Application of an Artificial Neural Network for Efficient Computation of Chemical Activities within an EAF Process Model

Abstract

1. Introduction

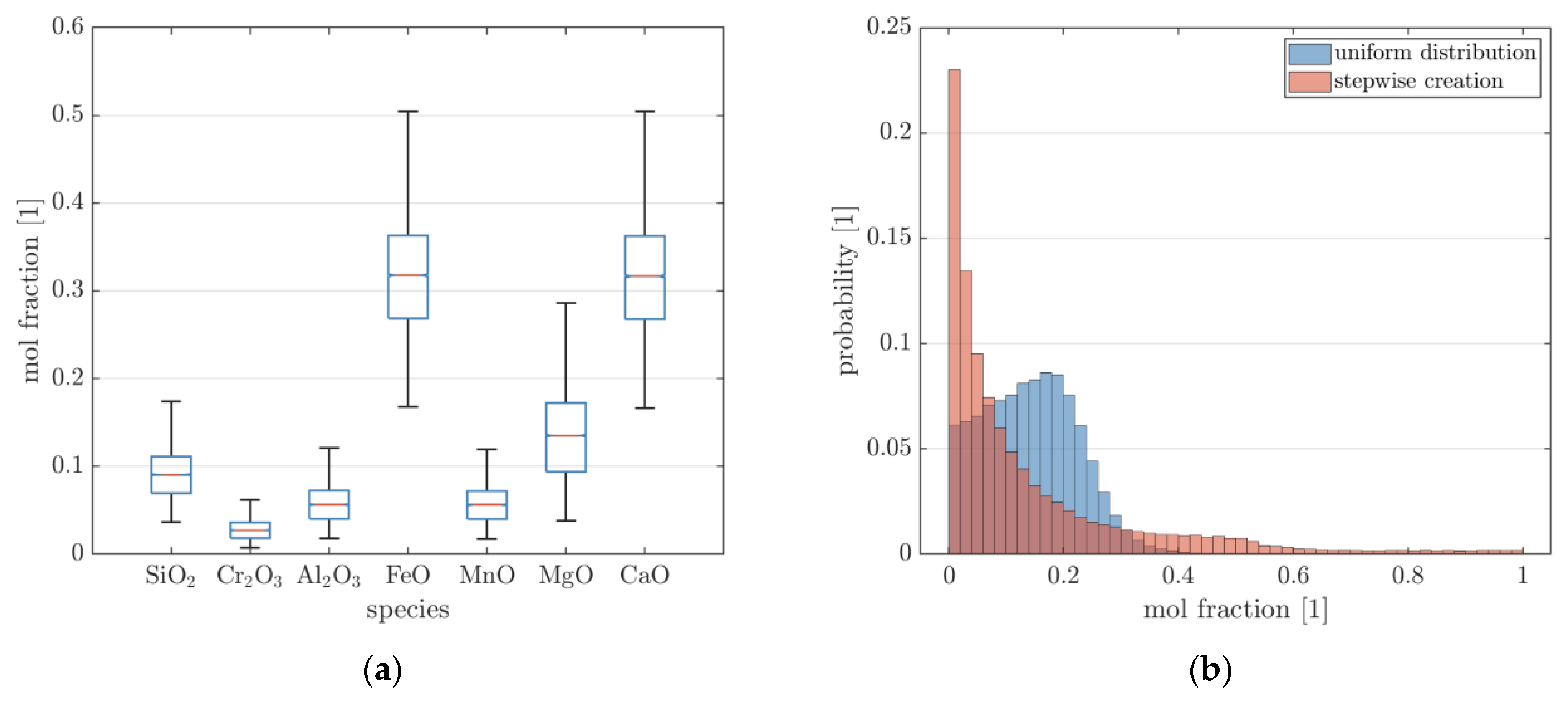

2. Materials and Methods

3. Results

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- World Steel Association. World Steel in Figures: Concise Version; World Steel Association: Brussels, Belgium, 2023; Available online: https://worldsteel.org (accessed on 6 February 2024).

- Demus, T.; Reichel, T.; Schulten, M.; Echterhof, T.; Pfeifer, H. Increasing the sustainability of steel production in the electric arc furnace by substituting fossil coal with biochar agglomerates. Ironmak. Steelmak. 2016, 43, 564–570. [Google Scholar] [CrossRef]

- Kirschen, M.; Hay, T.; Echterhof, T. Process Improvements for Direct Reduced Iron Melting in the Electric Arc Furnace with Emphasis on Slag Operation. Processes 2021, 9, 402. [Google Scholar] [CrossRef]

- Hay, T.; Visuri, V.-V.; Aula, M.; Echterhof, T. A Review of Mathematical Process Models for the Electric Arc Furnace Process. Steel Res. Int. 2021, 92, 2000395. [Google Scholar] [CrossRef]

- Carlsson, L.S.; Samuelsson, P.B.; Jönsson, P.G. Predicting the Electrical Energy Consumption of Electric Arc Furnaces Using Statistical Modeling. Metals 2019, 9, 959. [Google Scholar] [CrossRef]

- Meier, T. Modellierung und Simulation des Elektrolichtbogenofens; Verlagshaus Mainz: Mainz, Germany, 2016; ISBN 978-3-95886-129-9. [Google Scholar]

- Logar, V.; Dovžan, D.; Škrjanc, I. Modeling and Validation of an Electric Arc Furnace: Part 1, Heat and Mass Transfer. ISIJ Int. 2012, 52, 402–412. [Google Scholar] [CrossRef]

- Logar, V.; Dovžan, D.; Škrjanc, I. Modeling and Validation of an Electric Arc Furnace: Part 2, Thermo-chemistry. ISIJ Int. 2012, 52, 413–423. [Google Scholar] [CrossRef]

- Pfeifer, H.; Nacke, B.; Beneke, F. Praxishandbuch Thermoprozesstechnik: Band II: Anlagen-Komponenten-Sicherheit, 3rd ed.; Vulkan: Essen, Germany, 2022; ISBN 9783802731228. [Google Scholar]

- Ben Bowman, K.K. Arc Furnace Physics, 1st ed.; Stahleisen: Düsseldorf, Germany, 2009; ISBN 978-3514007680. [Google Scholar]

- Graham, K.J. Integrated Ladle Metallurgy Control. Ph.D. Thesis, McMaster University, Hamilton, ON, Canada, 2008. [Google Scholar]

- MacRosty, R.D.M.; Swartz, C.L.E. Dynamic Modeling of an Industrial Electric Arc Furnace. Ind. Eng. Chem. Res. 2005, 44, 8067–8083. [Google Scholar] [CrossRef]

- Hay, T.; Reimann, A.; Echterhof, T. Improving the Modeling of Slag and Steel Bath Chemistry in an Electric Arc Furnace Process Model. Metall. Mater. Trans. B 2019, 50, 2377–2388. [Google Scholar] [CrossRef]

- Shampine, L.F.; Reichelt, M.W. The MATLAB ODE Suite. SIAM J. Sci. Comput. 1997, 18, 1–22. [Google Scholar] [CrossRef]

- Lupis, C.; Elliott, J. Generalized interaction coefficients: Part II: Free energy terms and the quasi-chemical theory. Acta Metall. 1966, 14, 1019–1032. [Google Scholar] [CrossRef][Green Version]

- Pelton, A.D.; Bale, C.W. A modified interaction parameter formalism for non-dilute solutions. Metall. Trans. A 1986, 17, 1211–1215. [Google Scholar] [CrossRef]

- Basu, S.; Seetharaman, S.; Lahiri, A.K. Thermodynamics of Phosphorus and Sulphur Removal during Basic Oxygen Steelmaking. Steel Res. Int. 2010, 81, 932–939. [Google Scholar] [CrossRef]

- Michalek, K.; Čamek, L.; Gryc, K.; Tkadlečková, M.; Huczala, T.; Troszok, V. Desulphurization of the high-alloy and middle-alloy steels under the conditions of an eaf by means of synthetic slag based on CaO-Al2O3. Mater. Technol. 2012, 46, 297–303. [Google Scholar]

- Schrama, F.N.H.; Beunder, E.M.; van den Berg, B.; Yang, Y.; Boom, R. Sulphur removal in ironmaking and oxygen steelmaking. Ironmak. Steelmak. 2017, 44, 333–343. [Google Scholar] [CrossRef]

- Kirschen, M. Visualization of Slag Data for Efficient Monitoring and Improvement of Steelmaking Slag Operation in Electric Arc Furnaces, with a Focus on MgO Saturation. Metals 2021, 11, 17. [Google Scholar] [CrossRef]

- Ban-Ya, S. Mathematical Expression of Slag-Metal Reactions in Steelmaking Process by Quadratic Formalism Based on the Regular Solution Model. ISIJ Int. 1993, 33, 2–11. [Google Scholar] [CrossRef]

- Gaye, H.; Lehmann, J.; Matsumiya, T.; Yamada, W. A statistical thermodynamics model of slags: Applications to systems containing S, F, P2O5 and Cr oxides. In Proceedings of the 4th International Conference on Molten Slags and Fluxes, Sendai, Japan, 8–11 June 1992; ISIJ: Sendai, Japan, 1992; pp. 103–108. [Google Scholar]

- Hay, T. Mathematische Modellierung des Elektrostahlverfahrens. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2021. [Google Scholar]

- Xiao, Y.; Holappa, L. Thermodynamics of slags containing chromium oxides. In Proceedings of the INFACON 7, Trondheim, Norway, 11–14 June 1995; Norwegian Ferroalloy Research Organization (FFF): Trondheim, Norway, 1995. [Google Scholar]

- Bale, C.W.; Bélisle, E.; Chartrand, P.; Decterov, S.A.; Eriksson, G.; Gheribi, A.E.; Hack, K.; Jung, I.-H.; Kang, Y.-B.; Melançon, J.; et al. FactSage thermochemical software and databases, 2010–2016. Calphad 2016, 54, 35–53. [Google Scholar] [CrossRef]

- GTT, C. FactSage Database Overview. Available online: https://www.factsage.com/facthelp/FSNew_Databases.htm (accessed on 31 January 2024).

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Szandała, T. Review and Comparison of Commonly Used Activation Functions for Deep Neural Networks. In Bio-Inspired Neurocomputing; Bhoi, A., Mallick, P., Liu, C.M., Balas, V., Eds.; Springer: Singapore, 2021; pp. 203–224. ISBN 978-981-15-5495-7. [Google Scholar]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Renaud, O.; Victoria-Feser, M.-P. A robust coefficient of determination for regression. J. Stat. Plan. Inference 2010, 140, 1852–1862. [Google Scholar] [CrossRef]

- Romer, T.H.; Lee, D.; Voelker, G.M.; Wolman, A.; Wong, W.A.; Baer, J.-L.; Bershad, B.N.; Levy, H.M. The structure and performance of interpreters. In Proceedings of the Seventh International Conference on Architectural Support for Programming Languages and Operating Systems, Cambridge, MA, USA, 1–4 October 1996; Association for Computing Machinery: New York, NY, USA, 1996; pp. 150–159, ISBN 0897917677. [Google Scholar]

- Barany, G. Python Interpreter Performance Deconstructed. In Proceedings of the Workshop on Dynamic Languages and Applications, Edinburgh, UK, 12 June 2014; Association for Computing Machinery: New York, NY, USA, 2014; pp. 1–9, ISBN 9781450329163. [Google Scholar]

- Anaconda. Numba: User Manual. Available online: https://numba.readthedocs.io/en/stable/user/index.html (accessed on 3 June 2024).

| Temperature | FeO | Cr2O3 | Al2O3 | MnO | P2O5 | SiO2 | MgO | CaO | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Unit | K | wt.% | ||||||||

| Slag * | 35.6 | 2.5 | 6.1 | 6.4 | 0.3 | 11.9 | 9.6 | 25.8 | ||

| Scenario 1: tapping | LL | 1700 | 20 | 1 | 2.5 | 2.5 | 0 | 5 | 5 | 20 |

| UL | 2000 | 50 | 5 | 10 | 10 | 0 | 15 | 25 | 50 | |

| Scenario 2: process | LL | 1700 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| UL | 2000 | 100 | 100 | 100 | 100 | 0 | 100 | 100 | 100 | |

| Model | Execution Time for 1000 Samples | Species | MAE | R2 | 95% Percentile |

|---|---|---|---|---|---|

| RS | 0.037 s | SiO2 | 0.0279 | 0.71 | 0.1483 |

| Cr2O3 | 0.8059 | −10.1 | 0.9995 | ||

| Al2O3 | 0.0089 | 0.95 | 0.0563 | ||

| FeO | 0.1523 | −0.09 | 0.3543 | ||

| MnO | 0.0651 | −0.11 | 0.2815 | ||

| MgO | 0.0846 | −0.05 | 0.2424 | ||

| CaO | 0.0380 | −0.09 | 0.1097 | ||

| Cell | 9.848 s | SiO2 | 0.0289 | 0.65 | 0.1558 |

| Cr2O3 | 0.1483 | 0.15 | 0.5462 | ||

| Al2O3 | 0.0142 | 0.53 | 0.0480 | ||

| FeO | 0.1582 | −0.18 | 0.3823 | ||

| MnO | 0.0376 | 0.81 | 0.1210 | ||

| MgO | 0.0145 | 0.97 | 0.0425 | ||

| CaO | 0.0058 | 0.97 | 0.0191 | ||

| ANN | 0.115 s | SiO2 | 0.0086 | 0.97 | 0.0379 |

| Cr2O3 | 0.0163 | 0.98 | 0.0655 | ||

| Al2O3 | 0.0046 | 0.99 | 0.0201 | ||

| FeO | 0.0112 | 0.99 | 0.0354 | ||

| MnO | 0.0071 | 0.99 | 0.0232 | ||

| MgO | 0.0068 | 0.99 | 0.0222 | ||

| CaO | 0.0041 | 0.99 | 0.0137 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reinicke, A.; Engbrecht, T.-N.; Schüttensack, L.; Echterhof, T. Application of an Artificial Neural Network for Efficient Computation of Chemical Activities within an EAF Process Model. Metals 2024, 14, 736. https://doi.org/10.3390/met14060736

Reinicke A, Engbrecht T-N, Schüttensack L, Echterhof T. Application of an Artificial Neural Network for Efficient Computation of Chemical Activities within an EAF Process Model. Metals. 2024; 14(6):736. https://doi.org/10.3390/met14060736

Chicago/Turabian StyleReinicke, Alexander, Til-Niklas Engbrecht, Lilly Schüttensack, and Thomas Echterhof. 2024. "Application of an Artificial Neural Network for Efficient Computation of Chemical Activities within an EAF Process Model" Metals 14, no. 6: 736. https://doi.org/10.3390/met14060736

APA StyleReinicke, A., Engbrecht, T.-N., Schüttensack, L., & Echterhof, T. (2024). Application of an Artificial Neural Network for Efficient Computation of Chemical Activities within an EAF Process Model. Metals, 14(6), 736. https://doi.org/10.3390/met14060736