Effects of HIP on Microstructure and Mechanical Properties of LMD Fe36Mn21Cr1815NiAl10 High-Entropy Alloy

Abstract

1. Introduction

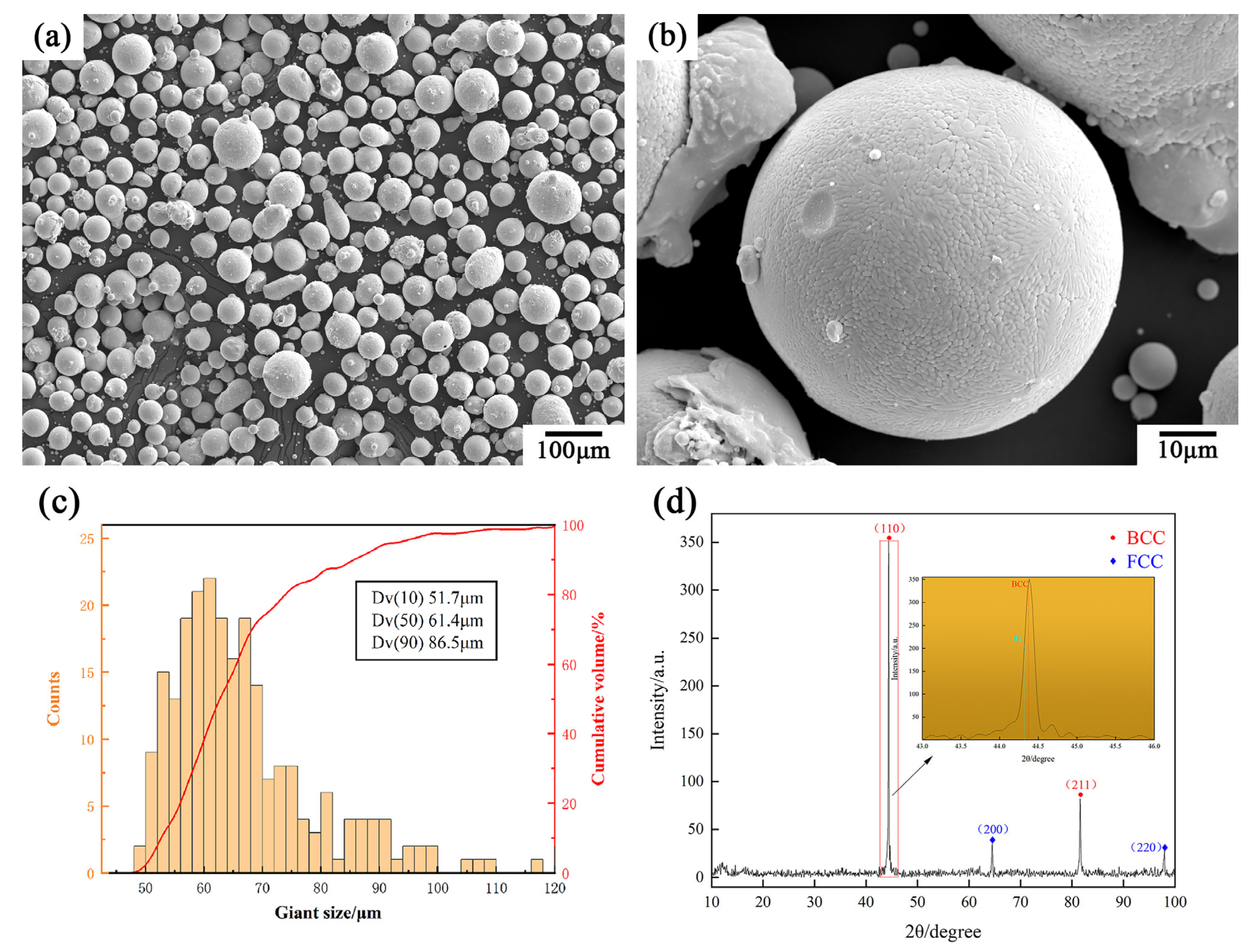

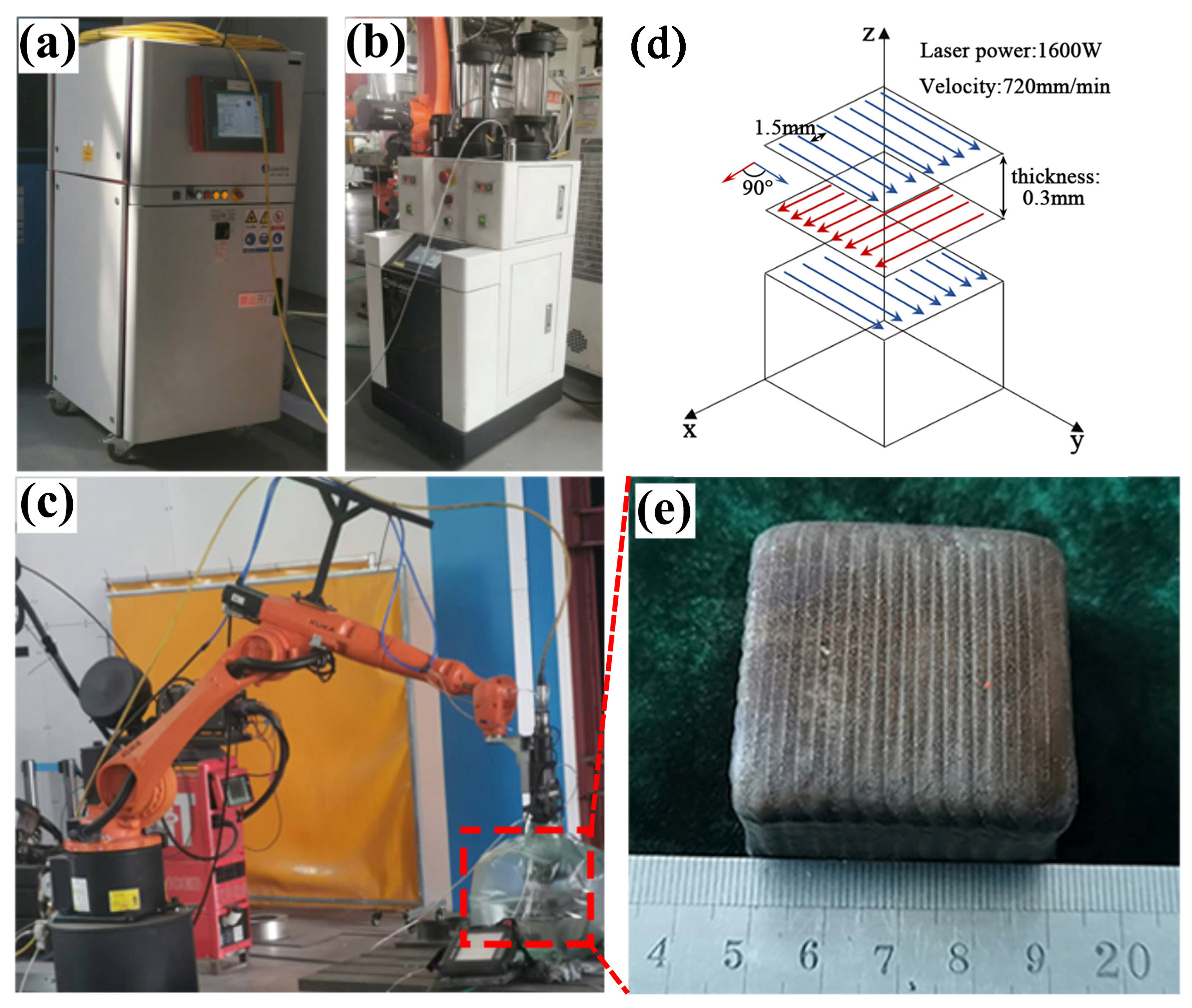

2. Materials and Methods

3. Results and Discussion

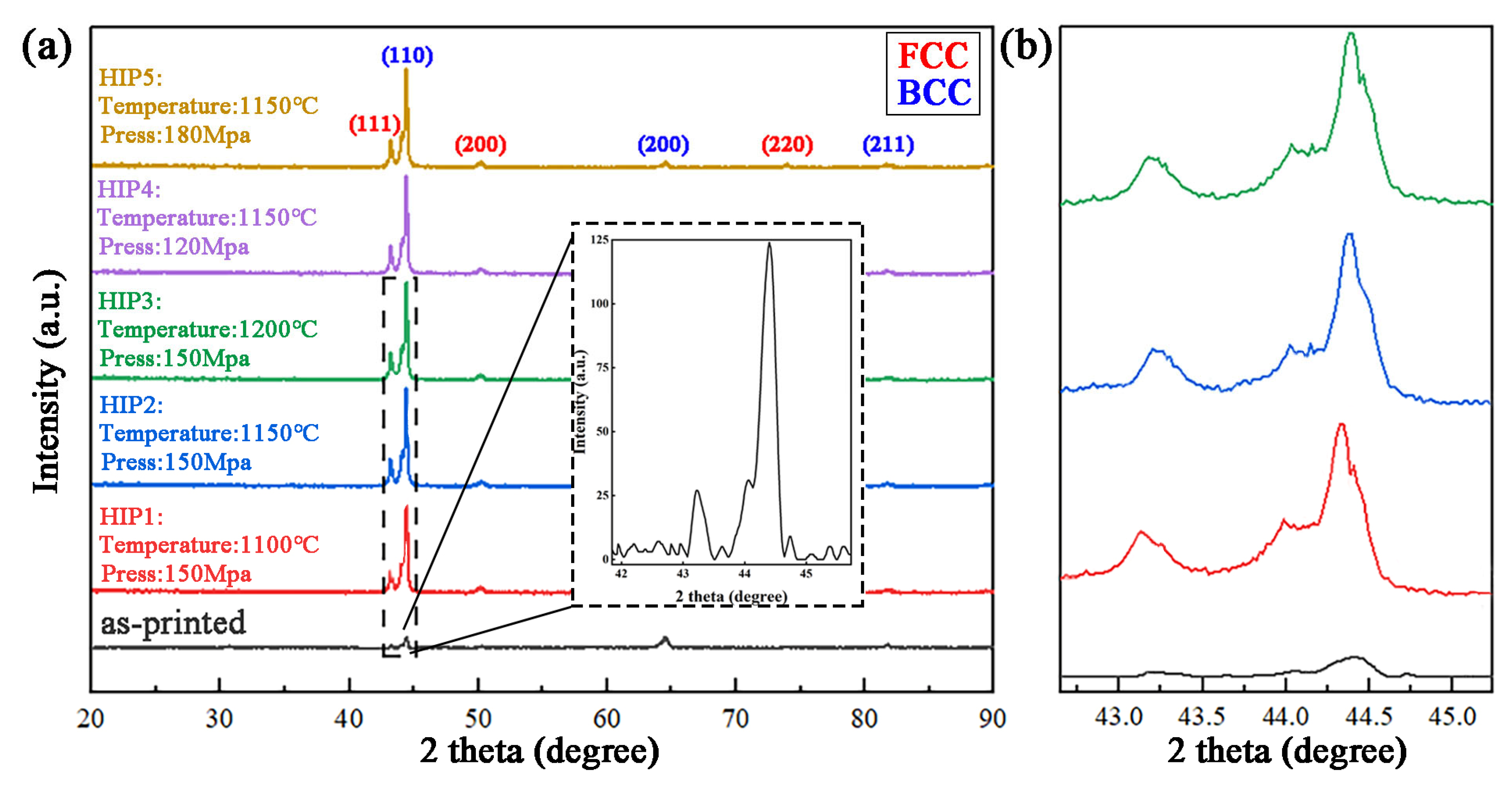

3.1. Phase Analysis

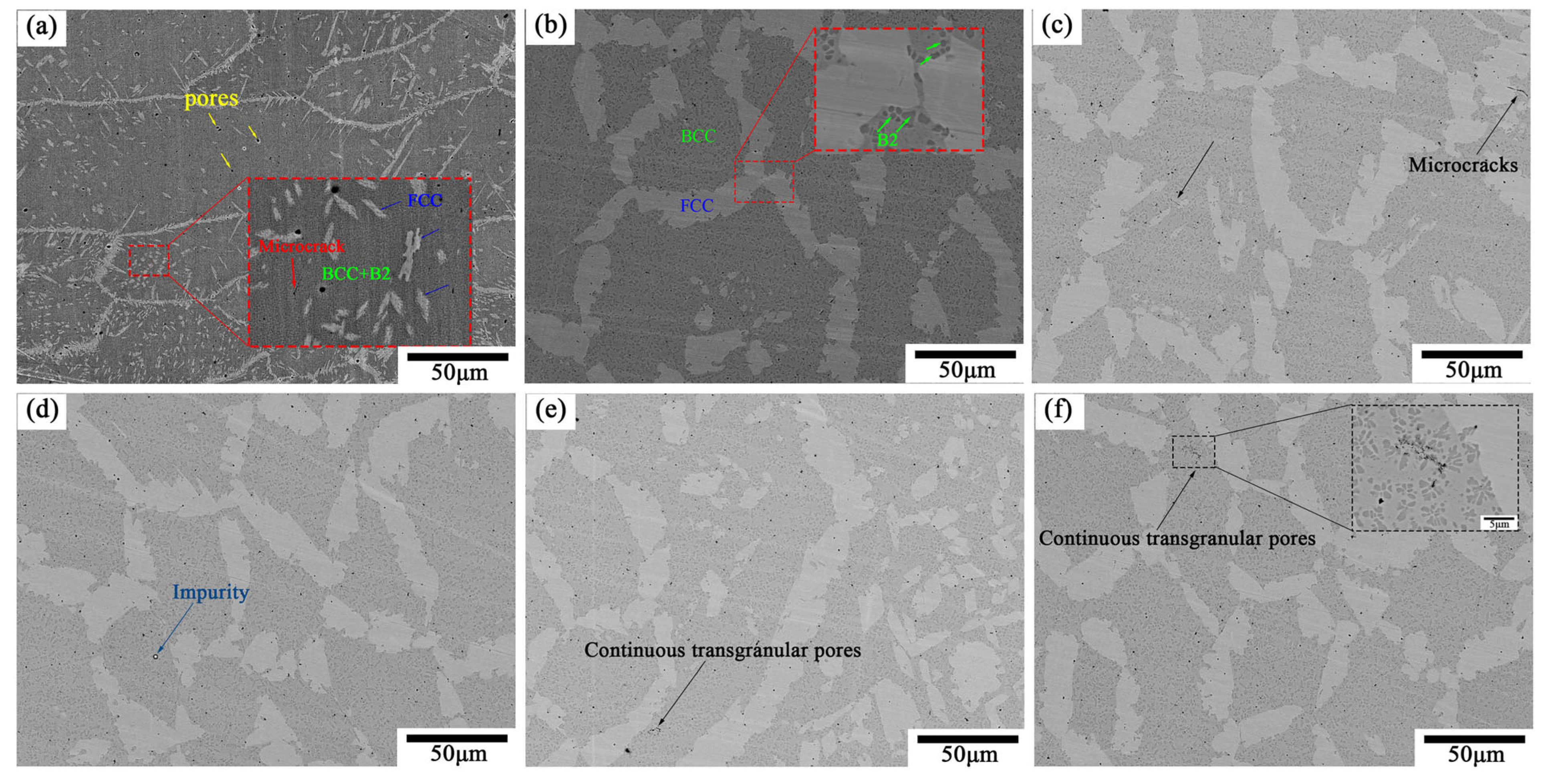

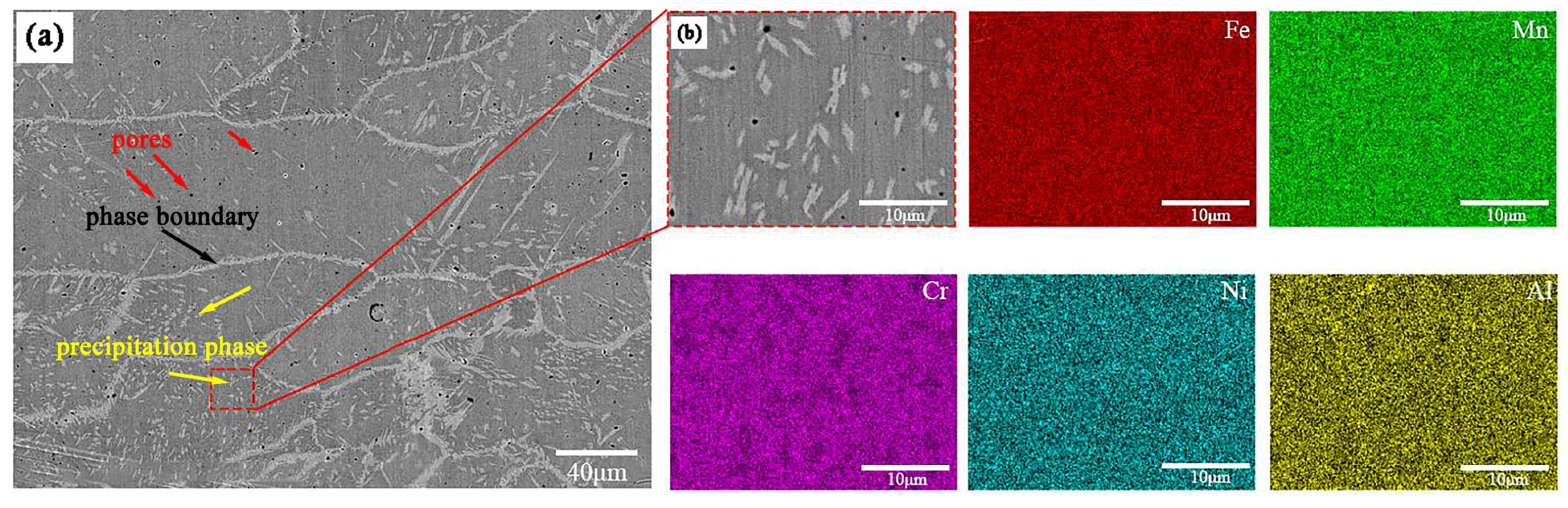

3.2. Structure Analysis

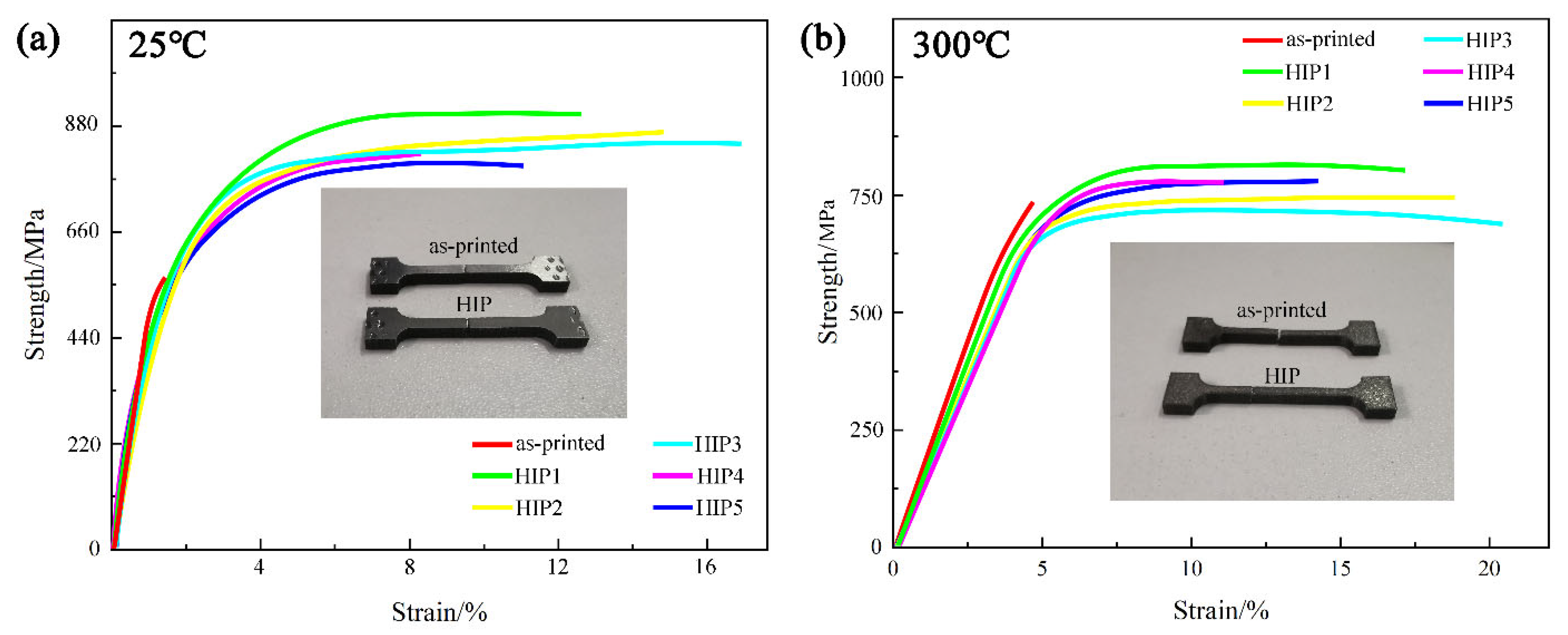

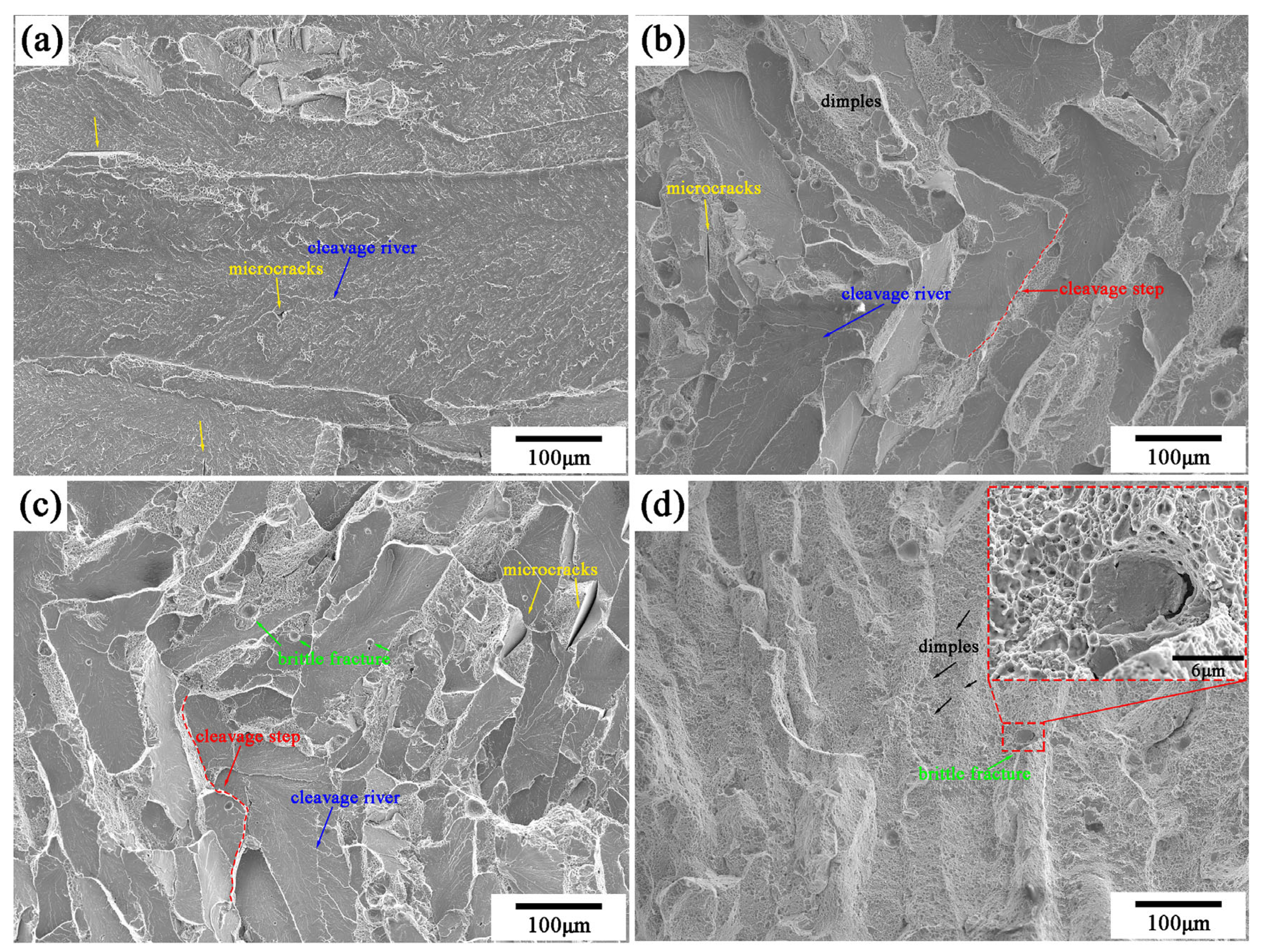

3.3. Tensile Properties and Analysis of Fracture Morphology

4. Conclusions

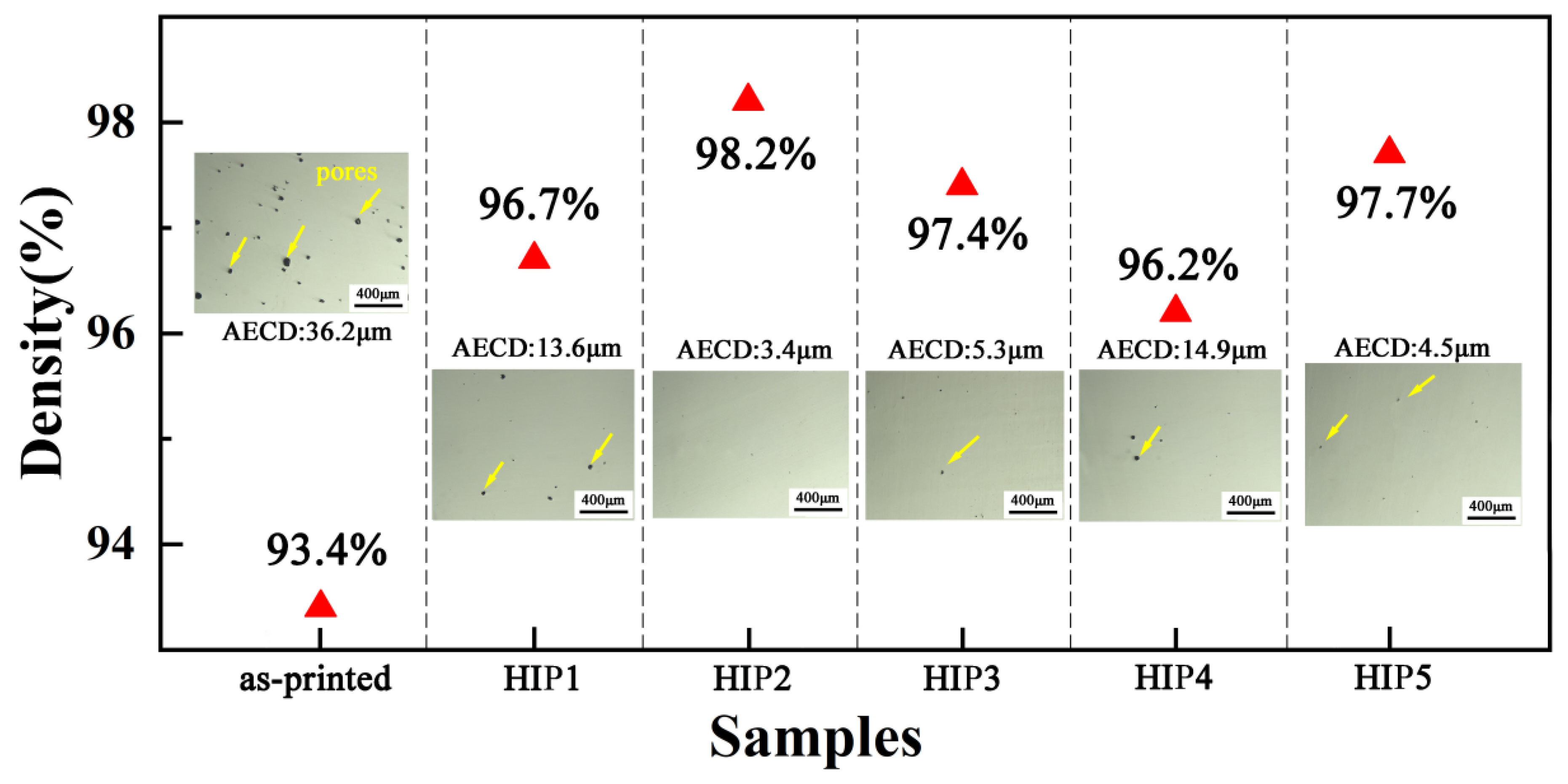

- The specimens in both the as-printed and HIPed states exhibit FCC and BCC/B2 phase structures. Compared to the as-printed specimens, HIP promotes the formation of the BCC phase in HEAs and increases the proportion of the BCC/FCC phases. Additionally, HIP effectively closes the pores, increasing the material’s density to 98.2%.

- For as-printed specimens, bright, needle-like (lamellar) FCC phases are irregularly distributed near grain boundaries and within grains, and uniformly distributed pores of varying sizes exist at the phase boundaries and within the phases, along with a limited number of microcrack defects. The BCC phase is uniformly distributed, with tiny clumps of B2 phases present on the BCC phase substrate. The microstructure of the HIPed specimens clearly showed a redistribution of two phases: the FCC phase is irregularly distributed between the BCC phase in the form of strips, while a substantial B2 phase is present within the BCC phase, and there is a notable reduction in defects such as porosity and microcracks.

- At room temperature, as-printed samples experienced premature fracture due to stress concentration caused by internal microcracks. In comparison to as-printed samples, the HIPed samples exhibited higher σUTS and εf, with σUTS reaching 903.9 MPa and εf reaching 17.4%. The tensile samples at 300 °C exhibit a similar trend, with the σUTS of HIPed samples reaching 800.7 MPa and the εf reaching 20.5%. An increase in HIP temperature results in a decrease in σUTS and an increase in εf, whereas an increase in pressure leads to a reduction in both σUTS and εf.

- The fracture mechanism of as-printed HEA samples is characterized by microcrack-induced cleavage fracture, while the fracture mechanism of HIP-treated samples transitions to a coexistence of cleavage fracture and ductile fracture at room temperature. At 300 °C, the fracture mechanism of as-printed HEA samples also exhibits a coexistence of cleavage and ductile fractures, whereas the fracture mechanism of HIPed samples evolves to primarily ductile fracture, with a limited number of brittle fracture points.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Tsai, M.; Yeh, J. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Guo, S.; Liu, C.T. Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci. 2011, 21, 433–446. [Google Scholar] [CrossRef]

- Joseph, J.; Jarvis, T.; Wu, X.; Stanford, N.; Hodgson, P.; Fabijanic, D.M. Comparative study of the microstructures and mechanical properties of direct laser fabricated and arc-melted AlCoCrFeNi high entropy alloys. Mater. Sci. Eng. A 2015, 633, 184–193. [Google Scholar] [CrossRef]

- Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef]

- Guo, L.; Gu, J.; Gong, X.; Li, K.; Ni, S.; Liu, Y.; Song, M. Short-range ordering induced serrated flow in a carbon contained FeCoCrNiMn high entropy alloy. Micron 2019, 126, 102739. [Google Scholar] [CrossRef] [PubMed]

- Brif, Y.; Thomas, M.; Todd, L. The use of high-entropy alloys in additive manufacturing. Scr. Mater. 2015, 99, 93–96. [Google Scholar] [CrossRef]

- Chou, H.-P.; Chang, Y.-S.; Chen, S.-K.; Yeh, J.-W. Microstructure, thermophysical and electrical properties in AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. Mater. Sci. Eng. B 2009, 163, 184–189. [Google Scholar] [CrossRef]

- Lin, C.; Tsai, H. Evolution of microstructure, hardness, and corrosion properties of high-entropy Al0.5CoCrFeNi alloy. Intermetallics 2011, 19, 288–294. [Google Scholar] [CrossRef]

- Li, R.; Niu, P.; Yuan, T.; Cao, P.; Chen, C.; Zhou, K. Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical property. J. Alloys Compd. 2018, 746, 125–134. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, Y.; Dong, W.; Liu, Z.; Lu, Y.; Zhang, Y.; Li, R.; Wang, Y.; Yu, P.; Gao, Y.; et al. Phase evolution, microstructure, and mechanical behaviors of the CrFeNiAlxTiy medium-entropy alloys. Mater. Sci. Eng. A 2020, 771, 138566. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Gao, P.; Xiang, Q.; Qu, Y.; Cheng, J.; Ren, Y.; Qiu, K. AlxFeCrNi medium entropy alloys with high damping capacity. J. Alloys Compd. 2021, 876, 159991. [Google Scholar] [CrossRef]

- Jiao, W.; Li, T.; Chang, X.; Lu, Y.; Yin, G.; Cao, Z.; Li, T. A novel Co-free Al0.75CrFeNi eutectic high entropy alloy with superior mechanical properties. J. Alloys Compd. 2022, 902, 163814. [Google Scholar] [CrossRef]

- Chen, X.; Qi, J.Q.; Sui, Y.W.; He, Y.Z.; Wei, F.X.; Meng, Q.K.; Sun, Z. Effects of aluminum on microstructure and compressive properties of Al-Cr-Fe-Ni eutectic multi-component alloys. Mater. Sci. Eng. A 2017, 681, 25–31. [Google Scholar] [CrossRef]

- Wang, M.; Wen, Z.; Liu, J.; Ma, B.; Wang, M.; Zou, Z.; Zhao, Y. Labyrinthine structure AlxCrFeNi (x ≥ 1) eutectic high entropy alloys with duplex reinforced phases. J. Alloys Compd. 2022, 918, 165441. [Google Scholar]

- Liu, M.; Zuo, L.; Li, X.; Li, R.; Zhang, T. Microstructure and Mechanical Properties of Al25−xCr25+0.5xFe25Ni25+0.5x (x = 19, 17, 15 at %) Multi-Component Alloys. Adv. Eng. Mater. 2018, 20, 1–7. [Google Scholar] [CrossRef]

- Tripathy, B.; Malladi, S.R.K.; Bhattacharjee, P.P. Development of ultrafine grained cobalt-free AlCrFe2Ni2 high entropy alloy with superior mechanical properties by thermo-mechanical processing. Mater. Sci. Eng. A 2022, 83, 142190. [Google Scholar] [CrossRef]

- Tripathy, B.; Saha, R.; Bhattacharjee, P.P. Microstructure and unusually strong recrystallization texture of the FCC phase of a cost-effective high-strength dual-phase AlCrFe2Ni2 high entropy alloy. Intermetallics 2022, 145, 107559. [Google Scholar] [CrossRef]

- Fan, J.; Fu, L.; Sun, Y.; Xu, F.; Ding, Y.; Wen, M.; Shan, A. Unveiling the precipitation behavior and mechanical properties of Co-free Ni47-xFe30Cr12Mn8AlxTi3 high-entropy alloys. J. Mater. Sci. Technol. 2022, 118, 25–34. [Google Scholar] [CrossRef]

- Song, F.-Y.; Zhang, J.; Guo, H.; Zhang, M.; Zhao, Y.; Sha, J.B. Research on application of hot isostatic pressing technology in the field of nickel-based cast superalloys. J. Mater. Eng. 2021, 49, 65–74. [Google Scholar] [CrossRef]

- Xuan, W.; Zhang, X.; Zhao, Y.; Li, J.; Wang, B.; Ren, X.; Ren, Z. Mechanism of improved intermediate temperature plasticity of nickel-base single crystal superalloy with hot isostatic pressing. J. Mater. Res. Technol. JmrT 2021, 14, 1609–1617. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, L.; Yu, W.; Ding, X.; Nan, H. Research Progress of Powder Hot Isostatic Pressing for Intermetallic Titanium Aluminide. Rare Met. Mater. Eng. 2021, 50, 3797–3808. [Google Scholar]

- Jin, X.; Bi, J.; Zhang, L.; Zhou, Y.; Du, X.; Liang, Y.; Li, B. A new CrFeNi2Al eutectic high entropy alloy system withexcellent mechanical properties. J. Alloys Compd. 2019, 770, 655–661. [Google Scholar] [CrossRef]

- Cui, P.; Liu, Y.; Zhou, F.; Lai, Z.; Zhu, J. Enhancing high temperature mechanical properties via modulating B2 phase with Al contents in FeCrNiAlx (x = 0.63, 0.71, 0.77) high entropy alloys. J. Alloys Compd. 2022, 903, 163883. [Google Scholar] [CrossRef]

- Chen, R.; Qin, G.; Zheng, H.; Wang, L.; Su, Y.; Chiu, Y.L.; Ding, H.; Guo, J.; Fu, H. Composition design of high entropy alloys using the valence electron concentration to balance strength and ductility. Acta Mater. 2018, 144, 129–137. [Google Scholar] [CrossRef]

- Dong, Y.; Yao, Z.; Huang, X.; Du, F.; Li, C.; Chen, A.; Cheng, Y.; Zhang, Z. Microstructure and mechanical properties of AlCoxFeCrNi3-x eutectic high-entropy-alloy system. J. Alloys Compd. 2020, 823, 153886. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Yang, T.; Tong, Y.; Wang, J.; Huan, J.H.; Jiao, Z.B.; Chen, D.; Yang, Y.; Hu, A.; Liu, C.T.; et al. Heterogeneous precipitation behavior andstacking-fault-mediated deformation in a CoCrNi-based medium-entropy alloy. Acta Mater. 2017, 138, 72–82. [Google Scholar] [CrossRef]

- Liu, N.; Ding, W.; Wang, X.J.; Zhang, J.; Zhou, P.J.; Chen, M. Phases, microstructures and properties ofmulti-component FeCoNi-based alloys. Mater. Sci. Technol. 2020, 36, 654–660. [Google Scholar] [CrossRef]

- Hemphill, M.A.; Yuan, T.; Wang, G.Y.; Yeh, J.W.; Tsai, C.W.; Chuang, A.; Liaw, P.K. Fatigue behavior of Al0.5CoCrCuFeNi high entropy alloys. Acta Mater. 2012, 16, 5723–5734. [Google Scholar] [CrossRef]

- Yang, T.F.; Xia, S.Q.; Wang, C.; Liu, S.; Zhang, Y.; Xue, J.; Yan, S.; Wang, Y. Effects of Al addition on microstructure and mechanical properties of AlxCoCrFeNi High-entropy alloy. Mater. Sci. Eng. A 2015, 648, 15–22. [Google Scholar] [CrossRef]

- Chao, Q.; Guo, T.; Jarvis, T.; Wu, X.; Hodgson, P.; Fabijanic, D. Direct laser deposition cladding of AlxCoCrFeNi high entropy alloys on a high-temperature stainless steel. Surf. Coat. Technol. 2017, 332, 440–451. [Google Scholar] [CrossRef]

- Asadikiya, M.; Zhang, Y.; Wang, L.; Apelian, D.; Zhong, Y. Design of ternary high-entropy aluminum alloys (HEAls). J. Alloys Compd. 2022, 891, 161836. [Google Scholar] [CrossRef]

- Gao, X.Z.; Lu, Y.; Zhang, B.; Liang, N.; Wu, G.; Sha, G.; Liu, J.; Zhao, Y. Microstructural origins of high strength and high ductility in an AlCoCrFeNi2.1 eutectic high-entropy alloy. Acta Mater. 2017, 141, 59–66. [Google Scholar] [CrossRef]

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Guo, S.; Ng, C.; Lu, J.; Liu, T. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J. Appl. Phys. 2011, 109, 103505. [Google Scholar] [CrossRef]

- Laughlin, D.E.; Soffa, W.A. Metals Handbook, 9th ed.; ASM Press: Washington, DC, USA, 1985; Volume 9. [Google Scholar]

- Para, S. Metallography and microstructure. In ASM Handbook; ASM Press: Washington, DC, USA, 2004; Volume 9. [Google Scholar]

- Wang, W.R.; Wang, W.L.; Yeh, J.W. Phases, microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloys at elevated temperatures. J. Alloys Compd. 2014, 589, 143–152. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Miller, M.K.; Yu, C.Y.; Liu, C.T. Effects of Mn partitioning on nanoscale precipitation and mechanical properties of ferritic steels strengthened by NiAl nanoparticles. Acta Mater. 2015, 84, 283–291. [Google Scholar] [CrossRef]

- Yao, M.J.; Pradeep, K.G.; Tasan, C.C.; Raabe, D. A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility. Scr. Mater. 2014, 72–73, 5–8. [Google Scholar] [CrossRef]

- Bracq, G.; Laurent-Brocq, M.; Perriere, L.; Pires, R.; Joubert, J.-M.; Guillot, I. The fcc solid solution stability in the Co-Cr-Fe-Mn-Ni multi-component system. Acta Mater. 2017, 128, 327–336. [Google Scholar] [CrossRef]

- Christofidou, K.A.; Pickering, E.J.; Orsatti, P.; Mignanelli, P.M.; Slater, T.J.A.; Stone, H.J.; Jones, N.G. On the influence of Mn on the phase stability of the CrMnx FeCoNi high entropy alloys. Intermetallics 2018, 92, 84–92. [Google Scholar] [CrossRef]

- Darwich, A.; Attieh, A.; Khalil, A.; Szavai, S.; Nazha, H. Biomechanical assessment of orbital fractures using patient-specific models and clinical matching. J. Stomatol. Oral Maxillofac. Surg. 2021, 122, E51–E57. [Google Scholar] [CrossRef]

- Kono, S.; Vaidya, A.; Takahashi, Y. Mechanisms of Development of Orbital Fractures: A Review. Ophthalmic Plast. Reconstr. Surg. 2023, 39, 542–547. [Google Scholar] [CrossRef]

- Li, B.; Yu, S.; Yang, L.; Zhu, W.; Xue, Y.; Feng, D.; Wang, C.; Chen, Y. Multiscale fracture characteristics and failure mechanism quantification method of cracked rock under true triaxial compression. Eng. Fract. Mech. 2022, 262, 108257. [Google Scholar] [CrossRef]

- Zheng, S.; Shen, J.; Lu, X.; Xie, H.; Wang, W.; Yue, X. Microstructure inducement of different tensile fracture mechanisms at 800 °C of directional solidified Ti-45Al-5Nb alloys produced by electromagnetic confinement. J. Alloys Compd. 2022, 912, 165200. [Google Scholar] [CrossRef]

- Yang, J.; Wang, K.; Wu, J.; Zhang, Q.; Zhao, G.; Hu, P. Effect of misorientation evolution on the fracture mechanism. Mater. Lett. 2024, 357, 135742. [Google Scholar] [CrossRef]

- Yang, X.; Liang, Z.; Wang, L.W.; Zhang, H.; Wang, D.L. Interface structure and tensile behavior of high entropy alloy particles reinforced Al matrix composites by spark plasma sintering. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2022, 860, 144273. [Google Scholar] [CrossRef]

- Xi, S.; Chen, H.; Zhou, J.; Zheng, L.; Wang, W.; Nie, H.; Zheng, Q.; Liu, B. A novel eutectic high-entropy matrix composites were prepared by selective laser melting: Microstructure evolution, strengthening and fracture mechanism. J. Manuf. Process. 2024, 120, 1035–1048. [Google Scholar] [CrossRef]

| Sample | Temperature/°C | Press/Mpa | Time/h |

|---|---|---|---|

| HIP1 | 1100 | 150 | 2 |

| HIP2 | 1150 | ||

| HIP3 | 1200 | ||

| HIP4 | 1150 | 120 | |

| HIP5 | 180 |

| Region | Composition/wt% | ||||

|---|---|---|---|---|---|

| Fe | Cr | Mn | Ni | Al | |

| Site1 | 36.78 | 14.58 | 22.78 | 17.22 | 8.65 |

| Site2 | 29.63 | 17.49 | 18.77 | 17.88 | 16.23 |

| Site3 | 44.67 | 25.46 | 20.51 | 4.33 | 5.03 |

| Samples | Tensile Properties (25 °C/300 °C) | ||

|---|---|---|---|

| σy/MPa | σUTS/MPa | εf/% | |

| as-printed | 461.2/606.4 | 556.6/744.8 | 1.8/5.1 |

| HIP1 | 440.5/587.6 | 881.5/800.7 | 12.9/16.8 |

| HIP2 | 445.6/601.3 | 903.9/713.5 | 14.7/18.1 |

| HIP3 | 441.2/588.6 | 899.4/706.2 | 17.4/20.5 |

| HIP4 | 440.6/600.2 | 802.3/696.7 | 8.8/11.6 |

| HIP5 | 435.1/595.5 | 789.2/700.8 | 11.5/14.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Lv, X.; Xv, X.; Zhang, R. Effects of HIP on Microstructure and Mechanical Properties of LMD Fe36Mn21Cr1815NiAl10 High-Entropy Alloy. Metals 2024, 14, 1452. https://doi.org/10.3390/met14121452

Wang G, Lv X, Xv X, Zhang R. Effects of HIP on Microstructure and Mechanical Properties of LMD Fe36Mn21Cr1815NiAl10 High-Entropy Alloy. Metals. 2024; 14(12):1452. https://doi.org/10.3390/met14121452

Chicago/Turabian StyleWang, Gang, Xvteng Lv, Xiangyu Xv, and Runbo Zhang. 2024. "Effects of HIP on Microstructure and Mechanical Properties of LMD Fe36Mn21Cr1815NiAl10 High-Entropy Alloy" Metals 14, no. 12: 1452. https://doi.org/10.3390/met14121452

APA StyleWang, G., Lv, X., Xv, X., & Zhang, R. (2024). Effects of HIP on Microstructure and Mechanical Properties of LMD Fe36Mn21Cr1815NiAl10 High-Entropy Alloy. Metals, 14(12), 1452. https://doi.org/10.3390/met14121452