Precipitation and Age-Hardening in Fe-25Co-15Mo Carbon-Free High-Speed Steel via Hot Isostatic Pressing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Microstructure Characterization

2.3. Mechanical Tests

3. Results and Discussion

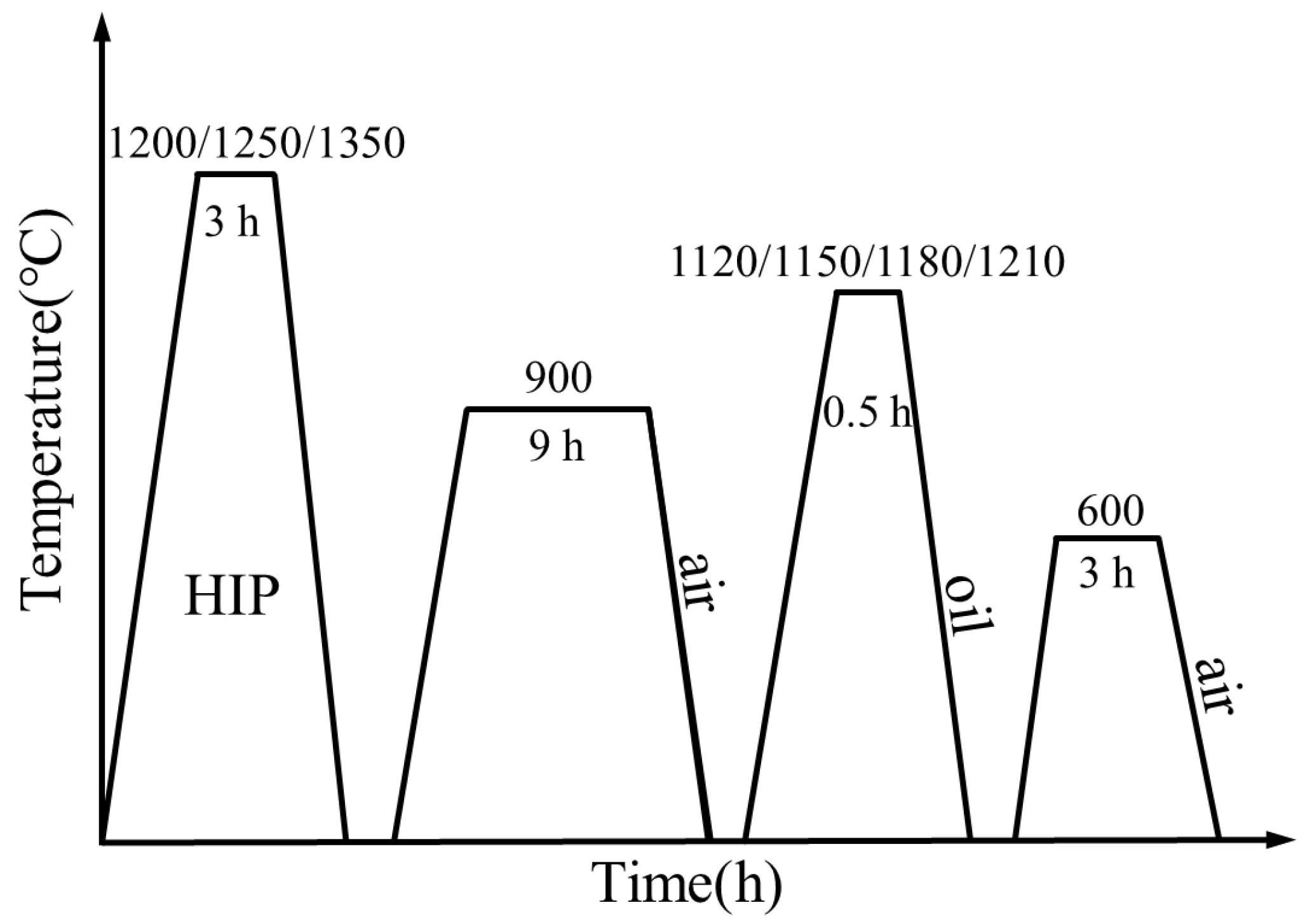

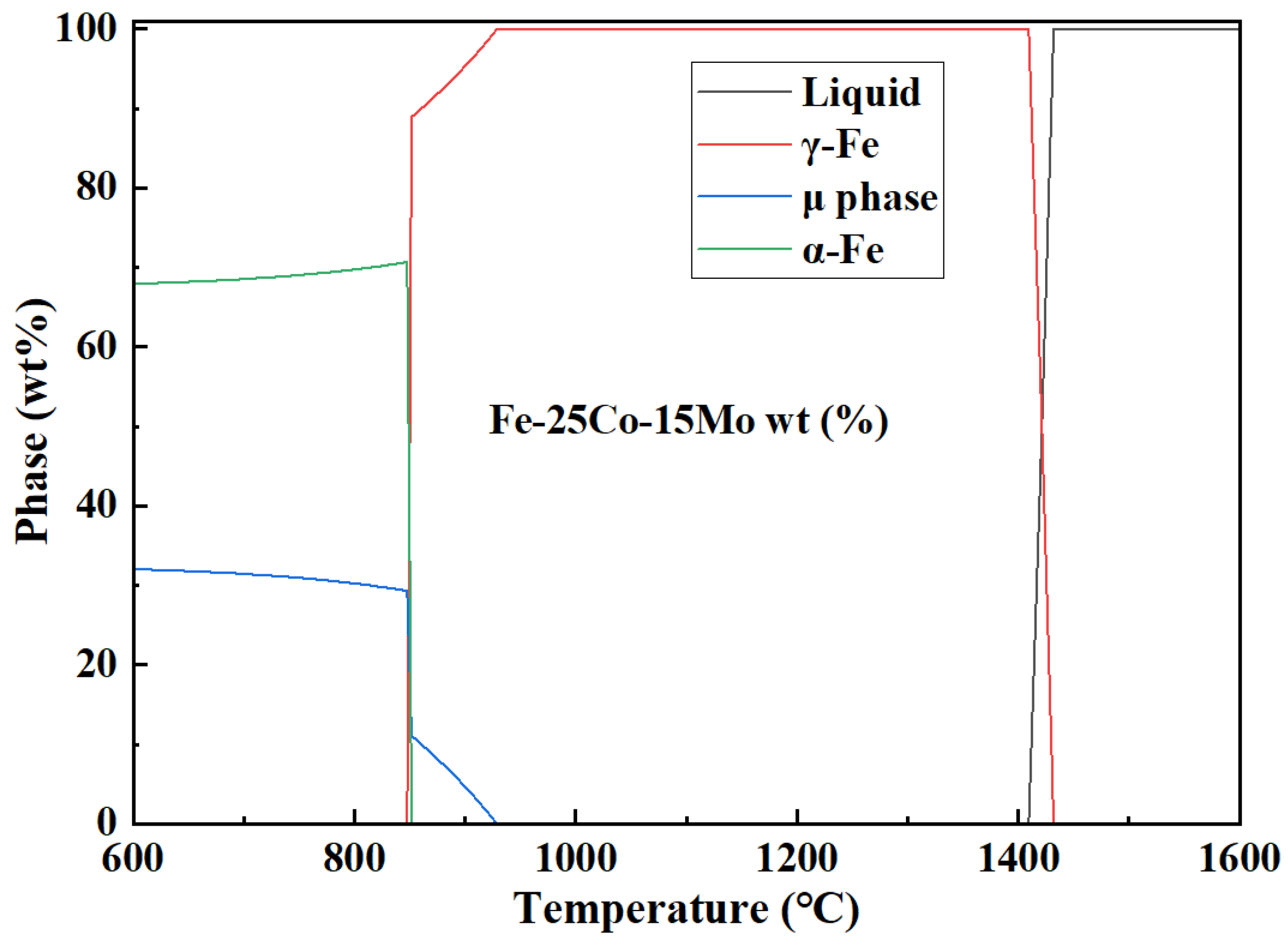

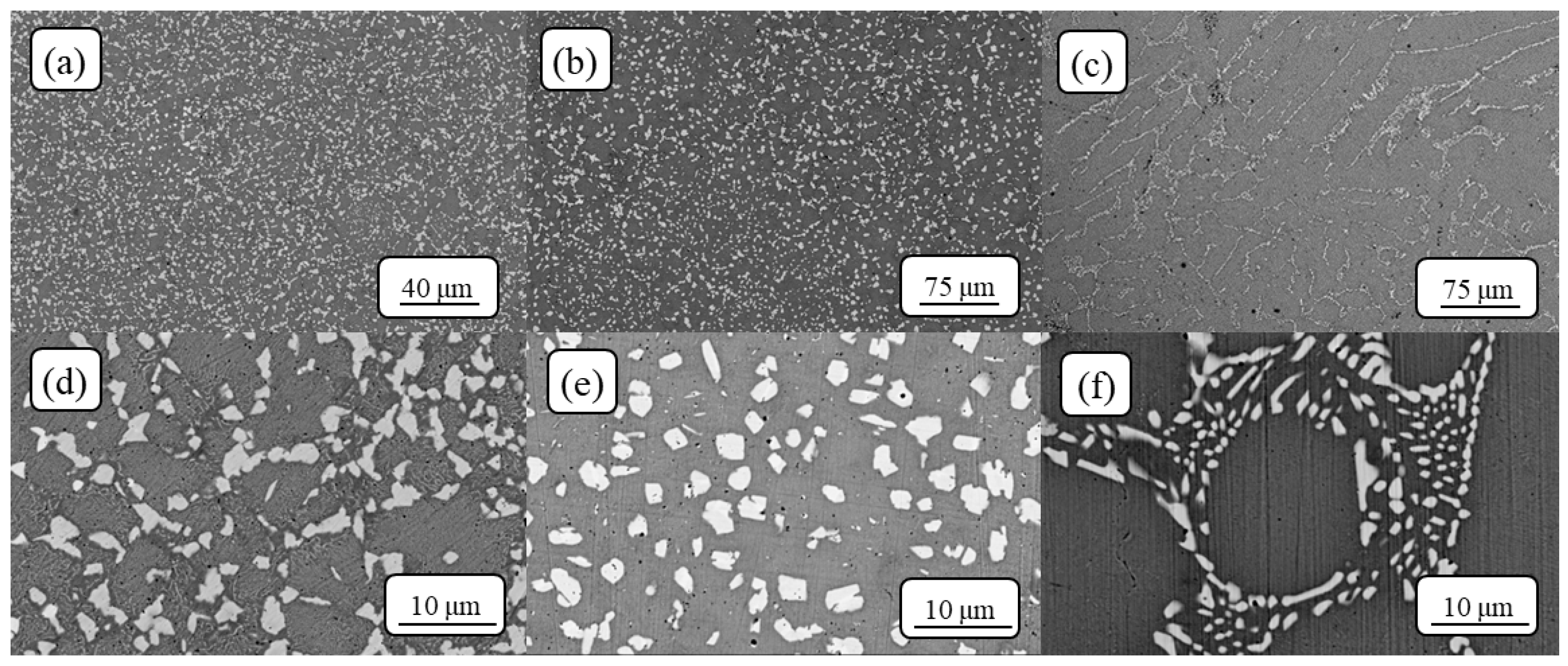

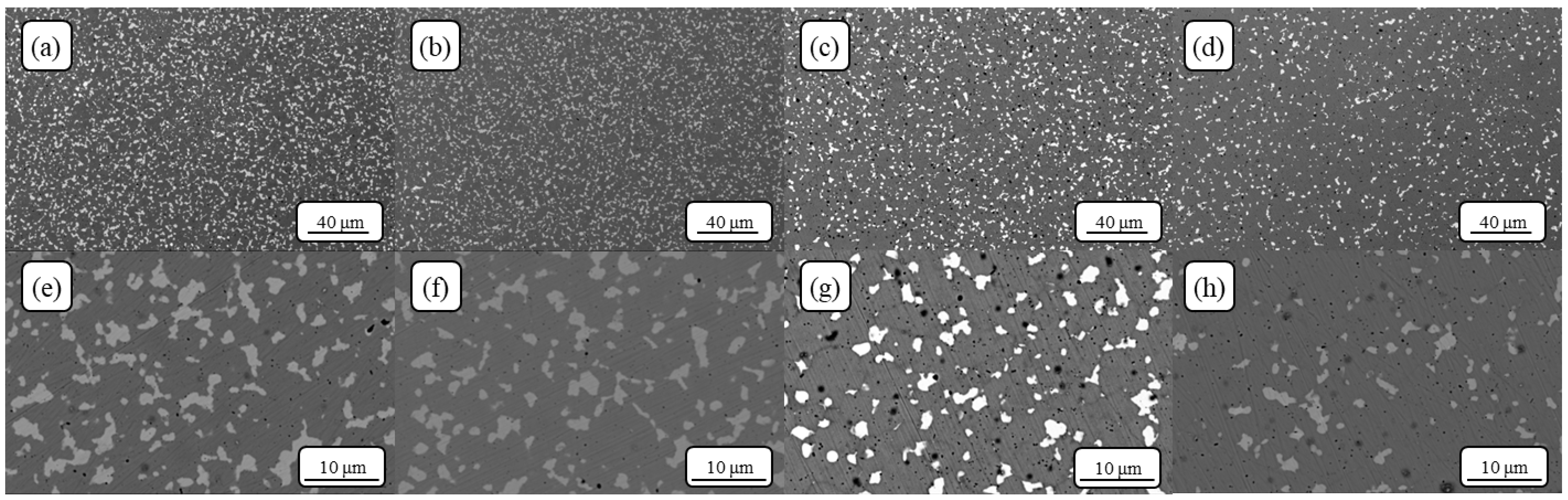

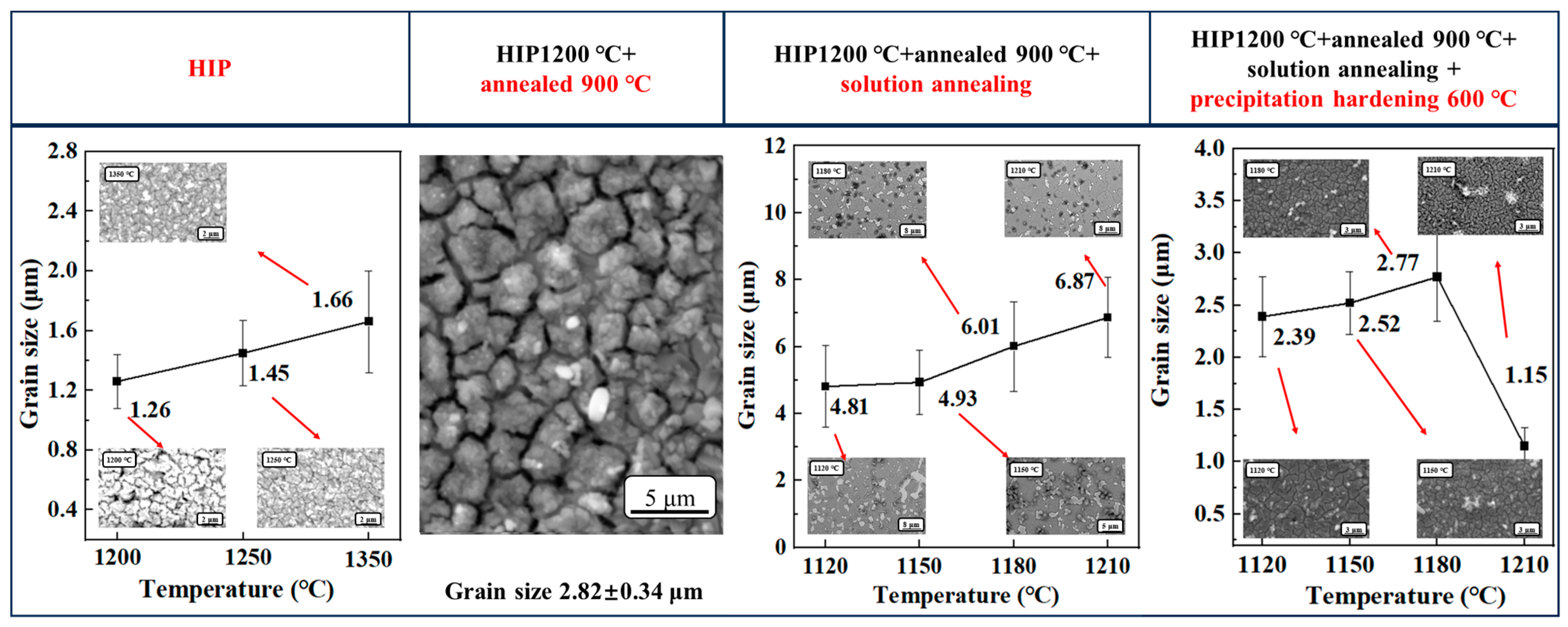

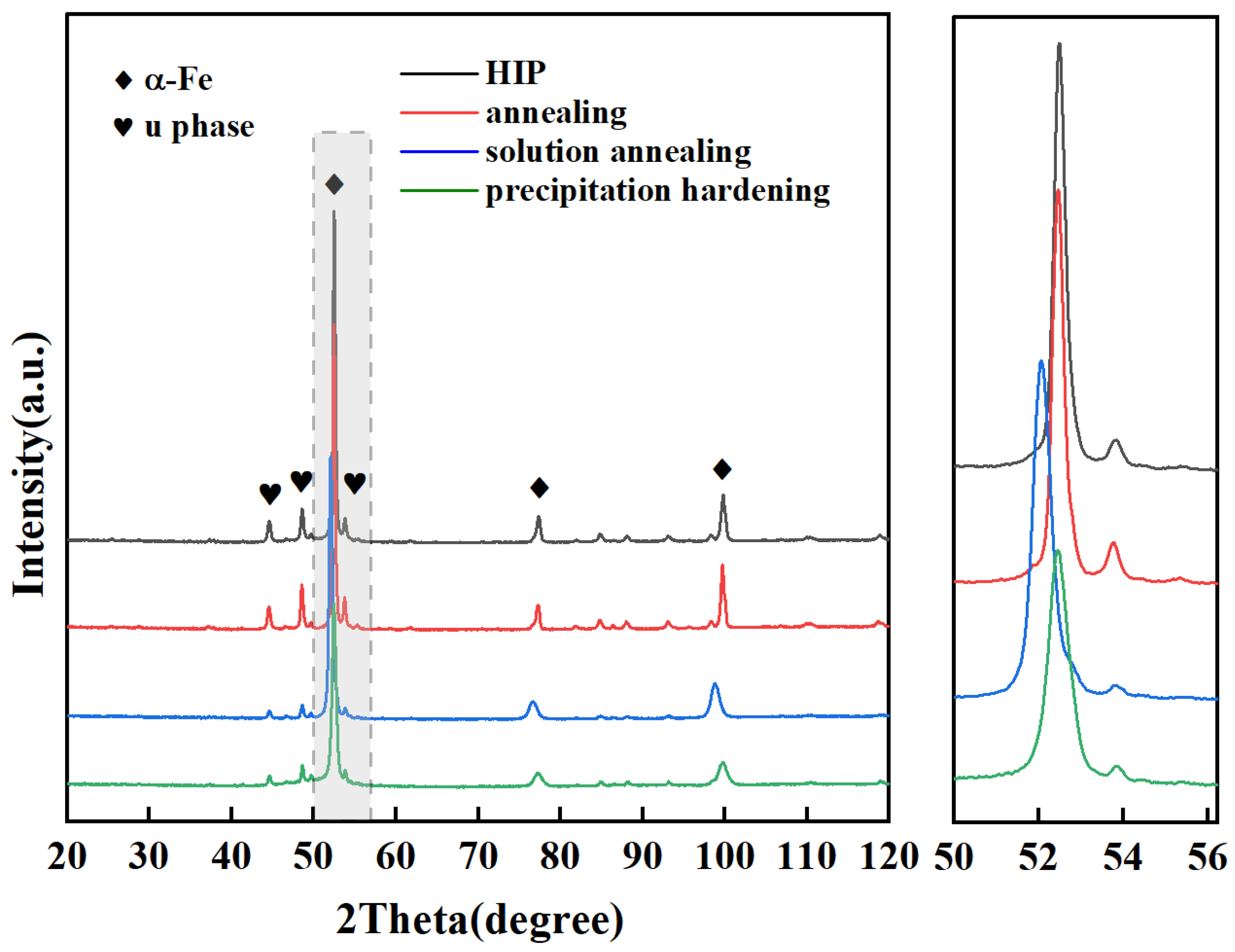

3.1. Effect of Sintering Temperature on Microstructure and Mechanical Properties

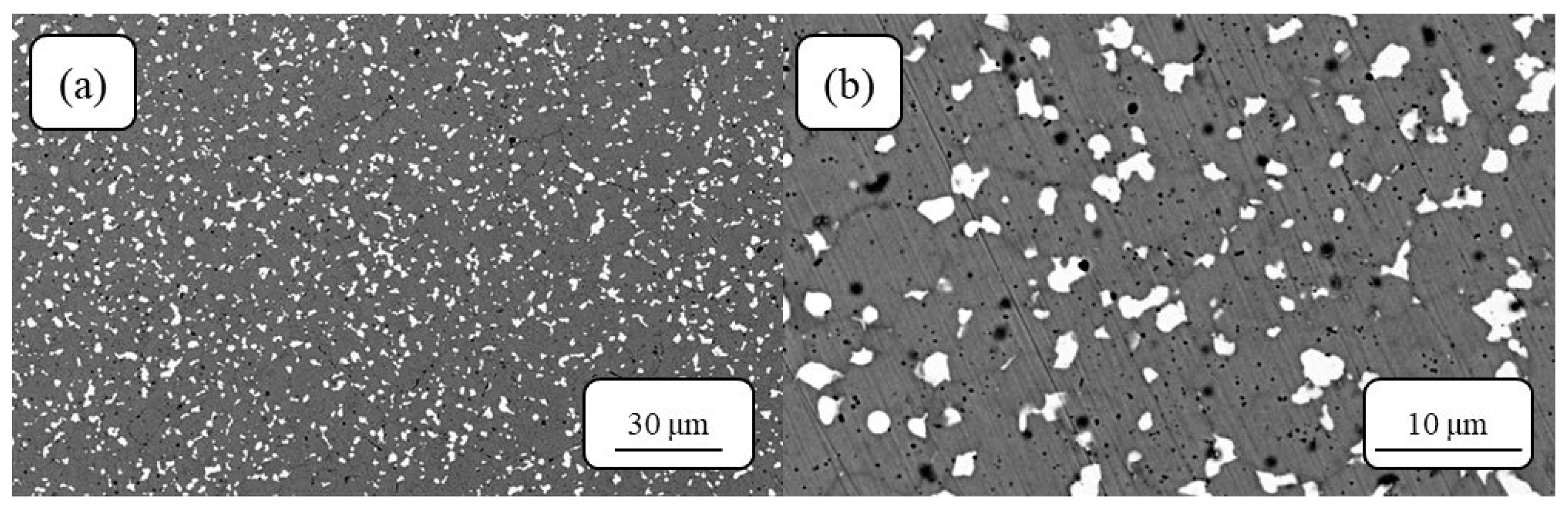

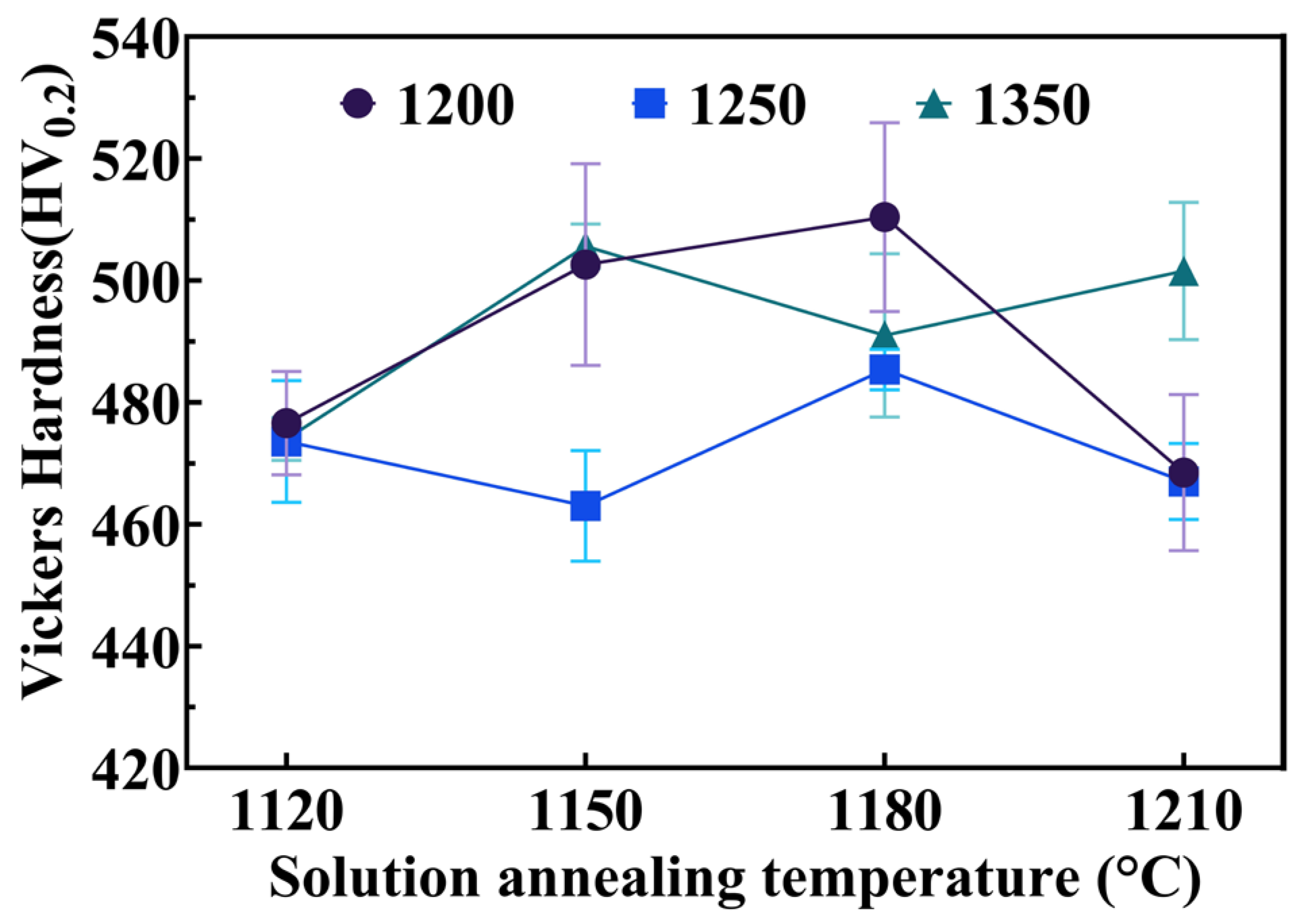

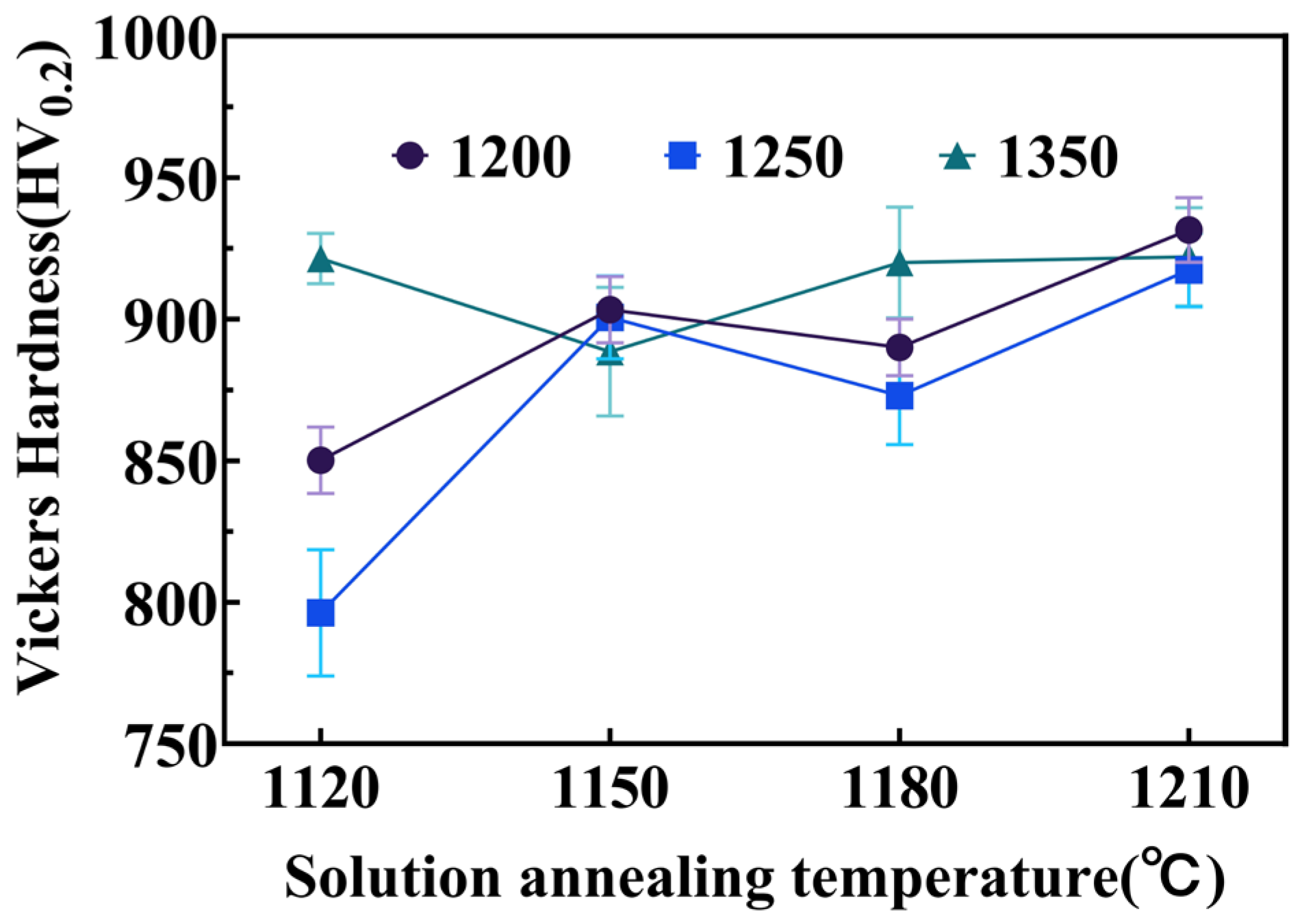

3.2. Effect of Solution Annealing Temperature on Microstructure and Mechanical Properties

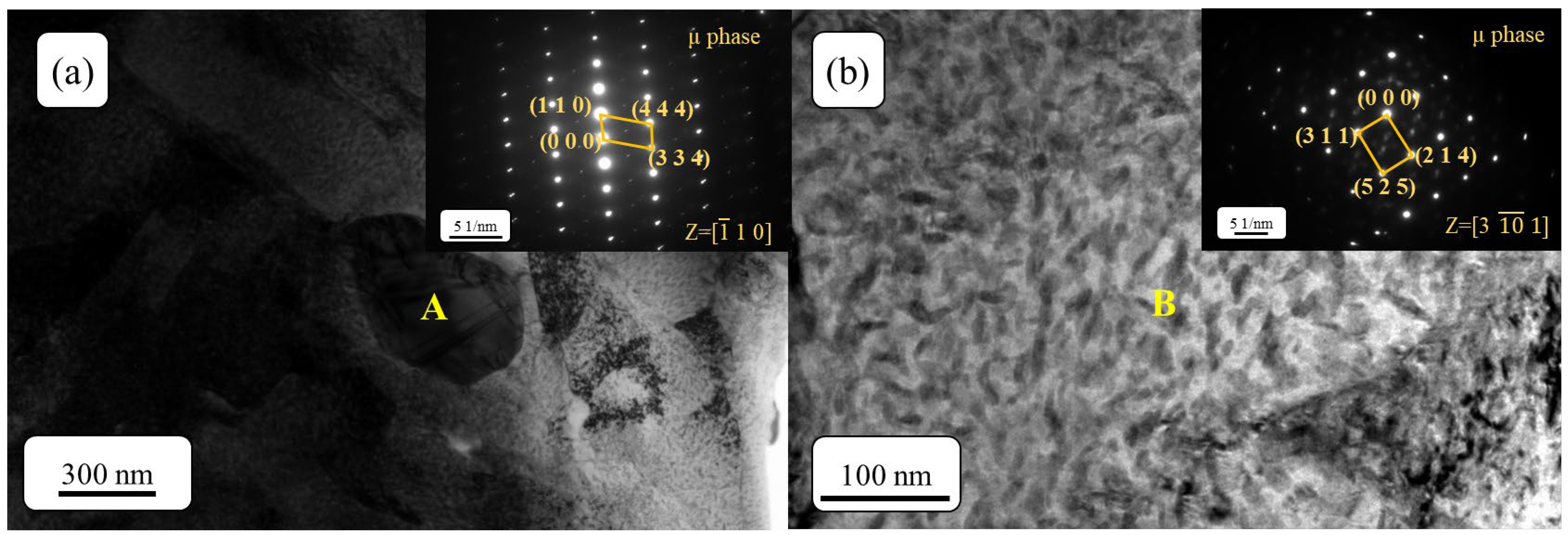

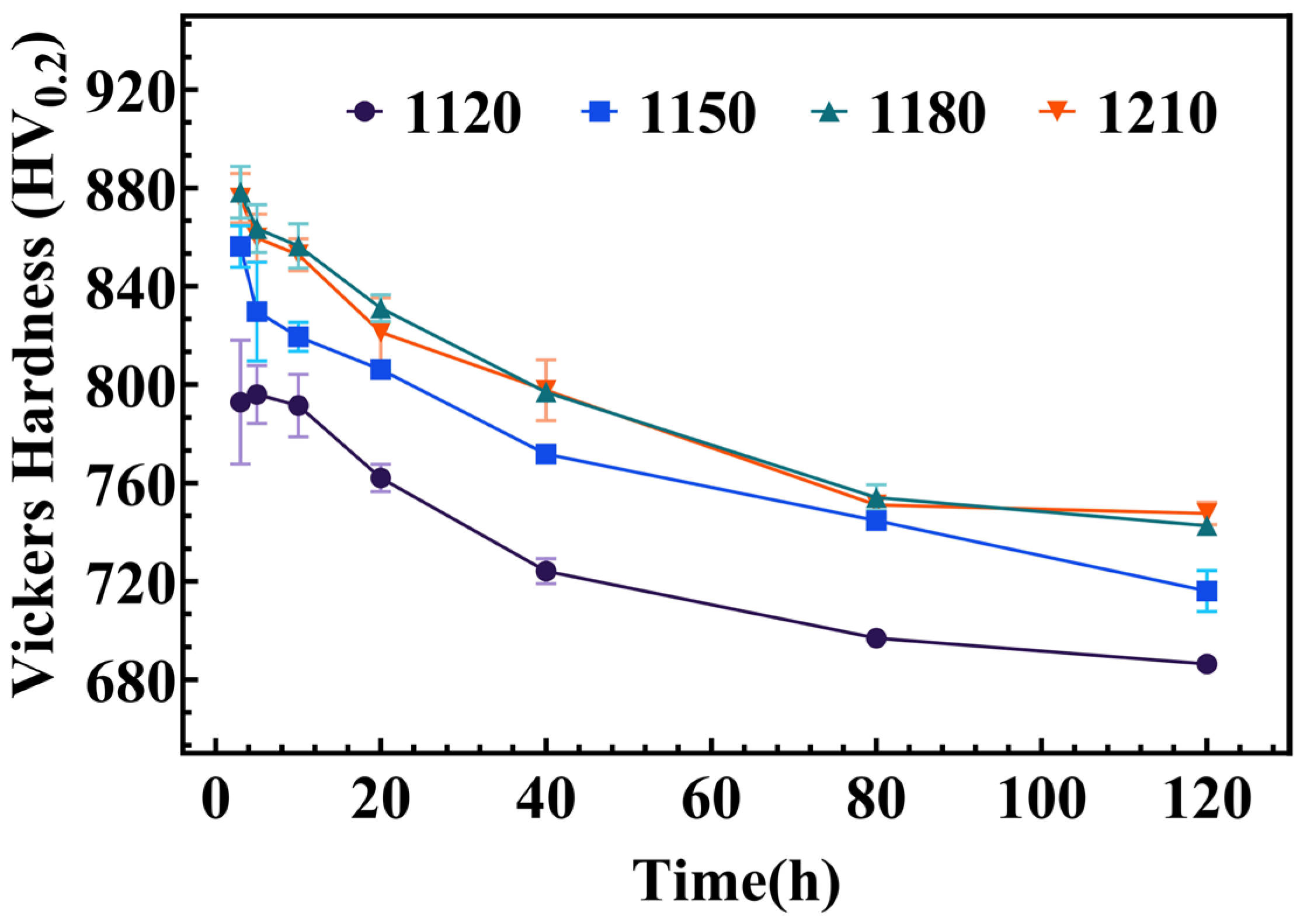

3.3. The Microstructure and Mechanical Properties After Precipitation Hardening

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Eidenberger, E.; Stergar, E.; Leitner, H. Combined use of small-angle neutron scattering and atom probe tomography for the analysis of precipitates in a Fe-15 m% Co-25 m% Mo alloy. Appl. Phys. A 2009, 97, 331–340. [Google Scholar] [CrossRef]

- Eidenberger, E.; Schober, M.; Schmoelzer, T. Analysis of the multistage phase separation reaction in Fe–25 at% Co–9 at% Mo. Phys. Status Solidi A 2010, 207, 2238–2246. [Google Scholar] [CrossRef]

- Galimberti, P.; Lay, S.; Antoni-Zdziobek, A. Precipitation and age-hardening in the Fe–27Co–8Mo alloy. Intermetallics 2012, 22, 33–40. [Google Scholar] [CrossRef]

- Yuan, Z.; He, Y.; Xie, F.; Kang, X. Effects of Ti(C,N) additions on the microstructure and properties of the carbon-free high speed steel reinforced by intermetallic compounds. Intermetallics 2022, 152, 11–16. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, M.; Chen, Y.; Si, Z.; Zhang, D. Effects of sintering temperatures on the microstructure and mechanical properties of S390 powder metallurgy high-speed steel. Front. Mater. 2023, 10, 1198776. [Google Scholar] [CrossRef]

- Gao, L.; Xu, C.; Ge, X.; Hu, Q.; Wang, X.; Meng, Y.; Lu, S.; Liu, B. Study on microstructure and properties between alloy steel and powder steel via hot isostatic pressing diffusion bonding. Mater. Today Commun. 2024, 41, 110390. [Google Scholar] [CrossRef]

- Povoden-Karadeniz, E.; Eidenberger, E.; Lang, P.; Stechauner, G.; Leitner, H.; Kozeschnik, E. Simulation of precipitate evolution in Fe-25Co-15Mo with Si addition based on computational thermodynamics. J. Alloys Compd. 2014, 587, 158–170. [Google Scholar] [CrossRef]

- Cui, C.; Leitner, H.; Platl, J.; Schnitzer, R. Influence of platform preheating on in situ precipitation in an FeCoMo alloy during laser powder bed fusion. Mater. Charact. 2023, 197, 112689. [Google Scholar] [CrossRef]

- Yermolenko, I.Y.; Ved, M.V.; Sakhnenko, N.D.; Sachanova, Y.I. Composition, Morphology, and Topography of Galvanic Coatings Fe-Co-W and Fe-Co-Mo. Nanoscale Res. Lett. 2017, 12, 352. [Google Scholar] [CrossRef]

- Danninger, H.; Rouzbahani, F.; Harold, C.; Ponemayr, H.; Daxelmüller, M.; Simančík, F.; Iždinský, K. Powder metallurgy carbon free tool steels Fe-Co-Mo with varying Co and Mo contents. Powder Metall. Prog. 2013, 13, 47–56. Available online: https://www.researchgate.net/publication/313854219_POWDER_METALLURGY_CARBON_FREE_TOOL_STEELS_Fe-Co-_Mo_WITH_VARYING_Co_AND_Mo_CONTENTS (accessed on 4 December 2024).

- Leitner, H.; Schober, M.; Clemens, H.; Caliskanoglu, D.; Danoix, F. Precipitation behaviour of an Fe-Co-Mo-alloy during nonisothermal ageing. Int. J. Mater. Res. 2008, 99, 367–374. [Google Scholar] [CrossRef]

- Platl, J.; Rainer, D.; Leitner, H.; Turk, C.; Galbusera, F.; Demir, A.G.; Previtali, B.; Schnitzer, R. Potential Causes for Cracking of a Laser Powder Bed Fused Carbon-free FeCoMo Alloy. Berg-Und Hüttenmännische Monatshefte 2022, 167, 325–331. [Google Scholar] [CrossRef]

- Turk, C.; Leitner, H.; Schemmel, I.; Clemens, H.; Primig, S. Atom probe study of B2 order and A2 disorder of the FeCo matrix in an Fe-Co-Mo-alloy. Micron 2017, 98, 24–33. [Google Scholar] [CrossRef] [PubMed]

- Turk, C.; Leitner, H.; Kellezi, G.; Clemens, H.; Gan, W.M.; Staron, P.; Primig, S. Impact of the B2 ordering behavior on the mechanical properties of a FeCoMo alloy. Mater. Sci. Eng. A 2016, 662, 511–518. [Google Scholar] [CrossRef]

- Bao, Y.; Guo, L.; Zhong, C.; Song, Q.; Yang, K.; Jiang, Y.; Wang, Z. Microstructure and Wear Resistance of Fe4CoCrNiB0.2Mox (x = 0, 0.5, 1) High Entropy Alloys. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2022, 37, 261–269. [Google Scholar] [CrossRef]

- Eidenberger, E.; Schober, M.; Stergar, E.; Leitner, H.; Clemens, H. Precipitation Behavior of Fe-25 At. Pct Co-9 At. Pct Mo Investigated by In-Situ Small-Angle Neutron Scattering and Complementary Methods. Metall. Mater. Trans. A 2010, 41, 1230–1234. [Google Scholar] [CrossRef]

- Houserová, J.; Včeřál, J.; Šob, M. Phase diagram calculations in the Co–Mo and Fe–Mo systems using first-principles results for the sigma phase. CALPHAD-Comput. Coupling Phase Diagr. Thermochem. 2005, 29, 133–139. [Google Scholar] [CrossRef]

- Liu, Q.; Su, Q.; Cheng, W.; Ding, J.; Zhang, W.; Wang, J.; Wang, Y.; Wang, X.; Huang, Y. Dual role of Fe boost lattice oxygen oxidation of Mo-based materials from kinetics and thermodynamics. Appl. Catal. B Environ. 2023, 340, 123188. [Google Scholar] [CrossRef]

- Mazilkin, A.; Abramova, M.M.; Enikeev, N.A.; Lomakin, I.V.; Valiev, R.Z.; Ivanisenko, Y. The effect of tungsten on microstructure and mechanical performance of an ultrafine Fe-Cr steel. Mater. Lett. 2018, 227, 292–295. [Google Scholar] [CrossRef]

- Pardal, J.M.; Tavares, S.S.M.; Fonseca, M.P.C.; Abreu, H.F.G.; Silva, J.J.M. Study of the austenite quantification by X-ray diffraction in the 18Ni-Co-Mo-Ti maraging 300 steel. J. Mater. Sci. 2006, 41, 2301–2307. [Google Scholar] [CrossRef]

- Wang, C.; Zheng, H.; Ding, H.; Hadjipanayis, G.C.; Wang, B.; Chen, J.; Cui, X. Effects of B addition on the microstructure and magnetic properties of Fe-Co-Mo alloys. J. Alloys Compd. 2018, 766, 355–362. [Google Scholar] [CrossRef]

- Xie, F.; He, Y.; Yuan, Z.; Kang, X. Microstructure and high-temperature sliding wear performance of Fe-Co-Mo alloy coating fabricated by plasma cladding. Surf. Coat. Technol. 2022, 444, 127429. [Google Scholar] [CrossRef]

- Li, M.; Peng, Z.; Shang, Y.; Liu, Y. Phase Equilibria in the Fe-Mo-Co System: Experimental Investigation and Thermodynamic Calculation. Coatings 2023, 13, 1215. [Google Scholar] [CrossRef]

| HIP Temperature (°C) | Density (g/cm3) | Relative Density (%) | Hardness (HV0.2) |

|---|---|---|---|

| 1200 | 8.30 | 99.40 | 473.1 ± 5.6 |

| 1250 | 8.32 | 99.64 | 506.6 ± 6.2 |

| 1350 | 8.34 | 99.99 | 592.0 ± 6.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, S.; Ge, X.; Hu, Q.; Gao, L.; Meng, Y.; Kuang, Y.; Lu, L. Precipitation and Age-Hardening in Fe-25Co-15Mo Carbon-Free High-Speed Steel via Hot Isostatic Pressing. Metals 2024, 14, 1400. https://doi.org/10.3390/met14121400

Lu S, Ge X, Hu Q, Gao L, Meng Y, Kuang Y, Lu L. Precipitation and Age-Hardening in Fe-25Co-15Mo Carbon-Free High-Speed Steel via Hot Isostatic Pressing. Metals. 2024; 14(12):1400. https://doi.org/10.3390/met14121400

Chicago/Turabian StyleLu, Shiteng, Xueyuan Ge, Qipeng Hu, Lei Gao, Yuan Meng, Ya Kuang, and Lei Lu. 2024. "Precipitation and Age-Hardening in Fe-25Co-15Mo Carbon-Free High-Speed Steel via Hot Isostatic Pressing" Metals 14, no. 12: 1400. https://doi.org/10.3390/met14121400

APA StyleLu, S., Ge, X., Hu, Q., Gao, L., Meng, Y., Kuang, Y., & Lu, L. (2024). Precipitation and Age-Hardening in Fe-25Co-15Mo Carbon-Free High-Speed Steel via Hot Isostatic Pressing. Metals, 14(12), 1400. https://doi.org/10.3390/met14121400