Indentation of Commercial Pure Titanium Processed by Cold Rolling

Abstract

1. Introduction

2. Experimental

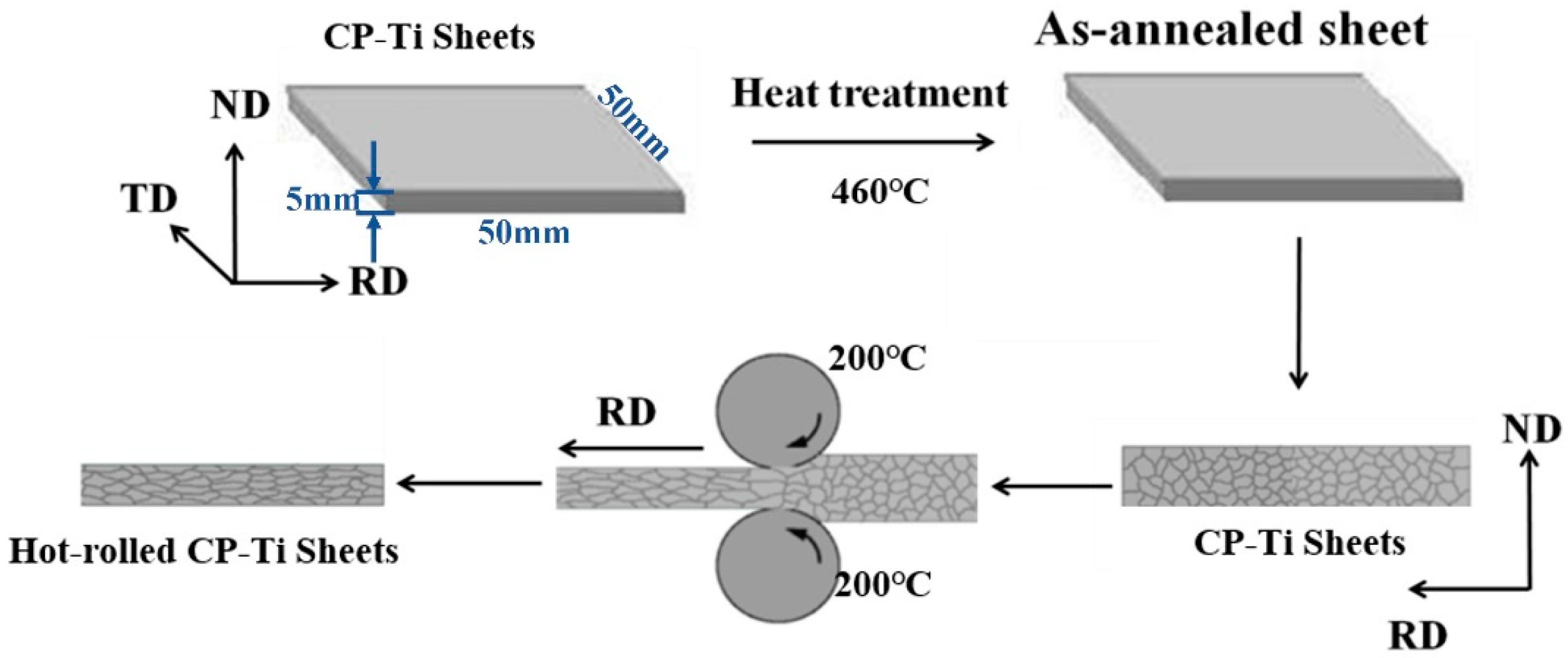

2.1. Materials and Processing Methods

2.2. Microindentation Tests

3. Results and Discussion

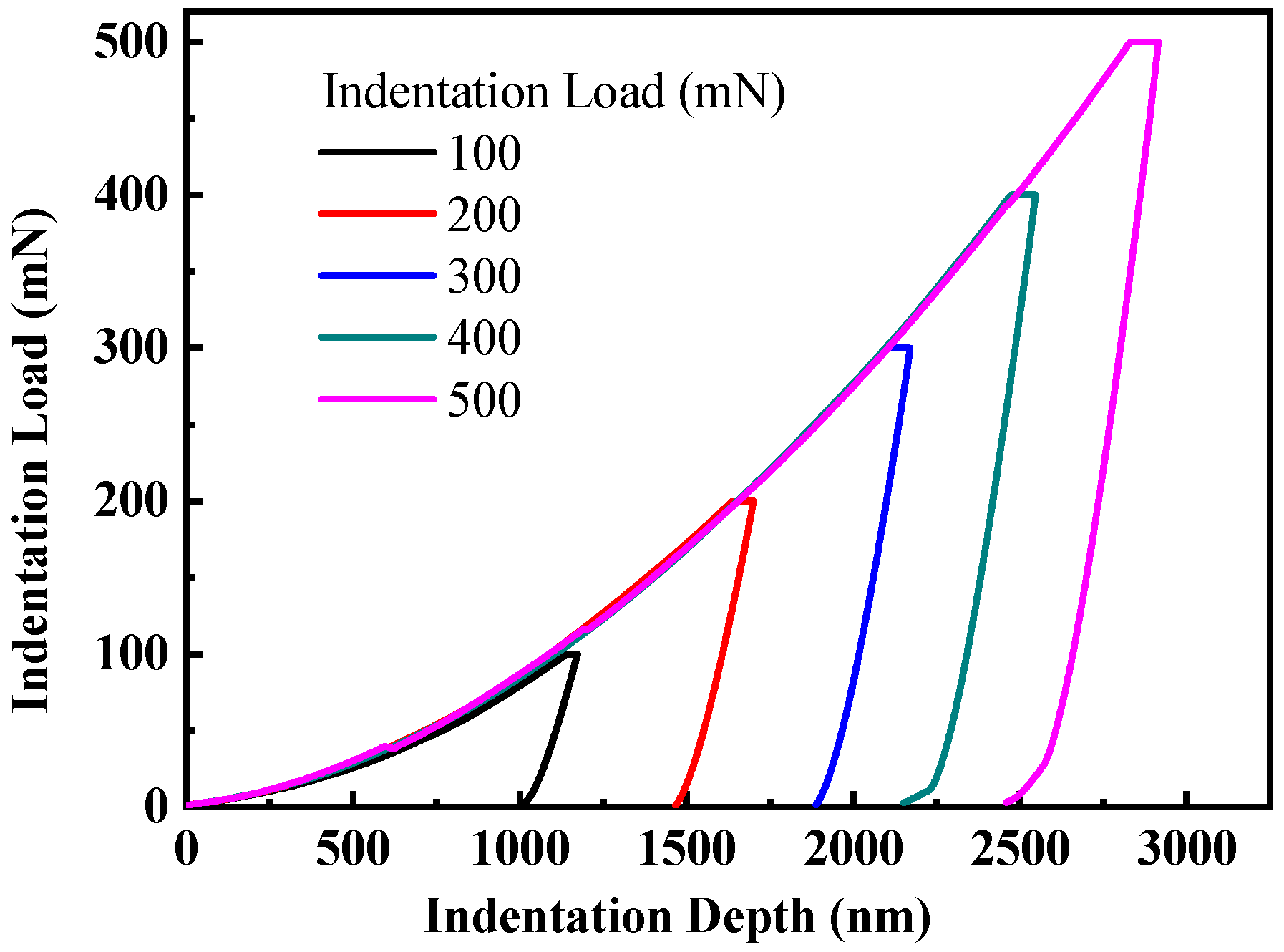

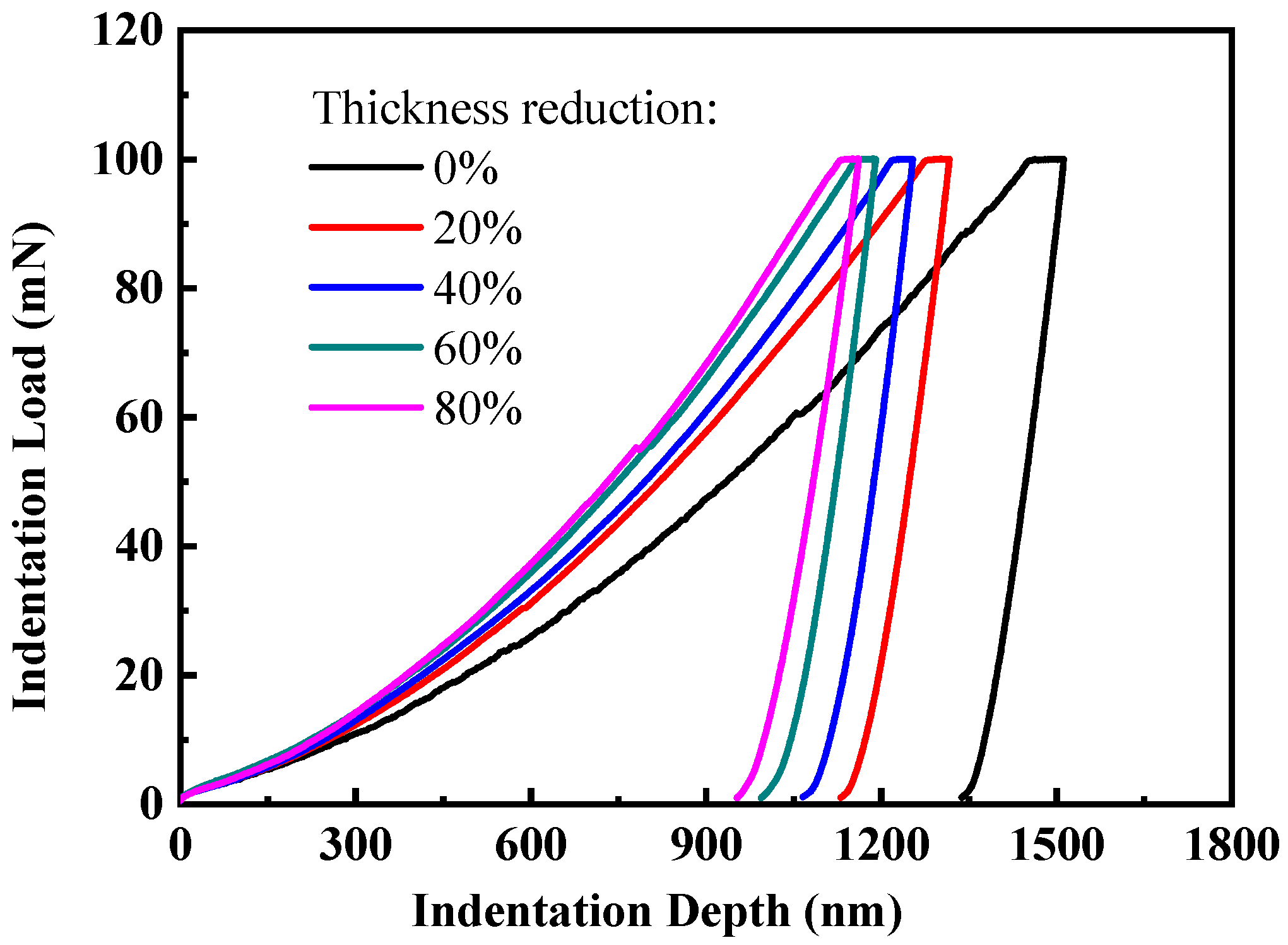

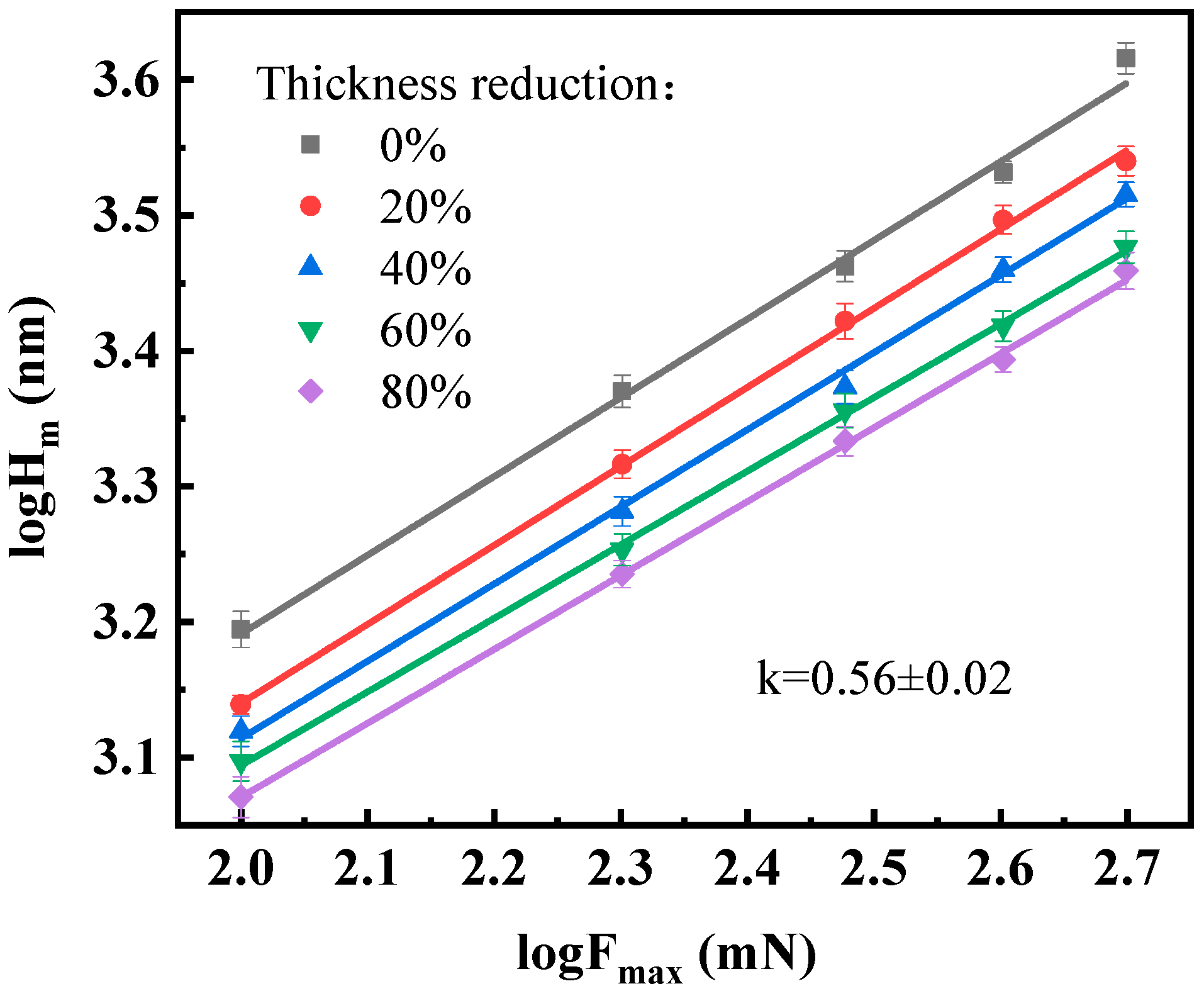

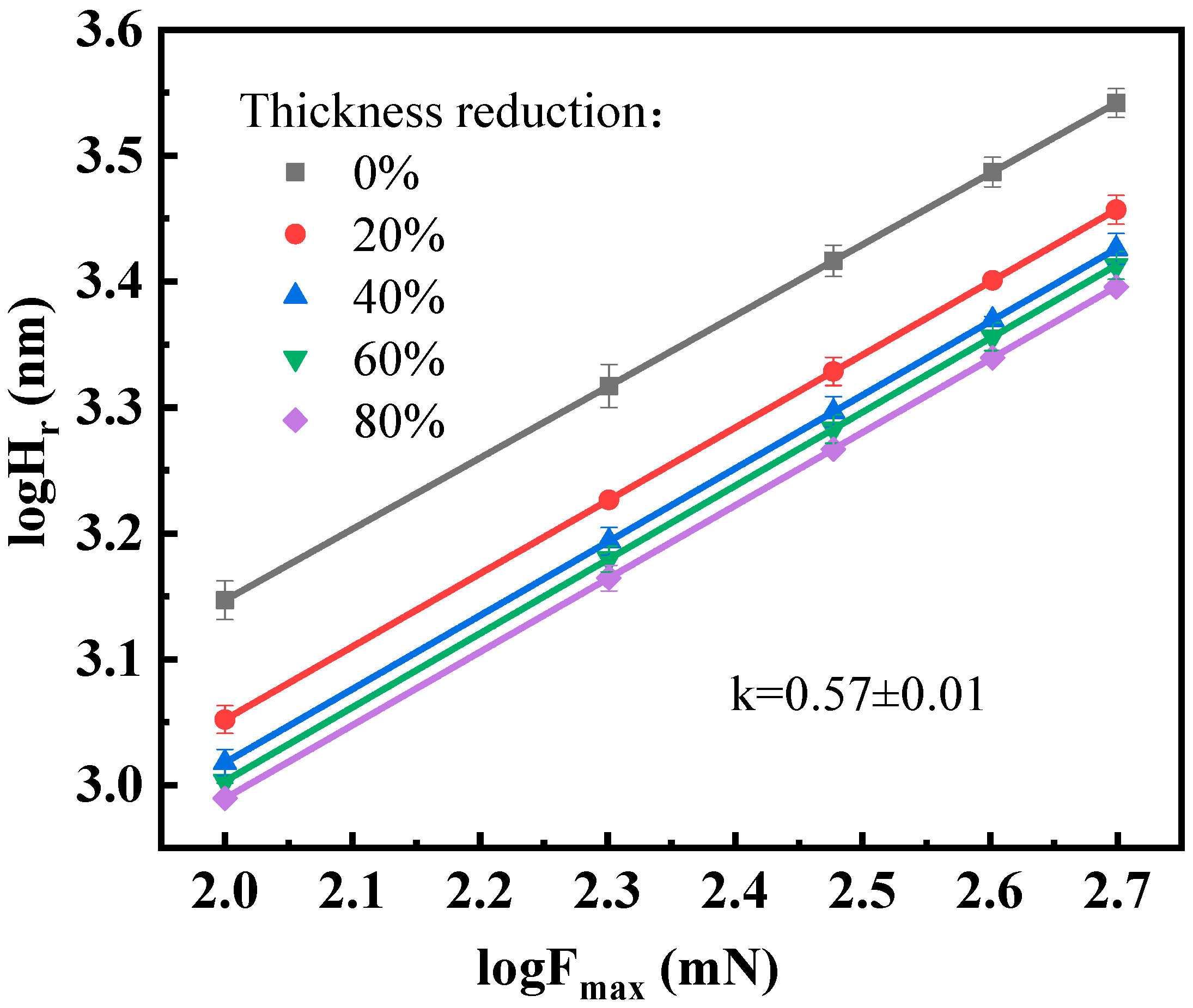

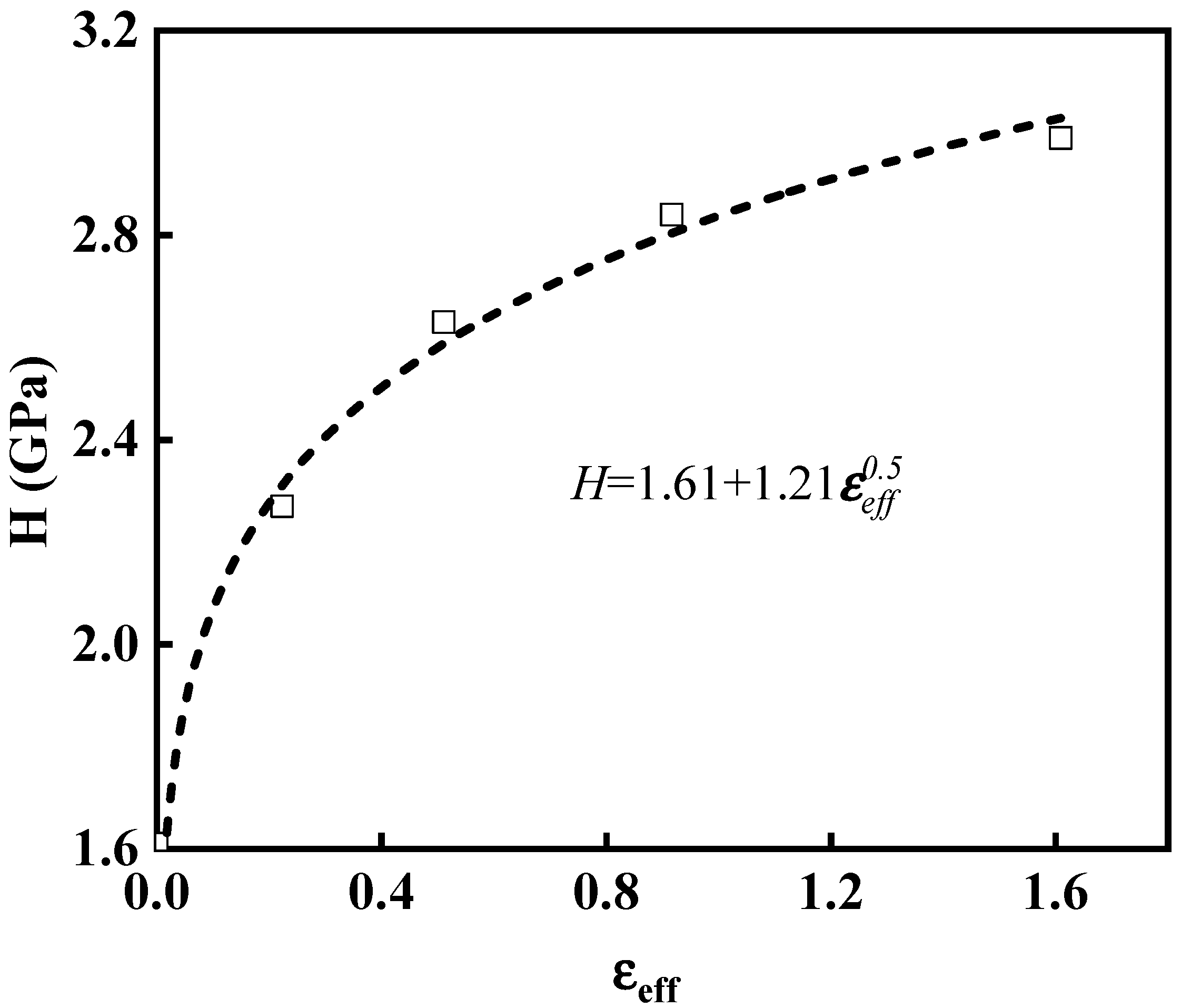

3.1. Indentation Deformation of the Cold-Rolled CP-Ti

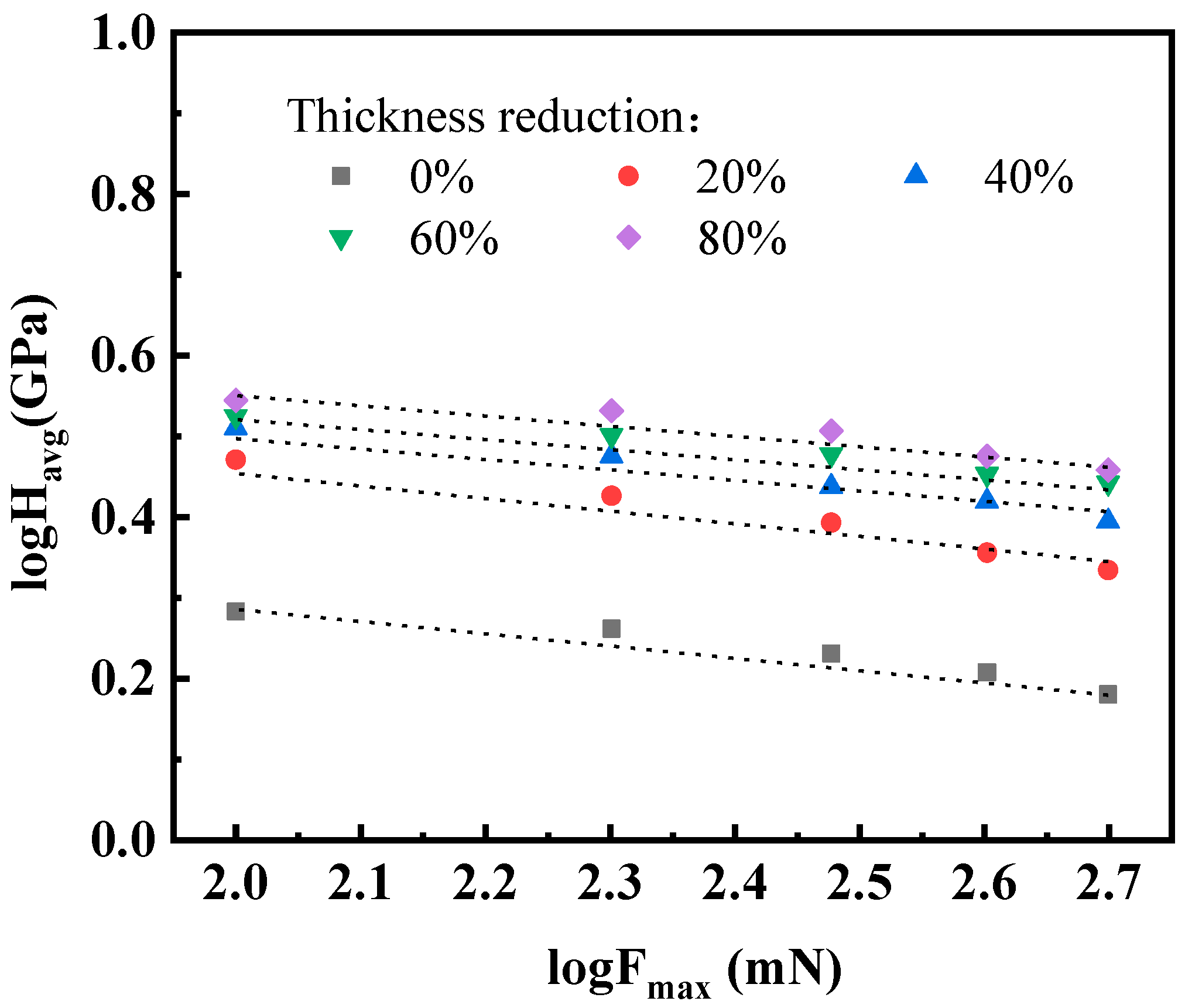

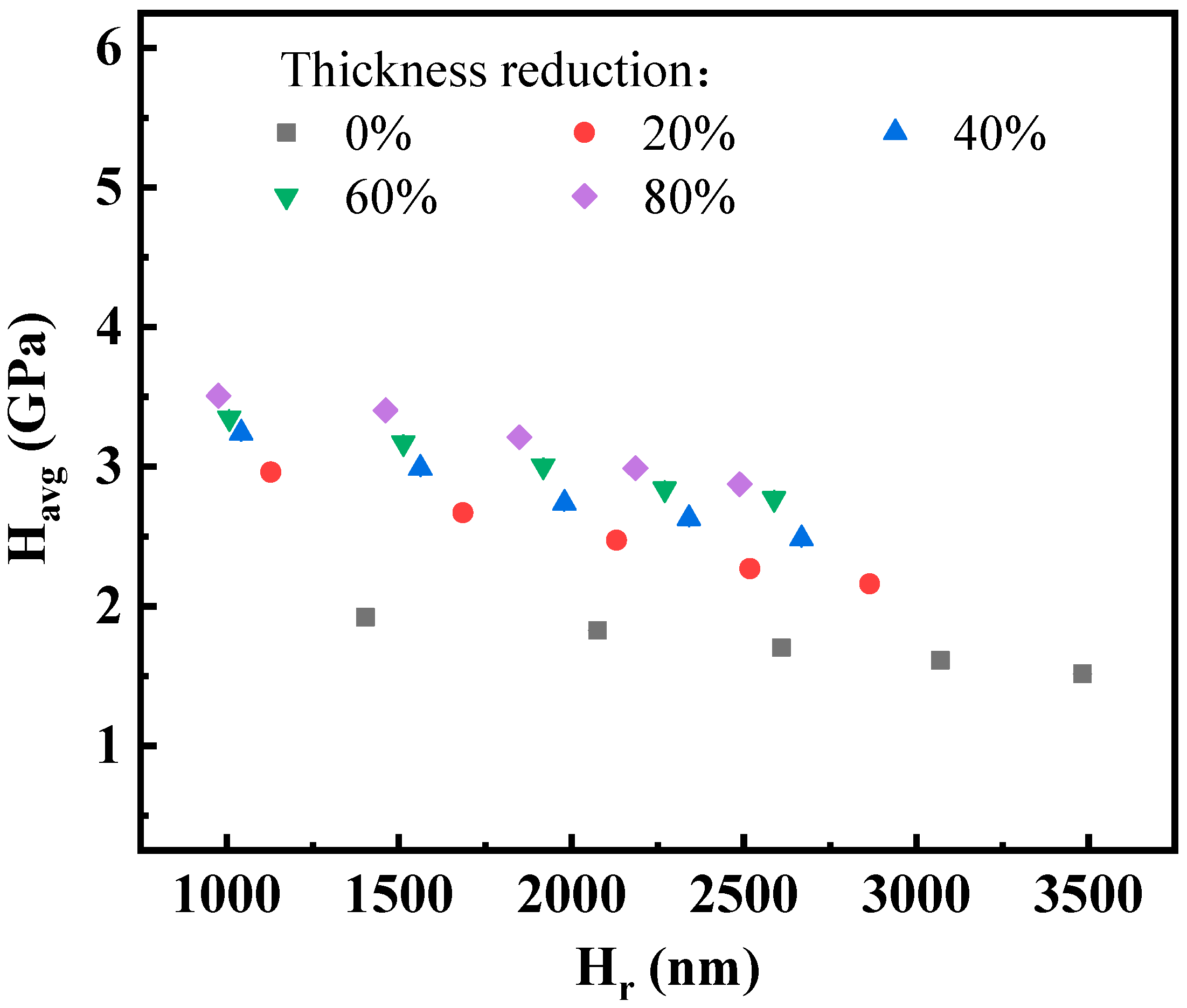

3.2. Vickers Hardness of the Cold-Rolled CP-Ti

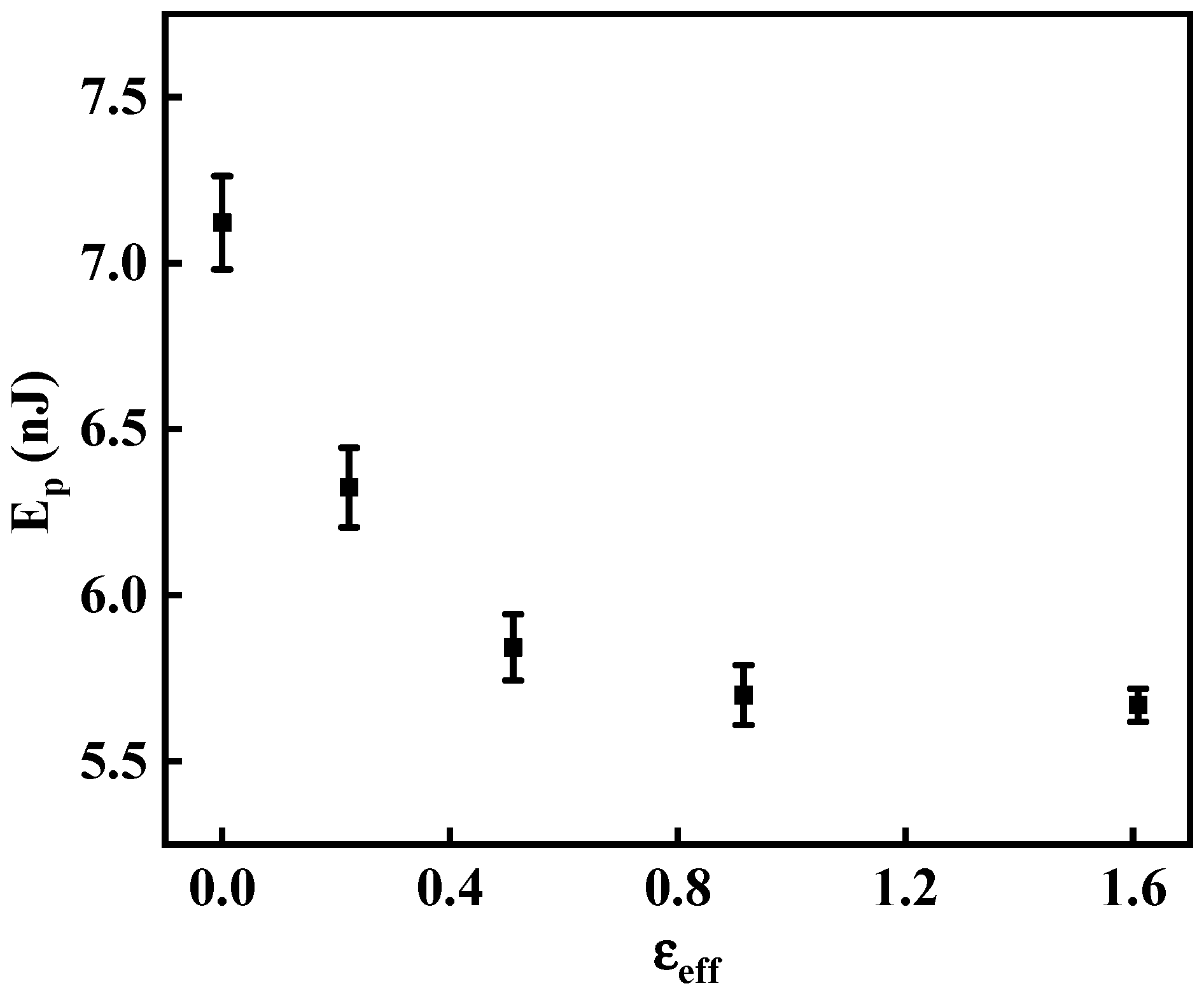

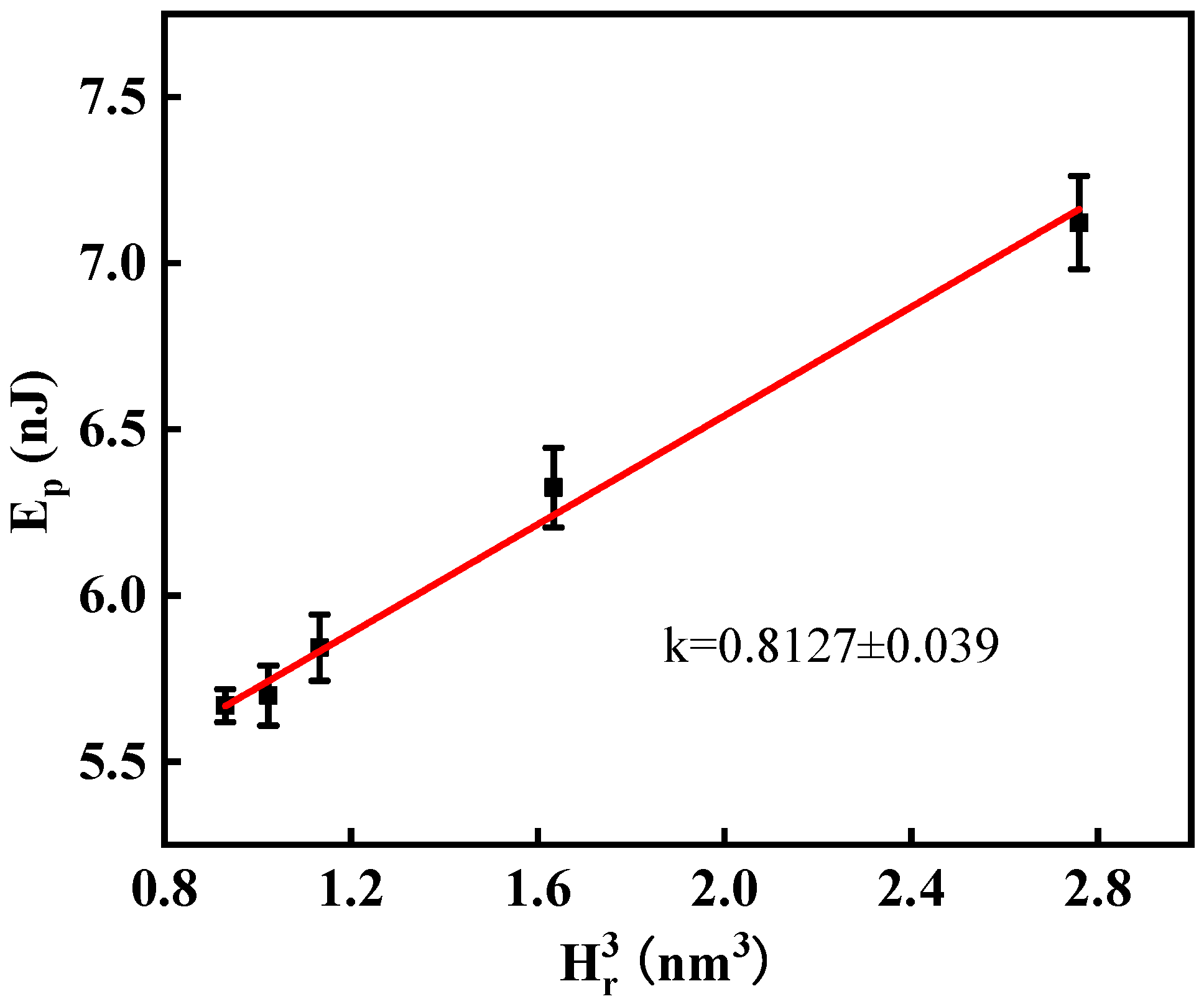

3.3. Energy Dissipation of the Cold-Rolled CP-Ti

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Liu, K.; Chen, T.; Xu, C.; Chen, C.; Yan, D.S.; Dippel, A.C.; Sun, J.; Ding, X.D. Inverse gradient nanostructure through gradient cold rolling demonstrated with superelasticity improvement in Ti-50.3Ni shape memory alloy. J. Mater. Sci. Technol. 2024, 185, 233–244. [Google Scholar] [CrossRef]

- Hussain, G.; Shehbaz, T.; Alkahtani, M.; Khaliq, U.A.; Wei, H. Nanomechanical, mechanical and microstructural characterization of electron beam welded Al2219-T6 tempered aerospace grade alloy: A comprehensive study. Heliyon 2024, 10, e23835. [Google Scholar] [CrossRef]

- Fattahi, M.; Hsu, C.-Y.; Ali, A.O.; Mahmoud, Z.H.; Dang, N.P.; Kianfar, E. Severe plastic deformation: Nanostructured materials, metal-based and polymer-based nanocomposites: A review. Heliyon 2023, 9, e22559. [Google Scholar] [CrossRef]

- George, V.; Mohammadreza, Y. Review of Nanoindentation Size Effect: Experiments and Atomistic Simulation. Crystals 2017, 7, 321. [Google Scholar]

- Bond, T.; Badmos, A.; Ahmed, R.A.; Obayemi, J.D.; Salifu, A.; Rahbar, N.; Soboyejo, W.O. Indentation size effects in aluminum and titanium alloys. Mater. Sci. Eng. A 2022, 839, 142542. [Google Scholar] [CrossRef]

- Stegall, D.E.; Mamun, M.A.; Crawford, B.; Elmustafa, A. Indentation size effect in FCC metals: An examination of experimental techniques and the bilinear behavior. J. Mater. Res. 2012, 27, 1543–1552. [Google Scholar] [CrossRef]

- Zong, Z.; Soboyejo, W. Indentation size effects in face centered cubic single crystal thin films. Mater. Sci. Eng. A 2005, 404, 281–290. [Google Scholar] [CrossRef]

- Pharr, G.M.; Herbert, E.G.; Gao, Y. The Indentation Size Effect: A Critical Examination of Experimental Observations and Mechanistic Interpretations. Annu. Rev. Mater. Res. 2010, 40, 271–292. [Google Scholar] [CrossRef]

- Hayes, J.; Keyte, R.; Prangnell, P. Effect of grain size on tensile behaviour of a submicron grained Al–3 wt-%Mg alloy produced by severe deformation. Mater. Sci. Technol. 2000, 16, 1259–1263. [Google Scholar] [CrossRef]

- Zhang, Z.; Hosoda, S.; Kim, I.S.; Watanabe, Y. Grain refining performance for Al and Al–Si alloy casts by addition of equal-channel angular pressed Al–5 mass% Ti alloy. Mater. Sci. Eng. A 2006, 425, 55–63. [Google Scholar] [CrossRef]

- Jun, T.S.; Sernicola, G.; Dunne, F.P.; Britton, T.B. Local deformation mechanisms of two-phase Ti alloy. Mater. Sci. Eng. A 2016, 649, 39–47. [Google Scholar] [CrossRef]

- Jawed, S.F.; Rabadia, C.D.; Khan, M.A.; Khan, S.J. Effect of Alloying Elements on the Compressive Mechanical Properties of Biomedical Titanium Alloys: A Systematic Review. ACS Omega 2022, 7, 29526–29542. [Google Scholar] [CrossRef]

- Meng, Q.; Bai, C.; Xu, D. Flow behavior and processing map for hot deformation of ATI425 titanium alloy. J. Mater. Sci. Technol. 2018, 34, 105–114. [Google Scholar] [CrossRef]

- Cao, F.; Liu, R.; Kong, S.; Guo, N.; Xu, P.; Xu, G. Microstructural evolution, high temperature tensile deformation behavior, and deformation mechanism in an Mg–Zn–Y–Ca–Zr alloy processed by multidirectional forging and hot rolling. J. Mater. Res. Technol. 2023, 27, 6729–6743. [Google Scholar] [CrossRef]

- Thakur, S.K.; Harish, L.; Das, A.K.; Rath, S.; Jha, B.K. Hot deformation behavior and processing map of Nb-V-Ti micro-alloyed steel. Mater. Today Proc. 2020, 28, 1973–1979. [Google Scholar] [CrossRef]

- Li, B.; He, W.; Chen, Z.; Huang, H.; Liu, Q. Evolution of interface and collaborative deformation between Ti and steel during hot roll bonding. Mater. Charact. 2020, 164, 110354. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, X.; Liu, X.; Qiang, M.; Yue, X.; Chen, W. Analysis of Microstructure, Texture Evolution, and the Mechanism of Grain Refinement of Commercially Pure Titanium During Cold Rolling: Experiment and Simulation. Adv. Eng. Mater. 2023. [Google Scholar] [CrossRef]

- Chen, W.; Liu, G.; Gao, Y.; He, W.; Chen, Z.; Jiang, B. Fabrication of dual-gradient microstructure and their effects on the mechanical properties of commercial pure Ti. J. Mater. Res. Technol. 2023, 24, 3309–3322. [Google Scholar] [CrossRef]

- Lee, M.-S.; Lee, J.-R.; Jeon, J.B.; Won, J.W.; Hyun, Y.-T.; Jun, T.-S. In-situ study of anisotropic strain-hardening and grain boundary mediated deformation in commercially pure titanium. J. Mater. Res. Technol. 2023, 24, 5389–5403. [Google Scholar] [CrossRef]

- Majchrowicz, K.; Sotniczuk, A.; Adamczyk-Cieślak, B.; Chromiński, W.; Jóźwik, P.; Pakieła, Z.; Garbacz, H. The influence of microstructure and texture on the hardening by annealing effect in cold-rolled titanium. J. Alloys Compd. 2023, 948, 169791. [Google Scholar] [CrossRef]

- Behera, A.; Gupta, R.; Yasin, G.; Nguyen, T.A.; Al, E. Mechanical and Tribological Properties Evaluation of Plasma-Sprayed Shape Memory Alloy Coating. J. Alloys Compd. 2021, 863, 158599. [Google Scholar]

- Rominiyi, A.; Mashinini, P.M. Nanoindentation study of mechanical and wear properties of spark plasma sintered Ti-6Ni-xTiCN composites. Ceram. Int. 2023, 49, 2194–2203. [Google Scholar] [CrossRef]

- Yapici, G.G.; Karaman, I.; Maier, H.J. Mechanical flow anisotropy in severely deformed pure titanium. Mater. Sci. Eng. A 2006, 434, 294–302. [Google Scholar] [CrossRef]

- Jiang, L.; Guo, L.F.; Kai, M.X.; Jie, Z.M.; Wei, Y.Z. Micromechanical Study of the Forged Ti-1023 Titanium Alloy by Micro-Indentation. Key Eng. Mater. 2018, 765, 160–165. [Google Scholar]

- Ellard, J.J.M.; Mathabathe, M.N.; Siyasiya, C.; Bolokang, A.S. Vacuum melting of compressed powders and hot rolling of the as-cast Ti-48Al-2Nb-0.7Cr-0.3Si intermetallic alloy: Mechanical properties and microstructural analysis. J. Manuf. Process. 2023, 101, 1214–1223. [Google Scholar] [CrossRef]

- Mahadule, D.; Demiral, M.; Mulki, H.; Khatirkar, R.K. Experiments and Crystal Plasticity Finite Element Simulations of Texture Development during Cold Rolling in a Ti-15V-3Cr-3Sn-3Al Alloy. Crystals 2023, 13, 137. [Google Scholar] [CrossRef]

- Arohi, A.C.; Shekhar, S.; Sen, I. Effect of thermomechanical processing on microstructure evolution and mechanical properties of metastable β Ti–5Al–5V–5Mo–3Cr alloy. Mater. Chem. Phys. 2024, 314, 128809. [Google Scholar] [CrossRef]

- Yang, F.; Du, W.; Okazaki, K. Effect of cold rolling on the indentation deformation of AA6061 aluminum alloy. J. Mater. Res. 2011, 20, 1172–1179. [Google Scholar] [CrossRef]

- Chen, R.; Yang, F.; Okazaki, K.; Imam, M.A.; Feng, C.R.; Pao, P. Indentation of titanium processed by equal channel angular pressing. J. Phys. D Appl. Phys. 2008, 41, 105407. [Google Scholar] [CrossRef]

- Yang, F.; Peng, L.; Okazaki, K. Microindentation of aluminum. Metall. Mater. Trans. A 2004, 35, 3323–3328. [Google Scholar] [CrossRef]

- Chen, R.; Yang, F.; Imam, M.A.; Feng, C.R.; Pao, P. Microindentation of titanium: Dependence of plastic energy on the indentation depth and time-dependent plastic deformation. J. Mater. Res. 2011, 23, 1068–1075. [Google Scholar] [CrossRef]

- Alcalá, J.; Pike, L.M.; Giovannoni, J.J. Identification of Plastome Variants useful for Cytoplasmic Selection and Cultivar Identification in Onion. J. Am. Soc. Hortic. Sci. 1999, 124, 122–127. [Google Scholar] [CrossRef]

- Pintaude, G. Hardness as an indicator of material strength: A critical review. Crit. Rev. Solid State Mater. Sci. 2023, 48, 623–641. [Google Scholar] [CrossRef]

- Zhou, D.; Du, W.; Wen, X.; Qiao, J.; Liang, W.; Yang, F. Local Deformation and Texture of Cold-Rolled AA6061 Aluminum Alloy. Materials 2018, 11, 1866. [Google Scholar] [CrossRef] [PubMed]

- Pugno, N.M. A general shape/size-effect law for nanoindentation. Acta Mater. 2007, 55, 1947–1953. [Google Scholar] [CrossRef]

- Mencik, J.; Swain, M.V. Micro-indentation Test with Pointed Indenters. Metals Forum 1994, 18, 277–288. [Google Scholar]

- Cheng, Y.; Cheng, C. Scaling, Dimensional Analysis, and Indentation Measurements. Mater. Sci. Eng. R 2004, 44, 91–149. [Google Scholar] [CrossRef]

| C | Fe | H | N | O | Ti |

| 0.08 | 0.3 | 0.0015 | 0.05 | 0.3 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, D.; Yu, J.; Dong, Y.; Qin, Y.; Hao, X. Indentation of Commercial Pure Titanium Processed by Cold Rolling. Metals 2024, 14, 327. https://doi.org/10.3390/met14030327

Zhou D, Yu J, Dong Y, Qin Y, Hao X. Indentation of Commercial Pure Titanium Processed by Cold Rolling. Metals. 2024; 14(3):327. https://doi.org/10.3390/met14030327

Chicago/Turabian StyleZhou, Diaoyu, Jiasheng Yu, Yiwei Dong, Yalu Qin, and Xinwei Hao. 2024. "Indentation of Commercial Pure Titanium Processed by Cold Rolling" Metals 14, no. 3: 327. https://doi.org/10.3390/met14030327

APA StyleZhou, D., Yu, J., Dong, Y., Qin, Y., & Hao, X. (2024). Indentation of Commercial Pure Titanium Processed by Cold Rolling. Metals, 14(3), 327. https://doi.org/10.3390/met14030327