Aging Treatment to Enhance Coercivity Through Grain Boundary Modification in SmFe10V2 Bulk Magnets

Abstract

1. Introduction

2. Experiments

3. Experimental Results and Discussion

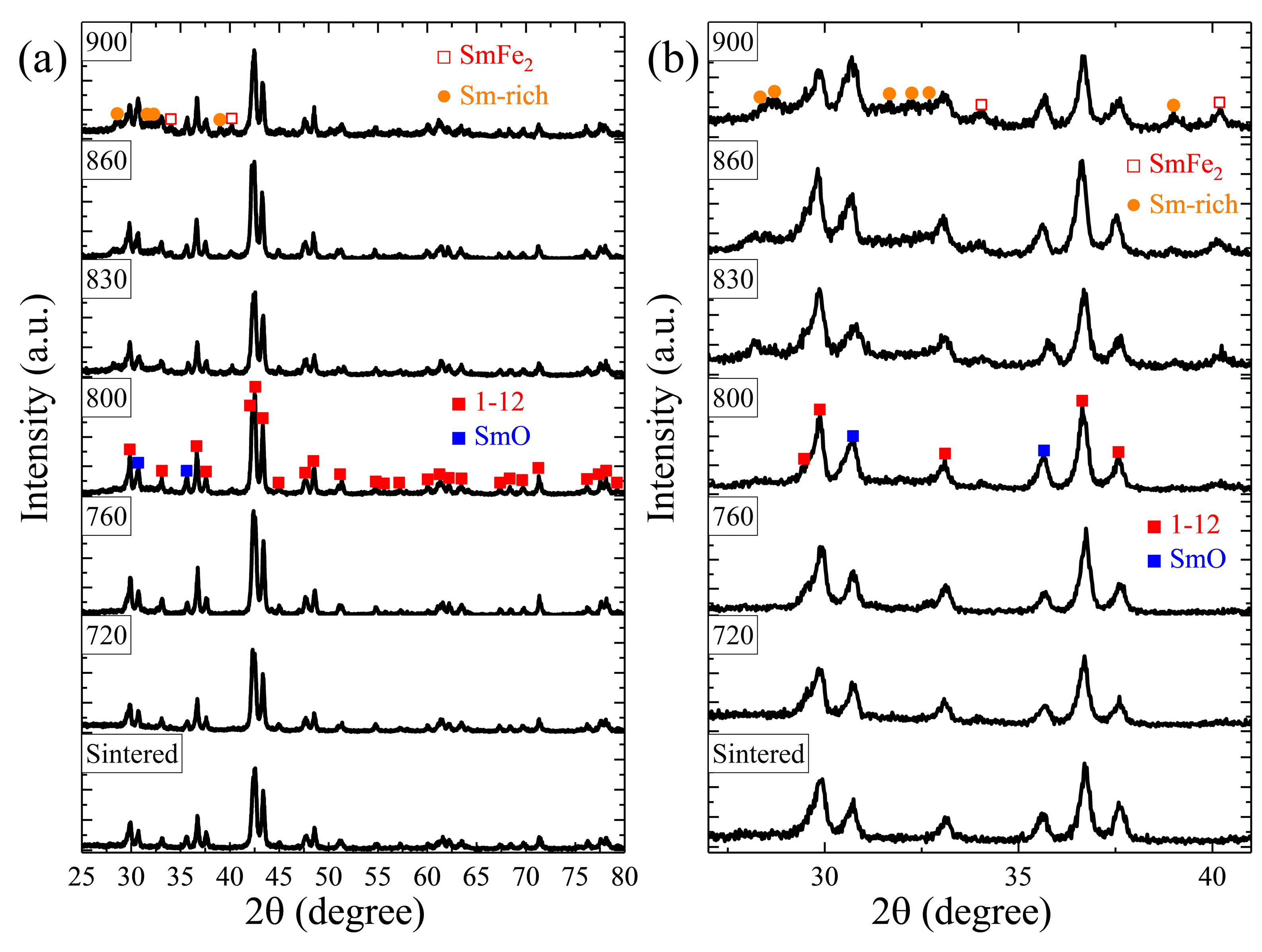

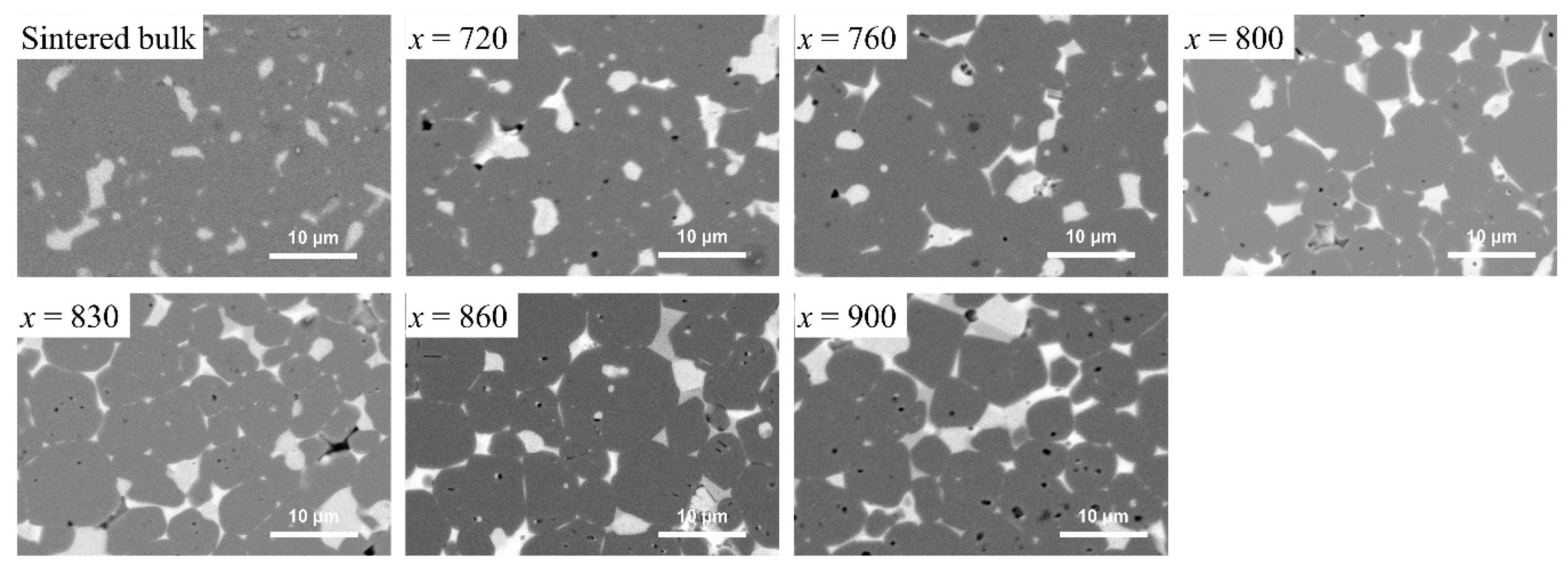

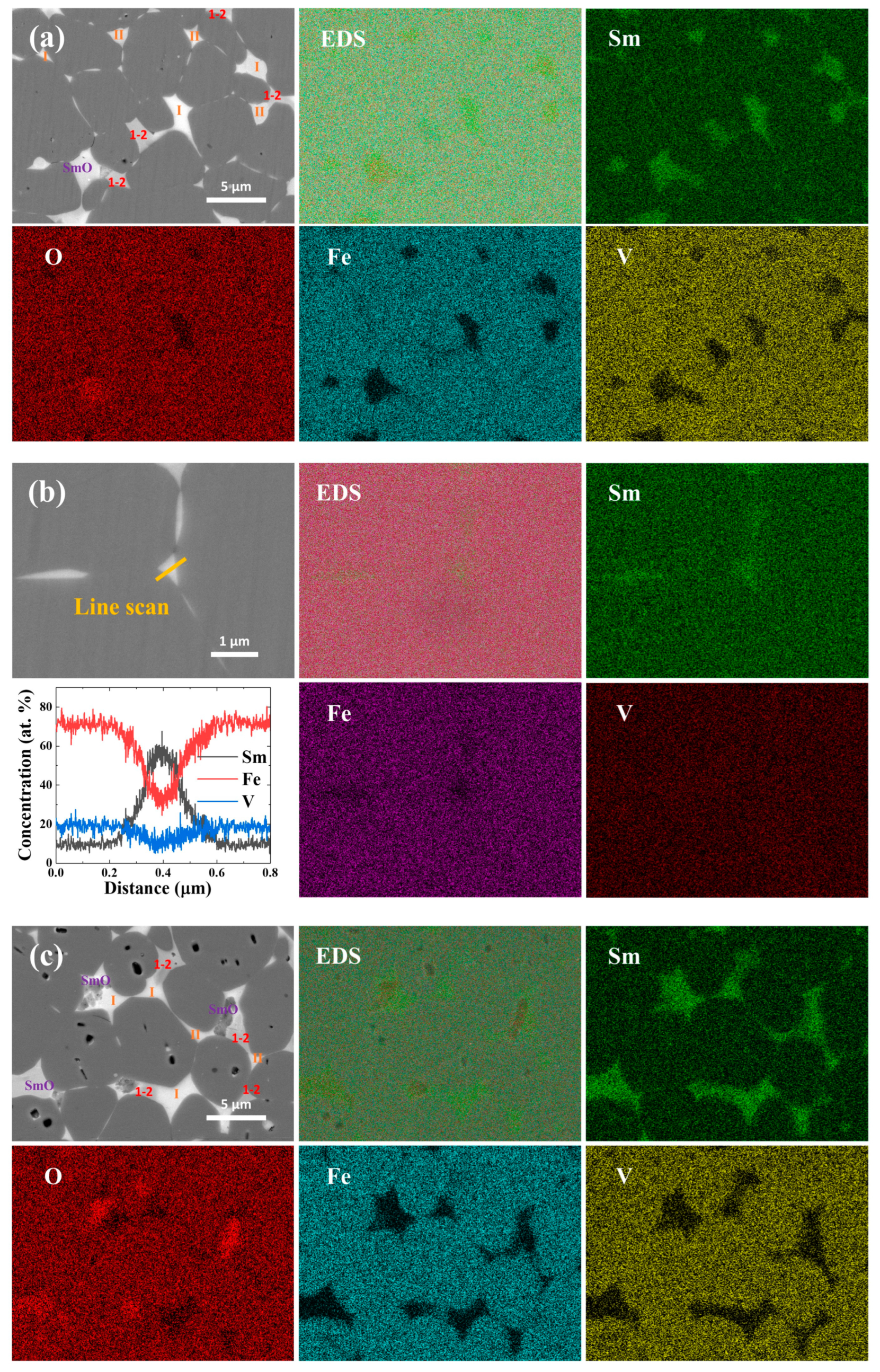

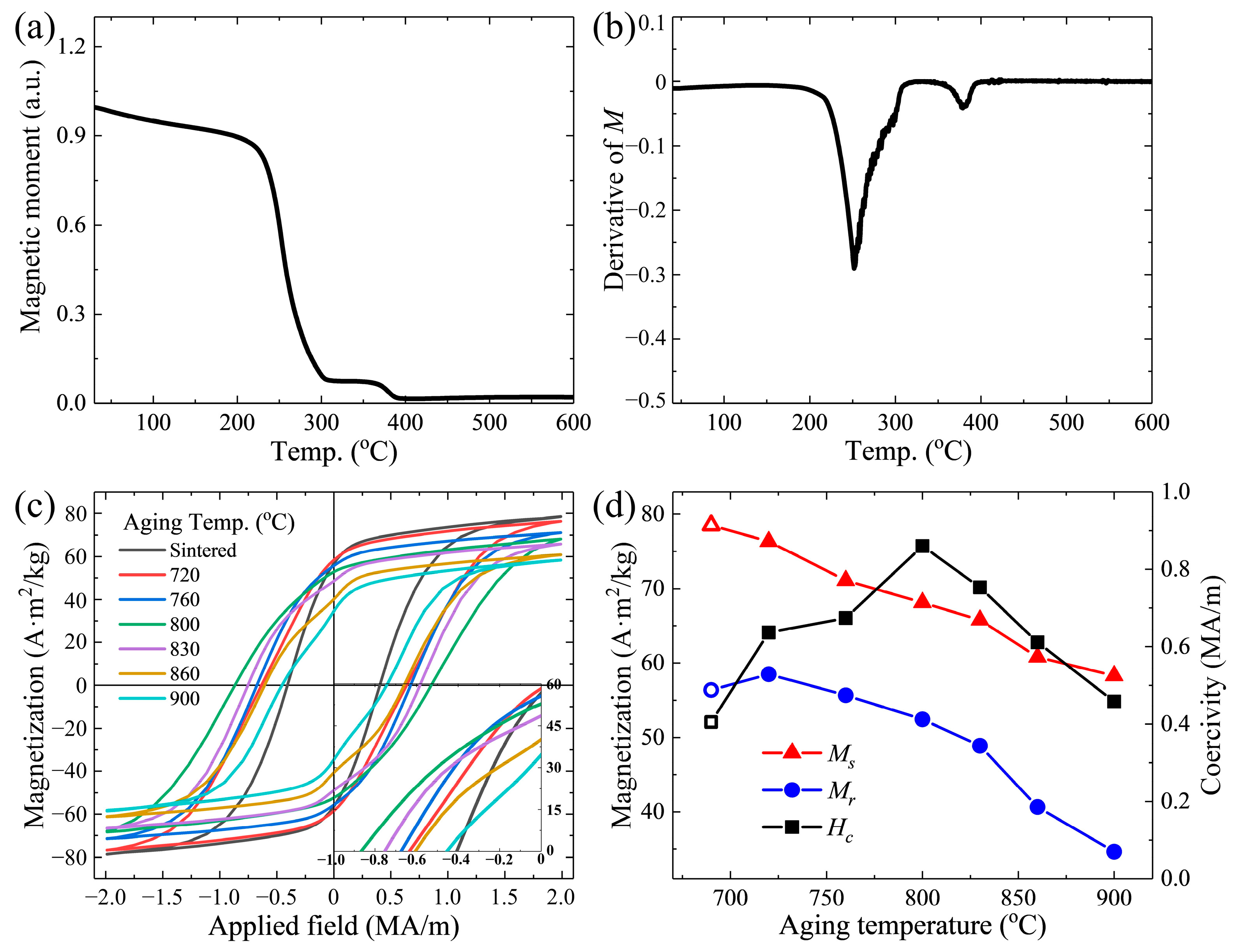

3.1. Aging Temperature Dependence

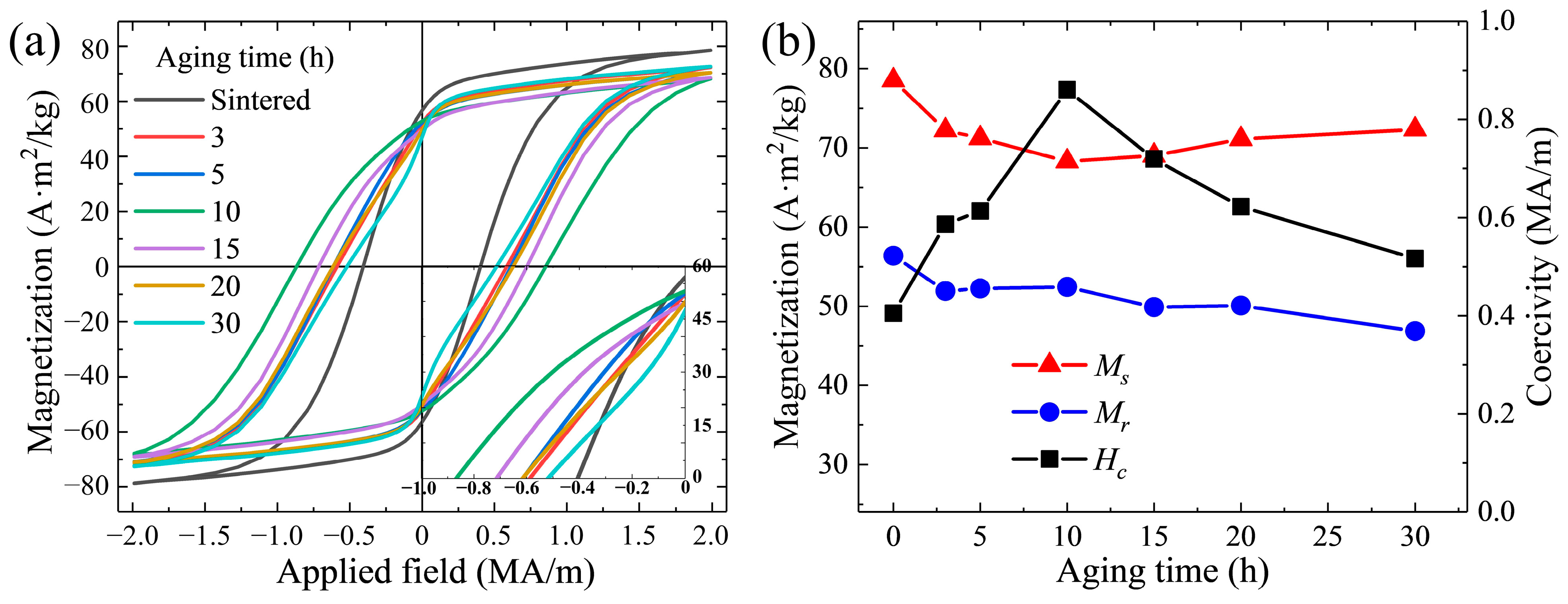

3.2. Aging Time Dependence

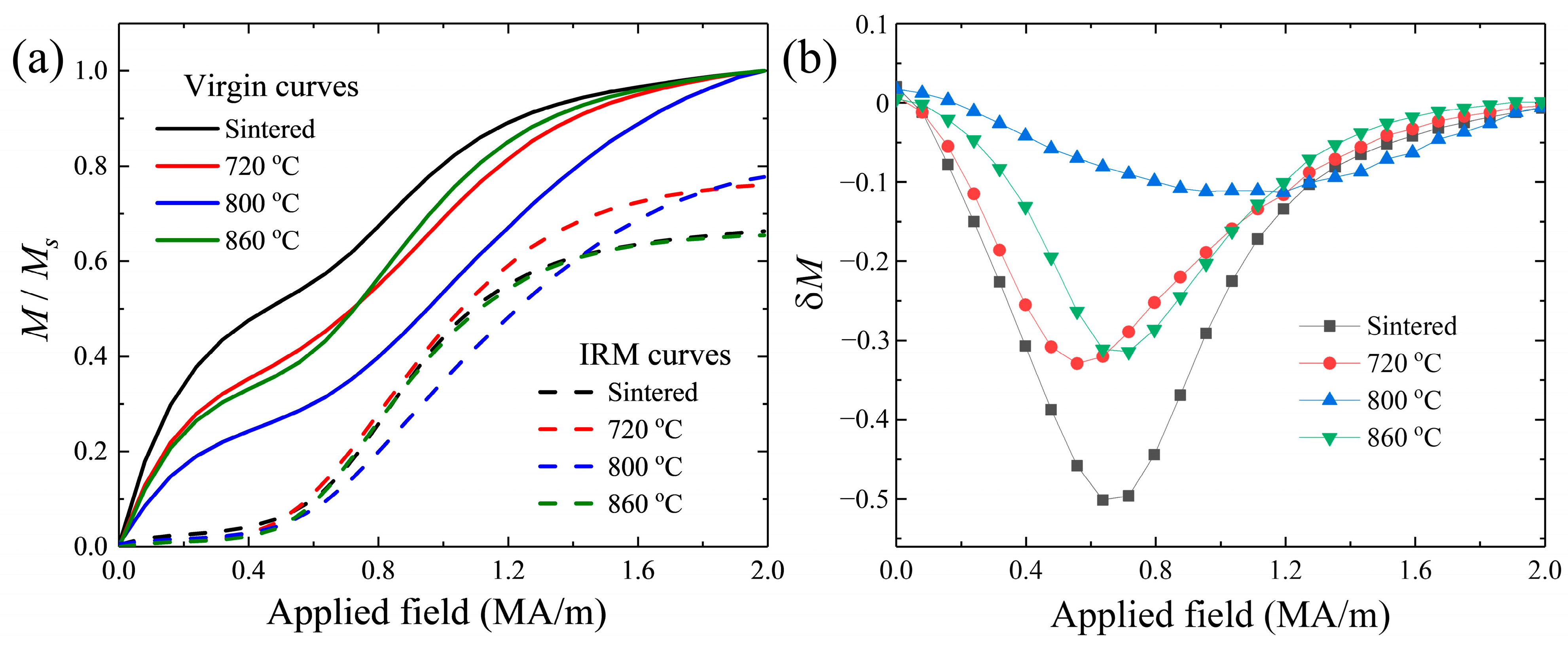

3.3. Discussion of Hc Enhancement Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hadjipanayis, G.C.; Gabay, A.M.; Schönhöbel, A.M.; Martín-Cid, A.; Barandiaran, J.M.; Niarchos, D. ThMn12-Type Alloys for Permanent Magnets. Engineering 2020, 6, 141–147. [Google Scholar] [CrossRef]

- Gabay, A.M.; Hadjipanayis, G.C. Recent Developments in RFe12-Type Compounds for Permanent Magnets. Scr. Mater. 2018, 154, 284–288. [Google Scholar] [CrossRef]

- Makurenkova, A.; Ogawa, D.; Tozman, P.; Okamoto, S.; Nikitin, S.; Hirosawa, S.; Hono, K.; Takahashi, Y.K. Intrinsic Hard Magnetic Properties of Sm(Fe,Co)12−xTix Compound with ThMn12 Structure. J. Alloys Compd. 2021, 861, 158477. [Google Scholar] [CrossRef]

- Coehoorn, R. Electronic Structure and Magnetism of Transition-Metal-Stabilized YFe12−xMx Intermetallic Compounds. Phys. Rev. B 1990, 41, 11790–11797. [Google Scholar] [CrossRef]

- De Mooij, D.B.; Buschow, K.H.J. Some Novel Ternary ThMn12-Type Compounds. J. Less Common Met. 1988, 136, 207–215. [Google Scholar] [CrossRef]

- Dirba, I.; Harashima, Y.; Sepehri-Amin, H.; Ohkubo, T.; Miyake, T.; Hirosawa, S.; Hono, K. Thermal Decomposition of ThMn12-Type Phase and Its Optimum Stabilizing Elements in SmFe12-Based Alloys. J. Alloys Compd. 2020, 813, 152224. [Google Scholar] [CrossRef]

- Tozman, P.; Fukazawa, T.; Ogawa, D.; Sepehri-Amin, H.; Bolyachkin, A.; Miyake, T.; Hirosawa, S.; Hono, K.; Takahashi, Y.K. Peculiar Behavior of V on the Curie Temperature and Anisotropy Field of SmFe12-xVx Compounds. Acta Mater. 2022, 232, 117928. [Google Scholar] [CrossRef]

- Zhang, J.S.; Tang, X.; Sepehri-Amin, H.; Srinithi, A.K.; Ohkubo, T.; Hono, K. Origin of Coercivity in an Anisotropic Sm(Fe,Ti,V)12-Based Sintered Magnet. Acta Mater. 2021, 217, 117161. [Google Scholar] [CrossRef]

- Zhou, T.H.; Song, Y.; Zhang, B.; Zheng, X.; Choi, C.-J.; Cho, Y.-R.; Park, J. Enhancing Coercivity through Grain Boundary Phase Modification in SmxFe10V2. J. Mater. Res. Technol. 2024, 30, 3092–3100. [Google Scholar] [CrossRef]

- Schönhöbel, A.M.; Madugundo, R.; Gabay, A.M.; Barandiarán, J.M.; Hadjipanayis, G.C. The Sm-Fe-V Based 1:12 Bulk Magnets. J. Alloys Compd. 2019, 791, 1122–1127. [Google Scholar] [CrossRef]

- Palanisamy, D.; Ener, S.; Maccari, F.; Schäfer, L.; Skokov, K.P.; Gutfleisch, O.; Raabe, D.; Gault, B. Grain Boundary Segregation, Phase Formation, and Their Influence on the Coercivity of Rapidly Solidified SmFe11Ti Hard Magnetic Alloys. Phys. Rev. Mater. 2020, 4, 054404. [Google Scholar] [CrossRef]

- Sugimoto, S.; Shimono, T.; Nakamura, H.; Kagotani, T.; Okada, M.; Homma, M. Phase Relation of Sm–Fe–V Alloys around the Compound Sm3(Fe,V)29. Mater. Trans. JIM 1996, 37, 494–498. [Google Scholar] [CrossRef]

- Tozman, P.; Sepehri-Amin, H.; Abe, T.; Hono, K.; Takahashi, Y.K. Exploring Secondary Phases in the Sm–Fe–V System Beneficial for Coercivity. Acta Mater. 2023, 258, 119197. [Google Scholar] [CrossRef]

- Schönhöbel, A.M.; Madugundo, R.; Barandiarán, J.M.; Hadjipanayis, G.C.; Palanisamy, D.; Schwarz, T.; Gault, B.; Raabe, D.; Skokov, K.; Gutfleisch, O.; et al. Nanocrystalline Sm-Based 1:12 Magnets. Acta Mater. 2020, 200, 652–658. [Google Scholar] [CrossRef]

- Zhao, L.; Li, C.; Zhang, X.; Bandaru, S.; Su, K.; Liu, X.; Zhou, Q.; Li, L.; Greneche, J.-M.; Jin, J.; et al. Effects of Sm Content on the Phase Structure, Microstructure and Magnetic Properties of the SmxZr0.2(Fe0.8Co0.2)11.5Ti0.5 (x = 0.8 − 1.4) Alloys. J. Alloys Compd. 2020, 828, 154428. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, Y.; Jia, W.; Song, X.; Xiao, A.; Yuan, T.; Wang, F.; Fan, J.; Ma, T. Revisiting the Pinning Sites in 2:17-Type Sm-Co-Fe-Cu-Zr Permanent Magnets. J. Rare Earths 2021, 39, 1560–1566. [Google Scholar] [CrossRef]

- Dong, C.H.; Wu, H.C.; Liu, L.; Xu, D.S.; Zhou, B.; Sun, Y.L.; Ding, Y.; Liang, J.C.; Yan, A.R. Growth of Defects around Grain Boundary and Evolution of Cellular Structure during Isothermal Aging Process in 2:17-Type SmCo Permanent Magnets. J. Magn. Magn. Mater. 2024, 593, 171823. [Google Scholar] [CrossRef]

- Zhou, T.H.; Zhang, B.; Zheng, X.; Song, Y.; Si, P.; Choi, C.-J.; Cho, Y.-R.; Park, J. Anisotropic SmFe10V2 Bulk Magnets with Enhanced Coercivity via Ball Milling Process. Nanomaterials 2024, 14, 1329. [Google Scholar] [CrossRef]

- Srinithi, A.K.; Tang, X.; Sepehri-Amin, H.; Zhang, J.; Ohkubo, T.; Hono, K. High-Coercivity SmFe12-Based Anisotropic Sintered Magnets by Cu Addition. Acta Mater. 2023, 256, 119111. [Google Scholar] [CrossRef]

- Samata, H.; Fujiwara, N.; Nagata, Y.; Uchida, T.; Lan, M.D. Crystal Growth and Magnetic Properties of SmFe2. Jpn. J. Appl. Phys. 1998, 37, 5544. [Google Scholar] [CrossRef]

- Yao, Y.F.; Hou, Y.H.; Li, H.F.; Chai, W.X.; Wu, Z.J.; Feng, Q.; Li, W.; Pang, Z.S.; Ma, L.; Yu, H.B.; et al. Microstructure and Magnetic Properties of Exchange-Coupled Nanocomposite Sm0.75Zr0.25(Fe0.8Co0.2)11Ti Alloy. J. Magn. Magn. Mater. 2023, 571, 170578. [Google Scholar] [CrossRef]

- Kelly, P.; O’grady, K.; Mayo, P.; Chantrell, R. Switching Mechanisms in Cobalt-Phosphorus Thin Films. IEEE Trans. Magn. 1989, 25, 3881–3883. [Google Scholar] [CrossRef]

- Vieira, C.; Gomes, R.C.; Silva, F.; Dias, A.; Aquino, R.; Campos, A.; Depeyrot, J. Blocking and Remanence Properties of Weakly and Highly Interactive Cobalt Ferrite Based Nanoparticles. J. Phys. Condens. Matter 2019, 31, 175801. [Google Scholar] [CrossRef] [PubMed]

- García-Otero, J.; Porto, M.; Rivas, J. Henkel Plots of Single-Domain Ferromagnetic Particles. J. Appl. Phys. 2000, 87, 7376–7381. [Google Scholar] [CrossRef]

- Popov, A.G.; Gaviko, V.S.; Popov, V.V.; Golovnia, O.A.; Protasov, A.V.; Gerasimov, E.G.; Ogurtsov, A.V.; Sharin, M.K.; Gopalan, R. Structure and Magnetic Properties of Heat-Resistant Sm(Co0.796−xFe0.177CuxZr0.027)6.63 Permanent Magnets with High Coercivity. JOM 2019, 71, 559–566. [Google Scholar] [CrossRef]

- Tang, X.; Li, J.; Srinithi, A.K.; Sepehri-Amin, H.; Ohkubo, T.; Hono, K. Role of V on the Coercivity of SmFe12-Based Melt-Spun Ribbons Revealed by Machine Learning and Microstructure Characterizations. Scr. Mater. 2021, 200, 113925. [Google Scholar] [CrossRef]

- Bolyachkin, A.S.; Komogortsev, S.V. Power-Law Behavior of Coercivity in Nanocrystalline Magnetic Alloys with Grain-Size Distribution. Scr. Mater. 2018, 152, 55–58. [Google Scholar] [CrossRef]

- Bolyachkin, A.S.; Alekseev, I.V.; Andreev, S.V.; Volegov, A.S. δM Plots of Nanocrystalline Hard Magnetic Alloys. J. Magn. Magn. Mater. 2021, 529, 167886. [Google Scholar] [CrossRef]

- Li, W.F.; Ohkubo, T.; Hono, K.; Sagawa, M. The Origin of Coercivity Decrease in Fine Grained Nd–Fe–B Sintered Magnets. J. Magn. Magn. Mater. 2009, 321, 1100–1105. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Ohkubo, T.; Takada, Y.; Sato, T.; Kato, A.; Kaneko, Y.; Hono, K. Formation of Non-Ferromagnetic Grain Boundary Phase in a Ga-Doped Nd-Rich Nd–Fe–B Sintered Magnet. Scr. Mater. 2016, 113, 218–221. [Google Scholar] [CrossRef]

| Region | Element (at. %) | Phase | ||||

|---|---|---|---|---|---|---|

| Sm | Fe | V | O | |||

| Sintering | Gray | 8.31 | 75.17 | 16.52 | - | 1–12 |

| White | 48.96 | - | 3.85 | 47.19 | SmO | |

| x = 720 | Gray | 7.98 | 75.30 | 16.72 | - | 1–12 |

| x = 760 | 7.85 | 76.06 | 16.09 | |||

| x = 800 | 7.79 | 75.74 | 16.37 | |||

| x = 830 | 7.74 | 75.90 | 16.36 | |||

| x = 860 | 7.79 | 75.93 | 16.28 | |||

| x = 900 | 7.71 | 76.01 | 16.28 | |||

| Aging Temp. | Region | Element (at. %) | |||

|---|---|---|---|---|---|

| Sm | Fe | V | O | ||

| 800 °C | 1-2 | 36.9 | 63.1 | - | - |

| I | 79.9 | 15.1 | 5 | - | |

| II | 69.8 | 30.2 | - | - | |

| SmO | 49.3 | - | - | 50.7 | |

| 900 °C | 1-2 | 26.8 | 67.4 | 5.9 | - |

| I | 77.5 | 22.5 | - | - | |

| II | 42.5 | 46.3 | 11.2 | - | |

| SmO | 47.6 | - | - | 52.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, T.-H.; Zhang, B.; Zheng, X.; Song, Y.; Si, P.; Choi, C.-J.; Cho, Y.-R.; Park, J. Aging Treatment to Enhance Coercivity Through Grain Boundary Modification in SmFe10V2 Bulk Magnets. Metals 2024, 14, 1387. https://doi.org/10.3390/met14121387

Zhou T-H, Zhang B, Zheng X, Song Y, Si P, Choi C-J, Cho Y-R, Park J. Aging Treatment to Enhance Coercivity Through Grain Boundary Modification in SmFe10V2 Bulk Magnets. Metals. 2024; 14(12):1387. https://doi.org/10.3390/met14121387

Chicago/Turabian StyleZhou, Tian-Hong, Baochao Zhang, Xing Zheng, Youngwoon Song, Pingzhan Si, Chul-Jin Choi, Young-Rae Cho, and Jihoon Park. 2024. "Aging Treatment to Enhance Coercivity Through Grain Boundary Modification in SmFe10V2 Bulk Magnets" Metals 14, no. 12: 1387. https://doi.org/10.3390/met14121387

APA StyleZhou, T.-H., Zhang, B., Zheng, X., Song, Y., Si, P., Choi, C.-J., Cho, Y.-R., & Park, J. (2024). Aging Treatment to Enhance Coercivity Through Grain Boundary Modification in SmFe10V2 Bulk Magnets. Metals, 14(12), 1387. https://doi.org/10.3390/met14121387