The Effect of a Coating Sprayed Using Supersonic Flame Coating Technology on the Mechanical Properties and Interface Structure of a Thick Steel/Aluminum Composite Plate during Hot Rolling

Abstract

1. Introduction

2. Experimental and Analytical Methods

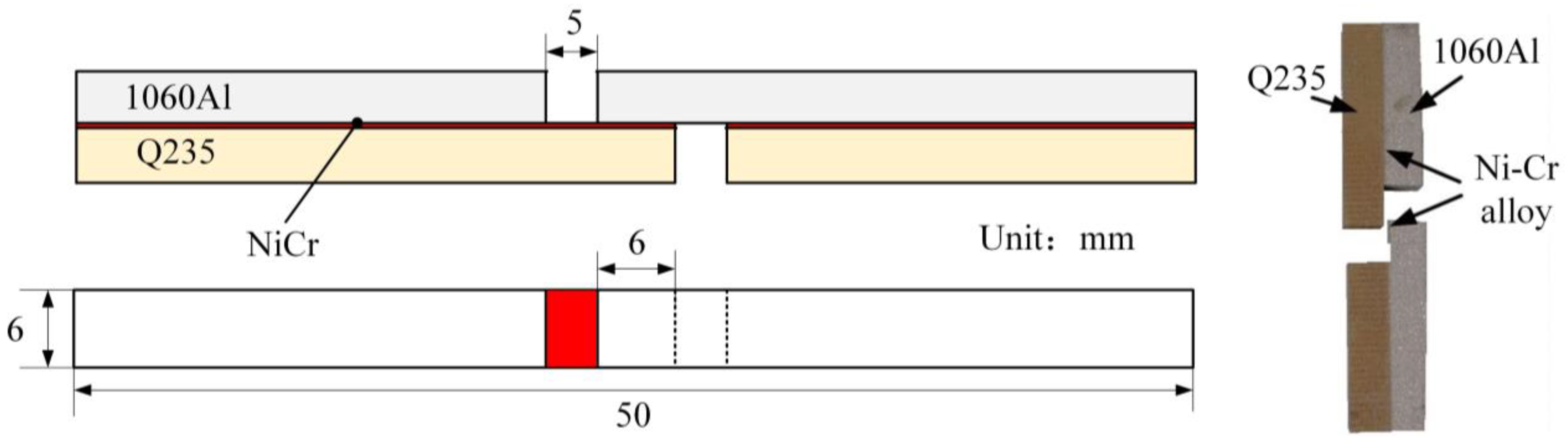

2.1. Scheme for the Rolling Experiment

- (1)

- Spray coating. The surface of the steel plate is sandblasted before spraying to remove the oxide layer from the surface of the steel plate and increase the surface roughness. Subsequently, the Ni–Cr coating is sprayed onto the surface of the steel plate by using supersonic flame spraying technology. The specific operation is as follows: first, oxygen is used as a combustion-supporting gas, and acetylene, kerosene, and other fuels burn violently and expand in the combustion chamber. A supersonic flame beam with a velocity of more than 1500 m/s is formed by Laval nozzle compression. At the same time, the sprayed powder is fed into the flame to produce molten or semi-molten particles, which hit the surface of the steel plate at high speeds to form a Ni–Cr alloy coating.

- (2)

- Surface treatment. The surfaces of each component metal plate are treated by removing the grease, dirt, and oxides and texturing and cleaning the bonding surface.

- (3)

- Anti-oxidation treatment. The polished slab is wiped and cleaned with alcohol, dried, and then riveted. The riveted composite plate is wrapped in 0.02 mm aluminum foil to prevent oxidation.

- (4)

- Preheating the plates. The front ends of component plates are riveted to ensure the stabilization of the bite stage. In addition, the component plates are covered with 0.2 mm aluminum foil and preheated at 400 °C for 15 min under a protective atmosphere.

- (5)

- Rolling compound. A plate is taken out and sent to a two-roll mill for rolling. The roll diameter is 200 mm and the roll speed is 60 mm/s. By adjusting the size of the roll gap, rolling reduction rates of 5%, 15%, 25%, 35%, and 45% for a single pass of a steel/aluminum composite plate are achieved.

2.2. Sample Preparation and Material Characterization

3. Results and Discussion

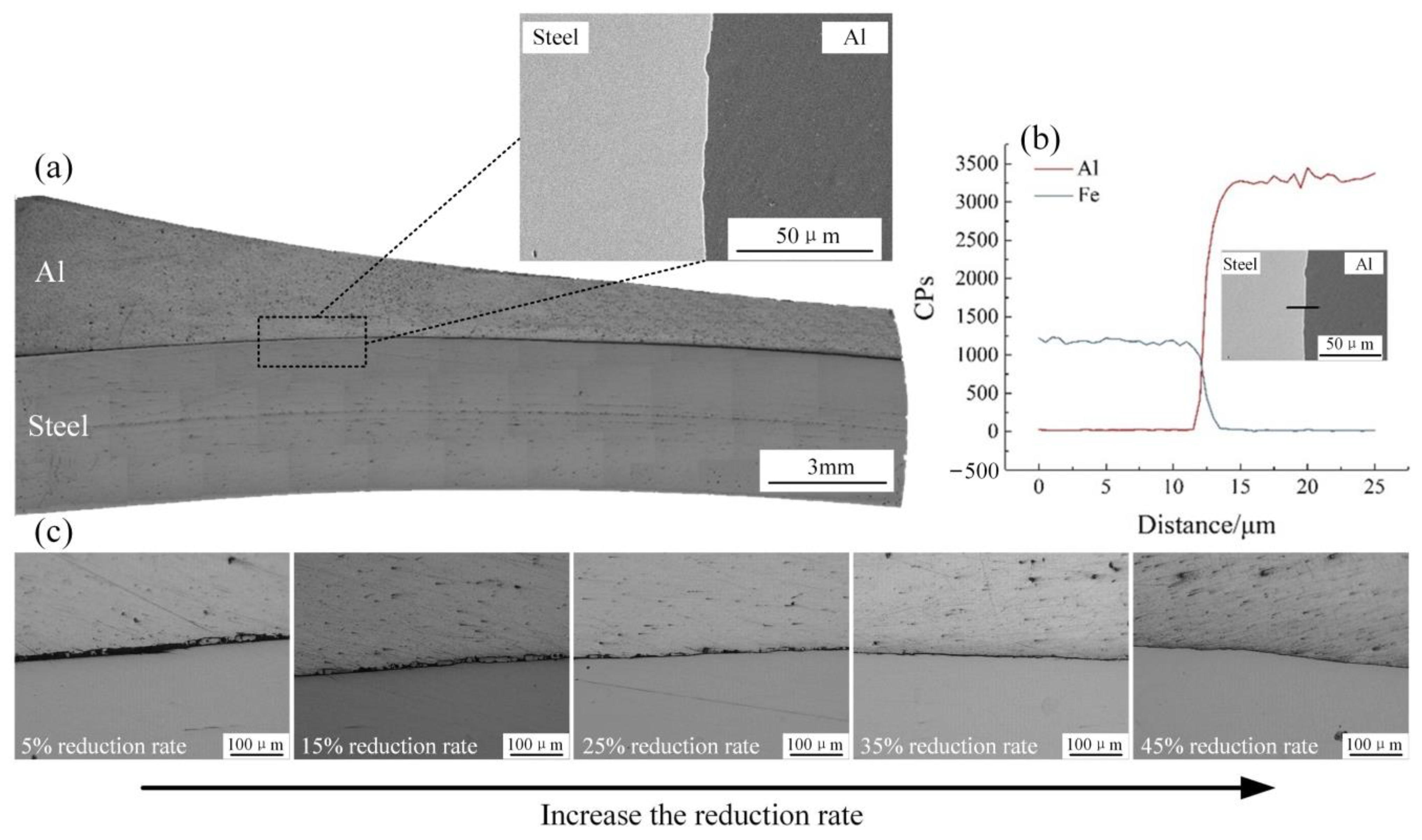

3.1. Analysis of the Warm Rolling Experimental Results for a Thick Steel/Aluminum Composite Plate

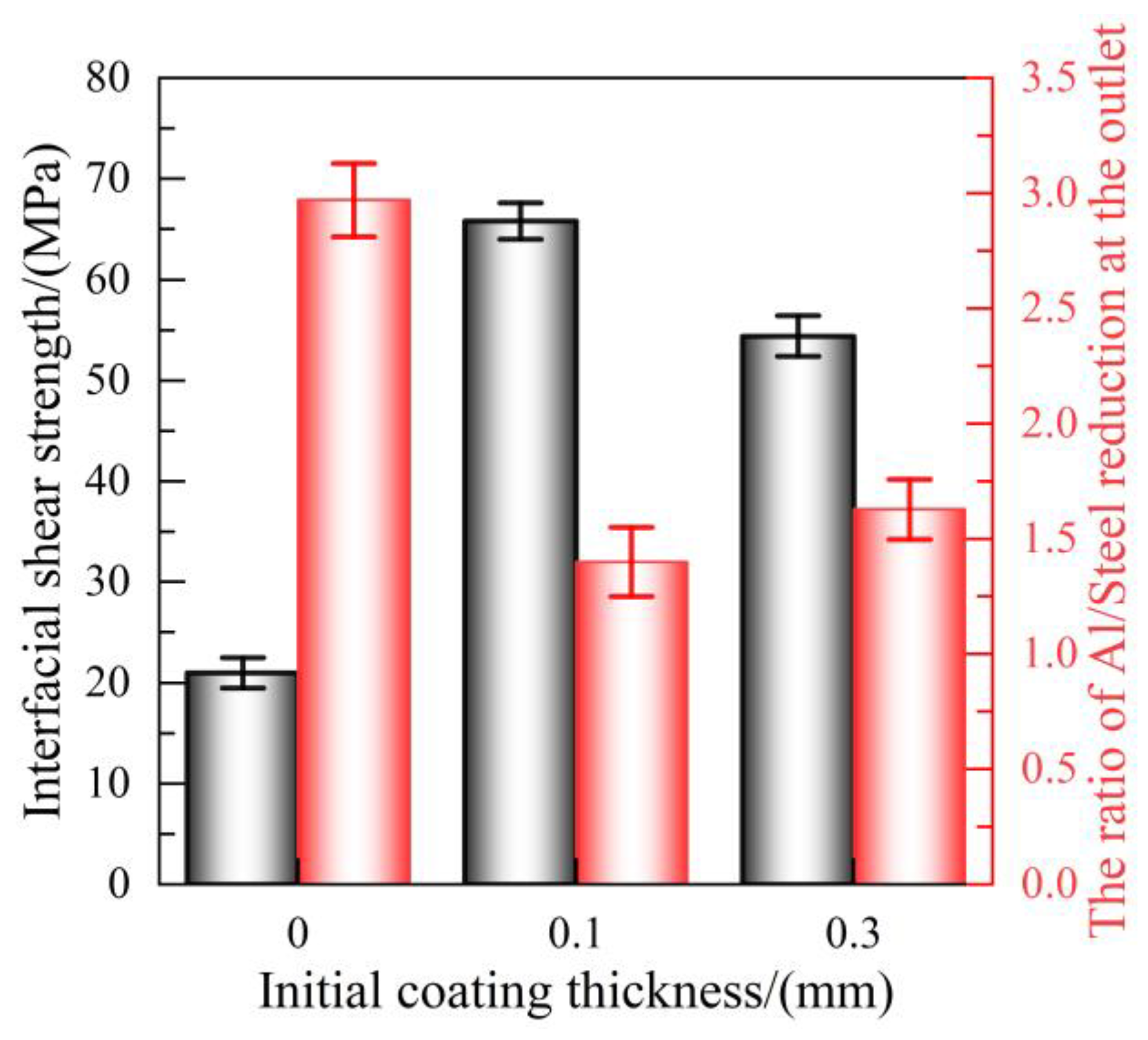

3.2. The Effect of a Coating on the Bonding Strength of the Steel/Aluminum Composite Plate

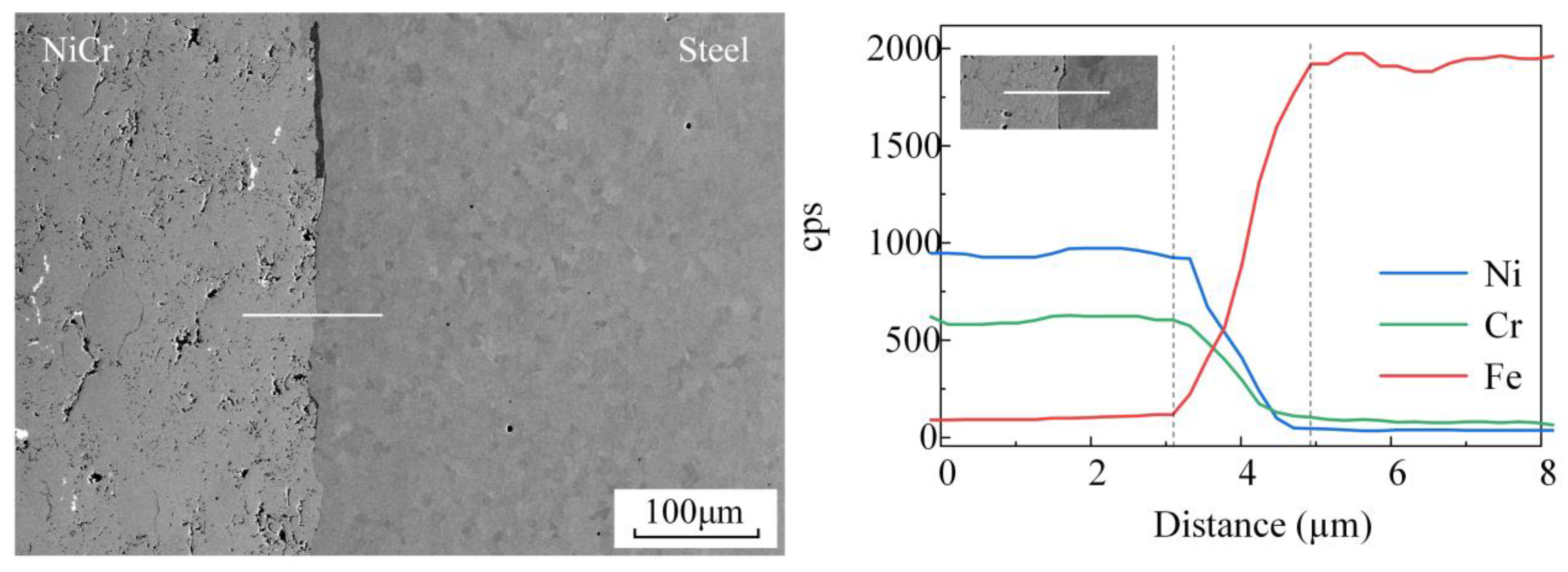

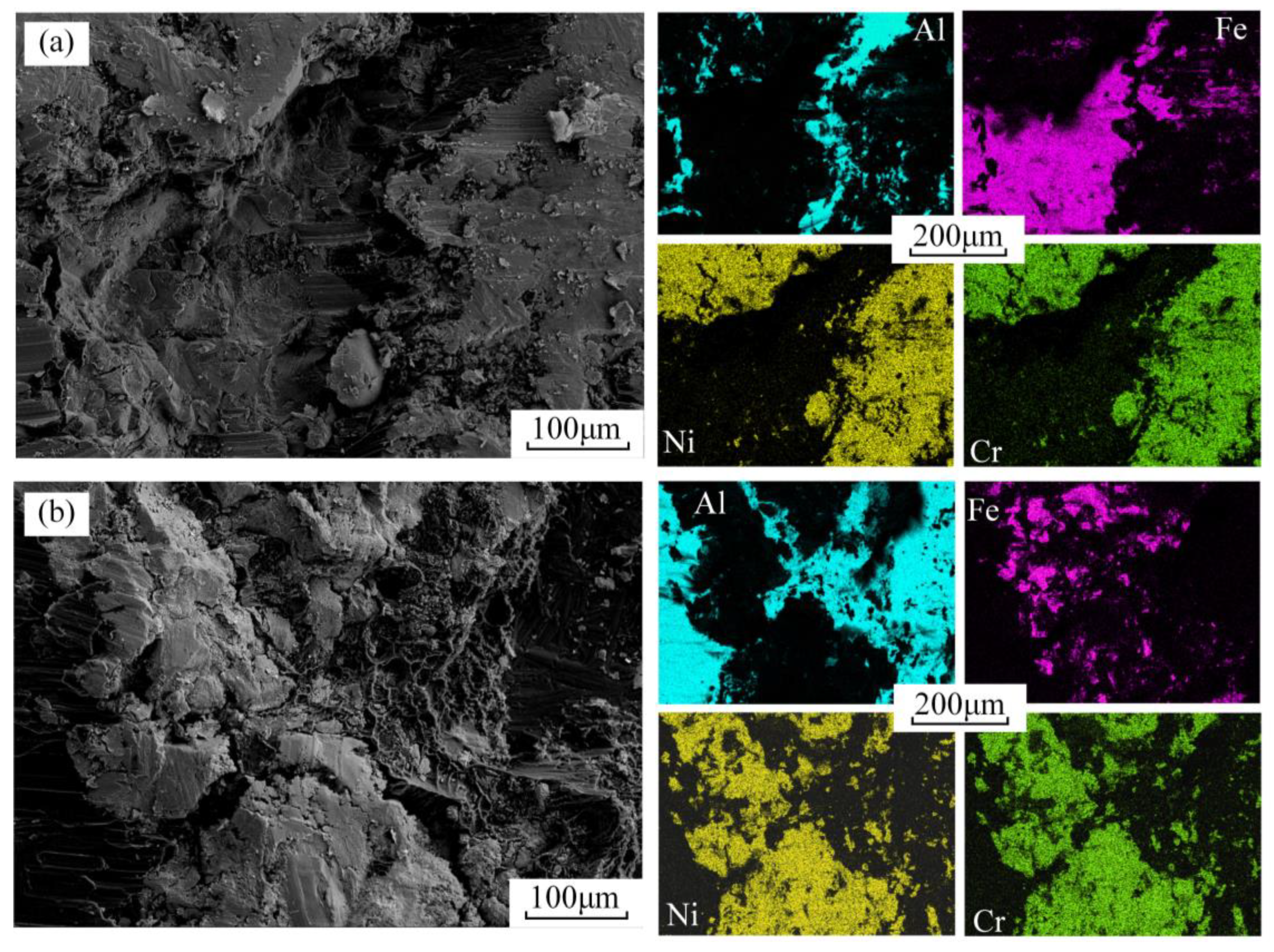

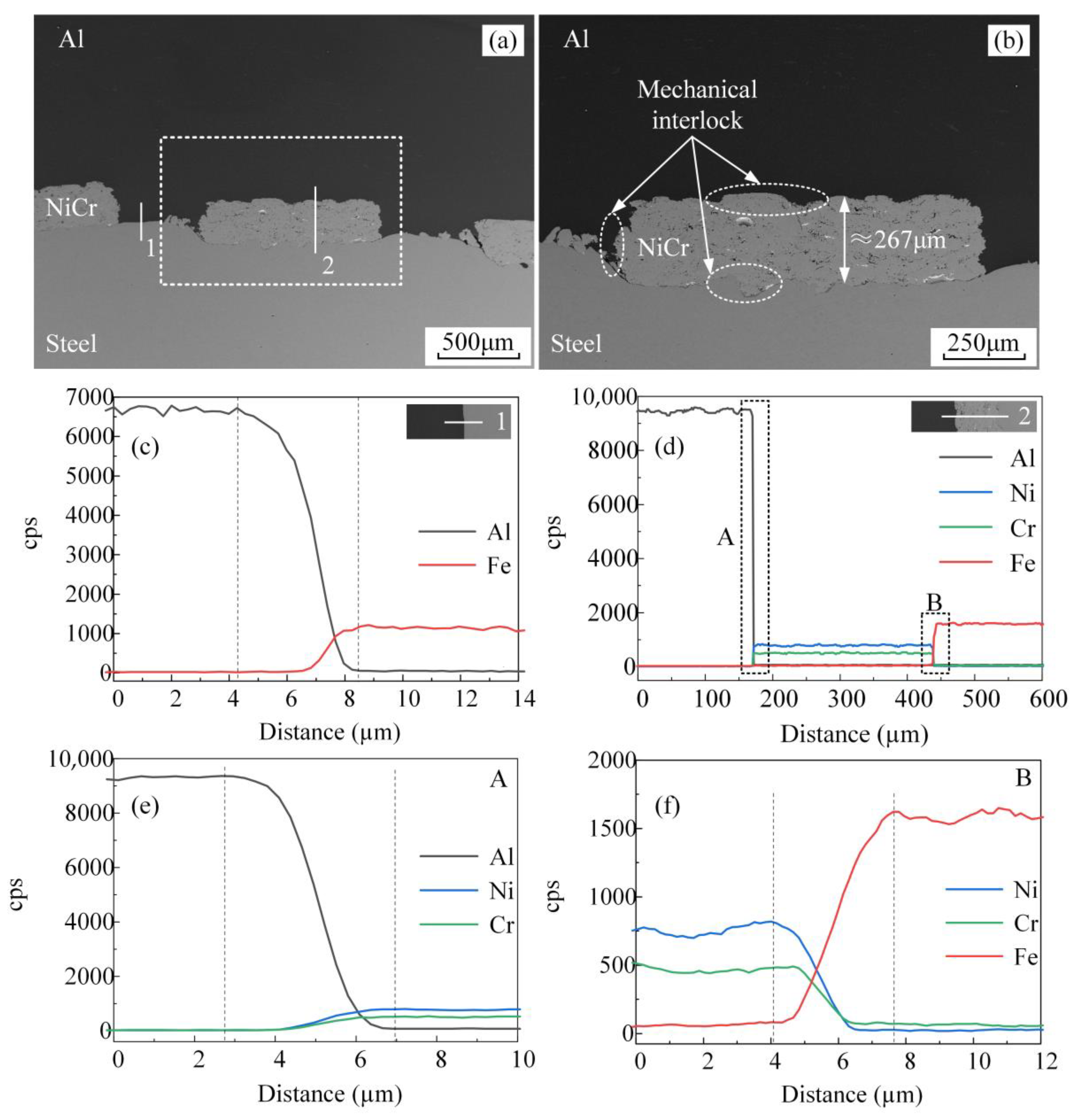

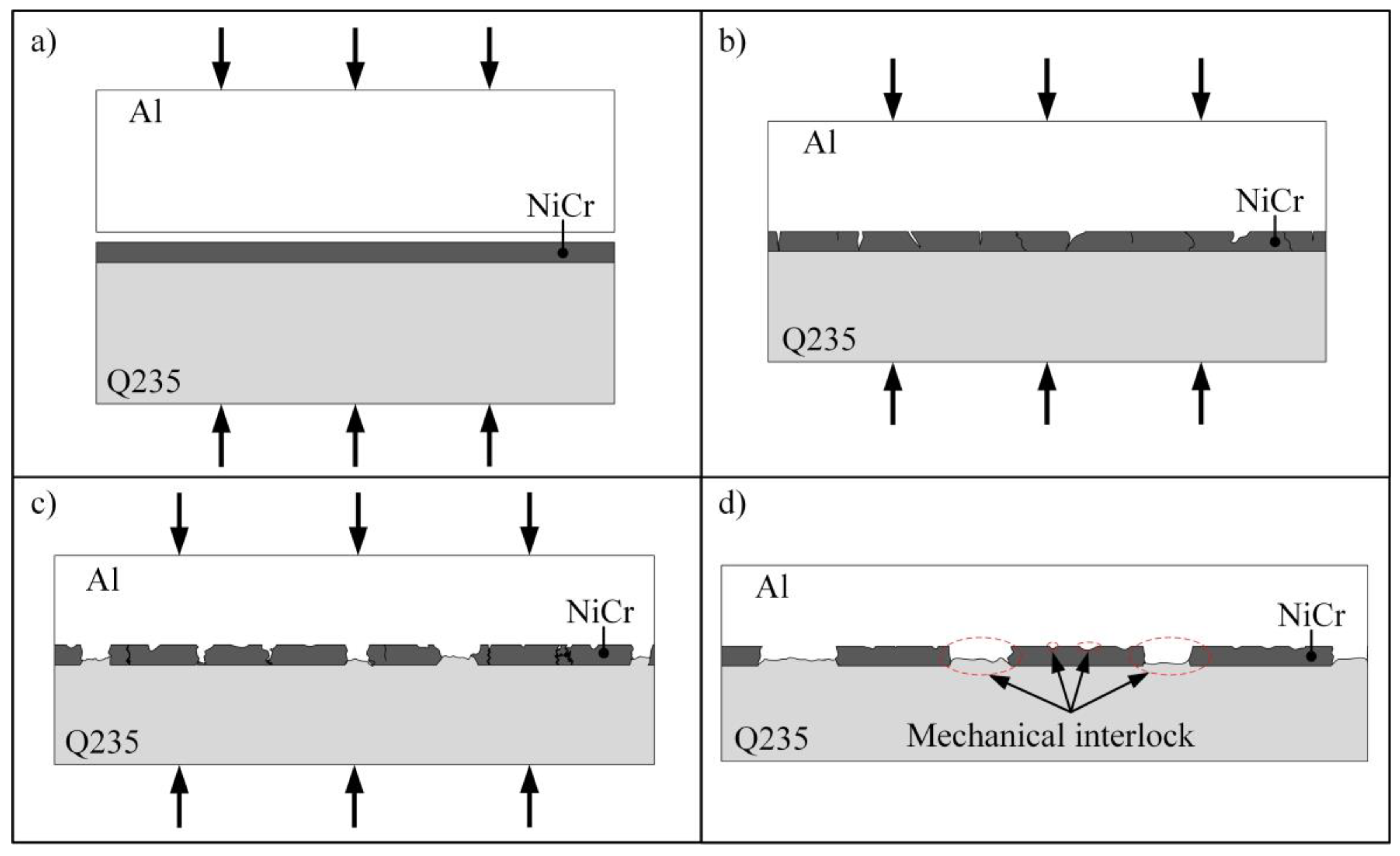

3.3. Bonding Mechanism of the Steel/Coating/Aluminum-Clad Plate during Rolling

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amanollahi, A.; Ebrahimzadeh, I.; Raeissi, M.; Saeidi, N. Laminated Steel/Aluminum Composites: Improvement of Mechanical Properties by Annealing Treatment. Mater. Today Commun. 2021, 29, 102866. [Google Scholar] [CrossRef]

- Dai, G.; Liu, Y.; Chen, K.; Liu, W.; Wang, T.; Huang, Q. Effect of cumulative deformation and interlayer mechanical properties on bonding strength of corrugated interface steel/aluminum composite plate. J. Manuf. Process. 2023, 103, 78–89. [Google Scholar] [CrossRef]

- Ghasri-Khouzani, M.; Li, X.; Bogno, A.; Chen, Z.; Liu, J.; Henein, H.; Qureshi, A. Fabrication of aluminum/stainless steel bimetallic composites through a combination of additive manufacturing and vacuum-assisted melt infiltration casting. J. Manuf. Process. 2021, 69, 320–330. [Google Scholar] [CrossRef]

- Kowalski, M.; Böhm, M.; Rozumek, D.; Kurek, A.; Correia, J. Fatigue strength of new explosively welded steel-aluminum transition joint used in ships. Ocean Eng. 2023, 288, 115990. [Google Scholar] [CrossRef]

- Kaya, Y. Microstructural, Mechanical and Corrosion Investigations of Ship Steel-Aluminum Bimetal Composites Produced by Explosive Welding. Metals 2018, 8, 544. [Google Scholar] [CrossRef]

- Yu, J.; Du, R.; Fan, Y.; Zhang, H. Unbalanced thermal field assisted thermo-compensated resistance brazing welding 6061 aluminum alloy to 304 stainless steel. J. Mater. Res. Technol. 2023, 24, 1216–1222. [Google Scholar] [CrossRef]

- Xie, J.; Cai, C.; Zhang, B.; Yu, J.; Liu, Y.; Chen, H. Microstructure evolution and fracture behavior of rotating laser welded-brazed 6061 aluminum alloys/304 SS dissimilar joint. Mater. Charact. 2023, 195, 112543. [Google Scholar] [CrossRef]

- Zha, Y.; Zhang, C.; Zhu, W.; He, X.; Zeng, X.; Li, N.; Song, C. Experimental and numerical investigations on the microstructural features and mechanical properties of explosively welded aluminum/titanium/steel trimetallic plate. Mater. Charact. 2024, 209, 113669. [Google Scholar] [CrossRef]

- Zhang, M.J.; Chen, G.Y.; Zhang, Y.; Wu, K.R. Research on microstructure and mechanical properties of laser keyhole welding-brazing of automotive galvanized steel to aluminum alloy. Mater. Des. 2013, 45, 24–30. [Google Scholar] [CrossRef]

- He, Z.; Zhou, D.; Liu, A.; Zhou, S.; Du, X.; Wang, X.; Liu, J. An investigation on rivet plug laser welding of hybrid joints between high-strength steel and aluminum alloy. Opt. Laser Technol. 2023, 164, 109470. [Google Scholar] [CrossRef]

- Tillmann, W.; Wojarski, L.; Liu, C.; Osmanda, A.M. Diffusion brazing of aluminium by PVD applied filler metals. Materialwiss. Werkstofftech. 2008, 39, 633–637. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, R.; Liu, B.; Zhu, Z.; Li, Y.; Chen, H. Interface characterization and tensile performance of deep-penetration welding-brazing of thick aluminium/steel butt joints. Mater. Charact. 2022, 186, 111811. [Google Scholar] [CrossRef]

- Yang, B.; Li, H.; Sun, H.; Xu, W.; Xia, H.; Su, X.; Chen, B.; Song, X.; Tan, C. Towards enhanced mechanical performance of Al/steel welded-brazed joints via laser surface texturing modification. J. Mater. Res. Technol. 2023, 27, 5278–5290. [Google Scholar] [CrossRef]

- Akbari-Mousavi, S.A.A.; Barrett, L.M.; Al-Hassani, S.T.S. Explosive Welding of Metal Plates. J. Mater. Process. Technol. 2008, 202, 224–239. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, Y.; Guo, C.; Guo, Y.; Guo, Z.; Liu, Y.; Liu, T. Effect of the Addition of Steel Fibers on the Bonding Interface and Tensile Properties of Explosion-Welded 2A12 Aluminum Alloy and SS-304 Steel. Materials 2023, 16, 116. [Google Scholar] [CrossRef]

- Liu, W.; Ma, J.; Atabaki, M.M.; Kovacevic, R. Joining of Advanced High-Strength Steel to AA 6061 Alloy by Using Fe/Al Structural Transition Joint. Mater. Des. 2015, 68, 146–157. [Google Scholar] [CrossRef]

- Chen, G.; Li, J.; Xu, G. Bonding Process and Interfacial Reaction in Horizontal Twin-Roll Casting of Steel/Aluminum Clad Sheet. J. Mater. Process. Technol. 2017, 246, 1–12. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, W.; Wang, T.; Li, T.; Huang, Q. Study on the effects of initial temperature and thickness ratio of component metals on the preparation of aluminum/steel clad plates by the new different temperature rolling method. J. Manuf. Process. 2023, 95, 229–241. [Google Scholar] [CrossRef]

- Nezhad, M.S.A.; Ardakani, A.H. A study of joint quality of aluminum and low carbon steel strips by warm rolling. Mater. Des. 2009, 30, 1103–1109. [Google Scholar] [CrossRef]

- Chen, K.; Liu, W.; Wang, T.; Wang, N.; Chen, Z. Experimental research on the technology of two-pass different temperature rolling for thick steel/aluminum/aluminum-alloy composite plate. Int. J. Adv. Manuf. Technol. 2022, 120, 7689–7705. [Google Scholar] [CrossRef]

- Huang, H.; Zhao, Y.; Wang, C.; Yan, M. Influence of plasma spraying on interfacial microstructure and mechanical property of thick steel/aluminum laminated plate by hot rolling. J. Mech. Eng. 2019, 14, 30–36. [Google Scholar]

- Tricarico, L.; Spina, R. Experimental investigation of laser beam welding of explosion-welded steel/aluminum structural transition joints. Mater. Des. 2010, 31, 1981–1992. [Google Scholar] [CrossRef]

- Wang, T.; Gao, X.-Y.; Zhang, Z.-X.; Ren, Z.-K.; Qi, Y.-Y.; Zhao, J.-W. Interfacial bonding mechanism of Cu/Al composite plate produced by corrugated cold roll bonding. Rare Met. 2021, 40, 1284–1293. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, W.; Jiang, R.; Wu, Y.; Xiao, H. Preparation Method and Properties of Q235/5083 Composite Plate with 1060 Interlayer by Differential Temperature Rolling with Induction Heating. Metals 2023, 13, 1501. [Google Scholar] [CrossRef]

- Xiao, H.; Xu, P.; Qi, Z.; Wu, Z.; Zhao, Y. Preparation of Steel/Aluminum Laminated Composites by Differential Temperature Rolling with Induction Heating. Acta Metall. Sin. 2020, 56, 231–239. [Google Scholar]

- Yang, X.D.; Shi, Y.; Liu, J. Effect of Cu Foil on Laser Butt Welding Quality of Aluminum/Steel Dissimilar Metals Joint. J. Mech. Eng. 2014, 50, 143–149. [Google Scholar] [CrossRef]

- Gladkovskii, S.V.; Trunina, T.A.; Kokovikhin, E.A.; Smirnova, S.V.; Kamantsev, I.S.; Gorbunov, A.V. Structural steel-aluminum sandwich composites based on low-carbon steel 006/IF. Met. Sci. Heat Treat. 2013, 55, 3–7. [Google Scholar] [CrossRef]

- Grewal, P.S.; Chawla, V.; Grewal, J.S. High Velocity Oxy-fuel Sprayed Coatings—A Review. J. Aust. Ceram. Soc. 2011, 47, 30–36. [Google Scholar]

- Basha, G.M.T.; Bolleddu, V. Tribological Behavior of Carbon Nanotubes Reinforced High Velocity Oxy-Fuel Sprayed WC-20 wt.% Co Coatings. J. Therm. Spray Technol. 2021, 30, 1653–1665. [Google Scholar] [CrossRef]

- MIL-J-24445A; Joint, Bimetallic Bonded, Aluminum to Steel. United States Department of Defense: Washington, DC, USA, 1977.

- Kumar, R.V.; Keshavamurthy, R.; Perugu, C.S.; Koppad, P.G.; Alipour, M. Influence of hot rolling on microstructure and mechanical behaviour of Al6061-ZrB2 in-situ metal matrix composites. Mater. Sci. Eng. A 2018, 738, 344–352. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, F.; He, J.; Qin, Y.; Liu, B.; Yang, M.; Yin, F. Microstructure, growth kinetics and mechanical properties of interface layer for roll bonded aluminum-steel clad sheet annealed under argon gas protection. Vacuum 2018, 151, 189–196. [Google Scholar] [CrossRef]

- Li, T.; Zhou, D.-W.; Yan, Y.-R.; Peng, P.; Liu, J.-S. First-principles and experimental investigations on ductility/brittleness of intermetallic compounds and joint properties in steel/aluminum laser welding. Trans. Nonferrous Met. Soc. China 2021, 31, 2962–2977. [Google Scholar] [CrossRef]

- Fu, L.; Xiao, H.; Yu, C.; Lv, Q.; Zhang, S.; Xie, H. Bonding enhancement of cold rolling Al/steel composite plates via self-nano film modification. J. Mater. Process. Technol. 2021, 300, 117427. [Google Scholar] [CrossRef]

- Arbo, S.M.; Bergh, T.; Holmedal, B.; Vullum, P.E.; Westermann, I. Relationship between Al-Ni intermetallic Phases and Bond Strength in Roll Bonded Steel-Aluminum Composites with Nickel Interlayers. Metals 2019, 9, 827. [Google Scholar] [CrossRef]

- Sharma, V.; Kumar, S.; Kumar, M.; Deepak, D. High temperature oxidation performance of Ni-Cr-Ti and Ni-5Al coatings. Mater. Today Proc. 2020, 26, 3397–3406. [Google Scholar] [CrossRef]

- Fu, L.; Xiao, H.; Yu, C.; Chen, N.; Guo, Y.; Yang, B.; Ren, Z. Analysis on mechanism of steel plate pre-oxidation in improving bonding properties of cold-rolled 6061 Al/Q235 steel composite plate. J. Mater. Process. Technol. 2023, 316, 117960. [Google Scholar] [CrossRef]

| Elements | C | Mn | S | P | Si | Fe |

|---|---|---|---|---|---|---|

| Q235 | 0.15 | 0.5 | 0.045 | 0.02 | 0.1 | balance |

| Elements | Si | Cu | Mn | Mg | Zn | V | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 1060 | 0.25 | 0.05 | 0.03 | 0.03 | 0.05 | 0.05 | 0.03 | balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, M.; Wang, M.-Y.; Cui, Z.-Y.; Xu, J.-B.; Huang, H.-G. The Effect of a Coating Sprayed Using Supersonic Flame Coating Technology on the Mechanical Properties and Interface Structure of a Thick Steel/Aluminum Composite Plate during Hot Rolling. Metals 2024, 14, 450. https://doi.org/10.3390/met14040450

Yan M, Wang M-Y, Cui Z-Y, Xu J-B, Huang H-G. The Effect of a Coating Sprayed Using Supersonic Flame Coating Technology on the Mechanical Properties and Interface Structure of a Thick Steel/Aluminum Composite Plate during Hot Rolling. Metals. 2024; 14(4):450. https://doi.org/10.3390/met14040450

Chicago/Turabian StyleYan, Meng, Meng-Ye Wang, Zi-Yi Cui, Jiu-Ba Xu, and Hua-Gui Huang. 2024. "The Effect of a Coating Sprayed Using Supersonic Flame Coating Technology on the Mechanical Properties and Interface Structure of a Thick Steel/Aluminum Composite Plate during Hot Rolling" Metals 14, no. 4: 450. https://doi.org/10.3390/met14040450

APA StyleYan, M., Wang, M.-Y., Cui, Z.-Y., Xu, J.-B., & Huang, H.-G. (2024). The Effect of a Coating Sprayed Using Supersonic Flame Coating Technology on the Mechanical Properties and Interface Structure of a Thick Steel/Aluminum Composite Plate during Hot Rolling. Metals, 14(4), 450. https://doi.org/10.3390/met14040450