Abstract

High-entropy alloys (HEAs) attract much attention as possible radiation-resistant materials due to their several unique properties. In this work, the generation and evolution of the radiation damage response of an FeNiCrCoCu HEA and bulk Ni in the early stages were explored using molecular dynamics (MD). The design, concerned with investigating the irradiation tolerance of the FeNiCrCoCu HEA, encompassed the following: (1) The FeNiCrCoCu HEA structure was obtained through a hybrid method that combined Monte Carlo (MC) and MD vs. the random distribution of atoms. (2) Displacement cascades caused by different primary knock-on atom (PKA) energy levels (500 to 5000 eV) of the FeNiCrCoCu HEA vs. bulk Ni were simulated. There was almost no element segregation in bulk FeNiCrCoCu obtained with the MD/MC method by analyzing the Warren–Cowley short-range order (SRO) parameters. In this case, the atom distribution was similar to the random structure that was selected as a substrate to conduct the damage cascade process. A mass of defects (interstitials and vacancies) was generated primarily by PKA departure. The number of adatoms grew, which slightly roughened the surface, and the defects were distributed deeper as the PKA energy increased for both pure Ni and the FeNiCrCoCu HEA. At the time of thermal spike, one fascinating phenomenon occurred where the number of Frenkel pairs for HEA was more than that for pure Ni. However, we obtained the opposite result, that fewer Frenkel pairs survived in the HEA than in pure Ni in the final state of the damage cascade. The number and size of defect clusters grew with increasing PKA energy levels for both materials. Defects were suppressed in the HEA; that is to say, defects were “cowards”, behaving in an introverted manner according to the anthropomorphic rhetorical method.

1. Introduction

The structural properties and performances of high-entropy alloys are unique and interesting issues that have attracted intensive attention [,,,,,,,,,]. HEAs consisting of four or more elements with equal atomic concentrations are intriguing materials because of their excellent comprehensive properties as structural materials [] which contribute to sluggish diffusion [,,], critical internal lattice distortion [,,,], and corrosion resistance [,,]. More demands for nuclear energy are met using HEAs, which are considered promising materials for fusion and generation IV fission reactors [,,,].

In general, the materials manifest sharply declining performances in hardening and swelling under irradiation [,,,,,,,,,]. Introducing several defects sinks can effectively enhance the radiation resistance of materials, such as oxide-dispersion-strengthened steels [,] and nanograined polycrystalline alloys []. Nevertheless, these structures almost always behave unstably in extreme radiation environments [,,,,,]. It has been reported that Ni-containing HEAs are strong at high-temperatures [,] and have excellent microstructural stability [,,]. In addition, Ni-containing HEAs can reduce structural damage under irradiation by adjusting their alloy composition without pre-existing defect sinks [,]. Recent studies (including experiments and simulations) have shown that these compositional effects reflect the advantages of radiation resistance on Ni-containing [] HEAs. In experiments, the various alloy compositions of Ni-containing HEAs can suppress radiation swelling [,]. In simulations, defect accumulation has been suppressed in NiCoCr [] and NiCoCrFeMn HEAs [].

Many studies have shown that these alloys participate in the damage cascade processes by which a considerable amount of information—the generation, distribution, and evolution of defects—is acquired in the mechanism of radiation resistance [,,,,]. The defect clusters (vacancy clusters and interstitial clusters) become independent individuals for Ni-containing HEAs that play a vital role in inhibiting swelling [,,,,,]. The generation of dislocation during the process of the damage cascade is beneficial for reducing the radiation hardening of FeNiMnCr HEAs at room temperature and higher []. For Ni-based high entropy alloys, there is a phenomenon of continuous defect generation compared to pure Ni, and refining grain size is also a means to reduce defect generation [,]. However, investigating the defects and dislocations generated by primary damage is lacking. Also, it is difficult to accurately research the evolution of atomic-level defects in experiments.

Molecular dynamics (MDs) can perform a damage cascade, defect evolution, and dislocation migration behavior at the atomic level, which is conducive to revealing the radiation resistance mechanism of HEAs. FeNiCrCoCu HEAs have recently attracted a lot of attention due to its excellent performance, and further research is needed on the irradiation displacement cascade process [,,,]. Due to the limited timescale and defect suppression, the formation of defect clusters is seldom observed in the MD simulation for FeNiCrCoCu HEAs.

In this work, variable PKA energies at the same temperature (300 K) accompanied by displacement cascade simulations were studied with MDs for FeNiCrCoCu HEAs and pure Ni. The generation and evolution of defects, clusters, and dislocations were captured in both materials. Additionally, it is notable that more defects are generated for the HEA than for pure Ni under the thermal peak state. However, the opposite results show that fewer defects are generated for the HEA than for pure Ni in the final state. HEAs have the effect of suppressing defects, which is beneficial for their nuclear material applications.

2. Methods

2.1. Model and Simulation

2.1.1. Search for Stable Structure

For the equimolar FeNiCrCoCu HEAs and pure Ni samples, the embedded atom method (EAM) potential [] used by Deluigi [] was adopted. Several investigations have conducted this potential in depth [] and described this HEA sample successfully [,]. In order to reach chemical equilibration, a hybrid method that combines the Metropolis Monte Carlo (MMC) method and MD was constructed, which is the way to reach the thermodynamically correct occupation of atomic sites. In the simulation process, the random distribution atom was chosen as the initial configuration, and the energy of the system was calculated using MD. The execution steps of MMC/MD, which is a self-compiled code, are as follows: (1) a new configuration is created by exchanging the position of two different atom types randomly; (2) the system energy of the exchanged configuration is calculated by MD after energy minimization; (3) the standard Metropolis method is used to determine whether a new configuration is accepted. The acceptance probability as follows: Pnew/Pold = exp {−ΔU/kT}, where kT is the Boltzmann factor and ΔU is the energy difference as a result of comparing the old state (before position exchange) and the new state (after position exchange). The new state is accepted when Pnew/Pold is larger than 1.0; otherwise, the new state is accepted within the probability Pnew/Pold []. The details of this method are widely used in the structural calculation of high-entropy alloy structures [,]. To identify whether the final configuration obtained from the MMC/MD method is realistic, we also created a configuration for the random distribution (RND) of atoms to contrast it with.

2.1.2. Irradiation Simulations

The whole process of studying the displacement cascade was conducted using a Large-scale Atomic/Molecular Massively Parallel Simulator (LAMMPS) [], and all initial random configuration samples were obtained with ATOMSK [].

The short-range potential function was needed to describe the interaction in the radiation cascade process, and the potentials transferred smoothly to the universal screened Ziegler–Biersack–Littmark (ZBL) potential [].

The FeNiCrCoCu HEA with random element distribution as the initial structure existed in a well-defined face-centered cubic (FCC) solid solution structure (which contained Fe, Ni, Cr, Co, and Cu elements in an equimolar ratio). Primary knock-on atoms (PKAs) with energy EPKAs of 500 eV, 1000 eV, 3000 eV, and 5000 eV were modeled within each simulation box; the size of the simulation box was determined by the incident atomic energy. For PKA energies of 500 eV, 1000 eV, 3000 eV, and 5000 eV, the simulation boxes were 20 a0 × 20 a0 × 25 a0, 25 a0 × 25 a0 × 30 a0, and 30 a0 × 30 a0 × 35 a0, respectively (here, a0 = 3.56 Å is the lattice parameter of the FCC FeNiCrCoCu HEA matrix). There is a vacuum space of about 5 a0 above the matrix surface in the simulation box. Thus, the simulation cells contained 32,000, 62,500, and 108,000 atoms, respectively. The z-direction [001] was set to the free surface as the incident plane. Furthermore, the x- (the [100] directions) and y-directions (the [010] directions) were periodic boundary conditions. In order to reach thermodynamic equilibrium before conducting the displacement cascade simulation, the NVT ensemble was adopted at approximately 200 ps while the simulation cell relaxes in the present form (at the temperature of 300 K). Here, the timestep was 1 fs. Then, the simulation method of impingement was similar to those in [,].

The simulation box can be applied in three parts perpendicular to the surface: in order to stabilize the center of mass of the substrate, the bottom two layers were fixed and immobile. To maintain the stability of the temperature source, a Nosé–Hoover thermostat was used to keep the temperature constant in the middle 3 lattice layers. We put enough space so that the displacement cascade could not reach the middle part in the top layers (the remaining portion except the middle and bottom layers) to simulate the impact of impingement on a free surface. There was no thermostat in this part; it was executed with standard velocity Verlet integration for both pure Ni and the FeNiCrCoCu HEA matrix, and the Ni atom was randomly selected from the surface as an incident atom into the free surface. At least 20 independent impingement events were simulated in order to ensure the accuracy of the simulation statistics. When simulating the incident events, we switched the fixed time step of 0.1 fs to a variable time step in the range of 10−6 to 10−1 fs, where the maximum distance for the movement of an atom in one time step was 0.01 Å. It took 20 ps to monitor the process of displacement cascade generation to ensure that each defect could be obtained. Thus, the whole process (the relaxation and cascade processes) took about 500 ps.

For comparison, the pure Ni (FCC crystal) simulation model, in which the lattice parameter a0 = 3.52 Å, were in the same sizes as well. Additionally, the calculation procedure was consistent with the above for FeNiCrCoCu HEA.

2.2. Short-Range Order Parameters

In order to research whether there was element enrichment in the HEA, we calculated the Warren–Cowley short-range order (SRO) parameters [,] of bulk FeNiCrCoCu, which can assess the local order degree. The following formula is the definition of the SRO parameter:

where αA-B is the SRO parameter for the binary A-B system. PA-B is the probability of finding the B atom from the first nearest neighbor of the A atom. CB is the proportion of type B []. Equation (1) defines the SRO parameter in a system with two elements. The system is a fully random state if αA-B is close to zero. A positive value indicates that A-B pairs are smaller than those in a fully random structure, and a negative one represents A-B pairs which become more numerous, meaning B atoms precipitate around type A []. For a system with N atom types, there exists a set of SRO parameters to describe the system’s parameter.

The visualization of the irradiation damage process and the defects were analyzed using the open-source application OVITO (ovito-basic-3.10.3-win64). The software is being developed, distributed, and supported by OVITO GmbH, a German software company founded by the original developer of OVITO, Dr. Alexander Stukowski, and other team members.) []. The vacancies, interstitials, and antisites were distinguished with the Wigner–Seitz method []. We denoted vacancies when there were no atoms in Wigner–Seitz cells. The interstitials were defined as when the Wigner–Seitz cells contained multiple atoms. Antisite defects were labeled when an atom occupied a site which was previously occupied by another atom type. In this work, the generation and evolution processes of vacancies and interstitials were mainly noticed. In addition, more studies should be performed on the generation and evolution of clusters in the process of displacement cascade generation. We defined clusters as two or more vacancy and interstitial aggregation behaviors. Here, clusters of different levels are defined as follows: (1) If the defect number count ranges from 2 to 10, it is called an intermediate-size cluster. (2) If the defect number count is greater than 10, the large-size clusters label is applied. This method of defining the sizes of clusters is the same as that in Ullah and co-workers’ investigation []. Finally, the dislocation extraction algorithm (DXA) was used as a tool for identifying the dislocation loops and dislocation lines [] and common neighbor analyses (CNAs) [,] were used to resolve atoms within the stacking fault regions.

3. Results

3.1. Lattice Distortion and Thermodynamic Equilibrium of FeNiCrCoCu

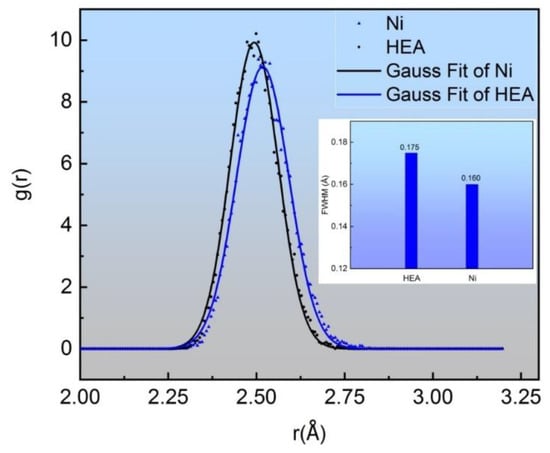

The intrinsic lattice distortions in HEAs, which are caused by different atomic sizes, are generally regarded as one of the main effects []. The full width at half maximum (FWHM) of the first peak in the radial distribution function g was calculated to evaluate the degree of the lattice distortions. The radial distribution g as a function of the interatomic distance r was obtained from Gaussian fitting. The comparison of the FeNiCrCoCu HEA with Ni allowed for a direct assessment of the thermal displacement magnitude.

In Figure 1, one can see that the first peak of the radial distribution function of Ni is higher than that of the HEA at 300 K, which implies that, in addition to the thermal distortion caused by temperature, intrinsic lattice distortions from the atomic radius in the HEA exist. The first peak representing the order degree of the system g(r) broadens. The HEA has a large FWHM of the radial distribution function (the FWHM of Ni and HEA are 0.16 Å and 0.175 Å, respectively, as shown on the right of Figure 1) at the same temperature (300 K). The finite width is attributed to the different atomic sizes leading to atomic displacements. This indicates that the atoms do not coincide with the ideal FCC lattice sites very well.

Figure 1.

Comparison of the first peak of the radial distribution function on Ni and FeNiCrCoCu (the inset on the right is the full width at half maximum of the first peak of the radial distribution function).

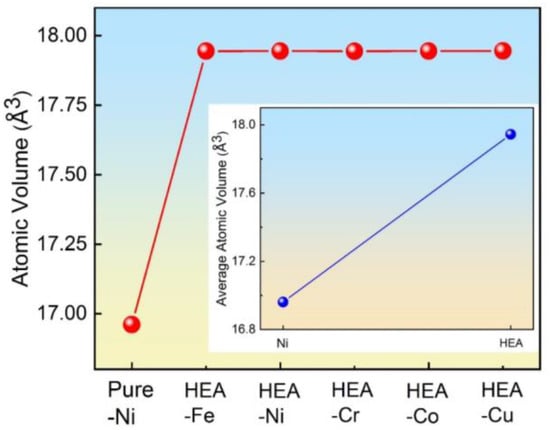

Figure 2 depicts the atomic volume per atom for the final state of the relaxation process, through which we could probe and directly compare the features of every different atom. The atomic volume of each atomic type in the HEA is larger than that in pure Ni. In addition, there also exist differences in the atomic volumes of Fe, Ni, Cr, Co, and Cu, which causes the intrinsic lattice distortions in the HEA. Additionally, the average atomic volume is consistent with the description of the above results, as shown in the inset of Figure 2. Here, the atomic volume is the Voronoi volume, which is defined as the smallest volume of a polyhedron enclosed by the vertical bisector of the line between the atom and its neighboring atoms.

Figure 2.

Atomic volume in A3 for different atomic species (Fe, Ni, Cr, Co, and Cu for the HEA, Ni for pure Ni) in the final steady state. The inset on the right is the average atomic volume of pure Ni and the HEA.

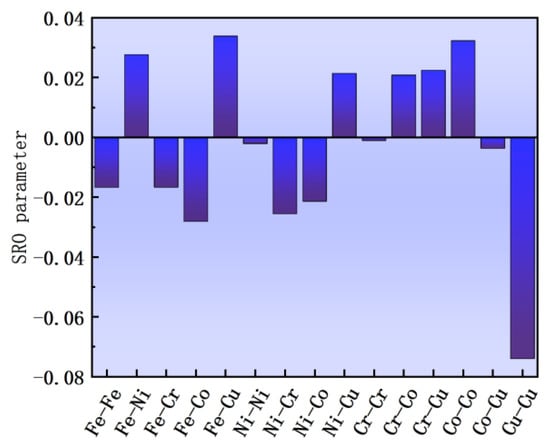

In order to research whether there was atom enrichment in the FeNiCrCoCu alloy, we calculated the Warren–Cowley short-range order (SRO) parameters [,] of bulk FeNiCrCoCu, which can assess the local order degree. Figure 3 shows the SRO parameters between different elements in the bulk HEA. It can be seen that the value of the Cu–Cu pair is relatively large but is below 0.1 (the values of all pairs are all close to zero), indicating there is almost no enrichment in bulk FeNiCrCoCu. Therefore, according to the conclusion of the CSRO, the high-entropy alloy structure calculated by MD/MC is similar to the random structure. In order to save computational resources and time, we selected the random-structure high-entropy alloy as the irradiation damage matrix in our work.

Figure 3.

Pairwise chemical short-range order (CSRO) parameter at 300 K.

3.2. Frenkel Pair Generation

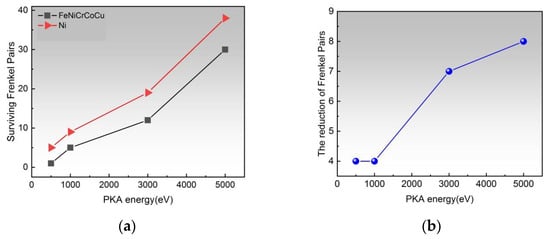

We compared the number of surviving Frenkel pairs (FPs) produced in the two cases (an FeNiCrCoCu HEA and pure Ni) under various PKA energies (500 eV, 1000 eV, 3000 eV, and 5000 eV). In addition, all simulated states were at a 300 K temperature and in the final state of cascade simulation, as shown in Figure 4a. When the PKA energy is relatively small, i.e., 500 eV, there are fewer defects in the substrate in the final state. By comparison, it is interesting to note that there are fewer surviving Frenkel pairs for the FeNiCrCoCu HEA than for pure Ni at the end state of the simulation for each PKA energy level. This phenomenon indicates that the retention of point defects (vacancies and interstitials) is inhibited as compared with pure Ni.

Figure 4.

(a) Number of surviving Frenkel pairs for pure Ni and the FeNiCrCoCu HEA at the end state of simulation at different PKA energies and (b) the reduction in Frenkel pairs in FeNiCrCoCu at different PKA energy levels (here, we define the reduction in Frenkel pairs as the number of surviving Frenkel pairs in pure Ni minus that in HEA).

The reduction in FPs (REFPs) emphasizes the inhibited magnitude. Here, we define REFPs as the number of surviving FPs in the FeNiCrCoCu HEA minus that in pure Ni. It can be seen from Figure 4b that there is an upward trend of REFPs with the increasing PKA energy, which indicates that FP suppression in HEAs is more intense with increasing PKA energy levels.

3.3. Defects Aggregate into Clusters

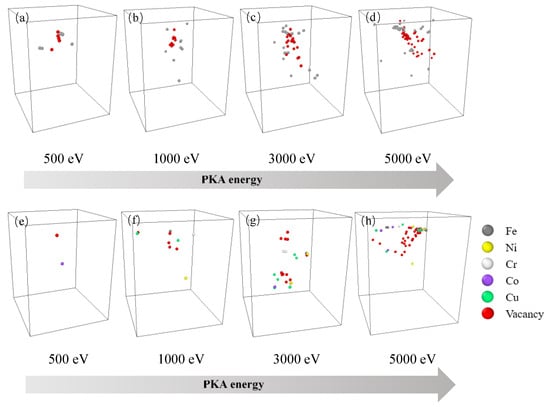

Figure 5 depicts snapshots of the defect distributions in the final state of pure Ni (a–d) and the FeNiCrCoCu HEA (e–h) with increasing PKA energy levels. In both cases, the number of defects and defect clusters generally grows with increasing PKA energy values. The vacancy is exactly in the initial position of the PKA after it departed. It is interesting to note that the stable defects are composed of self-interstitials in the substrate and adatoms on the surface. The adatom is hard to recombine with the vacancy due to its long distance. The release of internal stress after the displacement cascade is attributed to the adatoms. There are two types of distribution of interstitials; many of the interstitials beneath the surface migrate upward to form adatoms, and the others are stably located deeper in the substrate. On the contrary, the distribution of vacancies often gathers, and the interstitials are always around the periphery of the vacancies for both pure Ni and the FeNiCrCoCu HEA, which means the interstitials are relatively active, as shown in Figure 5. Evidently, this behavior is found in pure BCC tungsten (W) []. At low PKA energies (500 eV), interstitials exist in the form of single interstitials and are accompanied by a few intermediate-sized interstitial clusters for pure Ni (Figure 5a). However, only a single interstitial exists for HEAs even at 1000 eV of PKA energy (Figure 5e,f). When the PKA energy increased to 3000 eV (Figure 5c,g), small interstitial clusters frequently result from single interstitials starting to aggregate. The formation of interstitial clusters is severed when the PKA energy further increases (Figure 5d,h).

Figure 5.

Snapshots of defect distributions in the final state of pure Ni and the FeNiCrCoCu HEA with increasing PKA energy: (a) Ni-500 eV, (b) Ni-1000 eV, (c) Ni-3000 eV, (d) Ni-5000 eV, (e) HEA-500 eV, (f) HEA-1000 eV, (g) HEA-3000 eV, and (h) HEA-5000 eV. Here, the gray, yellow, white, purple, green, and red circles are Fe, Ni, Cr, Co, Cu, and vacancy atoms, respectively.

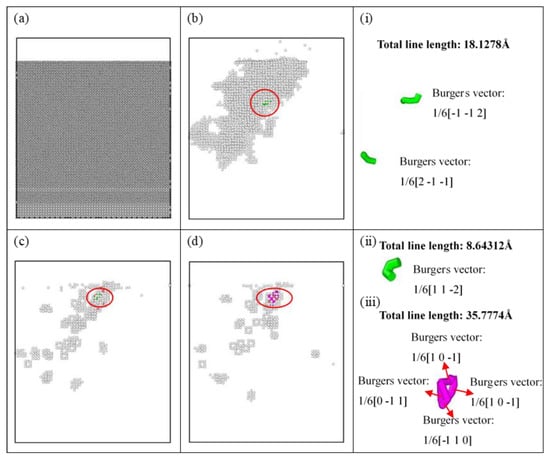

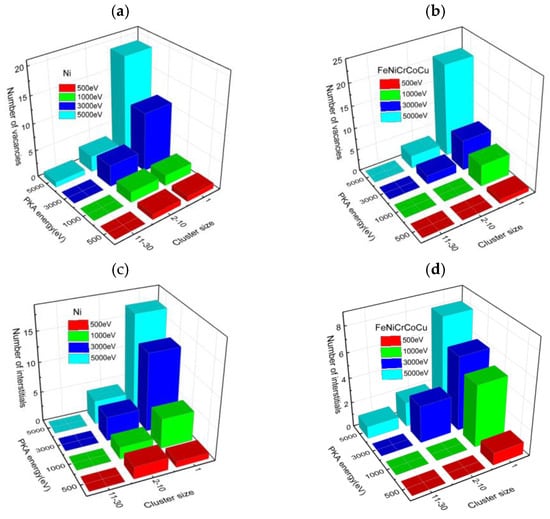

As a typical example, Figure 6 describes the cascade damage process for the PKA energy of 5000 eV at 300 K for Ni. White circles represent other structures that mean the structure is neither FCC nor BCC nor HCP. Before the PKA departs, all atoms are in their respective lattice positions, as shown in Figure 6a. The dislocations expressed by Burgers’ vector, 1/6[1 −1 2] and 1/6[2 −1 −1], first occur at t = 1.42 ps of the system (labeled with a red circle in Figure 6b), where the total line length is 18.128 Å. During the defect recombination process, a dislocation moves upward toward the top surface to release the internal stress and is transformed into adatoms at t = 5.37 ps; the total line length is 8.643 Å and is labeled as 1/6[1 1 −2] (green lines are Shockley−type dislocations). At approximately 229.93 ps, the dislocations near the surface change to another type (Stair–rod dislocation type), labeled as 1/6[1 0 −1], 1/6[0 −1 1], 1/6[−1 1 0], and 1/6[−1 1 0], and the total line length is 35.777 Å. The Stair–rod dislocations always exist in a stable state. A similar phenomenon is found in the FeNiCrCoCu HEA. The cascade damage process for the PKA energy of 5000 eV at 300 K for the HEA is shown in Figure 7. Before the PKA departs, all atoms (Fe, Ni, Cr, Co, and Cu) are in their respective lattice positions, although there is the internal lattice distortion caused by their different atomic radii, as shown in Figure 7a. The dislocation expressed by Burgers’ vector, 1/6[1 −1 2], first occurs at t = 0.25 ps of the system (labeled with a red circle in Figure 7b), which is earlier than that in pure Ni. The total line length is 9.295 Å. The dislocation moves toward the top surface to release the internal press over time. More internal stress is released on the further increasing number of adatoms at t = 0.75 ps; the total line length is 13.441 Å, labeled as 1/6[1 −1 2] (green lines are Shockley-type dislocations). At approximately 229.93 ps, the dislocations near the surface completely disappear.

Figure 6.

Snapshots of different cascade states for pure Ni: (a) the initial state, (b) the first occurrence of dislocation, (c) the second occurrence of dislocation, (d) the final state, (i) the only dislocation display of (b), (ii) the only dislocation display of (c), and (iii) the only dislocation display of (d). (The gray circles are a Ni atom in (a); the light gray circles represent other structures in (b–d). The green lines and red lines are Shockley and Stair–rod dislocations expressed in 1/6<1 1 2> and 1/6<1 1 0>, respectively).

Figure 7.

Snapshots of different cascade states for FeNiCrCoCu: (a) the initial state, (b) the first occurrence of dislocation, (c) the second occurrence of dislocation, (d) the final state, (i) the only dislocation display of (b), and (ii) the only dislocation display of (c). (The gray, purple, yellow, white, and green circles are Fe, Ni, Cr, Co, and Cu atoms in (a); the light gray circles represent other structures in (b–d). The green lines are Shockley dislocations expressed as 1/6<1 1 2>).

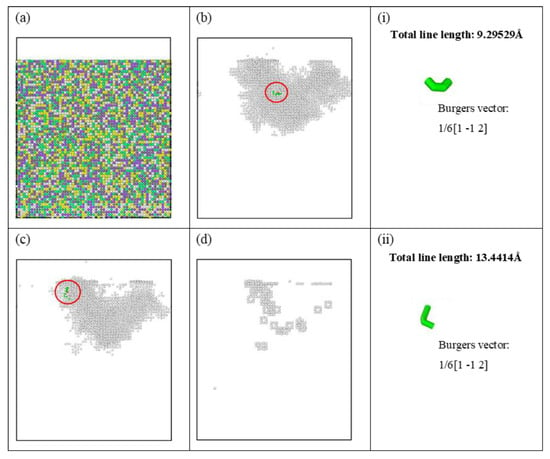

From the snapshots of the defect distribution (Figure 5), we can intuitively see that both the size and number of interstitial and vacancy clusters in FeNiCrCoCu are smaller than those in pure Ni for all PKA energy levels. This means the act of defect clustering is suppressed in HEAs compared with in pure Ni. Nevertheless, the magnitude of restrained effects on cluster formation for different PKA energies is different. The number of defects (vacancies and interstitials) in different cluster sizes in the final state of pure Ni and the FeNiCrCoCu HEA with variable PKA energies (500 eV, 1000 eV, 3000 eV and 5000 eV) are shown in Figure 8a–d. More cluster numbers and types emerge on further increasing the PKA energy for pure Ni and the HEA. Both vacancy clusters and interstitial clusters exist as a single vacancy and interstitial with 500 eV and 1000 eV PKA energy values for the HEA. The intermediate-size clusters are detected at 3000 eV PKA energy levels and even the large-size clusters are found when the PKA energy is 5000 eV for the HEA (Figure 8b,d). Unlike the above results, intermediate-size clusters emerge even if the PKA energy is 500 eV for pure Ni. Similar to the HEA case, the large defect clusters are only detected for higher PKA energies such as 5000 eV (Figure 8).

Figure 8.

Number of vacancies for (a) pure Ni, (b) FeNiCrCoCu HEA and number of interstitials for (c) pure Ni, (d) FeNiCrCoCu HEA in different cluster sizes in the final states with variable PKA energies (500 eV, 1000 eV, 3000 eV, and 5000 eV).

4. Discussion

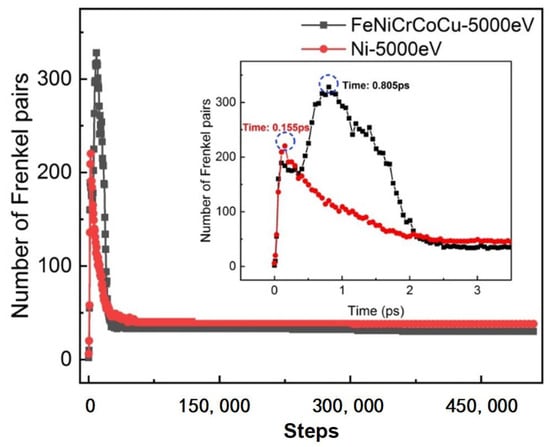

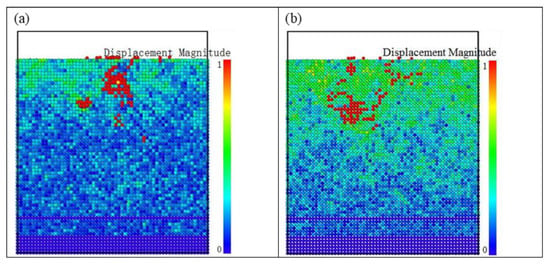

4.1. Atomic Displacement Distribution

To examine how the damage cascade evolves in both pure Ni and HEAs, we selected the PKA energy of 5000 eV as an example to observe the generation and evolution of the Frenkel pairs at 300 K, as shown in Figure 9; the inset on the right shows the number of Frenkel pairs as a function of the damage cascade time in the early state. In both cases, we can see that the system reaches the state of thermal spike rapidly in a very short time (0.155 ps and 0.805 ps for the pure Ni and HEA) and then smoothly decreases until it equals the stable value. Here, a thermal spike is defined as when the number of FPs reaches the maximum value. Although pure Ni reaches the maximum displacement cascade state (the so-called thermal spike) earlier than the HEA, there are fewer Frenkel pairs in the thermal spike state. It is worth noting that the number of stable defects is relatively high for pure Ni compared with the HEA in the final state, which indicates that the HEA can suppress the stable existence of defects and promote the easier binding and higher recombination rate of displaced atoms with vacancies. Driven by cascading collisions, the atoms around the PKAs move outward. A disordered, molten atomic-poor region is formed in a local area with a high deposition energy density, and dislocated atoms are distributed around the periphery of this molten region. Heat mainly accumulates in this area and then dissipates outward through thermal conduction. As the heat dissipates, interstitial atoms and vacancies gradually recombine and eventually achieve stability in the final state. Thus, we monitored the atomic displacement of each atom in the system at the end time of the displacement cascades. Figure 10 exhibits the displacement distribution of each atom in the final steady state after the displacement cascade. The overall atomic displacement in the HEA system is more severe than that in pure Ni. Additionally, we can evidently see that atoms with severe displacement tend to aggregate in the core region for pure Ni (Figure 10a) and, quite the contrary, are more dispersed in the HEA (Figure 10b). This precisely indicates that atoms in the HEA are so active that they can easily combine with vacancies to reset the original structure. Atoms in high-entropy alloys are more likely to overcome the potential barriers brought by surrounding atoms and run further away through energy transfer. This conclusion is consistent with how the addition of Fe and Cr elements can better suppress defects caused by irradiation damage [] and a higher defect recombination rate in NiCoCrFe HEAs, compared with that in pure Ni [].

Figure 9.

The variation in the number of Frenkel pairs over simulation steps for pure Ni and the FeNiCrCoCu at a PKA energy of 5000 eV (the inset on the right shows the number of Frenkel pairs as a function of the damage cascade time in the early state).

Figure 10.

The displacement distribution of each atom in the final steady state after the displacement cascade for (a) Ni and (b) FeNiCrCoCu. The displacement magnitude refers to the color bar on the right side.

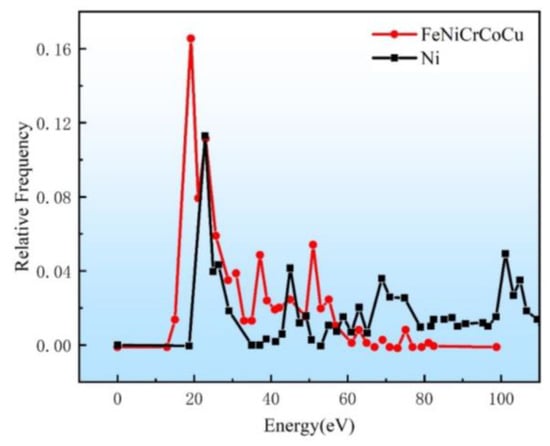

4.2. Threshold Displacement Energy (Ed)

Compared with pure Ni, HEAs exhibit varying degrees of chemical disorder and lattice distortion effects, depending on the type and quantity of elements. Due to the fact that HEAs are lattice structures formed by random combinations of multiple elements occupying positions, each atom in them may be in a unique chemical environment, and their lattice sites may deviate slightly from the neatly arranged lattice. Generally speaking, the more types of elements in HEAs, the stronger the lattice distortion effect and the lower the interstitial formation energy []. Therefore, atoms deviating from the lattice position are more likely to leave to become interstitial atoms compared with atoms on a perfect lattice. In order to deeply reveal the dependence of the phenomenon that suppressing defects in HEAs on the Ed, we plotted the graph of the two models’ Ed (Ni and HEA) as shown in Figure 11. It can be seen that the Ed value has the highest frequency distribution near the recoil energies of 20 eV and 22 eV for the HEA and Ni, respectively, and its frequency gradually decreases until it reaches 0 as the energy increases. The peak position of Ed frequency distribution for Ni has a rightward shift relative to the HEA, and the more types of elements in the HEA, the more leftward the peak position distribution is []. It can be seen that, compared with the HEA, the highest proportion of Ed in the pure Ni model is higher, and so is the average Ed, as shown in Table 1. We can see that the Cu atom has the highest mass result, and its Ed value is significantly higher than that of the other four atoms for the HEA. Both the atomic masses of Fe, Ni, Cr, and Co and the chemical environments in the same material are similar; therefore, they also have similar Ed values. However, even if Cu atoms have higher Ed values, the average Ed value of Cu containing HEAs is still lower than that of pure Ni. It can be seen that, compared with the HEA, the highest proportion of Ed in the pure Ni model is higher, and so is the average Ed, as shown in Table 1. We observe that the Cu atom has the highest mass result, and its Ed value is significantly higher than that of the other four atoms for the HEA. Both the atomic masses of Fe, Ni, Cr, and Co and the chemical environments in the same material are similar; therefore, they also have similar Ed values. However, even if Cu atoms have higher Ed values, the average Ed value of Cu containing HEAs is still lower than that of pure Ni. Ed can indirectly explain the radiation strengthening mechanism of high entropy alloys. The smaller Ed, the easier it is for atoms to leave their original positions and form defects, which is reflected in the fact that high entropy alloys produce more defects during the thermal peak. Similarly, due to its lower Ed, atoms leave their original positions and form defects are more likely to recover at lattice positions, which is reflected in the fact that at the final moment, the defect atoms in the high entropy alloy system are smaller than those in the pure Ni. Therefore, from the perspective of Ed, it can be reflected that having Ed is one of the factors that suppress defect generation in high entropy alloys.

Figure 11.

Frequency distribution of Ed values for FeNiCrCoCu and Ni.

Table 1.

The average value of Ed (eV) for each element in Ni and FeNiCrCoCu.

5. Conclusions

In this study, we researched the steady-state structure of FeNiCrCoCu HEA using hybrid MC/MD to explore as a substrate to radiation damage. It was found that there is almost no segregation phenomenon in bulk HEAs via CSRO analysis, which is almost consistent with the random structure. The defect behaviors of individual recoil for the HEA and unary Ni were investigated. A significant difference in irradiation defect performance between the complex alloys and the pure Ni was observed. It was found that more defects were produced in pure Ni than in the HEA after irradiation in the final state. The retention of point defects (vacancies and interstitials) is inhibited in the HEA. However, in the damage cascade process, the thermal peak appears earlier for pure Ni than for the HEA, and, at the same time, there are fewer Frenkel pairs for pure Ni than for the HEA. The larger lattice distortion in the HEA causes displaced defects to feature localized and concentrated distributions. The HEA presents a higher recombination rate and there exist fewer surviving defects than the elemental Ni under primary damage. In general, these defect features and low energy dissipation are due to a low displacement energy threshold. The increase in recoil atom energy further magnifies the difference in the defect numbers and morphology between the HEA and pure Ni. All the above events are sufficient to demonstrate that the residual defects are suppressed after irradiation in the HEA compared with those in pure Ni; the events have shown that the radiation tolerance of HEA is derived from the intrinsic distortion of the material, which provides theoretical guidance for the application of equiatomic ratio high-entropy alloys.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/met14030264/s1, Figure S1: Flowchart for calculating threshold displacement energy. References [,] are cited in Supplementary Materials.

Author Contributions

Conceptualization, W.Z. (Weiwei Zhang) and D.K.; methodology, W.Z. (Weiwei Zhang); software, W.Z. (Weiwei Zhang); validation, W.Z. (Weiwei Zhang), J.L. (Jing Liang) and Y.L.; formal analysis, W.B.; investigation, B.J.; resources, J.L. (Jianfeng Li); data curation, W.Z. (Wen Zhang); writing—original draft preparation, W.Z. (Weiwei Zhang) and W.Z. (Wen Zhang); writing—review and editing, W.Z. (Weiwei Zhang) and W.Z. (Wen Zhang); visualization, W.Z. (Weiwei Zhang) and W.Z. (Wen Zhang). All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Shaanxi Province Qin Chuangyuan, which cites high-level innovation and entrepreneurship talent projects (QCYRCXM-2022-271); the Shaanxi Province General Project—Youth Project (2024JC-YBQN-0064); the Shaanxi Province General Project—Youth Project (2024GX-YBXM-282); the Shaanxi Province Qin Chuangyuan, which cites high-level innovation and entrepreneurship talent projects (QCYRCXM-2022-164); China Postdoctoral Science Foundation (2023M742875); Shaanxi Province Postdoctoral Research Project Funding (2023BSHGZZHQYXMZZ28); Shaanxi Province General Project—Youth Project (2024JC-YBQN-0414); Key R&D projects in Shaanxi Province (2022GY-409); National Key R&D Plan projects (2022YFB3705403); the Major Special Projects of Science and Technology in Shaanxi Province (2020zdzx04-02-02); the Applied Basic Research Projects of the Northwest Institute for Nonferrous Metal Research (YK2109); and the special funds for scientific and technological innovation of the Shaanxi provincial state-owned capital operation budget.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Materials, further inquiries can be directed to the corresponding author/s.

Acknowledgments

Weiwei Zhang gratefully acknowledges data analysis support for this research from Ren Xianli who is from Guizhou University. This article’s contents are solely the responsibility of the authors and do not necessarily represent the official views of the Guizhou University.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Jo, Y.H.; Jung, S.; Choi, W.M.; Sohn, S.S.; Kim, H.S.; Lee, B.J.; Kim, N.J.; Lee, S. Cryogenic strength improvement by utilizing room-temperature deformation twinning in a partially recrystallized VCrMnFeCoNi high-entropy alloy. Nat. Commun. 2017, 8, 15719. [Google Scholar] [CrossRef]

- Miracle, D.B.; Miller, J.D.; Senkov, O.N.; Woodward, C.; Uchic, M.D.; Tiley, J. Exploration and development of high entropy alloys for structural applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, L. High-Throughput Determination of Interdiffusion Coefficients for Co-Cr-Fe-Mn-Ni High-Entropy Alloys. J. Phase Equilibria Diffus. 2017, 38, 457–465. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Horst, O.M.; Eggeler, G.; George, E.P. Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Vaidya, M.; Trubel, S.; Murty, B.S.; Wilde, G.; Divinski, S.V. Ni tracer diffusion in CoCrFeNi and CoCrFeMnNi high entropy alloys. J. Alloys Compd. 2016, 688, 994–1001. [Google Scholar] [CrossRef]

- Yeh, J.-W. Physical Metallurgy of High-Entropy Alloys. JOM 2015, 67, 2254–2261. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- Wang, P.W.; Li, M.F.; Malomo, B.; Yang, L. Lattice distortion and re-distortion affecting irradiation tolerance in high entropy alloys. Nanoscale 2023, 15, 16447–16457. [Google Scholar] [CrossRef]

- Shi, T.; Su, Z.X.; Li, J.; Liu, C.G.; Yang, J.X.; He, X.F.; Yun, D.; Peng, Q.; Lu, C.Y. Distinct point defect behaviours in body-centered cubic medium-entropy alloy NbZrTi induced by severe lattice distortion. Acta Mater. 2022, 229, 117806. [Google Scholar] [CrossRef]

- Wang, H.; He, Q.F.; Gao, X.; Shang, Y.H.; Zhu, W.Q.; Zhao, W.J.; Chen, Z.Q.; Gong, H.; Yang, Y. Multifunctional High Entropy Alloys Enabled by Severe Lattice Distortion. Adv. Mater. 2023, 2305453. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Shanina, B.D.; Berns, H. Ab initio development of a high-strength corrosion-resistant austenitic steel. Acta Mater. 2008, 56, 5071–5082. [Google Scholar] [CrossRef]

- Shi, Z.J.; Fang, Q.H.; Liaw, P.K.; Li, J. Corrosion-Resistant Biomedical High-Entropy Alloys: A Review. Adv. Eng. Mater. 2023, 25, 2300968. [Google Scholar] [CrossRef]

- Elkatatny, S.; Mohamed, L.Z.; Abd-Elaziem, W.; Abdelfatah, A. Corrosion resistance of nonequiatomic FeNiCrMnAlx high entropy alloys in hexamine as inhibitor in 3.5% NaCl. Mater. Corros. Werkst. Und Korros. 2024, 75, 235–246. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Lu, C.; Yang, T.; Jin, K.; Gao, N.; Xiu, P.; Zhang, Y.; Gao, F.; Bei, H.; Weber, W.J.; Sun, K.; et al. Radiation-induced segregation on defect clusters in single-phase concentrated solid-solution alloys. Acta Mater. 2017, 127, 98–107. [Google Scholar] [CrossRef]

- Wang, B.Y.; Yang, C.; Shu, D.; Sun, B.D. A Review of Irradiation-Tolerant Refractory High-Entropy Alloys. Metals 2024, 14, 45. [Google Scholar] [CrossRef]

- Han, J.H.; Zhang, Y.; Sun, Z.Y.; Zhang, Y.F.; Zhao, Y.L.; Sun, L.X.; Zhang, Z.W. Enhanced irradiation tolerance of a medium entropy alloy via precipitation and dissolution of nanoprecipitates. J. Nucl. Mater. 2023, 586, 154693. [Google Scholar] [CrossRef]

- Pu, G.; Sun, S.; Wang, S.S.; Gan, L.; Chen, S.; Ye, Z.B.; Huang, Z.Y.; Zheng, J.C.; Wang, Z.J.; Yang, C.; et al. A comparative study of irradiation response in amorphous TaTiWVCr refractory high entropy alloy with the counterpart of tungsten films. Intermetallics 2023, 156, 107850. [Google Scholar] [CrossRef]

- Chen, D.; Zhao, S.J.; Sun, J.R.; Tai, P.F.; Sheng, Y.B.; Zhao, Y.L.; Yeli, G.; Lin, W.T.; Liu, S.F.; Kai, W.; et al. Diffusion controlled helium bubble formation resistance of FeCoNiCr high-entropy alloy in the half-melting temperature regime. J. Nucl. Mater. 2019, 526, 151747. [Google Scholar] [CrossRef]

- Uberuaga, B.P.; Hoagland, R.G.; Voter, A.F.; Valone, S.M. Direct transformation of vacancy voids to stacking fault tetrahedra. Phys. Rev. Lett. 2007, 99, 135501. [Google Scholar] [CrossRef] [PubMed]

- Shen, S.K.; Chen, F.D.; Tang, X.B.; Lin, J.W.; Ge, G.J.; Liu, J. Effects of carbon doping on irradiation resistance of Fe38Mn40Ni11Al4Cr7 high entropy alloys. J. Nucl. Mater. 2020, 540, 152380. [Google Scholar] [CrossRef]

- Was, G.S.; Jiao, Z.; Getto, E.; Sun, K.; Monterrosa, A.M.; Maloy, S.A.; Anderoglu, O.; Sencer, B.H.; Hackett, M. Emulation of reactor irradiation damage using ion beams. Scr. Mater. 2014, 88, 33. [Google Scholar] [CrossRef]

- Fang, Q.H.; Peng, J.; Chen, Y.; Li, L.; Feng, H.; Li, J.; Jiang, C.; Liaw, P.K. Hardening behaviour in the irradiated high entropy alloy. Mech. Mater. 2021, 155, 103744. [Google Scholar] [CrossRef]

- Sadeghilaridjani, M.; Ayyagari, A.; Muskeri, S.; Hasannaeimi, V.; Salloom, R.; Chen, W.Y.; Mukherjee, S. Ion irradiation response and mechanical behavior of reduced activity high entropy alloy. J. Nucl. Mater. 2020, 529, 151955. [Google Scholar] [CrossRef]

- Patel, D.; Richardson, M.D.; Jim, B.; Akhmadaliev, S.; Goodall, R.; Gandy, A.S. Radiation damage tolerance of a novel metastable refractory high entropy alloy V2.5Cr1.2WMoCo0.04. J. Nucl. Mater. 2020, 531, 152005. [Google Scholar] [CrossRef]

- Ivanov, I.A.; Ryskulov, A.; Kurakhmedov, A.; Kozlovskiy, A.; Shlimas, D.; Zdorovets, M.V.; Uglov, V.V.; Zlotski, S.V.; Ke, J. Radiation swelling and hardness of high-entropy alloys based on the TiTaNbV system irradiated with krypton ions. J. Mater. Sci. Mater. Electron. 2021, 32, 27260–27267. [Google Scholar] [CrossRef]

- Hirata, A.; Fujita, T.; Wen, Y.R.; Schneibel, J.H.; Liu, C.T.; Chen, M.W. Atomic structure of nanoclusters in oxide-dispersion-strengthened steels. Nat. Mater. 2011, 10, 922–926. [Google Scholar] [CrossRef]

- Odette, G.R. Recent Progress in Developing and Qualifying Nanostructured Ferritic Alloys for Advanced Fission and Fusion Applications. JOM 2014, 66, 2427–2441. [Google Scholar] [CrossRef]

- Sun, C.; Zheng, S.; Wei, C.C.; Wu, Y.; Shao, L.; Yang, Y.; Hartwig, K.T.; Maloy, S.A.; Zinkle, S.J.; Allen, T.R.; et al. Superior radiation-resistant nanoengineered austenitic 304L stainless steel for applications in extreme radiation environments. Sci. Rep. 2015, 5, 7801. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.; Ma, Z.Q.; Yu, L.M.; Liu, Y.C. Achieving high strength and ductility in ODS-W alloy by employing oxide@W core-shell nanopowder as precursor. Nat. Commun. 2021, 12, 5052. [Google Scholar] [CrossRef] [PubMed]

- Was, G.S.; Wharry, J.P.; Frisbie, B.; Wirth, B.D.; Morgan, D.; Tucker, J.D.; Allen, T.R. Assessment of radiation-induced segregation mechanisms in austenitic and ferritic-martensitic alloys. J. Nucl. Mater. 2011, 411, 41–50. [Google Scholar] [CrossRef]

- Lu, C.Y.; Niu, L.L.; Chen, N.J.; Jin, K.; Yang, T.N.; Xiu, P.Y.; Zhang, Y.W.; Gao, F.; Bei, H.B.; Shi, S.; et al. Enhancing radiation tolerance by controlling defect mobility and migration pathways in multicomponent single-phase alloys. Nat. Commun. 2016, 7, 13564. [Google Scholar] [CrossRef] [PubMed]

- Oñoro, M.; Macías-Delgado, J.; Auger, M.A.; de Castro, V.; Leguey, T. Mechanical properties and stability of precipitates of an ODS steel after thermal cycling and aging. Nucl. Mater. Energy 2020, 24, 100758. [Google Scholar] [CrossRef]

- He, Z.Y.; Jiang, Y.; Chang, L.T.; Huang, H.F. Helium ion irradiation-induced damage of powder metallurgy-hot isostatic pressed Ni-based alloy GH3535 for molten salt reactor applications. J. Nucl. Mater. 2024, 589, 154871. [Google Scholar] [CrossRef]

- Zhu, B.; Zhao, D.; Niu, Y.H.; Zhang, Z.Q.; Zhao, H.W. The short-range ordering and atomic segregation in various phases of high-entropy alloy during the solidification process. Mater. Des. 2023, 234, 112290. [Google Scholar] [CrossRef]

- Zou, Y.; Ma, H.; Spolenak, R. Ultrastrong ductile and stable high-entropy alloys at small scales. Nat. Commun. 2015, 6, 7748. [Google Scholar] [CrossRef]

- Zhao, C.Q.; Xie, R.X.; Xu, C.L.; Tian, X.B.; Wang, Q.Y.; Jiang, W.T.; Fan, H.D. Molecular Dynamics Simulations of Displacement Cascade in Ni-Based Concentrated Solid Solution Alloys. Acta Mech. Solida Sin. 2024, 37, 82–89. [Google Scholar] [CrossRef]

- Kumar, N.; Li, C.; Leonard, K.J.; Bei, H.; Zinkle, S.J. Microstructural stability and mechanical behavior of FeNiMnCr high entropy alloy under ion irradiation. Acta Mater. 2016, 113, 230–244. [Google Scholar] [CrossRef]

- Zhang, C.L.; Luo, X.; Ma, L.F.; Hou, L.; Huang, B.; Hu, R. Study on Microstructure and Properties of WC Particle-Reinforced FeCoCrNi-Matrix High Entropy Alloy Composites. Materials 2023, 16, 7380. [Google Scholar] [CrossRef] [PubMed]

- Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef]

- Lu, C.Y.; Jin, K.; Béland, L.K.; Zhang, F.F.; Yang, T.N.; Qiao, L.; Zhang, Y.W.; Bei, H.B.; Christen, H.M.; Stoller, R.E.; et al. Direct Observation of Defect Range and Evolution in Ion-Irradiated Single Crystalline Ni and Ni Binary Alloys. Sci. Rep. 2016, 6, 19994. [Google Scholar] [CrossRef] [PubMed]

- Jin, K.; Lu, C.; Wang, L.M.; Qu, J.; Weber, W.J.; Zhang, Y.; Bei, H. Effects of compositional complexity on the ion-irradiation induced swelling and hardening in Ni-containing equiatomic alloys. Scr. Mater. 2016, 119, 65–70. [Google Scholar] [CrossRef]

- Doran, S.; Yan, Y.G.; Yang, L.Q.; Han, J.K.; Chen, D.; Wang, K.; Chen, Y.X.; Kawasaki, M.; Chen, T.Y. Microstructure and micromechanical responses of bulk nanostructured high entropy alloy after heavy-ion irradiation at 500 °C. Scr. Mater. 2023, 235, 115628. [Google Scholar] [CrossRef]

- Levo, E.; Granberg, F.; Fridlund, C.; Nordlund, K.; Djurabekova, F. Radiation damage buildup and dislocation evolution in Ni and equiatomic multicomponent Ni-based alloys. J. Nucl. Mater. 2017, 490, 323–332. [Google Scholar] [CrossRef]

- Do, H.S.; Lee, B.J. Origin of radiation resistance in multi-principal element alloys. Sci. Rep. 2018, 8, 16015. [Google Scholar] [CrossRef]

- Diaz de la Rubia, T.; Guinan, M.W. New mechanism of defect production in metals: A molecular-dynamics study of interstitial-dislocation-loop formation in high-energy displacement cascades. Phys. Rev. Lett. 1991, 66, 2766–2769. [Google Scholar] [CrossRef]

- Lang, L.; Deng, H.Q.; Tao, J.Y.; Yang, T.F.; Lin, Y.P.; Hu, W.Y. Comparison of formation and evolution of radiation-induced defects in pure Ni and Ni-Co-Fe medium-entropy alloy. Chin. Phys. B 2022, 31, 126102. [Google Scholar] [CrossRef]

- Wei, Y.X.; Gao, N.; Shen, Z.Y.; Chen, C.; Xie, Z.Y.; Guo, L.P. Interactions between hydrogen bubbles and prismatic interstitial dislocation loops in BCC iron. Comput. Mater. Sci. 2020, 180, 109724. [Google Scholar] [CrossRef]

- Vanhellemont, J.; De Gryse, O.; Clauws, P. Extended defects in silicon: An old and new story. In Gettering and Defect Engineering In Semiconductor Technology; Richter, H., Kittler, M., Eds.; IHP: Bristol, UK, 2004; Volume 95–96, pp. 263–272. [Google Scholar]

- Mardiyah, R.U.; Arkundato, A.; Misto; Purwandari, E. Energy Cohesive Calculation for Some Pure Metals Using the Lennard-Jones Potential in Lammps Molecular Dynamics. Proceedings of Seminar Nasional Fisika (Snf) Unesa, Surabaya, Indonesia, 19 October 2019. [Google Scholar]

- Hamdi, H.; Abedi, H.R.; Zhang, Y. A review study on thermal stability of high entropy alloys: Normal/abnormal resistance of grain growth. J. Alloys Compd. 2023, 960, 170826. [Google Scholar] [CrossRef]

- Polat, G.; Tekïn, M.; Kotan, H. Role of yttrium addition and annealing temperature on thermal stability and hardness of nanocrystalline CoCrFeNi high entropy alloy. Intermetallics 2022, 146, 107589. [Google Scholar] [CrossRef]

- Tian, Y.Y.; Fang, Q.H.; Li, J. Molecular dynamics simulations for nanoindentation response of nanotwinned FeNiCrCoCu high entropy alloy. Nanotechnology 2020, 31, 465701. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Li, Q. Molecular dynamics study on the dislocation evolution mechanism of temperature effect in nano indentation of FeCoCrCuNi high-entropy alloy. Mater. Technol. 2024, 39, 2299903. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, C.L.; Du, Y. Molecular dynamics study on dynamic mechanical behaviour of FeCoCrCuNi high entropy alloy. Mater. Technol. 2023, 38, 2200660. [Google Scholar] [CrossRef]

- Chen, M.Q.; Quek, S.S.; Sha, Z.D.; Chiu, C.H.; Pei, Q.X.; Zhang, Y.W. Effects of grain size, temperature and strain rate on the mechanical properties of polycrystalline graphene—A molecular dynamics study. Carbon 2015, 85, 135–146. [Google Scholar] [CrossRef]

- Foiles, S.M.; Baskes, M.I.; Daw, M.S. Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys. Rev. B Condens. Matter 1986, 33, 7983–7991. [Google Scholar] [CrossRef]

- Deluigi, O.R.; Pasianot, R.C.; Valencia, F.J.; Caro, A.; Farkas, D.; Bringa, E.M. Simulations of primary damage in a High Entropy Alloy: Probing enhanced radiation resistance. Acta Mater. 2021, 213, 116951. [Google Scholar] [CrossRef]

- Babicheva, R.; Jarlov, A.; Zheng, H.; Dmitriev, S.; Korznikova, E.; Nai, M.L.S.; Ramamurty, U.; Zhou, K. Effect of short-range ordering and grain boundary segregation on shear deformation of CoCrFeNi high-entropy alloys with Al addition. Comput. Mater. Sci. 2022, 215, 111762. [Google Scholar] [CrossRef]

- Ren, X.L.; Shi, P.H.; Zhang, W.W.; Wu, X.Y.; Xu, Q.; Wang, Y.X. Swamps of hydrogen in equiatomic FeCuCrMnMo alloys: First-principles calculations. Acta Mater. 2019, 180, 189–198. [Google Scholar] [CrossRef]

- Utt, D.; Stukowski, A.; Albe, K. Grain boundary structure and mobility in high-entropy alloys: A comparative molecular dynamics study on a Σ11 symmetrical tilt grain boundary in face-centered cubic CuNiCoFe. Acta Mater. 2020, 186, 11–19. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Hirel, P. Atomsk: A tool for manipulating and converting atomic data files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Sefta, F.; Juslin, N.; Hammond, K.D.; Wirth, B.D. Molecular dynamics simulations on the effect of sub-surface helium bubbles on the sputtering yield of tungsten. J. Nucl. Mater. 2013, 438, S493–S496. [Google Scholar] [CrossRef]

- Wang, Y.X.; Pan, Z.Y.; Ho, Y.K.; Xu, Y.; Du, A.J. Structural and dynamical properties of Al clusters adsorbed on Ni surface. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2001, 180, 251–256. [Google Scholar] [CrossRef]

- Cowley, J.M. Short- and Long-Range Order Parameters in Disordered Solid Solutions. Phys. Rev. 1960, 120, 1648–1657. [Google Scholar] [CrossRef]

- Cowley, J.M. An Approximate Theory of Order in Alloys. Phys. Rev. 1950, 77, 669–675. [Google Scholar] [CrossRef]

- Meshkov, E.A.; Novoselov, I.I.; Shapeev, A.V.; Yanilkin, A.V. Sublattice formation in CoCrFeNi high-entropy alloy. Intermetallics 2019, 112, 106542. [Google Scholar] [CrossRef]

- Stukowski, A. Structure identification methods for atomistic simulations of crystalline materials. Model. Simul. Mater. Sci. Eng. 2012, 20, 045021. [Google Scholar] [CrossRef]

- Nordlund, K.; Ghaly, M.; Averback, R.S.; Caturla, M.; Diaz de la Rubia, T.; Tarus, J. Defect production in collision cascades in elemental semiconductors and fcc metals. Phys. Rev. B 1998, 57, 7556–7570. [Google Scholar] [CrossRef]

- Ullah, M.W.; Aidhy, D.S.; Zhang, Y.W.; Weber, W.J. Damage accumulation in ion-irradiated Ni-based concentrated solid-solution alloys. Acta Mater. 2016, 109, 17–22. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Honeycutt, J.D.; Andersen, H.C. Molecular dynamics study of melting and freezing of small Lennard-Jones clusters. J. Phys. Chem. 1987, 91, 4950–4963. [Google Scholar] [CrossRef]

- Faken, D.; Jónsson, H. Systematic analysis of local atomic structure combined with 3D computer graphics. Comput. Mater. Sci. 1994, 2, 279–286. [Google Scholar] [CrossRef]

- Yeh, J.-W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Mat. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Zhang, W.W.; Shi, P.H.; Yao, B.D.; Wu, L.; Wu, X.Y.; Shi, L.Q.; Wang, Y.X. Panorama of ‘fuzz’ growth on tungsten surface under He irradiation. Appl. Surf. Sci. 2021, 542, 148543. [Google Scholar] [CrossRef]

- Lin, Y.P.; Yang, T.F.; Lang, L.; Shan, C.; Deng, H.Q.; Hu, W.Y.; Gao, F. Enhanced radiation tolerance of the Ni-Co-Cr-Fe high-entropy alloy as revealed from primary damage. Acta Mater. 2020, 196, 133–143. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Y.J.; Yang, F.; Xie, Z.; Wu, X.Y.; Wang, Y.X. Irradiation performance of concentrated solid-solution alloys: Insight into defect behaviors. J. Nucl. Mater. 2023, 583, 154510. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, B.W.; Zhang, L.M.; Liu, N.; Wang, T.S.; Duan, B.H.; Xu, X.G. Defect agglomeration induces a reduction in radiation damage resistance of In-rich In x Ga1−x N. J. Phys. D 2021, 54, 245104. [Google Scholar] [CrossRef]

- Nordlund, K.; Wallenius, J.; Malerba, L. Molecular dynamics simulations of threshold displacement energies in Fe. Nucl. Instrum. Methods Phys. Res. Sect. B 2006, 246, 322–332. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).