedein, S. Exit-hole repairing in friction stir welding of AA5456 pipe using consumable pin. Mater. Manuf. Process. 2020, 35, 1240–1250. [Google Scholar] [CrossRef]

- Han, B.; Huang, Y.; Lv, S.; Wan, L.; Feng, J.; Fu, G. AA7075 bit for repairing AA2219 keyhole by filling friction stir welding. Mater. Des. 2013, 51, 25–33. [Google Scholar] [CrossRef]

- Huang, Y.X.; Han, B.; Tian, Y.; Liu, H.J.; Lv, S.X.; Feng, J.C.; Leng, J.S.; Li, Y. New technique of filling friction stir welding. Sci. Technol. Weld. Join. 2011, 16, 497–501. [Google Scholar] [CrossRef]

- Meng, X.; Xie, Y.; Ma, X.; Liang, M.; Peng, X.; Han, S.; Kan, L.; Wang, X.; Chen, S.; Huang, Y. Towards Friction Stir Remanufacturing of High-Strength Aluminum Components. Acta Met. Sin. (Engl. Lett.) 2023, 36, 91–102. [Google Scholar] [CrossRef]

- Giuliodori, D.; Rodriguez, A. Analysis of the stainless steel market in the EU, China and US using co-integration and VECM. Resour. Policy 2015, 44, 12–24. [Google Scholar] [CrossRef]

- Deshmukh, D.D.; Kharche, Y. Influence of processing conditions on the tensile strength and failure pattern of resistance spot welded SS 316L sheet joint. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 1–13. [Google Scholar] [CrossRef]

- Li, H.; Jiang, Z.; Feng, H.; Zhang, S.; Li, L.; Han, P.; Misra, R.; Li, J. Microstructure, mechanical and corrosion properties of friction stir welded high nitrogen nickel-free austenitic stainless steel. Mater. Des. 2015, 84, 291–299. [Google Scholar] [CrossRef]

- Lunetto, V.; De Maddis, M.; Russo Spena, P. Pre-hole friction stir spot welding of dual-phase steels and comparison with resistance spot welding, conventional and pinless friction stir spot welding. Int. J. Adv. Manuf. Technol. 2023, 129, 2333–2349. [Google Scholar] [CrossRef]

- Yousefian, S.; Zarei-Hanzaki, A.; Barabi, A.; Abedi, H.; Moallemi, M.; Karjalainen, P. Microstructure, texture and mechanical properties of a nickel-free high nitrogen duplex stainless steel processed through friction stir spot welding. J. Mater. Res. Technol. 2021, 15, 6491–6505. [Google Scholar] [CrossRef]

- JIS Z 3136 Standard; Specimen Dimensions and Procedure for Shear Testing Resistance Spot and Embossed Projection Welded Joints. Japanese Standards Association: Tokyo, Japan, 2018.

- ASTM E112-13; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Mirandola, P.; Lunetto, V.; Novel, D.; Barozzi, M.; Bellutti, P.; De Maddis, M.; Russo Spena, P. Strength and microstructure of friction stir welded additively manufactured Scalmalloy® in as-welded and heat-treated conditions. J. Manuf. Process. 2023, 97, 1–11. [Google Scholar] [CrossRef]

- Jeon, J.; Mironov, S.; Sato, Y.; Kokawa, H.; Park, S.; Hirano, S. Friction stir spot welding of single-crystal austenitic stainless steel. Acta Mater. 2011, 59, 7439–7449. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Y.; Dong, J.; Wen, Q.; Gong, P.; Yue, Y. Eliminating Keyhole by Ultrasonic-Assisted Passive Filling Friction Stir Repairing Process. Trans. Indian Inst. Met. 2021, 74, 1501–1508. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | N | Ni |

|---|---|---|---|---|---|---|---|

| ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | 0.030 | 17.0–19.5 | ≤0.11 | 8.0–10.5 |

| Process | Pre-Hole Diameter (mm) | Disc Metal Filler Size | Dwell Time (s) | Rotational Speed (rpm) | Plunge Depth (mm) | Plunge Speed (mm/min) |

|---|---|---|---|---|---|---|

| P-FSSW | absent | absent | 10, 15 | 1000 | 1.3 | 50 |

| AF-FSR | absent | absent | 10, 15 | 1000 | 1.3 | 50 |

| PF-FSR | 2, 4, 6 | Φ 4 mm × h 2.5 mm | 15 | 1000 | 1.3 | 50 |

| PF-FSR | 6 | Φ 6 mm × h 2.5 mm | 15, 20 | 1000 | 1.3 | 50 |

| PF-FSR | 6 | Φ 6 mm × h 2.5 mm | 20 | 1500 | 1.3 | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lunetto, V.; Basile, D.; Razza, V.; Russo Spena, P. Active and Passive Filling Stir Repairing of AISI 304 Alloy. Metals 2024, 14, 911. https://doi.org/10.3390/met14080911

Lunetto V, Basile D, Razza V, Russo Spena P. Active and Passive Filling Stir Repairing of AISI 304 Alloy. Metals. 2024; 14(8):911. https://doi.org/10.3390/met14080911

Chicago/Turabian StyleLunetto, Vincenzo, Dario Basile, Valentino Razza, and Pasquale Russo Spena. 2024. "Active and Passive Filling Stir Repairing of AISI 304 Alloy" Metals 14, no. 8: 911. https://doi.org/10.3390/met14080911

APA StyleLunetto, V., Basile, D., Razza, V., & Russo Spena, P. (2024). Active and Passive Filling Stir Repairing of AISI 304 Alloy. Metals, 14(8), 911. https://doi.org/10.3390/met14080911