Fabrication and Dry-Sliding Wear Characterization of Open-Cell AlSn6Cu–Al2O3 Composites with LSTM-Based Coefficient of Friction Prediction

Abstract

1. Introduction

2. Materials and Methods

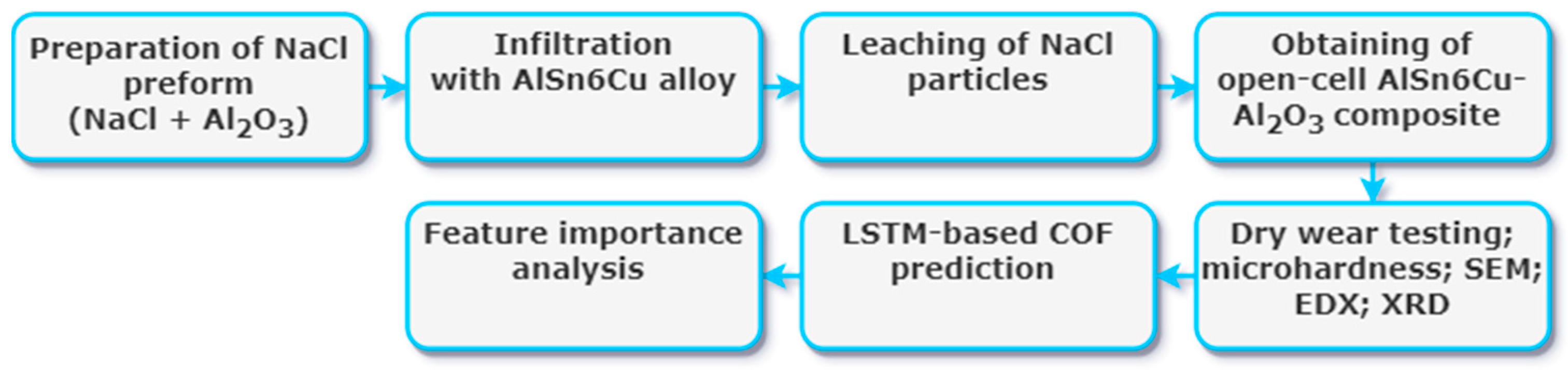

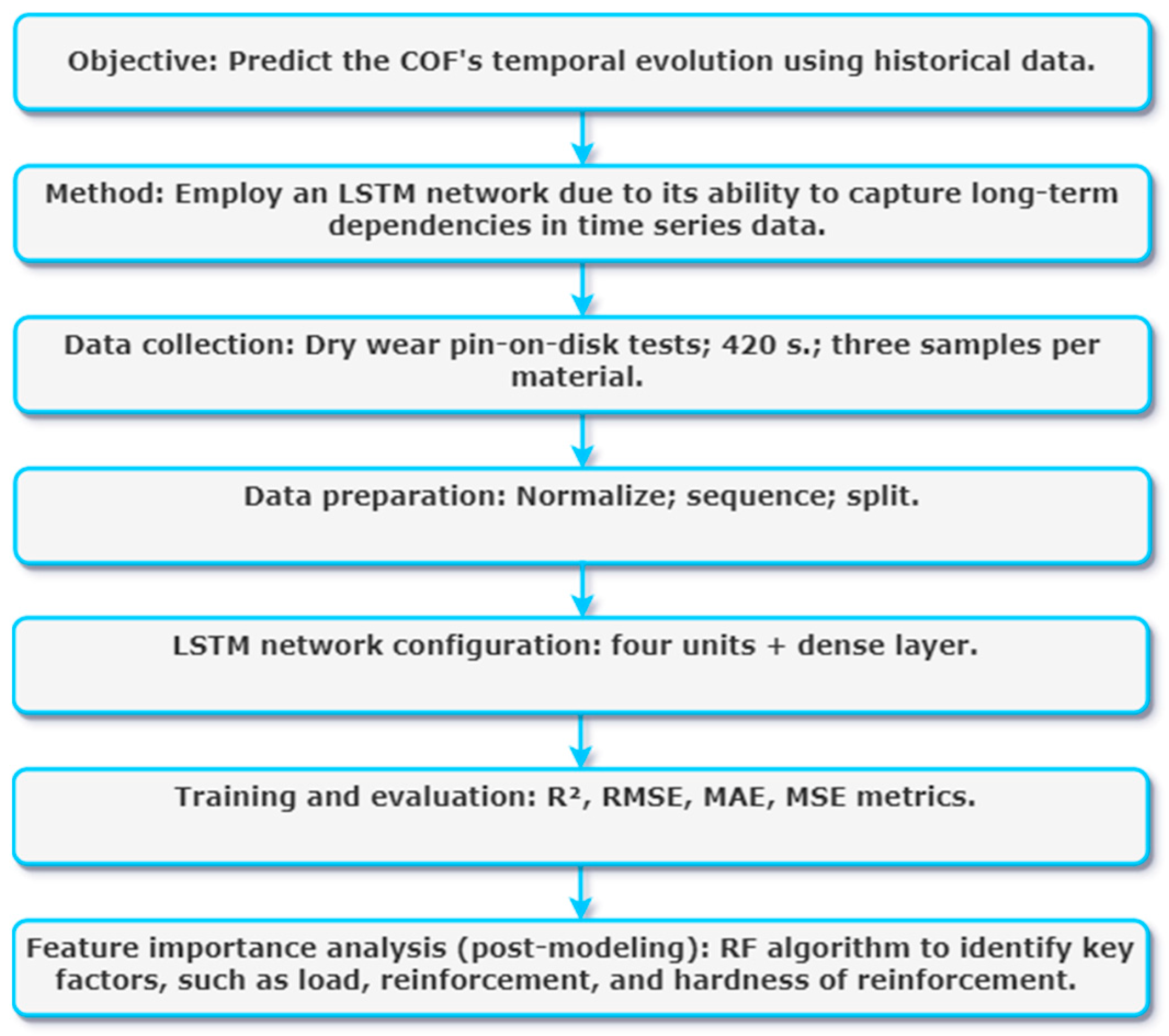

2.1. Fabrication

2.2. Characterization

2.3. Machine Learning Model

3. Results and Discussion

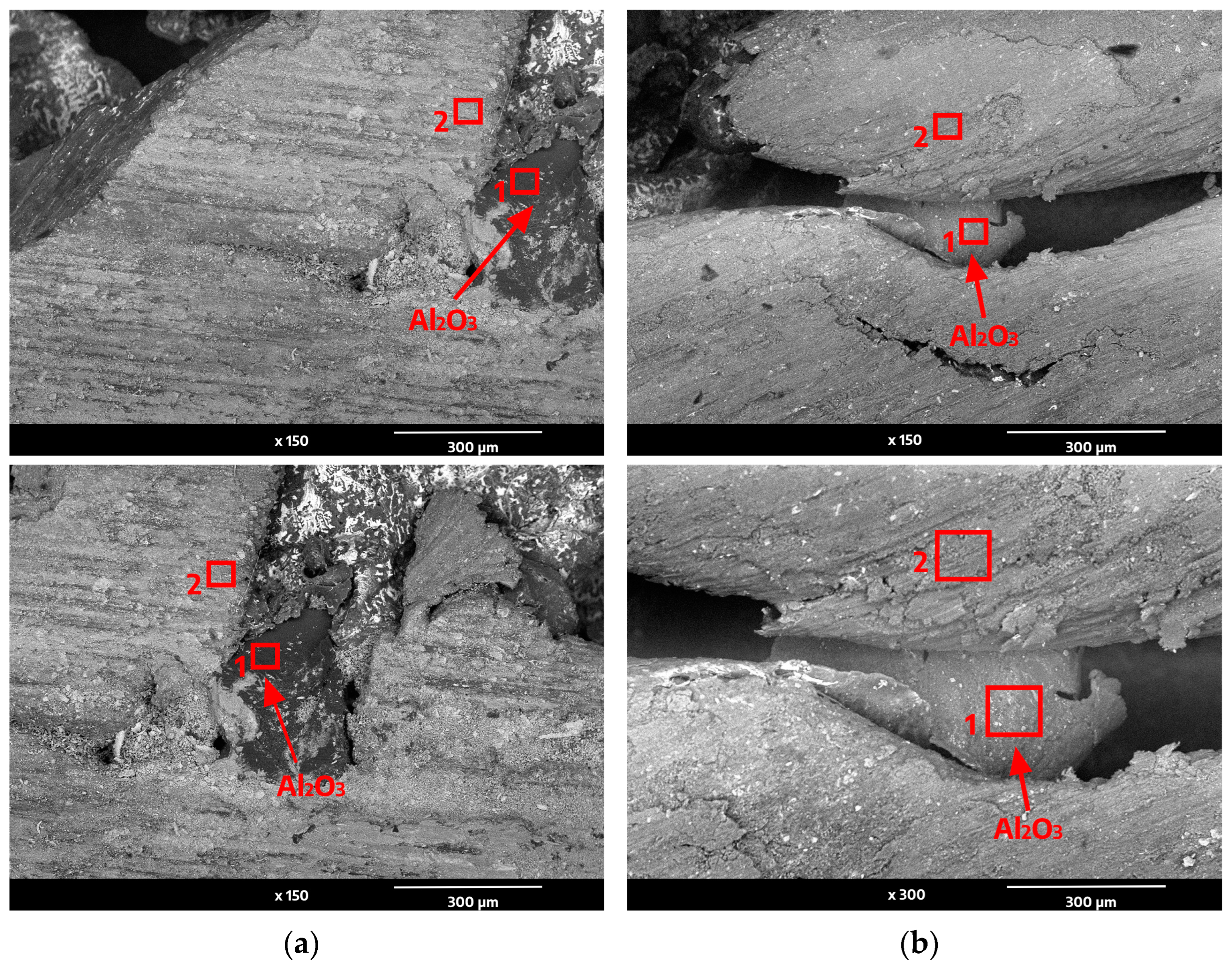

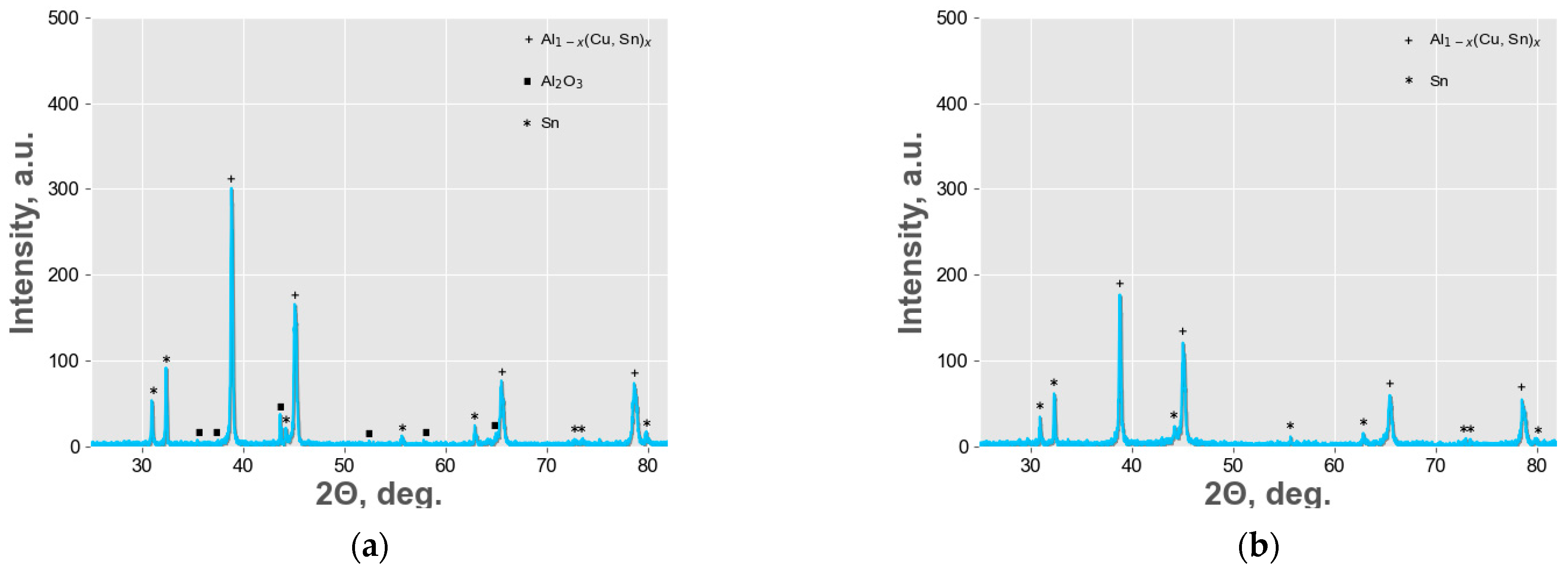

3.1. Microstructure

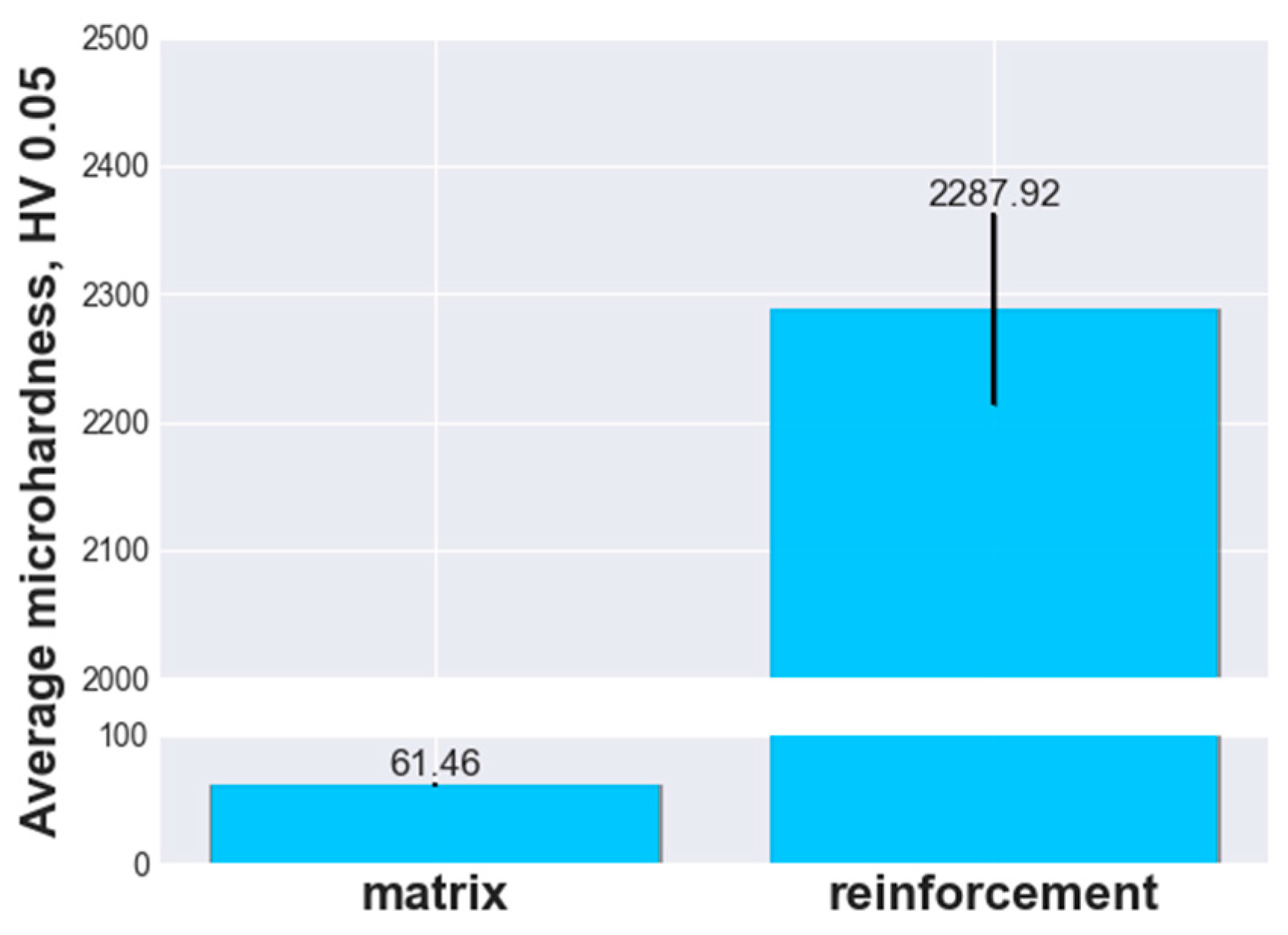

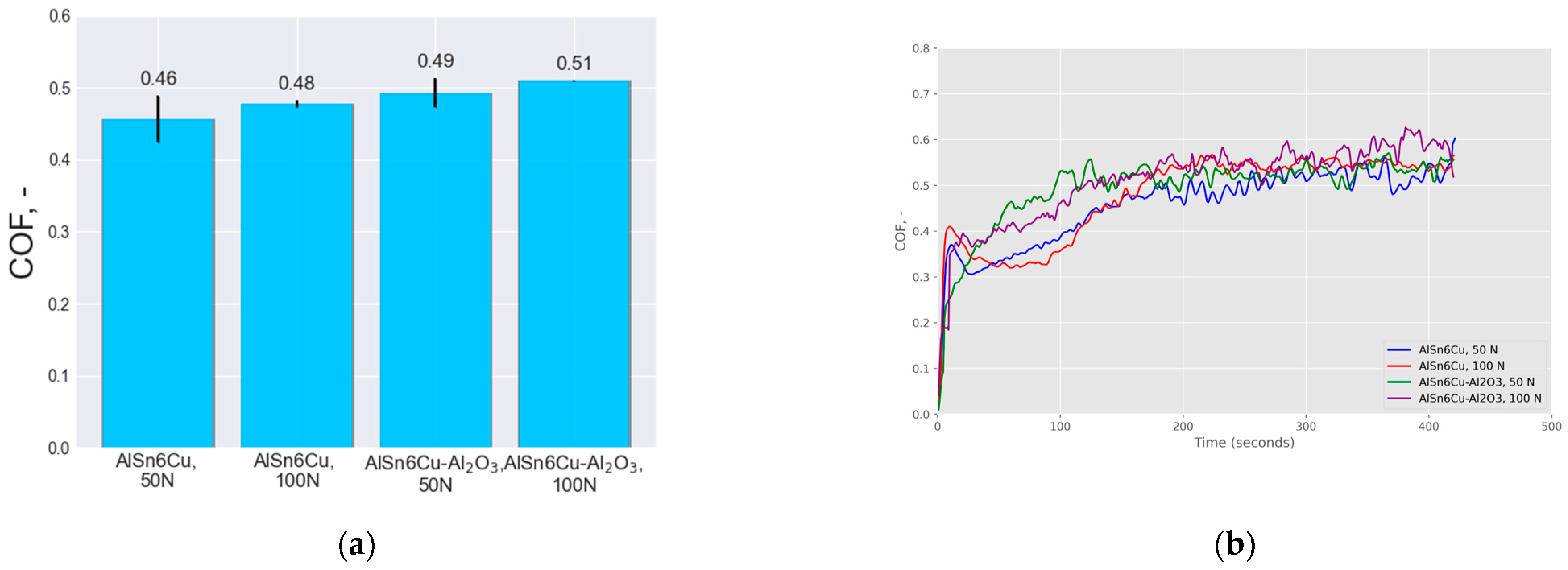

3.2. Micro-Hardness and Wear Behavior

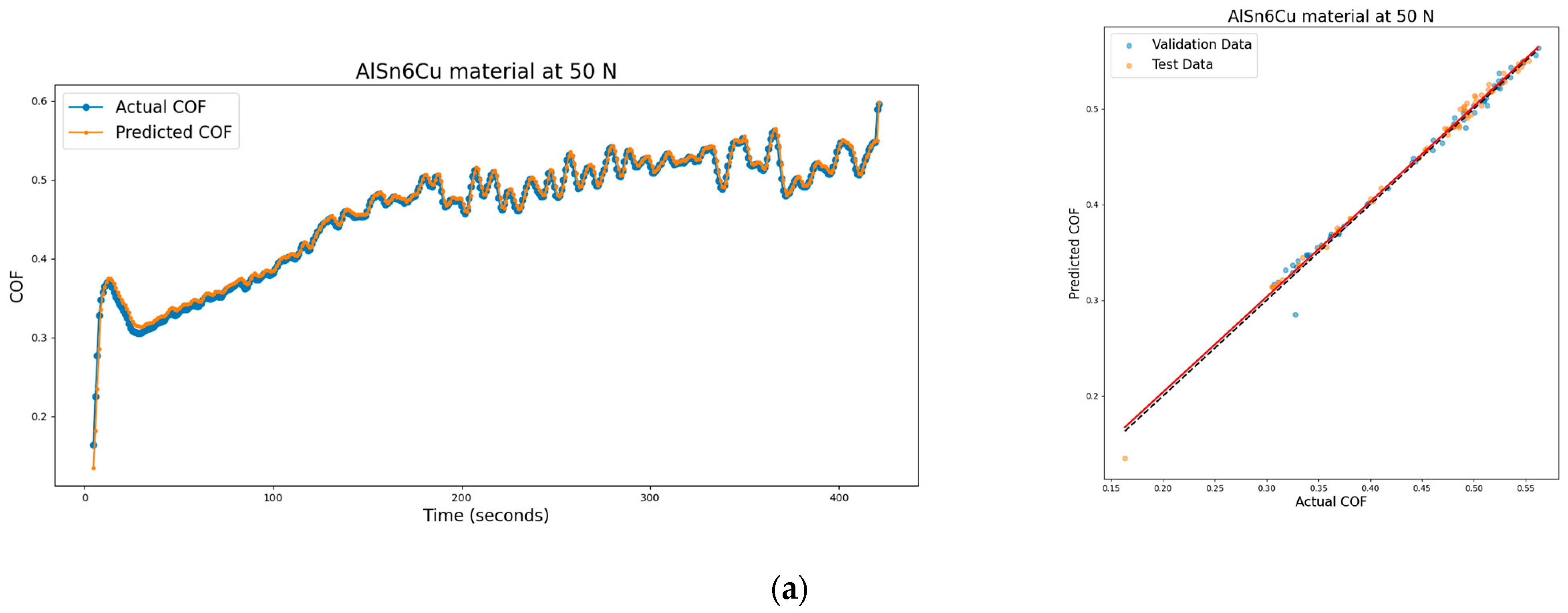

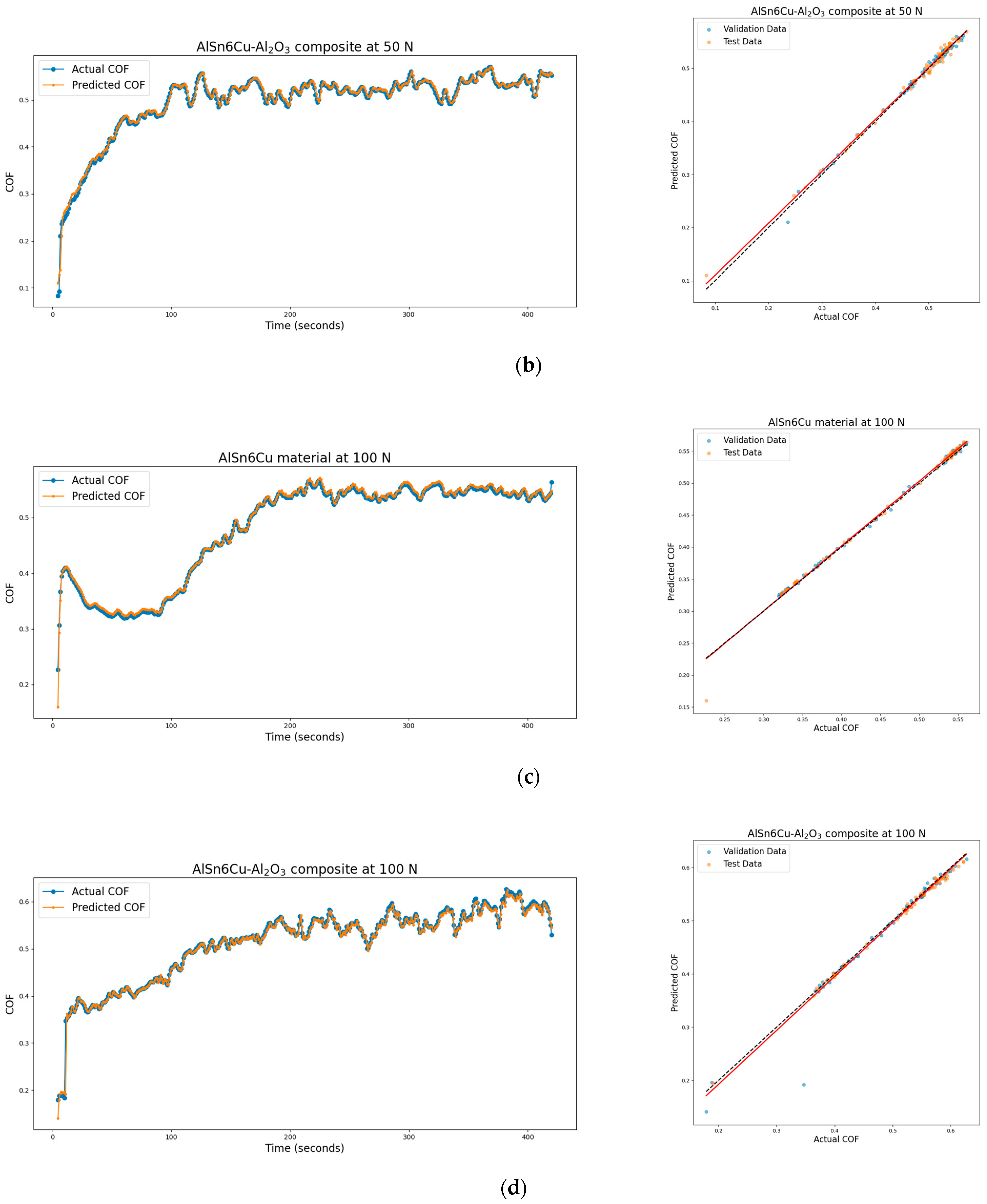

3.3. COF Prediction and Model Performance Evaluation

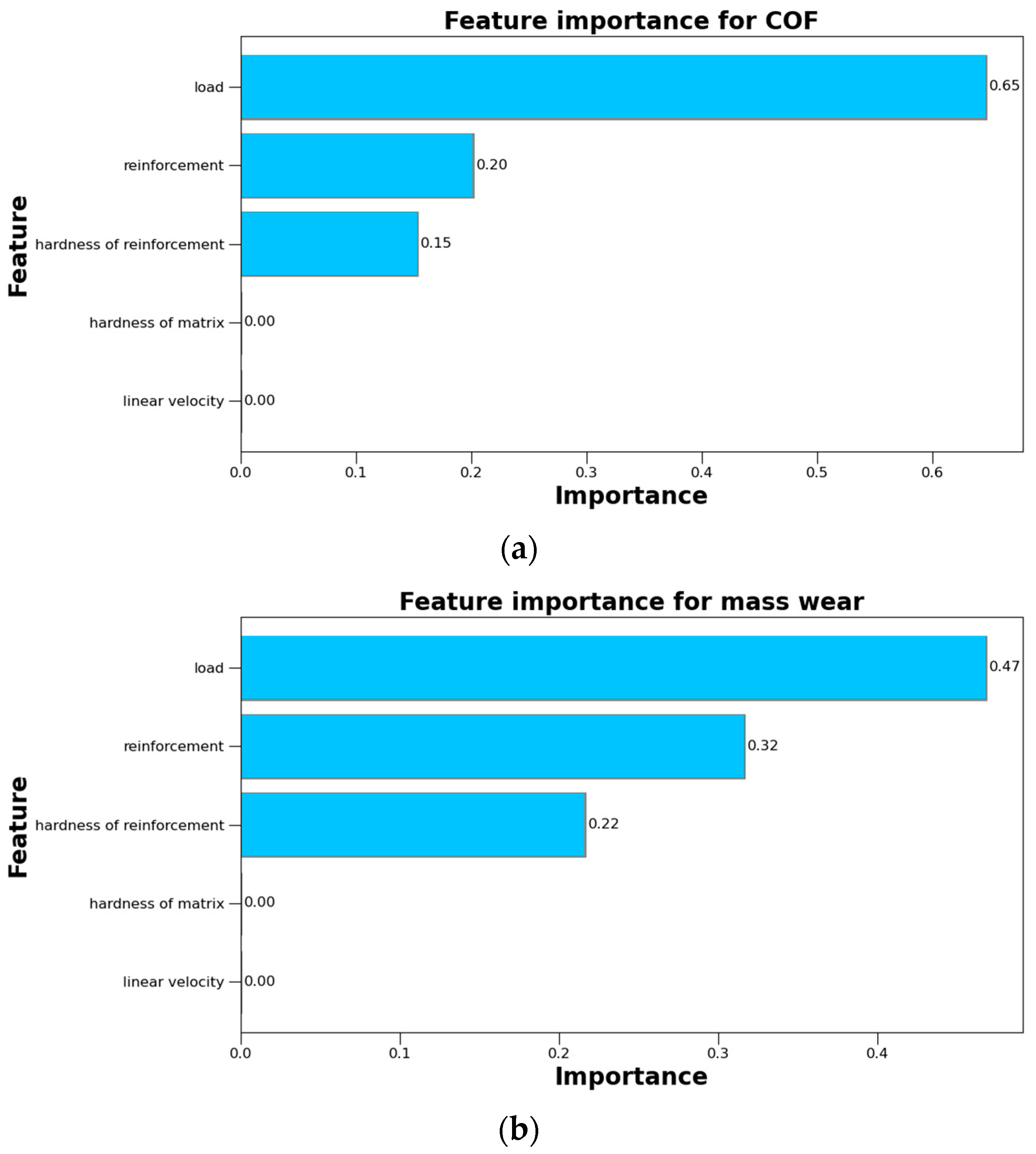

3.4. Feature Importance Analysis for Mass Wear and COF Prediction

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chelladurai, S.J.S.; Kumar, S.S.; Venugopal, N.; Ray, A.P.; Manjunath, T.C.; Gnanasekaran, S. A Review on Mechanical Properties and Wear Behaviour of Aluminium Based Metal Matrix Composites. Mater. Today Proc. 2021, 37, 908–916. [Google Scholar] [CrossRef]

- Nturanabo, F.; Masu, L.; Kirabira, J. Novel Applications of Aluminium Metal Matrix Composites. In Aluminium Alloys and Composites; BoD—Books on Demand: Norderstedt, Germany, 2019. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H.; Dora, T.L. A Review on Fabrication Methods, Reinforcements and Mechanical Properties of Aluminum Matrix Composites. J. Manuf. Process. 2020, 56, 1059–1074. [Google Scholar] [CrossRef]

- Stanev, L.; Kolev, M.; Drenchev, B.; Drenchev, L. Open-Cell Metallic Porous Materials Obtained Through Space Holders—Part II: Structure and Properties. A Review. J. Manuf. Sci. Eng. 2016, 139, 050802. [Google Scholar] [CrossRef]

- Garg, P.; Jamwal, A.; Kumar, D.; Sadasivuni, K.K.; Hussain, C.M.; Gupta, P. Advance Research Progresses in Aluminium Matrix Composites: Manufacturing & Applications. J. Jpn. Res. Inst. Adv. Copper-Base Mater. Technol. 2019, 8, 4924–4939. [Google Scholar] [CrossRef]

- Wan, T.; Liu, Y.; Zhou, C.; Chen, X.; Li, Y. Fabrication, Properties, and Applications of Open-Cell Aluminum Foams: A Review. J. Mater. Sci. 2021, 62, 11–24. [Google Scholar] [CrossRef]

- Kolev, M.; Drenchev, L.; Simeonova, T.; Krastev, R.; Kavardzhikov, V. Data on Mechanical Properties of Open-Cell AlSi10Mg Materials and Open-Cell AlSi10Mg-SiC Composites with Different Pore Sizes and Strain Rates. Data Brief 2023, 49, 109461. [Google Scholar] [CrossRef]

- Bhardwaj, A.R.; Vaidya, A.M.; Shekhawat, S.P. Machining of Aluminium Metal Matrix Composite: A Review. Mater. Today Proc. 2020, 21, 1396–1402. [Google Scholar] [CrossRef]

- Shyha, I.; Huo, D. Advances in Machining of Composite Materials: Conventional and Non-Conventional Processes; Springer Nature: Berlin/Heidelberger Germany, 2021; ISBN 9783030714383. [Google Scholar]

- Schmidt, A.; Siebeck, S.; Götze, U.; Wagner, G.; Nestler, D. Particle-Reinforced Aluminum Matrix Composites (AMCs)—Selected Results of an Integrated Technology, User, and Market Analysis and Forecast. Metals 2018, 8, 143. [Google Scholar] [CrossRef]

- Venkatesh, R.; Sethi, D.; Kolli, V.; Saha Roy, B. Experimental Investigation of Aluminium Matrix Composite Production and Joining. Mater. Today 2019, 18, 5276–5285. [Google Scholar] [CrossRef]

- Suthar, J.; Patel, K.M. Processing Issues, Machining, and Applications of Aluminum Metal Matrix Composites. Mater. Manuf. Process. 2018, 33, 499–527. [Google Scholar] [CrossRef]

- Luo, Y.; Yu, S.; Liu, J.; Zhu, X.; Luo, Y. Compressive Property and Energy Absorption Characteristic of Open-Cell SiCp/AlSi9Mg Composite Foams. J. Alloys Compd. 2010, 499, 227–230. [Google Scholar] [CrossRef]

- Monno, M.; Negri, D.; Mussi, V.; Aghaei, P.; Groppi, G.; Tronconi, E.; Strano, M. Cost-Efficient Aluminum Open-Cell Foams: Manufacture, Characterization, and Heat Transfer Measurements. Adv. Eng. Mater. 2018, 20, 1701032. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L.; Ren, Z. Crush Performance of Multifunctional Hybrid Foams Based on an Aluminium Alloy Open-Cell Foam Skeleton. Polym. Test. 2018, 67, 246–256. [Google Scholar] [CrossRef]

- Rusin, N.M.; Skorentsev, A.L.; Krinitsyn, M.G. Relationship between Wear Resistance under Dry Friction and Mechanical Properties of Sintered Al–Sn Composites. Inorg. Mater. Appl. Res. 2021, 12, 776–784. [Google Scholar] [CrossRef]

- Rusin, N.M.; Skorentsev, A.L.; Krinitcyn, M.G.; Dmitriev, A.I. Tribotechnical Properties of Sintered Antifriction Aluminum-Based Composite under Dry Friction against Steel. Materials 2021, 15, 180. [Google Scholar] [CrossRef] [PubMed]

- Rusin, N.M.; Skorentsev, A.L. Mechanical and Tribological Properties of Sintered Aluminum Matrix Al–Sn Composites Reinforced with Al3Fe Particles. Phys. Met. Metall. 2021, 122, 1248–1255. [Google Scholar] [CrossRef]

- Rusin, N.M.; Skorentsev, A.L.; Dmitriev, A.I. Effect of the Reinforcing Particle Introduction Method on the Tribomechanical Properties of Sintered Al-Sn-Fe Alloys. Metals 2023, 13, 1483. [Google Scholar] [CrossRef]

- Bertelli, F.; Freitas, E.S.; Cheung, N.; Arenas, M.A.; Conde, A.; de Damborenea, J.; Garcia, A. Microstructure, Tensile Properties and Wear Resistance Correlations on Directionally Solidified Al-Sn-(Cu; Si) Alloys. J. Alloys Compd. 2017, 695, 3621–3631. [Google Scholar] [CrossRef]

- Banerjee, T.; Dey, S.; Sekhar, A.P.; Datta, S.; Das, D. Design of Alumina Reinforced Aluminium Alloy Composites with Improved Tribo-Mechanical Properties: A Machine Learning Approach. Trans. Indian Inst. Met. 2020, 73, 3059–3069. [Google Scholar] [CrossRef]

- Wang, Y.; Soutis, C.; Ando, D.; Sutou, Y.; Narita, F. Application of Deep Neural Network Learning in Composites Design. Eur. J. Mater. 2022, 2, 117–170. [Google Scholar] [CrossRef]

- Thankachan, T.; Soorya Prakash, K.; Malini, R.; Ramu, S.; Sundararaj, P.; Rajandran, S.; Rammasamy, D.; Jothi, S. Prediction of Surface Roughness and Material Removal Rate in Wire Electrical Discharge Machining on Aluminum Based Alloys/Composites Using Taguchi Coupled Grey Relational Analysis and Artificial Neural Networks. Appl. Surf. Sci. 2019, 472, 22–35. [Google Scholar] [CrossRef]

- Idrisi, A.H.; Hamid Ismail Mourad, A. Wear Performance Analysis of Aluminum Matrix Composites Using Artificial Neural Network. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 26 March–10 April 2019. [Google Scholar]

- Wiciak-Pikuła, M.; Felusiak-Czyryca, A.; Twardowski, P. Tool Wear Prediction Based on Artificial Neural Network during Aluminum Matrix Composite Milling. Sensors 2020, 20, 5798. [Google Scholar] [CrossRef] [PubMed]

- Mishra, A.; Jatti, V.S. Prediction of Wear Rate in Al/SiC Metal Matrix Composites Using a Neurosymbolic Artificial Intelligence (NSAI)-Based Algorithm. Lubricants 2023, 11, 261. [Google Scholar] [CrossRef]

- Agme, V.N.; Ashish; Pant, R.; Sridevi, M.; Suman, A.; Vijaya Sekhar Babu, M. Analysis and Prediction of Wear Characteristics of Sustainable Metal Matrix Composites Using Machine Learning with Decision Making Algorithm. In Proceedings of the 2023 4th International Conference on Smart Electronics and Communication (ICOSEC), Trichy, India, 20–22 September 2023; pp. 1401–1407. [Google Scholar]

- Hasan, M.S.; Kordijazi, A.; Rohatgi, P.K.; Nosonovsky, M. Triboinformatic Modeling of Dry Friction and Wear of Aluminum Base Alloys Using Machine Learning Algorithms. Tribol. Int. 2021, 161, 107065. [Google Scholar] [CrossRef]

- Kolev, M.; Drenchev, L.; Petkov, V.; Dimitrova, R.; Kovacheva, D. Open-Cell AlSn6Cu-SiC Composites: Fabrication, Dry-Sliding Wear Behavior, and Machine Learning Methods for Wear Prediction. Materials 2023, 16, 6208. [Google Scholar] [CrossRef] [PubMed]

- Łazińska, M.; Durejko, T.; Lipiński, S.; Polkowski, W.; Czujko, T.; Varin, R.A. Porous Graded FeAl Intermetallic Foams Fabricated by Sintering Process Using NaCl Space Holders. Mater. Sci. Eng. A 2015, 636, 407–414. [Google Scholar] [CrossRef]

- Lefebvre, L.-P.; Banhart, J.; Dunand, D.C. Porous Metals and Metallic Foams: Current Status and Recent Developments. Adv. Eng. Mater. 2008, 10, 775–787. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, L.; Ye, W.; Li, Y.; Yang, F. Ultrasonic Lamination Defects Detection of Carbon Fiber Composite Plates Based on Multilevel LSTM. Compos. Struct. 2024, 327, 117714. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, Z.; Dong, Y.; Tu, J. An Interpretable LSTM Deep Learning Model Predicts the Time-Dependent Swelling Behavior in CERCER Composite Fuels. Mater. Today Commun. 2023, 37, 106998. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, W.; Wei, P.; Fang, P.; Zhang, X.; Yan, N.; Liu, W.; Zhao, H.; Wu, Q. Classification of Zambian Grasslands Using Random Forest Feature Importance Selection during the Optimal Phenological Period. Ecol. Indic. 2022, 135, 108529. [Google Scholar] [CrossRef]

- Alsagri, H.S.; Ykhlef, M. Quantifying Feature Importance for Detecting Depression Using Random Forest. Int. J. Adv. Comput. Sci. Appl. 2020, 11. [Google Scholar] [CrossRef]

- Wu, D.; Jennings, C.; Terpenny, J.; Gao, R.X.; Kumara, S. A Comparative Study on Machine Learning Algorithms for Smart Manufacturing: Tool Wear Prediction Using Random Forests. J. Manuf. Sci. Eng. 2017, 139, 071018. [Google Scholar] [CrossRef]

- Kolev, M.; Drenchev, L.; Petkov, V.; Dimitrova, R. Production and Tribological Characterization of Advanced Open-Cell AlSi10Mg-Al2O3 Composites. Metals 2023, 13, 131. [Google Scholar] [CrossRef]

- Kolev, M.; Drenchev, L.; Petkov, V. Fabrication, Experimental Investigation and Prediction of Wear Behavior of Open-Cell AlSi10Mg-SiC Composite Materials. Metals 2023, 13, 814. [Google Scholar] [CrossRef]

- Bharath, V.; Nagaral, M.; Auradi, V.; Kori, S.A. Preparation of 6061Al-Al2O3 MMC’s by Stir Casting and Evaluation of Mechanical and Wear Properties. Procedia Mater. Sci. 2014, 6, 1658–1667. [Google Scholar] [CrossRef]

- Ghanaraja, S.; Ravikumar, K.S.; Raju, H.P.; Madhusudan, B.M. Studies on Dry Sliding Wear Behaviour of Al2O3 Reinforced Al Based Metal Matrix Composites. Mater. Today 2017, 4, 10043–10048. [Google Scholar] [CrossRef]

| Analysis № | Al | Fe | O | Sn | Cu |

|---|---|---|---|---|---|

| 1 | 65.45 | 0.72 | 33.83 | - | - |

| 2 | 29.91 | 60.01 | 7.32 | 2.26 | 0.49 |

| Analysis № | Al | Fe | O | Sn | Cu |

|---|---|---|---|---|---|

| 1 | 58.03 | 6.11 | 35.85 | - | - |

| 2 | 52.95 | 31.03 | 11.44 | 3.68 | 0.90 |

| Analysis | Dataset | MSE | RMSE | MAE | R2 |

|---|---|---|---|---|---|

| AlSn6Cu–Al2O3 at 100 N | Validation | 0.00039 | 0.0198000 | 0.0066391 | 0.95585 |

| AlSn6Cu–Al2O3 at 100 N | Test | 0.00003 | 0.0053078 | 0.0041946 | 0.99638 |

| AlSn6Cu–Al2O3 at 50 N | Validation | 0.00004 | 0.0061351 | 0.0046952 | 0.99388 |

| AlSn6Cu–Al2O3 at 50 N | Test | 0.00005 | 0.0073764 | 0.0056358 | 0.99303 |

| AlSn6Cu at 100 N | Validation | 0.00002 | 0.0040804 | 0.0035303 | 0.99810 |

| AlSn6Cu at 100 N | Test | 0.00008 | 0.0091727 | 0.0043677 | 0.99056 |

| AlSn6Cu at 50 N | Validation | 0.00007 | 0.0081300 | 0.0052856 | 0.98978 |

| AlSn6Cu at 50 N | Test | 0.00004 | 0.006027 | 0.0046216 | 0.99494 |

| Analysis | Mean | Std | Min | 25% | 50% | 75% | Max |

|---|---|---|---|---|---|---|---|

| AlSn6Cu–Al2O3 at 100 N | 0.50967 | 0.08644 | 0.04160 | 0.46471 | 0.53642 | 0.56443 | 0.62715 |

| AlSn6Cu–Al2O3 at 50 N | 0.49294 | 0.08060 | 0.00990 | 0.49220 | 0.51990 | 0.53380 | 0.57070 |

| AlSn6Cu at 100 N | 0.47711 | 0.09410 | 0.01805 | 0.39445 | 0.53505 | 0.54580 | 0.56715 |

| AlSn6Cu at 50 N | 0.45710 | 0.08162 | 0.01520 | 0.39882 | 0.48275 | 0.51697 | 0.60240 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolev, M.; Drenchev, L.; Petkov, V.; Dimitrova, R.; Kolev, K.; Simeonova, T. Fabrication and Dry-Sliding Wear Characterization of Open-Cell AlSn6Cu–Al2O3 Composites with LSTM-Based Coefficient of Friction Prediction. Metals 2024, 14, 428. https://doi.org/10.3390/met14040428

Kolev M, Drenchev L, Petkov V, Dimitrova R, Kolev K, Simeonova T. Fabrication and Dry-Sliding Wear Characterization of Open-Cell AlSn6Cu–Al2O3 Composites with LSTM-Based Coefficient of Friction Prediction. Metals. 2024; 14(4):428. https://doi.org/10.3390/met14040428

Chicago/Turabian StyleKolev, Mihail, Ludmil Drenchev, Veselin Petkov, Rositza Dimitrova, Krasimir Kolev, and Tatiana Simeonova. 2024. "Fabrication and Dry-Sliding Wear Characterization of Open-Cell AlSn6Cu–Al2O3 Composites with LSTM-Based Coefficient of Friction Prediction" Metals 14, no. 4: 428. https://doi.org/10.3390/met14040428

APA StyleKolev, M., Drenchev, L., Petkov, V., Dimitrova, R., Kolev, K., & Simeonova, T. (2024). Fabrication and Dry-Sliding Wear Characterization of Open-Cell AlSn6Cu–Al2O3 Composites with LSTM-Based Coefficient of Friction Prediction. Metals, 14(4), 428. https://doi.org/10.3390/met14040428