Acid Treatments of Ti-Based Metallic Glasses for Improving Corrosion Resistance in Implant Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Metallic Glass Synthesis and Material State Characterization

2.2. Electrochemical Surface Treatment in Nitric Acid Solution and Surface State Analysis

2.3. Corrosion Testing of As-Spun and Surface-Treated Glassy Alloys in Phosphate-Buffered Saline

3. Results and Discussion

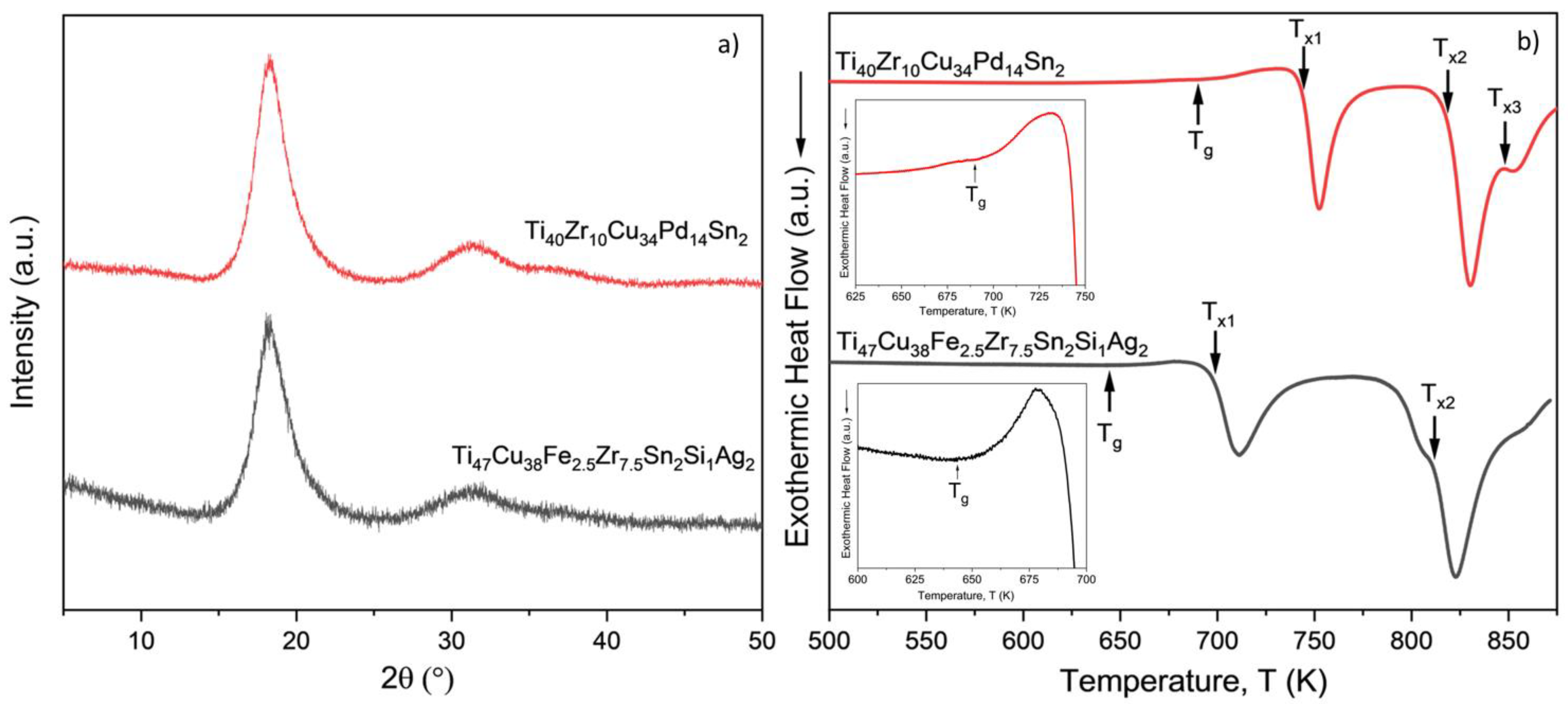

3.1. Characterization of Rapidly Quenched Ti-Based Alloy Samples

3.2. Electrochemical Surface Treatment in Nitric Acid Solution

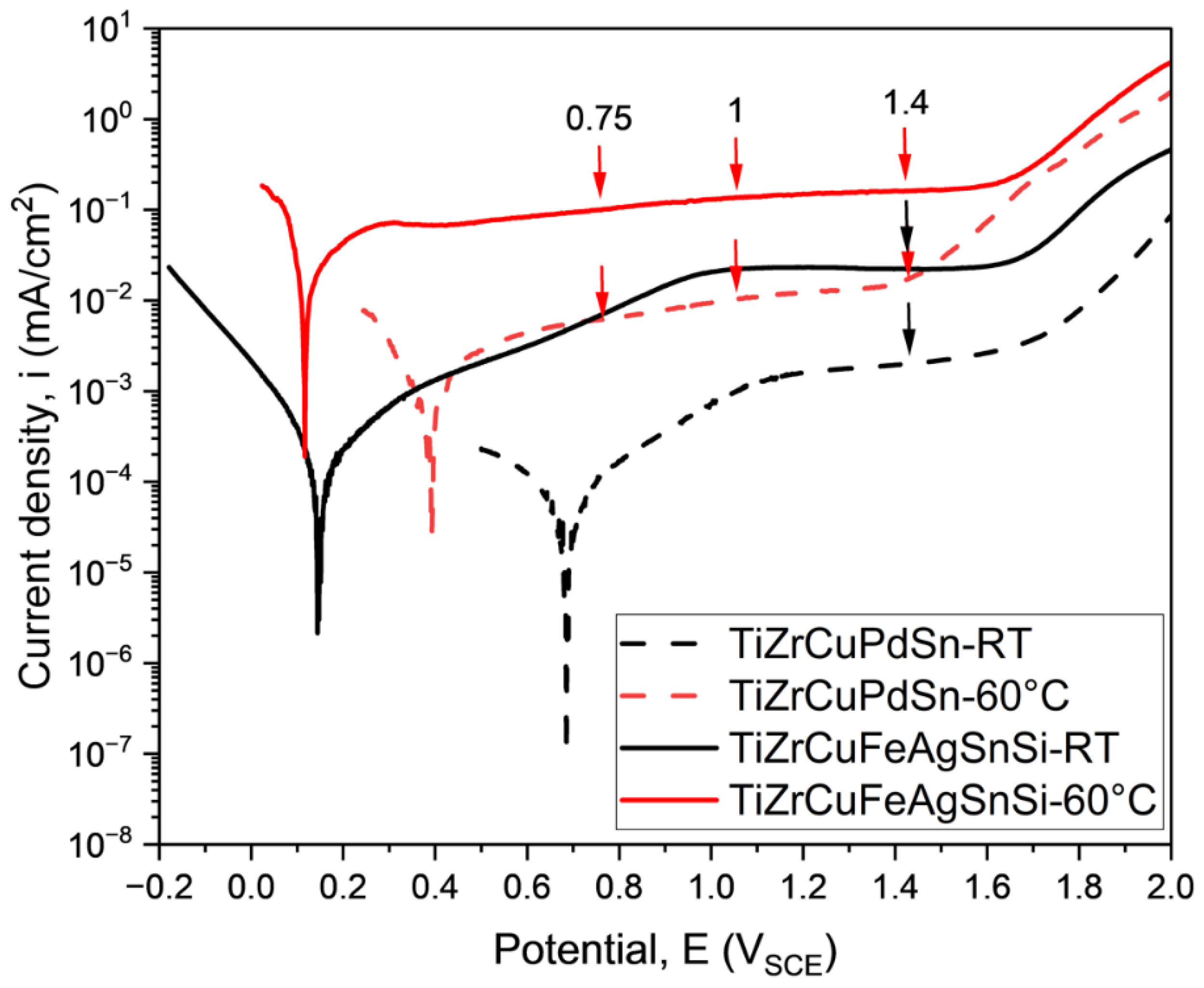

3.2.1. Potentiodynamic Polarization Studies

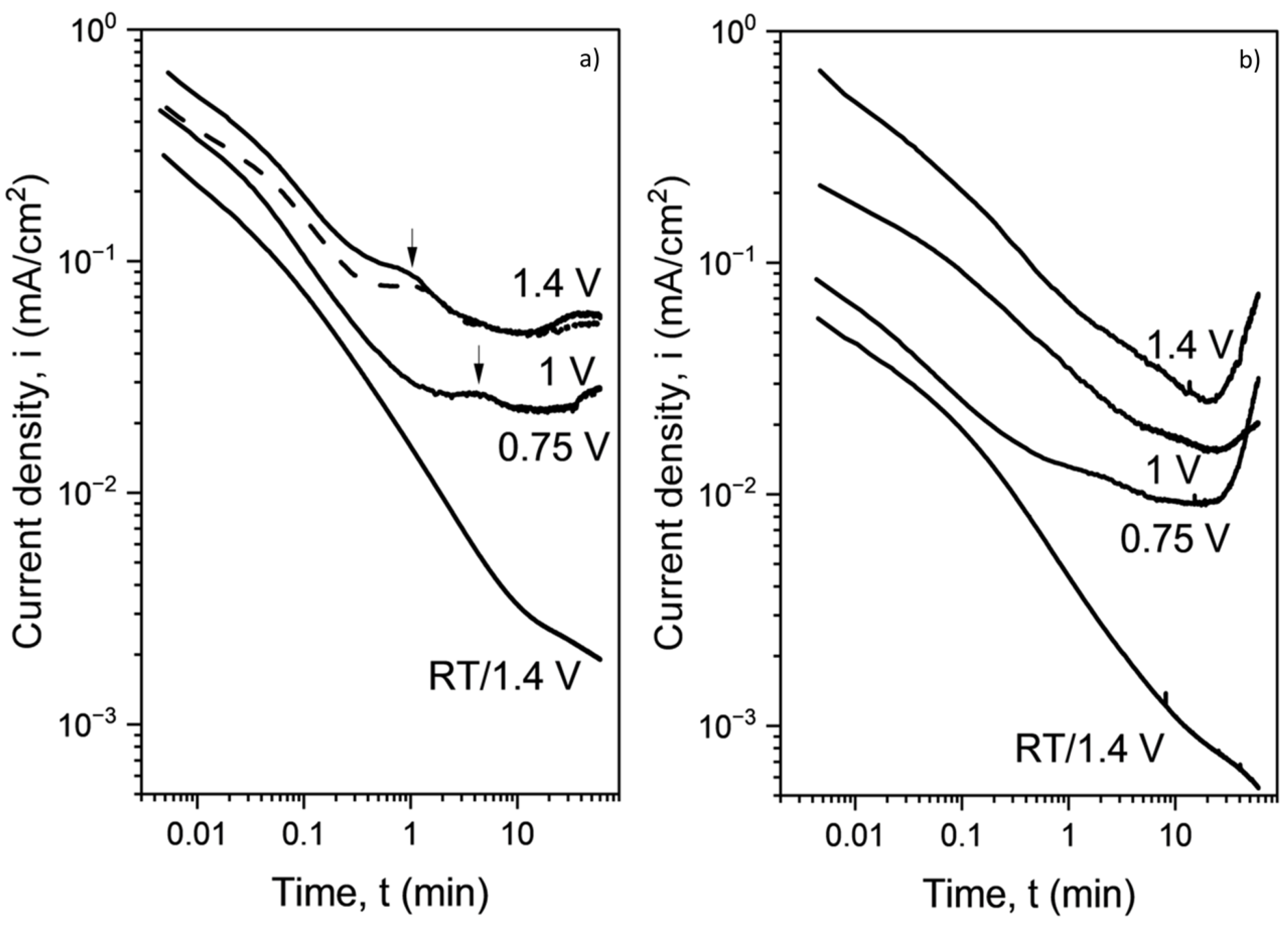

3.2.2. Potentiostatic Polarization Measurements and Surface Analysis

3.3. Impact of Surface Treatments of Glassy Alloys on Corrosion Performance in PBS Solution

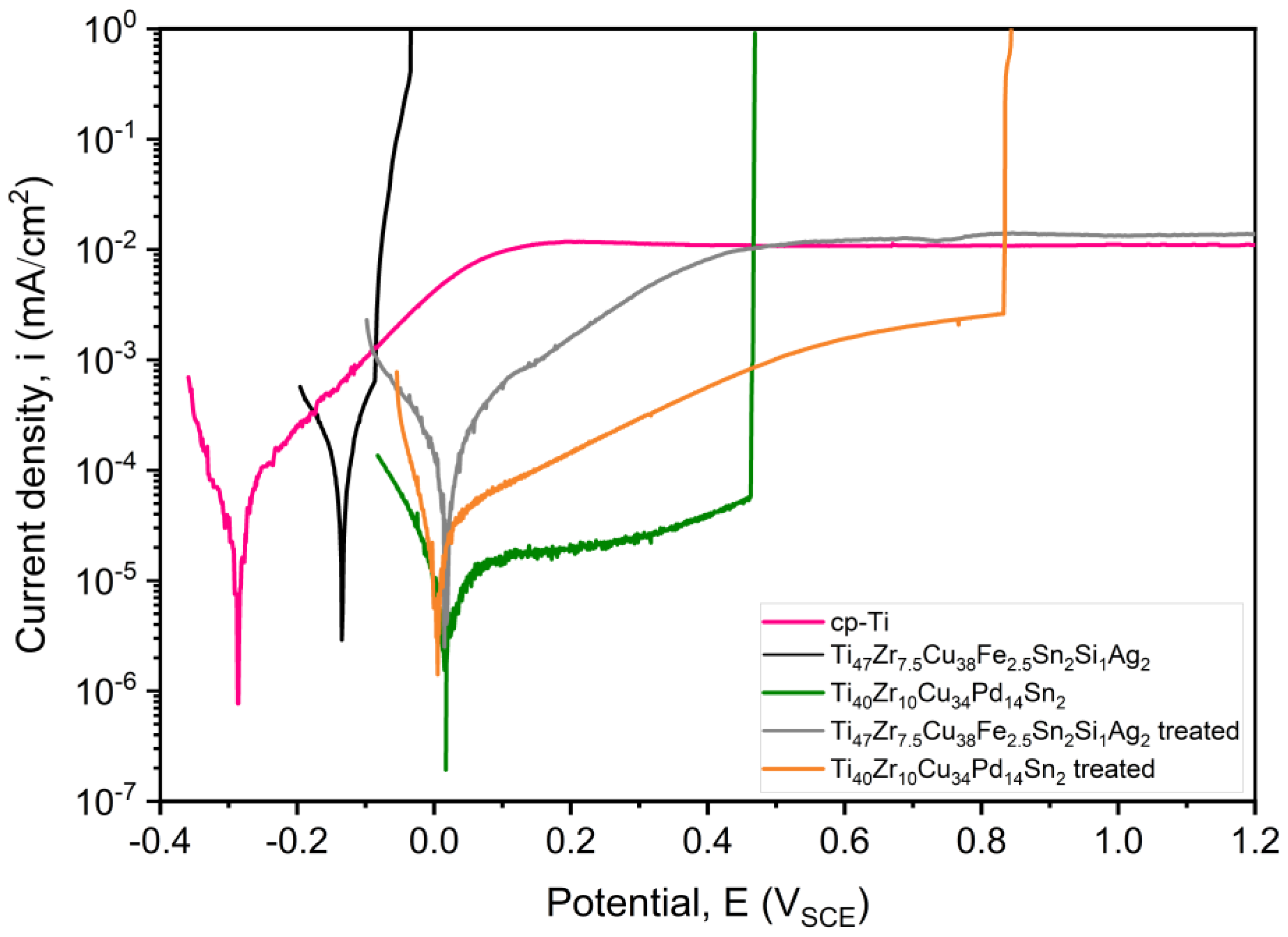

3.3.1. Electrochemical Analysis of Non-Treated and Treated Glassy Alloys and cp-Ti

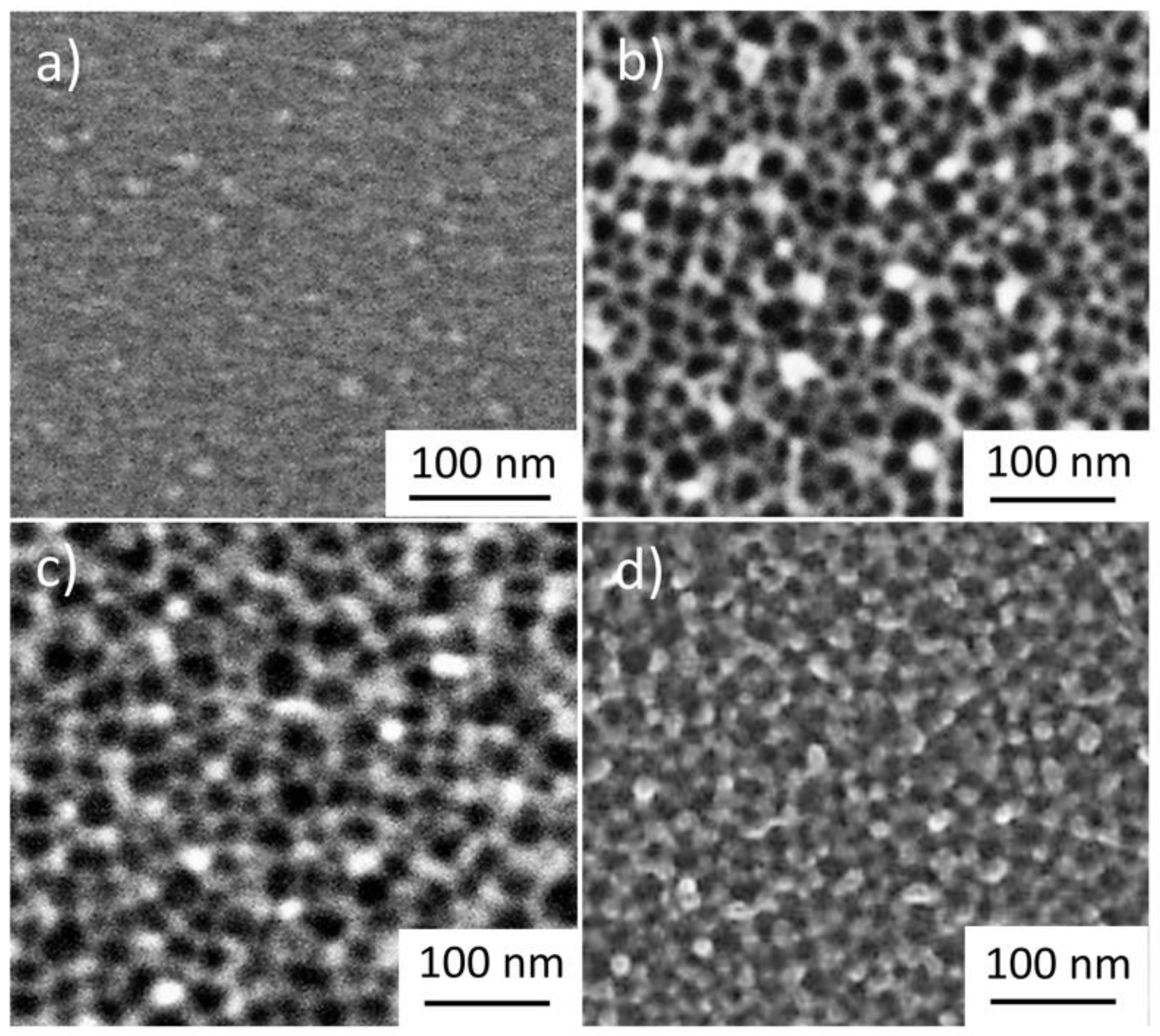

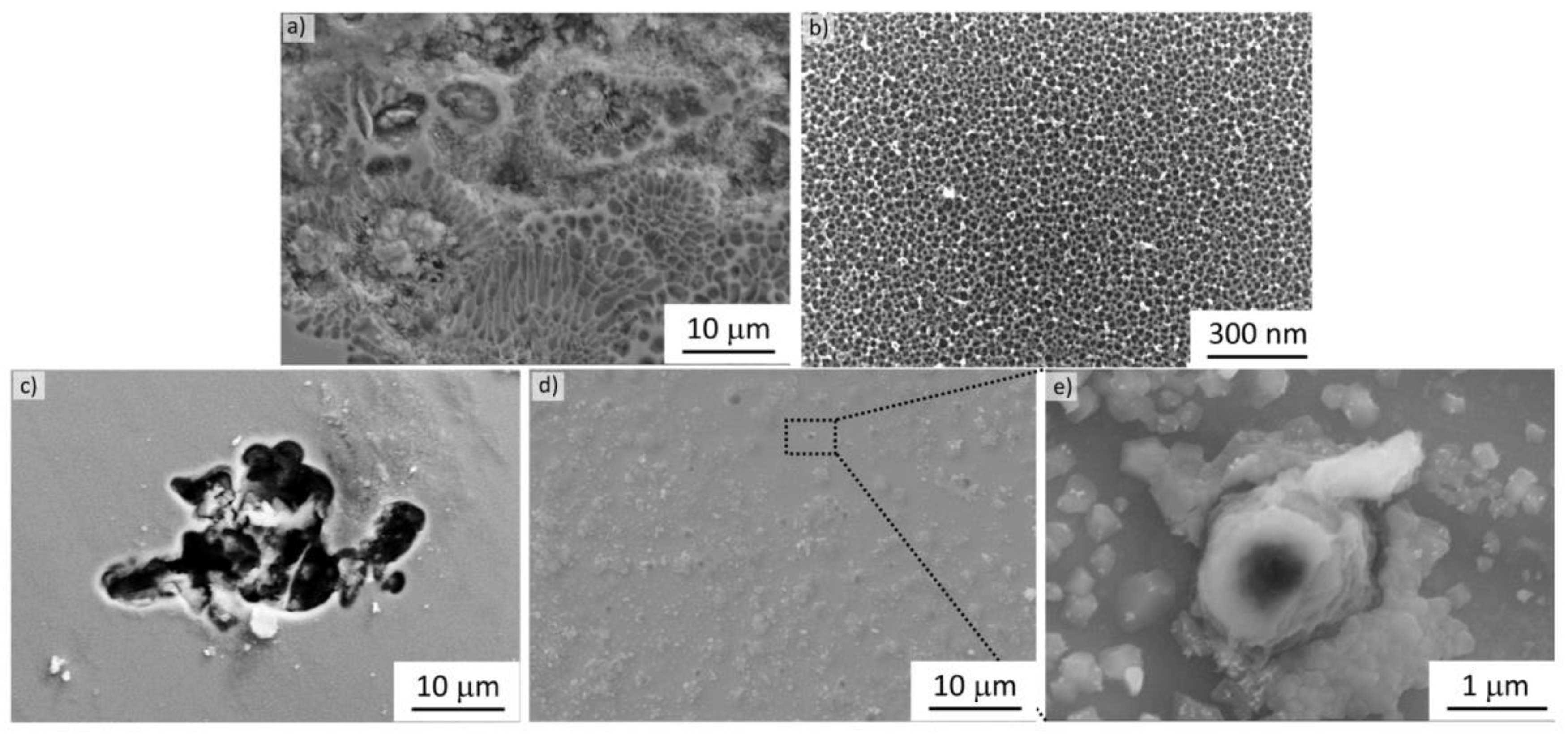

3.3.2. SEM Analysis of Corroded Alloy Surfaces after Polarization Measurements in PBS

4. Summary and Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, A.; Zadorozhnyy, V. Review of the recent development in metallic glass and its composites. Metals 2021, 11, 1933. [Google Scholar] [CrossRef]

- Gao, K.; Zhu, X.G.; Chen, L.; Li, W.H.; Xu, X.; Pan, B.T.; Li, W.R.; Zhou, W.H.; Li, L.; Huang, W.; et al. Recent development in the application of bulk metallic glasses. J. Mater. Sci. Technol. 2022, 131, 115–121. [Google Scholar] [CrossRef]

- Greer, A.L.; Costa, M.B.; Houghton, O.S. Metallic glasses. MRS Bull. 2023, 48, 1054–1061. [Google Scholar] [CrossRef]

- Jabed, A.; Bhuiyan, M.N.; Haider, W.; Shabib, I. Distinctive Features and Fabrication Routes of Metallic-Glass Systems Designed for Different Engineering Applications: A Review. Coatings. 2023, 13, 1689. [Google Scholar] [CrossRef]

- Sohrabi, N.; Jhabvala, J.; Kurtuldu, G.; Frison, R.; Parrilli, A.; Stoica, M.; Neels, A.; Löffler, J.F.; Logé, R.E. Additive manufacturing of a precious bulk metallic glass. Appl. Mater. Today 2021, 24, 101080. [Google Scholar] [CrossRef]

- Luo, H.; Du, Y. Mechanical Properties of Bulk Metallic Glasses Additively Manufactured by Laser Powder Bed Fusion: A Review. Materials 2023, 16, 7034. [Google Scholar] [CrossRef] [PubMed]

- Bera, S.; Sarac, B.; Balakin, S.; Ramasamy, P.; Stoica, M.; Calin, M.; Eckert, J. Micro-patterning by thermoplastic forming of Ni-free Ti-based bulk metallic glasses. Mater. Des. 2017, 120, 204–211. [Google Scholar] [CrossRef]

- Cai, F.F.; Sarac, B.; Chen, Z.; Czibula, C.; Spieckermann, F.; Eckert, J. Surmounting the thermal processing limits: Patterning TiZrCuPdSn bulk metallic glass even with nanocrystallization. Mater. Today Adv. 2022, 16, 100316. [Google Scholar] [CrossRef]

- Jafary-Zadeh, M.; Kumar, G.P.; Branicio, P.S.; Seifi, M.; Lewandowski, J.J.; Cui, F. A critical review on metallic glasses as structural materials for cardiovascular stent applications. J. Funct. Biomater. 2018, 9, 19. [Google Scholar] [CrossRef]

- Gong, P.; Deng, L.; Jin, J.; Wang, S.; Wang, X.; Yao, K. Review on the research and development of Ti-based bulk metallic glasses. Metals 2016, 6, 264. [Google Scholar] [CrossRef]

- Li, H.F.; Zheng, Y.F. Recent advances in bulk metallic glasses for biomedical applications. Acta Biomater. 2016, 36, 1–20. [Google Scholar] [CrossRef]

- Liens, A.; Etiemble, A.; Rivory, P.; Balvay, S.; Pelletier, J.M.; Cardinal, S.; Fabrègue, D.; Kato, H.; Steyer, P.; Munhoz, T.; et al. On the potential of Bulk Metallic Glasses for dental implantology: Case study on Ti40Zr10Cu36Pd14. Materials 2018, 11, 249. [Google Scholar] [CrossRef]

- Calin, M.; Gebert, A.; Ghinea, A.C.; Gostin, P.F.; Abdi, S.; Mickel, C.; Eckert, J. Designing biocompatible Ti-based metallic glasses for implant applications. Mater. Sci. Eng. C. 2013, 33, 875–883. [Google Scholar] [CrossRef]

- Lachová, A.; Stoica, M.; Michalik, Š.; Gostin, P.F.; Fujioka-Kobayashi, M.; Schaller, B.; Löffler, J.F.; Sovák, P. Modification of structural, mechanical, corrosion and biocompatibility properties of Ti40Zr10Cu36Pd14 metallic glass by minor Ga and Sn additions. J. Alloys Compd. 2023, 940, 168776. [Google Scholar] [CrossRef]

- Pang, S.; Liu, Y.; Li, H.; Sun, L.; Li, Y.; Zhang, T. New Ti-based Ti-Cu-Zr-Fe-Sn-Si-Ag bulk metallic glass for biomedical applications. J. Alloys Compd. 2015, 625, 323–327. [Google Scholar] [CrossRef]

- Deng, L.; Gebert, A.; Zhang, L.; Chen, H.Y.; Gu, D.D.; Kühn, U.; Zimmermann, M.; Kosiba, K.; Pauly, S. Mechanical performance and corrosion behaviour of Zr-based bulk metallic glass produced by selective laser melting. Mater. Des. 2020, 189, 108532. [Google Scholar] [CrossRef]

- Ma, Y.; Yan, J.; Yan, T.; Wang, Q.; Bao, Z.; Yi, Z. Biological properties of Cu-bearing and Ag-bearing titanium-based alloys and their surface modifications: A review of antibacterial aspect. Front. Mater. 2022, 9, 999794. [Google Scholar] [CrossRef]

- Wang, Y.B.; Li, H.F.; Cheng, Y.; Zheng, Y.F.; Ruan, L.Q. In vitro and in vivo studies on Ti-based bulk metallic glass as potential dental implant material. Mater. Sci. Eng. C. 2013, 33, 3489–3497. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.H.; Huang, C.H.; Chuang, J.F.; Huang, J.C.; Jang, J.S.C.; Chen, C.H. Rapid screening of potential metallic glasses for biomedical applications. Mater. Sci. Eng. C. 2013, 33, 4520–4526. [Google Scholar] [CrossRef] [PubMed]

- Gostin, P.F.; Addison, O.; Morrell, A.P.; Zhang, Y.; Cook, A.J.M.C.; Liens, A.; Stoica, M.; Ignatyev, K.; Street, S.R.; Wu, J.; et al. In Situ Synchrotron X-Ray Diffraction Characterization of Corrosion Products of a Ti-Based Metallic Glass for Implant Applications. Adv. Healthc. Mater. 2018, 7, 1800338. [Google Scholar] [CrossRef] [PubMed]

- Gostin, P.F.; Eigel, D.; Grell, D.; Eckert, J.; Kerscher, E.; Gebert, A. Comparing the pitting corrosion behavior of prominent Zr-based bulk metallic glasses. J. Mater. Res. 2014, 30, 233–241. [Google Scholar] [CrossRef]

- Gebert, A.; Oswald, S.; Helth, A.; Voss, A.; Gostin, P.F.; Rohnke, M.; Janek, J.; Calin, M.; Eckert, J. Effect of indium (In) on corrosion and passivity of a beta-type Ti-Nb alloy in Ringer’s solution. Appl. Surf. Sci. 2015, 335, 213–222. [Google Scholar] [CrossRef]

- Kirmanidou, Y.; Sidira, M.; Drosou, M.E.; Bennani, V.; Bakopoulou, A.; Tsouknidas, A.; Michailidis, N.; Michalakis, K. New Ti-Alloys and Surface Modifications to Improve the Mechanical Properties and the Biological Response to Orthopedic and Dental Implants: A Review. Biomed Res. Int. 2016, 2016, 2908570. [Google Scholar] [CrossRef]

- Fukushima, Y.; Katsumata, K.I.; Shengli, Z.; Guoqiang, X.; Niinomi, M.; Okada, K.; Matsushita, N. Solution process for synthesizing bioactive nano-mesh layer on Ti-based bulk metallic glasses. Mater. Trans. 2013, 54, 1343–1346. [Google Scholar] [CrossRef]

- Qin, F.X.; Wang, X.M.; Wada, T.; Xie, G.Q.; Asami, K.; Inoue, A. Formation of hydroxyapatite on Ti-coated Ti-Zr-Cu-Pd bulk metallic glass. Mater. Trans. 2009, 50, 605–609. [Google Scholar] [CrossRef]

- Pourbaix, M.; Zhang, H.; Pourbaix, A. Presentation of an Atlas of Chemical and Electrochemical Equilibria in the Presence of a Gaseous Phase; Trans Tech Publications Ltd.: Bäch, Switzerland, 1974. [Google Scholar] [CrossRef]

- Blanquer, A.; Hynowska, A.; Nogués, C.; Ibáñez, E.; Sort, J.; Baró, M.D.; Özkale, B.; Pané, S.; Pellicer, E.; Barrios, L. Effect of surface modifications of Ti40Zr10Cu38Pd12 bulk metallic glass and Ti-6Al-4V alloy on human osteoblasts in vitro biocompatibility. PLoS ONE 2016, 11, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Sittig, C.; Textor, M.; Spencer, N.D.; Wieland, M.; Vallotton, P.H. Surface characterization of implant materials c.p. Ti, Ti-6Al-7Nb and Ti-6Al-4V with different pretreatments. J. Mater. Sci. Mater. Med. 1999, 10, 35–46. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.L.; He, J.L.; Yang, X.J.; Cui, Z.D.; Pi, L.L. Ti oxide nano-porous surface structure prepared by dealloying of Ti-Cu amorphous alloy. Electrochem. Commun. 2011, 13, 250–253. [Google Scholar] [CrossRef]

- Zhu, S.; Xie, G.; Yang, X.; Cui, Z. A thick hierarchical rutile TiO2 nanomaterial with multilayered structure. Mater. Res. Bull. 2013, 48, 1961–1966. [Google Scholar] [CrossRef]

- Calin, M.; Stoica, M.; Zheng, N.; Wang, X.; Scudino, S.; Gebert, A.; Eckert, J. Thermal stability and crystallization kinetics of Ti40Zr 10Cu34Pd14Sn2 bulk metallic glass. Solid State Phenom. 2012, 188, 3–10. [Google Scholar] [CrossRef]

- Gebert, A.; Gostin, P.F.; Schultz, L. Effect of surface finishing of a Zr-based bulk metallic glass on its corrosion behaviour. Corros. Sci. 2010, 52, 1711–1720. [Google Scholar] [CrossRef]

- Paschalidou, E.M.; Scaglione, F.; Gebert, A.; Oswald, S.; Rizzi, P.; Battezzati, L. Partially and fully de-alloyed glassy ribbons based on Au: Application in methanol electro-oxidation studies. J. Alloys Compd. 2016, 667, 302–309. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, G.; Li, H.; Pang, S.; Chen, K.; Zhang, T. Ti-Cu-Zr-Fe-Sn-Si-Sc bulk metallic glasses with good mechanical properties for biomedical applications. J. Alloys Compd. 2016, 679, 341–349. [Google Scholar] [CrossRef]

- Hasannaeimi, V.; Sadeghilaridjani, M.; Mukherjee, S. Electrochemical and Corrosion Behavior of Metallic Glasses; MDPI: Basel, Switzerland, 2021. [Google Scholar] [CrossRef]

- Oak, J.J.; Inoue, A. Formation, mechanical properties and corrosion resistance of Ti-Pd base glassy alloys. J. Non. Cryst. Solids. 2008, 354, 1828–1832. [Google Scholar] [CrossRef]

- Tomashov, N.; Altvsky, R.; Chernova, G. Passivity and Corrosion Resistance of Titanium and Its Alloys. J. Electrochem. Soc. 1961, 108, 113–118. [Google Scholar] [CrossRef]

| Tg (K) | Tx1 (K) | ΔTx (Tx − Tg) (K) | Tx2 | Tx3 | |

|---|---|---|---|---|---|

| Ti47Cu38Fe2.5Zr7.5Sn2Si1Ag2 | 645 ± 2 | 701 ± 2 | 56 ± 2 | 809 ± 1 | - |

| Ti40Zr10Cu34Pd14Sn2 | 686 ± 6 | 728 ± 2 | 54 ± 5 | 798 ± 3 | 828 ± 4 |

| Metallic Glass Composition | T /°C | Ecorr /V vs. SCE | icorr /A/cm2 | ianodic (1 V vs. SCE) /A/cm2 |

|---|---|---|---|---|

| Ti47Cu38Fe2.5Zr7.5Sn2Si1Ag2 | RT | 0.15 ± 0.01 | 0.11 ± 0.04 × 10−6 | 1.52 ± 0.27 × 10−5 |

| Ti47Cu38Fe2.5Zr7.5Sn2Si1Ag2 | 60 | 0.12 ± 0.01 | 32.40 ± 14.56 × 10−6 | 1.31 ± 0.03 × 10−4 |

| Ti40Zr10Cu34Pd14Sn2 | RT | 0.70 ± 0.01 | 0.03 ± 0.01 × 10−6 | 1.20 ± 0.14 × 10−6 |

| Ti40Zr10Cu34Pd14Sn2 | 60 | 0.43 ± 0.06 | 1.51 ± 1.06 × 10−6 | 1.22 ± 0.26 × 10−5 |

| Material | OCPend/ V vs. SCE | icorr/ A/cm2 | Ecorr/ V vs. SCE | ipass/ A/cm2 | Epit/ V vs. SCE |

|---|---|---|---|---|---|

| cp-Ti, polished, air aged | −0.412 ± 0.014 | 0.25 ± 0.16 × 10−7 | −0.283 ± 0.122 | 1.52 ± 0.40 × 10−5 | - |

| Ti47Cu38Zr7.5Fe2.5Sn2Si1Ag2 as-spun, air-aged | −0.128 ± 0.016 | 0.31 ± 0.22 × 10−7 | −0.128 ± 0.008 | - | −0.054 ± 0.030 |

| Ti40Zr10Cu34Pd14Sn2 as-spun, air-aged | 0.058 ± 0.041 | 0.09 ± 0.02 × 10−7 | 0.017 ± 0.005 | 1.95 ± 0.61 × 10−8 | 0.462 ± 0.025 |

| Ti47Cu38Zr7.5Fe2.5Sn2Si1Ag2 treated | −0.017 ± 0.045 | 0.23 ± 0.16 × 10−7 | 0.003 ± 0.012 | 1.17 ± 0.19 × 10−5 | - |

| Ti40Zr10Cu34Pd14Sn2 treated | 0.076 ± 0.035 | 0.18 ± 0.06 × 10−7 | 0.054 ± 0.025 | 2.56 ± 0.42 × 10−6 | 0.732 ± 0.024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-Navas, N.; Shtefan, V.; Hantusch, M.; Gebert, A. Acid Treatments of Ti-Based Metallic Glasses for Improving Corrosion Resistance in Implant Applications. Metals 2024, 14, 241. https://doi.org/10.3390/met14020241

Fernández-Navas N, Shtefan V, Hantusch M, Gebert A. Acid Treatments of Ti-Based Metallic Glasses for Improving Corrosion Resistance in Implant Applications. Metals. 2024; 14(2):241. https://doi.org/10.3390/met14020241

Chicago/Turabian StyleFernández-Navas, Nora, Viktoriia Shtefan, Martin Hantusch, and Annett Gebert. 2024. "Acid Treatments of Ti-Based Metallic Glasses for Improving Corrosion Resistance in Implant Applications" Metals 14, no. 2: 241. https://doi.org/10.3390/met14020241

APA StyleFernández-Navas, N., Shtefan, V., Hantusch, M., & Gebert, A. (2024). Acid Treatments of Ti-Based Metallic Glasses for Improving Corrosion Resistance in Implant Applications. Metals, 14(2), 241. https://doi.org/10.3390/met14020241