Analysis of the Structure and Properties of As-Built and Heat-Treated Wire-Feed Electron Beam Additively Manufactured (WEBAM) Ti–4Al–3V Spherical Pressure Vessel

Abstract

1. Introduction

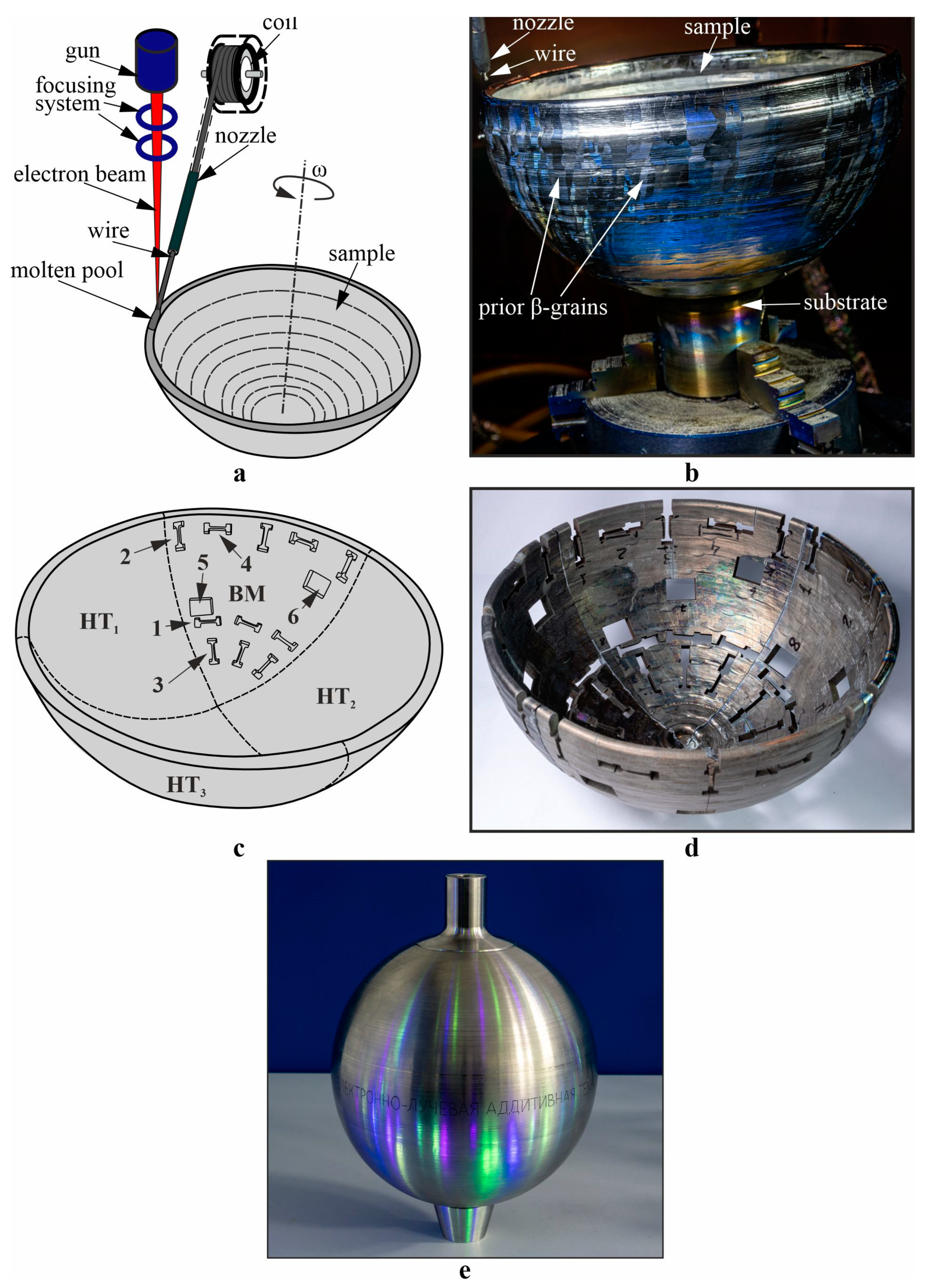

2. Materials and Methods

3. Results

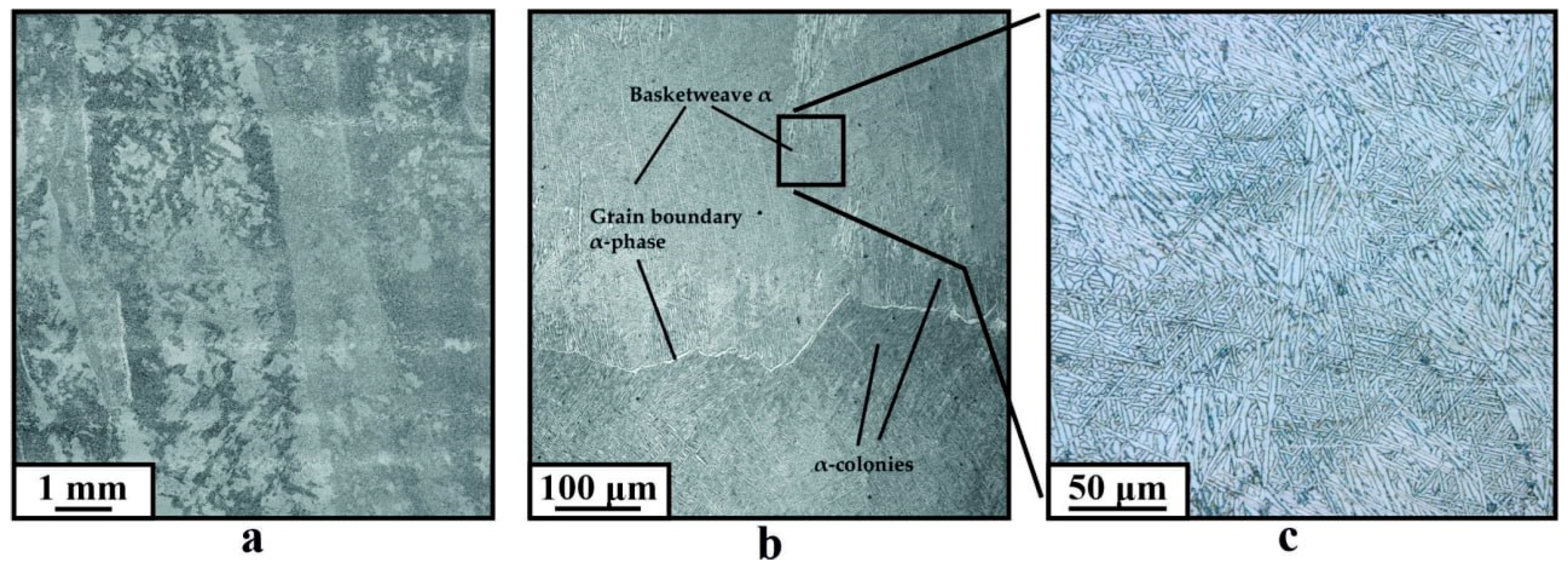

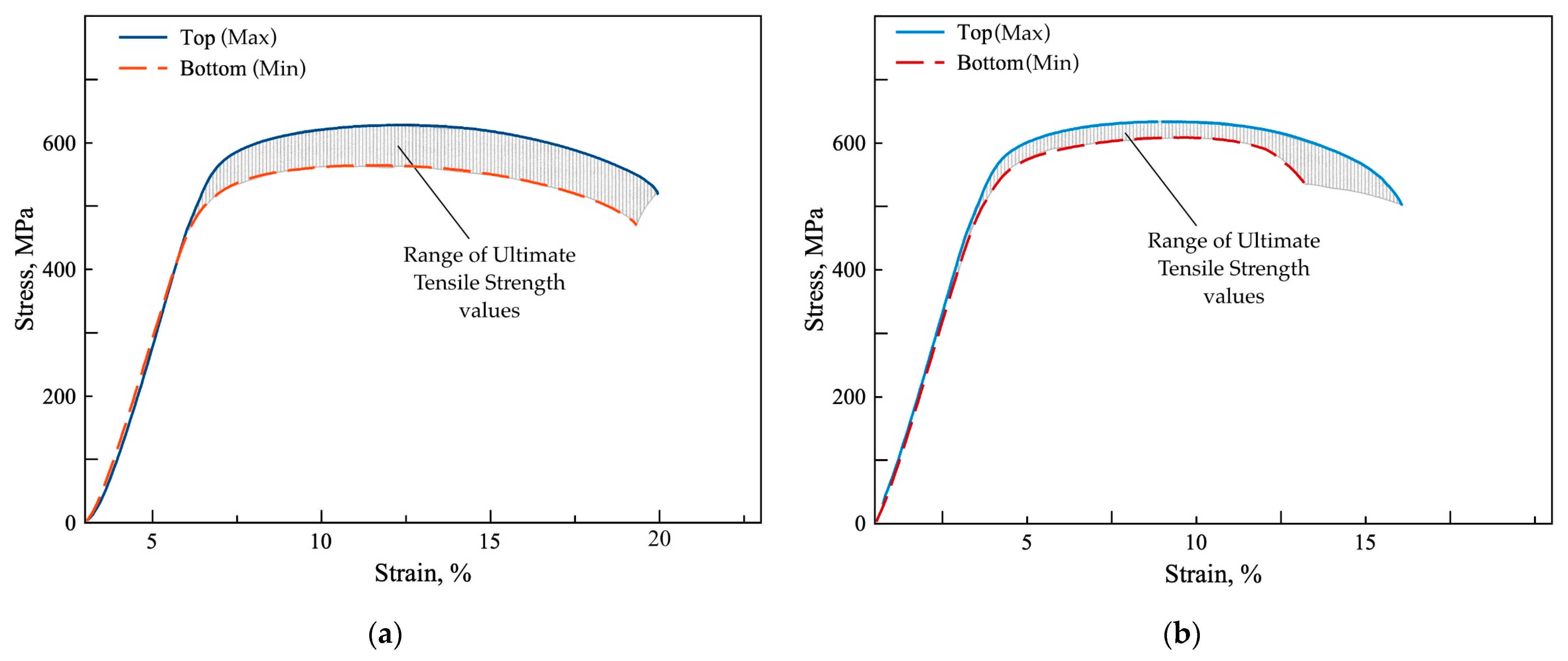

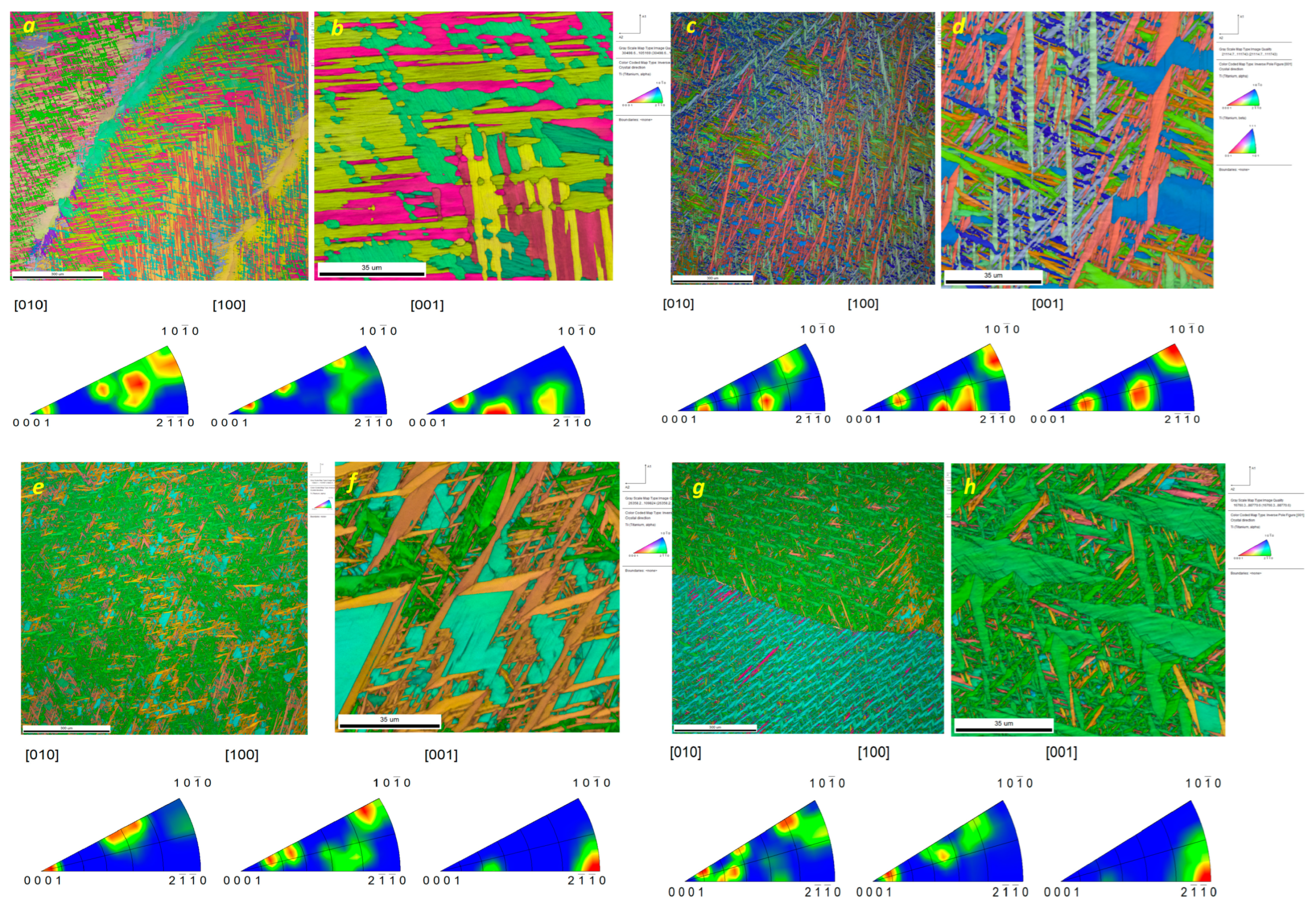

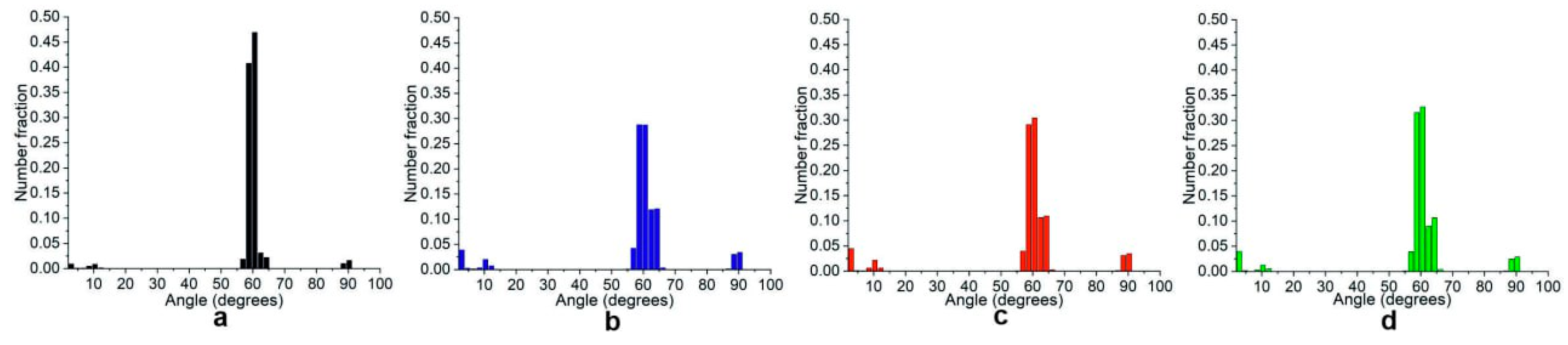

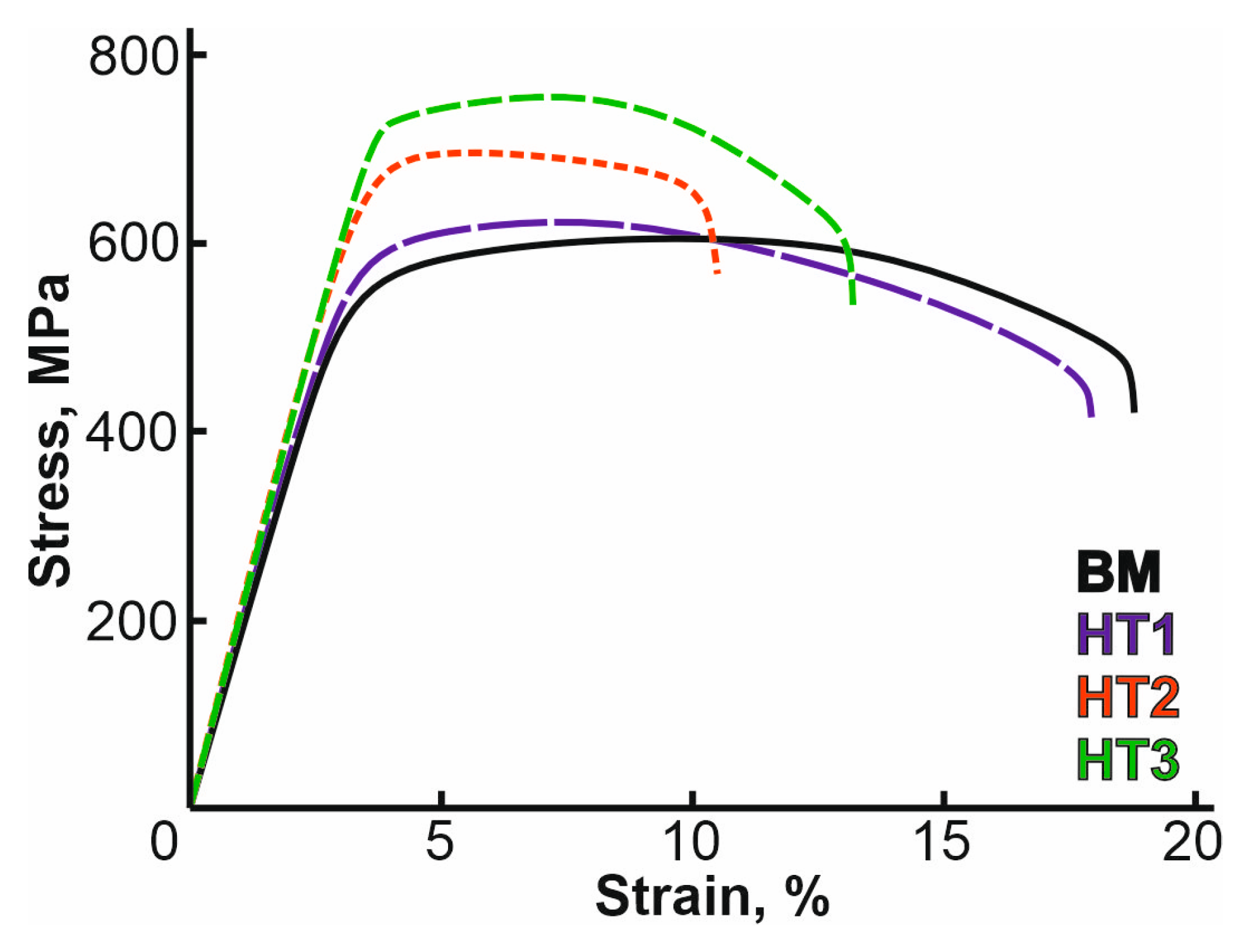

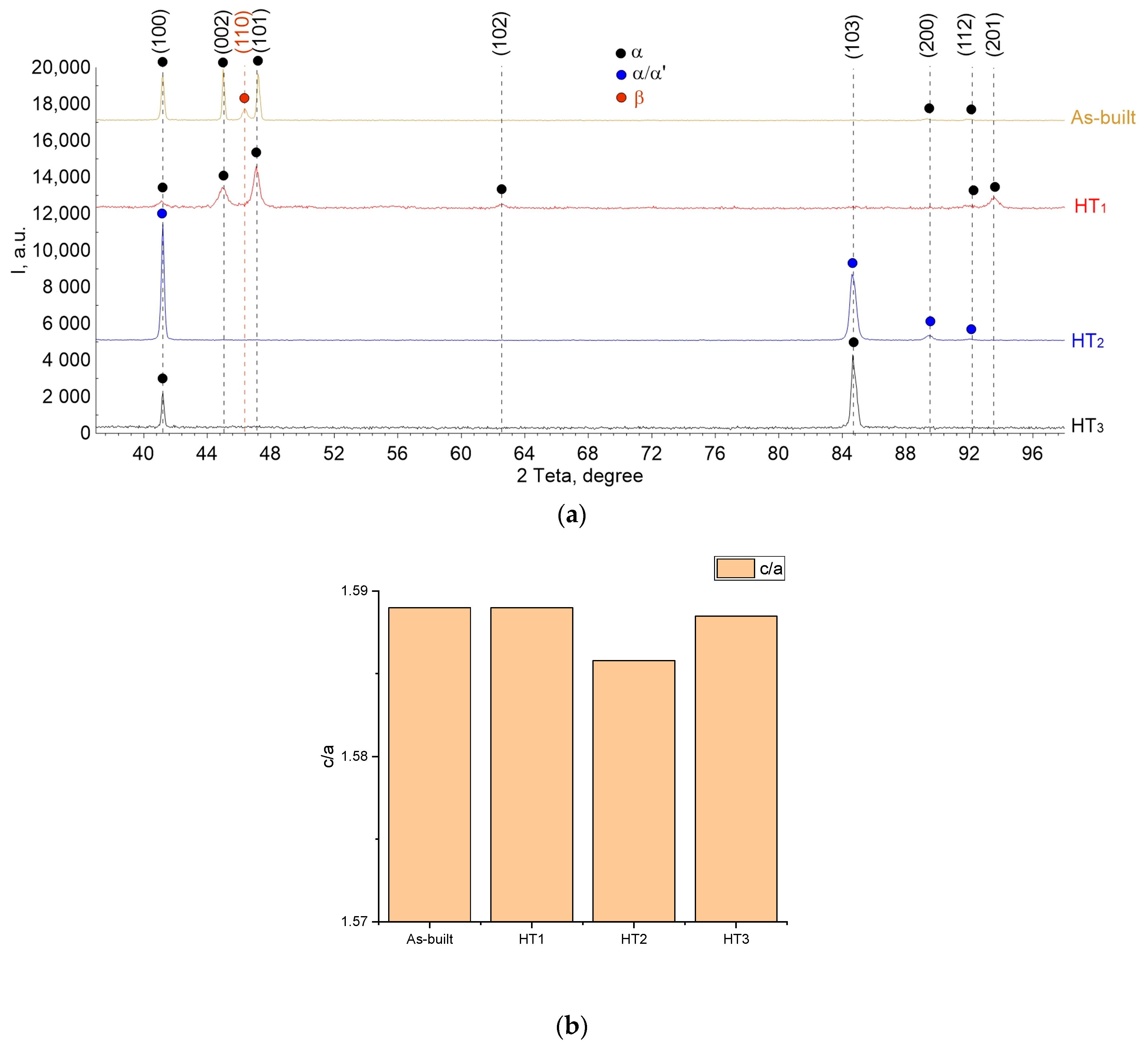

3.1. As-Built BM Material

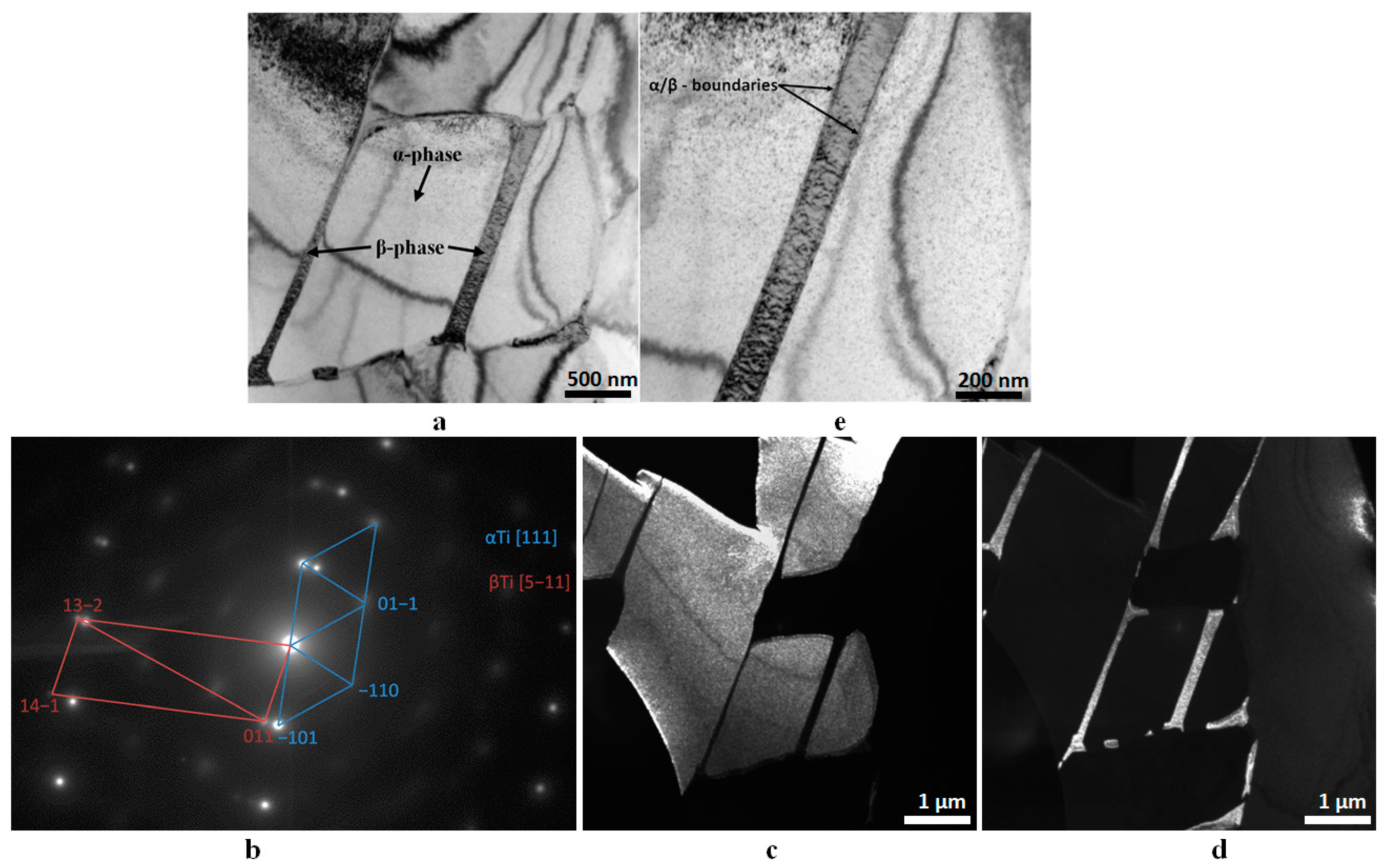

3.2. Heat-Treated Material

4. Discussion

5. Conclusions

- A pressure vessel fabricated by welding together two WEBAM-built hemispheres demonstrated its high resilience at a pressure twice as much as its working level.

- The method of wire-feed electron-beam additive manufacturing (WEBAM) allows for the production of a void-free product. However, the resulting material exhibits significantly reduced mechanical properties compared to those required for the Ti–4Al–3V alloy. This is attributed to the absence of active cooling and the complex printing path, which resulted in a material with an ultimate strength ranging from 582 to 632 MPa and a degree of anisotropy in mechanical properties reaching 7%.

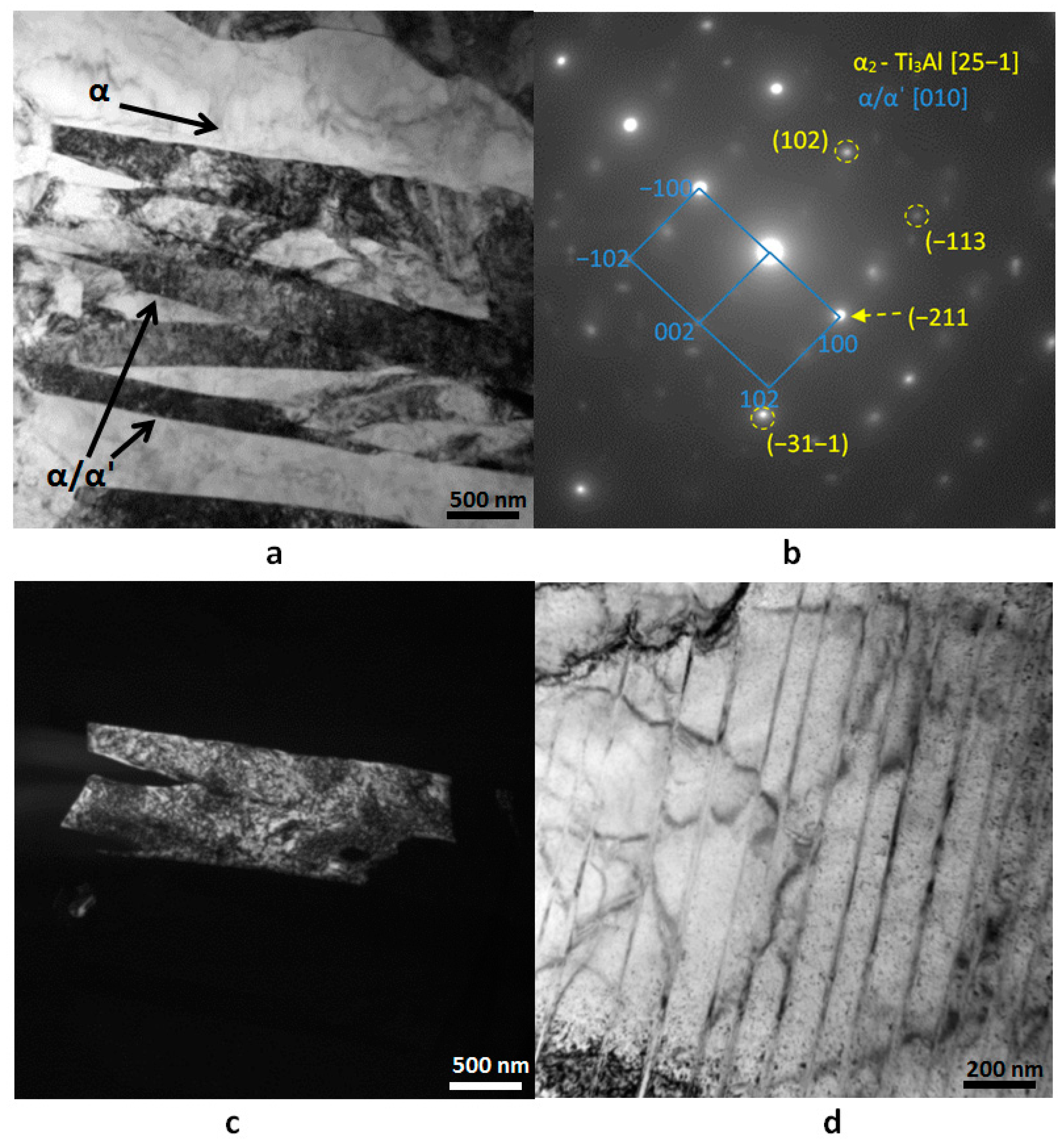

- The application of heat treatment in the form of subtransus annealing at 940 °C (HT1) resulted in β→α″ transformation and only a slight increase in the UTS. The degree of anisotropy was reduced to 4.5%.

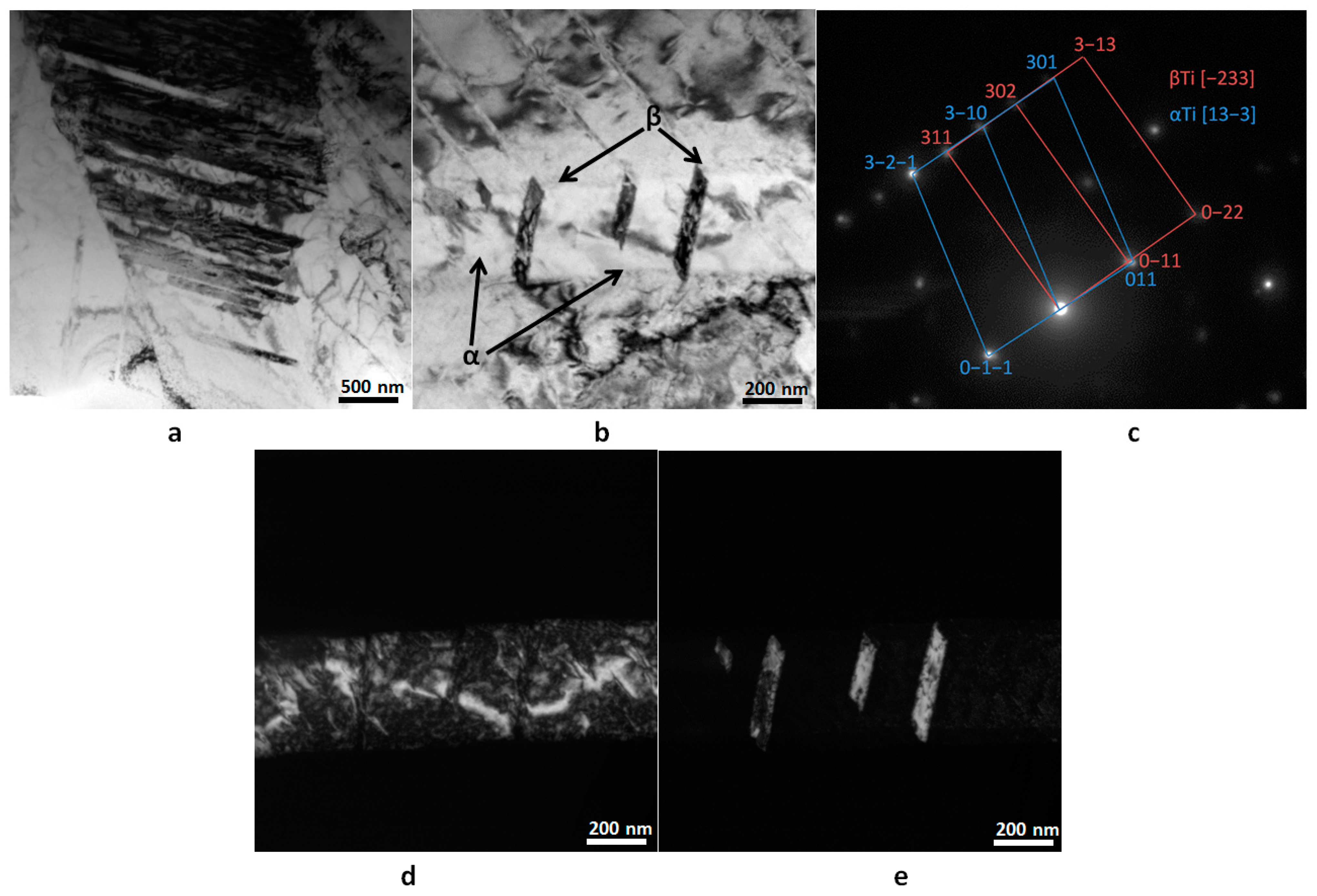

- Quenching in water after holding at 940 °C for 1 h (HT2) was observed to result in an increase in tensile strength by 11–20% due to β→α′ transformation and deformation twinning because of high transformation-induced stresses. Reduction in the degree of strength anisotropy by 1.3% was due to the formation of a modified microstructure.

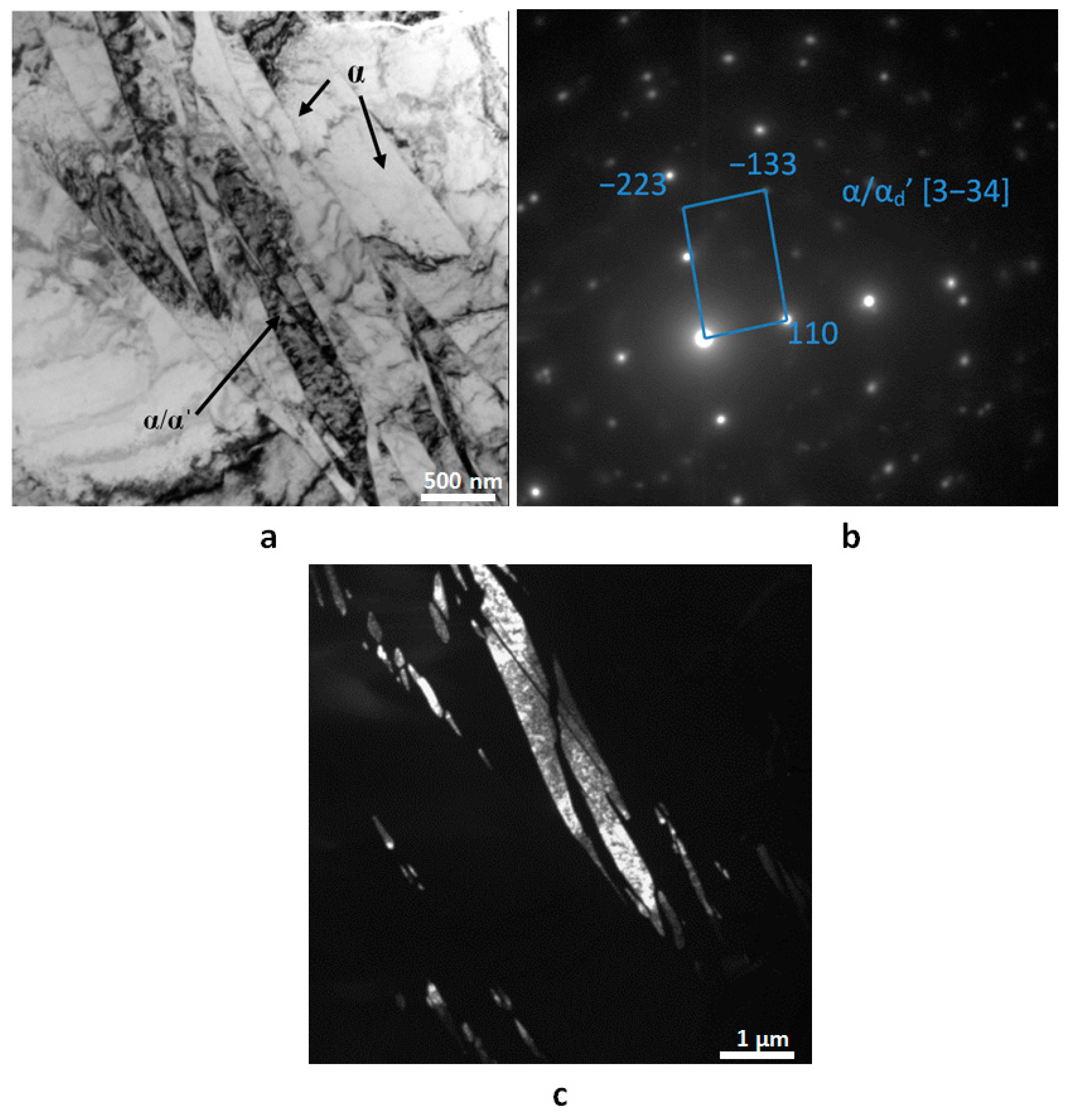

- The quenching followed by annealing at 540 °C (HT3) resulted in the decomposition of α′-Ti into α and fine β particles, preferentially inside the deformation twins, which, on the one side, caused both dispersion and grain boundary strengthening, leading to tensile strength improvement, and on the other side, served to relieve the transformation-induced stresses.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Milewski, J.O. Trends in AM, Government, Industry, Research, Business BT-Additive Manufacturing of Metals: From Fundamental Technology to Rocket Nozzles, Medical Implants, and Custom Jewelry; Milewski, J.O., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 255–292. ISBN 978-3-319-58205-4. [Google Scholar]

- Manoj, A.; Rao, M.A.; Basha, M.M.; Basha, S.M.; Sankar, M.R. State of Art on Wire Feed Additive Manufacturing of Ti-6Al-4V Alloy. Mater. Today Proc. 2020, 26, 2608–2615. [Google Scholar] [CrossRef]

- Zhang, Y.; Jarosinski, W.; Jung, Y.-G.; Zhang, J. 2-Additive Manufacturing Processes and Equipment. In Additive Manufacturing; Zhang, J., Jung, Y.-G., Eds.; Butterworth-Heinemann: Oxford, UK, 2018; pp. 39–51. ISBN 978-0-12-812155-9. [Google Scholar]

- Kanazawa, M.; Iwaki, M.; Minakuchi, S.; Nomura, N. Fabrication of Titanium Alloy Frameworks for Complete Dentures by Selective Laser Melting. J. Prosthet. Dent. 2014, 112, 1441–1447. [Google Scholar] [CrossRef] [PubMed]

- Hrabe, N.; Gnäupel-Herold, T.; Quinn, T. Fatigue Properties of a Titanium Alloy (Ti–6Al–4V) Fabricated via Electron Beam Melting (EBM): Effects of Internal Defects and Residual Stress. Int. J. Fatigue 2017, 94, 202–210. [Google Scholar] [CrossRef]

- Fuchs, J.; Schneider, C.; Enzinger, N. Wire-Based Additive Manufacturing Using an Electron Beam as Heat Source. Weld. World 2018, 62, 267–275. [Google Scholar] [CrossRef]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Demir, A.G. Micro Laser Metal Wire Deposition for Additive Manufacturing of Thin-Walled Structures. Opt. Lasers Eng. 2018, 100, 9–17. [Google Scholar] [CrossRef]

- Wanjara, P.; Watanabe, K.; de Formanoir, C.; Yang, Q.; Bescond, C.; Godet, S.; Brochu, M.; Nezaki, K.; Gholipour, J.; Patnaik, P. Titanium Alloy Repair with Wire-Feed Electron Beam Additive Manufacturing Technology. Adv. Mater. Sci. Eng. 2019, 2019, 3979471. [Google Scholar] [CrossRef]

- Wang, J.; Lin, X.; Wang, J.; Yang, H.; Zhou, Y.; Wang, C.; Li, Q.; Huang, W. Grain Morphology Evolution and Texture Characterization of Wire and Arc Additive Manufactured Ti-6Al-4V. J. Alloys Compd. 2018, 768, 97–113. [Google Scholar] [CrossRef]

- Lin, J.J.; Lv, Y.H.; Liu, Y.X.; Xu, B.S.; Sun, Z.; Li, Z.G.; Wu, Y.X. Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Wall Deposited by Pulsed Plasma Arc Additive Manufacturing. Mater. Des. 2016, 102, 30–40. [Google Scholar] [CrossRef]

- Kalashnikov, K.N.; Kalashnikova, T.A.; Gurianov, D.A. The Effect of the Ti-6Al-4V Titanium Alloy Cylindrical Sample 3D-Printing Trajectory on the Structure and Mechanical Properties. AIP Conf. Proc. 2020, 2310, 20131. [Google Scholar] [CrossRef]

- Fortuna, S.V.; Gurianov, D.A.; Kalashnikov, K.N. Directional Solidification Features of Nickel-Based Superalloy in the Electron Beam Additive Manufacturing Process. AIP Conf. Proc. 2019, 2167, 020107. [Google Scholar]

- Zhang, Y.; Feng, L.; Zhang, T.; Xu, H.; Li, J. Heat Treatment of Additively Manufactured Ti-6Al-4V Alloy: Microstructure and Electrochemical Properties. J. Alloys Compd. 2021, 888, 161602. [Google Scholar] [CrossRef]

- Venkatesh, B.D.; Chen, D.L.; Bhole, S.D. Effect of Heat Treatment on Mechanical Properties of Ti–6Al–4V ELI Alloy. Mater. Sci. Eng. A 2009, 506, 117–124. [Google Scholar] [CrossRef]

- Wang, S.C.; Aindow, M.; Starink, M.J. Effect of self-accommodation on α/αʹ boundary populations in pure titanium. Acta Mater. 2003, 51, 2485–2503. [Google Scholar] [CrossRef]

- Chung, C.C.; Wang, S.W.; Chen, Y.C.; Ju, C.P.; Lin, J.H.C. Effect of cold rolling on structure and tensile properties of cast Ti-7.5Mo alloy. Mater. Sci. Eng. A 2015, 631, 52–66. [Google Scholar] [CrossRef]

- Leuders, S.; Thone, M.; Riemer, A.; Niendorf, T.; Troster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatig. 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Vahidshad, Y.; Khodabakhshi, A.H. Effect of Solution Treatment and Aging Temperature on α′ and Ti3Al(α2) Phase Formation and Mechanical Properties of Water-Quenched Ti–6Al–4V. Metallogr. Microstruct. Anal. 2022, 11, 59–71. [Google Scholar] [CrossRef]

- Callegaria, B.; Marçola, J.V.; Aristizabal, K.; Soldera, F.A.; Mücklich, F.; Pinto, H.C. Effect of microstructure on Ti3Al precipitation during ageing of Ti-6Al-4V alloy. MATEC Web Conf. 2020, 321, 12014. [Google Scholar] [CrossRef]

- Zykova, A.; Panfilov, A.; Vorontsov, A.; Shmakov, V.; Savchenko, N.; Gurianov, D.; Gusarenko, A.; Utyaganova, V.; Krasnoveikin, V.; Tarasov, S. Microstructural and phase evolution of Ti6Al4V in electron beam wire additive manufacturing and on the subtransus quenching and normalization. Mater. Sci. Eng. A 2024, 898, 146384. [Google Scholar] [CrossRef]

- Williams, J.C.; Sommer, A.W.; Tung, P.P. The influence of oxygen concentration on the internal stress and dislocation arrangements in α titanium. Metall. Mater. Trans. B 1972, 3, 2979–2984. [Google Scholar] [CrossRef]

- Neeraj, T.; Mills, M.J. Short-range order (SRO) and its effect on the primary creep behavior of a Ti–6wt.% Al alloy. Mater. Sci. Eng. A 2001, 319, 415–419. [Google Scholar] [CrossRef]

- De Formanoir, C.; Martin, G.; Prima, F.; Allain, S.Y.P.; Dessolier, T.; Sun, F.; Vivès, S.; Hary, B.; Bréchet, Y.; Godeta, S. Microme-chanical behavior and thermal stability of a dual-phase α+α’ titanium alloy produced by additive manufacturing. Acta Mater. 2019, 162, 149–162. [Google Scholar] [CrossRef]

| Phases | Al | Ti | V |

|---|---|---|---|

| α | 5.87 ± 2.09 | 91.34 ± 3.28 | 2.78 ± 1.67 |

| β | 1.44 ± 0.65 | 77.74 ± 3.46 | 20.82 ± 3.18 |

| Phases | Al | Ti | V |

|---|---|---|---|

| α | 4.47 ± 0.41 | 93.17 ± 0.62 | 2.09 ± 0.36 |

| α″/β | 3.32 ± 0.70 | 89.89 ± 1.67 | 6.79 ± 2.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chumaevskii, A.; Tarasov, S.; Gurianov, D.; Moskvichev, E.; Rubtsov, V.; Savchenko, N.; Panfilov, A.; Korsunsky, A.M.; Kolubaev, E. Analysis of the Structure and Properties of As-Built and Heat-Treated Wire-Feed Electron Beam Additively Manufactured (WEBAM) Ti–4Al–3V Spherical Pressure Vessel. Metals 2024, 14, 1379. https://doi.org/10.3390/met14121379

Chumaevskii A, Tarasov S, Gurianov D, Moskvichev E, Rubtsov V, Savchenko N, Panfilov A, Korsunsky AM, Kolubaev E. Analysis of the Structure and Properties of As-Built and Heat-Treated Wire-Feed Electron Beam Additively Manufactured (WEBAM) Ti–4Al–3V Spherical Pressure Vessel. Metals. 2024; 14(12):1379. https://doi.org/10.3390/met14121379

Chicago/Turabian StyleChumaevskii, Andrey, Sergey Tarasov, Denis Gurianov, Evgeny Moskvichev, Valery Rubtsov, Nikolay Savchenko, Aleksander Panfilov, Alexander M. Korsunsky, and Evgeny Kolubaev. 2024. "Analysis of the Structure and Properties of As-Built and Heat-Treated Wire-Feed Electron Beam Additively Manufactured (WEBAM) Ti–4Al–3V Spherical Pressure Vessel" Metals 14, no. 12: 1379. https://doi.org/10.3390/met14121379

APA StyleChumaevskii, A., Tarasov, S., Gurianov, D., Moskvichev, E., Rubtsov, V., Savchenko, N., Panfilov, A., Korsunsky, A. M., & Kolubaev, E. (2024). Analysis of the Structure and Properties of As-Built and Heat-Treated Wire-Feed Electron Beam Additively Manufactured (WEBAM) Ti–4Al–3V Spherical Pressure Vessel. Metals, 14(12), 1379. https://doi.org/10.3390/met14121379