Optimization of Step Times for ASTM F1624 Methodology Applied to Small Punch Tests in Aggressive Environments

Abstract

1. Introduction

2. Materials and Methods

2.1. ASTM F1624 Method

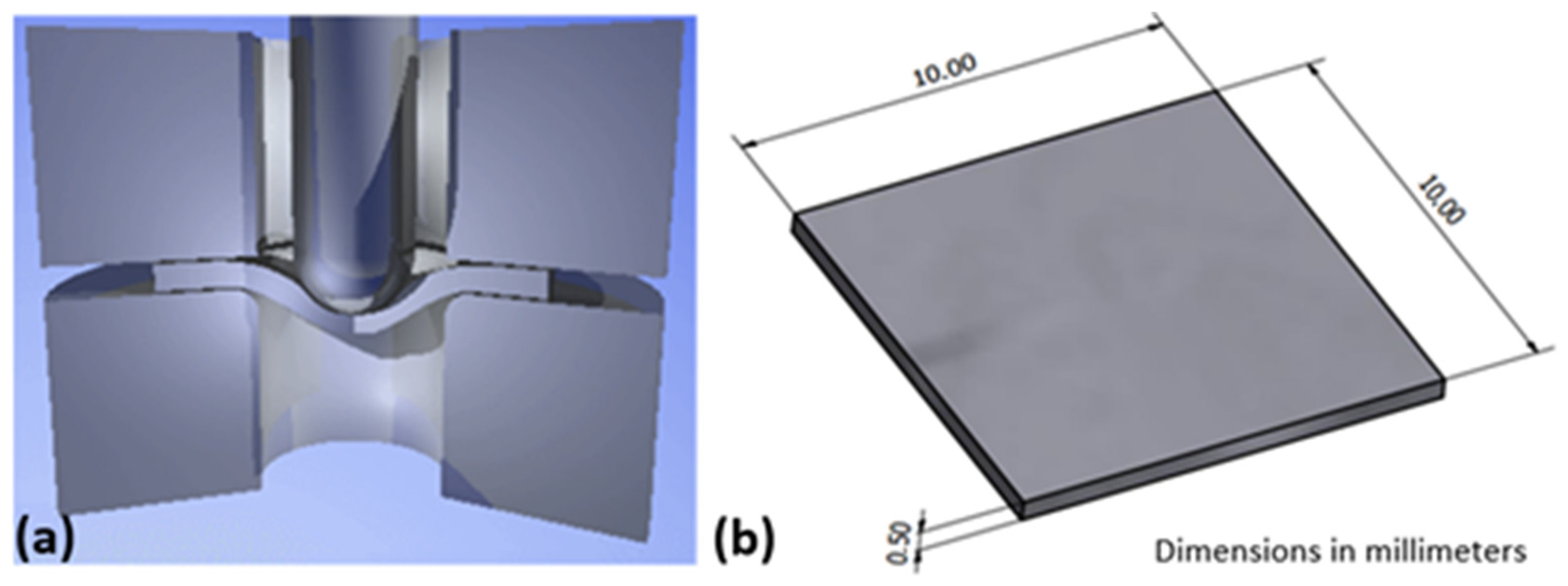

2.2. Application of Step Loading Technique from ASTM F1624 [18] to Small Punch Test

2.3. Materials and Environment Employed

3. Results

4. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dyal, R.K.; Paravathavarthini, N. Hydrogen in power plant steels. Sadhana-Acad. Proc. Eng. Sci. 2003, 28, 431–451. [Google Scholar]

- Rehrl, J.; Mrackez, K.; Pichler, A.; Werner, E. Mechanical properties and fracture behavior of hydrogen charged AHSS/UHSS grades at high and low strain rate tests. Mater. Sci. Eng. A 2014, 590, 360–367. [Google Scholar] [CrossRef]

- Carpio, J.; Casado, J.A.; Álvarez, J.A.; Gutiérrez-Solana, F. Environmental factors in failure during structural steel hot-dip galvanizing. Eng. Fail. Anal. 2009, 16, 585–595. [Google Scholar] [CrossRef]

- Bueno, A.H.S.; Moreira, E.D.; Gomes, J.A.C.P. Evaluation of stress corrosion cracking and hydrogen embrittlement in an API steel grade. Eng. Fail. Anal. 2014, 36, 423–431. [Google Scholar] [CrossRef]

- Tiwari, G.P.; Bose, A.; Chakravarty, J.K.; Wadekar, S.L.; Totlani, M.K.; Arya, R.N.; Fotedar, R.K. A study of internal hydrogen embrittlement of steels. Mater. Sci. Eng. A 2000, 286, 269–281. [Google Scholar] [CrossRef]

- Siddiqui, R.A.; Abdullah, H.A. Hydrogen embrittlement in 0.3% carbon steel used for petrochemicall applications. J. Mater. Process. Technol. 2005, 170, 430–435. [Google Scholar] [CrossRef]

- Micheler, T.; Naumann, J. Microstructural aspects upon hydrogen environment embrittlment of various BCC steels. Int. J. Hydrogen Energy 2010, 35, 1485–1492. [Google Scholar]

- Moody, N.R.; Robinson, S.L.; Garrison, W.M., Jr. Hydrogen effects on the properties and fracture modes of iron-based alloys. Res. Mech. 1990, 30, 143–206. [Google Scholar]

- Sedriks, A.J. Stress Corrosion Cracking Test Methods; National Asociation of Corrosion Engineers: Houston, TX, USA, 1989. [Google Scholar]

- Xu, H.; Xia, X.; Hua, L.; Sun, Y.; Dai, Y. Evaluation of hydrogen embrittlement susceptibility of temper embrtittled 2.25Cr1Mo steel by SSRT method. Eng. Fail. Anal. 2012, 19, 43–50. [Google Scholar] [CrossRef]

- ISO 7539; Corrosion of Metals and Alloys. Parts 1 to 9; International Organization for Standarization: Geneva, Switzerland, 2011.

- ASTM E1681-03; Test Method for Determining Threshold Stress Intensity Factor for Environment Assisted Cracking of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2013.

- Wang, Y.; Wang, X.; Gong, J.; Shen, L.; Dong, W. Hydrogen-precharged 304L austenitic stainless steel: Effect of plastic pr-strain. Int. J. Hydrogen Energy 2014, 39, 13909–13918. [Google Scholar] [CrossRef]

- Arroyo, B.; Andrea, L.; Gutiérrez-Solana, F.; Álvarez, J.A.; González, P. Threshold stress estimation in hydrogen induced cracking by Small Punch test based on the application of the incremental step loading technique. Theor. Appl. Fract. Mech. 2020, 110, 102839. [Google Scholar] [CrossRef]

- Arroyo, B.; Andrea, L.; Gutiérrez-Solana, F.; Álvarez, J.A. Time optimization of step loading technique in hydrogen embrittlement small punch tests. Theor. Appl. Fract. Mech. 2022, 117, 103206. [Google Scholar] [CrossRef]

- Álvarez, J.A.; Gutiérrez-Solana, F. An elastic-plastic fracture mechanics based methodology to characterize cracking behaviour and its applications to environmental assisted processes. Nucl. Eng. Des. 1998, 188, 185–202. [Google Scholar] [CrossRef]

- Gutiérrez-Solana, F.; Valiente, A.; González, J.J.; Varona, J.M. A strain-based fracture model for stress corrosion cracking of low-alloy steels. Metall. Mater. Trans. A 1996, 27, 291–304. [Google Scholar] [CrossRef]

- ASTM F1624-18; Standard Test Method for Measurement of Hydrogen Embrittlement Threshold in Steel by the Incremental Step Loading Technique. ASTM International: West Conshohocken, PA, USA, 2018.

- Stevens, M.F. Effect of Microstructure and Trapping on the Hydrogen Embrittlement Susceptibility of a Titanium Bearing HSLA Steel. Ph.D. Thesis, Carnegie-Mellon University, Pittsburgh, PA, USA, 1984. [Google Scholar]

- Arroyo, B.; Álvarez, J.A.; Gutiérrez-Solana, F.; Lacalle, R.; González, P. Rate effects on the estimation of fracture toughness by small punch tests in hydrogen embrittlement. J. Strain Anal. 2019, 54, 390–400. [Google Scholar] [CrossRef]

- ASTM E8/E8M 16a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- González, J.J.; Gutiérrez-Solana, F.; Varona, J.M. The effects of microstructure, strength level, and crack propagation mode on stress corrosion cracking behavior of 4135 steel. Metall. Mater. Trans. A 1996, 27, 281–290. [Google Scholar] [CrossRef]

- EN 10371; Metallic materials–Small Punch Test Method. European Standard: Brussels, Belgium, 2021.

| Hardness | Step | Step Load | Step Time (h) | Profile Code [18] |

|---|---|---|---|---|

| 33 ≤ HRC < 45 | 1–10 | 5% of PFFS | 2 | (10/5/2.4) |

| 11–20 | 4 | |||

| 45 ≤ HRC < 55 | 1–10 | 5% of PFFS | 1 | (10/5/1.2) |

| 11–20 | 2 | |||

| HRC ≥ 55 | 1–20 | 5% of PFFS | 1 | (10/5/1) |

| Hardness | Step | Proposal #1 (min) | Proposal #2 (min) | Proposal #3 (min) |

|---|---|---|---|---|

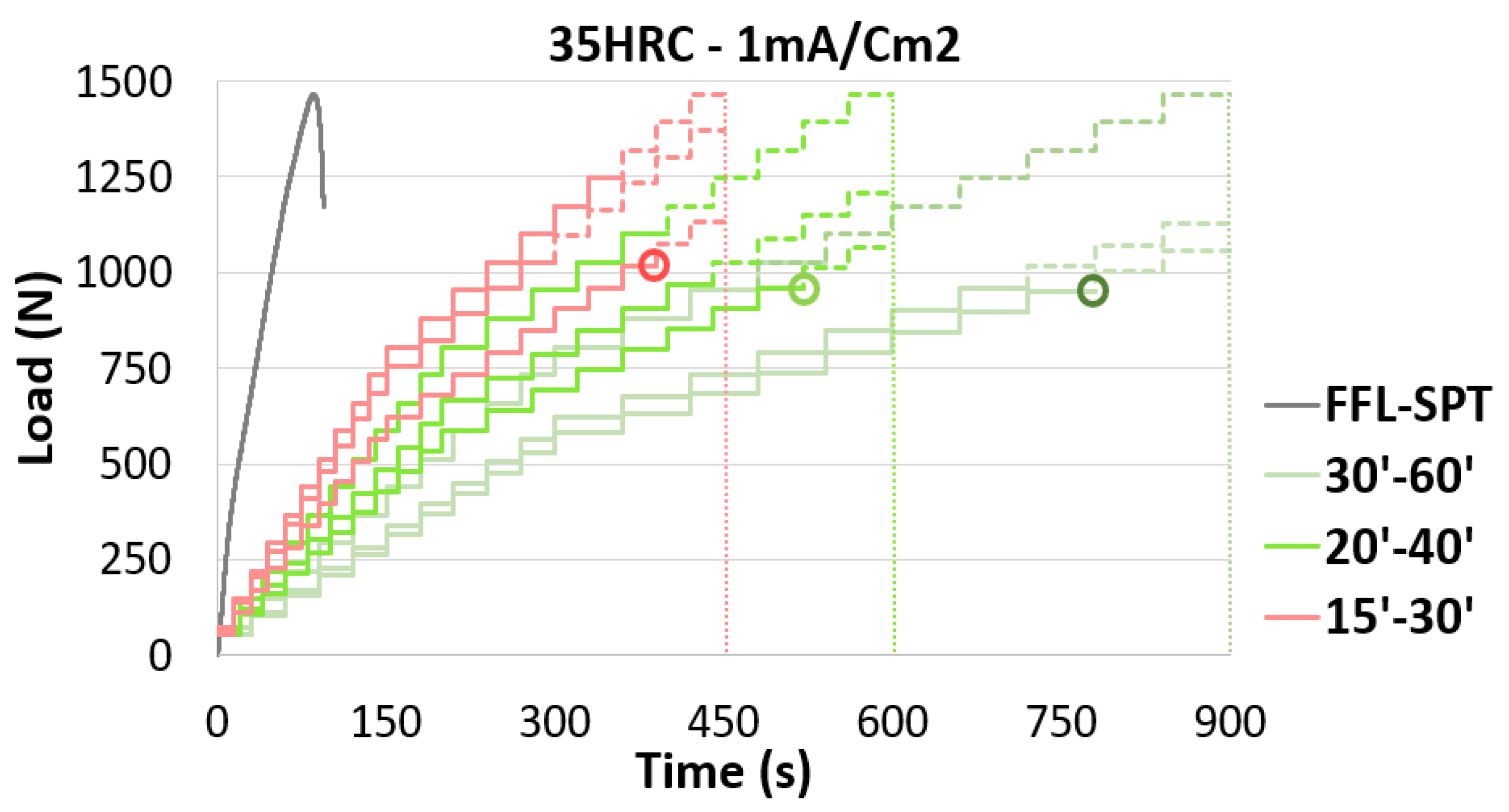

| 33 ≤ HRC < 45 | 1–10 | 30′ | 20′ | 15′ |

| 11–20 | 60′ | 40′ | 30′ | |

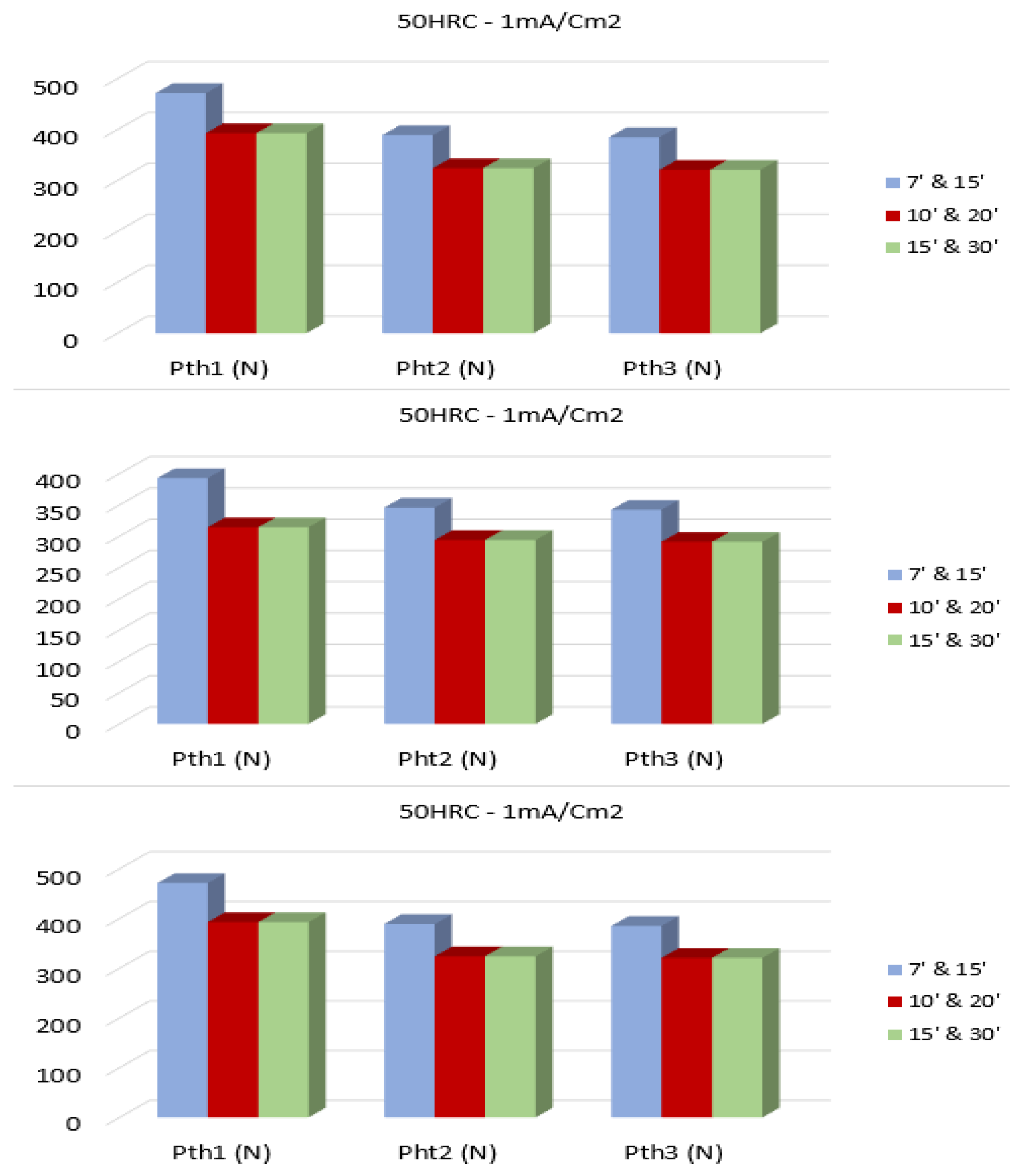

| 45 ≤ HRC < 55 | 1–10 | 15′ | 10′ | 7′ |

| 11–20 | 30′ | 20′ | 15′ | |

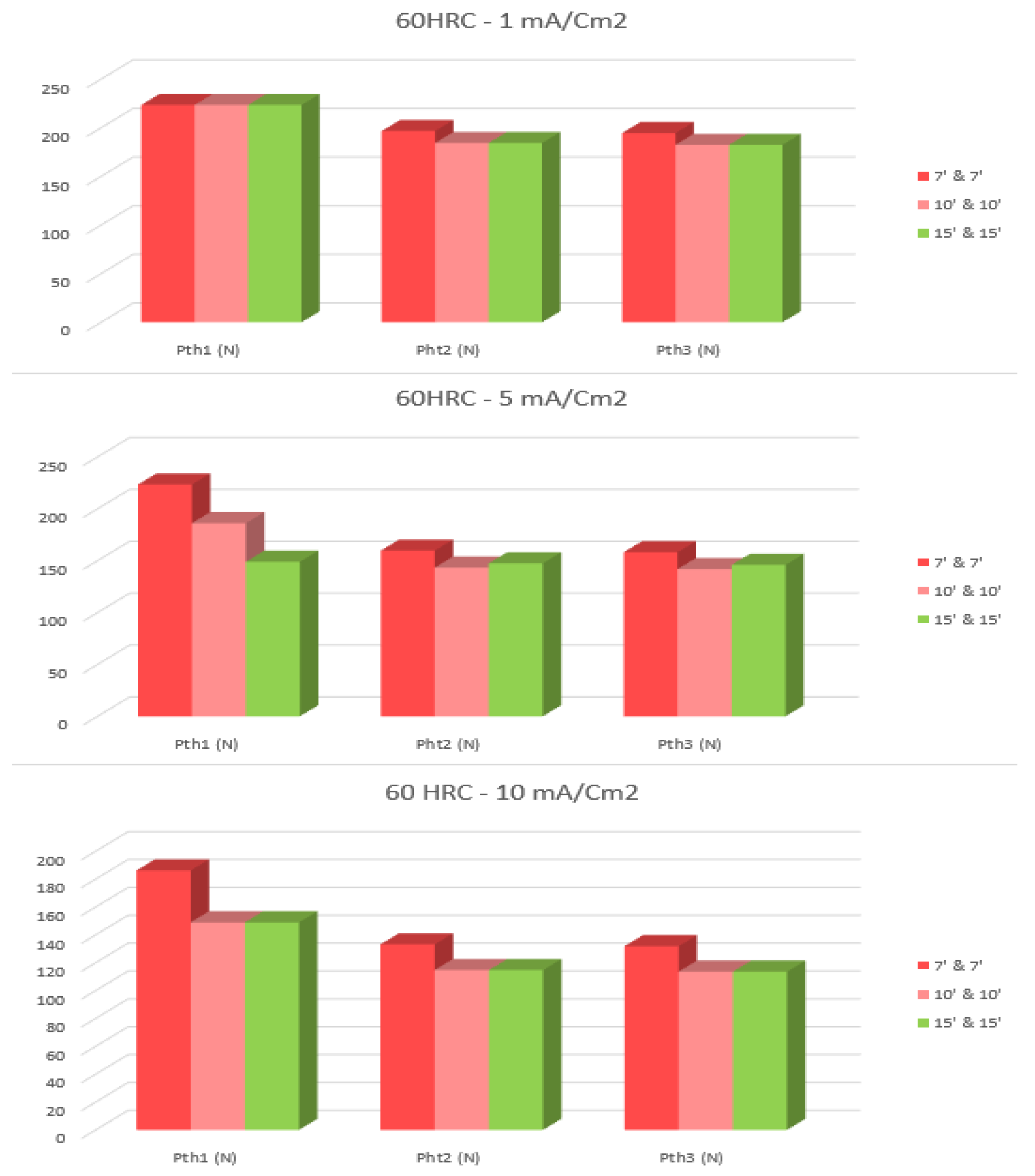

| HRC ≥ 55 | 1–20 | 15′ | 10′ | 7′ |

| Material and Environment | Steps Duration | PFFL-SPT (N) | Pth-1 (N) | Pth-2 (N) | Pth-3 (N) | Difference |

|---|---|---|---|---|---|---|

| 35 HRC 1 mA/cm2 | 15′–30′ | 1466 | 1246 | 1028 | 1018 | +6% |

| 20′–40’ | 1466 | 1099 | 968 | 958 | - | |

| 30′–60′ | 1466 | 1026 | 959 | 950 | −1% | |

| 35 HRC 5 mA/cm2 | 15′–30′ | 1466 | 953 | 786 | 778 | +16% |

| 20′–40′ | 1466 | 880 | 677 | 671 | - | |

| 30′–60′ | 1466 | 880 | 677 | 671 | 0% | |

| 35 HRC 10 mA/cm2 | 15′–30′ | 1466 | 880 | 774 | 766 | +25% |

| 20′–40′ | 1466 | 806 | 621 | 615 | - | |

| 30′–60′ | 1466 | 806 | 621 | 615 | 0% |

| Material and Environment | Steps Duration | PFFL-SPT (N) | Pth-1 (N) | Pth-2 (N) | Pth-3 (N) | Difference |

|---|---|---|---|---|---|---|

| 50 HRC 1 mA/cm2 | 7′–15′ | 1428 | 471 | 389 | 385 | +22% |

| 10′–20′ | 1428 | 471 | 324 | 321 | - | |

| 15′–30′ | 1428 | 471 | 324 | 321 | 0% | |

| 50 HRC 5 mA/cm2 | 7′–15′ | 1428 | 393 | 346 | 342 | +18% |

| 10′–20′ | 1428 | 314 | 294 | 291 | - | |

| 15′–30′ | 1428 | 314 | 294 | 291 | 0% | |

| 50 HRC 10 mA/cm2 | 7′–15′ | 1428 | 393 | 302 | 299 | +18% |

| 10′–20′ | 1428 | 314 | 259 | 257 | - | |

| 15′–30′ | 1428 | 314 | 259 | 257 | 0% |

| Material and Environment | Steps Duration | PFFL-SPT (N) | Pth-1 (N) | Pth-2 (N) | Pth-3 (N) | Difference |

|---|---|---|---|---|---|---|

| 60 HRC 1 mA/cm2 | 7′ | 677 | 223 | 197 | 195 | +7% |

| 10′ | 677 | 223 | 184 | 182 | - | |

| 15′ | 677 | 223 | 184 | 182 | 0% | |

| 60 HRC 5 mA/cm2 | 7′ | 677 | 223 | 160 | 158 | +8% |

| 10′ | 677 | 186 | 143 | 142 | - | |

| 15′ | 677 | 149 | 147 | 146 | +3% | |

| 60 HRC 10 mA/cm2 | 7′ | 677 | 186 | 133 | 132 | +16% |

| 10′ | 677 | 149 | 115 | 114 | - | |

| 15′ | 677 | 149 | 115 | 114 | 0% |

| Hardness | Step | Step Load | Step Time (min) |

|---|---|---|---|

| 33 ≤ HRC < 45 | 1–10 | 5% of PFFS-SPT | 20 |

| 11–20 | 40 | ||

| 45 ≤ HRC < 55 | 1–10 | 5% of PFFS-SPT | 10 |

| 11–20 | 20 | ||

| HRC ≥ 55 | 1–20 | 5% of PFFS-SPT | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrea, L.; Arroyo, B.; Álvarez, J.A.; Gutiérrez-Solana, F.; Cicero, S.; Guilbert, E. Optimization of Step Times for ASTM F1624 Methodology Applied to Small Punch Tests in Aggressive Environments. Metals 2024, 14, 863. https://doi.org/10.3390/met14080863

Andrea L, Arroyo B, Álvarez JA, Gutiérrez-Solana F, Cicero S, Guilbert E. Optimization of Step Times for ASTM F1624 Methodology Applied to Small Punch Tests in Aggressive Environments. Metals. 2024; 14(8):863. https://doi.org/10.3390/met14080863

Chicago/Turabian StyleAndrea, Laura, Borja Arroyo, Jose Alberto Álvarez, Federico Gutiérrez-Solana, Sergio Cicero, and Elise Guilbert. 2024. "Optimization of Step Times for ASTM F1624 Methodology Applied to Small Punch Tests in Aggressive Environments" Metals 14, no. 8: 863. https://doi.org/10.3390/met14080863

APA StyleAndrea, L., Arroyo, B., Álvarez, J. A., Gutiérrez-Solana, F., Cicero, S., & Guilbert, E. (2024). Optimization of Step Times for ASTM F1624 Methodology Applied to Small Punch Tests in Aggressive Environments. Metals, 14(8), 863. https://doi.org/10.3390/met14080863