Effect of Annealing Temperature on Microstructure and Mechanical Properties of 00Cr21CuTi Stainless Steel Cold-Rolled Sheets

Abstract

1. Introduction

2. Materials and Methods

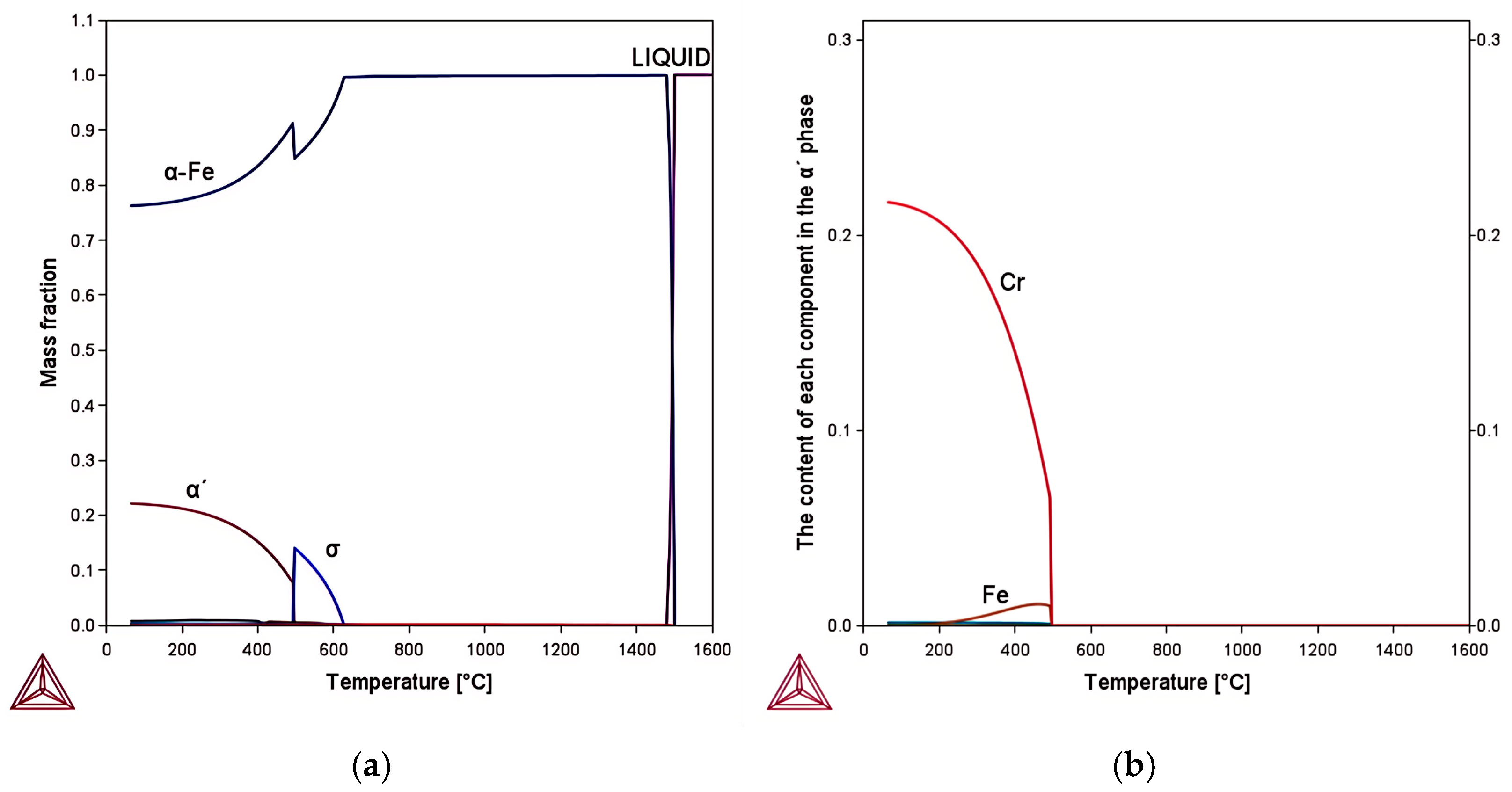

2.1. Experimental Materials

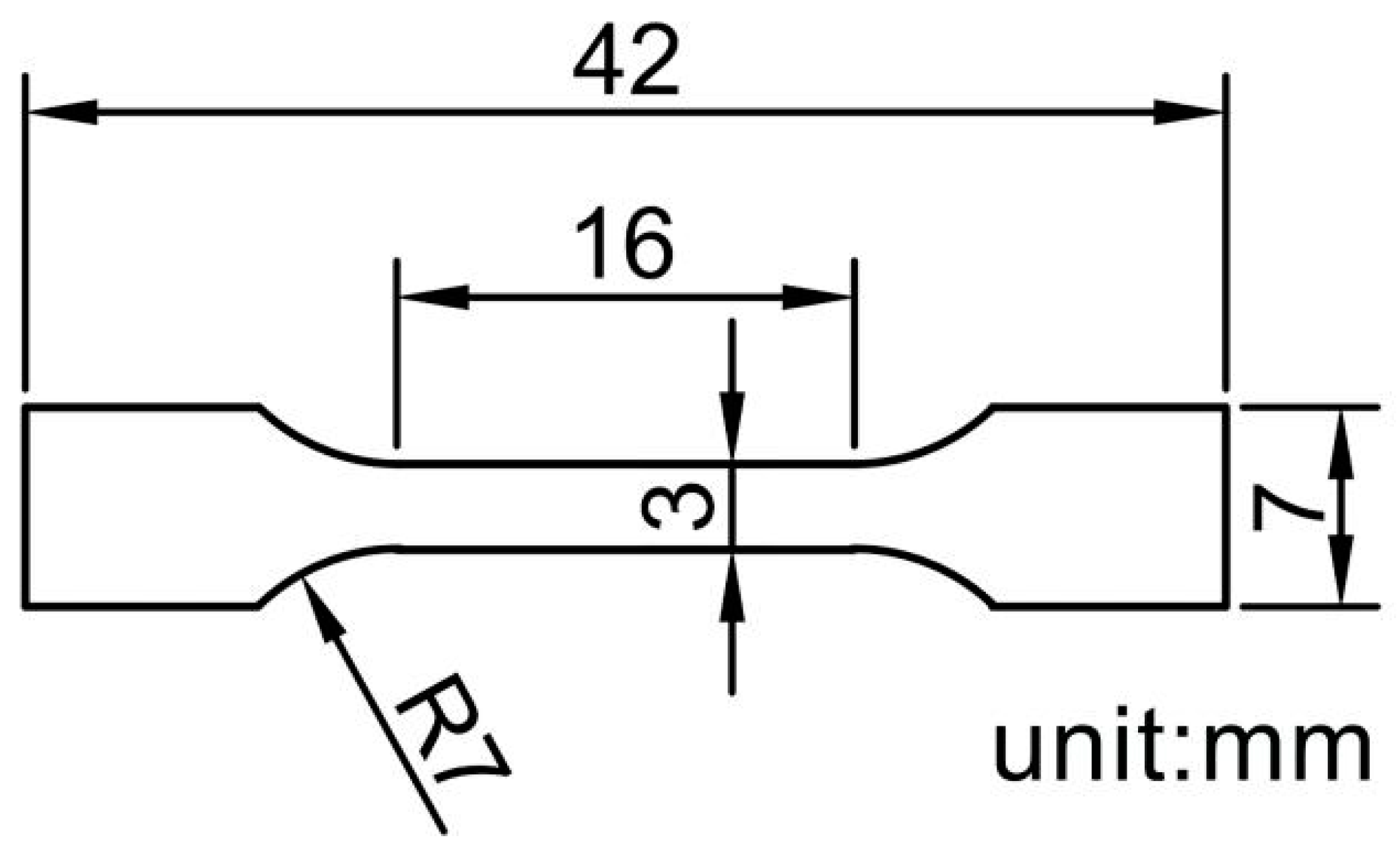

2.2. Testing Methods

3. Results and Discussion

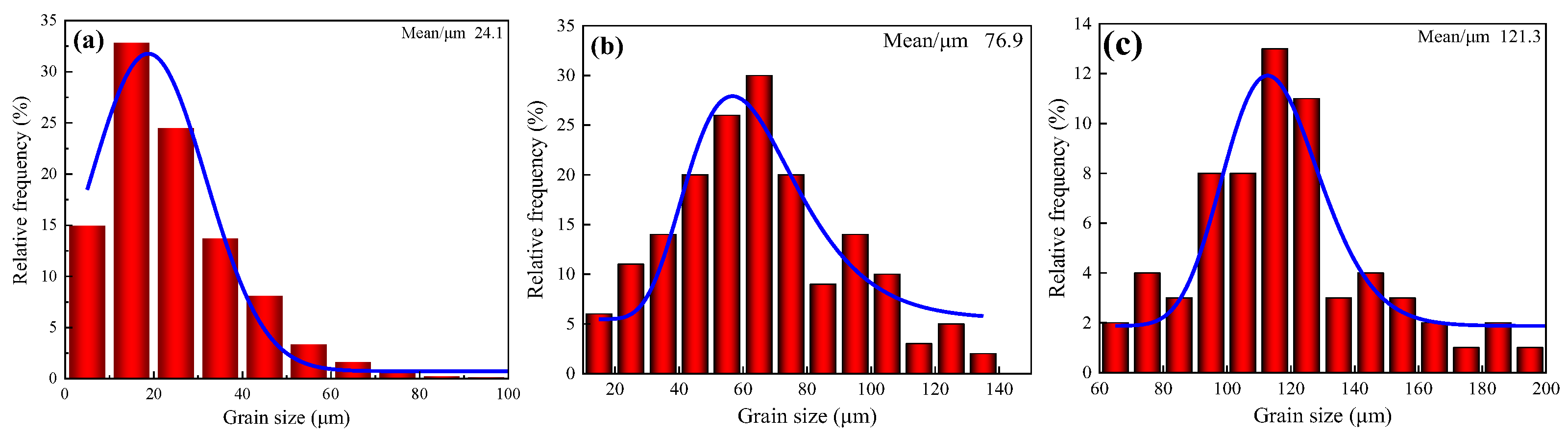

3.1. Microstructure

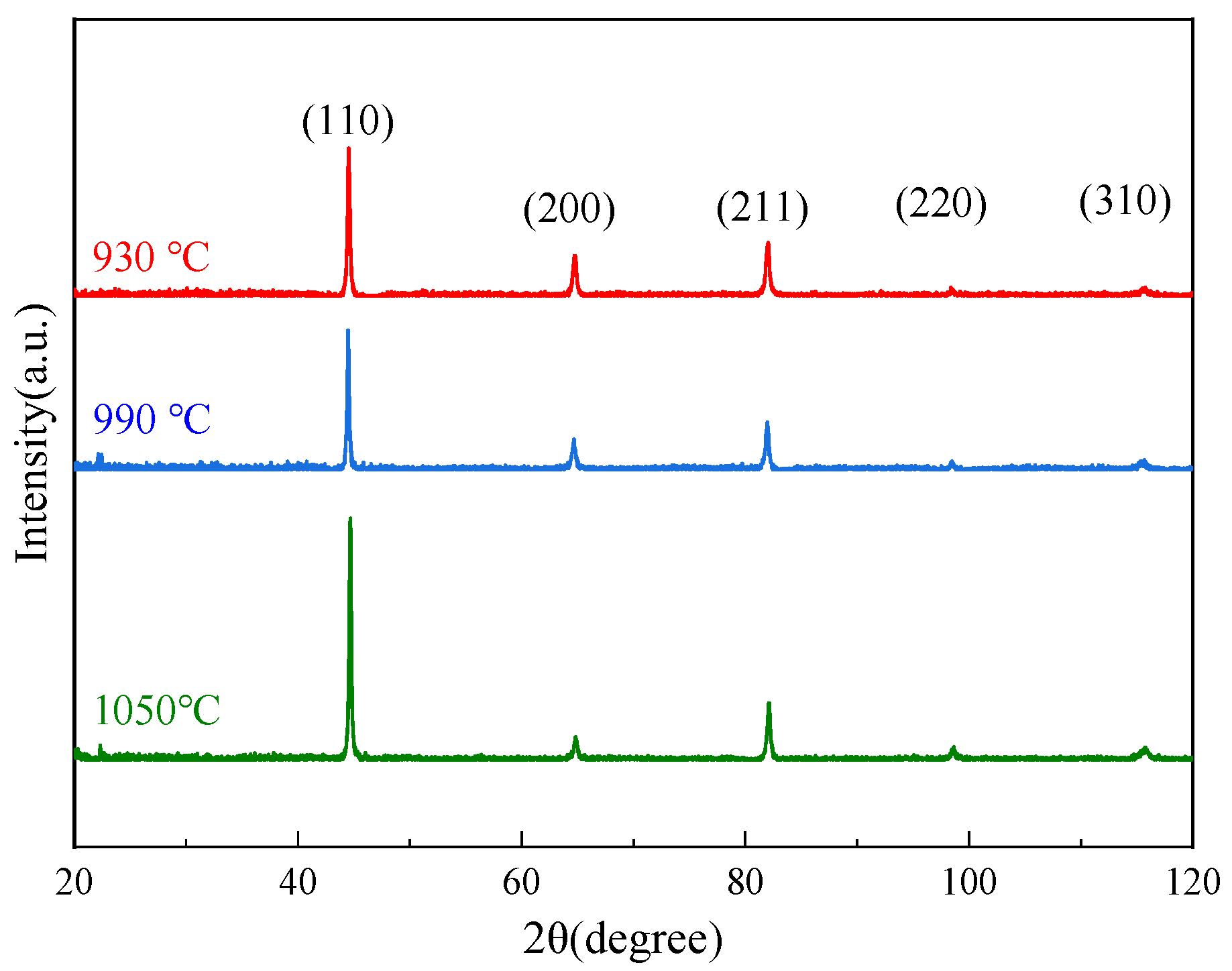

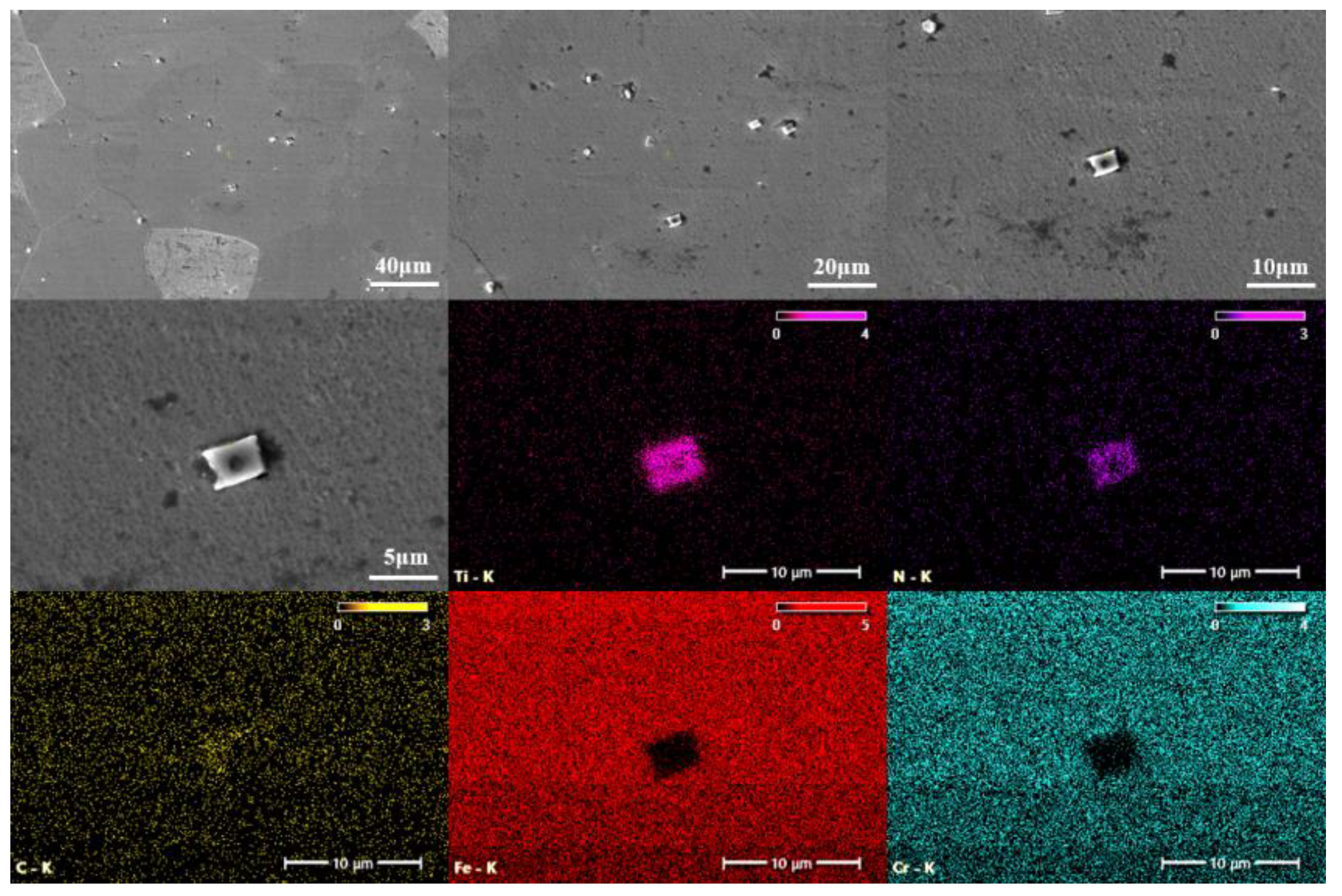

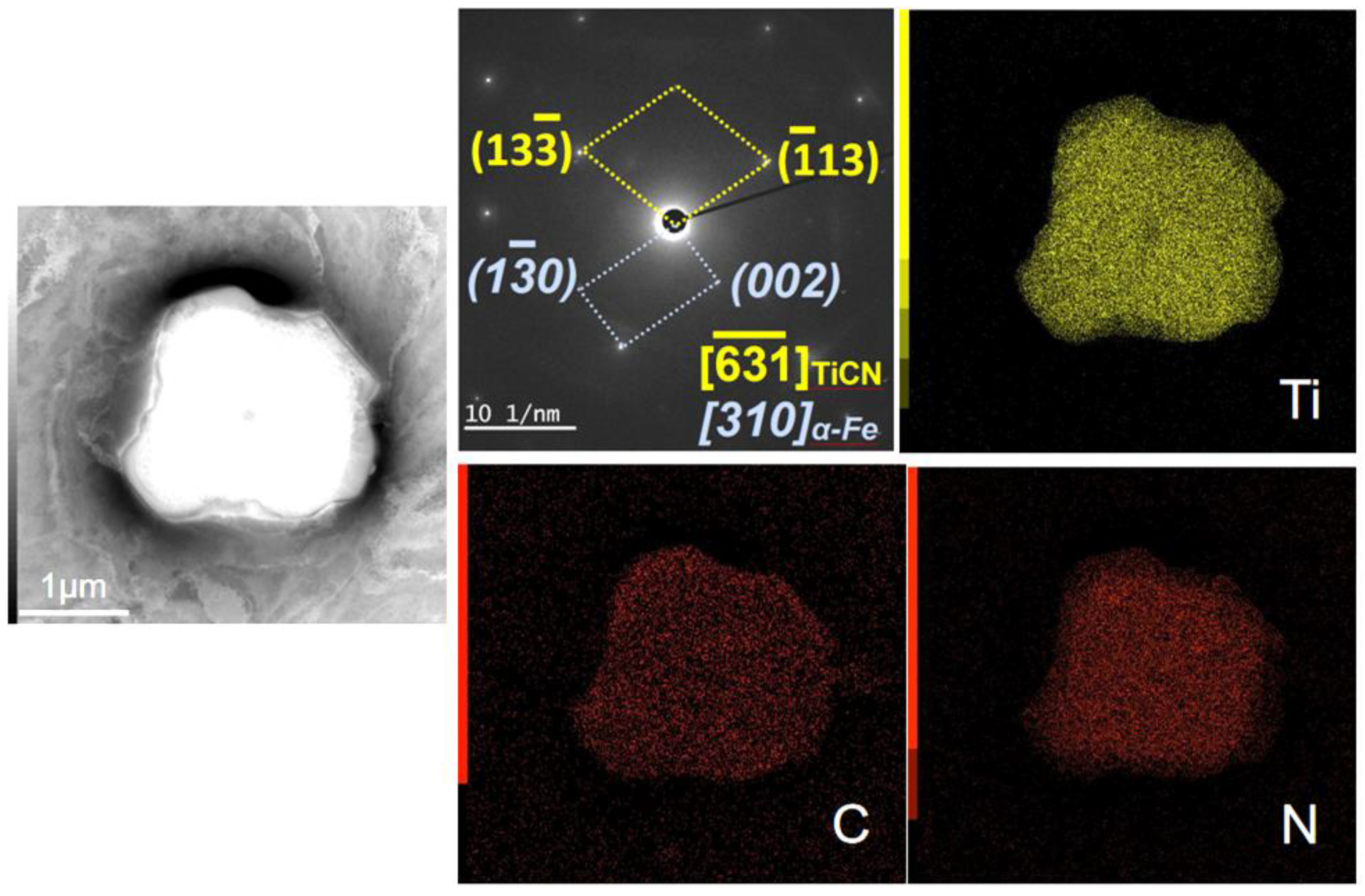

3.2. Analysis of Precipitate Phase

3.3. Mechanical Properties

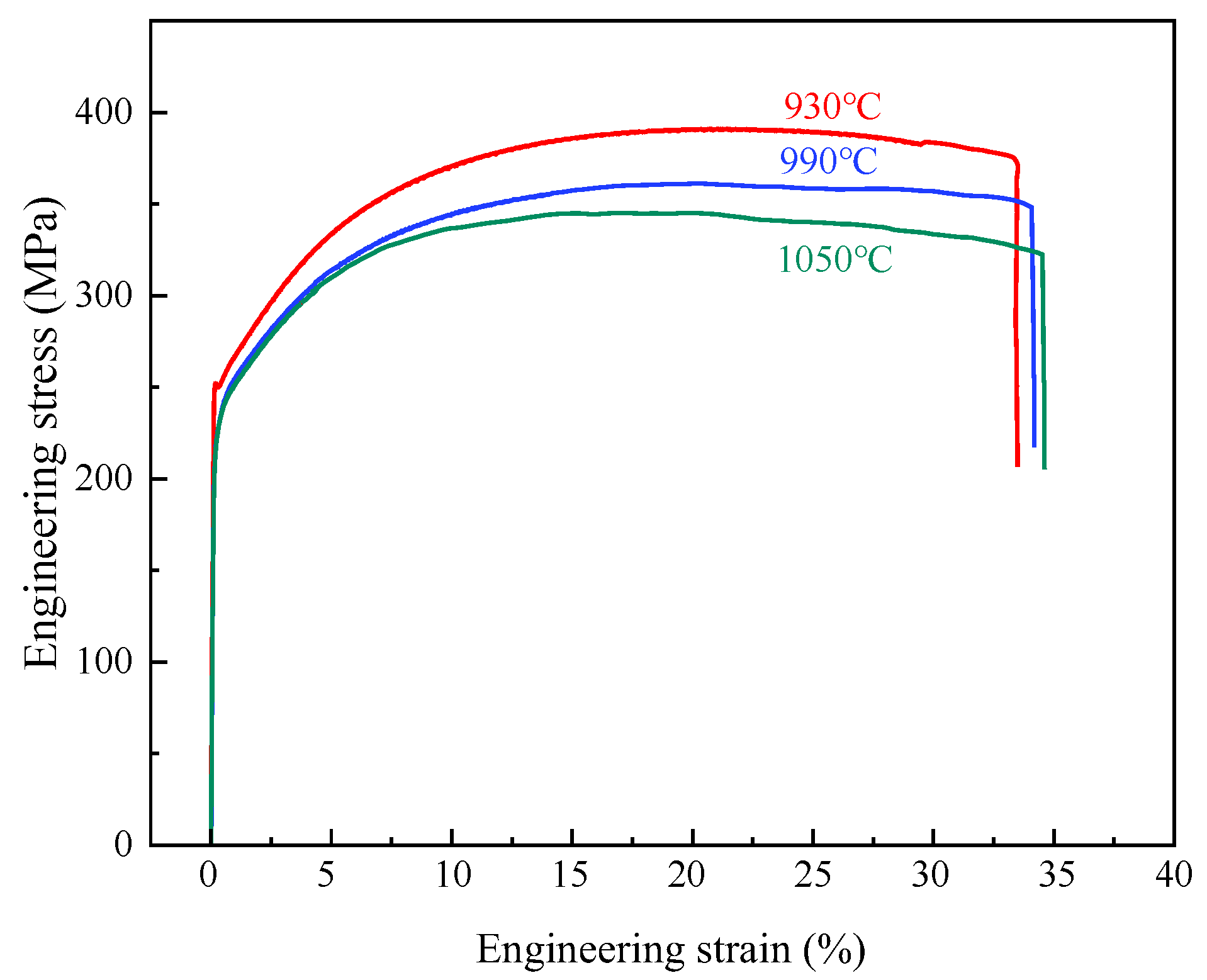

3.3.1. Tensile Properties

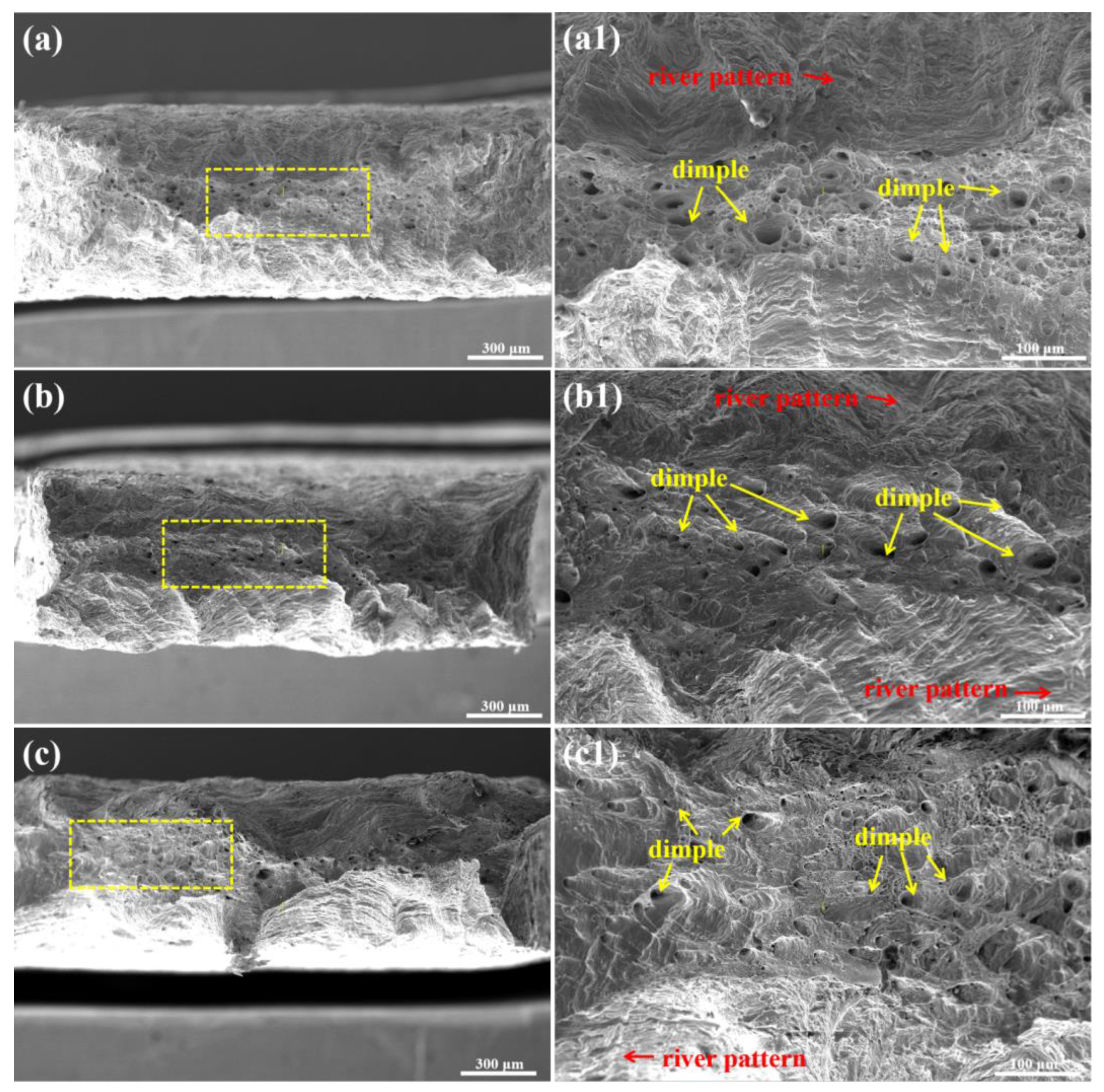

3.3.2. Fracture Morphology

3.3.3. Surface Roughness

3.4. Microscopic Texture Measurement of 70–930 °C Tested Steel

4. Conclusions

- Three tested steels 00Cr21CuTi retain within the ferrite single phase region throughout both the cold rolling and annealing processes, thereby preventing any α→γ phase transformation. After annealing, the steel undergoes recrystallization. Grain size significantly increases with the increase in annealing temperature. After annealing at 930 °C, the grains are fine and uniform which are mainly composed of equiaxed grains. and crystal orientations on the [111] crystal plane are determined.

- As the annealing temperature increases, grain size and elongation gradually increase, tensile strength slowly decreases, and the surface roughness first increases and then decreases trend. The maximum strength plastic product of the specimen is obtained during annealing at 930 °C, and the tested steel gets the best match of strength and plasticity.

- The analysis of the tensile fracture surface revealed the presence of fractured inclusion particles at the base of the tough pit, and it was determined that Ti(C,N) constituted the primary component of the precipitate. From the dimensions of these precipitates, it could be deduced that Ti(C,N) particles primarily form during the solidification process. Furthermore, thermodynamic calculations indicated that the theoretical yield strength of precipitation-strengthened steel was approximately 276.2 MPa, which closely corresponded with experimental measurements. Ti(C,N) functions predominantly as a precipitation-strengthening agent within the steel.

- Most of the grains had completed static recovery and recrystallization in 70–930 °C tested steel, with only a small number of grains in the recovery stage, and there were basically no deformed grains that had not undergone static recovery and recrystallization. FSS obtained a relatively complete fiber texture after cold rolling and annealing, with the strong points of the texture mainly concentrated near {334}<03> and {554}<22>.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, G.B.; Cheng, G.G.; Li, J.Y.; Ruan, Q.; Pan, J.X.; Chen, X.R. Decarburization modelling of VOD in ultra-pure ferritic stainless steel. J. Iron Steel Res. 2020, 32, 968–976. [Google Scholar]

- Shanmugam, K.; Lakshminarayanan, A.K.; Balasubramanian, V. Tensile and impact properties of shielded metal arc welded AISI 409M ferritic stainless steel joints. J. Mater. Sci. Technol. 2009, 25, 181–186. [Google Scholar]

- Sheng, J.; Wei, J.F.; Li, Z.N.; Man, K.; Chen, W.Q.; Ma, G.C.; Zheng, Y.H.; Zhan, F.Q.; La, P.Q.; Zhao, Y.C.; et al. Micro/nano-structure leads to super strength and excellent plasticity in nanostructured 304 stainless steel. J. Mater. Res. Technol. 2022, 17, 404–411. [Google Scholar] [CrossRef]

- Panfilova, L.M.; Smirnov, L.A. Structural features of structural steels microalloyed with nitrogen and vanadium. Metallurgist 2015, 58, 916–920. [Google Scholar] [CrossRef]

- Liu, J.Y.; Cheng, Z.; Huang, Y.H. Hot ductility of a Nb-microalloyed 1800 MPa grade hot-stamping steel. Iron Steel 2023, 58, 169–177. [Google Scholar]

- Singh, N.; Casillas, G.; Wexler, D.; Killmore, C.; Pereloma, E. Application of advanced experimental techniques to elucidate the strengthening mechanisms operating in microalloyed ferritic steels with interphase precipitation. Acta Mater. 2020, 201, 386–402. [Google Scholar] [CrossRef]

- Wang, H.C.; Li, Y.J.; Detemple, E.; Eggeler, G. Revealing the two-step nucleation and growth mechanism of vanadium carbonitrides in microalloyed steels. Scr. Mater. 2020, 187, 350–354. [Google Scholar] [CrossRef]

- Hu, J.J.; Ren, Y.; Zhang, L.F. Formation mechanism of NbC precipitates in micro-alloyed Nb high-strength steel. Chin. J. Eng. 2023, 45, 1729–1739. [Google Scholar]

- Liu, H.L.; Liu, L.L.; Li, X.; Chen, L.Q. Influence of cold rolling process on formability of a ferritic stainless steel. J. Northeast. Univ. (Nat. Sci.) 2019, 40, 1009–1104. [Google Scholar]

- Wang, Y.W.; Cai, Q.W.; Zhang, C. Effect of annealing temperatureon recrystallization microstructure and texture of ultra-pure ferritic stainless steel. In Proceedings of the 10th China Iron and Steel Annual Conference and the 6th Baosteel Academic Annual Conference, Shanghai, China, 21 October 2015. [Google Scholar]

- Su, H.D.; Fan, W.; Feng, Y.L. Effect of annealing temperature on microstructure and mechanical properties of cold-rolled Fe-0.4C-10Mn-6Al high strength steel. Heat Treat. Met. 2022, 47, 126–131. [Google Scholar]

- Tanure, L.P.D.A.R.; Alcântara, C.M.D.; Oliveira, T.R.D.; Santos, B.D.; Gonzalez, B.M. Microstructural characterization and mechanical behavior during recrystallization annealing of Nb-stabilized type ASTM 430 and Nb-Ti-stabilized ASTM 439 ferritic stainless steels. J. Mater. Res. Technol. 2019, 8, 4048–4065. [Google Scholar] [CrossRef]

- Chen, C. Effect of Rolling and Heat Treatment on Microstructure and Properties of Ferritic Stainless Steel. Master’s Thesis, Changchun University of Technology, Changchun, China, 2022. [Google Scholar]

- Gao, F.; Liu, Z.Y.; Zhang, W.N. Microstructure texture and deep drawability of ultrapurified ferritic stainless steel. J. Northeast. Univ. (Nat. Sci.) 2009, 30, 661–664. [Google Scholar]

- Liu, H.T.; Gao, F.; Ma, D.X.; Liu, Z.Y.; Wang, G.D. Effect of annealing temperature of an ultra-purified Cr17 ferritic stainless steel hot-rolled sheet on formability of cold-rolled and annealed sheet. Iron Steel 2010, 45, 75–79. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, K.Y.; Lee, Y.D.; Yong, D. Evolution of microstructure and texture associated with ridging in ferritic stainless steels. ISIJ Int. 2002, 42, 100–105. [Google Scholar] [CrossRef]

- Shen, K.; Duggan, B.J. Microbands and crystal orientation metastability in cold-rolled interstitial-free steel. Acta Mater. 2007, 55, 1137–1144. [Google Scholar] [CrossRef]

- Yang, Y.G.; Luo, X.; Lei, M.G.; Fang, X.; Li, S.H.; Wu, Y.X.; Mi, Z.L. Microstructure evolution and strengthening mechanisim of air-hardening steel subuected to the austenitizing annealing treatment. Mater. Res. Express 2023, 10, 106502. [Google Scholar] [CrossRef]

- Li, B.Y.; Liu, K.; Feng, Y.L.; Li, T.; Wang, S.H.; Su, H.D. Effect of cold rolling reduction on microstructure and mechanical properties of Fe-10Mn-6Al-0. 4C steel. Iron Steel 2024, 59, 159–167. [Google Scholar]

- Meng, Y.H.; Sheng, J.; Ma, Z.W.; Gao, Y.; Tuo, L.X.; Duan, H.Y.; Man, K. The inffuence of the hot-rolling temperature on the microstructure and mechanical properties of Ti-Nb microalloyed 21%Cr ferritic stainless steel. Metals 2024, 14, 1099. [Google Scholar] [CrossRef]

- Choi, W.J.; Lee, S.Y.; Park, C.W.; Park, J.H.; Byun, J.M.; Kim, Y.D. Effect of titanium addition on mechanical properties of Mo-Si-B alloys. Int. J. Refract. Met. H. 2019, 80, 238–242. [Google Scholar] [CrossRef]

- Sheng, J.; Man, K.; Ma, G.C.; Meng, Y.H.; Li, Y.F.; Gao, Y.; Yang, P.H.; Wei, J.F.; La, P.Q. Effect of annealing temperature on properties and second phase characteristics of 443 stainless steel hot-rolled sheets. Ferroelectrics 2024, 618, 2181–2195. [Google Scholar] [CrossRef]

- Xu, S.K.; Sun, X.Y.; Chen, L.; Li, J.H.; Zhang, M.Y. Effect of annealing on microstructure and mechanical properties of cold-rolled 430 ferritic stainless steel. Chin. J. Process. Eng. 2024, 2–10+1. Available online: http://kns.cnki.net/kcms/detail/11.4541.TQ.20240711.1645.002.html (accessed on 24 November 2024).

- GB/T 6394-2002; Method for Determination of Average Grain Size of Metals. Standardization Administration of the People’s Republic of China: Beijing, China, 2002; p. 11.

- GB/T 228.2-2010; Method for Tensile Testing of Metallic Materials at Room Temperature. Standardization Administration of the People’s Republic of China: Beijing, China, 2010; p. 12.

- GB/T 1031-2009; Parameters and Values of Surface Roughness. Standardization Administration of the People’s Republic of China: Beijing, China, 2009.

- Park, J.T.; Szpunar, J.A. Evolution of recrystallization texture in non-oriented electrical steels. Acta Mater. 2003, 51, 3037–3051. [Google Scholar] [CrossRef]

- Liu, H.T.; Ma, D.X.; Gao, F.; Wang, G.D. Effect of annealing temperature on formability of cold-rolled ultra-purified Cr17 ferritic stainless steel sheet. J. Northeast. Univ. (Nat. Sci.) 2010, 31, 1266–1269. [Google Scholar]

- Yang, S.Q.; Li, W.H. Surface Roughnessing Theory and New Technology; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Zhang, P.C.; Wu, H.B.; Tang, D.; Huang, J.G.; Wang, L.B. Dissolving behaviors of Carbonitrides in Nb-V-Ti and V-Ti microalloying steels. Acta Metall. Sin. 2007, 7, 753–758. [Google Scholar]

- Sun, H.; Ren, H.P.; Jin, Z.L.; Han, M. The affection of annealing on the recrystallization. In Proceedings of the 2nd National Conference on Backscatter Electron Diffraction (EBSD) Technology and Its Applications and the 6th National Conference on Materials Science and Image Technology, Baotou, China, 20 August 2007. [Google Scholar]

- Wang, K.L.; Wang, P.B.; Zhang, Y.; Qiao, C.B.; Li, Q.L. Microstructure and mechanical properties of Al-7Si alloy with trace AlFeCuTi alloy addition. Chin. J. Rare Met. 2024, 48, 922–932. [Google Scholar]

| Cr | Ti | Cu | Ni | Mn | Si | P | S | C | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 20.67 | 0.31 | 0.38 | 0.16 | 0.16 | 0.28 | 0.013 | 0.0008 | 0.01 | 0.008 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, G.; Sheng, J.; Gao, Y.; Tuo, L.; Li, Y.; La, P. Effect of Annealing Temperature on Microstructure and Mechanical Properties of 00Cr21CuTi Stainless Steel Cold-Rolled Sheets. Metals 2024, 14, 1367. https://doi.org/10.3390/met14121367

Ma G, Sheng J, Gao Y, Tuo L, Li Y, La P. Effect of Annealing Temperature on Microstructure and Mechanical Properties of 00Cr21CuTi Stainless Steel Cold-Rolled Sheets. Metals. 2024; 14(12):1367. https://doi.org/10.3390/met14121367

Chicago/Turabian StyleMa, Guocai, Jie Sheng, Yang Gao, Lixu Tuo, Yufeng Li, and Peiqing La. 2024. "Effect of Annealing Temperature on Microstructure and Mechanical Properties of 00Cr21CuTi Stainless Steel Cold-Rolled Sheets" Metals 14, no. 12: 1367. https://doi.org/10.3390/met14121367

APA StyleMa, G., Sheng, J., Gao, Y., Tuo, L., Li, Y., & La, P. (2024). Effect of Annealing Temperature on Microstructure and Mechanical Properties of 00Cr21CuTi Stainless Steel Cold-Rolled Sheets. Metals, 14(12), 1367. https://doi.org/10.3390/met14121367